Partner with us to optimize pharmacy purchasing, simplify 340B administration, ensure compliance, and benefit from the dedication and knowledge

subject matter and gain insight through expert videos.

Partner with us to optimize pharmacy purchasing, simplify 340B administration, ensure compliance, and benefit from the dedication and knowledge

subject matter and gain insight through expert videos.

INDICATIONS1

Treatment of Hypoprothrombinemia Due to Vitamin K Deficiency or Interference: Phytonadione injectable emulsion is indicated for the treatment of the following coagulation disorders which are due to faulty formation of factors II, VII, IX and X when caused by vitamin K deficiency or interference with vitamin K activity:

· anticoagulant-induced hypoprothrombinemia caused by coumarin or indanedione derivatives;

· hypoprothrombinemia due to antibacterial therapy;

· hypoprothrombinemia secondary to factors limiting absorption or synthesis of vitamin K, e.g., obstructive jaundice, biliary fistula, sprue, ulcerative colitis, celiac disease, intestinal resection, cystic fibrosis of the pancreas, and regional enteritis;

· other drug-induced hypoprothrombinemia where it is definitely shown that the result is due to interference with vitamin K metabolism, e.g., salicylates.

Prophylaxis and Treatment of Vitamin K-Deficiency

Bleeding in Neonates: Phytonadione injectable emulsion is indicated for prophylaxis and treatment of vitamin K deficiency bleeding in neonates.

BOXED WARNING1

WARNING - HYPERSENSITIVITY REACTIONS WITH INTRAVENOUS AND INTRAMUSCULAR USE: Fatal hypersensitivity reactions, including anaphylaxis, have occurred during and immediately after intravenous and intramuscular injection of phytonadione injectable emulsion. Reactions have occurred despite dilution to avoid rapid intravenous infusion and upon first dose. Avoid the intravenous and intramuscular routes of administration unless the subcutaneous route is not feasible and the serious risk is justified.

Please see www.ciplausa.com

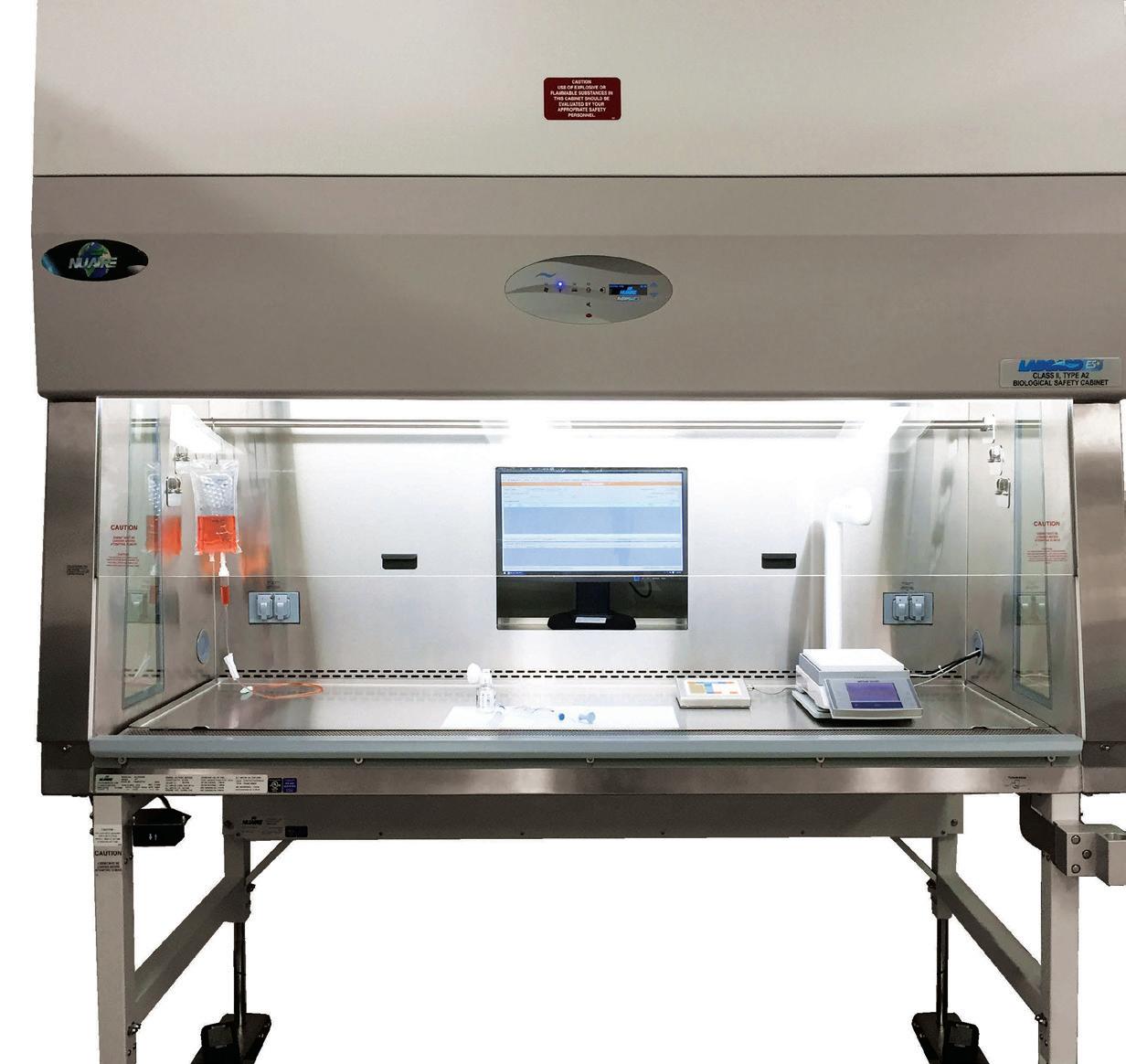

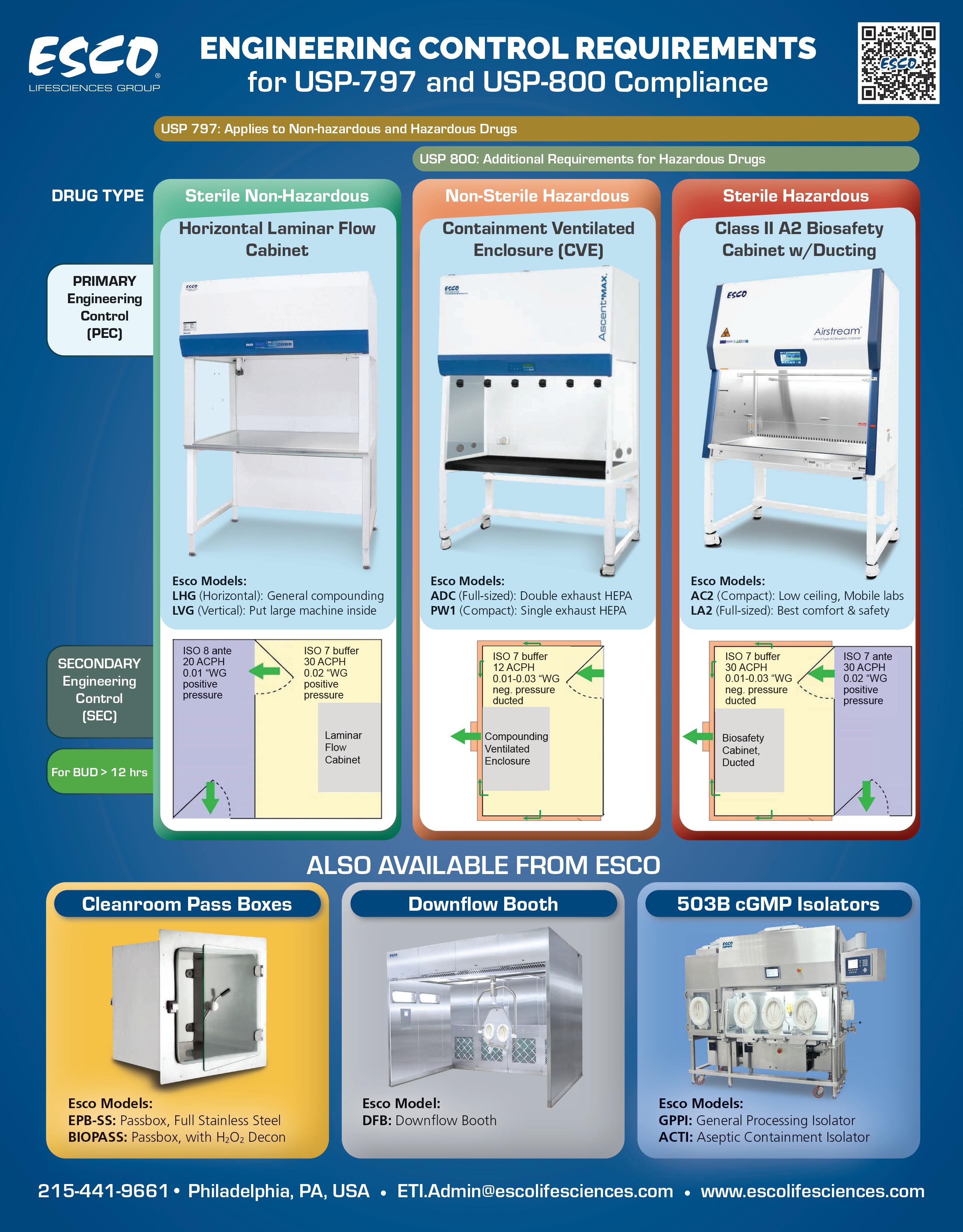

Whether planning a cleanroom renovation or building a new cleanroom, Modular Devices’ mobile cleanrooms provide an expedited option combining a modular and prefabricated approach by delivering a readyto-use, turnkey cleanroom that only requires utility connections upon delivery. Our pharmacy compounding cleanrooms are available to rent or purchase! Experience unmatched quality, state-of-the-art materials and equipment, a cleanroom that will exceed your expectations, and USP 797/800!

