*Product shown with optional/custom features

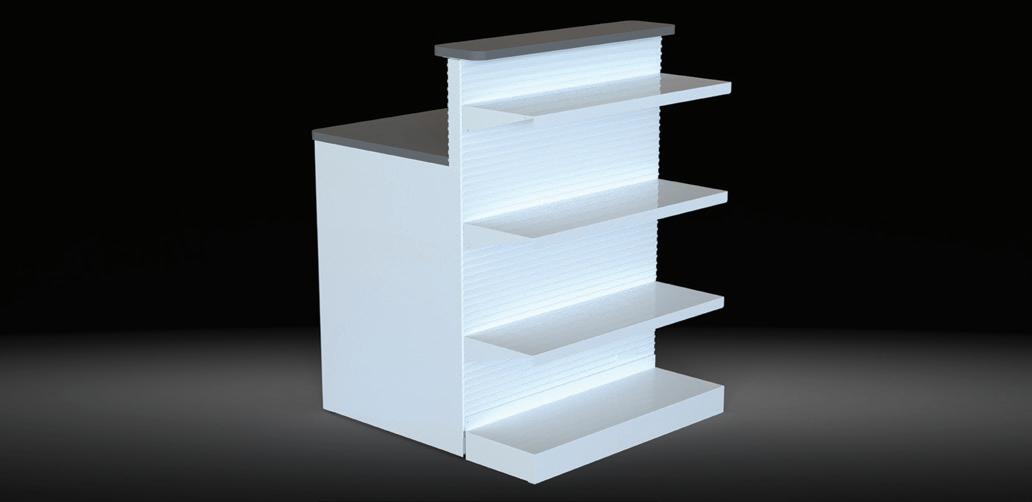

Containment Primary Engineering Control (C-PEC)

Protection: Product, Personnel, & Environmental

Containment Primary Engineering Control (C-PEC)

Optimized for Sterile Hazardous Drug Compounding Systems

Telescoping or Mechanical Auto-Rising Base Stand Options

Optional IV Bar with 3 Height Locations and 6 SST Hooks

Interior Duplex Outlets and Cord Pass-Through Port

Custom Back-Wall Viewing Window for PC Monitor

Up to 12 inch (305 mm) Access Opening

LabGard ES NU-813 Series

Optimized for Non-Sterile Hazardous Drug Compounding

Telescoping or Mechanical Auto-Rising Base Stand Options

Optional Ergonomic Mount for PC Monitor, Keyboard, and Mouse

Double Exhaust Filter with Bag-In/Bag-Out Options

Polycarbonate Viewing Window and Sidewalls

Sidewall Waste Pass-Through Ports

Protection: Personnel & Environmental

*Product shown with optional features

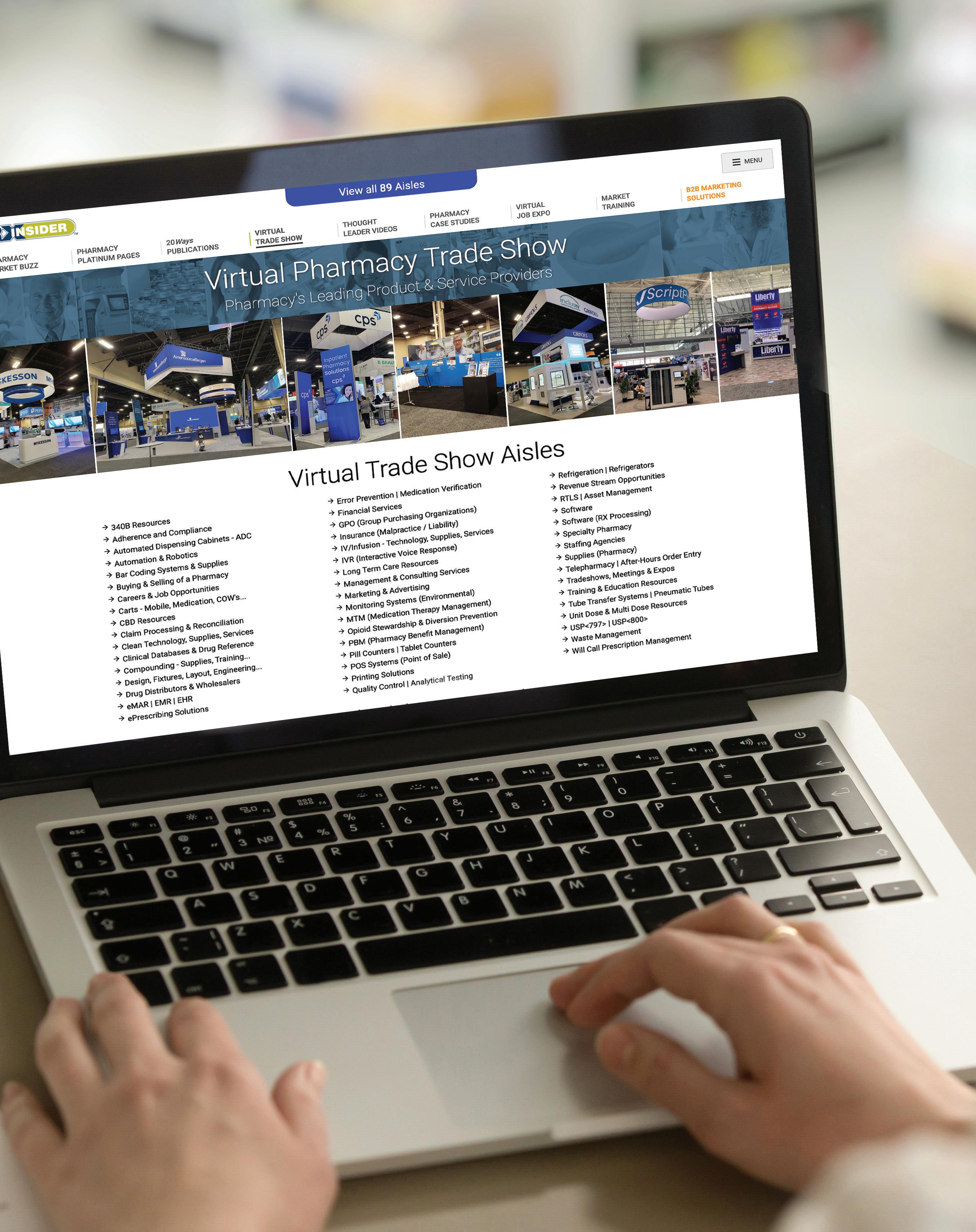

In the ever-evolving world of hospital and health system pharmacies, staying at the forefront of technology, services, and products isn’t just about keeping pace — it’s about ensuring your patients receive the highest quality care and that your operations run smoothly and effectively. This Winter issue of 20Ways is here to support you in that journey, highlighting the latest advancements in clean technology, supply chain innovations, and customized service solutions that truly address the unique needs of your pharmacy.

Inside, you’ll find valuable insights into navigating the Drug Supply Chain Security Act (DSCSA) and understanding the vital role centralized medication access teams play in hospital settings, two areas shaping the future of pharmacy operations. And, of course, this issue would not be complete without twenty impactful product and service profiles designed to support your goals — whether it’s improving patient compliance, streamlining workflows, or strengthening your pharmacy’s financial performance.

Thank you for your unwavering dedication to advancing patient outcomes. We hope this issue brings you practical tools, fresh perspectives, and, most importantly, inspiration to help your pharmacy continue to thrive.

Greg Cianfarani, RPh Founder & CEO

CEO & FOUNDER

Gregory Cianfarani, RPh

DESIGN & PRODUCTION

Design & Layout: Lora Bourque

Multimedia: Eric Simmons

MARKETING & OPERATIONS

Director of Marketing & Operations, Samantha Roy

Marketing & Operations Coordinator, Amanda D’Amico Credit Analyst & Bookkeeper, Kristin Fennessey

SALES & BUSINESS DEVELOPMENT

EVP, Sales & Marketing, Mike Rahme

VP of Strategic Accounts, Chris Kolkhorst

Executive Sales Director, Shaun Russell Account Executive, Savannah DaSilva Account Executive, Jeff Rackliff

PHARMACY MARKET INTELLIGENCE

Marketing Manager, Alexa DiLuca

Pharmacy Market Analyst, Lexi Cianfarani Pharmacy Market Analyst, Michael McEwen

EDITORIAL ADVISORY BOARD

Amanda Binkley, PharmD, BCIDP, AAHIVP Clinical Pharmacy Specialist Infectious Diseases Penn Presbyterian Medical Center

Miriam Cho, PharmD President & Chief Pharmacy Officer MacRx

Lindsey Dymowski Constantino

President & Cofounder

Centennial Pharmacy Services & LTC@Home Pharmacy Network

Mark Garofoli, PharmD, MBA, BCGP, CPE, CTTS Director of Experiential Learning and Clinical Assistant Professor West Virginia University of Pharmacy

Sebastian Hamilton, BSP, RPh, MBA, PharmD, ACE Chief Pharmacy Officer, Operations and Community/ Ambulatory Partnerships, 340B ACE Boston Medical Center

