FUTURE SYSTEMS

How new technology is improving visualization and increasing reliability in the construction industry

Real estate

Three major themes are driving changes in the location of industrial hubs

Safety

Recommendations to help plan construction work zones and ensure safety

Collaboration

The right software can facilitate effective communication

Vol 20, Iss 1 - 2023

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Consultant Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Alex Caesari, Danielle Champ, Annabelle Crook, Steven Dobinson

Editorial Administrator Amy Gilks, Afiya Lucombe-Davis

Creative Lead Lee Protheroe

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe

Artwork Administrator

Rochelle Broderick-White

Sales Director Alasdair Gamble

Project Directors

Philip Monument, Joy Francesconi

Head of Content Management

Adam Blanch

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell

Content Managers Johanna Bailey, Mark Cowles, Jeff Goldenberg, Wendy Russell, Richard Saunders, Kieran Shukri

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Hello and welcome to the January issue of Construction Today. In this issue’s features, our authors take a look at collaboration, technology, safety and industrial real estate. In the latter, author Mark Russo, Head of Industrial Research at Savills, reports on the trends across the US that are influencing demands for industrial property. He highlights three themes that are being reflected in the changes in market inventory rankings and states that ‘in a changing world, the most important industrial hubs of yesterday will not necessarily be the top markets of tomorrow.’ Take a look at page 12 and find out where tenants and investors might be looking to locate.

© 2023 Finelight Media Group

Corporate Head Office

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K.

T: (312) 854-0123 T: +44 (0) 1603 274130

www.construction-today.com

US Office 2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426

T: (561) 778-2396

LH@finelightmediagroup.com

In January’s cover story, Architect Saurabh Goenka takes a look at technology. Find out how various solutions have brought improved visualization and increased reliability to construction projects. Turn to page 8 to learn more.

Recommendations to help plan construction work zones and ensure safety Three major themes are driving changes in the location of industrial hubs The right software communication How new technology is improving visualization and increasing reliability in the construction industry FUTURE SYSTEMS Please note: The opinions expressed by contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Libbie Hammond, Editor

Follow construction today at @ConstructToday construction-today-magazine Welcome construction-today.com 1

Trends 24 28 Case study Inside this issue 8 Collaboration 20 16 Industrial Real Estate Technology Cover Story Contents 2

Security 32 News 40 Case study 36 CSI Construction 54 ROSS Companies 44 Harold K. Jordan 50 construction today construction-today.com 3

60 Stanley Martin Homes

72 Gulf Coast Housing Partnership

78 Cornerstone General Contractors

60 Stanley Martin Homes

72 Gulf Coast Housing Partnership

78 Cornerstone General Contractors

84 Dargan Construction Contents 4

Spence Brothers Construction

88 104

116

Genesis AEC

94 HTS

Heart of America Group

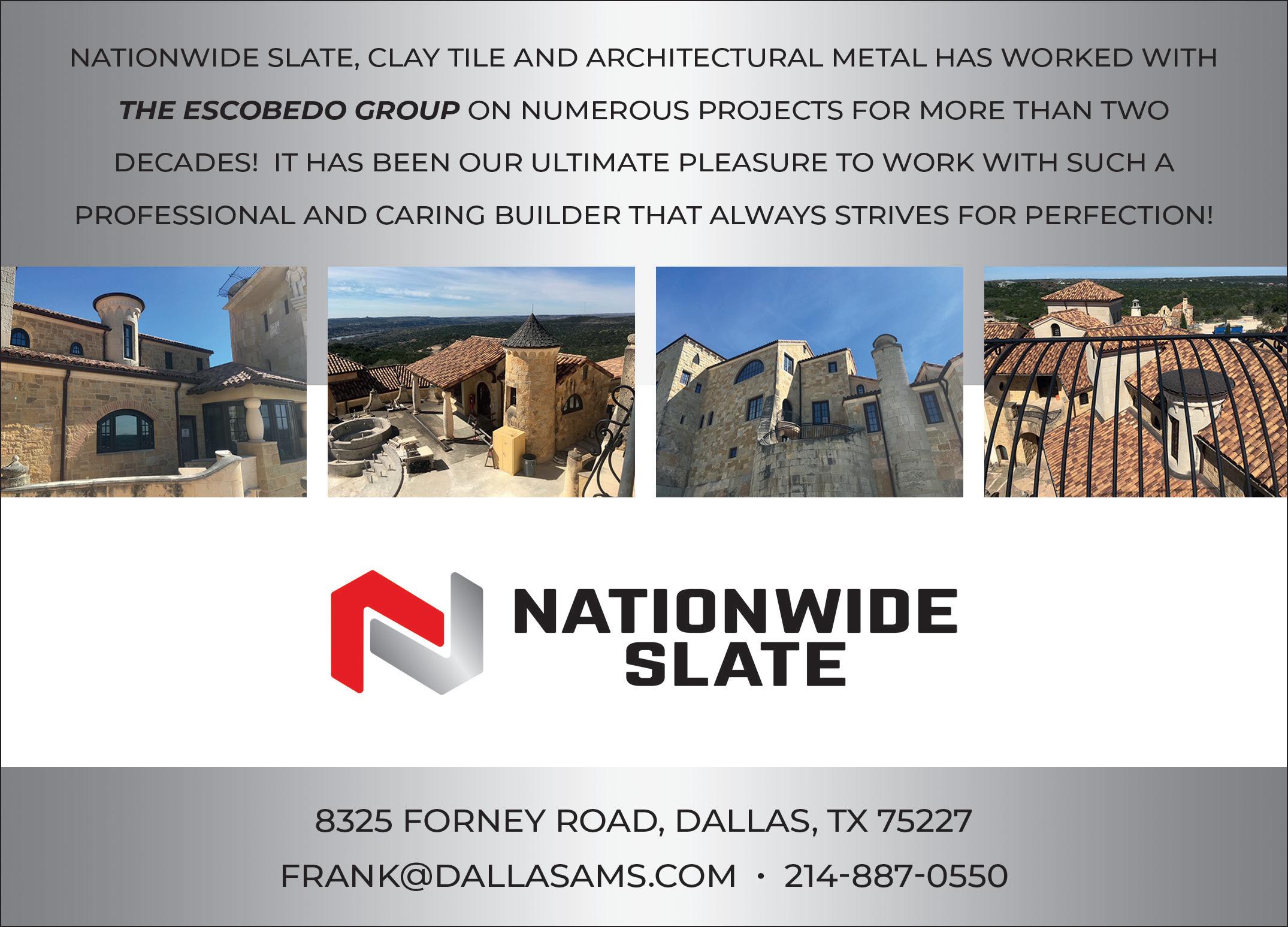

Escobedo Group

110 construction today 5

Chase Lumber

Horch Roofing

148 Kaufman Lynn

Horch Roofing

148 Kaufman Lynn

138 T&G

156 ONEC Construction 152 Holland Construction 122 Contents 6

National Cement Company of Alabama

Constructors

BUILDING

BUILDING MATERIALS | DOOR & MILL SHOP | KITCHEN + DESIGN | MASONRY PRODUCTS We feature high-quality Andersen® products. “Andersen” and all other marks where denoted are trademarks of Andersen Corporation. ©2022 Andersen Corporation. All rights reserved.

ARNOLD LUMBER COMPANY

TRUST SINCE 1911

FUTURE SYSTEMS

The importance of technology in empowering the construction industry

By Saurabh Goenka

By Saurabh Goenka

From raising large blocks of stone using pulleys to having powerful cranes lifting massive steel girders onto skyscrapers, construction technology has indeed come a long way. In particular, the rapid advancement of immersive and assistive construction technologies within the last decade has been a watershed moment. It has made the construction process more efficient, interactive, and ingrained with real world data, as never imagined before. Artificial intelligence, virtual reality, and advanced data analytics can help build smarter cities driven by real-time data, functioning almost like a living organism. Buildings can then communicate with each other, with the user, as well as its surroundings, to improve livability, increase safety, and protect the natural environment. I will next, consider in detail how some of these technologies have enabled the industry to build with improved visualization and increased reliability.

