One vision

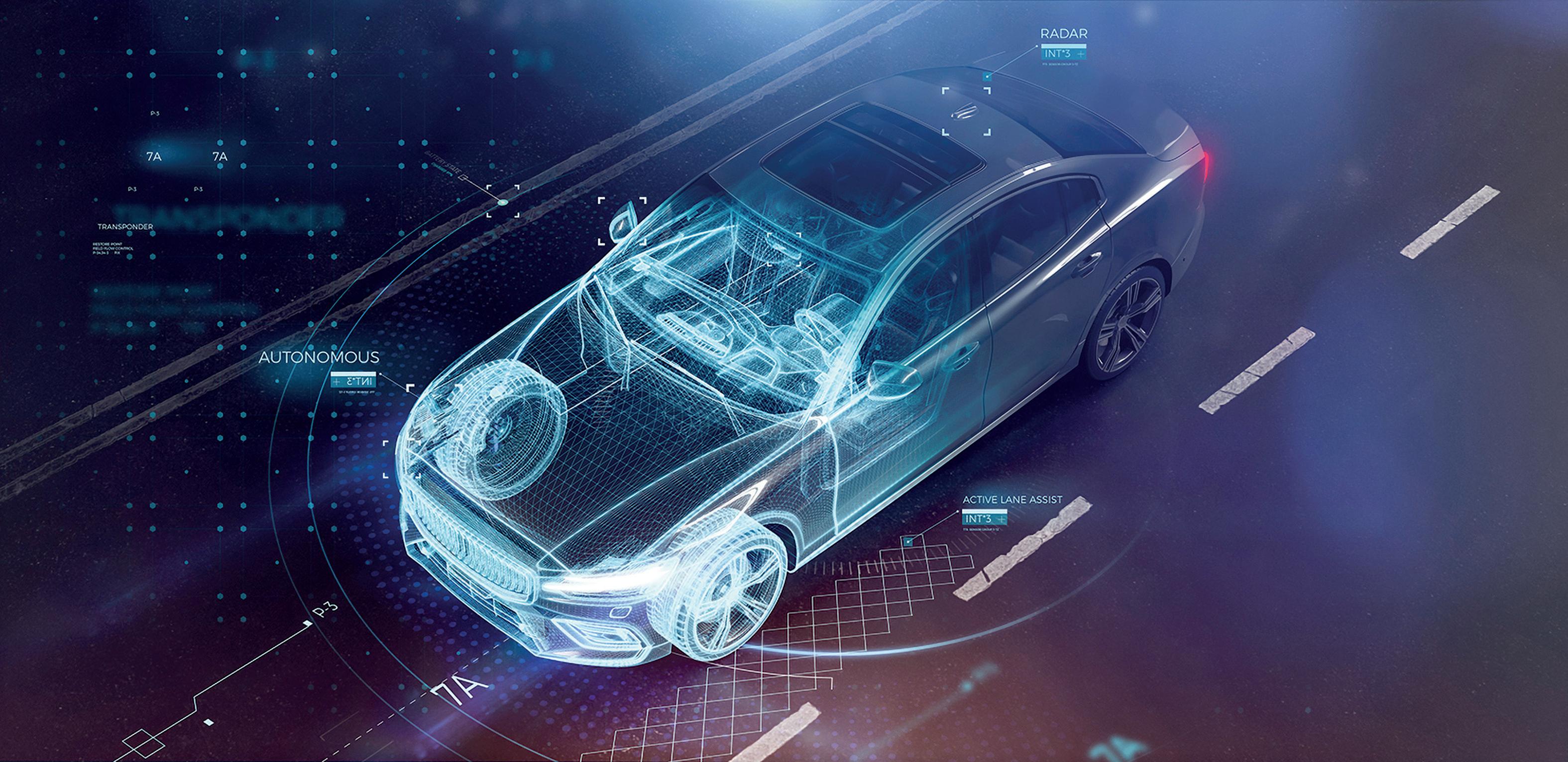

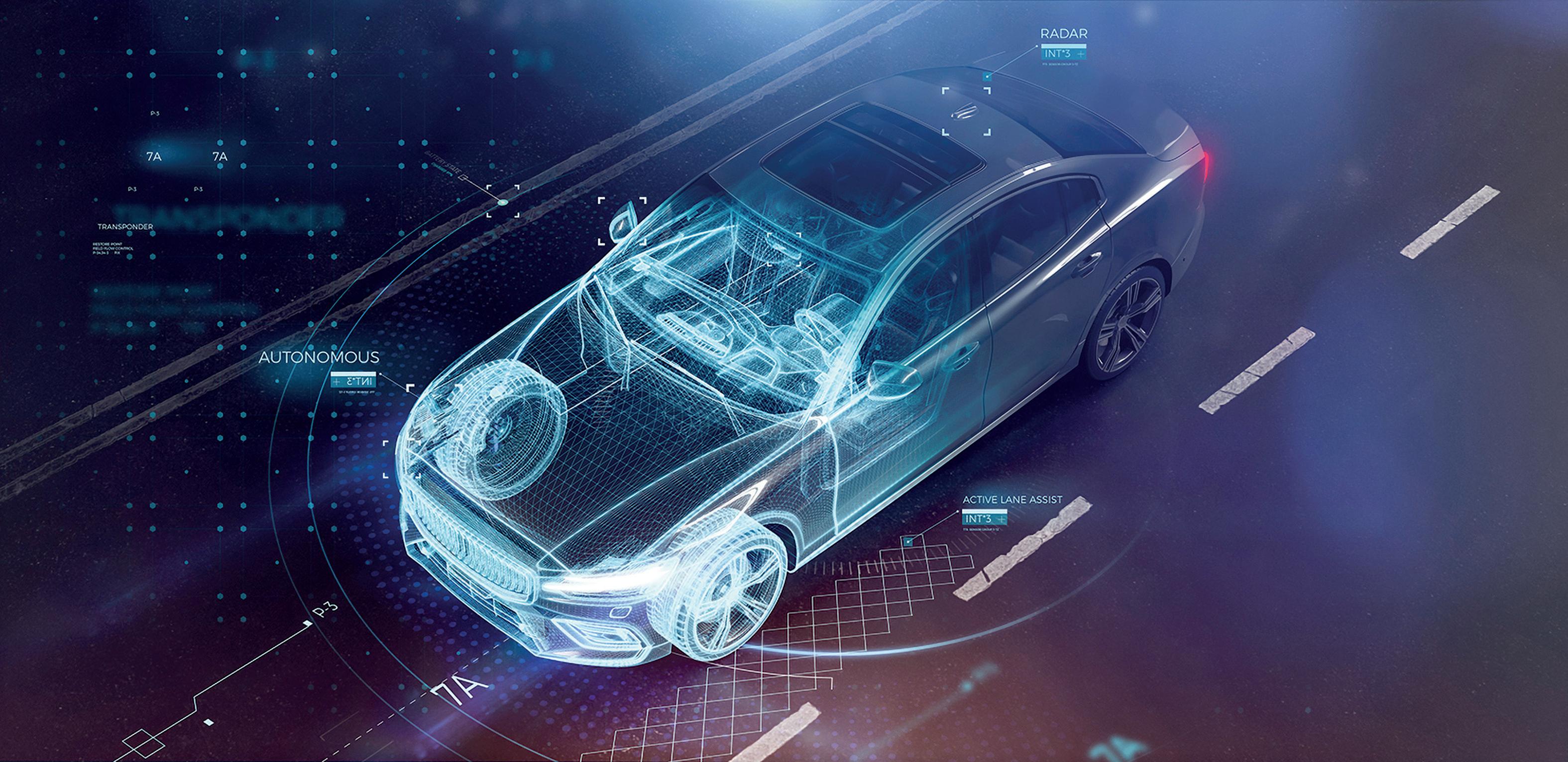

Automation

Container shipping

Vol 10 Iss 10/11 - 2022

Identifying those parts of the warehouse that would benefit from automation

Sustainability What happens next in the transition to electric vehicles?