14' wide x 48' long

Meets and Exceeds USP797 & 800

Large Fleet and Nationwide Coverage

Hands-free Scrub Sinks

Hands-free Interlocked Doors

Continuous Data Logging & Monitoring

Includes 4' BSC’s and 4' LFH’s

Includes Dedicated Refrigerators

HEPA Filtered Interlocked Passthroughs

Dedicated Haz & Non-Haz Gowning Rooms

USP 800 Negative Pressure Unpack/

Storage Room

Hands-free Flush Mount Intercoms

Guaranteed Environmental Control

Guaranteed Certification

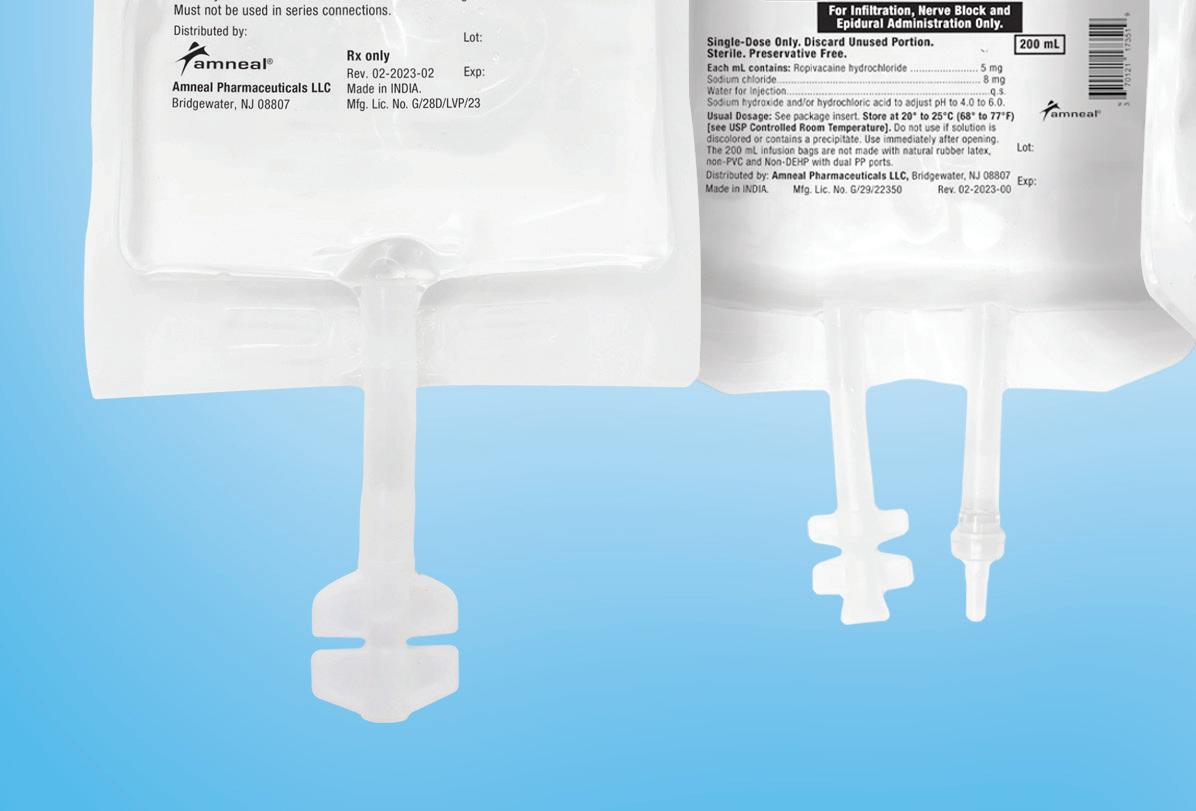

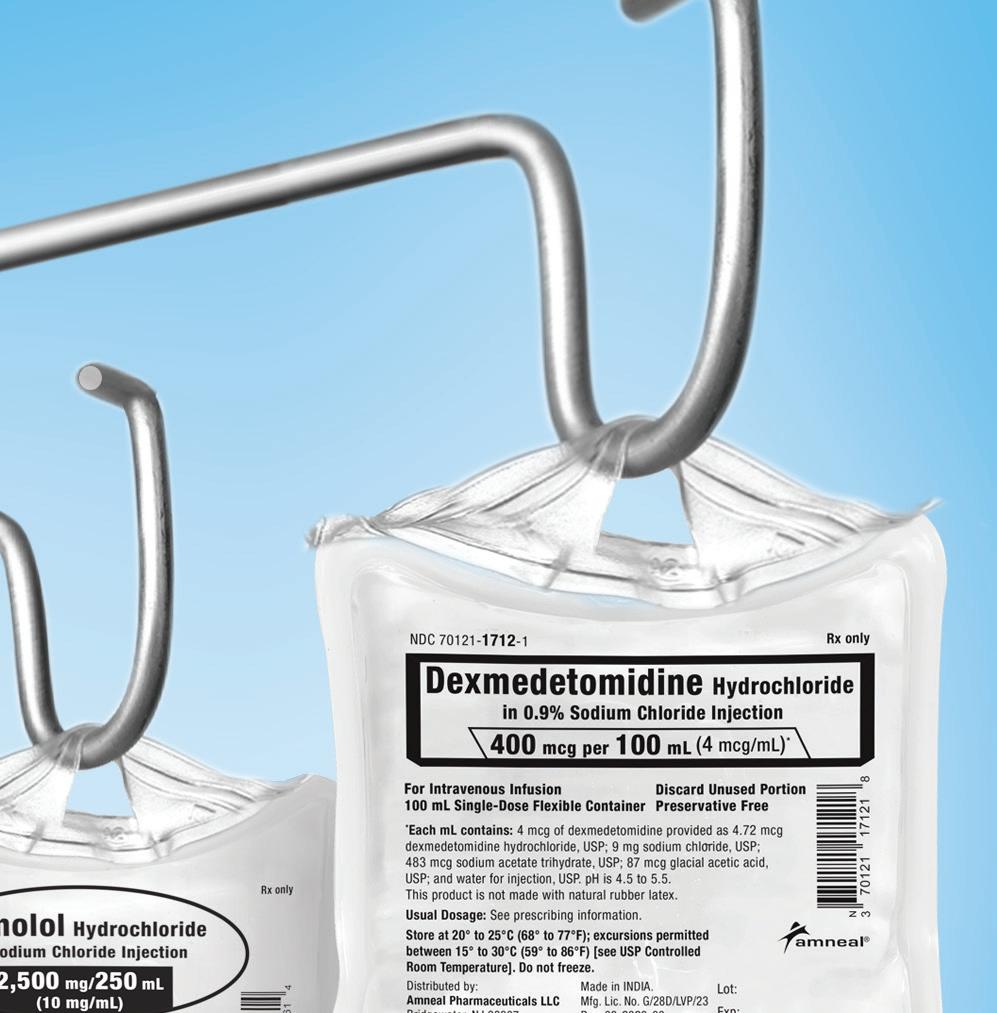

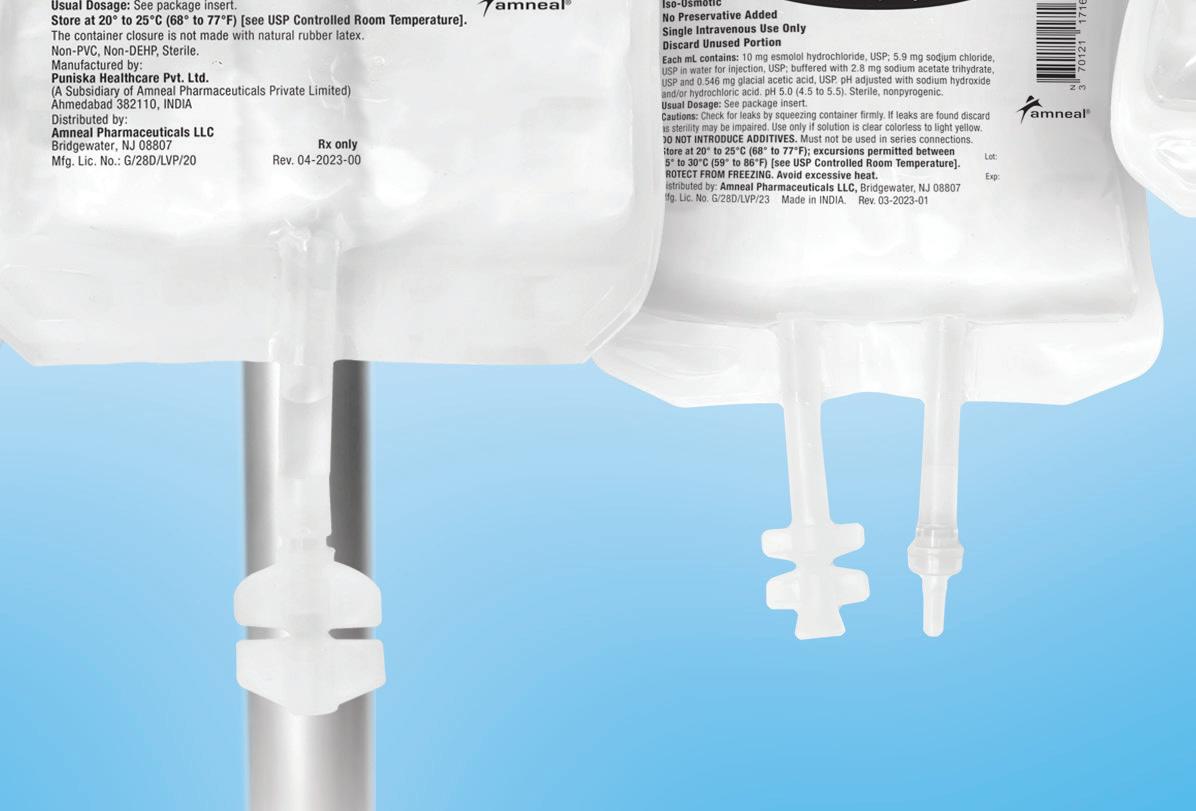

Propofol Injectable Emulsion, USP supplied by Samson Medical Technologies, under the Avet label, is the smart choice for your pharmacy service, offering you the same formulation as Diprivan® , free of benzyl alcohol, sulfites, and latex, with the easy ordering and excellent service that you have come to expect from the providers of SmartPak® .

SmartPak® provides a revolutionary delivery system for these essential drugs, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service.

This important product now in the exclusive delivery system.

important product now in the exclusive delivery system. provides a

This important product now in the exclusive delivery system.

SmartPak® provides a revolutionary delivery system for these essential drugs, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service.

delivery system for this essential drug, offering faster, easier more economically. It’s also safer. The SmartPak bag system is a convenient using multiple glass vials. No glass means no breakage during handling. SmartPak labor with less waste. SmartPak — the smart choice for your pharmacy service

SmartPak® provides a revolutionary delivery system for this essential drug, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service

66288-1100-11100

SmartPak® provides a revolutionary delivery system for this essential drug, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service

SmartPak® provides a revolutionary delivery system for these essential drugs, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service.

Inc./EPS, Inc. Delivers Bar Coding, Packaging, and Labeling Pharmacy Solutions Improve your Solid Oral Unit Dose needs with our comprehensive Bar Coding, Packaging, and Labeling Solutions — designed by healthcare professionals. American Health Packaging (AHP) is a Leading Manufacturer of Serialized Barcoded Unit-Dose Products With a responsive line of barcoded unit-dose oral solutions, a growing liquid unit-dose offering, as well as individually wrapped inhalants.

Leiters Health is a trusted FDAregistered 503B outsourcing provider of ready-to-administer compounded sterile preparations, committed to providing healthcare professionals and their patients with the highest-quality medications.

page 45 page 54-55 page 57 page 51 page 53

and

Ensure your health-system’s compounded drug products and facilities consistently meet quality standards.