The power of real-time collaboration

Increased complexity of buildings has led to progressively more specialized systems. Collaboration, more than ever before, has become a key component for success of any construction project. Virtual Reality (VR) and Augmented Reality (AR) have enabled us to design and build in an immersive digital environment with instant visualization. VR is a powerful tool that offers a life-like experience by delving into virtual models using headsets. Design and construction teams can access the same computergenerated model simultaneously and conduct group charrettes. The VR experience today has been simplified to an extent that models can be viewed on smartphones while on the go. Its use as a collaboration tool can improve communication and accelerate the decision-making process.

8

Technology 9 construction-today.com

Like VR, AR has revolutionized collaboration processes by allowing an overlay of 3D models or 2D plans onto construction sites. The software can identify missing components as well as inaccurate dimensions, which enables construction teams to detect errors earlier in the process and avoid future ramifications. Building Information Modelling (BIM) can provide a single source of coordinated and computable information in a model-based framework. Sharing realtime data with the project team allows for real time clash-detection and reduces scope for miscoordination. Contractors can use these computer-generated models for fabrication and installation as well.

Digital twins and Internet of Things

Digital twin, a digital replica of the physical building, gathers data through smart sensors to better analyze a physical structure. There has been a swift progress in our ability to use this technology during pre-construction

for constructability assessments, inventory management and trial-and-error evaluations among others; all of which greatly benefit the outcome. Internet of Things (IoT) can control real world objects digitally and make our living environment more responsive. Use of drones can provide real-time imagery and supercharge the construction process by allowing for faster surveying, inspection, and surveillance of construction sites.

Time is money

It is known that reduction in construction time can reduce the overall project cost. Use of pre-fabrication has been particularly impactful in amplifying our ability to reduce construction time by digitally manufacturing portions of buildings. While it may have been commonplace to 3D-print, laser-cut or CNC-mill hardware or interior millwork, technology today is precise enough to digitally compute and manufacture portions of facades, building cores and structural systems off-site, in a fraction of time as compared

10

to on-site construction. Taking this a notch further, modularization and standardization of components can allow for reduced installation time, material usage and waste. Complex projects are not so daunting anymore.

Site safety

Accidents at construction sites are an interminable problem that the construction industry must deal with, especially now as we build towers and skyscrapers one after another. Here too, technology can help.

Wearables are transforming the ways we can maintain site safety, through use of connected hard hats (with cameras, microphones, and GPS), smart jackets and boots that alert workers of hazardous conditions. These devices allow workers to request help with just a tap and can be automatically triggered by impact.

Self-driving heavy equipment with perimeter sensor detection can reduce chances of mishaps due to overturning equipment. Drones can automate buildings’ exterior inspections, thus eliminating human trips and falls from unsecured perimeters. Chemical hazards such as discharged toxins, pipe leaks and presence of asbestos are other site-safety concerns. Frequently, workers are unable to see these and are forced to inhale them unknowingly. Just as smart sensors with built-in alarms can protect occupied buildings, they must be commissioned during the construction process as well to augment various site safety procedures.

Sustainability

Any planned alteration of the built environment requires well defined goals and keen foresight. The way we manage the process throughout the project’s lifecycle is critical to ensure success in the long term. In that regard, large advancements in tech-enabled solutions have empowered this process to be more efficient. BIM for instance, is useful not only in project

design and construction, but also in management and operations. AI based management platforms can determine energy usage patterns to conserve energy and improve thermal comfort, while also monitoring leaks or malfunctions. These systems may come at a higher initial cost, but that must be evaluated against the long-term advantages of better quality, increased reliability, and reduced risks. ■

Saurabh Goenka https://s9architecture.com/

Saurabh Goenka is an AIA

Licensed Architect and a LEED Accredited Professional. Currently practicing in New York as a Senior Associate at S9 Architecture, Saurabh has over a decade of experience leading prominent projects in complex urban environments. He is equally adept at using advanced digital technologies and has often leveraged their power not only to create beautiful buildings but also to ensure efficient construction and operations.

S9 Architecture (S9) is a New York-based architecture firm dedicated to designing spaces, buildings, and neighborhoods with a unique design approach rooted in ‘modern contextualism’ and inspired by urban narratives.

Technology 11 construction-today.com

12

Hub evolution

Top industrial markets restack, reflecting a changing nation

By Mark Russo

Three massive hubs long dominated the US industrial landscape: Los Angeles, Chicago and Northern New Jersey. These markets, which service the country’s largest metropolitan regions, historically held the highest positions in terms of sheer square footage, trade volume flowing through ports and railyards and capital invested. However, since the turn of the 21st century, the industrial real estate landscape has been shifting, reflecting transformational changes in demographics and technology, which the pandemic further accelerated.

Savills Research examined changes in size rankings of 16 top markets beginning in 2000, when online sales represented a mere one percent of overall retail and 14 years before Florida surpassed New York as the third most populous state.

The notable changes in market inventory rankings since 2000 reflect the following major themes:

Population migration to Sun Belt

Demand for industrial property is closely tied to consumption, which is about people, a fact that has become even more pronounced as the ecommerce penetration rate has grown to 14.5 percent of retail sales. Occupiers, and the developers trying to attract them, are following the rooftops, and those households have been migrating southward, drawn by warmer climates and lower living costs. One top destination has been Texas, which has seen its resident population grow by nearly 40 percent in two decades. Mirroring this change, the Dallas-Fort Worth industrial market added 348 million square feet (msf) of building inventory, causing it

Industrial real estate 13 construction-today.com

Savills Top Markets Ranked by Inventory (MSF)

Stable

to rise from number five to the second-largest market in the US, now exceeding Los Angeles. Similar stories unfolded in other Sun Belt cities, including Atlanta and Phoenix, where warehouse inventory grew by 53 percent and 78 percent, respectively, since 2000. Despite the construction boom, vacancy ranges from 3.9 percent to 6.2 percent in these markets.

Land scarcity in core markets

Despite being in high demand, a limited amount of land in the densely developed coastal markets has been pushing developers and tenants seeking space into adjacent markets. The Inland Empire and Pennsylvania’s I-81/78 corridor started as lower-cost alternatives to the expensive and famously tight Los Angeles and Northern New Jersey markets but have been coming into their own. The Inland Empire more than doubled in size since 2000, growing

2000 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Chicago (1,297 4) Dallas-FW (884.1) Los Angeles (877.1) Atlanta (782.2) Northern NJ (709

from 272 msf to 666 msf, and is now the 6th-largest market. However, they too are running out of space, with the Inland Empire now seeing a 1.2 percent vacancy rate, the lowest of any major market.