Brian Musiak, PharmD, MBA, CPEL System Director of Pharmacy Care New England

Abby Roth

Owner/Microbiologist

Pure Microbiology

FOLLOW US

LinkedIn @RXinsider Facebook /RXinsiderB2BSolutions X @RXinsider

Instagram @rxinsider

Pinterest /RXinsider

Vimeo /rxinsider

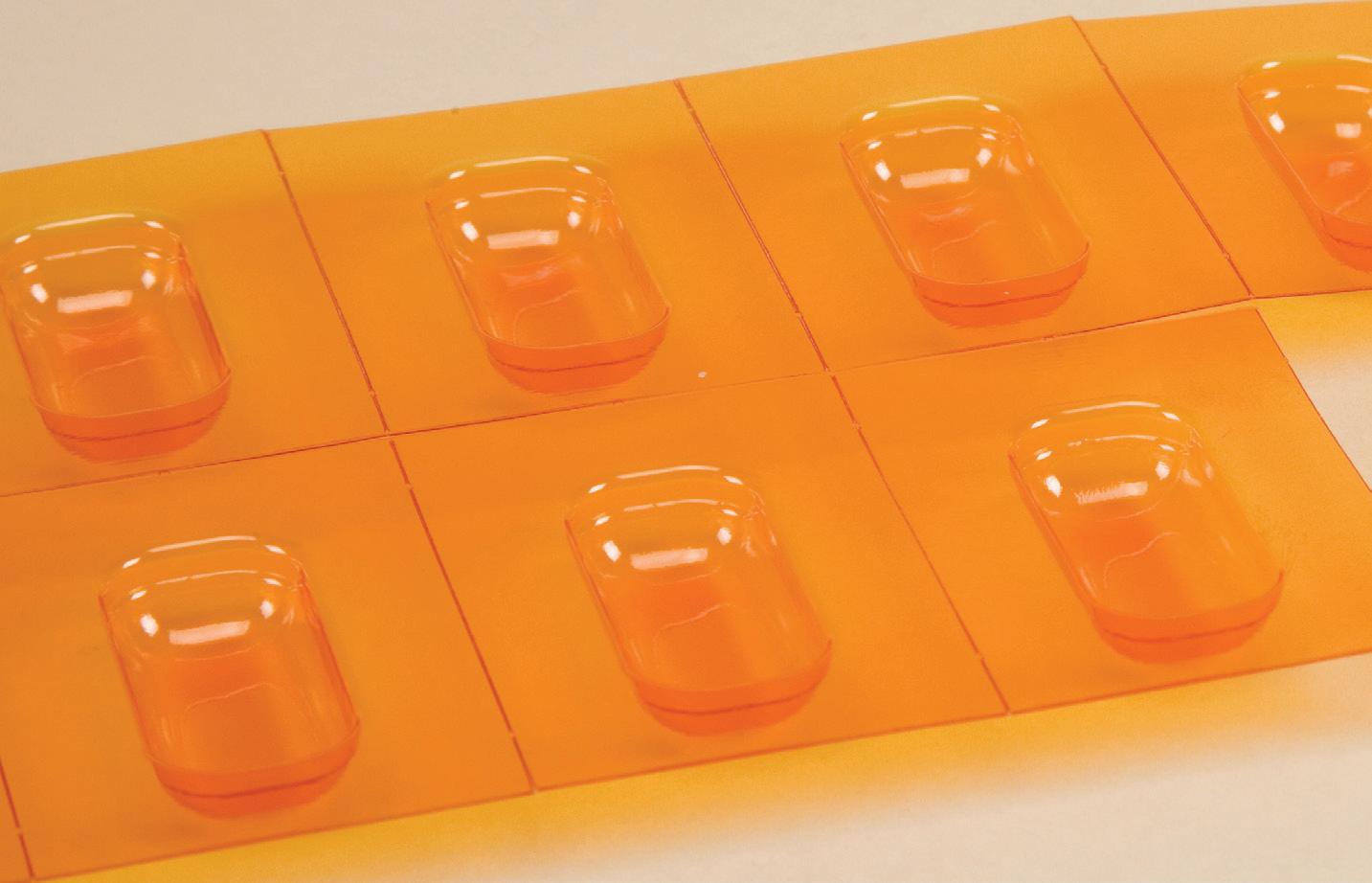

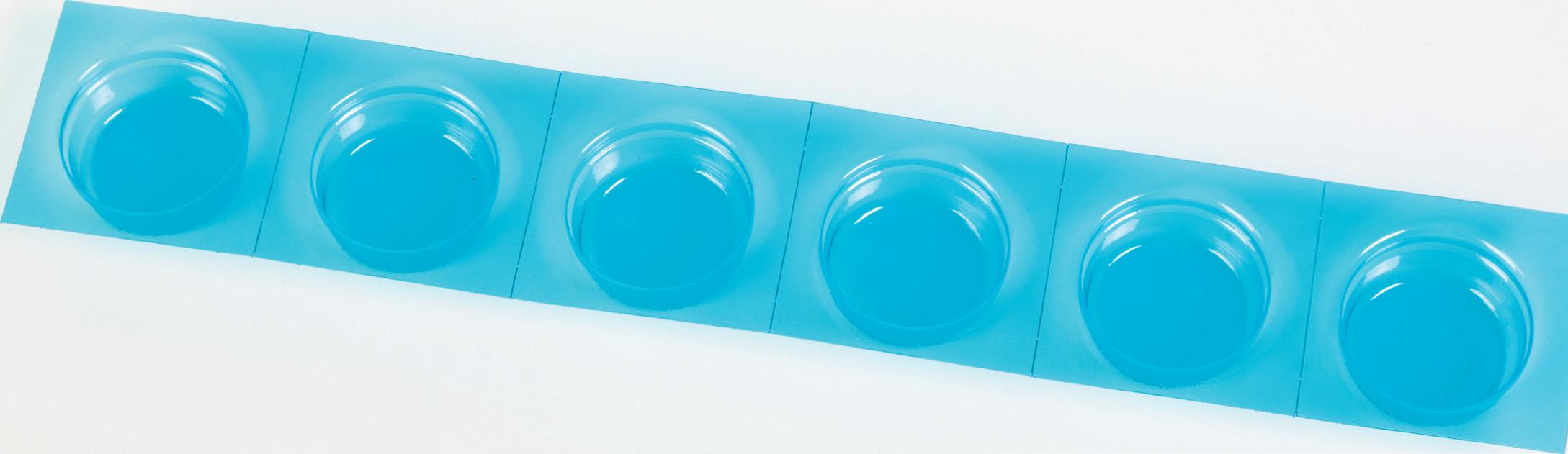

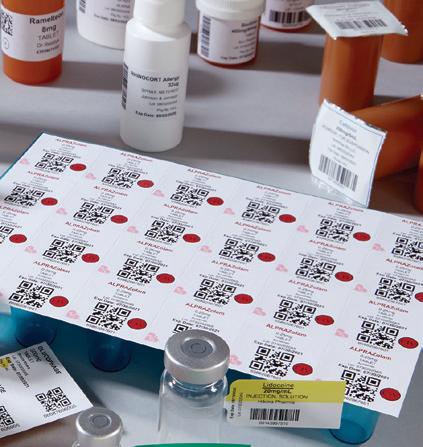

Propofol Injectable Emulsion, USP supplied by Samson Medical Technologies, under the Avet label, is the smart choice for your pharmacy service, offering you the same formulation as Diprivan® , free of benzyl alcohol, sulfites, and latex, with the easy ordering and excellent service that you have come to expect from the providers of SmartPak® .

SmartPak® provides a revolutionary delivery system for these essential drugs, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service.

This important product now in the exclusive delivery system.

important product now in the exclusive delivery system. provides a

This important product now in the exclusive delivery system.

SmartPak® provides a revolutionary delivery system for these essential drugs, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service.

delivery system for this essential drug, offering faster, easier more economically. It’s also safer. The SmartPak bag system is a convenient using multiple glass vials. No glass means no breakage during handling. SmartPak labor with less waste. SmartPak — the smart choice for your pharmacy service

SmartPak® provides a revolutionary delivery system for this essential drug, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service

66288-1100-11100

SmartPak® provides a revolutionary delivery system for this essential drug, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service

SmartPak® provides a revolutionary delivery system for these essential drugs, offering faster, easier preparation more economically. It’s also safer. The SmartPak bag system is a convenient alternative to using multiple glass vials. No glass means no breakage during handling. SmartPak saves time and labor with less waste. SmartPak — the smart choice for your pharmacy service.

CLEAN TECHNOLOGY, SUPPLIES, SERVICES

Clean technology, supplies, and services industry expert Q&A, Market’s Leaders Buyer’s Guide, and more. page 46

THE VALUE OF A CENTRALIZED MEDICATION ACCESS TEAM

Discover the benefits of Centralized Medication Access (CMA), which simplifies specialty medication processes, enabling clinical teams to focus on patient care. page 28

FROM BOTTLENECKS TO BREAKTHROUGHS; LEVERAGING TECHNOLOGY TO OPTIMIZE PHARMACY WORKFLOWS

Exploring the impact of network platforms and digitalization on the end-to-end healthcare supply chain. page 92

HOW STANDARDIZATION LED TO CONSISTENCY, VISIBILITY, AND LESS RISK

Helmer Scientific — Improving Your Cold Storage Through Standardization page 22

SOUTHERN OHIO MEDICAL CENTER

PUTS PATIENTS FIRST WITH INNOVATIVE SPECIALTY PHARMACY SERVICES

CPS — The Mission: Making a Difference page 36

DBA KCCARE HEALTH CENTER

TRANSFORMS PATIENT CARE FOR THE UNDERSERVED COMMUNITIES

Elevating Patient Health With ScriptPro’s Pharmacy Solutions page 56

GROWING A SUCCESSFUL COMPOUNDING

PHARMACY: THE CRITICAL ROLE OF ENVIRONMENTAL MONITORING

Rees Scientific and Olive Tree Compounding Pharmacy page 84

USP <800> RESOURCES

Leading pharmacy suppliers of USP <800> compliant solutions. page 14

TRADE SHOW & MEETING EVENT CALENDAR

Detailing key industry events throughout the year. page 74

PHARMACY CASE STUDIES

Discover the stories, research, and reports from real pharmacies. page 68

Gowning Service to Help Keep Your Controlled Environment Ready for the Workday®

PROTECT YOUR PEOPLE. PROTECT YOUR PROCESS.

When you need Cleanroom garments — and the peace of mind that comes with them — Cintas delivers. With strategic ISO 5 Cleanrooms across the U.S., we support a diverse range of industries.

COVERALLS

Get the right coverall for your specific controlled environment needs.

FROCKS, ESD LAB COATS & SPECIALTY GARMENTS

Many options to keep your employees in the cleanroom Ready™ .

BOOTS AND SHOE COVERS

The right footwear for your controlled environment.

GOGGLES

Protective eyewear for your team. Gamma sterilization compatible.

Innovative cleaning solutions at your fingertips.

WIPES

Cleanroom cleaning wipes delivered with your gowning.

VERITY SOLUTIONS — THE FUTURE OF HIGH-PERFORMING HEALTHCARE IS HERE

We serve all healthcare facilities and 340 covered entities by combining innovative technology and best-in-class partnership to optimize pharmacy supply chain outcomes for better financial results and patient care. page 19

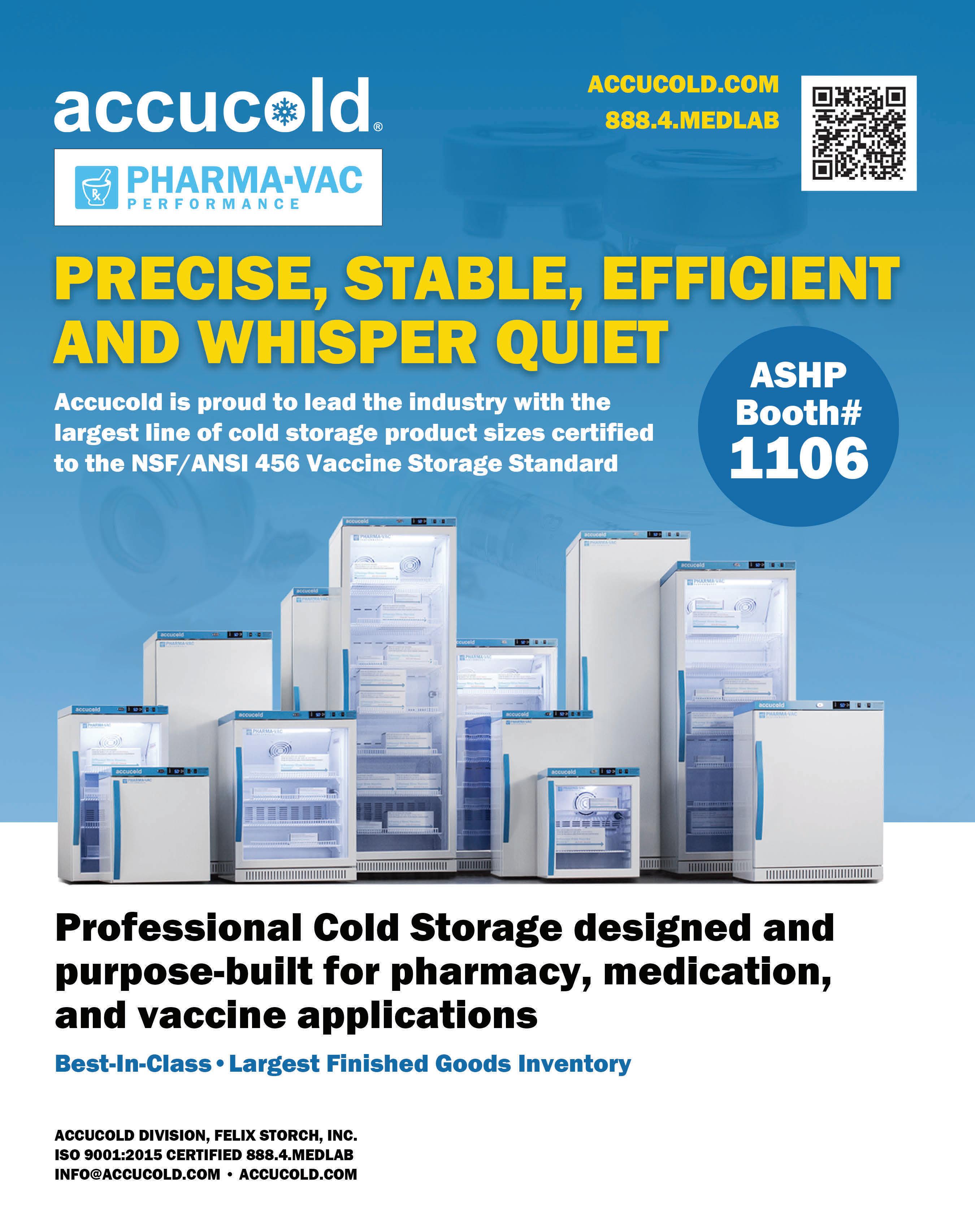

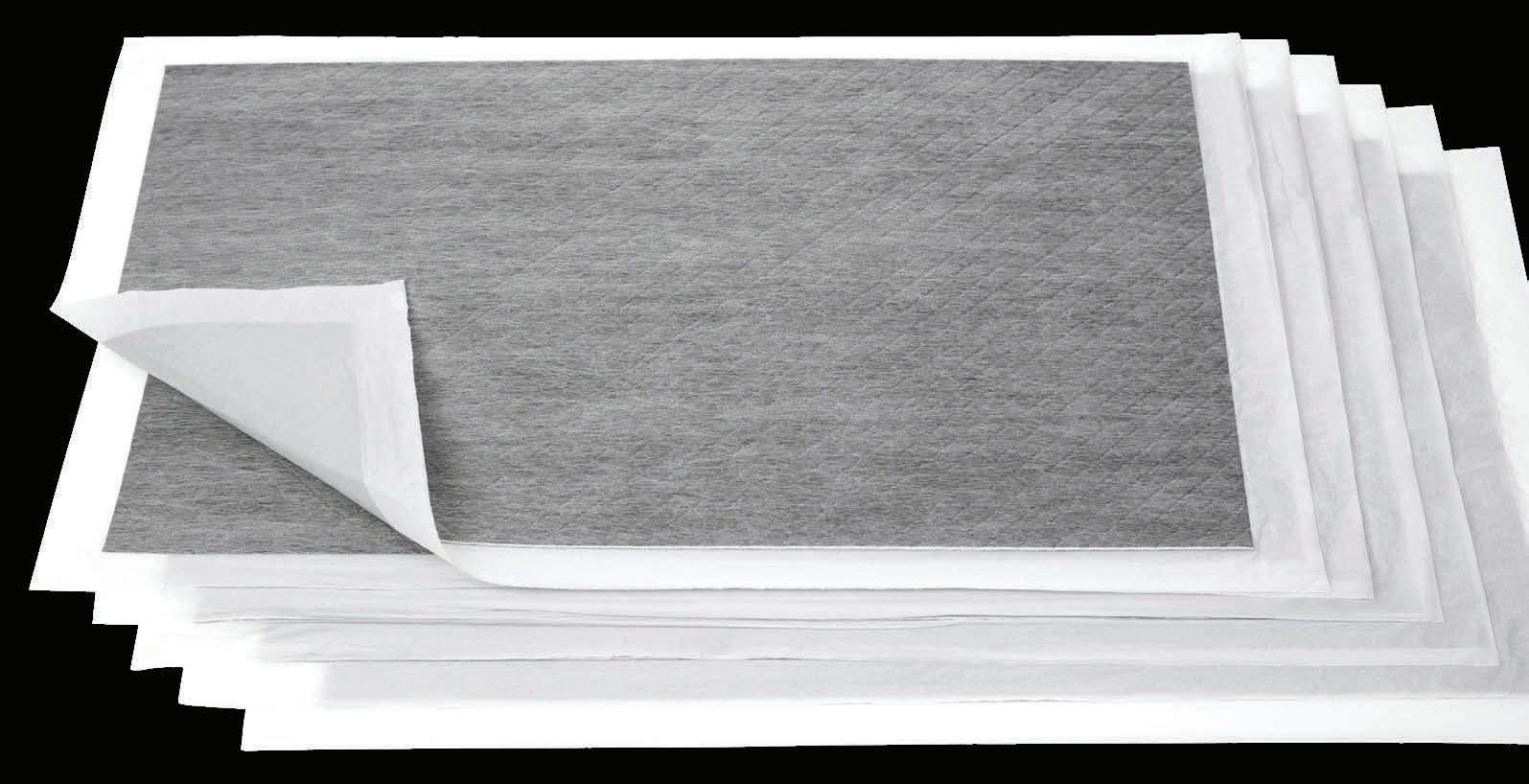

RXCARBON® POLY STERILE AND NON-STERILE CHEMO MAT FROM RXCARBON, LLC. — INCREASE SAFETY, LOWER COST

Why are RxCarbon® Poly Chemo Mats the color gray? RxCarbon Poly Mats have two layers of RP718 activated carbon which makes our patented mats appear gray. RP718 activated carbon sequesters oncology and hazardous drugs, mitigating exposure risks to both practitioners and our environment. page 21