Contributed by Clinical Assistant Professor & Clinical Pain/SUD Pharmacist, Mark Garofoli, PharmD, MBA, BCGP, CPE, CTTS, at West Virginia University School of Pharmacy.

As one of the top leading suppliers for pharmacy cleanroom supplies, we provide an unparalleled selection of specialized medical products, globally trusted quality and service, and delivery convenience for meeting USP <797> and USP <800> standards.

Pharmacy Claim Adjudication

Pharmacy Benefit Administration

Self-Funded Employer Services

Hospital & Health System Services Pharmacy Savings Card Programs

Better insights. Bigger returns. By seamlessly integrating 340B and PBM management, PharmaForce unlocks significant cost savings and delivers a holistic and transparent view of your pharmacy operations. Our unique platform empowers informed decision-making with actionable insights. We offer comprehensive reporting, analytics and leakage identification tools to optimize both your 340B program and employee health plans, substantially reducing drug costs across the board.

Not convinced? Give us 30 minutes. We’ll show you real savings (with your actual claims). A PharmaForce specialist will analyze your claims for free, revealing how much you could be saving with our 340B + PBM solution. We’re confident we can deliver better insights and bigger returns. Schedule a consultation.

Let us show you how: www.thePharmaForce.com/demo

Every

Pharmacist ... is a Great Resource.

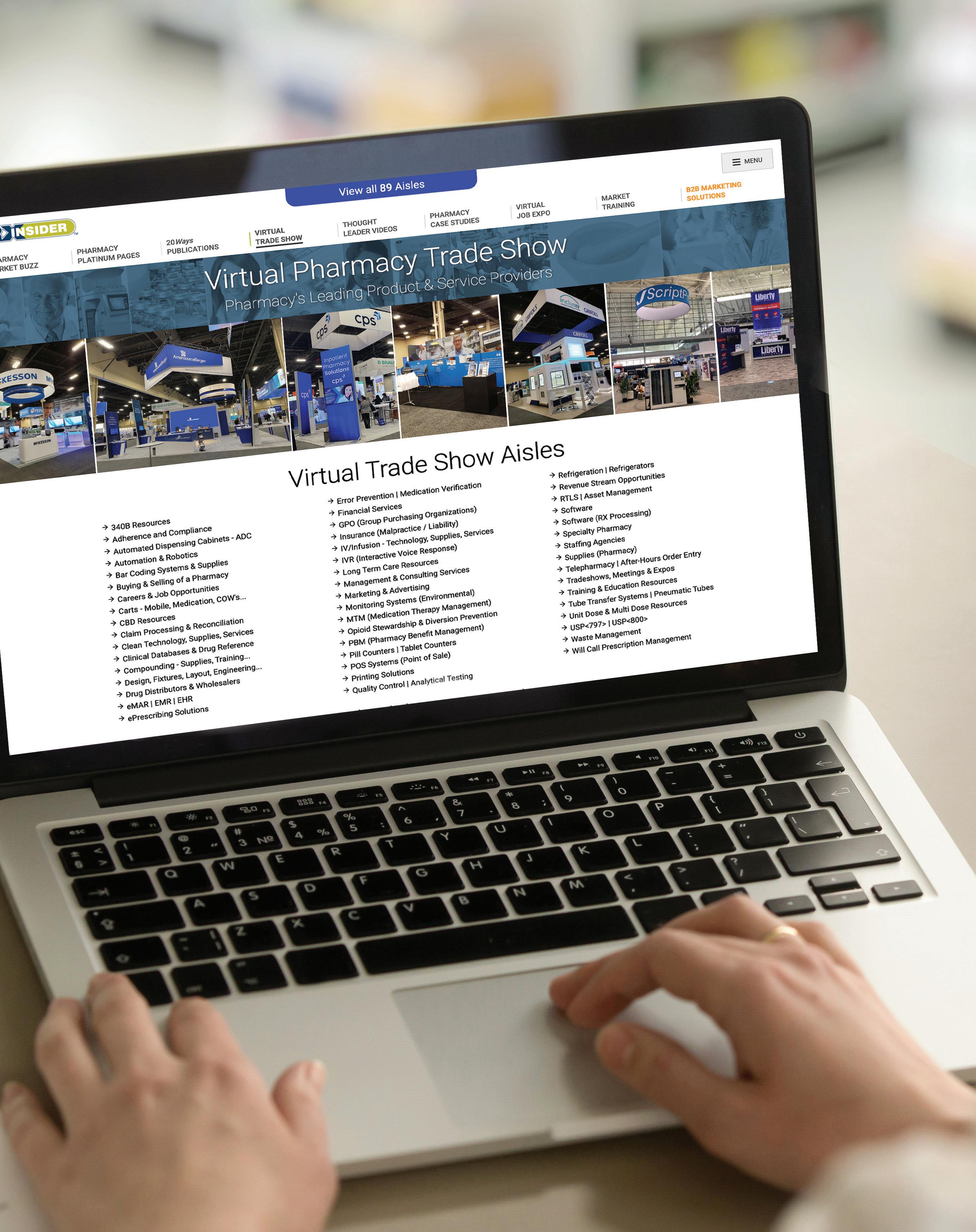

RXinsider’s Video Series are informative videos comprised of interviews, facility tours, trainings, and case studies throughout the pharmacy profession. Explore niche subject matter and gain insight though hundreds of expert videos.

USP <800> Compliance: Looking Back, Looking Forward.

Contributed by Clinical Program Managers, Annie Lambert, PharmD, BCSCP, and Jennifer Smith, PharmD, BCSCP, at Simplifi+ Pharmacy Compliance Solutions, Wolters Kluwer.

Prudential Cleanroom Services (PCS) — ISO 9001 Certified Quality Management System

PCS specializes in cleanroom garment processing services for aseptic, particulate, and ESD controlled environments.

500 of the most impactful pharmacy supply chain companies and associations in the U.S.

PUBLISHER

RXinsider, LTD

RXinsider CEO Gregory Cianfarani, RPh

DESIGN AND PRODUCTION

Design & Layout

Lora Bourque

Multimedia Eric Simmons

Marketing and Operations

SALES AND BUSINESS DEVELOPMENT

Samantha Roy Alexa DiLuca Kristin Fennessey

Chris Kolkhorst, EVP chris.kolkhorst@rxinsider.com

Mike Rahme mike.rahme@rxinsider.com

Shaun Russell shaun.russell@rxinsider.com

Savannah DaSilva savannah.dasilva@rxinsider.com

Jeff Rackliff jeff.rackliff@rxinsider.com

Email sales@rxinsider.com

Fax 646.329.9766 Website www.RXinsider.com

20Ways is published quarterly by RXinsider LTD, 1300 Division Road, Suite 103, West Warwick, RI 02893. Postmaster: Send address changes to 20Ways/RXinsider, 1300 Division Road, Suite 103, West Warwick, RI 02893. Notification of address change must be made six weeks in advance, including old and new address with zip code.

Editorial – views expressed in articles or profiles in the 20Ways are those of the author(s) and do not necessarily reflect the policies and opinions of RXinsider, our editorial board(s), our advisory board(s), or staff. Advertising – products, services, and educational institutions advertised in 20Ways do not imply endorsement by RXinsider.

Copyright © 2024 RXinsider LTD. All rights reserved. Reproduction without permission is prohibited.

General Information: 20Ways@RXinsider.com Circulation: See page 5

www.RXinsider.com/USP800

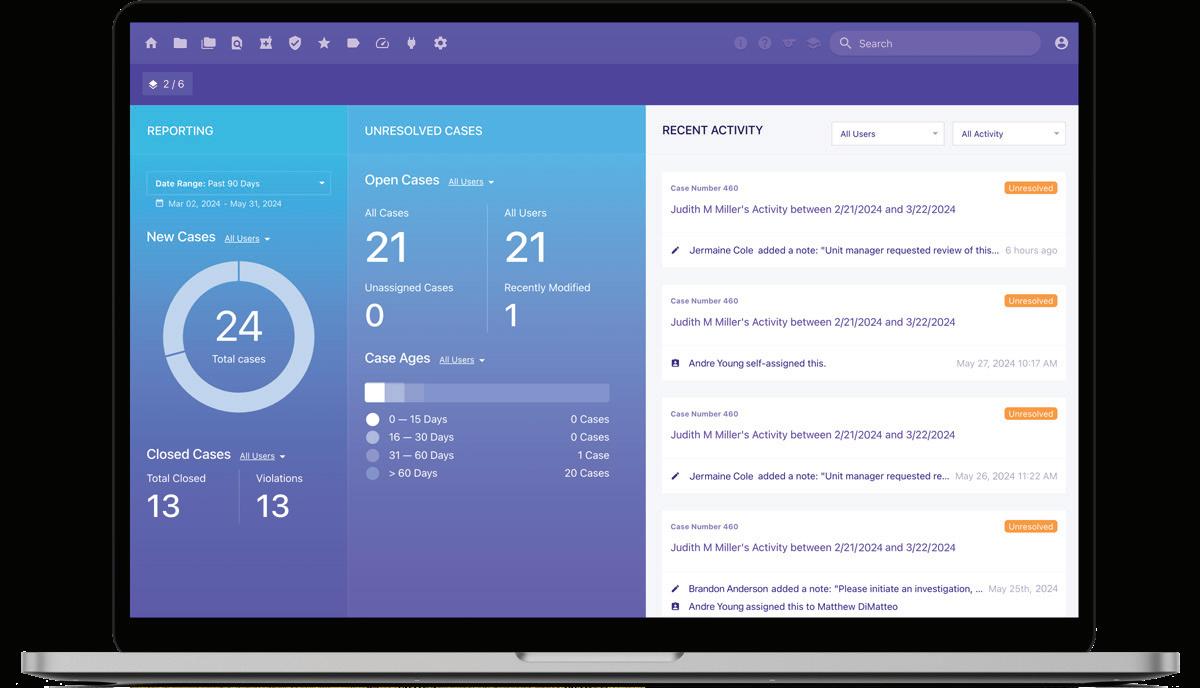

Verity Solutions® is a recognized leader in 340B program optimization and innovator of pharmacy purchasing solutions that drive compliance and savings. Our continually improved products and commitment to client satisfaction mean you can dedicate less time to program administration and more focus on patients.

Optimize savings on qualified transactions.

Automatically selects the best priced drug before order is placed.

Extend 340B savings through retail chain and independent pharmacies.

Leverage our preferred Specialty and Infusion partnerships.

Automated replenishment solution that simplifies owned outpatient pharmacy program management and improves savings.

Boost 340B savings with our no risk tools and support services.

Restore access to eligible 340B claims.

Consolidate 340B ordering, reporting and financial functions across multiple third party administrator (TPA) relationships.

*340B program participation not required.

Partner with us to optimize pharmacy purchasing, simplify 340B administration, ensure compliance, and benefit from the dedication and knowledge of our expert team.