8)

Redevelopment of obsolete product

wrecking 2000 2022 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 (1,054.5) Chicago (817.2) Los Angeles (645 2) Northern NJ (572 4) Detroit (536.4) Dallas-FW (510.7) Atlanta (431.2) Philadelphia (397 1) Houston (386 8) PA I-81/78 Corr (286.8) South Florida (272.5) Inland Empire (235.7) Seattle/Puget S. (221 7) Columbus (204.8) Denver (194.6) Phoenix (174.8) Baltimore

(1,054 5) Chicago (817.2) Los Angeles (645.2) Northern NJ (572.4) Detroit (536 4) Dallas-FW (510.7) Atlanta (431.2) Philadelphia (397.1) Houston (386 8) PA I-81/78 Corr (286 8) South Florida (272.5) Inland Empire (235.7) Seattle/Puget S. (221.7) Columbus (204 8) Denver (194 6) Phoenix (174.8) Baltimore

The biggest slide in size ranking occurred in the Rust Belt capital of Detroit. While the market did grow slightly since the turn of the century, it went from the nation’s 4th largest to 9th place. This is unsurprising given the sluggish population growth in the region. Also at play is the demolition of older manufacturing buildings, which reduces the overall inventory. Roughly 54 percent of the buildings in Detroit are more than 40 years old and do not offer what most tenants are looking for in terms of ceiling height and layout, conditions that are not easily remedied and result in their seeing the

Rising

Inland Empire

Houston

PA

Detroit

Phoenix

Seattle

Denver

Baltimore (216.0) Rising Stable Falling y (MSF) 2022 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 14

Savills Top Markets Ranked by Inventory (MSF)

(666 7)

(640.4)

I-81/78 Corr. (601.0)

(600.0) Philadelphia (477 5) South Florida (380.5)

(345.7) Columbus (306.4)

/Puget S (298 9)

(269 8)

Chicago (1,297 4)

Dallas-FW

Los

(884.1)

Angeles (877.1)

Atlanta (782.2)

Northern NJ

(709 8)

Inland Empire (666.7)

Houston

PA I

(640.4)

-81/78 Corr. (601.0)

Detroit (600 0)

Philadelphia (477 5)

South Florida (380.5)

Phoenix (345.7)

Columbus (306.4)

Seattle

Denver

/Puget

(269 8)

S

(298 9)

Baltimore (216.0)

ball. Looking ahead, onshoring and the growth of new industries like EV manufacturing are reasons why Detroit and other Midwest markets may start expanding again in the future, but with new inventory up to modern specs.

Beyond the 16 top markets analyzed in this study, other future top industrial hubs have emerged. For example, Savannah, Georgia, which was barely a dot on the map in terms of warehousing, has grown to become a nearly 100 msf market and is forecast to double in size by 2027. Other up-and-coming industrial clusters, such as Las Vegas, Salt Lake City and Greenville, South Carolina, are increasingly on the lists of tenants and investors as the industrial real estate landscape continues to evolve in response to a changing nation.

Looking ahead in 2023, construction activity is expected to slow as new projects become tougher to finance as well as lease due to the impact of higher interest rates on the capital and leasing markets. This will translate into a pause in the aforementioned trends around expansion of market inventories and relative rankings. However, when the cycle begins again, similar patterns are likely to resume but with some new twists. The reaction to the Covid-era supply chain crisis will likely be one of them as occupiers diversify locations including ports of entry to build resilience. One thing is clear: in a changing world, the most important industrial hubs of yesterday will not necessarily be the top markets of tomorrow. ■

Sources: U.S. Census, U.S. Department of Commerce, Savills Research Note: For this analysis, market inventory has been standardized to include all industrial property over 10,000 square feet and may differ from figures reported in other Savills Research reports .

Mark Russo www.savills.com

Mark Russo is Senior Director, Head of Industrial Research at Savills. Savills helps organizations find the right solutions that ensure employee success. Sharply skilled and fiercely dedicated, the firm’s integrated teams of consultants and brokers are experts in better real estate. With services in tenant representation, workforce and incentives strategy, workplace strategy and occupant experience, project management, and capital markets, Savills has elevated the potential of workplaces around the corner, and around the world, for 160 years and counting.

Stable Falling 2022 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Industrial real estate 15 construction-today.com

16

The right protection

Proper work zone setup and training increase site safety says Mark Ludewig

Construction can be a serious risk when work zones are near or on roadways and motorists do not respect the work zone. Guiding the public through these sites in a safe and efficient manner depends on proper setup and training. Motorists may be required to navigate through complex work zones with an array of signs, barrels and lane changes. When drivers are not paying attention, it can lead to a dangerous outcome. Likewise, an ineffective work zone setup and/or lack of preparation only invites greater risks. The following recommendations can help you plan proper construction work zones and improve safety. While each zone is different and deserves careful consideration, these guidelines generally apply to all job sites.

The cardinal rules of work zone safety

There are basic rules that should be applied to setting up and protecting any work zone. In combination these measures create a stronger defense against the unpredictable by keeping eyes - and minds - on risks at all times. Critical considerations include:

l A detailed hazard assessment delivered as part of a pre-job safety briefing

l The use of visual/audible traffic control PPE designated for the project

l The use of proper safety equipment such as arrow and message boards

l An on-site Qualified Traffic Observer (a protector/flagger) to alert people to danger

Safety briefing

The pre-job safety briefing is a meeting with members of the work crew to discuss the type and phasing of the work being performed, hazards in and around the work area, configuration of the work zone, set-up of the work zone, temporary traffic controls and other protections utilized, emergency signals and procedures, and all STOP WORK procedures. A briefing should ALWAYS be completed at the beginning of EVERY job before setting up the work zone for that day. A new safety briefing should also be completed with each shift change or if the work assignment changes, if environmental conditions change, when new personnel come aboard, or as additional work site hazards are identified.

PPE

Every work site demands the selection, use and care of appropriate PPE for each affected worker who is responsible for having these items at all times, maintaining issued items and using them when applicable. This includes:

Safety 17 construction-today.com

▲ Did you know? Daylight hours are the most dangerous time to travel through a work zone. Urban interstates are the only type of roadway that report higher accident rates at night. In all cases, proper setup is critical to protecting people inside and outside the work zone

l High-Visibility class three apparel such as reflective safety vests and related apparel that are widely available for a variety of project needs and environmental conditions

l A hard hat, safety glasses, gloves and safety toe boots that should be standard wear for those assigned to protect work sites

l A storm whistle that is worn and accessible at all times, that is also attached to a breakaway lanyard so as not to pose a choking hazard. Whistles should only be used to alert workers to imminent danger and never to get the attention of a driver

Safety equipment

A broad range of traffic control equipment is required to meet various project needs. Commonly this includes channelizing devices

such as barricades, cones and barrels as well as Truck-Mounted Attenuators (TMA), arrow boards and signs/message boards. From shoulder work to parking lane closures to lane shifts, each temporary traffic control scenario must be set up according to the specific requirements of the site. No two scenarios are exactly alike as street design, traffic volume, motorist line-of-site and a host of environmental factors - that can change rapidly - all play a part in determining the need. A traffic management services provider will follow approved procedures for safe work zone setup that also align to state and local regulations. The Manual on Uniform Traffic Control Devices for Streets and Highways, or MUTCD, defines the standards used by road managers nationwide to install and maintain traffic control devices on all public streets, highways, bikeways and private roads. The

18

MUTCD is published by the Federal Highway Administration (FHWA) under 23 Code of Federal Regulations (CFR), Part 655, Subpart F. Note these are standard guidelines only - all work zone setups should have the full consideration and approval of a qualified traffic control specialist prior to deployment.

Traffic observer

Construction projects can occur in close proximity to road traffic, creating a potentially dangerous environment for workers, drivers, and pedestrians. In many cases a temporary traffic control zone is needed to protect workers, as well as to allow for the safe and efficient movement of pedestrians and traffic through or around the zone. In addition to their duties as a protector/ flagger, a qualified traffic observer will continually monitor traffic conditions and warn co-workers who are installing temporary channelizing devices like cones and barrels, or who are removing debris from the roadway. This person must:

l Remain vigilant and alert at all times to recognize dangerous traffic situations

l NEVER turn their back on traffic.

l Already know their method(s) of escape if a vehicle enters the zone

l Protect themselves first—then use their storm whistle to alert others

A total approach to training

Comprehensive training and support including coursework and real-life scenario modeling are what ultimately sets field teams apart in their readiness and commitment to work zone safety. At minimum, every field team member assigned to the site should complete certified flagger training, first-aid and CPR courses, and state-specific Department of Transportation training. At Area Wide Protective (AWP), protectors who will operate vehicles in work zones also

complete the Smith Driving System, which promotes safer driving habits.