COREPOINT ® SCIENTIFIC — MAKE EVERY DROP COUNT WITH LIFESAVING COLD STORAGE

Precision cooling for life-saving storage. Corepoint Scientific’s line of blood bank refrigerators and plasma freezers ensure consistent temperatures, regulatory compliance, and reliable performance — protecting the integrity of critical blood and plasma supplies. page 27

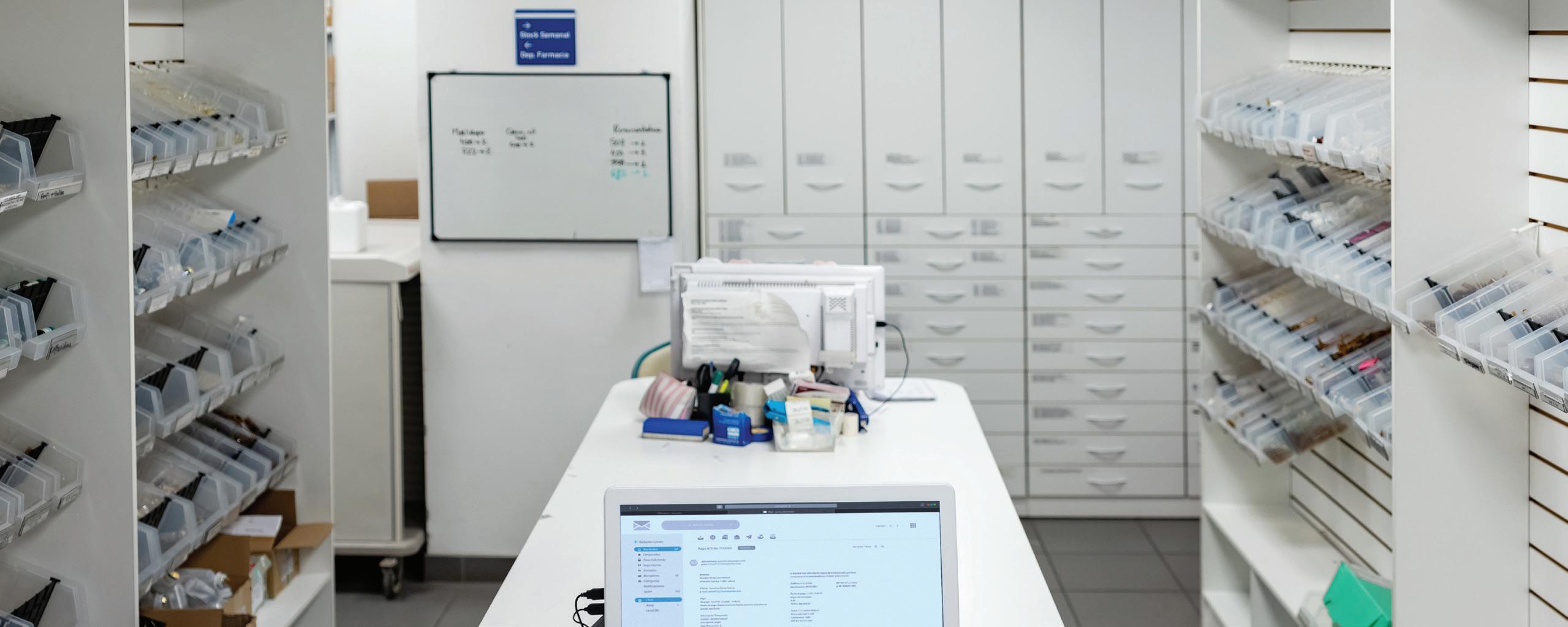

SWISSLOG HEALTHCARE — OPTIMIZED PHARMACY WORKFLOWS FROM INVENTORY MANAGEMENT TO CSC

Deliver exceptional patient care with innovations from the core of the central pharmacy to enhance performance workflow efficiency, improve accuracy, and increase safety. page 33

NOVUM IQ INFUSION PLATFORM FROM BAXTER IS A PUMP PLATFORM LIKE NO OTHER

At every step, the Novum IQ Infusion Platform with Dose IQ Safety Software helps you build and deploy one of the safest and most effective drug libraries possible for large volume, syringe, and enteral infusions. page 35

KWIKDOSE ORAL DISPENSERS FROM MEDSAFETY SOLUTIONS, LLC

KwikDose oral dispensers accurately deliver small volumes of oral liquid medication. Enlarged numbers and easy-to-read marking lines allow for quick and accurate volume identification, even with dark liquids. The unique tip prevents wrong-route administration. page 41

STERI-TAMP ® TAMPER-EVIDENT STERILE SEALS BY ALLIED PHARMACY PRODUCTS, INC.

The only single-use, tamper-evident seal that provides and maintains a 100% sterile barrier. page 43

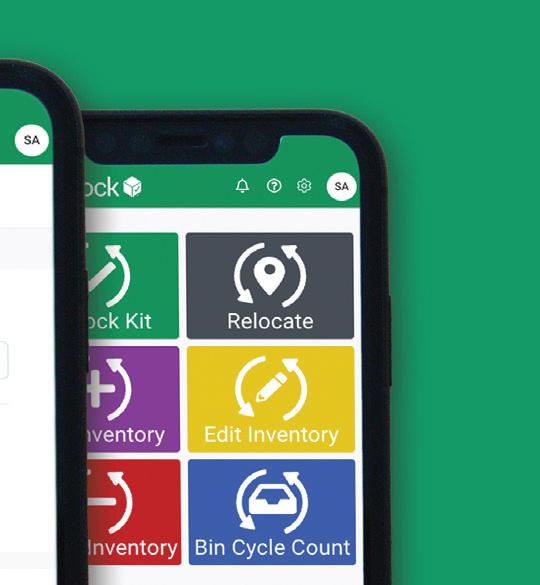

HCL ® ’S EXCLUSIVE OFFERINGS GIVE PHARMACIES MORE UNIT DOSE PACKAGING POWER

Improve confidence in the quality of tablet repackaging and unit dose batching from start to finish. page 53

VISANTE – HIGH-PERFORMING PHARMACY SOLUTIONS FOR HOSPITALS AND HEALTH SYSTEMS

Our mission is to transform healthcare through pharmacy. We help hospitals and health systems optimize pharmacy operations, improve financial performance, and deliver better patient care. page 55

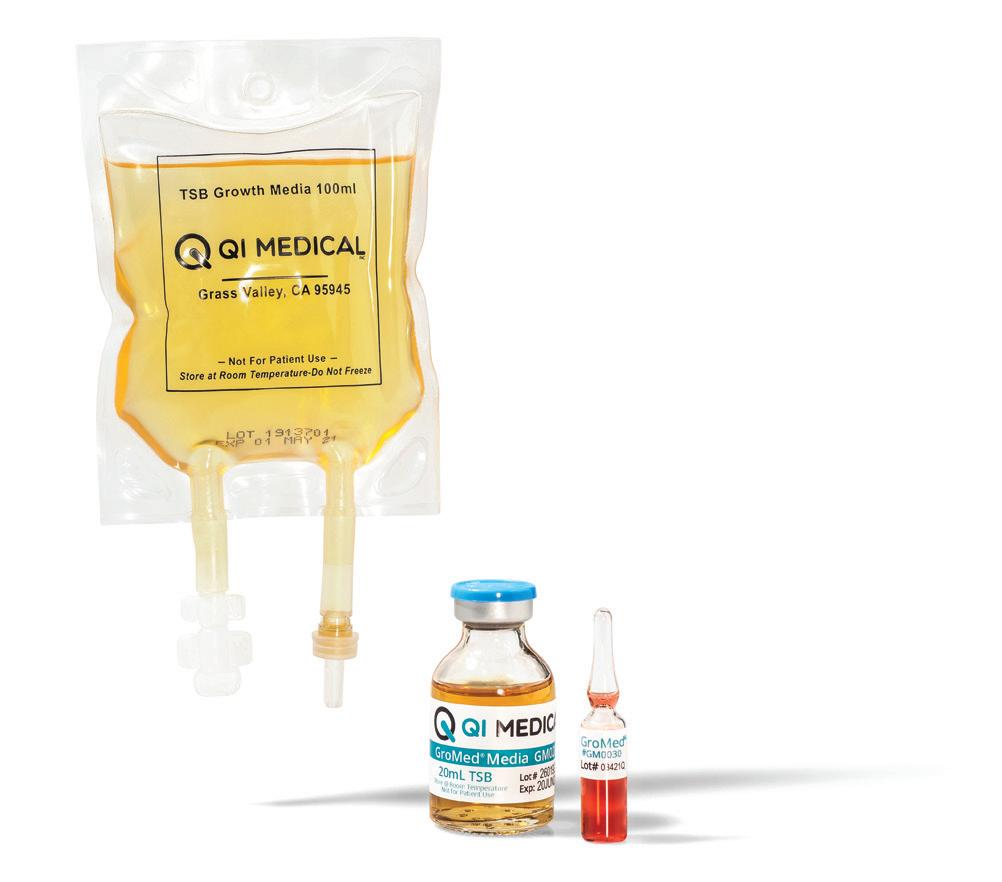

Q.I. MEDICAL, INC.™ YOUR PARTNER IN USP <797> PHARMACY COMPLIANCE

Providing quality assurance products to hospitals and pharmacies practicing sterile compounding, with a singular focus on pharmacy compliance. Our long-standing regional distribution partners are able to provide exceptional in-person service and training. page 61

Gowning Service to Help Keep Your Controlled Environment Ready for the Workday®

PROTECT YOUR PEOPLE. PROTECT YOUR PROCESS.

When you need Cleanroom garments — and the peace of mind that comes with them — Cintas delivers. With strategic ISO 5 Cleanrooms across the U.S., we support a diverse range of industries.

COVERALLS

Get the right coverall for your specific controlled environment needs.

FROCKS, ESD LAB COATS & SPECIALTY GARMENTS

Many options to keep your employees in the cleanroom Ready™

BOOTS AND SHOE COVERS

The right footwear for your controlled environment.

GOGGLES

Protective eyewear for your team. Gamma sterilization compatible.

Innovative cleaning solutions at your fingertips.

Cleanroom cleaning wipes delivered with your gowning.

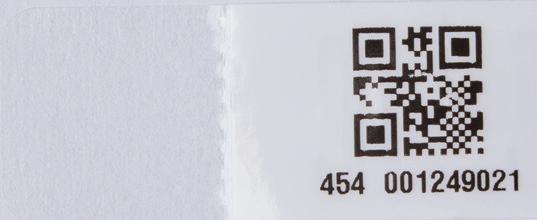

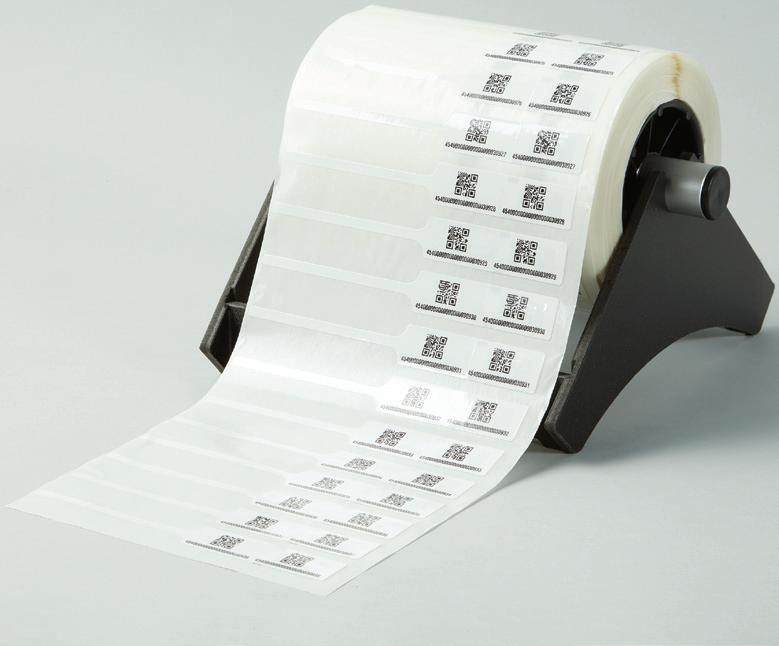

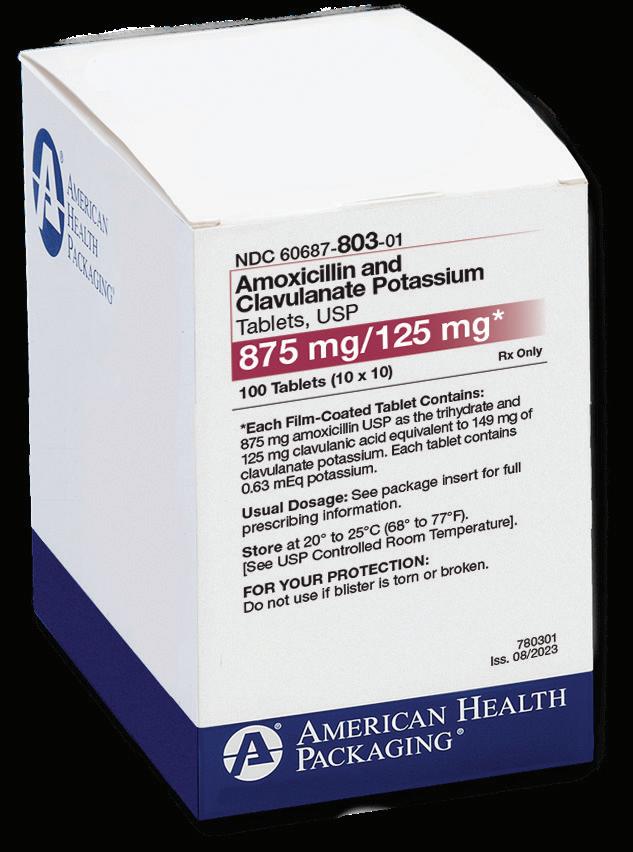

AMERICAN HEALTH PACKAGING (AHP) IS A LEADING MANUFACTURER OF SERIALIZED, BARCODED UNIT-DOSE PRODUCTS

With a responsive line of barcoded unit-dose oral solutions, a growing liquid unit-dose offering, as well as individually wrapped inhalants, AHP continues to deliver on it’s commitment to supporting pharmacy efficiency. page 63