CEO: George Puckett

Founded: 2015

Employees: 140

Toll-Free Phone: (800) 581-1378

Phone: (425) 947-1922

Address: 12131 113th Avenue NE, #200 Kirkland, WA 98034

Website: www.verity340b.com

Verity Solutions is a leader in 340B program administration and innovator of pharmacy purchasing optimization. Recognized as Best in KLAS: 340B Management Systems for six years, we are on a mission to create pharmacy excellence for 340B and beyond through predictable automation and outstanding support so that every customer can maximize their savings. We partner with integrated healthcare systems, acute-care hospitals, community health centers, federally qualified health centers, pharmacies, and 340B-eligible covered entities throughout the U.S. who rely on Verity software and services to successfully manage their pharmacy purchasing and 340B program.

Our powerful cloud-based software platform provides comprehensive solutions for split billing, contract pharmacy, specialty contract pharmacy, plus a contract pharmacy gateway solution called VHUB®. Our purchase optimization product, VERISAVE®, automatically selects the best blended priced NDC available for your complete order before it is submitted, reducing tedious manual processes and dramatically decreasing your drug spend. Our depth of in-house technical and software development resources and our highly skilled account management team are closely aligned to swiftly adapt as changes arise in the 340B program. We offer:

• Agile Software Platform: Built and deployed with security, performance, scalability, and agility as primary goals.

The Verity 340B platform is HITRUST® certified, demonstrating robust HIPAA compliance.

• Intuitive Application: Designed with our users in mind, we maintain ongoing feedback and collaboration with our clients. This collaboration steers our continual software and services development.

• Responsive Support: Designated account managers provide focused support, training, audit readiness, and regular business reviews to maximize your 340B program success and help you maintain compliance.

We continually invest in our technology and people to ensure pharmacy program success for our clients. With increasing 340B regulatory complexity and ongoing pressure for improved margins, it’s more important than ever to have the right solution for your 340B and pharmacy program management — and the right partner.

• Industry leading core functionality of our V340B platform with optional, patent-pending add-on modules to enhance all aspects of 340B operations in challenging and unique environments.

• Rapid 120-day average implementation time frame for both split billing and contract pharmacy solutions upon receipt of compliant dataset.

• Access to your own unique 340B program test environment — before and after implementation. Test environment runs continually in parallel to your live system.

• Easy and exportable reporting functionality including detailed data for manufacturer audits, HRSA audits, and UDS reporting.

• Advanced Reporting Insights gives users rich data visualization, interactive reports, and performance trends to help drive strategic change.

• Transition from one electronic medical record (EMR) to another without downtime (contingent upon receipt of dispense file from the covered entity).

• Multiple vendor support with controlled substances ordering system (CSOS) — efficiently place orders with both EDI (electronic data interchange) and non-EDI vendors.

• Two-week sprint release cycles ensure timely software updates driven by customer feedback, regulatory changes, and user needs.

• Flexible and “winners only” contract pharmacy pricing models. No true-ups.

• Verity Care Card Program — directly pass 340B savings to uninsured and underinsured patients.

• Referral capture solutions, self-serve or full service, to compliantly add meaningful savings lift to your 340B program.

• Responsive customer service provided by our in-house staff and the ability to submit and track issues in our online customer portal.

• 80% of our customer support cases resolve within two hours, and 95% within 24 hours.

• 97% highly satisfied rating of account management support.

• Own Use Program for any non-profit hospital to optimize your owned outpatient pharmacy for additional savings.

President & CEO: Nick Culbertson

Founded: 2014

Employees: 110

Phone: (410) 995-8811

Fax: (410) 995-8842

Utilize artificial intelligence and advanced analytics to audit 100% of medication use transactions — reducing the risk to your workforce, organization, and most importantly, your patients.

Address: 1629 Thames Street, Suite 200 Baltimore, MD 21231

Website: www.protenus.com

Founded in 2014, Protenus is an innovative, technology-first company headquartered in Baltimore, MD. Our team of problem solvers, subject matter experts, and support stewards spans the entire country. Protenus was born of a determination to solve problems in healthcare that would provide better patient outcomes and increase patient trust in the healthcare organizations where they sought care.

Although hospitals in the U.S. spend $39 billion per year to maintain compliance, most of it goes towards time-consuming, inefficient manual tasks. We thought the money could be better allocated to improving patient outcomes, so through innovation we began to tackle common healthcare compliance challenges. First focusing on protecting patient privacy, we then broadened our scope to issues of healthcare workers stealing or misusing controlled substances. In the years since, we’ve empowered hundreds of healthcare organizations to reduce risk. We’ve also cultivated the largest collaborative user community of healthcare compliance peers and experts from Protenus, PANDAS, that continues to move healthcare forward. That same innovation, determination, and community are still the pillars of Protenus today and carry us forward in our belief that the delivery of care should be without risk.

It’s important to partner with a vendor who understands current industry drivers and challenges, is aligned with your organization’s compliance and risk strategies, and is focused on providing the guidance and solutions to help you achieve your goals. Our powerful healthcare compliance platform harnesses the power of artificial intelligence (AI) to identify and surface inappropriate behavior that may otherwise go unnoticed as it happens, reducing risk to your workforce, your organization, and most importantly, the patients you serve.

When you choose Protenus as your partner, you are choosing a company that makes a commitment to innovation, determination, and community to better protect your organization, workforce, and patients. When working with Protenus, you will benefit from cutting-edge technology and a team that is dedicated to helping you navigate the complex landscape of healthcare compliance and risk management.

Who We Serve: Our sole focus is on healthcare organizations such as hospitals, health systems, AMCs, and large physician groups, supporting their risk elimination and compliance efforts as well as strategic initiatives like reducing costs, maintaining a stellar organizational reputation, and protecting their patients, workforce, and community at-large.

Our Vision: We believe that the delivery of care should be without risk.

Our Mission: We empower healthcare organizations with AI-powered, scalable risk-reduction solutions built to deliver cohesive and actionable data when and where needed. Ultimately, protecting the delivery of care while challenging the industry to focus on what matters most by driving the safest, highest quality patient outcomes.

Drug Diversion Surveillance, developed by Protenus, identifies and helps prevent clinical drug diversion incidents that occur within healthcare organizations. Awarded 2023 Best in KLAS for Drug Diversion Monitoring, the Protenus solution uses the power of artificial intelligence (AI) to monitor up to 100% of medication use transactions, it identifies unseen behavior as it happens, reducing risk to workforces, organizations, and most importantly, patients.

n Protenus Drug Diversion Surveillance Offers

• Visibility Into Incident Generation: Platform is powered by data covering 100% of medication use transactions to give investigators complete visibility into potential drug diverters’ behavior patterns that may otherwise go unnoticed.

• Time Savings and Efficiencies: Each incident is surfaced along with clear and concise background information to allow investigators to resolve incidents quickly. Customers have reported a five to 15 minute incident evaluation time using the Protenus platform.

• Flexible, User-Friendly Analytics and Dashboards: User-friendly dashboards reduce the need for manual analytics and report creation. Our File and Error Delivery dashboards empower IT end users to monitor and troubleshoot the robust set of data feeds that power the Protenus platform.

• Commitment to Continuous Innovation: Our product and engineering teams partner to receive feedback directly from our customers and deliver maximum value. Customers have forwardlooking visibility into planned feature and functionality enhancements.

The Drug Diversion Checkup [DDC] offers a quarterly or annual review of a healthcare organization’s overall drug diversion surveillance program, answering the question, “how is our program doing and how can we improve?” The DDC is included as part of the Premium Services Package or can be purchased as an add-on.

Key Business Partners/Supplier Contracts

Business Partner: Inmar Intelligence | Supplier Contract: Premier Inc.

Annie Lambert, PharmD, BCSCP, Clinical Program Manager

Topics Include:

• The role of pharmacists: How have they evolved, and what challenges they face.

• Regulatory changes and how pharmacies can stay up-to-date.

• How pharmacy CE requirements have evolved over the last 10 years.

• Effective pharmacy team training.

Erick Siegenthaler, Senior Director of Infusion Strategy, Kristin Fox-Smith, Managing Director 340B ACE, Angela De Ianni, Senior Director, Angie Amado, Director of Specialty Pharmacy Services, and Herolind Jusufi, Consultant

Topics Include:

• Five keys to success with specialty pharmacy.

• Partnering with Visante for infusion strategy.

• 340B optimization.

Nicole Faucher, President, Allison Arant, Senior Vice President of Client Development & Marketing, Mo Kharbat, Vice President of Industry Affairs, Alex Pham, Vice President of Client Strategy, Rusty Atkinson, Vice President of Information Technology, and Daniel Gladwell, Associate Vice President of Finance

Topics Include:

• Clearway Health: Specialty Pharmacy Accelerator.

• Three key elements that establish a healthy and effective partnership.

• How the information technology team impacts patients’ lives.

Jason Dutcher, Director of Strategic Accounts

Topics Include:

• Discussion on the Mundus HD Mini by EQUASHIELD.

• Demo of the Mundus HD Mini.

Immediate access to energy efficient and sustainable ultra-cold storage.

HELMER’S EXCLUSIVE OPTICOOL™ TECHNOLOGY

DELIVERS SUSTAINABLE, ENERGY-EFFICIENT WORLDCLASS TEMPERATURE PERFORMANCE

SUPPORTS TEMPERATURE UNIFORMITY

GX Solutions offer optimized temperature uniformity and recovery

ENERGY EFFICIENT

ENERGY STAR® certified ULTs are 35-45% more energy efficient than conventional medical-grade ULTs.

SUPPORTS SUSTAINABILITY

Environmentally-friendly natural HC refrigerants reduce heat output, decrease the carbon footprint, and decrease global warming potential.

IMMEDIATE ACCESS ULTRA-COLD STORAGE

GX Solutions ultra-low freezers are available for immediate shipment. Why wait?

General Manager: Matt Barga

Sales Leader: Betsy Cox

Toll-Free Phone: (800) 743-5637

GX Solutions ULTs provide immediate access to energy efficient and sustainable ultra-cold storage.

Address: 14400 Bergen Boulevard Noblesville, IN 46060

Website: www.helmerinc.com

Helmer Scientific, now part of Trane Technologies Life Science Solutions, is a U.S.-based manufacturer and worldwide distributor of medical-grade cold storage and laboratory processing equipment. We have over 45 years of experience providing high-quality temperature-controlled environments, with our products being used in over 125 countries. Precise temperature performance and control are essential to the successful storage of pharmaceuticals, and Helmer cold storage products are designed and developed with these considerations.

Product Overview

n GX Solutions ULT Freezers

GX Solutions ULT Freezers are designed and tested to deliver world-class temperature performance. Featuring OptiCool™ Cooling Technology, GX ULTs offer:

• Tight temperature uniformity and fast recovery after door openings.

• Quiet operation.

• Sustainable, natural hydrocarbon refrigerants.

n Efficiency and Sustainability

GX Solutions ultra-low temperature freezers support efficiency and sustainability initiatives without sacrificing performance. Helmer ULTs have been recognized by the U.S. Environment Protection Agency (EPA) as meeting Energy Star® certification requirement for the High-Performance Laboratory Grade Freezer category.