Properly planned and staffed work zones help to eradicate fatalities and life altering injuries by eliminating at-risk behaviors that could result in a vehicle accessing the work zone. Protecting those inside and outside the zone is a serious responsibility that requires the constant vigilance of a certified traffic management services professional. ■

Mark Ludewig

www.awptrafficsafety.com

Mark Ludewig is the Vice President of Safety for Area Wide Protective (AWP). He has over 30 years of experience in environmental, health and safety management, and leads AWP’s ongoing enterprise initiatives to deliver the safest work zones by leveraging industry data, aligning enterprise with all-encompassing traffic control solutions, and ensuring compliance at all levels.

As North America’s leader in professional traffic management, AWP protects the public and the people who make infrastructure possible. The company’s capabilities include work zone flagging, design and engineering for transportation management plans, equipment sales, rental and 24/7 support. AWP employs 6800 team members across 28 US states and four Canadian provinces.

Safety 19 construction-today.com

times Changing

20

How tangled supply chains upend relationships and shift profits throughout industry

By Andrew Zukoski

Our snarled supply chains are upending not just the working lives of project teams engaged in design, planning and preconstruction but the business relationships that define our industry.

A few weeks ago, I had conversations with two very different stakeholders who shared a common theme. One was a senior leader at a major university. The other was an executive with a national building product distributor. Despite their different perspectives, the conversations were similar.

The university leader relayed that their facilities department - responsible for billions of dollars’ worth of capital projects over the next few years - had a new building going in. The facilities leader, who was facing the same supply chain issues as the rest of the industry, was advocating something unusual: that the owner purchase steel before identifying a general contractor. This is an experienced owner, but purchasing materials before having overall cost certainty and a construction partner is a big step.

Collaboration 21 construction-today.com

The second conversation was with a VDC leader at a building product distributor. Not a BIM manager at a design or engineering firm, not a VDC leader at a general contractor or MEP specialty contractor, but a distributor. This team represents a new initiative for the distributor, and a chance for the company to better support customers and project teams by offloading detailed BIM work and making critical systems decisions earlier.

For a company that traditionally has focused on trade contractor relationships, this new exposure to general contractors, owners and engineers has been an exciting new service for them to provide. It’s also led to new requests from owners and general contractors who now want to purchase directly from the supplier.

A simplistic view of the construction industry is that an owner works with architects and engineers to design and specify a project, and then hires a general contractor to build

it. In turn, the general contractor hires trade contractors, who purchase materials from distributors and manufacturers. As these two conversations illustrate, there are wild deviations in the real world, with the purchaser for various materials shifting upstream. This complicates matters for teams, upends traditional commercial relationships, and shifts potential profit between different stakeholders.

The teams that are being tasked to execute in this environment must move at lightning speed to keep up. They also often find themselves collaborating with a much wider set of stakeholders than they used to and must integrate a wider range of perspectives.

For example, estimating departments, and the software and technologies that support them, grew out of a world where teams added numbers to complete sets of construction documents once, during a bid phase. In our present world, these teams are being asked to perform ‘continuous estimating’ -

22

keeping up with design ideas, sketches and documents that are changing dayby-day and sometimes, it seems, minuteby-minute. Preconstruction roles now layer communication and collaboration duties on top of the traditional estimating and planning skill sets. As these jobs have become more complicated, however, the potential to provide an excellent client experience and predictable project delivery has grown. Teams are demanding new tools and systems to support these efforts.

McKinsey predicts that hundreds of billions of dollars in profits will shift in coming years. The ongoing challenges of a snarled supply chain are only accelerating this trend. Decisions and procurement that deviate from the simplistic model above depend on specific context, and occur project by project. For example, engaging a multi-trade offsite prefabrication strategy depends on everything from matching design and system

constraints to finding sufficient lie-down space near the site. Identifying opportunities for expanded profit, protecting existing business, and most of all finding areas of mutual gain requires that stakeholders throughout projects engage on a collaborative footing early. While stakeholder incentives do not always align, building trust shortens the route to GMP and successful project execution.

Nearly every construction technology company has trotted out another McKinsey study from a few years ago that purportedly proves construction is a stagnant industry defined by low productivity and innovation. This is clearly wrong: construction is dynamic, with teams coming together every day to design, plan and execute difficult work. Supply chain chaos is accelerating changing relationships amongst key stakeholders on every project, and these teams are adopting new digital technologies to keep up.

Powerful collaboration software enables teams to streamline processes and facilitates effective communication among stakeholders at every stage of a project. Beyond that, the right digital collaboration platforms help establish trust across a project, which will continue to be a critical component as relationships and expectations evolve throughout the industry. ■

For a list of the sources used in this article, please contact the editor.

Andrew Zukoski www.join.build

Andrew Zukoski is Co-Founder and CEO of Join, the decision-making platform for the built environment. Join is a collaboration software that addresses the multidisciplinary nature of AEC decision-making. Join allows all stakeholders to gain real-time visibility into each decision and its impact. Industry leaders use Join to make timely and smart decisions that drive projects forward.

Collaboration 23 construction-today.com

sands

All images courtesy of Del Amo Construction

All images courtesy of Del Amo Construction

24

Del Amo Construction has renovated a century-old building on Venice Beach boardwalk

On the sands of the iconic Venice Beach boardwalk stands a new community hub for The Jewish Federation of Greater Los Angeles - BAR Center at the Beach. Built by Southern California-based Del Amo Construction, the nearly 100-year-old building is now open and equipped with exciting new spaces to gather, connect and live.

The Del Amo Construction team was tasked with implementing a total renovation of the former Israel Levin Senior Center, which was built in 1927 and originally served as a dance hall with multiple additions and remodels over the years, including the removal of its second floor following severe damage incurred by the 1994 Northridge earthquake. As a result, the building had become somewhat of a ‘Frankenstein’, which gave rise to multiple challenges throughout the construction process.

Some of the most significant constructability challenges that Del Amo Construction faced during the project involved navigating the unique site conditions, modernizing the historic building while maintaining its structural integrity and executing intricate architectural and design features.

Site on the sand

BAR Center at the Beach serves its community from a prime location on the Venice boardwalk. However, this meant the Del Amo Construction team was working directly on the beach and within an exceptionally confined area throughout the entirety of the project. Furthermore, the building’s original foundation was built on the sand itself, requiring the team to shore the existing walls in place while the new footings and slabs were being constructed via a relocated and cantilevered shoring system.

Case study 25 construction-today.com

The team gave constant attention to shoring, navigating new underground utilities in and around the temporary shoring and bracing to ensure the existing brick walls that were to remain withstood all new construction activities.

Historic roots

With consideration to the century-old structure, Del Amo Construction also needed to find ways to incorporate the original brick walls into the new center while strengthening its structural integrity. The team chose to apply Fabric-Reinforced Cementitious Matrix

(FRCM) to encapsulate the existing brick walls and provide increased structural strength that now supports new floors above. New materials and constructability approaches like the FRCM allowed the construction team to provide the Jewish Federation of Greater Los Angeles with a new building that is structurally sound for generations to come.

Design complexity

Designed by Belzberg Architects, BAR Center at the Beach displays an architecturally stunning, three-dimensional façade that functions as a sculptural art piece to help

26

the building standout in its oceanfront community. In order to bring this technically challenging architectural feature to fruition, Del Amo Construction orchestrated meticulous pre-planning with the design team, manufacturer and installers to ensure proper constructability of this unique element, including guaranteeing that every dimension would seamlessly integrate with the building, the lighting systems and storefront.

In particular, the lighting integration into the façade required a one-of-a-kind system that was installed by a process of trial and error to ensure that cabling to each of the individual three-dimensional panels would be fed without being seen from onlookers on the boardwalk. Furthermore, each section needed to be programmed to provide specific color schemes so that the wall façade would achieve the design team and owner’s vision. Del Amo Construction’s nimble construction processes and ability to make real-time adjustments helped the team to successfully implement this design element.

