Turbine Flowmeters

Oval Gear Flowmeters

Instrumentation

Titan Enterprises is a leading design and manufacturer of innovative end user and OEM high-performance flowmeters and flow measurement instrumentation, used within a wide range of processes, environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• NSF-Approved mini turbine flowmeters

• ATEX-compliant and high pressure Oval Gear models

• OEM bespoke design capability Titan’s liquid flowmeters are designed and manufactured to ISO 9001 with traceable calibrations.

+44 (0)1935 812790 sales@flowmeters.co.uk www.flowmeters.co.uk

Providing timely industry news, exclusive features on advancing technology, equipment, materials, show previews, content marketing services for our valued clients and much more!

4

Why Altrad mandates all supervisors sit ECITB Leading a Team Safely course

14

Kent expands strategic presence in Houston, signaling commitment to the U.S. Market

20

Professor Robert Hairstans of NMITE named Pioneer of the Year at construction industry awards

9

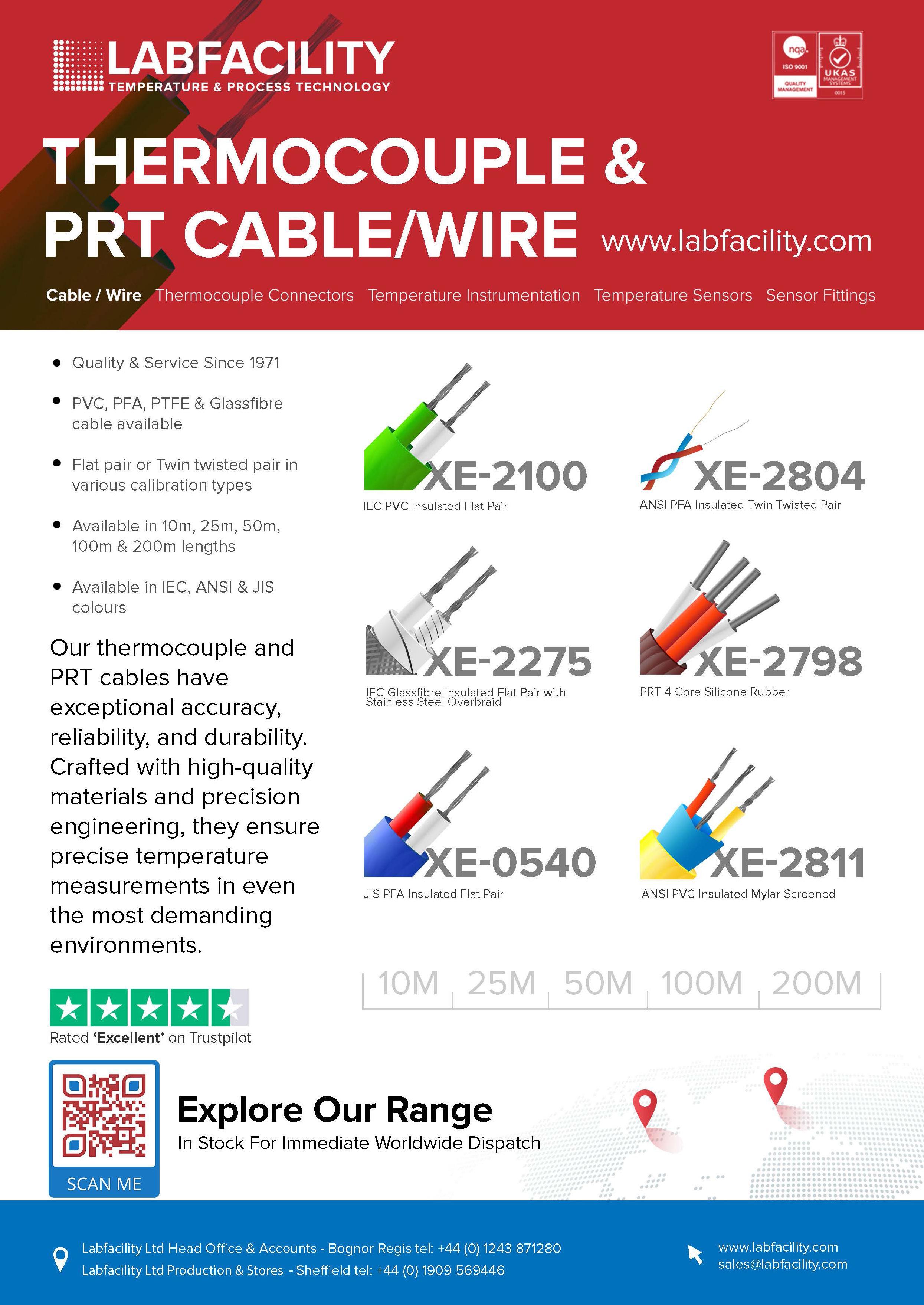

Thermocouple & PRT

Cable/Wire

18

IDS showcases groudbreaking 2D, 3D, and AI-based vision systems at SPS 2024 in Nuremberg, Germany