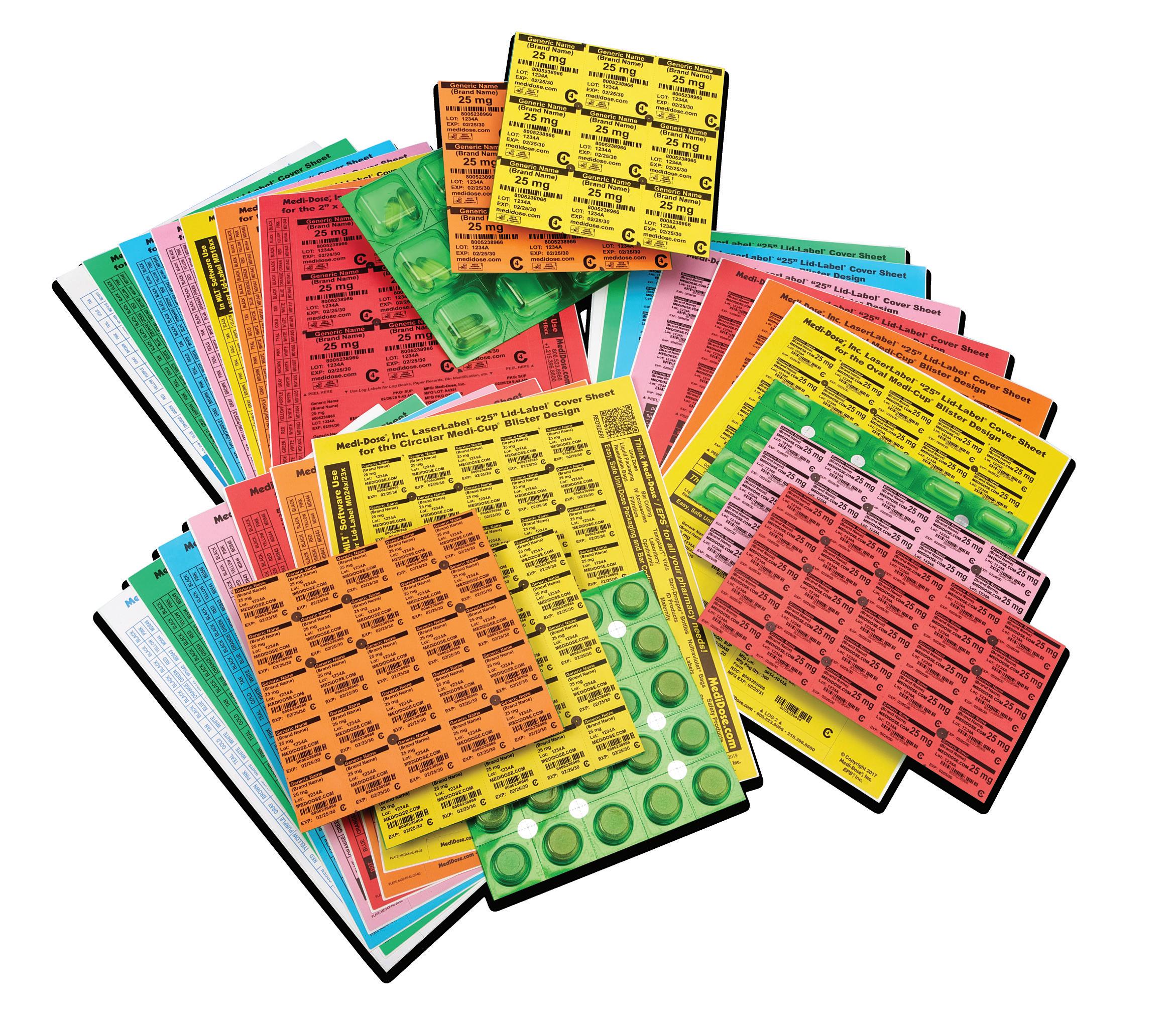

MEDI-DOSE, INC./EPS, INC. DELIVERS BAR CODING, PACKAGING, AND LABELING PHARMACY SOLUTIONS

Improve your Solid Oral Unit Dose needs with our comprehensive Bar Coding, Packaging, and Labeling Solutions — designed by healthcare professionals, for healthcare professionals. page 67

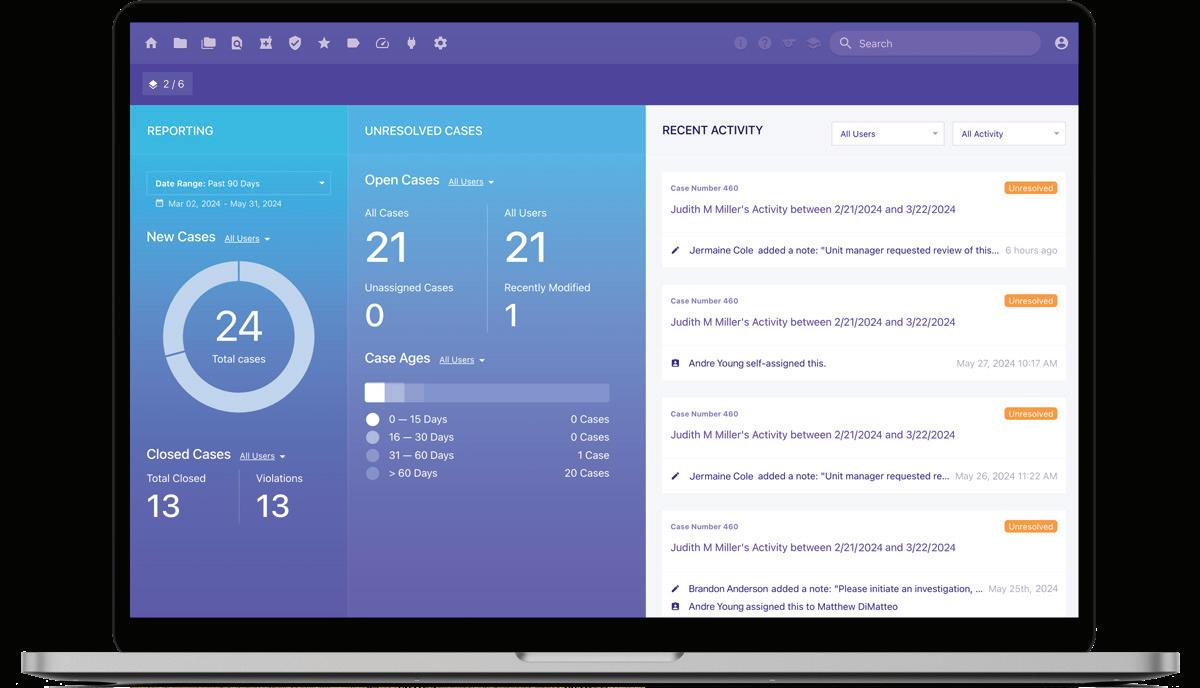

REDUCE THEFT AND MISUSE OF CONTROLLED SUBSTANCES IN YOUR ORGANIZATION WITH PROTENUS DRUG DIVERSION SURVEILLANCE

Utilize artificial intelligence and advanced analytics to audit 100% of medication use transactions — reducing the risk to your workforce, organization, and most importantly, your patients. page 71

ISO-MED — YOUR ASSURANCE FOR TOP-QUALITY PRODUCTS

As a leading provider of pharmacy cleanroom supplies, ISO-MED is dedicated to offering an unparalleled selection of specialized medical, compounding, and cleanroom supplies. We understand the importance of meeting the requirements of USP, accreditation organizations, State BoPs, and the FDA. page 73

NUVEM’S HOLISTIC SOLUTION DELIVERS 100% PATIENT SCRIPT VISIBILITY

Empowering covered entities to successfully manage all their patient scripts with one holistic pharmacy solution, positively impacting patient health and financial outcomes. page 81

MEDIZAP — TERMINAL STERILIZER BY E-BEAM | X-RAY IRRADIATION BUILT FOR COMPOUNDING

Combining expertise and advanced tech, we elevate sterile compounding for 503A and 503B pharmacies. Our solutions enhance safety and effectiveness in custom sterile drugs, addressing FDA shortages for hospitals and patients. page 83

ARL BIO PHARMA — THREE STERILITY TESTING OPTIONS, ONE STANDARD OF EXCELLENCE

Get sterility test results in as little as four hours with rapid test methods. page 89

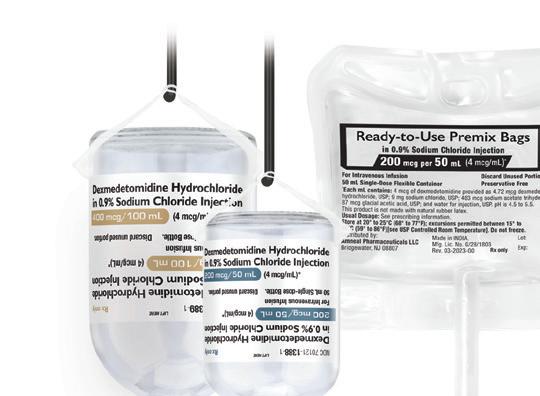

TRUDELIVERY ® — READY-TO-USE (RTU) PRODUCTS BY ENDO

The TruDelivery® RTU portfolio helps meet the real-world challenges of hospital pharmacies — and is always ready when you are. It’s about time. page 91

SO-LOW ENVIRONMENTAL — YOUR TRUSTED COLD STORAGE MANUFACTURER

For over 65 years, So-Low has been manufacturing ULT freezers and medical-grade refrigeration equipment. Our goal is to provide the highest quality cold storage equipment with a personalized customer service experience. page 95

SIMPLIFI+ ® PHARMACY COMPLIANCE AND SENTRI7 ® CLINICAL SURVEILLANCE — WOLTERS KLUWER

Simplifi+® and Sentri7® applications on one powerful SoleSource® platform help to standardize clinical, pharmacy, and compliance programs. Customers access evidenced-based content, tailored workflows, and robust analytics to improve patient care, quality, and safety. page 97

20Ways MISSION

To educate pharmacy management on products and services that serve to improve patient care or improve a pharmacy’s financial bottom line, while distilling and presenting this relevant information via 20 product profiles.

VIEW 20Ways ONLINE

RXinsider.com/20Ways

GENERAL SUBSCRIPTION INQUIRIES

RXinsider LTD c/o 20Ways

1300 Division Road, Suite 103 West Warwick, RI 02893

General Information: 20Ways@RXinsider.com

20Ways is an official publication of RXinsider.

NOTICE OF POLICY

20Ways is published quarterly by RXinsider LTD, 1300 Division Road, Suite 103, West Warwick, RI 02893. Postmaster: Send address changes to 20Ways/RXinsider, 1300 Division Road, Suite 103, West Warwick, RI 02893. Notification of address change must be made six weeks in advance, including old and new address with zip code.

Editorial — views expressed in articles or profiles in the 20Ways are those of the author(s) and do not necessarily reflect the policies and opinions of RXinsider, our editorial board(s), our advisory board(s), or staff. Advertising – products, services, and educational institutions advertised in 20Ways do not imply endorsement by RXinsider.

Copyright © 2024 RXinsider LTD. All rights reserved. Reproduction without permission is prohibited.

With increasing drug shortages and supply chain disruptions, access to quality medicine is more important than ever.

Leiters Health is an FDA-registered 503B outsourcing provider of high-quality compounded sterile preparations and pharmacy services including:

Pre-filled syringes and IV bags; pre-labeled and ready to administer. ON-Q* Pain Relief System Pharmacy Fill Service. Opioid-free surgical pain services medications.

Ophthalmic medications including FDAcompliant repackaged Avastin

Contact us to learn how we can support your hospital pharmacy and your patients.