The future outlook for supply, demand, and industry developments

Dionne Redpath, Group COO at Europa Worldwide Group,

discusses how innovation and investment have underpinned its journey through Brexit

CEO Andrew Schofield

Group COO Joe Woolsgrove

Creative Director Tom Vince

Data & Insights Director Jaione Soga

Editor Libbie Hammond

Assistant Editor Mary Floate

Content Editors Daniel Baksi, Alex Caesari, Danielle Champ

Editorial Administrator Amy Gilks

Managing Art Editor Fleur Daniels

Art Editors Paul Gillings, David Howard, Charlie Protheroe, Lee Protheroe

Artwork Administrator Rochelle Broderick-White Sales Director Alasdair Gamble

Project Directors Philip Monument, Joy Francesconi

Head of Content Management Adam Blanch

Client Sales Executives

Chloe Allman, Mark Cawston

Project Managers Lewis Bush, Natalie Griffiths, Jo-Ann Jeffery, Ben Richell

Content Managers Johanna Bailey, Mark Cowles, Jeff Goldenberg, Wendy Russell, Richard Saunders, Kieran Shukri

Media Sales Executives Mike Berger, Jessica Eglington, Will Gwyther, Reid Lingle, Sam Surrell

General Manager Florida Division Ryan Finn

Social Media Co-ordinator Rosie Clegg

IT Support Iain Kidd

Administration Natalie Fletcher, Rory Gallacher, Ibby Mundhir

Cringleford Business Centre, 10 Intwood Road. Cringleford, Norwich NR4 6AU U.K. T: (312) 854-0123 T: +44 (0) 1603 274130 US Office 2240 West Woolbright Road, Suite 402 Boynton Beach. FI 33426 T: (561) 778-2396

Hello and welcome to the latest digital issue of Transportation & Logistics International

This is the first magazine in our new design – what do you think? We’ve not only refreshed our magazine design, but are also working on a new website and new content for readers. I look forward to updating you in the future on what is coming next from the magazine.

In this month’s pages we look at a variety of topics that I am sure will be on your agenda, from digital transformation to sustainability. The latter piece, by Steve McEvoy at Expleo, discusses the need for collaboration across the automotive industry as the electric vehicle transition progresses. He asks ‘what can the automotive industry do to ensure it is ready for the switch to electric vehicles?’ Do you have the answers? In our cover story, Dionne Redpath describes the journey Europa Worldwide Group has undergone as it navigates the challenges of Covid and Brexit. Find out more about the successful strategies and approaches underway at the Group. Turn to page 4 to learn more.

lh@finelightmediagroup.com

contributors and advertisers within this publication do not necessarily coincide with those of the editor and publisher. Every reasonable effort is

Please note: The opinions

Identifying those parts of the warehouse that would Sustainability What happens next on the transition to Container shipping The future outlook for supply, demand, and Dionne Redpath, Group COO discusses how innovation and investment have underpinned its journey through Brexit One

vision

expressed by

made to ensure that the information published is accurate, and correct at time of writing, but no legal responsibility for loss occasioned by the use of such information can be accepted by the publisher. All rights reserved. The contents of the magazine are strictly copyright, the property of Finelight Media Group, and may not be copied, stored in a retrieval system, or reproduced without the prior written permission of the publisher.

Follow Transportation & Logistics International at @TLImagazine transportation-logistics-int

Libbie Hammond, Editor

© 2022 Finelight Media Group Corporate Head Office

Welcome tlimagazine.com 1

Sustainability 2 Inside this issue Digital transformation Internet of Things 24 Automation 18 Supply chain Cover Story Contents

tlimagazine.com 3 Maritime sector Container shipping 34 28 Youngs Transportation and Logistics 40 Restore Harrow Green 52 XDP TVS Interfleet BM2 Freight 68 62 58 transportation & logistics international

4

One

By Dionne Redpath

According to a recent report conducted by leading audit, tax and consulting firm RSM UK, called ‘The Real Economy’, 25 percent of businesses experiencing upstream supply chain issues say their reputation is deteriorating as a result. More than a third (38 percent) experiencing supply chain problems said they had seen an overall decline in customer satisfaction, and just over a

quarter (28 percent of businesses), said they have lost one or more key customers within the past year due to unanticipated supply chain pressures.

Despite a tough financial climate and the after effects of the global pandemic, businesses that are robust and set to weather the economic challenges all have three things in common: resilience, agility and focus on people.

Companies that have overcome adversity and hardship in the past have done so because they have planned, prepared and invested significant resources into developing viable solutions.

Across all sectors and industries, agile operators are those who will flourish, by offering new solutions.

The changes one firm made to successfully navigate through Brexit.

vision Supply chain tlimagazine.com 5

“ “

Operators in the logistics sector specifically have been required to evolve quickly to respond to the pandemic which caused unprecedented flux across networks. Yet there remains one constant which underpins dynamic supply chains, and that is innovation. Never has the phrase ‘necessity is the mother of invention’ been more apt.

Europa Worldwide Group – which employs over 1300 people across the UK and globally provides multimodal services covering air

and sea freight, European road freight and third-party logistics services with a growing international footprint - focused on invention and innovation. This approach is proving effective, with Europa’s recent financial results showing a tripling in profits – up to £10m from £3.6m (to end of December 21) and increased turnover to £325m for the last 12 months to date.

Investment in innovation has been key at Europa, with two specific areas of its operation delivering pioneering new solutions to keep customers and the supply chain moving.

Necessity is the mother of invention

6

It is vital that logistics companies leave no stone unturned when it comes to ensuring that every part of the supply chain has what it needs to deliver

“ “

The Brexit transit time challenge

In terms of the Brexit changes specifically, the team identified that the greatest challenges for goods moving smoothly between the UK and Europe would be that goods are delayed in transit, to pay VAT and any duty. The firm made it their primary objective to focus efforts to come up with a solution which addressed this single biggest issue, enabling paperwork to be completed whilst goods moved across the channel.

The team developed Europa Flow, the firm’s frictionless customs product – offering

customers a route for continued operational activity on the continent, tackling the new border regime by removing lengthy fee and paperwork barriers that would otherwise hold goods up in transit. The system allows customers to trade on terms which makes trading with the UK (as an EU buyer) as simple as it was before Brexit.

By January 2021, Europa Flow transactions were already averaging around 4000 per month. As customer confidence grew, volumes have increased rapidly over the ensuing months. One year on, the average

tlimagazine.com 7 Supply chain

monthly transactions had more than doubled, meaning that by the end of the first 12 months over 100,000 consignments had utilized the product, keeping goods flowing and customers happy.

As well as tackling post Brexit challenges, and reducing delays at customs, successful road freight operators are those who focus on the wider issue of reducing transit times. Designing simple and effective processes which remove complexities from importers and exporters, making trade easy, are required.

Innovation is crucial

Whilst road freight systems keep shipments moving, third party logistics is an essential part of a successful supply chain. Again, adopting and investing in an innovative approach is required. Third-Party Logistics (3pl) providers focus on integrated operations that are centered around customers’ needs. This is key to tackling the growing reputational concerns as outlined in the RSM report; operators must focus on nurturing a robust, long-term partnership with customers. An approach is needed to seek to provide insights, expertise and know-how in order to enhance the customer’s operation and to facilitate business growth. It is only by working closely with customers that they can understand their business needs and objectives.