22

Altus hosts record-breaking ‘Factory of the Future’ event

Stephen Thompson - 01227 314 329 Publication Manager | steve@worldwide-enegineering.com

Katie Sirdefield - 01227 314 329 Editorial Assistant | katie@worldwide-enegineering.com

Orla McGill - 01227 314 329 Newsletter/Editorial Assistant | orla@worldwide-enegineering.com

Daisy Shingles - 01227 314 329 Graphic Designer | design@worldwide-engineering.com

One of the largest employers in the engineering construction industry has mandated that all its supervisory staff complete the ECITB’s Leading a Team Safely (LaTS) course

Altrad has trained around 1,000 UKbased supervisors on the course in the space of 18 months to ensure they are aware of and working to the latest safety protocols and operational best practices.

The attendees have included supervisors, chargehands, foremen and even senior managers. Those promoted or new supervisory staff joining Altrad sit the course straight away as part of their personal development.

Donna Mulvihill, Head of Learning & Development at Altrad, said: “The LaTS course is instrumental in equipping our staff with the skills and knowledge necessary to maintain the highest standards of safety and operational efficiency.

“By mandating the course and integrating it with our other safety initiatives, Altrad not only adheres to industry standards but also sets a new benchmark for safety and operational excellence.”

The Engineering Construction Industry Training Board’s (ECITB) Leading a Team Safely (LaTS) course is a oneday workshop designed to provide an essential introduction to managing teams within the context of health and safety.

The course focuses on the essentials of leadership such as planning, implementing and reviewing, with a natural emphasis on health and safety.

Altrad has been running the course at its centres across the UK, including those run by trainer Mark Cockin at its Altrad Babcock office in Selby (pictured).

Mark has been involved in training ECITB courses for two years and

his industry background means he understands first-hand the benefits of safety training, having started out as an apprentice in 1985 before taking on a site supervisor role at Altrad in 2005 and becoming site manager at Drax Power Station in 2014.

“Without good leadership, planning and clear, concise communication people will assume things are right and that’s how accidents happen, so the course helps coach people in these areas,” said Mark.

“This course ensures workers are more confident seeing their leaders being visible, involving everyone in the team and doing everything safely.”

Phil Watt, Maintenance Manager at VPI Power Station in Immingham, added: “All supervisory staff being put through the course sends a good message out about the culture around safety at Altrad.

“It also means we’re all singing off the same song sheet and understand the standards we’re all working to.”

Find out more about the Leading a Team Safely (LaTS) course at: www.ecitb.org.uk/professionaldevelopment/ccnsg/leading-a-teamsafely-lats/

3.7 million days lost annually due to accidents at work*

The CCNSG Safety Passport has been a trailblazer for quality-assured safety training across the UK engineering construction industry and many other sectors for 30 years, helping reduce accidents and lost time incidents on sites.

“As one of the largest employers in the engineering construction industry, Altrad completely supports the principles of the CCNSG and the benefits it brings to the workforce. It gives a baseline level of safety knowledge across all our projects and sites.”

Mark Poole, Learning and Competence Manager for UK and Ireland, Altrad

With projects ramping up, be confident workers on your sites at all levels have a common awareness of health and safety to keep themselves and their colleagues safe.

Find out more about the ECITB’s nationally recognised safety card

Precision liquid flow measurement supports innovation and diversification in the oil, gas and energy industries.

The pressure towards sustainability is pushing the oil, gas and energy sectors to evolve innovative and diverse solutions in a move to create an energy efficient future.

Major transformations within the oil and gas industry in the form of adopting sustainable practices, developing new revenue streams and pushing the boundaries of technology, are being trialled and delivering success. Expanding into new areas such as renewable energy, advanced chemicals and biofuels, is driving innovation and diversification.

Titan Enterprises provides optimised and custom designed liquid flow measurement solutions for oil, petrochemical and green energy applications for OEM customers. These have included bespoke oval gear flow meters for marine fuel flow measurement, monitoring the volume of grease lubricating wind turbine bearing mechanisms, high pressure intrinsically safe units for offshore oil drilling additive

injection, and for biodiesel plants converting bio waste into sustainable biofuels.