The Energy Star® program helps safeguard the environment by promoting superior energy efficiency across a broad range of products, including testing and recognition of cold storage devices used for clinical applications. This equipment category is used across healthcare and research facilities to store medications, vaccines, and more.

The energy management afforded by the OptiCool™ cooling system means that GX Solutions ULTs are 35-45% more energy efficient than conventional medical-grade ultra-low freezers. By using multi-stage cascade refrigeration technology combined with dual capacity compressors (VCCs) and natural hydrocarbon refrigerants, OptiCool™ efficiently manages both low and highstage cooling loops.

n

The OptiCool™ system uses naturally occurring refrigerants R170 and R290 that are EPA, Significant New Alternatives Policy (SNAP), and EU F-Gas compliant. These natural refrigerants are environmentally friendly, having no impact on ozone depletion and a very low Global Warming Potential (GWP) grade.

The use of natural hydrocarbons:

• Reduces Heat Output — allows facilities to place freezers in small work areas while limiting impact on HVAC systems.

• Decreases Carbon Footprint — uses natural hydrocarbon (HC) refrigerants to dramatically decrease global warming potential.

• Helps meet ever-changing energy standards.

Sustainability in the healthcare and life science industries has become a focus the past several years. While healthcare systems are responsible for treating patients impacted by climate change, they are also major contributors to the overall problem.

Helmer and its parent organization, Trane Technologies, are fully committed to supporting global sustainability initiatives. We have committed to removing a gigaton of greenhouse gas emissions from our customers’ carbon footprints by 2030.

Need an ultra-low freezer but don’t have time to wait? Helmer Scientific GX Solutions are available for immediate shipment.

Contact a Helmer Scientific sales representative at sales@helmerinc.com.

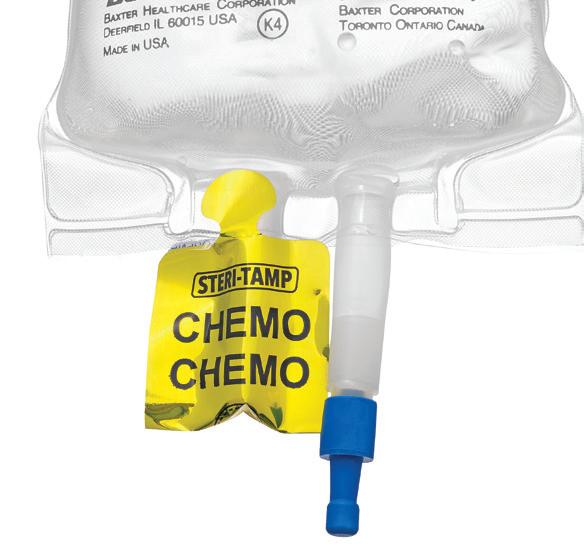

Avoid unwanted outcomes for critical drug products that need to be held at room temperature prior to administration.

President & CEO: Gary Sharpe

Founded: 1978

Employees: 300+

Toll-Free Phone: (800) 848-1633

Phone: (740) 477-3755

Address: P.O. Box 25 Circleville, OH 43113

Website: goHCL.com

What began in 1978 as a garage-based business at the home of HCL® Owner Gary Sharpe now encompasses five well-equipped facilities in central Ohio and reaches customers around the globe. Employment has grown too, with more than 300 employees now dedicated to the company’s mission of providing value with every interaction.

Sharpe discovered early in his career the need for healthcare products in sizes, quantities, and materials not readily available, and was determined to deliver. And has he ever.

Today HCL’s inventory includes more than 9,000 different products all designed to provide “Special Answers to Special Problems.” Most of these items are maintained locally in more than 320,000 sq. ft. of warehouse space and meet the supply needs of hospitals, pharmacies, chain drug stores, pharmaceuticals, and many other facets of healthcare.

Pre-administration vaccine protocol isn’t merely a suggestion, it’s a series of procedures designed to protect patient safety. Our temperature management solutions allow pharmacies to have processes in place that match industry standards so personnel can provide more confident care.

Using Controlled Room Temperature Cabinets, pharmacy staff can safeguard the vaccine supply and avoid unwanted treatment outcomes. Our inventory includes five units that maintain a range of 20ºC - 25ºC (68ºF - 77ºF) to keep specified doses such as smallpox, mpox, and some COVID-19 vaccines within safe parameters when they need to be stored in a freezer, then held at room temperature prior to administration.

Each unit includes a key lock to protect contents as well as audible and visual alarms. Choose from multiple sizes, all with glass doors, to meet a range of unique vaccine storage needs.

Refrigerators and freezers that provide reliable and consistent temperature control are the gold standard in pharmacies of all sizes, but knowing which ones to choose can be a challenge. We’ve taken the guesswork out of the process by filling our inventory with solutions designed to fit any footprint.

From full-size freestanding units to compact countertop models, we’re proud to offer cold storage options that provide these benefits — and many others:

• Proper storage to extend the shelf life of temperaturesensitive medications and reduce waste plus the cost of replacing items.

• Reliable temperature control to maintain drug integrity and minimize the risk for damage or degradation.

• Solid door gaskets to seal out the risk for environmental contaminants that can lead to bacterial growth or crosscontamination.

• Locking doors to protect controlled medications.

• Compliance to assure items are stored in accordance with the regulatory guidelines of agencies such as the CDC, FDA, and JCAHO.

In addition to appliances, we offer a full line of temperature monitoring devices along with vaccine storage and transport containers.

Our additional lines include unit dose; storage; IV accessories and injectables; compounding and dispensing; seals; plastic bags; refrigerators, freezers and accessories; temperature monitoring; infection prevention; carts and accessories; pharmacy supplies; crushers, cutters, and organizers; and error prevention.

We serve central supply/purchasing/MM; emergency department; facilities/engineering/maintenance; infection control/sterile processing; labs/clinical; nursing; oncology/ hematology; infusion; O.R.; pharmacy; and surgery centers.

We offer small package quantities, no order minimums, free samples, and ship most orders the same day. Our hassle-free return policy allows you to return any product, at any time, for any reason. Connect with our live chat team from 8 a.m. to 8 p.m. EST Monday - Friday.

Sponsored by an Educational Grant From Baxter

The right drug with the right diluent for the right dose at the right time has been and remains the ever-present responsibility of a pharmacist. The introduction of IV Workflow Management systems (IVWFM) into the sterile compounding space has significantly reduced the effort and improved the chances of consistently meeting this responsibility. This type of quality assurance verification has been the primary use of IVWFM systems since their introduction into the United States in 2008 when DoseEdge Pharmacy Workflow Manager system (DoseEdge) was introduced. However, the pharmacist’s responsibilities continue to grow with the increasing number and ever more strict regulations and guidelines governing the processes for compounding sterile preparations and the environments they are prepared in. Therefore, pharmacists must consider how these IVWFM systems can be used to support these needs.

Accurate and consistent data from published literature on the incidence of IV compounding errors is difficult to find as most facilities and pharmacists are reluctant to share this type of information. Confounding this is the fact that there is no single recognized definition of what constitutes these types of medication errors. The relatively small number of data sets that are available for error rates at individual facilities or groups of facilities not using any type of IVWFM system (or technology-assisted workflow systems) can range from 0.22%1 to 9%2. These errors can result from pharmacy staff not knowing with specificity what drugs, diluents, and volumes should be used to prepare a compounded sterile preparation (CSP).

Before automation, pharmacists had to verify every CSP dispensed from the cleanroom using manual and sometimes inexact methods. It was not always possible to determine if the correct drug and/or amount was added to

an IV container. Therefore, the true number of compounding errors could not be determined.

The Institute for Safe Medication Practices (ISMP) published a survey in October of 2020 that included 634 respondents, 80% of whom were pharmacists, and another 18% were pharmacy technicians3. The survey results demonstrated some concerning results3:

• 56% of all responders (355) reported always having and following standard operating procedures for the compounding process.

• 48% of pharmacist responders (243) stated that it was always easy to identify with certainty which drugs, diluents, and volumes were used when verifying the preparation of a CSP.

• 57% of respondents (361) were using technologies to support sterile compounding.

• 47% of the 361 respondents using technology (170) were taking advantage of IVWFM systems that included both barcode scanning and image capture to help manage risks.

Additionally, on November 1, 2022, the United States Pharmacopeia (USP) published the revised General Chapter <797> Pharmaceutical Compounding — Sterile Preparations (USP <797>) which provides the new minimum acceptable standards for sterile compounding. In recent years, USP <797> requirements seem to also be garnering more attention from organizations such as The Joint Commission and other accrediting bodies which now conduct inspections according to these requirements.

Many of the updates to USP <797> are relatively minor changes, and the basic principles remain the same. Examples of this are the need to maintain acceptable levels of viable and non-viable particle counts in the classified areas. However, more detail is provided around the performance and frequency of the required sampling. These changes in testing detail don’t affect the basic requirements of how many particles per cubic meter or colony forming units per cubic meter are acceptable as those limits are set by separate ISO standards. However, as with previous revisions of the chapter, some changes in the guidelines are more significant and may require considerable

changes to pharmacy and cleanroom operations. An example of this type of significant change would be how restricted-access barrier systems (RABS) can be used. In the 2008 version of the chapter, the ISO 5 environment that can be achieved with these systems alone was considered sufficient to apply extended Beyonduse Dates (BUDs) for CSPs regardless of where the RABS was located4. However, the 2023 version of USP <797> requires that the RABS be located in an ISO 7 environment to apply Category 2 or 3 beyond-use dating5. Essentially, a RABS in an unclassified space is now equivalent to a segregated compounding area. In any case, whether the standards of the 2008 and 2023 versions of the chapter remain the same, or they receive minor or significant updates, history tells us that they can be challenging to consistently adhere to for many pharmacies. In the 2023 State of Pharmacy Compounding survey published in Pharmacy Purchasing and Products, only 31% of respondents indicated their facilities were in full compliance with standards that will become effective in November of 20236. An even more alarming statistic is that only 76% of respondents indicated their facilities were in full compliance with the 2008 version of USP <797>6

The compounded sterile preparation goals of ISMP and USP are both rooted in ensuring that safe medications are available to patients when they are needed, ISMP with the Guidelines for Sterile Compounding and the Safe Use of Sterile Compounding Technology, and USP with General Chapter <797>. Although, in some ways, the two organizations approach the goals differently, there is overlap in that they both focus on processes to achieve the goals. It’s this process overlap that can allow IVWFM systems with broad functionality such as the DoseEdge system to support the needs of pharmacies in their pursuit of compliance with both organizations’ guidelines.