The result of this complex restoration project is three floors and 7,000 square

feet of new community space including a reception area, spacious community room, commercial kitchen, meeting rooms, classrooms, flex spaces, library and a new rooftop deck shaded by an angular, chuppah-reminiscent trellis. A threebedroom apartment sits atop the building to offer housing for recent college grads in exchange for them leading on-site activities between diverse sections of the community. This living component addition is a first amongother community centers within the federation.

The new BAR Center at the Beach not only accommodates the diverse needs of the populations it serves, but also enhances the building’s presence on the iconic Venice Beach boardwalk and brings new life and vibrance to the area. With its increased capacity and usability, its reach is projected to extend past Venice to greater LA’s Jewish community at large. Furthermore, in keeping with the neighborhood’s rich history, the center offers programming for all to experience and enjoy, regardless of religion. ■

www.delamoconstruction.com

Case study 27 construction-today.com

SHAPING tomorrow

Gregg Healy highlights how recent legislation aims to rebuild America

28

Too often Americans tend to view the relationship between government and industry as one in which the role of government is perceived as inhibiting business growth through legislation. This year though, through the passage of three major bills, Congress has significantly moved the needle to promote reshoring of manufacturing in America as well as secure investment in industries of the future.

The Infrastructure Investment and Jobs Act, the Chips Act and the Inflation Reduction Act are three major legislative bills that will help to reshape the America of tomorrow. Each offer its own benefits, but together they are truly driving longterm investment and transformation.

Of the three major bills, the Infrastructure Investment and Jobs Act was signed a year ago in November. It includes provisions to invest over $110 billion dollars in America’s roads and bridges, $66 billion in rail infrastructure, $17 billion in ports and waterways and $25 billion in airports among other major investments. All are significant investments and the American populous, as well as industry will reap the benefits. Not only will there be an increase in construction jobs to build these improvements, but data shows that private investment also closely

follows infrastructure investments creating a multiplier effect of both public and private investment in local communities. Better infrastructure also means that the cost of transporting good within the country, as well as for both importing and exporting of products will be reduced while the speed of travel increases. It is no wonder why countries like China have invested a significantly larger percentage of their GDP in infrastructure and now have the largest airports, over 22,000 miles of high-speed rail, the best ports and an advanced network of highways. They understand that as the manufacturing center of the world, they can keep the flow of commerce moving quickly and cheaply by maintaining efficient infrastructure. Additionally, the World Bank notes that the most effective way to increase GDP is to invest in infrastructure. This is the first step.

With all the disruption over the past several years from a shortage of microchips, many of which are made overseas, the passage of the Chips and Science Act in August of 2022 is significant as it incentivizes industries to produce microchips in the Unites States as well as promotes the further research and development of chip related technologies. Currently, Taiwan is the largest producer of semiconductors in the world. With China claiming

Trends 29 construction-today.com

dominance over Taiwan and overall global instability, there is now an impetus to manufacture more of these products – which so many of our consumer goods rely on such as automobiles, planes, appliances and computers - in the United States and rely less on imports. Nearly $53 billion has been set aside in incentives for manufacturing and research in this vertical, with an objective to solidify America’s dominance in semiconductor research while enhancing its ability to produce locally. This reinvestment in American manufacturing will only reap benefits for Americans as we increase our national security and independence,

we will also be able to create hundreds of thousands of jobs in STEM related fields that pay well above median wages in the communities where they are located. Already we have seen Taiwan Semiconductor Manufacturing Corporation (TSMC) announce a $12 billion investment in Phoenix to build a new manufacturing location, followed by Intel announcing another $30 billion investment in nearby Chandler as well as a staggering $20 billion investment in a new production facility in Ohio. These are just a few of the major recent announcements which highlight the communities that will benefit from these manufacturing and research facilities.

30

The third, and most recent legislation to pass in Congress is the Inflation Reduction Act, having passed right behind the Chips Act, also in August of 2022. There are many provisions in this bill addressing various aspects of healthcare, deficit reduction and energy production. However, the area that is particularly interesting to those looking to reinvest in America are the provisions around the accelerated interest in developing technologies to fight climate change and incentivizing investment around transforming our energy policy to promote sustainability goals. Clean energy, including solar panels and the adoption of electric vehicles, is not just an American objective. Globally we are

seeing many nations pivoting towards green initiatives and the incentives to produce products in the United States will strengthen our leadership in this space, create more jobs in this sector at home and help establish the US as an exporter of this technology. Already we are seeing the results of this bill as Savills tracking of electric vehicle investment shows that it exceeds $80 billion dollars and has created more than 83,000 net new jobs.

Individually, these three legislative actions are directionally positive towards promoting investments in the technologies of tomorrow, and moreover returning robust manufacturing jobs to the United States. Together, these three bills are a major catalyst in the momentum to reinvest in America and represent what is right when politicians lean into the industries of the future and target direct incentives to stimulate the macroeconomy. ■

Gregg Healy www.savills.us/industries/ industrial.aspx

Gregg Healy is Executive Vice President, Head of Savills Industrial Services Group in North America. Savills helps organizations find the right solutions that ensure employee success. Sharply skilled and fiercely dedicated, the firm’s integrated teams of consultants and brokers are experts in better real estate. With services in tenant representation, workforce and incentives strategy, workplace strategy and occupant experience, project management, and capital markets, Savills has elevated the potential of workplaces around the corner, and around the world, for 160 years and counting.

Trends 31 construction-today.com

Plan ahead

Cyberattacks pose a serious risk to the construction industry. Here’s how to mitigate the risk.

By Carl Cadregari

By Carl Cadregari

32

Ransomware poses a risk to every industry, nationwide, however the construction industry faces heightened and unique challenges that make mitigating the risk of a security breach even more critical.

Demonstrating this, Nordlocker recently analyzed 1,200 companies in 35 industries globally that were the victims of cyber extortion between 2020 and 2021, and the results showed that the construction industry faced the most instances of targeted attacks. In an industry that relies heavily on confidential documents like drawings, contracts, budgets, and engineering notes, cyberattacks can pose risks that range from the external sharing of protected information to the inability of developers to access the documents they need for the successful completion of a project.

With cyber criminals becoming more and more sophisticated over the years, the potential damage and costs related to a successful attack are more worrisome and disruptive than ever before. In fact, a US Government interagency report estimated that, in the next year, cybercrimes will cost American companies over $6 trillion in damages.

Thankfully, the more common these attacks become, the more intel industry experts have been able to gather to

prevent future attacks and/or recover quickly if your construction business falls victim to a breach.

Stay up-to-date on data privacy and cybersecurity laws

Data laws and privacy regulations are ever-changing. To ensure compliance, construction developers and leaders should perform annual reviews of their data as it relates to the most up-to-date guidance to ensure that they are taking the proper safety measures. Establishing a process for this analysis will make certain that the review is done efficiently and effectively. For those that are busy with ongoing projects or don’t feel comfortable assessing data themselves, working with a thirdparty cybersecurity vendor can ensure that the reviews and updates are done by experts in a timely and accurate manner. However, if you are going to engage a vendor for a task of such importance, it is important that they understand your expectations around security and are meeting your mitigation standards.

Conduct regular internal risk assessments

Do you have user authentication systems in place? What about password protection? When’s the last time you changed your password? These are just a few and some of the

Security 33 construction-today.com

simplest questions that construction leaders should be asking themselves often to ensure they don’t fall victim to easily avoided breaches. One of the biggest mistakes that leaders make is to have all important documentation stored on one device, with no external backup. The breadth of damage caused by a ransomware attack can be minimized by making sure that critical contracts, sketches, plans and more are all saved in multiple locations, especially on an external hard drive. For heightened protection, utilize what’s known as the ‘3-2-1’ rule for optimized security, including creating up to at least three copies of important data, establishing two different storage formats, and keeping a copy of important documents offsite. Lastly, pay attention to security breach alerts and consider implementing an Endpoint Detection & Response (EDR) solution and Mobile Device Management (MDM) application for proactive threat identification.