Monitoring Grease Lubrication Flow in Wind Turbines

One of the fundamental requirements for ensuring reliable and efficient wind turbine operation is to keep the heavily loaded main bearings fully lubricated in all operating conditions. Fully IP65 / NEMA 4 compliant, Titan’s compact oval gear flowmeters are optimised for measuring the flow of viscous liquids. Designed to operate at pressures of up to 700 bar and temperatures up to 150°C, and with a standard flow range of 0.01 to 4.0 litres/min on 30Cstk oil, the OG1 or OG2 models can routinely achieve outstanding accuracy (0.75%) and repeatability (0.1%).

Optimum Flow Meter Accuracy Critical to Biofuel Production

Titan’s Oval Gear (OG) flow meters are an intrinsic component within Green

Fuels’ biodiesel plants converting bio waste into sustainable biofuels. Green Fuels’ award-winning research and pioneering process plants have powered buildings with sustainable fuel from used cooking oil, with ongoing development to convert fish oil and sewage sludge into biofuel. Simple, accurate and chemically resistant, Titan’s OG flow meters, with the addition of the Namur switch, have proved the ideal solution for precise chemical dosing for Green Fuels’ biofuel plants within a potentially hazardous environment.

Titan Enterprises offer special options and adaptive designs of its Oval Gear (OG) flow sensors to meet specific highpressure requirements, aid chemical compatibility, and ensure safe operation in potentially explosive atmospheres. Titan’s Oval Gear range include ATEX compliant IP65/NEMA 4 protection models, and devices that offer intrinsically safe options for processes that operate within harsh environmental conditions, such as explosive or corrosive atmospheres, where flowmeters are required to withstand tough environments whilst maintaining accurate and reliable measurement.

The pivotal role of oval gear flow meters lies in controlling precise liquid dosage for efficient and economical process operations. Within the petrochemical sector, a chemical injection system employs accurate low-flow measuring sensors to inject a precision dosage of chemicals required, including

antifoaming scale inhibitors and methanol, into oil wells. Accurate chemical dosing is essential for the optimal functioning of the well system, promoting efficiency and heightened productivity without excessive costs. OG flowmeters are critical in preventing overdosing that can lead to unnecessary expenses, or underdosing that may trigger premature maintenance and suboptimal well performance.

For measuring high viscosity liquids like thick oils, bitumen and tar, precisionengineered flow meters are necessary. Titan’s standard OG flowmeters are

designed to provide highly accurate flow measurement up to 1000 cSt. For viscosities above 1000 cSt, Titan provides High Viscosity OG options specially designed with profiled gears to facilitate additional flow of the liquid and prevent hydraulic lock.

Visit Titan Enterprises’ website for further information on flow measurement: flowmeters.co,uk

Or to discuss specific OEM applications, please contact Titan Enterprises on +44 (0)1935 812790 or email: sales@flowmeters.co.uk.

INEOS Automotive has launched a straightforward vehicle locator for all pre-configured new and Certified by INEOS used Grenadier stock

It will provide customers with full details of every Grenadier model currently on sale in their country, as well as presenting finance packages available from Santander Consumer Finance (UK, DE, US) and Pepper Money (AU).

The new tool has now launched in the UK, with a planned roll-out in Germany, Australia, South Africa and the US before the end of 2024. As well as incorporating a gallery of images, videos and full specifications for each vehicle, the locator will also detail the service history for all Certified by INEOS used vehicles.

Mike Whittington, Chief Commercial Officer, INEOS Automotive, comments, “From the earliest days of the business, we focused on providing an exceptional buying experience for customers. This new platform will ensure our customers have simple and quick online access to every available Grenadier model on sale in their country, so they can easily choose and finance their vehicle with peace-of-mind.”

INEOS Automotive partnered with digital automotive sales specialist Nexus Point to develop the new service. Nexus Point’s scalable online vehicle locator plug-in is directly integrated into INEOS Automotive’s existing management software systems, helping retail partners centrally manage all new and certified used vehicle stock.

“Our scalable Apex platform is perfectly tailored to work with INEOS Automotive’s growing sales network and its combination of agency and dealership models,” says Ross Giblin, Sales Director, Nexus Point. “Apex plugs directly into INEOS Automotive’s existing software and will accelerate sales growth by ensuring potential customers will have access to every

Grenadier on sale in their market. We’re looking forward to rolling it out to other key markets.”

To view pre-configured and Certified by INEOS vehicles, visit: stock.ineosgrenadier.com

Accumold will be participating in the MD&M Minneapolis event on October 16-17, where it will feature a selection of incredibly detailed and miniature components designed for medical device OEMs at Booth 3210.

As a leading innovator in micro-molded plastic part manufacturing, Accumold specializes in creating components ranging in size from 5 cm down to less than 1 mm. The company’s capabilities include insert molding, cleanroom production, and two-shot molding. Using materials like PEEK, Ultem, LCP, and various engineered thermoplastics, Accumold serves sectors such as micro-electronics, healthcare, microoptics, sensor technologies, and emerging tech industries.