Leiters.com | 800.292.6772 | info@leiters.com

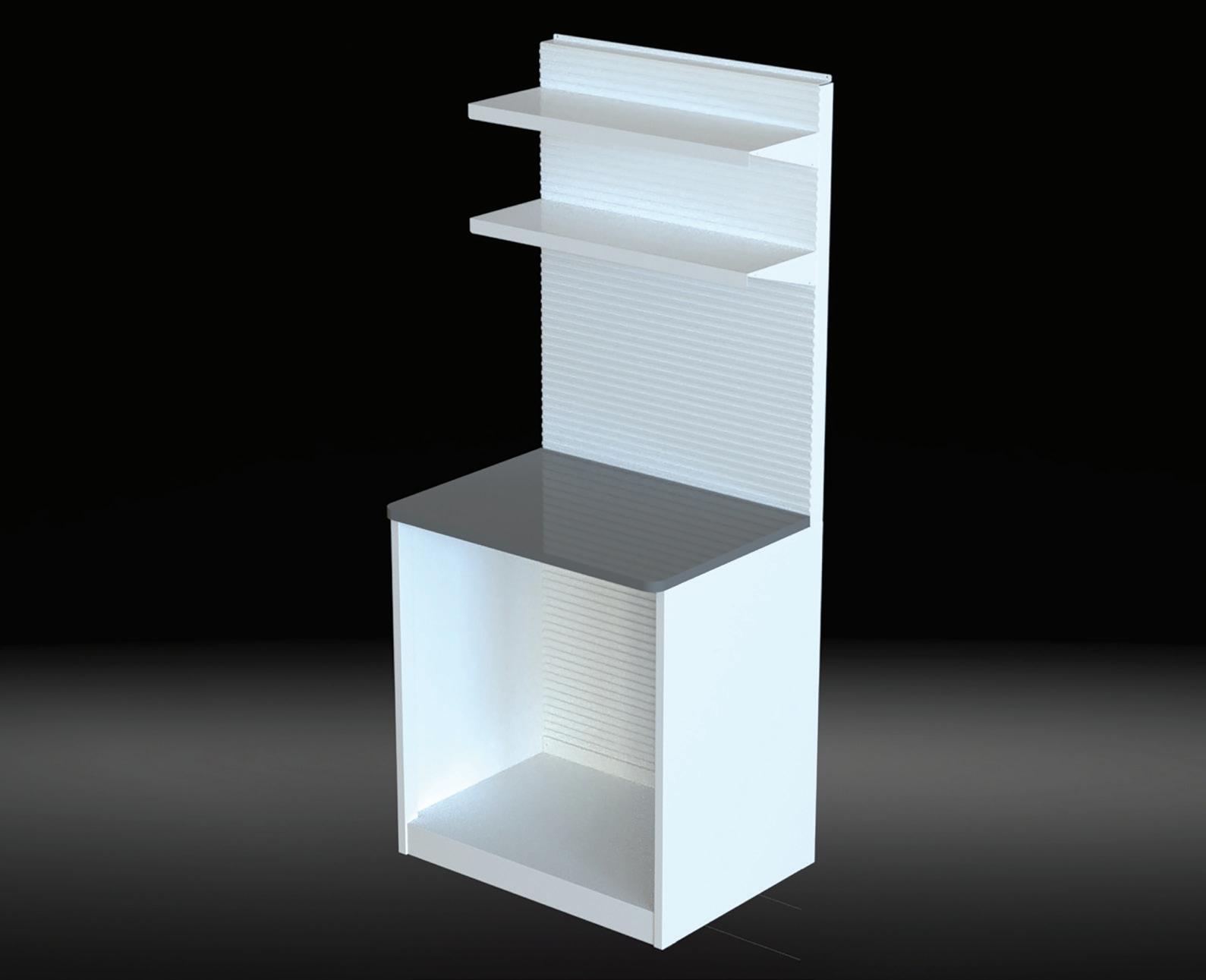

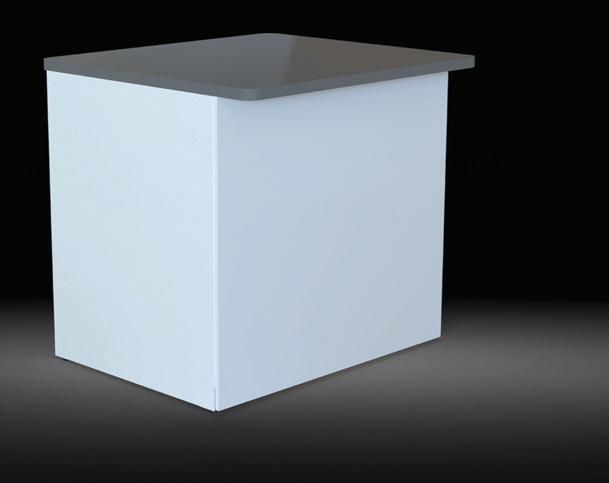

48”W x 25-1/2”D x 40”H x 84”H

36”W x 25-1/2”D x 40”H x 84”H

24”W x 25-1/2”D x 40”H x 84”H

48”W x 25-1/2”D x 40”H x 54”H

36”W x 25-1/2”D x 40”H x 54”H

24”W x 25-1/2”D x 40”H x 54”H

48”W x 32-3/4”D x 34”H 36”W x 32-3/4”D x 34”H

x 32-3/4”D x 34”H

The workstations can be prewired or supplied with a blank quad and data box for easy wiring. As your needs change, so can your design!

Non-electrical ships in 7-10 business days after payment. Pre-wired takes a few weeks.

All include Slate Grey laminate tops, Designer White décor panels, and RX White metal components.

www.RXinsider.com/USP800

We serve all healthcare facilities and 340 covered entities by combining innovative technology and best-in-class partnership to optimize pharmacy supply chain outcomes for better financial results and patient care.

CEO: George Puckett

Founded: 2015

Employees: 160

Toll-Free Phone: (800) 581-1378

Phone: (425) 947-1922

Address: 12131 113th Avenue NE, #200 Kirkland, WA 98034

Website: www.verity340b.com

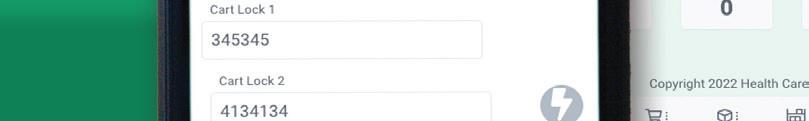

Verity Solutions has been the leader in 340B program administration and now offers pharmacy supply chain optimization solutions for all healthcare entities. Recognized as Best in KLAS: 340B Management Systems for six years, and in the 2024 KLAS Emerging Solutions Top 20 Report, we are on a mission to create pharmacy excellence through predictable automation and outstanding support so that every customer can maximize their savings. We partner with integrated healthcare systems, acute-care hospitals, community health centers, federally qualified health centers, pharmacies, and 340B-eligible covered entities throughout the U.S. who rely on Verity software and services to successfully manage their pharmacy purchasing and 340B program.

Our powerful cloud-based software platform provides comprehensive 340B program management solutions, including split billing, contract pharmacy, and specialty contract pharmacy. Plus, a contract pharmacy gateway solution called VHUB®

Our pharmacy purchase optimization products offer real-time, intelligent solutions that automatically verify contract pricing and select the best priced NDC available for your complete order. We enable pharmacy buyers to dramatically decrease drug spend and save time while maintaining supply.

Our depth of in-house technical and software development resources and our highly skilled account management team are closely aligned to swiftly adapt as changes arise. We offer:

• Agile Software Platform: Built and deployed with security, performance, scalability, and agility as primary goals.

The Verity 340B platform is HITRUST® certified, demonstrating robust HIPAA compliance.

• Intuitive Application: Designed with our users in mind, we maintain ongoing feedback and collaboration with our clients. This collaboration steers our continual software and services development.

• Responsive Support: Designated account managers provide focused support, training, audit readiness, and regular business reviews to maximize your 340B program success and help you maintain compliance.

We continually invest in our technology and people to ensure success for our clients. With increasing pharmacy costs and complexity, it is more important than ever to have the right solutions — and the right partner.

n Highlights

• Industry-leading core functionality of our platform with optional, patent-pending add-on modules to enhance all aspects of 340B operations in challenging and unique environments.

• Access to your own unique program test environment — before and after implementation. Test environment runs continually in parallel to your live system.

• Easy and exportable reporting functionality, including detailed data for manufacturer audits, HRSA audits, and UDS reporting.

• Multiple vendor support with controlled substances ordering system (CSOS) — efficiently place orders with both EDI (electronic data interchange) and non-EDI vendors.

• Two-week sprint release cycles ensure timely software updates driven by customer feedback, regulatory changes, and user needs.

• Verity Care Card Program — directly pass 340B savings to uninsured and underinsured patients.

• Referral capture opt-in functionality to compliantly add meaningful savings lift to your 340B program.

• Responsive customer service provided by our in-house staff — 80% of our customer support cases are resolved within two hours; 95% resolved within 24 hours.

Specifications:

• Validated Sterile, Gamma Irradiated

• 600 ml spill capacity

AT $.71/PAD

• RxCarbon Poly protects surfaces during transport, storage, compounding, and infusions.

• Virtually eliminates cross-contamination of liquid hazardous drugs

• Meets ISO 9073-10 and BS EN 13795 standards for low lint and low particulate matter

RxCarbon® Poly Protects:

Employees, patients, and environment by deactivating and absorbing HD/Oncology liquids during:

• Administration, Infusion, Spills, Transporting , and Compounding

Unlike White or Blue Mats, our Gray Mats, with TWO layers of RP718 Activated Carbon, Sequesters Hazardous Drugs The Next Generation Surface Protection & Wipe With Hazardous Drug (HD) Deactivation

Place RxCarbon Poly on the surface. Hazardous Drugs are adsorbed/absorbed preventing surface contamination.

Hazardous drugs are prevented from being released into the environment and contaminating our water. Easy

Responsible

Protect healthcare workers, patients and the public from hazardous oncology liquids.

President & CEO: Gregg Short

Founded: 2003

Employees: <20

Toll-Free Phone: (866) 436-9264

Phone: (760) 930-9101

Why are RxCarbon® Poly Chemo Mats the color gray? RxCarbon Poly Mats have two layers of RP718 activated carbon which makes our patented mats appear gray. RP718 activated carbon sequesters oncology and hazardous drugs, mitigating exposure risks to both practitioners and our environment.

Address: 6054 Corte del Cedro Carlsbad, CA 92011

Website: www.rxcarbon.com

RxCarbon®, LLC was founded in 2019, and our pads are protected by U.S. Patent #11,344,933. RxCarbon is the only absorbent pad that sequesters liquid controlled and hazardous drugs with two layers of RP718 activated carbon. We started out looking for a way to eliminate illegal diversion of narcotics. RxCarbon® Pad was developed for existing RCRA and Sharps waste containers to help address illegal diversion from waste containers. Our pads can easily be placed inside waste containers by end users or waste container manufacturers as a replacement of the current absorbent pads.

After designing the pad, we recognized a need to address USP 797 and USP 800 standards and decided to add an impermeable backing to the pad, creating RxCarbon® Poly. Practitioners handling hazardous drugs during compounding, infusions, transporting, or as a clean-up wipe can use RxCarbon Poly.

RxCarbon® Poly Chemo Mat product line comes in sterile and non-sterile versions, is 11x17" lying flat, and can be used as a clean-up wipe. Each mat has an absorption capacity of 600 mL. Our sterile version is validated sterile and gamma irradiated. We designed RxCarbon Poly to provide surface protection during compounding, infusions, transporting, and as clean-up wipes. Practitioners handling hazardous drugs risk occupational exposure. RxCarbon absorbent pads sequester liquid hazardous drugs and reduce continued exposure and cross-contamination. RxCarbon Poly Mats meet ISO 9073-10 and BS EN 13795 standards for low lint. RxCarbon provides increased safety and lower cost when comparing other blue chemo mats.

“As studies have repeatedly shown, hazardous drugs often migrate past compounding hoods and work surfaces as far as counters, doorknobs, and elevator buttons. The new RxCarbon pads and wipes are a major leap forward in providing a simple, cost-effective method for greatly reducing contamination by these pharmaceuticals that are life-saving when administered appropriately but potentially harmful when present consistently in the work environment. I have personally witnessed the absorption capacity of the pads which is also a benefit in the case of spills or a leaking IV set. I highly recommend them for both hazardous drug compounding areas and hazardous drug administration settings. Using the RxCarbon® wipes routinely during compounding and adding them to all HD spill kits is the next step in reducing routine contamination and protecting employees and patients.”

— Charlotte A. Smith, R. Ph., M.S., President, GreatWorks LLC

• HCP — Hospital Pharmacy Conference

• ASHP

GPO Affiliations

• Premier, Inc.

Ordering Information

For more information or a quote, email info@rxcarbon.com or call (866) 436-9264.

RxCarbon® Poly Sterile (RXCp1117PS-(1)cs): Case quantity 300, individually bagged, master bag of 25, 12 master bags in case.

MSRP $362.50

RxCarbon® Poly-Sterile (RXCp1117PS-(5)cs): Case quantity 300, five pack, master bag of 25, 12 master bags in case.

MSRP $324.00

RxCarbon® Poly Non-Sterile (RXCp1117P-(10)cs): Case quantity 300, 10 pack, master bag of 50, six master bags in case.

MSRP $212.50

“Since switching, we have not experienced temperature excursions, and the units maintain their setpoint.”

The hospital facility is the flagship location of a widely-recognized integrated, not-forprofit healthcare system. This location boasts yearly net patient revenues of over $2B and over 38,000 annual discharges.

As the main campus of a leading health system in medical research and patient care, the organization’s core values of innovation, excellence both for patients and staff, and stewardship of resources demanded this problem be addressed. Every temperature excursion was an opportunity for a drug to lose safety or viability, causing danger to patients and financial loss to the hospital.

With over 1,000 staffed beds and several outpatient facilities to support, the pharmacy manager at this nationally-recognized research hospital was looking to streamline oversight of the eighty-five pieces of cold storage equipment responsible for storing and distributing life-saving vaccines and medications across her facility.

Her existing cold storage fleet included a collection of mismatched units from various vendors that required a staggering 1,000 manual log recordings per week. Recognizing the value of consistent monitoring and the immense burden of weekly manual temperature logs, the pharmacy director installed a remote-monitoring system to track cold storage performance in real time.

Not long after the installation of the new monitoring equipment, performance issues began to surface in the cold storage fleet. The facility was experiencing temperature excursions in some of their refrigerators multiple times per day. The pharmacy team spent weeks “chasing their tails” adjusting and readjusting units that had fallen out of acceptable temperature range.

“These units are reliable and consistent, which is a huge relief for me and my team, as the previous units were a big point of stress and difficult to manage.”

The problem of temperature-controlled transportation and storage is not new in the medical industry, however in recent years, particularly with the advent of biologic medications, the medical cold chain has become a critical and central component in the healthcare industry with manufacturers and health systems spending millions of dollars each year to produce, transport, and store temperature sensitive medications, vaccines, and other necessary patient care material.

Improper temperature storage can have potentially dangerous health risks to patients. Improper storage can reduce the effectiveness of vaccines, medications, and diagnostic tools. Exposure to improper storage can render some vaccines inert and can lead to a false sense of security with patients believing that they are protected from certain ailments, when they are not. Improper storage can also reduce the potency of medications, resulting in poor patient outcomes, and reagents and samples stored at improper temperatures can create testing inaccuracies that can lead to misdiagnosis.

Surprisingly, until recently, regulations on refrigerators for use in healthcare settings were relatively lax. Many patient care settings relied on food-grade refrigerators to store medications. However, recognizing the potential risk to patients, the CDC released the Vaccine Handling Toolkit with recommendations that vaccines be stored in purpose-built units both to protect temperature sensitive materials and to reduce the burden on staff for manual monitoring and adjustment.

Constant monitoring and adjustment of eighty-five refrigerators and freezers, many of which were non-medical-grade units, spread across the central pharmacy and throughout the nursing floors was an unsustainable arrangement for this respected hospital.

Every minute spent outside of proper storage temperature, hospital resources and patient health were at risk, and the overloaded staff struggled to keep up with the necessary adjustments each time a unit fell out of the acceptable temperature range. It was clear that standardizing to medical-grade cold-storage would be imperative for this health system to maintain their commitment to delivering the best outcomes for patients and the best experiences for staff.