Block unauthorized user access

The more important the data, the harder it should be to access. Whether it’s limiting credentials to select leaders as information gatekeepers or setting up multifactor authentication, it should not be a simple task to find and review confidential materials and communications. Additionally, be sure to have a swift and effective system in place with your human resources or administrative team to remove credentials for employees immediately following their termination or willful departure from your company. While you hope

that a former employee would respect the privacy of data, it’s best not to leave it up to chance.

Train your employees & hold them accountable

In today’s age, every onboarding schedule should have a cybersecurity element included. From there, annual trainings should be held to ensure that security measures are top of mind for employees. Once they have learned the basics and warning signs of an attack, challenge their understanding through methods like phishing email tests. Also, whenever baseline controls are updated, ensure that employees

34

are notified right away so they can do their part in protecting sensitive data. While human error is inevitable, leaders can add layers of protection through programs like multi-attempt password locks or encrypting critical files as added safeguards.

Lean on your peers

The global construction industry is a massive community, and it’s likely that others in the trade have the same concerns and experiences when it comes to cybersecurity as you do. Participating in information-sharing forums, sitting in on speaker sessions, or even having a conversation with

an old business partner can help construction leaders stay up to date on the most recent threats, draw insights from the mistakes of others, and learn about effective mitigation tactics with proven results. Another resource to consider is guidance made available by the US Computer Emergency Readiness Team (US-CERT).

Even with the strongest controls and prevention programs in place, a cyberattack is always a possibility, especially in a high stakes industry like construction. However, having the proper mitigation plans, training, and tools in place to protect your data can minimize damages and avoid costly disruptions. ■

Disclaimer: The summary information presented in this article should not be considered legal advice or counsel and does not create an attorney-client relationship between the author and the reader. If the reader of this has legal questions, it is recommended they consult with their attorney.

Carl Cadregari www.foxpointesolutions.com

Carl Cadregari is an Executive Vice President in the FoxPointe Solutions Information Risk Management Division of The Bonadio Group. He has more than 28 years of experience providing actionable technology, cybersecurity and data governance architecture, controls auditing and general cybersecurity planning. His experience includes over 18 years in regulatory auditing and standards compliance assessments, developing and executing programs predicated upon ensuring that client computer controls are functioning.

Security 35 construction-today.com

A success clear

36

Silver Spring Township, Pennsylvania is currently the fastest growing community in the greater Harrisburg, PA area. The township’s wastewater treatment plant serves a population of approximately 18,000 residents with an average treatment of .8 MGD and design capacity of 1.2 MGD. Knowing the number of customers to be served will continue to rise, it was looking for solutions to give its annual budget some breathing room while increasing the plant’s overall efficiency and capacity to stay ahead of the increased demand. Lowering operating costs for aeration, sludge removal and structure maintenance were also goals.

Solution

Silver Spring accepted an opportunity to have a riskfree performance trial of a new autonomous bio-augmentation technology from Enbiorganic Technologies. The performance trial would last for 60 days and at the conclusion, the city would have the option to keep the technology on a TaaS (Treatment as a Service) basis. A single EBS-Di unit from EnBiorganic Technologies (EBT) was set up by ABEL RECON, a licensed installer of EBT in one of Silver Spring’s lift stations approximately four miles from the treatment plant’s headworks.

Case study 37 construction-today.com

cleaner and easier to maintain once treatment commenced. Algae growth which typically required pressure washing and physical scraping to remove, can now be eliminated by a normal water hose. Over time the microbes will continue to progress upstream and positively impact other portions of the system.

Sludge Handling Costs

EBS-Di System Projections Current Operations

Demonstrated in Figure A, is the significant reduction in KWh used to operate the plant. Compared to the five months prior to installation, the EBS-Di system is providing 37 percent KWh reduction at an estimated savings of about $1600/ month. Even compared to averages of the same months the year before

5-months

38

KWh

prior April-July 2021 2021 average

or an aggregate of all KWh usage in 2021, this demonstrates a 28 percent reduction in energy consumption. The second major impact is the reduction in water consumption utilized for sludge handling. Sludge processing has now become more efficient, and less water is being sent to the landfill. It is estimated that $18/ton reduction for sludge handling will be realized. The total sludge load has also been affected. Jim Stevens, operator at the plant noted that the plant may be down to as low as seven loads from the usual nine. With this data trend, it is anticipated that a 62 percent reduction in monthly sludge handling costs will also be gained. As shown in Figure B, this will equate to approximately $4,284 per month in savings. Prior to the start of the performance trial an Economic Impact Report (EIR) was created to determine if the technology could provide benefit and to what degree. At only 90 days into operation, 46 percent of the total estimated savings anticipated by the EIR have already been reached and this will rise over time.

Due to the results, at the conclusion of the performance trial, Silver Springs decided to sign a long-term contract with ABEL RECON for the EBS-Di technology and service, realizing that the cost savings in sludge hauling, treatment energy needs and maintenance labor derived from having the unit would more than cover the expense for the service contract and put it on an excellent footing for meeting its growing community’s needs. ■

EnBiorganic Technologies, founded in 2019, bridges science and technology to contribute to a living planet. It believes in synergy – various parts working together to produce an enhanced result, and is driven to build innovative solutions based on a foundation of solid science. Its team is focused on solving big issues that will have a significant impact in its backyard and beyond. Its current breakthroughs in wastewater solutions, HAB mediation and animal agriculture create value for clients, while protecting the planet’s most valuable resources.

Case study 39 construction-today.com

News in Brief Profitable partnership

Associated Builders and Contractors (ABC) and leading global construction management software provider, Procore, have expanded their existing relationship through a strategic partnership that will provide ABC members with trusted, innovative technologies to help better develop people, win more work, create safer jobsites and increase profitability.

“Procore’s solutions will strengthen the value proposition of any contractor within the community,” says Michael Bellaman, ABC president and CEO. “We are thrilled that Procore is joining our group of handselected, trusted resources for ABC’s more than 22,000 member companies.”

Connected construction

Trackunit, the global leader in telematics solutions for OEMs, rental, and contractors is attending CONEXPO-CON/AGG 2023 in Las Vegas from March 14th to 18th. It will be demonstrating its latest range of construction equipment and tools apps to increase site, personnel, and equipment safety, productivity, and sustainability.

Based on data insights, Trackunit’s technology solutions reduce loss and theft across the project site and rental yard. “CONEXPO is a key opportunity to interact with the whole industry,” says David Swan, Senior VP Products. “Construction now understands that technology, and connected machines and systems are a major contributor in maximizing fleet utilization and improving employee safety.”

Trackunit will announce new collaborations and partnerships that demonstrate its continued ecosystem expansion.

major milestone McCarthy Building Companies, Inc. has celebrated the topping out of Houston Methodist’s new Cypress Hospital campus located in the greater Houston area. Sitting on 105 acres and consisting of a seven-story hospital, two medical office buildings, and a central utility plant, the campus boasts a mixture of built-out space as well as a shell for future growth. McCarthy broke ground in February 2022, and construction is scheduled to achieve substantial completion by the end of 2024.

A

To acknowledge the construction milestone, speakers reflected on the work accomplished safely and look ahead to the work needed to complete the campus.

Luxury living

Cushman & Wakefield has advised Optima in the acquisition of a 22-acre development site in northern Scottsdale, Arizona.

Chicago-based Optima is constructing a new luxury mixed-use residential project named Optima McDowell Mountain Village™. The project will consist of six eight-story buildings totalling approximately 1330 residential units plus 36,000 square feet of commercial space and amenities.

Optima acquired the land for $44.75 million. “This will be a world-class residential project, providing much-needed upscale housing in the growing Scottsdale area. It is strategically located along the freeway, making it very convenient for residents to access any destination,” says Don Arones, Managing Director with Cushman & Wakefield in Phoenix.