The demand for micro molding is being driven, in large part, by the medical device industry. The need for less invasive treatments and diagnostics is pushing the development of increasingly small, intricately designed

components with thin walls and complex features. Additionally, as healthcare providers seek to reduce treatment costs, medical device manufacturers are continuously searching for cost-effective and efficient manufacturing solutions.

Brett Saddoris, Technical Marketing Manager at Accumold, notes, “In micro molding, experience matters. Since 1985, Accumold has been at the forefront of micro molding technology and is recognized globally as the leader in manufacturing minuscule plastic components with extreme precision, often down to the micron level. However, micro molding for medical devices is rarely simple. Micro medical devices often integrate

different materials — thermoplastics, biocompatible metals, and silicones — and utilize overmolding techniques. Successfully managing these challenges requires a deep understanding of material compatibility and cutting-edge technology. Medical device OEMs must partner with skilled micro molders who understand the intricacies of tool design, material selection, and the complex processes involved in micro molding. We look forward to discussing your project needs at Booth 3210 at MD&M Minneapolis.”

Accumold has collaborated with numerous global medical device manufacturers, ensuring that every partnership strategically enhances product development efficiency. With

over four decades of experience in micro molding and manufacturing, Accumold is both the largest and most experienced micro molder worldwide. This provides its clients with the peace of mind that comes from working with a strong, reliable partner capable of scaling production from prototypes to mass manufacturing at affordable costs. Additionally, Accumold is ISO 13485 certified, reflecting its adherence to the rigorous quality management standards essential for medical devices.

Saddoris adds, “Regulatory demands are increasingly critical for medical device OEMs. Working with a micro molder which understands the shifting regulatory landscape is key. The 510(k) approval process is becoming more

complex, with the FDA tightening its requirements. Today, more first-round 510(k) submissions are being flagged for additional information, leading to delays and increased costs. Partnering with an experienced micro molder can significantly reduce time-to-market and expense.”

Known for delivering consistent, highquality production, Accumold has the capacity to produce from prototype volumes to millions — or even billions — of parts. In the medical device sector, the company serves as a key partner in bringing increasingly innovative and intricate designs to life.

For more information, please visit: accu-mold.com

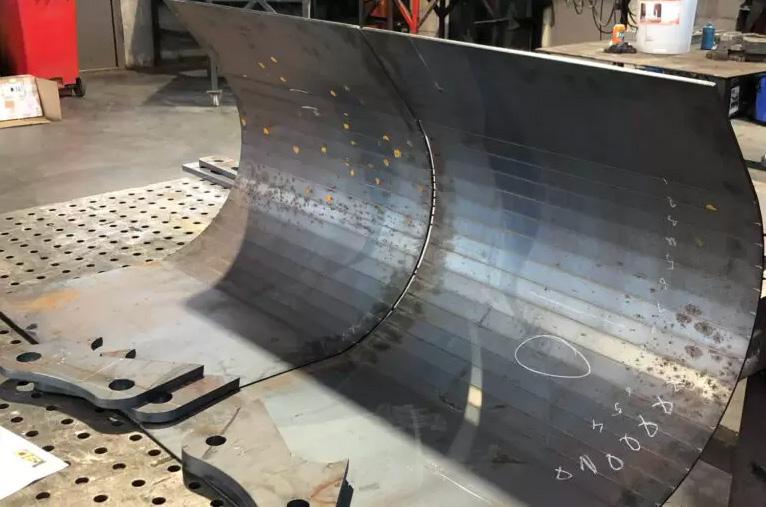

A13 Engineering moved from plasma cutting to laser cutting in October 23 with the installation of a Bodor 12kW Laser and Lantek Expert software

Harry Hodgetts, Managing Director at A13 Engineering says, “With highdefinition plasma, we found that it was not suitable for about 10% of our production, driving us to invest in a laser cutter giving higher accuracy and automatic part etching for easy component identification.”

The Worcester based company is a one stop shop, with both fabrication and machining capabilities, designing and manufacturing a range of attachments for excavators, diggers and tractors, as well as farm and factory structural steel buildings. Part identification is crucial during the manufacture and build of these products, with many very similar components. This own product aspect of the business takes up around half of

the capacity, with the remainder filled with subcontract work.

Harry Hodgetts says, “We were already aware of Lantek and chose it without hesitation because it met all our needs. The decision was straightforward. Laser cutting allows us to handle a variety of materials, and with the software, we can seamlessly import customers’ CAD files into the Expert software. The majority of our work is cutting mild steel between 2mm and 30mm thick and stainless between 1mm and 10mm thick. The machine has a shuttle table so we can unload parts while the machine is cutting the next sheet. With Lantek’s nesting we can tag parts in the sheet and nest parts in larger holes, which would otherwise be scrap, add the

odd part in a spare area, and have the flexibility to use up remnants of material, maximising our material utilisation.”