From an ISMP perspective, the use of technology such as an IVWFM system to improve the safety, efficiency, and prioritization of compounding within the cleanroom is a well-known and frequent topic of discussion. In fact, ISMP includes this in their 2022-2023 Targeted Medication Safety Best Practices for Hospitals and has done so since 20167. These improvements can be achieved by automating potentially error-prone processes that have traditionally been performed manually. These error-prone processes can include researching and following the correct and complete compounding process, manually performing dose calculations and determining appropriate BUDs, prioritizing urgently needed products and using the ‘syringe pull-back’ or ‘proxy’ method for indicating volumes of drugs injected into final containers. Additionally, in 2022, “ISMP Guidelines for Sterile Compounding and the Safe Use of Sterile Compounding Technology” was published. It contains essential technology attributes, safe pharmacy processes, safety gaps, and associated

best practices for various technologies such as automated compounding systems, IV robotics and IVWFM systems.

The ISMP essential attributes for IVWFM systems are listed below. Many align nicely to address the gaps or issues associated with CSP preparation8

IV workflow management systems are interfaced with the electronic health record to eliminate order transcription from one system into another. If a compounded sterile preparation has been discontinued before initiation of the compounding process, the system interface allows for the removal of these products from the queue.

IV workflow management systems allow users to create a master formulation record for nonpatient specific batch, stock solution, and patientspecific compounded sterile preparations.

When master formulation records are created, the IV workflow management system prompts for an independent double check, which is documented in the system.

Master formulation record changes are timestamped, saved, and identify the user who made the modification.

IV workflow management systems provide an electronic log of changes made to the database by users.

IV workflow management systems allow users to customize the incoming order queue to prioritize work.

Machine-readable coding (e.g., barcode, RFID) is used to verify source products, including diluents, during the compounding process.

IV workflow management systems automatically perform calculations or conversions.

IV workflow management systems guide users through essential steps in the compounding process including which steps require video or still images or gravimetric analysis.

Image-capture pictures are clear such that syringe graduation marks, drug and/or diluent names, lot numbers, and expiration dates are easily visible.

System Functionality

IV workflow management systems that use gravimetric analysis prevent users from creating master formulation records for preparations that are outside the system’s tolerance limits, and if staff attempt to weigh a volume outside the integrated scale’s tolerance limit the IV workflow management system alerts the user.

IV workflow management systems document all steps and components of the compounding process (e.g., products used, the practitioner who performed the compounding, the primary engineering control, machine readable code scans, date and time of preparation, alerts or warnings presented during the process, the practitioner who verified the preparation), and the information is available to users in a log and/or report.

IV workflow management systems allow for remote verification using video or image capture, and, when used, gravimetric analysis.

IV workflow management systems track beyond-use dating of opened or reconstituted products to warn practitioners and prevent use of an expired product.

IV workflow management systems allow for customization of labels (e.g., tall man lettering, color print, reverse print, electronic health record compatible barcode).

IV workflow management systems limit the printing of the dispensing label until the compounding process is complete.

Workload (e.g., incoming load) is documented by the technology and captured in a report to inform and facilitate operational improvement.

Close-call compounding events (e.g., wrong drug scans) intercepted by the technology are captured in a report to facilitate compounding error analysis and process improvement. Data in vendor reports are provided in a useful format and do not require significant manipulation by the end user.

When a system update is available, IV workflow management system vendors ensure all customers receive and install the update in a reasonable timeframe.

The use of IVWFM systems to help meet the Chapter <797> standards is discussed far less, if at all. However, given the broad functionality of some of these systems, such as the DoseEdge system, they can influence pharmacy procedures and documentation practices etc. which can directly or indirectly support these requirements.

The following are many of the standards from the 2023 version of USP <797> that could potentially be supported by using IVWFM systems5

USP Chapter <797> Standards How DoseEdge Functionality Could Provide Support

Personal hygiene and garbing are essential to maintain microbial control of the environment. Most microorganisms detected in cleanrooms are transferred from individuals. Squamous cells are normally shed from the human body at a rate of 106 or more per hour, and those skin particles are covered with microorganisms. Individuals entering a compounding area must be properly garbed and must maintain proper personal hygiene to minimize the risk of contamination to the environment and/or CSPs.

Individuals that may have a higher risk of contaminating the CSP and the environment (e.g., personnel with rashes, recent tattoos, oozing sores, conjunctivitis, or active respiratory infections) must report these conditions to the designated person(s).

The designated person(s) is responsible for evaluating whether these individuals should be excluded from working in compounding areas before their conditions have resolved because of the risk of contaminating the CSPs and the environment.

The design of the facility should take into account the number of personnel and their movements.

4.1 Protection from Airborne Contaminants

Proper design and controls are required to minimize the risk of exposure of CSPs to airborne contaminants.

Total airborne particle counts by ISO classification must not be exceeded:

ISO 5 = 3520 particles/m3

ISO 7 = 352,000 particles/m3

Remote verification could help decrease the number of pharmacists required to enter the cleanroom to verify doses including in-process and final checks.

This can be especially beneficial on off-shifts when staffing may be lower or when pharmacist verifiers with higher risks for contamination may be the only pharmacist on duty.

Remote verification can help minimize the number of pharmacist verifiers needing to enter the cleanroom which may be able to affect the overall design. This decrease in staff needing to enter the cleanroom can also be used as a control mechanism to decrease airborne contaminants.

6. MICROBIOLOGICAL AIR AND SURFACE MONITORING

6.2.3 Viable air sampling data evaluation and action levels

Viable airborne particle counts by ISO classification must not exceed actionable levels:

ISO 5 > 1 cfu/m3

ISO 7 > 10 cfu/m3

6.3.3 Surface sampling data evaluation and action levels:

ISO 5 > 1 cfu/media device

ISO 7 > 10 cfu/media device

11.1 Creating Master Formulation Records (MFR)

An MFR is a detailed record of procedures that describes how the CSP is to be prepared. An MFR must be created for all CSPs prepared from nonsterile ingredient(s) or CSPs prepared for more than one patient.

11.2 Creating Compounding Records (CR)

CR documents the compounding of each CSP. A CR must be created for all Category 1, Category 2, and Category 3 CSPs. A CR must also be created for immediate-use CSPs prepared for more than one patient. The CR must be created to document the compounding process. A prescription or medication order or label may serve as the CR. If an ACD, workflow management system, or other similar equipment is used, the required information in the CR may be stored electronically as long as it is retrievable and retains the required information.

12.2 Sterility Testing

For Category 2 CSPs assigned a BUD that requires sterility testing (see Table 13) and all Category 3 CSPs, the testing must be performed.

12.3 Bacterial Endotoxins Testing

Category 2 injectable CSPs compounded from one or more nonsterile component(s) and assigned a BUD that requires sterility testing and Category 3 injectable CSPs compounded from one or more nonsterile component(s) must be tested to ensure that they do not contain excessive bacterial endotoxins.

The decrease in staff needing to enter the cleanroom associated with remote verification can also be used as a control mechanism to decrease viable air and surface contaminants.

Each CSP label must state the date, or the hour and date, beyond which the preparation must not be used and must be discarded (i.e., the BUD). The BUD is determined from the date and time that preparation of the CSP is initiated.

14.2 Parameters to Consider in Establishing a BUD

When establishing a BUD for a CSP, compounders must consider parameters that may affect quality.

The following DoseEdge functionality can be used in aggregate to support most/all the requirements for the contents of an MFR and CR, and help ensure that the MFRs and CRs are followed:

• Customizable Drug Formulary

• Customizable Product Formulary

• Customizable Actions

• Customizable Procedures

• Customizable Scan Events

• Storage capabilities

• Customizable product-specific information fields

Customizable Actions and/or Procedures can be used to remind compounders when sterility and/or bacterial endotoxin testing (or other requirements) needs to be completed.

The BUDs for CSPs are based primarily on factors that affect the achievement and maintenance of sterility, which include, but are not limited to:

• Conditions of the environment in which the CSP is prepared

• Aseptic processing and sterilization method

• Starting components (e.g., sterile or nonsterile ingredients)

• Whether or not sterility testing is performed

• Storage conditions (e.g., packaging and temperature)

14.3 Establishing a BUD for a CSP

The BUD must not exceed the shortest remaining expiration date of any of the commercially available starting components.

14.5 Multiple-Dose Containers

The use of preservatives must be appropriate for the CSP formulation and the route of administration. For example, the preservative must not be inactivated by any ingredients in the CSP, and some preservatives are not always appropriate for the patient (e.g., neonates) or route of administration (e.g., intrathecal or ophthalmic injection).

After a multiple-dose CSP container is initially entered or punctured, the multiple-dose container must not be used for longer than the assigned BUD or 28 days if supported by antimicrobial effectiveness testing results on the CSP, whichever is shorter.

BUDs are automatically calculated from the time the compounding process is initiated. They can be customized and automated to account for the many options that are available between and within the three Compounding Categories

BUDs can be customized at the dose level based on:

• Starting components used in the dose

• Location of preparation (environmental conditions such ISO classified vs SCA/RABS)

• Storage conditions

• Processes used during preparation (including sterility testing)

The BUD of individual doses are compared to the BUDs or expiration dates of the components used in dose to ensure they are appropriate.

With ‘Preservativefree” and “Route of Administration” designations in the Product Formulary, inappropriate component use can be prevented.

“Work in Progress” products and labels can automate BUDs for components used during preparation

15. USE OF CONVENTIONALLY MANUFACTURED PRODUCTS AS COMPONENTS

15.1 Use of Conventionally Manufactured Single-Dose Containers

A conventionally manufactured single-dose container is a container closure system that holds a sterile product for parenteral administration (injection or infusion) that is not required to meet the antimicrobial effectiveness testing requirements. If a single-dose vial is entered or punctured only in an ISO Class 5 or cleaner air, it may be used up to 12 h after initial entry or puncture as long as the labeled storage requirements during that 12-h period are maintained. Opened single-dose ampules must not be stored for any time period.

15.3 Use of Conventionally Manufactured Pharmacy Bulk Packages

A conventionally manufactured pharmacy bulk package is a container of a sterile product for parenteral use that contains many single doses. The contents are intended for use in a pharmacy admixture program and are restricted to the sterile preparation of admixtures for infusion or, through a sterile transfer device, for the filling of empty sterile containers. The pharmacy bulk package must be used according to the manufacturer’s labeling (see <659>, General Definitions, Injection Packaging Systems). The pharmacy bulk package must be entered or punctured only in an ISO Class 5 PEC.

18.1 Notification About and Recall of Out-ofSpecification Dispensed CSPs

If a CSP is dispensed or administered before the results of release testing are known, the facility must have procedures in place to:

•Immediately notify the prescriber of a failure of specifications with the potential to cause patient harm (e.g., sterility, strength, purity, bacterial endotoxin, or other quality attributes)

•Recall any unused dispensed CSPs and quarantine any stock remaining in the pharmacy.

•Determine the distribution of any affected CSP, including the date and quantity of distribution.

•Identify patients who have received the CSP.