While standardization required significant upfront investment, the benefits were clear.

• Reduced clinical staff-hours spent adjusting out-of-range units

• Reduced biomedical staff-hours spent repairing low-quality units

• Reduced risk of material and reputation loss to the hospital

• Reduced health risk to the patient

“Switching to Helmer refrigerators has been a night and day difference.”

“Having the peace of mind is priceless.”

Given these benefits, the pharmacy manager decided to swap out all eighty-five of her cold storage units in favor of medical-grade, NSF/ANSI 456 certified GX Solutions cold storage units from Helmer Scientific.

After replacing her eighty-five mismatched units with GX solutions refrigerators, the pharmacy manager had this to say:

“Since switching, we have not experienced temperature excursions, and the units maintain their setpoint. They are reliable and consistent, which is a huge relief for me and my team, as the previous units were a big point of stress and difficult to manage.”

In addition to peace of mind and reduced staff burden, the hospital has experienced several unexpected benefits from standardizing.

• Reduction in noise output – At roughly the noise output of a quiet library, Helmer GX solutions reduce distractions and improve experience on patient floors.

• Efficiency from standardization – Staff need only learn the systems once and can successfully operate any cold storage unit in the hospital.

• Reduced down-time – As a bulwark for reliability in the medical-grade refrigeration industry, Helmer’s GX Solutions are designed and tested to perform under extreme conditions, providing performance and reliability for the long-term.

• Repair and maintenance efficiencies – Since all eighty-five units are Helmer units, the biomedical staff requires technical knowledge for fewer units, allowing for easier and faster repairs, more efficient preventative maintenance, and the ability to carry replacement parts on-hand.

When asked about the investment to standardize to Helmer GX Solutions cold storage units, the pharmacy manager replied, “Switching to Helmer refrigerators has been a night and day difference.”

The standardization process was so successful that the health system has now added Helmer cold storage units as a standard part of the blueprint for any facility expansion or renovation.

Medical-grade cold storage is imperative for hospitals and health systems that value patient outcomes. Trends in diagnostics and medicine demand higher volume and higher levels of precision for temperature sensitive materials. The increased demand for cold storage will add operational complexity for both clinical staff and biomedical teams. Investing in reliable cold storage across the care setting can reduce complexity by creating uniform processes for staff operators, reducing technical knowledge burden on biomedical teams, streamlining parts ordering and, as the pharmacy manager put it, “having the peace of mind is priceless”.

Consistency, visibility, and less risk for sensitive pharmaceuticals, vaccines, and biologics

UPGRADE TO STATE-OF-THE-ART BLOOD BANK REFRIGERATORS AND FREEZERS

Maximize blood banking efficiency with our advanced cold storage solutions, featuring generous storage capacity, precise temperature control, and an optional chart recorder for continuous monitoring. These units create the ideal conditions for preserving life-saving inventory, ensuring reliability when every drop counts.

Industry Compliant

Class II Medical Device

21CFR Part 820 Compliant

• AABB’s StandardsCompliant Product

• EPA SNAP Compliant

ETL and cETL Listed

Units include stainless steel sliding drawers with a 400+ blood bag capacity for single door units and an 800+ bag capacity for double door units.

Our models are equipped with advanced temperature monitoring systems and a full array of alarms.

Efficient Cooling

Designed with natural, hydrocarbon refrigerants and variable speed compressors, resulting in minimal noise levels and reduced operational costs.

Preserving Life, Ensuring Safety Blood Bank Refrigerators and Plasma Freezers

President: Laura Steiner

Founded: 1994

Employees: 150+

Toll-Free Phone: (800) 648-4041

Phone: (843) 821-8010

Precision cooling for life-saving storage. Corepoint Scientific’s line of blood bank refrigerators and plasma freezers ensure consistent temperatures, regulatory compliance, and reliable performance — protecting the integrity of critical blood and plasma supplies.

Address: 125 Varnfield Drive Summerville, SC 29483

Website: corepointscientific.com

Corepoint® Scientific, a Horizon Scientific Inc. brand, provides a full range of temperature-controlled equipment to our customers across healthcare, laboratory and clinical research, pharmaceutical, and industrial segments. Our extensive portfolio of quality products ranges from small capacity countertop refrigerators and freezers to special purpose, application-specific models such as blood bank and plasma storage. Ensuring customer requirements are met, all products are designed in a variety of configurations, from general purpose cold storage to medical and pharmaceutical storage with stringent temperature performance requirements. With over 25 years of experience, Corepoint® Scientific excels at quickly developing customer solutions at competitive price points while providing industry-leading service levels. Our advantage includes a comprehensive array of products and services to meet your temperature-controlled storage needs, an industry leading warranty, a dedicated support team, and many models are available from in-stock inventory and are ready to ship.

Blood bank refrigerators and plasma freezers are essential components in the safe and effective management of blood products. Designed to maintain precise temperature controls, these specialized storage units protect the integrity and viability of blood and plasma. With advanced cooling technology, they provide a stable environment that prevents spoilage and ensures that blood products remain usable for transfusions and other medical procedures. Units feature easy-to-read temperature displays, alarms for temperature deviations, and reliable backup systems, guaranteeing that your critical supplies are always protected.

At Corepoint® Scientific, we prioritize compliance with industry regulations to ensure the highest standards of safety and quality for our blood bank refrigerators and plasma freezers. Our products meet the stringent requirements set forth by the AABB (American Association of Blood Banks), which mandates rigorous quality assurance processes and performance standards for blood storage. Additionally, all of our units are designed to comply with FDA regulations, guaranteeing that they meet the necessary criteria for safe and effective use in medical facilities. By choosing our certified storage solutions, you can be confident that your blood products are stored in environments that adhere to the most respected industry standards.

Each unit in our lineup is engineered for dependable, long-lasting performance with energy-efficient designs and intuitive features. Corepoint® Scientific refrigerators and freezers are ideal for blood banks, hospitals, and research laboratories, delivering unmatched reliability to ensure that critical supplies are consistently preserved and readily accessible.

• Precise temperature control technology ensures consistent maintenance of temperature ranges for storing blood products.

• AABB and FDA Compliance: Meets stringent AABB standards for safety and quality of blood-based products, while adhering to FDA regulations for Class II Medical Devices.

• Stainless steel sliding drawers optimize storage space and provide easy access to products.

• Units include a 400+ blood bag capacity for single door units and an 800+ bag capacity for double door units.

• Designed with natural hydrocarbon refrigerants and variable speed compressors, resulting in minimal noise levels and reduced operational costs.

• Real-Time Temperature Monitoring: Equipped with digital displays and alarms for immediate alerts on temperature deviations.

• User-Friendly Interface: Easy-to-navigate controls and displays for convenient operation.

Centralized medication access (CMA) is revolutionizing the patient journey to specialty care. We consistently see the challenges that arise from the lack of medication access and believe that a centralized medication access team is the solution. It allows the clinical team to concentrate on what matters most: direct patient care. At the same time, it makes the process of obtaining specialty medications for patients much more straightforward.

Contributors:

Angie Amado, PharmD, CSP, Senior Director at Visante

Amy O’Kroley, CPhT, PACS, Specialty Pharmacy Service Manager at Visante

The Challenges: What Happens When CMA Isn’t in the Picture?

CMA is a network where a pharmacy-driven medication access team manages all aspects of medication authorization and distribution. This ensures streamlined processes and improved access and affordability for patients.

Unfortunately, a CMA team is the missing piece in many struggling healthcare systems. To put it simply, medication access is absolutely necessary to achieve the best possible patient and healthcare outcomes.

n Increased Administrative Burden

One of the primary challenges for organizations lacking a CMA model is the increased administrative burden on providers and their staff. They are required to manage time-consuming tasks such as writing appeal letters and navigating insurance coverages, which detracts from their ability to focus on direct patient care. This administrative overload is not only a source of frustration but also a major contributor to provider and staff burnout.

n Inefficiencies in Operations

Without CMA, healthcare operations become less efficient. The absence of streamlined processes means that more time and effort are needed from healthcare providers and clinical staff to manage medication-related tasks. This hampers overall workflow and productivity.

Poor management of medication access often results in financial inefficiencies and reduced financial performance, which can further stress already limited healthcare resources.

n Delayed Treatment

Patients are directly affected by the lack of CMA through delays in receiving their medications. Slower authorization processes can impede access to necessary treatments.

Additionally, this often leads to missed opportunities for financial assistance, resulting in higher out-of-pocket costs for patients. This financial burden can be particularly challenging for patients with chronic conditions who require ongoing medication.

n Patient Stress and Confusion

The complexities of authorization and financial assistance processes without a centralized medication access team can also cause significant stress and confusion for patients. Navigating these complexities can be overwhelming, especially for those who are already dealing with serious health issues.

In fact, without streamlined access and comprehensive financial support, patients are less likely to adhere to their prescribed treatments. Lower medication adherence leads to poorer health outcomes and difficulties in managing chronic conditions.

n Logistical Challenges

Logistical challenges arise as patients may face hassles in obtaining specialty medications. They often have to rely on specialty mailorder pharmacies or navigate complex insurance directives, which can be cumbersome and inefficient for both patients and providers.

From writing appeal letters to navigating insurance coverage, providers and their staff are often required to take on tasks that distract from patient care. A centralized medication model offers several benefits:

• Reduced Administrative Burden: Centralized services take over administrative tasks like handling prior authorizations, managing insurance claims, and coordinating with pharmacies, allowing providers to focus on direct patient care. Studies indicate that up to 75% of healthcare providers believe that centralized systems, like electronic health records (EHRs), enable them to deliver better patient care.

• Enhanced Operational Efficiency: Streamlined processes reduce the time and effort required from healthcare providers, improving overall workflow. Implementing CMA can lead to increased patient throughput and reduced medication errors.

• Improved Financial Performance: Better management of medication access leads to improved financial outcomes

for healthcare facilities. Efficient patient access systems ensure accurate and timely capture of patient information, avoiding claim denials, underpayments, and delays in revenue collection.

• Better Clinical Outcomes: Hospitals with CMA have reported improvements in patient compliance with prescribed medications, resulting in better management of chronic diseases and reduced hospital readmissions.

From skyrocketing medication prices to treatment delays, patients often face significant challenges with the medication access process. CMA offers several benefits for patients, including:

• Timely Medication Access: Centralized services expedite the authorization process, ensuring patients receive their medications faster. This leads to improved treatment outcomes as patients can start their therapies promptly.

• Financial Assistance: CMA connects patients with comprehensive financial support, including copay assistance and drug assistance programs.

This reduces the financial burden on patients, making essential medications more affordable.

• Reduced Stress: By handling the complexities of authorization and financial assistance, CMA simplifies the process of receiving medications. Additionally, clear communication and streamlined procedures help reduce patient anxiety and confusion.

• Improved Health: With reduced financial and administrative barriers, patients are more likely to adhere to their prescribed treatments. This is crucial for achieving better health outcomes and managing chronic conditions effectively.

CMA: Your Comprehensive Solution

Centralized medication access is essential for the modern healthcare system; it solves many logistical challenges, boosts efficiency, and provides patients with peace of mind.

What's more, some covered entities generate as much as 600% in

In short, your patients benefit -and so does your health system.

Turn to dedicated mentorship and accredited in-house continuous education (CE) for ongoing training

Rely on CPS’ network of pharmacy experts for regulatory compliance, clinical, financial, and operational support whenever you need it

Thrive

Work for an organization where you can advance your career trajectory and move up into new roles over time

Nationwide Opportunities:

Corporate Office

Hospital Pharmacy

Health-System Specialty Pharmacy

Part- & Full-Time Positions:

Director of Pharmacy

Staff Pharmacist

Pharmacy Technician

Great Benefits*

Competitive Salary

Medical, Dental, & Vision Insurance

Generous PTO Package

401k Match Program

* Full-time positions only

SCAN TO SEE CURRENT JOB LISTINGS ABOUT CPS FOR

Founded over 50 years ago, CPS Solutions, LLC (“CPS”) is one of the nation’s leading providers of pharmacy and hospital services, employing over 2,500 pharmacy and healthcare professionals and servicing over 800 healthcare facilities nationwide. CPS helps its clients develop and accelerate their own specialty pharmacy services and enables its clients to optimize the efficiency and cost savings of traditional inpatient pharmacy services. CPS’ offerings include specialty pharmacy management, inpatient pharmacy management, pharmacy consulting, 340B program consulting, telepharmacy, supply chain, rehabilitation, and technology solutions.

President & CEO: Cory Kwarta

Founded: 1915

Employees: 500-1000

Toll-Free Phone: (800) 396-9666

Deliver exceptional patient care with innovations from the core of the central pharmacy to enhance performance workflow efficiency, improve accuracy, and increase safety.

Address: 11080 Circle Point Road #500 Westminster, CO 80020

Website: www.swisslog-healthcare.com

Headquartered in Westminster, CO, Swisslog Healthcare has been delivering best-in-class automation solutions and services for more than 100 years. At Swisslog Healthcare, we lead change for better care. Our focus is on improving workflows and reducing the time clinicians spend doing repetitive tasks — enabling more time for patient care. Discover how our pharmacy automation solutions can boost efficiency, improve care, and reduce costs at www.swisslog-healthcare.com.

Hospitals today are held to increasingly higher accountability for the overall patient experience. The timely dispense and delivery of correct medications are critical to improving patient outcomes and fostering a positive experience. Whether on a large scale or small, the right automation can enhance patient safety, decrease medication waste and drug shortages, reduce costs, and enable staff to spend more time focusing on clinical activities. Swisslog Healthcare enables forwardthinking health systems to create a connected medication ecosystem.

n BoxPicker® Automated Pharmacy Storage System provides pharmacies with secure, high-density, modular storage of medications, controlling access, improving pharmacy workflows, and expediting the picking process. The modular design of the BoxPicker enables hospitals to tailor the system to their exact needs. The ability to add multiple operator stations allows for simultaneous operations, significantly increasing efficiency as one technician can stock medications while another can complete dispensing activities. Automated medication storage and retrieval not only eliminates picking errors and increases safety at dispense, but also creates, a more efficient pharmacy workflow. Designed to eliminate the need for static shelving, BoxPicker allows pharmacy staff to focus on clinical tasks and spend less time locating, picking, and verifying medications.

n PillPick® Automated Packaging and Dispensing System is a completely automated solution that decreases human touches in packaging, storing, dispensing, and returning unit-dose medications. The patented PickRing® delivers patient-specific medication on a single ring ready for administration, reducing the opportunity for missed medications

and speeding up administration time. With the ultimate automated pharmacy system for patient safety and operational efficiency, nurses can spend more time delivering high-quality care.