40

Strong solution

CINTEC North America, a world leader in the field of structural masonry retrofit strengthening, repair, and preservation, has revealed that its CINTEC Reinforcement System was used to repair the John Sopinka Courthouse in Hamilton, Ontario, Canada.

a+LiNK Architecture was retained and provided specialized knowledge to preserve the cultural heritage of the building by Infrastructure Ontario. The practice provided an investigation, analysis and a proposed solution for the stone façade restoration of this historic courthouse. The restoration included repairs

and re-attachment to five storeys of stone on the building envelope, original masonry components and the metal canopy. With this analysis it was determined that the original ties were loose, deteriorated and failing.

The CINTEC Reinforcement System was used to re-attach the stone to the diverse brick back-up wall. The fact that the CINTEC anchors attached both adhesively and mechanically, which provided progressive failure as opposed to brittle fracture, as well as inherent fireproof capability were a strong consideration.

▲ John Sopinka Courthouse

▲ John Sopinka Courthouse

Industry News construction-today.com 41

ROSS

can

Founded in 1983 by Beth and Scott Ross and today led by CEO Dave Miskovich, ROSS Companies (ROSS) has operated – at least historically – in the metropolitan area of Washington, DC with a distinct, family-owned business mentality. Such an ethos has inspired dedication, commitment, and personal accountability across the team – or, in short, all the things that makes ROSS stand out in an increasingly competitive US construction market.

“When I joined the company in 2003, my goal was to embrace the family-owned atmosphere, while, at the same time, leading the company

into the future through technologybased innovation and attracting the best multi-family professionals to key positions within the organization,” says Dave Miskovich, CEO at ROSS. “Since then, we have gone on to become a full-service, vertically integrated organization. We acquire through ROSS Development & Investment, manage, and lease through ROSS Management Services, and renovate through ROSS Renovation and Construction. On every project, we work from a deal and managerial point of view, ensuring we incorporate property management into our underwriting and construction budgets.”

As it turns up the heat with acquisitional and organic growth, complex projects are becoming small fry for ROSS Companies

44

construction-today.com 45 ROSS Companies

Strategic planning begets commercial growth. This much has been made evident by ROSS. In 2017, for instance, the company made the bold decision to expand south, opening a satellite office in Richmond, Virginia. The move has paid dividends. Now the company proudly provides efficient, hands-on services to Richmond, Hampton Roads, and the Carolinas.

Today, ROSS is widely respected in all aspects of multi-family property management, ownership, renovation, and construction. “It is important to understand the critical components which lead to longterm success before starting a renovation or construction project,” asserts Dave. “Our approach to asset preservation and managerial efficiencies provides a unique operational perspective and forms the backbone of our relationships with clients and vendors, which we have built up over the past 40 years.

United as one

“Historically, the multi-family industry has been slow to adopt innovation,” he goes on. “However, one of the biggest lessons over the past three years has been the importance of embracing it, which will not only make our business more efficient but also help clients to understand the importance of technology. We are constantly evaluating tools to improve efficiency, working with our technology partners to understand industry trends and, more recently, looking outside the industry to find cutting-edge products and services that will enable us to stay up to date with latest market trends.”

This is just one of many lessons learned since the pandemic began. The last few years have served as a litmus test, clearly discerning the kind of stuff a company is made from. Fortunately, ROSS passed with flying colors. The pandemic forced every company to reevaluate and rethink. With ROSS, it was no different. “Not only did Covid-19 cause

us to pause and reflect on who we are, but it also redirected our focus back to how we do business on a fundamental level,” says Dave. “The companies that survived were the ones that had strong foundations and a robust leadership team. Our ability to adapt to unforeseen working conditions was solely due to the strength of our people; we tackle every challenge as a family. Over the past two years, we united to overcome even the most trying of obstacles, and came out a stronger, more determined company.

“As a network, we quickly pivoted our strategy to adapt to the pandemic and the various regulations that were put in place,” he continues. “We relied on the strength of our employees, and trusted that together we would persevere. We knew we had a great team before the pandemic, but I believe we surprised ourselves in how quickly individuals stepped up to support each other. Their ability to shift to a remote working environment, implement safety protocols, and ensure high morale in extremely uncertain times stands as a testament to their pride and commitment to our organization.”

It is clear that people are central to ROSS – the name itself is the name of its founders, and like the family that established it, that sense of belonging and commitment keeps the company afloat when the going gets tough. “We have always operated with a family-owned mentality and the understanding that our most valuable asset is – without any doubt – our employees,” notes Dave. “The core values that our company was founded on are integrated into every aspect of our culture, which inspires collaboration and teamwork across departments.

“Since employees are trusted by management, they feel empowered and they understand that they are an integral part of the overall success of the company,” he goes on. “Consequently,

ROSS Companies 46

construction-today.com 47

we have built a sense of loyalty across our employee network. As is evident, I possess a great deal of pride for our team and the individuals who make a difference in our organization each and every day.”

The conversation then moves onto projects that the close-knit, family-oriented team has been working on. “On our most recent project, the Opportunity Zone deal, we worked closely with our client to secure approvals from all housing authorities,” Dave reveals. “Whenever we are taking on a renovation project with a client, we take a full-service approach by providing a scope, budget, and timeline. Complex projects such as this require tremendous coordination, communication, and support to reach the finish line. To accomplish this in the midst of a pandemic was extremely satisfying for us and our partners.

“It has been a good year,” he recalls. “One of the top highlights of 2022 was the closing and start-up of a substantial Opportunity Zone project in Newport News, Virginia, where we will be completing a string of $65,000-to-$70,000-unit renovations. This project was extraordinary in that it was not only our first Ozone project, but also included the placement of tax credits. The deal has

proved complex and has taken over two years to come to fruition, involving various lender and jurisdictional partners to complete.”

As we move into the new year, Dave reveals that ROSS’ biggest focus will be on acquisition and management of company growth. “Returning to a period of normalcy, we want to build on the strength of our team,” he concludes. “I would like to see ROSS further expand into the southern region, doubling our renovation and construction volume. We strongly feel our investment and commitment to growth has put us in a strong position for continued expansion and success in this market.” ■

www.ross-companies.com

Apartment Turnovers and Apartment Restorers

Apartment Turnovers and Apartment Restorers is proud to be part of the ROSS Companies vendor family. We are a good team because our dedication to excellence mirrors the hard work, integrity, and dedication that ROSS embodies. The residents, tenants, and property management industry as a whole is better because of the associates who represent the ROSS Companies. We applaud the company’s major milestone of 40 Years. Well done!

48 ROSS Companies

VISION

OF SUCCESS

How Harold K. Jordan pivots to keep pace with the changing face of construction

Harold K. Jordan & Company (HKJ) is a general contractor that specializes in both public and private, multifamily residential communities and commercial housing. Founded by Harold K. Jordan in Apex, North Carolina, in 1989, the company has grown to include offices in Wilmington, North Carolina, and Myrtle Beach, South Carolina.

Despite decades in the industry, the last couple of years have seen the business thrive exponentially to grow to almost double in size from $150 million to $300 million. As Director of Business Development, Scott Niebauer, explains: “We have been fortunate to sustain a large growth pattern while we experience growing pains from it. Finding new qualified staff has been a challenge, and right now,

50

it’s all hands on-deck. Most of our clients are repeat customers, and we have managed to maintain those relationships and our reputation throughout the growth process. Of course, there have been challenges, particularly surrounding schedules, pricing and the supply chain. As a third-party contractor, we are at the mercy of our clients’ and partners’ schedules. From architects and engineers to local municipality inspection departments, everyone, like us, is busy. Our goals require tighter management of schedules and trying to complete our projects as quickly as possible. We’re always innovating to resolve issues for our clients.”