“Work in Progress” products and labels can also automate BUDs for single dose products, multiple dose products and pharmacy bulk packages used during preparation

The safety, efficiency, and waste-reduction benefits with the use of IVWFM systems are well-established. ISMP has put forth much effort in defining what an effective system should be capable of and recommending their use among other technologies in the cleanroom. Although IVWFM systems are only used in a minority of facilities, that number continues to grow due to an ever-increasing focus on safety and efficiency.

With the updated version of USP <797> effective on November 1, 2023, there is also a heightened interest in what facilities need to do to become compliant before the effective date.

IVWFM systems with broad functionality such as the DoseEdge system, can help support pharmacies in their pursuit of regulatory compliance, optimized workflows, compounding efficiency, and most of all, patient safety.

The DoseEdge System is not intended to replace the knowledge, judgment or expertise of pharmacists and pharmacy technicians in the preparation of IV admixtures or oral doses.

For safe and proper use of the product mentioned herein, please refer to the appropriate Operator's Manual.

Chuck Ferris, R.Ph. Associate Director, Medical Affairs ~ Baxter Healthcare Corporation

Jeff Brittain, PharmD, BCPS Senior Manager, Medical Affairs ~ Baxter Healthcare Corporation

References

Lot number tracking can be used to trace products and components to individual patient doses.

1. Stephen F Eckel, et al. Multicenter study to evaluate the benefits of technology-assisted workflow on i.v. room efficiency, costs, and safety, American Journal of Health-System Pharmacy, Volume 76, Issue 12, 15 June 2019, Pages 895–901.

2. Elizabeth Flynn, et al. Observational study of accuracy in compounding i.v. admixtures at five hospitals, American Journal of Health-System Pharmacy, Volume 54, 15 April 1997, Pages 904-12.

3. ISMP Medication Safety Alert Newsletter October 22, 2020 Volume 25, Issue 21. Pg 1-5

4. Pharmaceutical compounding—sterile preparations (general information chapter 797). In: The United States Pharmacopeia, 35th rev., and the National Formulary, 30 ed. Rockville, MD: The United States Pharmacopeial Convention; 2012: pp 2-38 State of Pharmacy Compounding.

5. Pharmaceutical compounding—sterile preparations (general information chapter 797). In: The United States Pharmacopeia, https://online.uspnf.com/uspnf/document/1_GUIDA4CAAA8B-6F02-4AB8-8628-09E102CBD703_7_en-US35th rev.pp 1-33

6. Pharmacy Purchasing and Products, 2023; 4:1-53 National Survey (Can’t get fill reference info)

7. ISMP Targeted Medication Safety Best Practices for Hospitals, 2022-2023

8. 2022 ISMP Guidelines for Sterile Compounding and the Safe Use of Sterile Compounding Technology

Baxter and DoseEdge are trademarks of Baxter International Inc. US-MD14-230014 v1.0 10/2023

Medication errors can occur at any point in the infusion therapy process.

Help protect patients, from dose preparation to administration.

CEO: Steve Rough

Founded: 1999

Toll-Free Phone: (866) 388-7583

We’re in the business of advancing pharmacy. Our consultants work with hospitals and health systems combining a wealth of expertise with personalized and comprehensive support to optimize your pharmacy operations and deliver better patient care.

Address: 101 East 5th Street, #2220 St. Paul, MN 55101

Website: www.visanteinc.com

Visante is a specialized consulting firm focused exclusively on helping health systems accelerate strong financial and operational performance through pharmacy. Our team of professionals brings deep, contemporary expertise and innovation to optimizing all aspects of a fully integrated health system pharmacy program, driving significant value quickly. By providing customized solutions to fit the needs of our clients, we deliver sustained financial results through revenue growth, cost savings, and optimal business performance.

n Specialty Pharmacy Services

A clearly defined specialty pharmacy strategy can help improve patient care and greatly improve your bottom line. Developing a specialty pharmacy strategy or expanding your existing services can be a complex process, but our team of experts guides you through each phase and delivers lasting ROI. Our specialty pharmacy consulting capabilities include: operational assessment and pro forma models; multi-year business and strategic plans; facility design including workflow and automation options; implementation and project management; accreditation support (URAC/ACHC/CPPA); contract pharmacy strategy, if applicable; wraparound strategy to include consideration for site of care challenges (infusion); and home infusion, DME strategies, and business planning.

n

A comprehensive infusion services strategy can help lower total cost of care, maximize patient outcomes and access to quality care, and optimize organizational financial performance. Visante infusion consulting helps with business planning, design, and implementation of comprehensive infusion care strategies using our deep and specialized expertise in all areas, including home infusion therapy, specialty pharmacy, 340B program management, supply chain strategies, and innovative solutions to drug delivery and therapy administration.

n 340B Solutions

Visante’s independent, external audit support provides transparency to your 340B processes, allowing you to recognize compliance gaps while focusing on new opportunities within the program. Our 340B team

offers unique expertise in supporting 340B ESP™ data submission and price restoration analysis. Our services include: internal and external audit support, on-site HRSA audit support, and corrective action plan guidance in the event of HRSA audit findings; gap analysis and targeted recommendations, focusing on long-term strategy in the mixed-use and contract pharmacy space to ensure program optimization; program implementation and development of internal oversight structure and maintenance; and split billing RFP guidance, implementation, and program re-designs.

n Pharmacy Revenue Cycle

Sustained financial growth is one of the top challenges for even the most successful organizations in the healthcare industry. Effective pharmacy programs can increase revenue by maximizing existing opportunities, creating new programs and services, and reducing costs. Our team of experts are here to help maximize financial performance within your organization through our mastery of both pharmacy and revenue cycle operations. Our consultants bring a wide range of experience to the table to assist each of our clients in a way that best fits them and their financial goals.

n Pharmacy Supply Chain Optimization

Supply chain and utilization management are complex and ever-changing functions of a pharmacy enterprise. To find success in these areas, disciplined focus and alignment must be prioritized. Visante’s supply chain experts help hospitals and health systems achieve reliable, safe, and efficient drug supply chain performance while also realizing significant financial returns.

Left: GM7030 PATT2®, Personal Aseptic Technique test kit, 3mL ampules, 20mL vials, 100mL partially lled minibag. Below: ET1000 EnviroTest® TSA with Lecithin & Tween 80 growth media paddles for surface, air, or glove ngertip sampling.

President & CEO: Brady K. Schwarz

Founded: 1992

Toll-Free Phone: (800) 837-8361

Phone: (530) 272-8700

Fax: (530) 272-8702

Providing quality assurance products to hospitals and pharmacies practicing sterile compounding, with a singular focus on pharmacy compliance. Our long-standing regional distribution partners are able to provide exceptional in-person service and training.

Address: 1415 Whispering Pines Lane, Suite 150 Grass Valley, CA 95945

Website: www.qimedical.com

Q.I. Medical, Inc. was founded in 1992 with a focus on providing the sterile compounding industry with testing kits and products to assure proper technique and quality is maintained in their facility. We have a broad network of distribution partners throughout North America, Canada, and other international markets. These distribution partners provide in-person servicing and education to accounts to comply with USP guidelines.

Our cost-effective, disposable products are available for various needs in the compounding pharmacy. Aseptic technique validation kits are available for low, medium, and high-risk settings. We also sell multiple à la carte sizes of vials, bags, tubes, and syringes of growth media for facilities looking to create a custom media fill test that mimics their day-to-day practice. In regard to environmental monitoring/gloved fingertip sampling, our EnviroTest™ paddle is ideal for both. The rectangle shape and built-in hinge allow for testing critical areas such as the edges and corners of a hood and behind latch handles. Sterility testing products are available in both USP <71> approved methods of testing. For the full filtration method, the QT Micro™ and QT Junior™ systems work for both small and large volume solutions. For the direct inoculation methods, our TuffTest 2™ product is ideal.

All Q.I. Medical growth media is challenged with a battery of USP specified organisms and lot specific Certificate of Analysis (CofA) are available for download.

All products are sold through regional stocking distributors in order to provide fast local service and support.

Additional products are available for validation of hazardous drug handling, automated compounder manipulation validation, filter integrity testing, and vial adaptors.

n Support Equipment Includes:

• Incubators

• Sterile Filters

• Vial Blocks

• UV Lights

To learn more about how Q.I. Medical, Inc. can help your facility, please contact us at (800) 837-8361 or email info@qimedical.com.

Explore our inhalation line at American Health Packaging

Order inhalation products through your preferred wholesaler and experience the reliability of AHP’s serialized, barcoded unit dose offerings for acute care centers, hospitals, and long-term care facilities.

Exciting new products are on the horizon! Stay tuned for what’s next in our commitment to enhancing patient care.

Inhalation

Metered dose inhaler (MDI)

Click here to explore our inhalation line!

AD202404-0212

With a responsive line of barcoded unit-dose oral solutions, a growing liquid unitdose offering, as well as individually wrapped inhalants, AHP continues to deliver on it’s commitment to supporting pharmacy efficiency.

Senior VP &

General Manager: Sasha Kellerman

Toll-Free Phone: (800) 707-4621

Address: Columbus, OH 43217

Website: www.americanhealthpackaging.com

Located in Columbus, Ohio, American Health Packaging (AHP) is an industry leader in manufacturing serialized, barcoded unit-dose (UD) medications provided for the healthcare marketplace. As a UD manufacturer, AHP’s commercially-available UD products are available to hospital, institutional, and long-term care pharmacies nationwide through partner GPOs and wholesalers.

AHP’s reputation for quality is supported by a 30+ year history of broad manufacturing expertise — operating a facility that is registered with the FDA, fully adherent to cGMP guidelines, and licensed by the DEA to package Schedule II-V controlled substances. Synonymous with unit dose, following years of success and leadership in the production of oral solids, AHP expanded their offering and now includes liquid unit-dose cups, inhalants, and powder/granule oral suspension.

AHP is committed to supporting pharmacy efficiency through a diverse range of both high-utilization and niche treatments. Producing nearly 600 UD oral solid SKUs for the healthcare marketplace, AHP’s broad selection of products are produced with quality components and printed with legible barcodes that facilitate effective execution of BCMA initiatives. Their wide selection of products reduces the gap between what pharmacies are forced to repackage themselves, and what is commercially available on the market — supporting health systems nationwide in their efforts to create efficiencies throughout the chain of care.

AHP’s tailored offering of UD oral liquids provide similar efficiency, safety, and cost-savings benefits as their oral-solids products. Product features include right-sized packaging, thoughtful tray design, differentiated labelling, and accurate barcodes. AHP’s unit-dose inhalants provide efficiency and feature individually-wrapped vials and pouches barcoded to the dose level. AHP oral solids, liquids, and inhalants include major therapeutic classes and product groups to meet unique pharmacy needs. They are continuously evolving to meet the changing demands of caregivers and staff to support more effective medication procurement strategies.

As facilities nationwide compete to demonstrate they provide the highest quality of care, AHP UD supports caregivers as they strive to promote positive outcomes for patients. Pharmacies simultaneously strive to be cost-effective as they provide necessary resources for caregivers.