The subcontract side of the business has required A13 Engineering to generate a large volume of quotations. Previously this was done using a series of spreadsheets which took over 20 minutes for each quotation. By adding Lantek iQuoting the time has been reduced to 5 minutes. The software holds material prices and allocations of material. Nesting and machining times are simulated as is gas use. Harry Hodgetts adds, “iQuoting is in the Cloud so can be operated from anywhere creating a quotation around 10 times faster than we could do previously and much more accurately. Gas usage

is a big variable cost which is highly job dependent. Stainless steel and aluminium use a lot of gas for example. We have done trials and found that the usage calculated by iQuoting is very close to what we actually use.”

The Lantek software can aggregate multiple materials and thicknesses from subcontract enquiries and orders, automatically splitting them out so that nests can be created in sheets or remnants, mixing parts from different customers in the same type of sheet, showing what is left and giving A13 the ability to add individual extra parts, if it chooses, to fill the sheet completely.

Once completed, iQuoting generates a pdf quotation which is emailed directly to the customer. When the

order is received, all the manufacturing information is already in the system so the job simply needs to be released to the workshop ready for manufacture.

Harry Hodgetts says, “The support from Lantek has been excellent both online and in person, helping us to get the best out of both the machine and the software. As Lantek can program many different makes and technologies of sheet metal machinery, we are also well-prepared for any future investment we might make, such as tube cutting machinery. In our fast-paced industry, Lantek Expert and iQuoting have become indispensable to us. Has it been a benefit to us? Absolutely.”

For information, please visit: www.lantek.com

Kent is significantly increasing its investment in Houston, reinforcing its commitment to the U.S. market as a central hub for its global operations

Kent, a global leader in engineering, project management, and energy services, is strengthening its presence in Houston, Texas, with significant strategic investments aimed at expanding its operations and capabilities in the region. Building on its 66-year legacy in the Americas, the company is doubling down on its commitment to the U.S. market as a central hub for its global operations.

In the first half of 2024 alone, Kent secured $1.2 billion in new contract awards, a testament to the company’s robust capabilities and trusted reputation in delivering complex energy projects. The new investments in Houston are designed to further enhance Kent’s ability to serve its clients across North America, particularly in the areas of engineering, project delivery and digital transformation.

Recently appointed Scott Tanley, Vice President of Operations USA, will spearhead this expansion. With over three decades of industry experience, Tanley brings a deep understanding of the U.S. energy landscape and a commitment to driving operational excellence across all of Kent’s projects in the region.

“Houston has always been at the heart of our operations in the Americas,” said Tanley. “This investment underscores our confidence in the U.S. market and our determination to support our clients with world-class solutions that are faster, cheaper, and better than anyone else. We are excited about the opportunities ahead and are committed to helping our clients navigate the energy transition with the scale, attitude, and people to get it done.”

Kent’s Houston headquarters will continue to serve as the epicenter for the

company’s operations in North America, providing consulting, engineering, project management and commissioning and star- up services across the energy sector, including oil and gas, offshore wind, hydrogen, carbon capture, utilisation, and storage (CCUS), and chemicals. The company’s end-to-end service offerings, combined with its agile and client-focused approach, position Kent as a key player in the energy transition and a leader in delivering sustainable energy solutions.

As part of its ongoing commitment to the U.S. market, Kent will be showcasing its latest innovations and services at Gastech 2024, one of the world’s largest gatherings for the global energy industry. Attendees are invited to visit Kent at Stand No. C160 to learn more about the company’s projects and how it can support clients in achieving their energy goals.

With over 100 years of frontline experience and a presence in 24 countries, Kent is uniquely positioned to lead the market in innovation and sustainability. The company’s track record includes involvement in some of the world’s most ambitious low-carbon projects, such as the world’s largest integrated CO2 capture system at Boundary Dam in Canada and Project Greensand in the North Sea.

As Kent continues to grow its U.S. footprint, it remains committed to investing in the people, technology, and resources needed to meet the evolving needs of its clients. With a strong foundation in Houston and a global network to draw upon, Kent is poised to play a pivotal role in shaping the future of energy.

For more information, please visit: www.kentplc.com

TTI IP&E – Europe, a leading specialty distributor of electronic components, is supplying Mean Well power components, including the very latest DHP-1UT-B(HV) mounting rack power shelf, to support electronics engineers designing and building the next generation of renewable and hydrogen energy systems.