It is vital that logistics companies leave no stone unturned when it comes to ensuring that every part of the supply chain has what it needs to deliver.

Businesses that are utilizing technology to create added value need to encompass a tailored solution which meets the business requirements of customers. Finding the right technologies that help to drive up productivity, improve quality, remove waste and stabilize workflows is essential.

This strive for innovation led Europa’s 3pl logistics team to invest £11m in

implementing automation technology at its newest and largest £60m, 750,000-squarefoot facility in Corby, Northamptonshire, commissioned in the Covid peak. This tailored automation solution was designed to meet specific customer business requirements and speeds up not only output but also significantly impacts on improving quality.

Having automation is one thing but having a team with the skills, expertise and experience to operate it successfully is quite another

8

“ “ “ “

Having automation is one thing, but having a team with the skills, expertise and experience to operate it successfully is quite another. Working with the right people is vital – it’s this collaboration between the two which drives success.

Across logistics sites a warehouse needs to focus on utilization of its team, in full collaboration with technology, to drive

productivity and quality up – doing more with less, being smart about utilization of resources so that even in limiting or challenging environments the customer experience continues to be enhanced.

Teamwork

Although the logistics market continues to face external challenges, companies like Europa are gaining market share and solidifying their financial position as one of the largest, most exciting and successful operators in the industry. This, however, cannot be achieved without the right values, vision and HR strategies that help to create an engaged and happy team.

As reported by the Chartered Institute of Purchasing and Supply (CIPS), the logistics sector is predicted to face a massive 400,000 workforce shortfall by 2026 if action is not taken. Businesses must work hard to build a culture that embraces change and demonstrates to its team that they are an important and indispensable part of the next generation of logistics.

To tackle the continued supply chain challenges, firms must focus on nurturing a robust, long-term partnership with all its customers, whilst having a focused, engaged team with an innovative approach. ■

For a list of the sources used in this article, please contact the editor

www.europa-worldwide.com

Dionne Redpath is Group Chief Operating Officer at Europa Worldwide Group. Europa Worldwide Group has three divisions –Europa Road, Europa Air & Sea, and Europa Warehouse – and has featured in The Sunday Times Top Track 250 for three years running.

Europa Worldwide Group employs over 1,00 staff, with 16 sites in the UK, Hong Kong, Shanghai, Dubai, and Belgium.

Dionne Redpath

tlimagazine.com 9 Supply chain

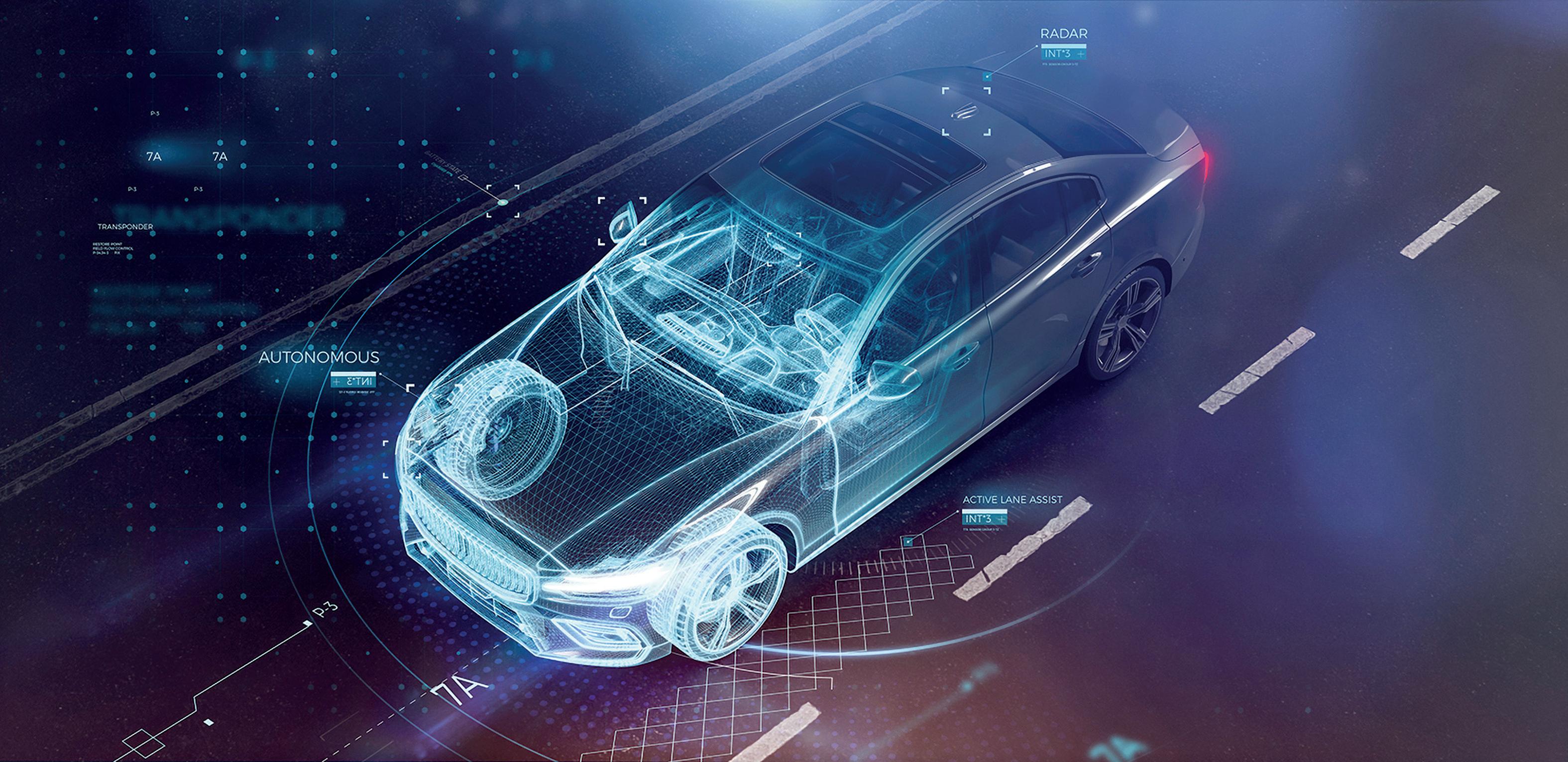

Get smarter

Digital strategies to improve risk management

By Lisa Paul

In the current, challenging economic environment, a transportation carrier’s main riskmanagement goals should be to optimize their Total Cost of Risk (TCOR), maintain contract compliance of independent contractors, and retain and train good drivers in order to meet the demands of coverage. Challenges to each of these goals

have arisen in recent years, and the strain on the system has trickled down and driven up costs as well.

For each of these goals, digital technology can help inform decisionmaking by aggregating operational and safety data on both drivers and vehicles, giving carriers a unique opportunity to reduce risk. The good news is, many trucking companies

10

have already begun the transition to collecting data that can be used to minimize risk. The roadblock, however, has been integrating that data into automatic driver training, insurance management, and recruiting and onboarding.

Insurance carriers use TCOR to measure a business’ risk management performance.

Simplified, TCOR takes the total amount spent on premiums and adds the cost of retained losses paid through deductibles or self-insurance, and any additional risk management expenditures, such as safety professional payroll, training, safety signage and equipment.