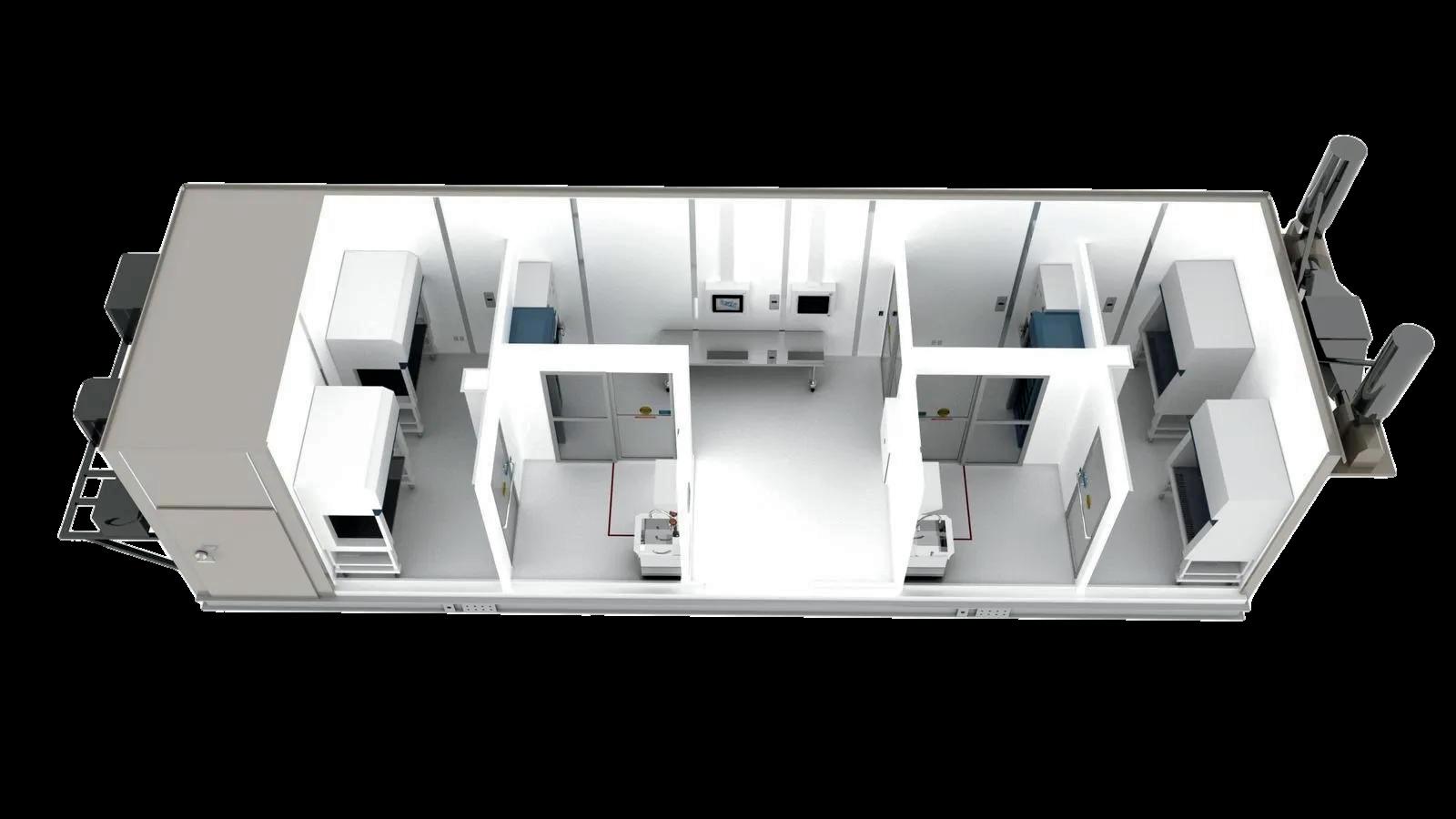

n Consolidated Service Centers (CSCs) or Integrated Service Centers (ISCs) enable forward-thinking organization to combat challenges presented by an increasingly complex supply chain by centralizing supply chain and pharmacy operations off-site. Partnering with Swisslog Healthcare for CSC implementations helps healthcare organizations actualize their CSC goals and maximize benefits from streamlined pharmacy operations. Effective CSCs automate manual processes and standardize workflows, improving operations system wide.

n AutoPack™ Automated Oral Solid Packager is an oral solid packager that integrates easily with pharmacy operations to provide fully automated, patient specific, unit-dose or multi-dose oral solid medication packaging, ensuring that 100% of medications are scan-ready at the bedside.

n ezCUT Automated Tablet Cutter might be compact in size, but offers unparalleled optimization. Tablets of varying sizes (round and oblong) are flawlessly halved, and damaged or irregular tablets are automatically discarded — ensuring the accuracy of every dose. Manually cutting tablets is time-consuming and strenuous, but automating the process with ezCUT saves time and energy, allowing pharmacy staff to focus on high-value clinical tasks. ezCUT can be used as a standalone solution or complementary to either the PillPick® or AutoPack™

n AutoCarousel® Semi-Automated Pharmacy Storage System, together with medication management software, transforms medication management by reducing labor, drug waste, missing medications, and picking mistakes.

AutoCarousel is accurate and reliable, and the vertical design ensures maximal storage in a compact footprint. In addition, AutoCarousel helps pharmacies ensure medication safety with password-protected access and barcode scanning during the stocking and dispensing processes to track the chain of custody and manage all items comprehensively.

n Delivery Manager is a sophisticated application that enables your hospital to achieve a complete chain of custody, ensuring compliance, control, and, most importantly, patient safety. The Delivery Manager application reports carrier locations, identifies the sender and receiver, and enables visibility into carrier contents. Adding the Delivery Manager application to your TransLogic pneumatic tube system technology helps department leaders in your facility gain ultimate visibility into what is being delivered throughout the hospital. When Delivery Manager is combined with RFID, WhoTube® and timely software updates from TransLogic, your facility achieves a complete chain-of-custody. Implementing intelligent tracking with Delivery Manager provides a single point of control, accountability, and traceability throughout the entire delivery process — from your tube system to your manual transport.

According to ISMP guidance for Optimizing Safe Implementation and Use of Smart Infusion Pumps, the goal for drug library compliance should be 95% or greater. Even a single percentage point increase in drug library compliance can significantly reduce the number of unprotected infusions.2 Baxter infusion platforms with Dose IQ Safety Software deliver 97% compliance within one month of implementation.1

AVAILABLE IN THE NOVUM IQ INFUSION PLATFORM. POWERED BY

President & CEO: Jose Almeida

Founded: 1931

Employees: 50,000 globally

Stock Symbol: BAX

Toll-Free Phone: (800) 422-9837

Phone: (224) 948-1812

Address: One Baxter Parkway Deerfield, IL 60015

At every step, the Novum IQ Infusion Platform with Dose IQ Safety Software helps you build and deploy one of the safest and most effective drug libraries possible for large volume, syringe, and enteral infusions.

Website: baxter.com and novumiq.com

For over 90 years, Baxter has introduced significant medical innovations, including the first commercially produced intravenous (IV) solutions and the first home-based dialysis system as an alternative to hemodialysis in a hospital or clinic. Baxter has been highly innovative in providing healthcare solutions to unmet medical needs through scientific advancement as well as strategic acquisitions and partnerships.

Every day, millions of patients, caregivers, and healthcare providers rely on Baxter’s leading portfolio of diagnostic, critical care, kidney care, nutrition, hospital, and surgical products used across patient homes, hospitals, physician offices, and other sites of care. We’ve been operating at the critical intersection where innovations that save and sustain lives meet the healthcare providers who make it happen. With products, digital health solutions, and therapies available in more than 100 countries, Baxter’s employees worldwide are now building upon the company’s rich heritage of medical breakthroughs to advance the next generation of transformative healthcare innovations. To learn more, visit baxter.com and follow us on X, LinkedIn, and Facebook.

n Novum IQ Infusion Platform — Large Volume and Syringe Pump Models

Benefit from an elevated infusion experience. The Novum IQ Large Volume Pump and the Novum IQ Syringe Pump share advanced technology and enhancements to help protect patients and standardize infusion administration.

• Streamlined workflows and intuitive operation to drive compliance in the use of pump safety software, helping to ensure a safe continuum of care for patients.

• An easy-to-use common interface across large volume and syringe pumps, supported by 350+ hours of human factors testing, helps to simplify pump operation for clinicians and streamline training.

• On-screen barcodes with scan prompts ensure that pumps are correctly identified, helping to provide safety and efficiency during auto-programming and drive auto-programming compliance.

• A visual beacon so clinicians can see from a distance that a pump needs attention.

• A backlit keypad and an ambient light sensor to improve visibility.

• Baxter single set technology accommodates both large volume pump and gravity infusions to deliver efficiency, safety, and savings.

• A broad range of compatible syringes have been qualified for use with the Novum IQ Syringe Pump.

n Dose IQ Safety Software

Rely on Dose IQ Safety Software to help you protect more infusions and reduce the risk of preventable errors. Accurate and up-to-date drug libraries are important to help ensure patient protective measures are maintained throughout infusion therapy, especially for patients receiving critical medications. However, even when drug libraries are used, current implementation practices can limit their effectiveness. At every step, webbased Dose IQ Safety Software helps you build and deploy one of the safest and most effective drug libraries possible. Dose IQ Safety Software offers unique and best practice capabilities.

• Titration error prevention technology allows Novum IQ pumps to intercept dose and rate changes that could be potentially harmful.

• Unique drug-linking feature that provides more library capacity and flexibility with 32 care areas and 10,000+ drug entries across large volume and syringe pumps.

• Comprehensive units of measure, including MillionUnit dosing.

• Color coding for enteral infusions.

• Configurable anesthesia care area settings with optional passcode protection.

• Standardized drug library creation in partnership with First Databank (FDB) and incorporation of its FDB Infusion Knowledge database.

Count on rigorous cybersecurity to provide advanced protection for patients’ infusion data. The Novum IQ Infusion Platform is built to meet stringent cybersecurity protocols.

• UL 2900 certification, which attests to independent cybersecurity testing and assessment for the IQ Enterprise and Dose IQ2.

• Secure remote updates to IQ Enterprise Connectivity Suite on both servers and network.

• Encrypted software and firmware to pumps.

• Collaboration with Health-ISAC and ICS-CERT organizations.

• 95% field serviceability to help get pumps back in use, potentially reducing cost and downtime.

• Modular design with cost-effective field-replaceable units to streamline service and maintenance.

• Remote troubleshooting and diagnostics combined with parts ordering, to help reduce maintenance burden.

The Mission: Making a Difference

Rory Phillips, BSPh, MBA, CPEL, RPh

Director of Pharmacy & Respiratory Services

~ Southern Ohio Medical Center (SOMC)

Founded in 1954, Southern Ohio Medical Center (SOMC) is located in Portsmouth, Ohio. The Main Campus features a 211-bed not-for-profit hospital providing emergency and surgical care to the surrounding community. These services include an inpatient pharmacy and several outpatient clinics offering various healthcare services ranging from oncology and cardiology to rheumatology and primary care, among others. With 60+ offices throughout southern Ohio and northeastern Kentucky, SOMC has 2,600+ full- and part-time staff and 140+ physicians, specialists, and advanced practice providers (APPs).

The health system’s mission is to make a difference in the lives of its patients, employees, and the community. With this mission in mind, Director of Pharmacy & Respiratory Services Rory Phillips, BSPh, MBA, CPEL, RPh, began exploring how to create a specialty pharmacy to better serve SOMC's patients and medical staff members.

Historically, SOMC worked with a mail-order specialty pharmacy to meet patient needs. “The physicians and APPs were happy with the process, but I wanted to deliver a higher level of patient and medical staff satisfaction,” explains Phillips. “I wanted patients and medical staff members to be able to rely on people from here — people who truly understood and cared about the local community ” However, as he began researching who could help him achieve this goal, he found many operated on a call center model. Phillips ultimately chose CPS Solutions, LLC (CPS), one of the nation’s largest pharmacy and hospital service providers, to help build and manage SOMC’s specialty pharmacy.

$2.4M

PATIENT FINANCIAL ASSISTANCE, 2023

92%

TREATMENT ADHERENCE

96%

PATIENT SATISFACTION

100%

MEDICAL STAFF SATISFACTION

“CPS’ patientcentered approach to specialty pharmacy is truly making a difference at SOMC.”

Rory Phillips, BSPh, MBA, CPEL, RPh

Director

of Pharmacy & Respiratory Services

~ Southern Ohio Medical Center (SOMC)

“CPS’ emphasis on local care was a big deciding factor for me,” he says. “But so was their approach. They spent a day and a half with me and others on the leadership team to ensure buy-in and gain a thorough understanding of our health system's operations and priorities.”

SOMC is CPS’ longest-running specialty pharmacy client. With CPS, team members are on site, which means medical staff members and patients talk to their neighbors to help them navigate the complex specialty pharmacy landscape. “As far as patients and medical staff members are concerned, CPS pharmacists and liaisons are SOMC staff,” says Phillips. “This is exactly what I wanted — specialty pharmacy staff building relationships with patients and medical staff members, giving patients familiar people to reach out to for help.”

“[CPS] Pharmacists and liaisons assist physicians and patients in managing all of their prescriptions. It is a holistic approach and includes all of the patient’s medications. The CPS team contacts the patient and manages new and refill prescriptions proactively,” explains Phillips.