“EU Environmental regulations require 45% of Europe’s energy generation to come from renewable sources by 2030,” says Markus Lorenz, Director Industry Marketing, Industrial, TTI Europe. “To achieve this, green energy generated from wind turbines and solar panels must be stored efficiently. Hydrogen is also expected to play a major part in the transition towards a more sustainable future as using hydrogen power is the most efficient way to transport and store energy with

higher density and over a longer time frame without losses.”

The Mean Well DHP-1UT-B(HV) mounting rack power shelf for standard 19” cabinets enables a reliable power supply in a modular design and is ideal for applications including electrolysis, distributed power architecture and EV charging stations.

The rack can house up to four Mean Well NCP-3200-380 power supplies in a row to provide 12.8kW power per rack, and up to 10 rack shelves can be connected in parallel to deliver total power of up to 128kW. This modularity gives users the flexibility to scale when additional power is required and to cope with future power demands.

The power rack supports redundancy as power supplies can be set up as

an N+1 system, delivering maximum operational reliability. Should a single power supply fail, the operator can easily replace the defective supply without having to disrupt and shut down the whole system.

As part of a wider smart system power solution, Mean Well DHP-1UT-B(HV) is available with power components including the NCP-3200-380 power module and the CMU2 smart power controller.

For more information on Mean Well’s rack mount power supplies available from TTI Europe, please visit: www.ttieurope.com

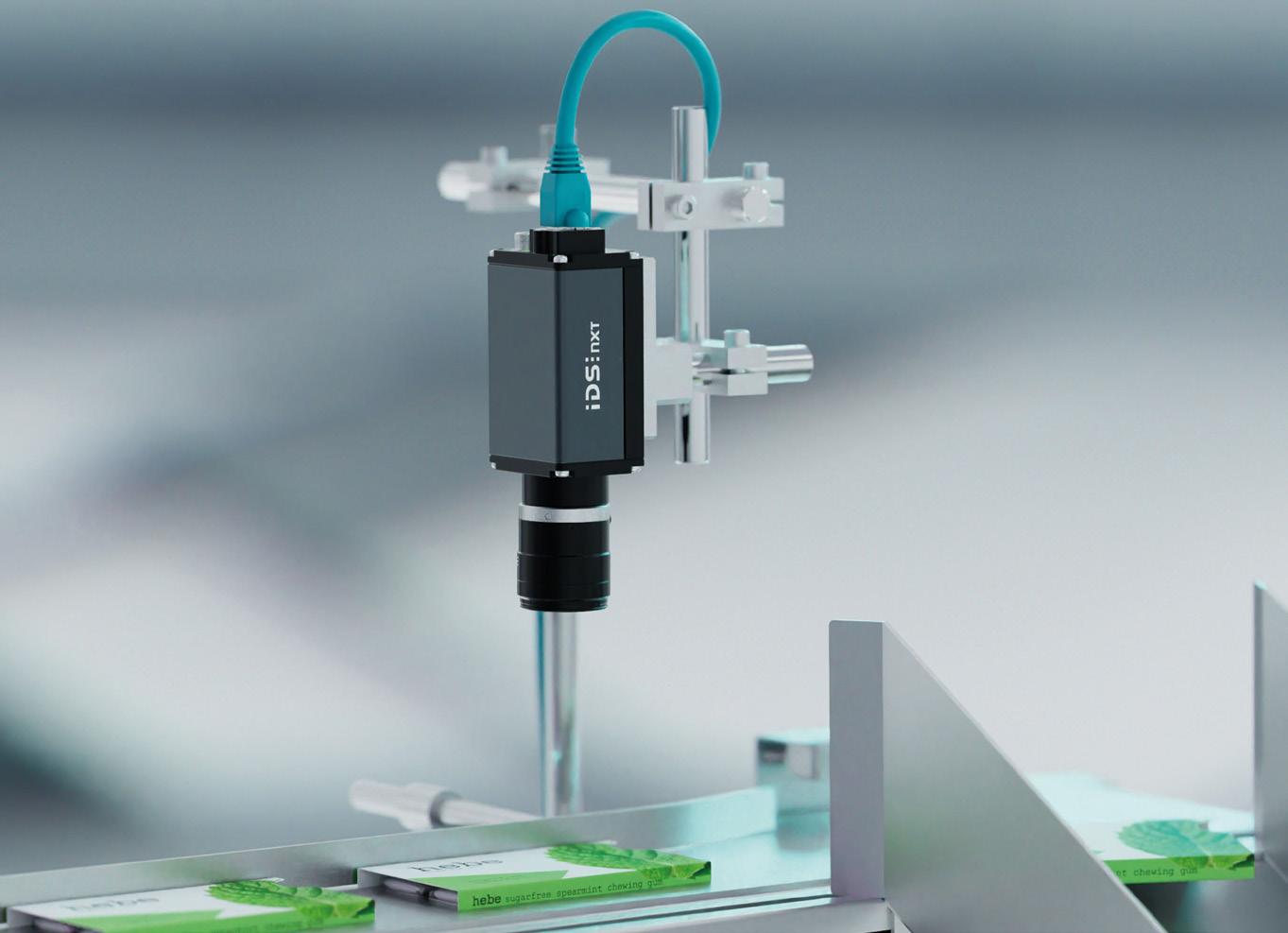

Innovative Industrial Cameras for Robotics and Process Automation to Take Center Stage at Stand 6-360