Optimizing TCOR requires business owners to balance risk with premium by understanding what drives their losses. Digital technology is revolutionizing the owner’s ability to understand every aspect of their risk by incorporating real-time data into decisionmaking and risk response. For example, after an accident, a digital tool can leverage in-cab and phone data to determine if the accident was an isolated incident or a more chronic risk management problem throughout the organization. It can also enable claims scenario tracking — key to passing an FMCSA audit and improving CSA scores, which are critical to winning new business and retaining good drivers.

Electronic Logging Device (ELD) technology, or in-cab telematics, has been mandated for long-haul commercial drivers since 2017, and insurers are expected to increase the use of mobile driver data and dashboard cameras to underwrite risk, gather crash data, and recreate crashes for claims remediation. However, opportunity remains for

With each driver lost, so is productivity and expertise - and the expenses of recruiting, hiring, and training new drivers are incurred Digital transformation tlimagazine.com 11

“ “ “ “

transportation carriers to integrate this data into their own risk management processes.

At the intersection of driver retention and training

The US driver shortage continues to hamper the ability of carriers to control risk. With each driver lost, so is productivity and expertise - and the expenses of recruiting, hiring, and training new drivers are incurred.

A strong driver onboarding and retention program revolves around

safety, and digital technology can play a significant role. Telematics have been used to monitor drivers while on the road, but they can also provide insight into training gaps and provide real-time data on new recruits. Further, integrating telematics can lead to creation of driver incentive programs based on the data collected, helping boost retention of a fleet’s safest drivers and keep insurance costs depressed. Digital tools also streamline the administrative work of onboarding

12

by enabling employers to file job applications, Motor Vehicle Report (MVR) records, and drug tests, and by linking that data to workflows that automate insurance purchasing.

Contract compliance of independent contractors

Fleet owners can significantly benefit from hiring contract drivers to fill specific runs and supplement fulltime staff. Yet, owners must ensure all contractors are trained appropriately and the proper steps are taken to manage compliance. Converting the process to digital can relieve some of the stress. Maintaining contracts and agreements digitally can help coordinate the multiple insurance policies, contract renewals, and potential claims that come with hiring contractors. It also makes it easier to flag documentation that needs to be reviewed for liability risks and indemnification clauses.

Tackling risk management as a solution

It’s no longer a question whether it’s necessary to invest in risk management solutions. Now, the question is, what is the smartest way to tackle risk? Here, too, digital solutions can be of service. Integration of digital technology with risk management programs and service providers is key, but if the data is collected and analyzed but not leveraged to manage risk and lower costs, then the point has been missed.

Video telematics has grown in popularity as well, driven by the opportunity to help resolve claims more quickly and accurately. Following an accident, video can be

linked into a push of first notice of loss, allowing adjusters quick access to accurate incident information. Video also carries with it a measure of protection for fleet owners, eliminating uncertainty over whether their driver was at fault in an accident or not.

The investment in ELD and other digital technologies can be significant, but the opportunity to reduce risks and cost can also be significant, as it gives deeper insight into how to improve compliance, calculate cost-per-mile in real time, and determine a carrier’s TCOR. ■

Lisa R Paul, CPCU, is Chief Strategy Officer for Transportation at global insurance brokerage, Hub International. Creating, planning and strategizing for success in transportation, relative to the cost of risk, margin objectives and driving organic growth through the digitalization of data for transportation, clients and insurance brokerage operations, and their insurance risk partners, is her primary objective. This includes linking small to large transportation businesses and their inter-related needs in transportation segmented insurance programs across a broad range of transportation businesses from dock to door. Lisa has over 30 years in commercial auto underwriting, program and product development, including MGA start from scratch and growth to $100M of premium prior to being acquired by Hub International in 2017.

Lisa R Paul www.hubinternational.com

transformation tlimagazine.com 13

Digital

A new era

Steve McEvoy reports

The urgency around climate change has continued to increase over the last few years, with the EU focusing heavily on transforming Europe into a modern, more sustainable economy. The recent European Green Deal is the foundation of this urgency and 2022 has seen more policies introduced to support its goals.

Consumer demand is one of the reasons for the increase in green policies. A recent IBM

study found that 51 percent of consumers say environmental sustainability is more important to them than it was 12 months ago.

One of the major emissions cuts that consumers are making themselves involves reducing their carbon footprint through greener modes of transport. The study reveals that four out of ten who care deeply about the environment say that their environmental concerns compelled them to reduce or

Is the UK ready for the Electric Vehicle revolution?

14

eliminate travel by traditionally powered private cars and planes in the last year. And almost half of all travelers increased their use of Electric Vehicles (EVs) for the same reason.

Despite the current cost-of-living crisis and soaring electricity prices, sales of EVs have increased in Europe over the last year, with many UK drivers opting for battery or EVs. And for now at least, consumers can still save

money while running an EV, which is cheaper than driving a petrol car, even with the rising electricity prices.

Yet, the IBM study reveals that there are still several barriers preventing consumers from making more sustainable travel choices, such as cost and accessibility.

So, what can the automotive industry do to ensure it is ready for the switch to EVs?

Sustainability tlimagazine.com 15

Moving to the green lane

With the UK government announcing that sales of all new petrol and diesel cars and vans will cease by 2040, as part of its ‘Clear Air Strategy’, the automotive industry is under pressure to innovate.

EVs are more efficient when being driven, they waste less energy and thereby reduce the amount of air pollutants released, which means everyone benefits from cleaner air and quieter cities.

With Net Zero on the horizon, the automotive industry is at full throttledeveloping automated, electrical vehicles with sustainability at the forefront of the thinking. However, the race to adopt EV as the primary choice for personal transport could lead to significant infrastructure challenges if we do not diversify and offer alternative green fuels.

Infrastructure and supply issues

The increase in demand on the grid caused by the increase in EVs has the potential for major disruption.

Without careful planning, the grid will struggle to charge large numbers of EVs simultaneously as the strain it will put on the network has the potential to cause blackouts during ‘peak’ charging times. In addition, our reliance on imported energy to meet supply requirements is currently impacted by geopolitically motivated supply issues, further reducing the grids’ capability to meet a surge in demand from EVs.

The industry therefore needs to create ‘smart’ charging systems that integrate seamlessly with the existing infrastructure and that use less energy – while ensuring EVs are an affordable option for consumers.

16

We need to consider the alternatives

The long-term benefits of EV ownership are now being rocked by rising prices in the electricity markets, and the rare materials needed to produce high performance automotive batteries continue to rise in price. This is likely to make EV a more expensive option over time, reducing its attractiveness and creating a new problem for the industry to address.

And while current investment is focused on adapting infrastructure to EVs, leaders in both the energy and automotive industry agree that hydrogen power offers gamechanging potential due to its storability and transportability.

The use of hydrogen continues to grow, and it is already being used in aviation for container ships (H2 ships) and in the industrial sector for carbon-free steel production. Hydrogen really could provide the flexibility and the reassurance the automotive industry needs, but there remains some uncertainty due to infrastructure challenges and issues surrounding the production of green hydrogen. Although hydrogen buses are now operating in some cities in the UK (particularly London), the majority do not use green hydrogen – which somewhat defeats the point of the ‘emission free’ bus.

Although aware of the potential, the UK E&U industry seems cautious about committing to developing scalable hydrogen infrastructure and supply to support its use as a fuel for automotive. Although the technology is available, without significant investment in the infrastructure needed to produce, store and transport green hydrogen, manufacturers will continue to have their doubts.

There is still work to be done

Although it’s evident that we need to develop national hydrogen infrastructure for EV to meet transport requirements, the first step towards this is greater collaboration between

the government, automotive and utility industries. Only by working together can we address the big issues, developing diversified solutions across e-mobility and hydrogen, that benefit both the consumer and the infrastructure – while also addressing the Net Zero challenge.