In 2023 alone, SOMC provided $2.4M in financial assistance for its patients. “CPS’ patient-centered approach to specialty pharmacy is truly making a difference at SOMC,” says Phillips. Medical staff members and patient satisfaction scores are 100% and 96%, respectively, for 2023. “That, to me, is a clear demonstration of our success,” he adds. “When specialty pharmacy staff can talk to patients or colleagues about their kids, their job, or even the county fair, they put patients at ease and trust pharmacy staff to care for them.”

One of the aspects Phillips appreciates most about CPS is that they are a true teammate for the long run. “Over the years, our goals and priorities have evolved — and CPS has been willing to shift right along with us.”

A significant goal for SOMC is to improve patient care through chronic disease management (CDM). That’s why the health system implemented CPS’ CDM services in all family practice clinics in late 2021. SOMC also worked with CPS to focus on medication adherence, which resulted in patient adherence reaching 92% last year.

Since the third quarter of 2023, CPS has been assisting SOMC with its transition of care processes and the hospitals’ Medicare Star Ratings. The goal is to minimize readmissions, which can improve patient outcomes while also reducing hospital costs incurred for inpatient stays and procedures. Through this process, CPS coordinates prior authorizations for medications given to SOMC patients at the time of discharge and also submits patient medication counseling documentation in a web-based performance

“With CPS’ help, the pharmacy is no longer considered a cost center — it’s a revenuegenerating operation.”

Rory Phillips, BSPh, MBA, CPEL, RPh Director of Pharmacy & Respiratory Services

~ Southern Ohio Medical Center (SOMC)

information tool to give SOMC credit for performing medication therapy management. SOMC’s specialty staff and the CPS team manage all patient medications holistically; they are doing the work. They are now documenting this work to increase Medicare Star Ratings, thereby reducing direct and indirect renumeration (DIR) fees and improving prescription reimbursement. “It’s one more example of how CPS goes the extra mile.”

In just 10 years, SOMC opened six community pharmacies and has secured space for building pharmacies seven and eight. Revenue growth was dramatic in SOMC’s first year of operation — and they have continued to achieve double-digit gains year after year. “With CPS’ help, the pharmacy is no longer considered a cost center — it’s a revenuegenerating operation,” notes Phillips.

Consequently, SOMC’s specialty pharmacy services became a lifeline for the community. As chain pharmacies began closing stores in the area, some patients were faced with the prospect of driving long distances to get their medications. “The addition of the specialty pharmacy has just lowered barriers for patients to access medication,” he says. “Beyond that, it’s enhanced the quality of care SOMC clinics and medical staff members can deliver.”

Phillips and SOMC do not plan to stop there. “Because CPS represents multiple organizations, they can address limited distribution drugs with manufacturers and payer lockouts with health plans better than I can as a stand-alone pharmacy,” explains Phillips. That dedicated support, amongst many other reasons, is why the health system has signed a contract with CPS through 2035.

Operating a successful health system pharmacy is more complex now than ever before.

With 50+ years’ experience in hospital and health system pharmacy, CPS understands what you are facing. Pharmacy leaders across 800+ healthcare organizations rely on our proven expertise, technology, and services to improve patient care and thrive today and in the future.

Our Solutions:

Compliance, Operations, and

Specialty Pharmacy Patient Management Software Telepharmacy

Remote Order Entry 340B Program Compliance and Optimization

KwikDose oral dispensers accurately deliver small volumes of oral liquid medication. Enlarged numbers and easy-to-read marking lines allow for quick and accurate volume identification, even with dark liquids. The unique tip prevents wrong-route administration.

President & CEO: Steve van Engen

Founded: 2016

Phone: (720) 500-2500

Fax: (720) 500-2571

Address: 11233 E. Caley Avenue Suite 300 Centennial, CO 80111

Website: medsafetysolutions.com/kwikdose

Founded in 2016 by industry professionals with decades of collective medical device experience, the MedSafety Solutions team speaks your language and understands your hospital pharmacy’s non-negotiable need for quality, efficiency, and predictability when selecting critical equipment and supplies. Nimble by design and friendly by nature, our team will do whatever is needed to make sure that you are well informed about your IV administration choices and completely satisfied with the products and services you receive. Our goal is to be a trusted partner, and we know that reliability, responsiveness, expertise, and a friendly, human touch are what it takes to earn that trust.

The latest addition to Medsafety Solution’s product family is the KwikDose oral dispenser. The KwikDose oral dispensers offer the same high-quality oral dispensers pharmacies know and trust. The unique tip prevents wrong-route administration. Enlarged numbers and easy-to-read marking lines allow quick and accurate volume identification, even with dark liquids. KwikDose oral dispensers are available in six convenient sizes (0.5, 1, 3, 5, 10, and 20 mL), in both clear and amber. Also available with blue self-righting tip caps.

Product Specifications

• Sizes: 0.5, 1, 3, 5, 10, and 20 mL

• Available in Clear and Amber

• Made in Denmark

TwoFer Huber-Tipped Needles enable vented and non-vented vial additions and withdrawals, effectively performing the functions of two devices. The TwoFer Needle facilitates the movement of liquid drugs from one container to another without the time and expense of changing needles. Color-coded and available in 1.5" and 1.0" lengths, the TwoFer Needle is appropriate for a variety of receptacle sizes and applications.

n Tamper-Resistant Add Port Caps

Tamper-Resistant Add Port Caps are easy-to-use, hinged plastic caps that impede tampering when storing and transporting IV solutions.

n Female Luer Lock Cap

The Female Luer Lock Cap is designed to seal male Luer fittings on devices such as manifolds, stopcocks or IV sets, reducing the risk of touch contamination and medication leakage.

n KwikVial™ Oral Liquid Containers

KwikVial Containers are used for unit-dose packaging, delivery, and administration of oral liquid medications. Versatile and easy to use, they can accommodate a variety of dosage volumes, are sealed for tamper-prevention resistance and detection, and are designed for efficient packaging and administration.

Key Business Partners

KwikDose and our other products are available directly from MedSafety Solutions and from various distribution partners.

Trade Shows/Meetings Attended

Stop by our booth #439 at ASHP Midyear 2024 in New Orleans.

Ordering Information

For more information or to preorder today visit our website medsafetysolutions.com/kwikdose.

• Sterile and Paper Free (USP 797 Compliant).

• Maintains a 100% sterile barrier* with 3X greater adhesion. *Tested in Nelson Labs, Salt Lake City, UT

• Helps prevent contamination of drugs and provides added protection to pharmacists.

• Will not fall off, even in cold storage conditions (down to -20 degrees centigrade).

• Patented dual-layer indicates true tamperevidence, with “OPENED” marking.

National Sales

Manager: Alex Meadow

Phone: (516) 374-8862

The only single-use, tamper-evident seal that provides and maintains a 100% sterile barrier.

Address: 2905 South Congress Avenue, Suite A Delray Beach, FL 33445

Website: steri-tamp.com

Email: info@steri-tamp.com

Established in 2010, Allied Pharmacy Products, Inc. was created from a commitment to enhance the preparation and distribution of intravenous medication within hospital pharmacies and compounding environments. The development of Steri-Tamp® stems from the insights of a pharmacist who recognized the imperative for improved tamper-evident measures and sterility in IV preparation. Throughout our journey, Allied Pharmacy Products, Inc. has remained dedicated to listening and responding to the needs of pharmacists. This ongoing responsiveness has been instrumental in our continuous product line expansion.

The Steri-Tamp® product line features seven cutting-edge tamperevident seals. Our IV bag port seals come in blue, red, and yellow (labeled CHEMO) variants. For vial seals, we offer options in 13 mm (red), 20 mm (silver), and 28 mm (blue). Among these, our belly button bag seals (green) stand out for their ability to adhere to both the ICU medical “belly button” bag port and the top of a 13 mm vial.

Steri-Tamp® has introduced specialized IV bag port seals tailored to meet the labeling requirements of USP 800 and ISMP. These seals offer a streamlined solution for handling paralytic agents and hazardous drugs in a unified workflow.

What sets Steri-Tamp seals apart is their true tamper-evident design. Utilizing dual-layer technology, these seals serve as a clear indicator to hospital staff if a bag or vial has been tampered with or used. Removing the top foil layer reveals an “opened” layer, after which it cannot be reapplied. Thanks to a 3X stronger adhesive, Steri-Tamp ensures a 100% sterile barrier.

In addition to our sterile options, we also offer two non-sterile syringe seals. These seals boast increased tensile strength, making them easy to remove from the liner and apply to a wide range of containers, including syringes, inhalers, EpiPens, insulin pens, and more. Our latest innovation, the Tamper-Clear Syringe Seal®, enables visibility of syringe markings and barcode scanning on syringes, inhalers, insulin pens, and other related items.

n Steri-Tamp® IV Bag Port Seals:

• Deliver a foolproof and potentially life-saving method to ascertain medication dispensing.

• Safeguard the IV admixture bag’s point of entry from contamination and accidental double dosing.

• Securely attach to the port through a simple “twist” mechanism, ensuring an airtight seal.

• The green belly button bag seal is purpose-built for the unique “belly button” port on ICU medical bags and can also be used on 13 mm vial tops.

n Steri-Tamp® Vial Seals:

• Designed to lie flat on the vial top, effectively preventing bacteria from entering the vial, without overlapping the edges.

• Preserve the medication’s integrity.

• Specially sized for 28 mm, 20 mm, and 13 mm vial tops, ensuring the right seal for the corresponding vial size.

n Steri-Tamp® Syringe Seals:

• Offer non-sterile solutions to provide tamper-evidence for syringes and other medical containers.

• The innovative Tamper-Clear Syringe Seal® provides clear visibility to the syringe barrel and facilitates barcode scanning, making it ideal for sealing small oral, pediatric, and NICU syringes.

n Available in rolls of 1,000 seals each.

n All our seals contribute to reducing waste, streamlining workflow, and ultimately saving you time and money.

“Tamper-Clear works great! Helps prevent the caps falling off the syringes.”

— Lead Pharmacy Technician, Colorado Springs, CO

“They’re the best seals we use. It’s a must have!”

— Pharmacy Purchasing Specialist, Orangeburg, SC

“Love the syringe seals. Able to remove them without them breaking beforehand. It really is a higher quality seal!”

–– Pharmacy Tech/Purchasing Lead, Houston, TX

Additional Product Lines

Stay tuned for exciting updates to our products set to launch in 2024!

Trade Shows/Meetings Attended

ASHP Midyear, EAHP, NPPA Conference, and various ASHP state affiliate pharmacy conferences.

Ordering Information

Available through major wholesalers and distributors. Visit our “order info” page at steri-tamp.com to find Steri-Tamp® order numbers for your preferred vendor.

• ULPA filter, creating ISO 3 workzone, cleaner than standard ISO 5

• ECM blower, creating stable airflow at energy-efficient 150 Watts

• Comfortable low noise at 55 dBA, full legroom, dished work tray

• 7” Touchscreen Controller With built-in user guide, and 21 CFR Part 11 compliance

• ULPA filter, creating ISO 3 workzone, cleaner than standard ISO 5

• Comfortable low noise at 58 dBA, dished work tray, builtin armrest

• Lowest height in the market at 55”, suitable for cleanroom

• Two HEPA filter in series, allowing exhaust to room instead of ducting

• Comfortable low noise at 57 dBA and full-width front access opening

• Dished phenolic resin worktop, preventing spill, scratch, and corrosion

• Fully customizable according to your needs Model: LHG-4BS-F9

• High-grade stainless steel 316 construction

• Multi-step stations combining several isolators

• Optional integrated VHP generator and freeze dryer

Q. What are the key differences between pharmacy isolators, cleanrooms, and barrier isolators in terms of functionality and regulatory compliance?

Pharmacy isolators, cleanrooms, and barrier isolators (also known as Restricted Access Barrier Systems or RABS) serve distinct roles in pharmacy operations, each with unique functionalities and regulatory compliance requirements. Both pharmacy isolators and RABS are categorized as Primary Engineering Control (PEC) while cleanrooms can be categorized as Secondary Engineering Control (SEC) where the PEC is housed.

• Pharmacy isolators are designed to provide a controlled environment for aseptic processing and compounding of sterile drugs. They are fully enclosed systems that prevent contamination from external sources. Pharmacy isolators need to be pressure tested according to ISO 14644-7 and ISO 10648-2 with a stringent leak rate. Thanks to this design principle, pharmacy isolators can be equipped with a quantifiable and automated decontamination system, as well as good reliability for toxic containment.

• Barrier isolators, or RABS, also provide a controlled environment and an enclosure with the separative partial barrier, however, as per CETA CAG-002-2006, there is no requirement for the RABS to be pressure tested. RABS will be highly dependent on operator aseptic techniques to reduce the contamination risk and has low capability in toxic containment.

• Cleanrooms are also designed to provide a controlled environment via an open system and will refer to regulatory standards like ISO 14644.

In summary, while pharmacy isolators, cleanrooms, and barrier isolators all aim to ensure safe and effective compounding processes, they differ significantly in functionality and regulatory compliance requirements.

Q. How would a facility determine the appropriate cleanroom classification needed for their specific pharmacy operations?

First, the pharmacy facility will need to define the compounding activities and risk levels. Will it be for non-sterile compounding or sterile compounding? If it is sterile compounding, will it be a sterile hazardous (HD) or non-hazardous (non-HD) compounding? Will the pharmacy operations produce Compounded Sterile Preparations (CSP) Category 1 or Category 2?

The U.S. Pharmacopeia (USP) standards, especially USP <797> and USP <800>, outline cleanroom requirements for sterile compounding (797) and hazardous drug handling (800). Critical areas where sterile compounding occurs, whether it is hazardous or non-hazardous drugs, should maintain an ISO Class 5 classification. This air cleanliness can be achieved with the use of Primary Engineering Control (PEC), which can be either a pharmacy isolator or RABS.

Depending on the product categories based on the risk of microbial contamination and whether the CSPs are HD or

non-HD, the pharmacy facility can consider the following:

• For non-HD CSPs with a beyond-use date of less than 12 hours stored in temperature or less than 24 hours refrigerated, PECs (laminar flow hoods, biosafety cabinet class II, and compounding aseptic isolator/RABS) can be located in an unclassified room or segregated compounding area with no air changes per hour requirement.