Detecting the smallest errors, increasing throughput rates, preventing wear – industrial cameras provide important information for automated processes. IDS will be demonstrating which technologies and products are particularly relevant at SPS / Smart Production Solutions in Nuremberg, Germany, from 12 to 14 November. If you want to experience how small cameras can achieve big things, stand 6-360 is the right place to visit.

Around 1,200 companies will be represented in a total of 16 exhibition halls at the trade fair for smart and digital automation. IDS will be taking part for the first time, focussing on industrial image processing for robotics, process automation and networked systems. Philipp Ohl, Head of Product Management at IDS, explains: “Automation and cameras? They go together like a lock and key. Depending on the task, very different qualities are required – such as particularly highresolution images, remarkably fast cameras or models with integrated intelligence.” Consequently, the products and demo systems that the company will be showcasing at SPS are highly diverse.

The highlights of IDS can be divided into three categories: 2D, 3D and

AI-based image processing. The company will be presenting uEye Live, a newly developed product line. These industrial-grade monitoring cameras enable live streaming and are designed for the continuous monitoring and documentation of processes. IDS will also be introducing a new event-based sensor that is recommended for motion analyses or high-speed counting. It enables the efficient detection of rapid changes through continuous pixelby-pixel detection instead of the usual sequential image-by-image analysis.

In the 3D cameras product segment, IDS will be demonstrating the advantages of the new stereo vision camera Ensenso B for precise closerange picking tasks as well as a prototype of the first time-of-flight camera developed entirely in-house. Anyone interested in robust character recognition will also find what they are looking for at the trade fair stand: Thanks to DENKnet OCR, texts and symbols on surfaces can be reliably identified and processed. IDS will be exhibiting at SPS, stand 6-360.

For more information, please visit: www. ids-imaging.com

New Model Institute for Technology & Engineering’s sustainable construction expert, Professor Robert Hairstans has been recognised with a prestigious industry award

Professor Hairstans, founding Director of the Centre for Advanced Timber Technology (CATT) at NMITE was named Pioneer of the Year at the 2024 Offsite Awards, which were held in Coventry this week.

Hosted by UK construction industry publication Offsite Hub, the accolades aim to recognise significant figures, organisations, and projects in the sector. They focus on projects where parts of the construction process have been designed, planned, and built away from their final location.

There were more than 200 entries for this year’s awards, with Professor Hairstans emerging successful from a final shortlist of five in the Offsite Pioneer of the Year category.

As well as his role at NMITE, he is the Professor of offsite and industrialised construction at Edinburgh Napier

University’s School of Computing, Engineering & the Built Environment (SCEBE). The partnership between NMITE and ENU has drawn particular praise from industry and government for its part in developing innovation in timber construction.

The winning entry included some of Professor Hairstans’ work to develop collaborations across the sustainable construction trade, while also driving the innovation of new construction technologies.

Reacting to the win, Professor Hairstans said: “I’m truly delighted to have this industry endorsement for the collaborative effort of NMITE and Edinburgh Napier in timber offsite and modern methods of construction research and education.

“The recent government announcement to deliver 1.5m homes will only be

achieved by these technologies.

“We are working hard collectively to ensure the next generation of built environment professionals are equipped with latest knowledge to achieve this in the most sustainable way using timber.”

This award is the latest accolade in an accomplished career for Professor Hairstans, who has been involved in leading research into industrialised timber and offsite construction solutions, while also developing several innovative products. Professor Hairstans also contributed to a new strategy for the future of timber construction, which was published by the UK government in December.

For more information on CATT, please visit: www.nmite.ac.uk/CATT

Altus Group, a leading distributor of capital equipment in the UK and Ireland, in partnership with Fuji Corp, recently held its second ‘Factory of the Future’ event at the Advanced Manufacturing Technology Centre (AMTC) in Coventry

The two-day symposium marked a significant milestone as the largest event ever organised by Altus, showcasing the latest advancements in electronics manufacturing.

Building on the success of its inaugural event in 2022, this year’s ‘Factory of the Future’ attracted over 200 participants and featured nearly 30 suppliers, offering hands-on experiences with nearly 40 unique processes. This expanded scale allowed attendees to explore a comprehensive range of technologies essential for SMT, NPI, and through-hole production lines, as well as component management and peripheral production.