Scott is proud of the service HKJ provides. From simplifying the construction process to completion and handover, the business strives

Harold K. Jordan

to ensure seamless project delivery. “We always make sure we meet and exceed the expectations of every single client. What sets us apart from the competition is, we are able to finish the job. Most contractors can achieve 95 percent completion, but always seem to struggle with the last five percent. We don’t have those struggles. We achieve 100 percent,” he enthuses. “Our goals are to turn over units during construction, so our clients obtain income to pay down the interest from their loan. This process requires extensive planning and execution.”

One recent project is The Artreaux complex in North Carolina. Located in the Industry Hill neighborhood, in Winston-Salem’s downtown arts and entertainment district, the 242-unit complex boasts five stories with a parking deck. Scott elaborates: “Right now, we are in the finishing stages of that project. We are framed up, the roof is on, exterior façade almost completed and the subcontractors are currently finishing in the interior units. We are very close to substantial completion leading to a final CO.”

An equally exciting project is The Residences at Glenwood Place. This 275-unit, high-end project promises a superior aspect and finish, as reflected in the top-end market rates. The Residences at Glenwood Place has contemporary architecture, unrivaled amenities, local retail, and a beautiful landscape design. It is located inside the beltline and connected to the Greenway in the heart of Raleigh. This multifaceted lifestyle destination with airy, thoughtfully finished apartments places residents in the middle of The Triangle’s finest culture, cuisine, and entertainment. This is truly one of the best projects HKJ has built.

Accomplishing the impressive scale of these projects involves collaboration. As Scott explains: “We work closely with our clients and their design teams to accomplish their vision. There are always initial expectations of their vision, and while we work to achieve those expectations, we always must factor in additional changes or considerations due to the increasing cost of materials. For the project to be successful,

construction-today.com 51

we need to ensure the design aligns with the proposed budget.”

This unique way of working filters down to all members of staff and is cemented within the company culture. “We don’t micro manage our employees,” Scott highlights. “We have an expectation that they will represent HKJ, at its finest, and we allow our people the freedom to work on a project. Our employees are empowered to take ownership and make decisions to accomplish our tasks. Challenges are presented on every project. We focus on resolving those challenges early and proceed

with meeting our goals. While our culture is generally laid back, we are focused on getting the job done.”

This culture of ownership and empowerment is reinforced and rewarded with staff benefits. Scott continues: “Our employees have great benefits. We offer competitive pay, insurance, 401ks, and great potential to advance within our company. We make sure our people feel valued and reduce turnover within the company. Our staff are truly a talented group that enjoy their careers with HKJ. HKJ is committed to creating the best work environment – a place

52

where everyone’s voice is heard, and where communication, feedback, and employees are free to talk with any manager at any time about any topic.

“We also hold an annual event that includes announcing awards based on health and safety achievements. We are a safety-driven company and are always looking out for the best interests of our people. We believe it is important to recognize achievements of our talented employees.”

The pandemic is a pertinent example of a pressing health and safety situation, and HKJ responded with the safety of its workforce in mind. As Scott explains: “From face coverings to testing, we paid close attention to what was required of us, and that attention extended to our sub-contractors. It was a challenging time. Communication became key to the successful management and control of the infection. While we’re getting back to normal now, we’re still feeling the effects of that time.”

Future predictions

The supply chain was hit hard. Materials and delivery delays and availability forced the business to reassess its procurement and planning processes. “The pandemic caused attention to potential scheduling and procurement issues. We took the necessary steps to ensure materials were secured for our projects. This included subcontractors and labor in our process. As mentioned before, it’s been all hands on-deck, with existing staff working across multiple functions, hiring more people, and opening our vendor relationships to reach out to other subcontractors. The rising price of materials and labor has been a challenge. In some cases, we’ve had to renegotiate contracts to account for those increases, and this can only happen with open communication across the board.”

With three new projects in the pipeline, and currently, at full capacity, business doesn’t look set to slow down any time soon. Looking to the future, Scott believes that multi-family housing will continue on its trajectory. “Primarily

because interest rates are increasing, it’s making it tougher for individuals to move into single family homes. However, as things stand, at some point, the market will drop. What’s going to happen when it does, is something I can’t predict. Five years from now however, I would like to think that HKJ will have the same clientele. While we strive to secure new clients, our current customers are ecstatic with the work we do, and our ongoing projects with them leave little capacity for widening the gene pool. One challenge, which is out of our control, will the banks continue to lend to commercial construction? I think contracts will still get signed but the loan structure will be different. In the next five years, we will continue to grow, but perhaps, there will be a greater concentration of affordable housing, as well as alternatives for new market rate product.” ■

www.HKJconstruction.com

construction-today.com 53

Harold K. Jordan

54

CONSTRUCTING

Gabe Godwin of CSI Construction discusses the company’s working relationships, its latest ventures in Colorado Springs, and entering its 45th year in business

We currently have eight large multi-family (apartment buildings) projects for multiple clients in Colorado Springs. There are a couple of local developers reinventing downtown, and it’s very exciting to be part of that,” begins Gabe Godwin, President of CSI Construction since 2013.

“Colorado Springs was a hidden gem,’” Gabe continues. “The multifamily sector has been fairly dormant until five to seven years ago, but the market has recently blown

up! Colorado Springs is a beautiful city and an hour away from Denver, so it’s finally getting known and people are moving in.” With Colorado Springs now often ranked as one of the best places to live in the US, it is not surprising that multi-family projects are in high demand. Gabe explains “One of our largest projects is an eight-story apartment building and parking structure in downtown Colorado Springs. It’s 408 units, 721,536 square feet, and located right next to the new Weidner Field Soccer Stadium.

CSI Construction construction-today.com 55

▲ ECO Apartments in downtown Colorado Springs, amenity area on podium

▲ ECO Apartments in downtown Colorado Springs, amenity area on podium

56

▲ The Mira Apartments in Lafayette, Colorado, amenity area

Colorado Structures Inc (CSI Construction) was founded in 1978 and is currently licensed in 19 western states. Current Owner, Tim Phelan, has owned the Company since 1986. Gabe started with the company in its Portland office in 1994, eventually running the office for 13 years before becoming President in 2013 and moving to its headquarters in Colorado Springs. Its revenue has grown year-on-year, with a turnover of $430 million making 2022 its biggest success to date. Gabe states that “we had to reinvent ourselves with the downfall in the market in 2008 to 2009. One of our big goals was to diversify into one third multifamily and senior living, one third retail and commercial, and the final third as other – whether that’s site development, medical, or hospitality. However, the big picture right now means multifamily occupies most of our time and accounts for approximately half our total revenue.”

Company growth

Despite these obvious successes, CSI Construction did not escape the difficulties of the Covid-19 pandemic. “A lot of things changed overnight so it was a big challenge for us, especially having four offices in multiple states,” Gabe reflects. “We were working in San Francisco and the rules were a lot different than they were in say, Colorado Springs, where our head office is located. That was the biggest challenge – keeping up with the different rules and regulations for every state, county, and city, and making sure we stayed within the correct guidelines. We were considered an essential business for most of our projects so for the most part we kept working through Covid. We did have some projects shut down but we tried not to lay anyone off and did the best we could to accommodate the issues that everyone was dealing with.” Since we last spoke to CSI Construction in 2018, it has expanded to a fifth office in

Arizona. “I would say opening the Arizona office last year is the biggest change and addition we have had, and it’s still happening right now. Todd Asburry, who has been with the company for 20 years, has moved from our Portland office to run the new one in Arizona,” Gabe tells us. “Although we have worked in Arizona for a number of years on mostly small commercial projects for repeat clients, we haven’t had an office presence there. As such, we plan to grow our local reputation and we have just commenced our first large project there.”

Family culture

Despite its tremendous growth over the last decade, CSI Construction has maintained the familial company atmosphere and culture that it always embraced. “Our employees are what makes

CSI Construction construction-today.com 57

▲

Apartments,