As we move into the new era of mobility and sustainability, it is important for those of us in the automotive industry to collaborate with others, finding opportunities to speed up the transition to EVs, support environmental targets, and improve accessibility to emerging technologies. ■

For a list of the sources used in this article, please contact the editor.

Steve McEvoy www.expleo.com/global/en/ Steve McEvoy is Vice President - Automotive at Expleo, a global engineering, technology and consulting service provider that partners with leading organizations to guide them through their business transformation, helping them achieve operational excellence and future-proof their businesses. Expleo benefits from more than 40 years of experience developing complex products, optimizing manufacturing processes, and ensuring the quality of information systems.

Sustainability tlimagazine.com 17

Automated response

Warehouse automation and the reasons to have this on your agenda

By Paul Freeman

More and more SME warehouse operators and e-commerce retailers are deploying automated intralogistics technology to ensure that they meet delivery promises to online shoppers.

With developments in technology leading to the emergence of flexible and scalable products that deliver a notably faster return-on-investment than the type of often costly fixed assets that, at one time, were considered central to any automated

warehouse project, more and more companies are choosing to automate part, or - in some cases - all, of their intralogistics processes.

Indeed, such is the willingness to embrace automated hardware and the software systems that drive it, that, according to a recent report on the warehouse automation market by Interact Analysis, the sector is set to see a period of exponential growth, with global sales forecast to climb six percent by 2023.

18

Automation tlimagazine.com 19

handling solutions were already high on the logistics industry’s agenda before Covid-19, there is little doubt that the increase in automated warehouse activity can, in part, be attributed to the social and economic fall-out from the pandemic. The global health emergency and the subsequent collapse of bricks and mortar retailing, has forced many companies to accelerate their existing intralogistics project plans or even change their strategy completely.

But it isn’t just the likes of Amazon and Alibaba that are embracing automation: many smaller companies

would, until relatively recently, have been financially out of reach, are now benefitting from the operational gains that today’s highly cost efficient automated systems offer and, as a consequence, the profile of the typical automation user is evolving.

Small and medium sized warehouse operators and e-commerce retailers faced with a need to reconfigure their operation to comply with new workplace social distancing rules or, perhaps, requiring a faster or more accurate order picking regime to ensure that they meet their next-day delivery promises, now see automated

20

handling and storage technology as the optimum solution to their issues.

Key factors

Several key factors are driving the growing market for automated handling solutions. Firstly, there is a shortage of skilled people to operate forklifts; secondly, the operational cost of automation is usually lower than manuallyoperated processes; and, thirdly, in this era of e-commerce there is a need for streamlined delivery, which forces logistics providers to plan and predict their logistics flows more consistently to achieve next-day or even same-day delivery.

Furthermore, because automated guided vehicles follow the route around the warehouse that they have been programmed to follow – unlike most operator-controlled forklifts where the temptation to take a potentially dangerous ‘quick cut’ is, it seems, omnipresent among some drivers – the likelihood of an automated truck damaging either the warehouse building, the storage system within it or the load being carried is virtually zero. This built-in safety functionality also means that the risk of the equipment causing injury to warehouse personnel working in the same area as an automated machine is minimal.

And, it is often overlooked but, in terms of environmentalfriendliness, an automated guided vehicle uses less energy and can be expected to have a longer working life than a manuallyoperated forklift.

But, despite its myriad benefits, automation is not the answer to everything. Every logistics flow, every warehouse set-up and every supply chain is different and what works for one business may not be appropriate for another.

Onboarding automated guided vehicles gives warehouse managers and logistics teams the peace of mind that comes with knowing that the step-by-step flow of materials will continue uninterrupted Automation tlimagazine.com 21

“ “ “ “

So, is automation suitable for your operation? As a starting point, consider the following questions in relation to your facility:

l Are warehouse-driven delays a common issue?

l Do everyday workflows include a vast amount of manual, repetitive tasks?

l Is output directly affected by limitations within the workforce?

l Are inventory counts regularly affected by inaccuracies?

Anyone that answers ‘yes’ to any of the above, simply has to have automated solution technologies on their radar.

For example, take question one: are warehouse-driven delays a common issue? Without the right processes or machinery, problems with inventory tracking, picking,

receiving and put-away can regularly halt the flow of goods through a warehouse. Automated vehicles can be programmed to ensure that the transported goods reach their destination within the store on time every time.

What about question two? Do your everyday workflows include a vast amount of repetitive tasks that are currently undertaken manually? Manual, repetitive tasks use up staff resources and effort and ensuring they are completed properly can waste valuable management time. As a result, focus can be lost and more important tasks may fail to receive the attention that they should to the detriment of the business.

Onboarding automated guided vehicles gives warehouse managers and logistics teams the peace of mind that comes with knowing that the

22

step-by-step flow of materials will continue uninterrupted, leaving them free to focus on other vital tasks that require their expertise.

Is output directly affected by limitations within the workforce? Human error is a common issue and sometimes mishaps go unnoticed within the wider business. But, all too frequently, mistakes cause delays and impact negatively on profitability.

There is no 100 percent foolproof way of guaranteeing that staff will not make mistakes, which is a compelling argument for introducing automation to those points in the warehouse flow process where errors are most frequent or particularly costly.

Are inventory counts regularly affected by inaccuracies? It is no longer viable to carry out manual inventory tracking. Improvements

in warehouse management, such as integrated inventory management, mean visibility over inventory is easily accessed, reducing the amount of counting inaccuracies that can lead to misplaced stock.

Predictable pattern

Significantly, adopting automation no longer requires every aspect of the warehouse or distribution center to be automated – just the parts of it that will benefit most from the technology – and automating those aspects of the warehousing operation that follow a predictable pattern makes a lot of sense. ■

For a list of the sources used in this article, please contact the editor.

Paul Freeman www.toyota-forklifts.co.uk

Paul Freeman works at Toyota Material Handling. Toyota Material Handling has successfully delivered more than 250 automated projects featuring over 800 automated guided vehicles across Europe. It works with customers to determine the specific challenges they face and tackle them one step at a time. Breaking the process down into small modules gives clients essential scalability and means that, if they wish to, customers can partially automate their processes while retaining the option to introduce more automated technology as future demands change.

Automation tlimagazine.com 23

WWW 24

IoT comes of age

With an expected 5.2 billion connected devices by 2025, IoT is now a fundamental component of both government policy and corporate strategy

The ability to track, monitor, record and analyze through an extraordinary array of hugely innovative sensors has already transformed many organizations, including the supply chain and logistics sector. But, to date, the true power of IoT has been constrained by the limits of fixed and wireless connectivity: just 15 percent of the planet is covered by affordable, accessible IoT connection.

If supply chains are to harness the power and sophistication of IoT, connectivity has to extend around the globe. It needs to be affordable and accessible – yet the only alternative to wireless networks has been Satellite IoT at a price point that cannot be justified by the vast majority of businesses or use cases. Until now.

Laurent Vieira de Mello explains how affordable, end-to-end technology models are transforming accessibility and unleashing unprecedented innovation that will totally redefine the power, value and perception of IoT.

Driving value

The post-pandemic economy has inspired an evolution in business drivers, with both private and public sector organizations increasingly focused on delivering value – to

customers, employees and the wider global stakeholder community. But how is that value measured, verified or communicated in a world demanding rapid results and immediate decision making?