AHP UD supports these objectives while providing cost-savings opportunities. Sourcing pre-packaged UD allows pharmacies to obtain adequate supply while mitigating capital expenses, such as those related to repackaging equipment, bulk supply, and labor.

n Patient Safety: Ensuring the right medication is given to the right patient at the right time — and in the right strength — is imperative. Pharmacies can facilitate effective execution of these “rights” by providing caregivers with as many products in a pre-packaged UD format as possible. Removing repackaging tasks from the pharmacy eliminates a potential point of failure during the UD process as medications arrive to pharmacies ready to dispense.

n Pharmacy Efficiency: Pharmacies strive to process orders and supply the proper medications to caregivers for their patients as quickly as possible. Adding potentially-complex repackaging steps to the procurement process not only harms the ability of pharmacy to supply caregivers effectively, but also removes clinicians from their core patient care competencies. In addition, pre-packaged UD often allows for products to be sourced more quickly than third-party repackaging can support.

n Cost-Savings Opportunity: Health systems that choose to package on-site must consider all direct costs, such as purchasing capital equipment for packaging areas and paying highly trained clinical professionals to perform, manage, and support non-core work. AHP UD products allow for pharmacies to avoid these costs while also shifting the potential costs associated with packaging errors. The pre-packaged format also prevents additional fees that may result from utilizing thirdparty repackaging services.

n Liability Management: Pharmacy repackaging operations can be subject to distractions from a variety of sources. An active pharmacy environment can encourage lapses in concentration and present opportunities for staff error. Since these errors may vary in gravity and place liability on the facility and caregivers, mitigation of risk is key. Unit dose from American Health Packaging can help shift liability burden away from staff.

Effective execution of BCMA initiatives require medications that scan correctly at the bedside. With a robust, growing, unit-dose portfolio AHP provides reliable access to UD treatments. AHP products promote safety towards BCMA and efficiency in pharmacy while freeing up internal resources. AHP UD supports pharmacies as they strive for compliance with USP General Chapter <800> guidelines. As pharmacies craft effective procurement strategies to meet the needs of their facilities, protecting patients and caregivers alike from potential harm while handling hazardous drugs is a priority. AHP’s UD portfolio has a number of NIOSH/USP <800> products already packaged for bedside dispensing which supports compliance to USP <800> handling procedures.

Dan Cleveland, PharmD, BCPS

System Director of Pharmacy Services

~ Union Health

Kathy Canup, PharmD

Clinical Operations Manager

~ CPS Solutions, LLC/Union Health

n An Integrated Health System Dedicated to Treating the Whole Patient Union Health is an integrated health system serving communities throughout western Indiana and eastern Illinois. The main campus, Union Hospital, is a 350-bed not-for-profit community hospital in Terre Haute, Indiana. The health system also includes Union Medical Group, which is comprised of over 130 providers in 20 specialties practicing at locations throughout the region — making it Wabash Valley’s largest multi-specialty provider group.

Union Health strives to provide patient-centered care using a collaborative, multidisciplinary approach. An essential part of that care is helping patients get affordable access to the medications they need. That’s why Union Health had long operated two outpatient retail pharmacies — one in the main hospital serving discharged patients and employees and another for the general public in their medical office building. However, at that time, the health system did not have its own specialty pharmacy, which left a gap in its ability to provide exceptional patient care for those prescribed complex, expensive therapies to manage cancer, rheumatoid arthritis, HIV, multiple sclerosis, and other chronic conditions.

n Navigating the Complexities of Specialty Medication Access

According to System Director of Pharmacy Services, Dan Cleveland, PharmD, BCPS, for Union Health, without a specialty pharmacy — patients and providers were left to navigate an often confusing process on their own.

“The trouble is that process is not always straightforward,” explains Cleveland. That’s because specialty medications require pre-authorizations, so there can be a lot of back and forth and follow-up required. “We were hearing from providers, especially

“Hospitals our size don’t often have an onsite specialty pharmacy. Being able to help our patients access and manage these complex medications improve their experience and outcomes — and that’s something we couldn’t have done without the help of CPS.”

Dan Cleveland, PharmD, BCPS System Director of Pharmacy Services

~ Union Health

those in the oncology and rheumatology space, that patients were waiting weeks before they started therapy.”

Plus, since specialty medications are often very expensive, most patients need financial assistance above and beyond insurance coverage. “That’s just another process to be managed and can be a barrier to treatment,” says Cleveland. “And while our providers did what they could — they simply didn’t have the dedicated staff necessary to handle all the administration that comes along with specialty medications.” That’s why he decided to explore how Union Health could establish an onsite specialty pharmacy to elevate patient care.

n A Partnership That Paved the Way for Patient-Centered Specialty Pharmacy Services

After conversations with a number of potential partners, Union Health ultimately chose CPS Solutions, LLC (CPS), one of the nation’s largest pharmacy and hospital services providers, to build out and manage their specialty pharmacy. “One of the things that stood out about CPS was their expertise and relationships with payors and manufacturers,” Cleveland says. Most payors require dual accreditation for specialty pharmacies to gain access to their specialty networks and limited distribution drugs — and CPS’ team of experts helps systems like Union Health earn those accreditations rapidly. “I just knew my team and I would not have the time to navigate that piece of the puzzle, so it was important for me.”

While payor access is one of the keys to a successful specialty pharmacy — having the people and processes in place to help patients is also critical. That’s why CPS hires and integrates pharmacists and liaisons in clinics to work directly with staff and providers under Union Health’s brand. The benefit of CPS’ locally-focused approach is that when one of the specialty pharmacy team reaches out to patients — they know they are talking to someone from their community. “We’ve found that having a local Terre Haute patient talking to a Terre Haute-based pharmacist or liaison has made a difference in building trust and helping them understand we have a specialty pharmacy right here onsite,” says Senior Vice President, Zel Skrtic, PharmD, of Onsite Operations for CPS.

Clinical Operations Manager, Kathy Canup, PharmD, who grew up in Wabash County and has been with the health system for 13 years, oversees the specialty pharmacy operations. She and her team take the time to work with patients to get medications into their hands as quickly as possible. “We get prior authorizations and do what we can to make the medication affordable through insurance, copay cards, financial assistance programs, or grants,” Canup says. Beyond that, specialty pharmacists and liaisons support patient needs — walking them through treatment plans, helping them manage refills, and more.

n Fast, Affordable Access to Critical Specialty Medications

Union Health Specialty Pharmacy opened its doors in February of 2021. “Once we signed the contract — it was pretty much plug and play from our standpoint,” says Cleveland. CPS handled everything, including absorbing the upfront risk from a capital and operational staffing perspective. “Hospitals our size don’t often have an onsite

“We’ve found that having a local Terre Haute patient talking to a Terre Hautebased pharmacist or liaison has made a difference in building trust and helping them understand we have a specialty pharmacy right here onsite.”

Zel Skrtic

Senior Vice President of Onsite Operations

~ CPS Solutions

specialty pharmacy,” he explains. “Being able to help our patients access and manage these complex medications improves their experience and outcomes — and that’s something we couldn’t have done without the help of CPS.”

Today, the specialty pharmacy supports Union Health’s patients who are dealing with various cancers, rheumatoid arthritis, neurological disorders, infectious diseases, and respiratory conditions. Canup says having pharmacists and liaisons onsite is a big win for clinic staff. “I didn’t realize the workload nurses were taking on trying to obtain prior authorizations and help patients research and apply for financial assistance ” Now, with dedicated staff to manage the process, provider satisfaction has improved. Moreover, patients are better able to access and afford their therapies. “The specialty pharmacy maintains a 96.7% prior authorization approval rate and has saved patients over $2 6M in financial assistance,” says Canup.

As a result, patient satisfaction has increased, too. Union Health earned a Net Promoter Score (NPS) of 97.7, placing it as the 2024 winner and top performer for patient loyalty in Managed Markets Insight & Technology’s (MMIT) 9th Annual Specialty Pharmacy Patient Choice Awards. This is a significant honor as the MMIT awards recognize health system specialty pharmacies nationwide that provide exemplary patient satisfaction.

n Uncovering New Opportunities

Working with CPS provides Union Health with opportunities to serve that community that would not otherwise have been possible. This includes focusing on programs and initiatives to improve patient adherence and outcomes.

In 2023, the specialty pharmacy team began working with a group of local neurologists to follow their migraine patients closely. “Starting with a patient’s baseline migraines, we track their progress once they’ve started therapies to confirm treatment is effective and migraine days are decreasing each month,” explains Canup. If there isn’t improvement after three months, the pharmacist works closely with the neurologist to adjust and optimize therapy. “And when an office visit is required for further evaluation, we can typically get patients seen faster so they are able to adjust therapies as needed in a more timely fashion.”

Working with the rheumatology clinic, the specialty pharmacy team also conducted a study to determine if self-administered subcutaneous injections could be a more affordable and convenient option for patients with autoimmune diseases being treated with intravenous (IV) therapies. The catalyst for the study was related to the cost of IV therapies, which were becoming unaffordable for many patients, even with financial assistance, as well as the time and expense spent traveling to a medical facility for treatment. Self-administered medications were delivered to the homes of patients who agreed to participate. Union Health specialty pharmacists then interviewed participants using a standardized six-question survey to measure patient satisfaction, ease and convenience of use, and confidence in the self-administered medication. Overall, 87% of participants said the self-administered medication was either extremely convenient or very convenient. With this, the specialty pharmacy team began working with rheumatology patients to

The specialty pharmacy maintains a 96.7% prior authorization approval rate and has saved patients over $2.6M in financial assistance.”

Kathy

Canup,

PharmD Clinical Operations Manager

~ CPS Solutions, LLC/ Union Health

educate them on at-home treatments — helping them transition from IV therapies and secure financial assistance to cover more of the medication costs.

Overall, how would you rate the convenience of receiving your medication with the autoinjector?

Extremely Convenient

Moderately Convenient

Very Convenient

• 80% increase in Rx volume.

• 50% growth in the number of patients serviced.

• 92% patient adherence.

• $2.6 million in financial assistance secured.

• 94% provider satisfaction.

“What we do on a daily basis is very rewarding,” says Canup. “Patients are constantly thanking us for making a complex and scary situation more manageable.” That includes helping them get access to the specialty medications they need, as well as the financial assistance to make treatment more affordable. She also notes that being in the clinics helps doctors and nurses understand exactly what the specialty pharmacy team can do for them. “The CPS team frees clinicians up to do what they are trained to do — build relationships with and care for their patients,” says Skrtic. “That’s why we’ll continue looking for more opportunities to help other specialty providers increase patient satisfaction.”

From Cleveland’s perspective, he believes many directors of pharmacy in smaller hospitals might not think they can embed a specialty pharmacy. “That’s just not the case. I had no idea what opportunity was waiting for us until we decided to establish a specialty pharmacy.” As a result of adding specialty pharmacy services, Union Health’s pharmacy department continues to exceed its operational margin goal. “I think any hospital with 340B access that offers specialty services should explore what is possible working with a partner like CPS.”