The event introduced several innovations to the UK market for the first time, including the Scienscope Xspection 3000 Batch Xray, the Inertec Cube 460 selective soldering unit, the Koh Young Neptune Conformal Coating Inspection System, actnano’s disruptive coating materials, and the YJ Link vision inspection buffer.

Joe Booth, CEO of Altus Group, said: “What an incredible few days! Organising an event of this scale is a monumental effort, and the Altus team truly outdid themselves this time. The positive feedback from our customers and partners has been exceptional, and having over 200 participants is a clear indicator of our growing presence in the UK and Ireland. We’re excited to build on this momentum and turn the interest from the event into successful projects in the months ahead.”

Artur Tobolski, Fuji Regional Account Manager, said: “The Factory of the Future event was a tremendous success, bringing together top industry leaders and showcasing the latest

innovations. It gave UK manufacturers a unique opportunity to engage with cutting-edge technology and gain insights into future trends. Fuji is proud to have partnered with Altus for this landmark event and looks forward to continuing our collaboration with the industry.”

The comprehensive program included 16 presentations from industry leaders, addressing several topics, including the future of electronics manufacturing and current industry trends and challenges. The timing of the event was particularly opportune, coinciding with a notable increase in capital equipment investment following the new government’s election, which has contributed to enhanced stability and growing manufacturing demand.

For more information, please visit: www.altusgroup.co.uk

Industrial automation specialist Festo is making it easier for manufacturers to harness the power of digital automation and artificial intelligence (AI) to optimise process efficiency. Festo AX is a suite of AI-based software solutions enabling customers to increase efficiency in their production processes

Festo AX makes digitalisation scalable and supports the advancement of Industry 4.0 in production. This means that manufacturing companies of all sizes can benefit from innovative technologies, while original equipment manufacturers can set up new business models immediately without the need for years of development work.

Steve Sands of Festo said: “We are excited to offer our customers this rapidly expanding range of solutions that make them more efficient and more productive. By using AI-supported tools, our customers can increase their competitiveness and take their production to a new level. Our AX latest Motion Insight Apps offer exactly that: easy-to-install, scalable solutions that enable effective implementation of predictive maintenance.”

The Festo AX suite currently comprises AX Industrial Intelligence, AX Solutions, AX Industrial Apps and AX Smartenance.

Festo AX Industrial Intelligence is a project based industrial software solution that uses artificial intelligence to turn plant data into actionable intelligence. It enables users to increase productivity, reduce energy costs, avoid quality losses and — in coordination with machine builders — establish new business models. Festo AX Industrial Intelligence thus enables optimisation in three typical fields of application: Predictive Maintenance, Predictive Energy and Predictive Quality. Customer experience shows optimisation rates

of over 20 percent, a clear indication of how much potential there is in deploying AI-driven data and algorithms.

With Festo AX Industrial Apps, the company is utilising its application knowledge to focus in on subsystems such as welding, glueing, riveting or packaging creating scalable solutions that allow customers to install standardised AI applications themselves without needing any AI expertise. They overcome the oftenencountered gap in the application of AI that lies between the computer scientists who can model and detect anomalies in data and the real-life interpretation of the output into actionable alerts.

The latest release is the AX Motion Insights Pneumatic App. It uses machine learning AI to detect anomalies in the behaviour of pneumatic drives early and reliably, without the need for additional, complex sensor technology. This enables companies to execute preventive maintenance measures and minimise unplanned downtimes. The Festo AX Motion Insights Pneumatic App offers a user-friendly interface within the containerised app and simple integration into existing systems. It enables companies to implement the monitoring of application critical pneumatic components independently and without the need for data science specialists.

The AX Smartenance package is the ideal companion to Industrial Apps or Motion Insight packages as it offers a solution for customers’ maintenance management to digitalise and simplify maintenance and servicing processes in a consistent and intuitive way. AX Smartenance closes the loop by using notification data from the AX Apps to deliver condition-based recommendations for action to the right addressee in the maintenance process at the right time. It also provides a platform for the management of routine maintenance tasks with the ability to

store all machinery documentation, drawings and multi-media information such as ‘how-to’ videos, photographs of previous fixes and links to supplier support portals.

Industrial apps also on Siemens Industrial Edge

Festo is also part of the Siemens Industrial Edge ecosystem. The Festo AX Data Insights App, available on the Siemens marketplace, feeds data from Festo components into Siemens Industrial Edge to supply analysis applications with data. Based on this data, customers can set up monitoring within the Siemens environment to improve maintenance processes, reduce their energy consumption and improve quality. More industrial apps from Festo will soon be available via this route, including versions for AI-based monitoring of pneumatic and electric drives.