Further, after two years of disruption, businesses need to be able to achieve and demonstrate true innovation in supply chains that support new efficiency paradigms and deliver tangible shareholder value. Post COP26, environmental protection has risen up the corporate agenda too. Companies must prove their sustainability strategies to avoid the risk of greenwash accusations. The continuous connection of IoT clearly has a key role to play in enabling innovation, and is proving its value.

From connected vehicles to industrial equipment tracking and environmental monitoring, increasingly sophisticated IoT sensors are already embedded within global infrastructure. Yet, with 85 percent of the world not covered by cellular technology, IoT is simply not an option for vast numbers of organizations. Supply chain managers, for instance, are eager to embrace technologies that enable a proactive approach to cargo and fleet management. They seek track and trace solutions that enable them to monitor moving assets anywhere and anytime along

Internet of Things tlimagazine.com 25

their journey. They want to more effectively manage the movement of containers across the world – especially the cold chain. But, without complete, global coverage, the true power of IoT to enable fundamental change will never be realized.

Cost effective SatIoT

With the arrival of low cost Satellite IoT (SatIoT), hundreds and thousands of assets can now be deployed cost effectively around the globe – to even the most remote and inaccessible regions. This is inspiring the creation of an extraordinary array of powerful applications that will accelerate change and deliver tangible value to business, individuals and the environment.

A compelling cost model, however, is just one part of the equation. While the pent up demand for SatIoT solutions is significant, this is a new market for systems integrators and one that raises a new set of challenges and opportunities. Additionally, by default, these kinds of IoT solutions are going to be deployed in remote locations – such as containers located in the middle of the ocean –which means minimizing the need for human intervention and repair, wherever possible, to safeguard the business case.

Device size, power consumption and reliability are priority concerns. Small-sized devices offering low power consumption is vital, as battery life is extended. What is the weight and cost differential offered by smaller antennas? What is the viable battery life? These are key issues to consider before embarking upon a strategic SatIoT initiative. For example, combining good quality battery technology with an intelligent approach to transmission extends the lifecycle of the IoT solution. By

ensuring the device is only transmitting when the satellite is in range, rather than continuously, radically increases battery life, especially in applications that do not require constant information updates.

Innovative thinking

For integrators, access to cost effective SatIoT is already inspiring new thinking and extraordinary innovation. The ability to work seamlessly with existing cellular IoT solutions, ensuring accurate tracking and monitoring as assets transit between connections, transforms the visibility of global freight assets. In addition to improving efficiency and reducing the financial losses associated with product damage and wastage, global tracking has an even more powerful potential - it can help address the huge proportion of vaccines that are damaged, lost or stolen in transit. SatIoT

26

can provide confidence in the integrity of the cold chain and identify areas of elevated risk, allowing protection to be prioritized in the right areas, safeguarding this vital global resource.

Bidirectional IoT also has a significant role to play. The ability to send commands back to assets, rather than just receive data, is powerful and enables an array of new use cases, including remote management of equipment. Supply chains and cargo managers can change the temperature set point of a reefer container. Bidirectional communication capability underpins this, and is essential for confirming that data transfer has been achieved through an acknowledgement mechanism.

Couple this with information seamlessly integrated with existing analytics, AI, or machine learning solutions, organizations now have the power to not only use this data

to improve understanding; but immediately respond and use new insights to inform timely commands to remote assets.

Complete solution

Low-cost SatIoT is opening a new world of IoT opportunities. It is enabling transport and logistics firms to embark upon innovating thinking, and explore new use cases for IoT. It is enabling them to track and trace goods more effectively, monitor the cold chain, and make better business decisions about cargo in transit. Systems integrators, with an existing portfolio of cellular IoT solutions and customers, now also have the chance to not only extend their reach and plug the gaps in IoT connectivity, but also embrace innovation and fulfil the potential of IoT in this sector. ■

Laurent Vieira de Mello is COO at Astrocast. Astrocast SA operates the most advanced global nanosatellite IoT network, offering services in industries, such as Agriculture & Livestock, Maritime, Environment & Utilities to name a few. The Astrocast network enables companies to monitor, track, and communicate with remote assets from anywhere in the world. It relies on superior L-band spectrum through a strategic alliance with Thuraya. In partnership with Airbus, CEA/LETI and ESA, Astrocast developed Astronode S, an ultra-low power and miniaturized module compatible with inexpensive L-band patch antennas.

Laurent Vieira de Mello www.astrocast.com

Laurent Vieira de Mello www.astrocast.com

Internet of Things tlimagazine.com 27

Shaping the future

Expectations for the container shipping market

By David Dierker, Ezra Greenberg, Steve Saxon, and Tewodros Tiruneh

By David Dierker, Ezra Greenberg, Steve Saxon, and Tewodros Tiruneh

28

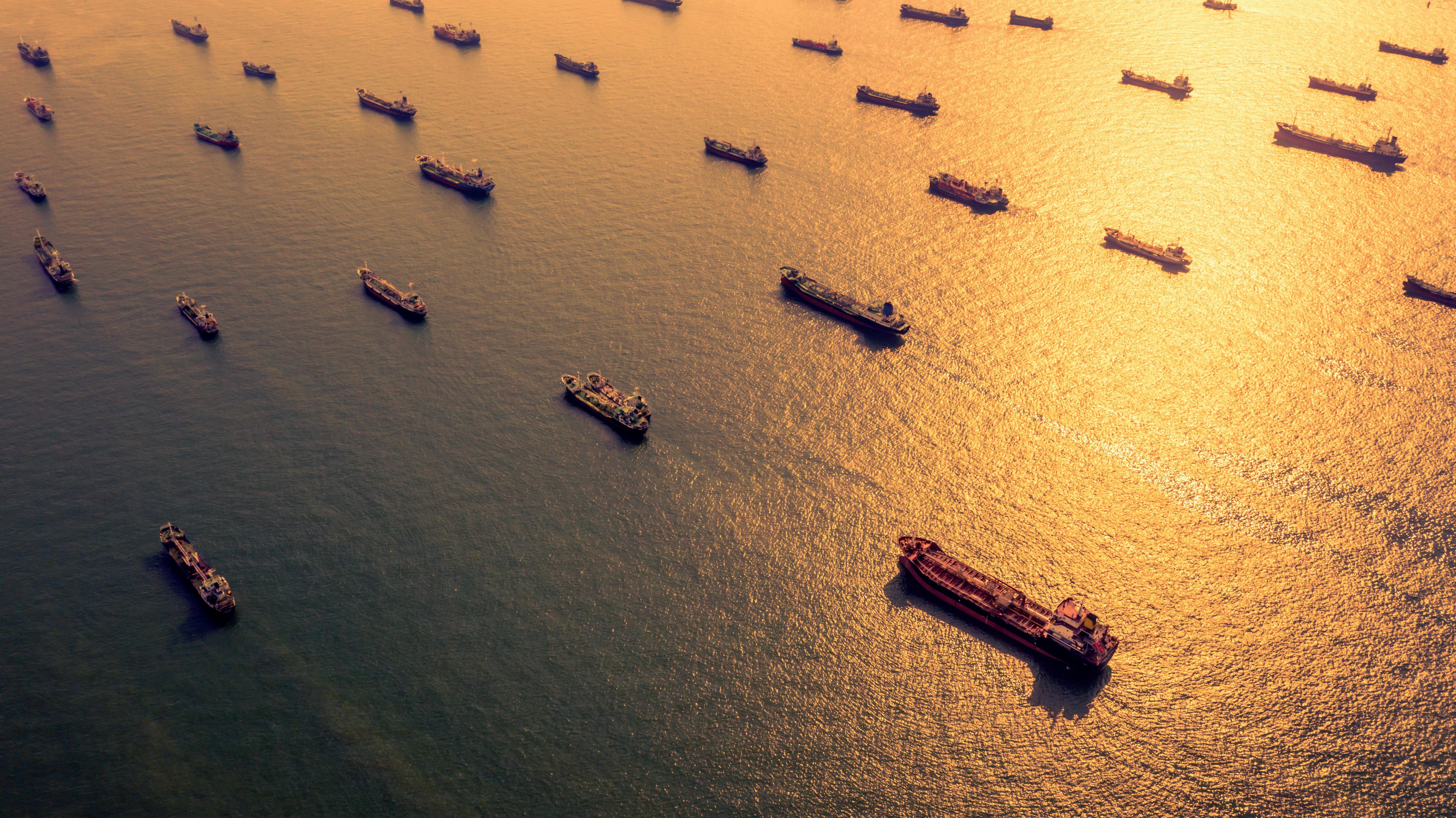

As consumer demand softens and containership effective capacity rebounds, freight rates are expected to normalize. This article explains the outlook for supply, demand, and container industry developments that will shape freight rate developments over the coming years.

Following the surge in North American consumer demand and supply chain congestion issues

brought about by Covid-19, shippers saw freight rates rise to six-to-seven times over 2019 averages. Freight rates have begun to fall since January 2022, dropping 30 to 50 percent from their earlier highs (see Exhibit 1 overleaf)

This drop in rates is expected and is occurring a little later than many industry experts (including McKinsey) had predicted. Future expectations should be rooted in an updated understanding of what caused, and sustained, the meteoric rise in rates.

Container shipping tlimagazine.com 29

1

In times of under capacity and high demand, rates rise to levels of the marginal shipper’s willingness to pay Container freight rates are predominately driven by containerized goods demand, effective containership supply, and carriers’ cost to operate their supply. When demand rises or effective supply is reduced, rates will increase to levels of the marginal shipper’s willingness to pay. This willingness to pay is high for many shippers, as the value of most goods moved in containers is high, and there are limited alternative options for short-term transport. Price rises can therefore be quick and high. This is a well-known behavior to microeconomists and is seen in many commodity industries: they call it a “fly up”.

When effective supply exceeds demand, in a competitive market, rates are determined by the carriers cost to operate their supply –this can effectively be thought of as a rate floor.

Covid-19 increased containerized goods demand, but globally the increases were

only around five percent annual growth. The container industry should have been able to handle five percent growth, through some additional capacity, fuller ships, and faster sailing. The challenge however came from congestion overloading container terminals, inland depots, and warehouses (see Exhibit 2 top right) This congestion was especially acute in North America, which did see a demand spike of 20 to 40 percent above 2019 levels. This additional demand overwhelmed the supply chain, at a time when ports and inland infrastructure was also struggling to get labor to work due to Covid-19 infections. At one point, over 100 ships were waiting for berths off Los Angeles and Long Beach. This led to lengthening of containership transits as a result of port congestion. An estimated 19 percent of effective containership capacity was removed from the system between October 2020 and August 2022 because of congestion. The moderate increased demand and significantly reduced effective supply caused rates to spike, resulting in some freight rates seven times higher than their 2019 average.

30

Exhibit

Exhibit 2

2

Framing the outlook

Demand for containerized goods is stabilizing. As we write in October 2022, container demand has been lower than 2021 in nine out of the last ten months. Inflationary expectations may dampen future consumer spending, and retailers have built up inventories to levels that they can now take a more conservative approach to ordering. Our demand outlook, based on McKinsey’s most recent macroeconomic economic scenarios and container-trade-to-GDP-multipliers of around one show a demand increase between one to three percent over the next two years.

Effective supply is forecast to increase as ports continue to work through Covid-19 induced congestion, and containership transits are moving closer to their published schedules. Ships ordered during the last two years will deliver an additional 25 percent supply to the market, creating a market with ample supply (see Exhibit 3 overleaf)

Freight rates are always uncertain; a stable demand and increasing scenario likely has rates 50 percent higher than 2019 levels.

In times of ample supply, which has been the case for most of the last two decades of container shipping, price in a competitive market falls to the carriers’ cost to operate their supply.

A fall to 2019 freight rates seems unlikely, given the carriers’ higher cost bases. Bunker costs are 30 to 90 percent higher than 2019 levels, depending on if the carriers are using heavy fuel oil with scrubbers or low-sulfur fuels. Ship costs are higher for recently chartered-in vessels. Crew costs are higher from wage inflation as the support of seafarers is tight. A stable rate could therefore be above the 2019 levels. Additionally, the industry is more consolidated, and while still competitive, we can observe carriers taking out capacity through blanking sailings or cancelling some services to closer match supply to demand, which should stabilize rates.

In a scenario where demand remains weak, and congestion continues to improve, we could see rates stabilize at maybe 50

tlimagazine.com 31

Exhibit

Container shipping

percent higher than 2019 levels. This price level would be a relief to many shippers, and permit carriers to make returns on capital in line with their investors’ expectations.

Port and inland congestion could return: for example, further Covid-19 related closures in China, or industrial action. An alternative scenario has rates remaining at an elevated level – maybe double 2019 levels – due to capacity shortages. There remains a longterm challenge that many regions are not

investing sufficiently in the infrastructure needed to support continued growth: North America especially needs more port capacity and inland capacity investments.

A third scenario would have price flying back up to 2021’s levels. For this to occur, we would need to see demand return strongly, and, a major take out of capacity from a major external event, such as a lengthy major labor dispute or closure o a key waterway.

Finally, container shipping must decarbonize. The IMO requires a 40 percent reduction in absolute emissions by 2030 from 2008 levels, and a trajectory towards this, marked by the Carbon Intensity Index (CII) starts taking effect in 2023. Some ships may require retrofits to meet these requirements; others will likely sail slower to meet the emissions requirements. This has the effect of taking out effective supply from the market. While we do not see a lack of supply resulting, given the orderbook of 25 percent of the current fleet, it will impact the overall market supply.

32

Exhibit 3

and carriers can tlimagazine.com 33 Container shipping

Shippers

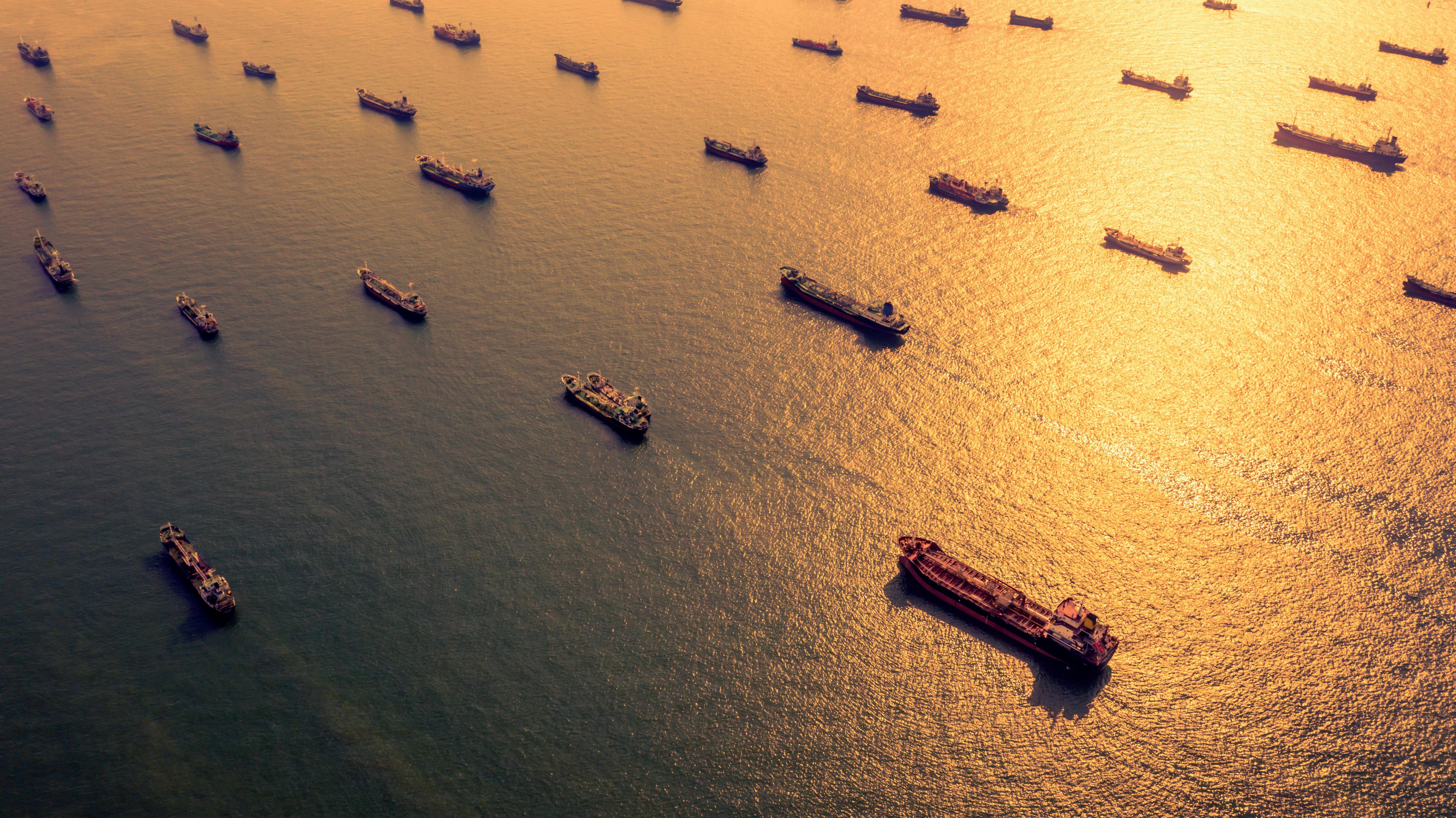

Steps in the right direction

Jonathan Taylor explains how to promote greener ways of working in the maritime sector

34

The global maritime industry has set its sights on transitioning to Net Zero carbon by 2050, but decarbonizing the sector will not be an easy journey. To align with the International Maritime Organization’s (IMO) 2050 target, a sizeable number of the world’s 100,000 vessels will need to reduce emissions by 40 percent by 2030. And that’s not all, as the UK government has set its own target to reduce shipping emissions by 78 percent by 2035 as part of its wider Net Zero ambitions.

Ninety-five percent of British imports and exports are transported by sea, and cargo ships alone release around one billion tons of CO2 emissions every year. As the equivalent of three percent of total global emissions, it’s clear the industry has a huge mountain to climb.

While this paints a challenging picture, there is reason to be positive. The sector is aware that decarbonization is a priority and there are practical steps we can take.

Collaboration is key

Sustainability is an issue that affects every aspect of and player in the industry - it cannot be achieved by acting in silos. A collaborative approach will be the cornerstone of success. This means regulators, manufacturers, technology companies, governments, academia, and others bringing their skills, experience and outlook to the table to solve challenges. This collaboration shouldn’t end with the traditional maritime ecosystem though.

Green engineering will play a crucial role in achieving Net Zero and has already positively impacted the automotive industry, which is leading the way in adopting electric and hydrogen fuel cell technology. These learnings and advances can be applied and adapted to the maritime industry to jump-start sustainability projects.

Creating a collaborative environment will help to bring passionate individuals together who understand the meaningful impact of decarbonizing – a crucial first step in propelling the marine industry towards its green ambitions.

Maritime sector tlimagazine.com 35

Step-by-step to success

There is an awareness that there is no silver bullet when it comes to decarbonization. No single technology will eliminate greenhouse gas emissions overnight. The road to Net Zero will be an incremental process.

Today, the global shipping fleet numbers around 100,000, acting as the main artery for global commerce and economic activity. The average vessel has a 30-year lifespan and estimates suggest the majority of those on the sea today will still be operational in 2035. Replacing the fleet in one go is neither practical nor economically viable so we need to look at the short-term measures we can take alongside the long-term changes required and accept that we might not see tangible results for a number of years.

Retrofitting today’s fleet to become more sustainable is an often overlooked

option. By retrofitting to adopt new fuel sources, means of propulsion and adapting modes of operation, we can cut emissions quickly and meet interim Net Zero goals. Efficient ship design and provisioning with new technologies will help to significantly reduce fuel consumption and greenhouse gases – leading to better performance, efficiency gains and cost savings.

In parallel, work can be done to develop new vessels built from the ground up to be Net Zero, with solutions and design profiles tailored to their power requirements and operational profile.

Alternative fuel sources

When we look at fostering a green future for maritime, we must consider how we fuel our vessels. Over-reliance on fossil fuels is perhaps the biggest single issue to solve.

36

‘Going green’ is often associated with an additional cost that doesn’t offer direct ROI. But a move to new fuel sources has the potential to prove more cost-effective. Sixty percent of the lifetime cost of a vessel is attributed to fossil fuels, and the maritime industry will also be able to save money by using more cost-effective carbon-neutral options. Just this year, Expleo developed a closed-loop e-methanol fuel solution for shipping to deliver a 92 percent reduction in Greenhouse Gas (GHG) emissions and potential OPEX savings of £1.4 million a year, per vessel.

Hydrogen and methanol are just two fuels being explored, but to ensure uptake they need to guarantee comparable performance compared to fossil fuels. Hydrogen and methanol both require more on-board space to store, so the immediate focus should be on designing new and efficient ways to minimize this using smart technologies like AI.

The role of Artificial Intelligence (AI)

While much focus is placed on traditional engineering – the fuels and engines driving the global fleet – digital technology should also support maritime’s push for sustainability.

A significant proportion of its carbon footprint can be traced back to inefficiencies in the operation of ships. By making shipping smarter, it can become greener too. Although its application in shipping is relatively immature, AI has the potential to be a gamechanger, due to its ability to be applied to a broad range of challenges. AI can be used to track real-time fuel consumption and make vessels more efficient, predict energy consumption, identify optimal system, trim, speed and engine settings to reduce emissions.

AI can also help seafarers make better decisions by monitoring real-time data

around sea and weather conditions. With this visibility, crews will be able to optimize how the ship should be sailed and consider when best to recharge, use more fuel or start up generators.

AI technology is developing all the time, and we are just beginning to understand what is possible.

No quick fixes

While the route ahead will have its challenges, progress is already being made. I believe the maritime industry can inspire other sectors to a greener future. An emphasis on collaboration, continued investment in innovation and embracing digital and emerging technology will be the three pillars of future success.

It’s an innovative time for the maritime sector and by pushing boundaries, bringing great minds together and taking inspiration from other industries, we can work to solve the decarbonization challenges ahead. ■

For a list of the sources used in this article, please contact the editor.

Jonathan Taylor www.expleo.com/global/en/

Jonathan Taylor is Vice President of Marine at Expleo, a global engineering, technology and consulting service provider that partners with leading organizations to guide them through their business transformation, helping them achieve operational excellence and future-proof their businesses. Expleo leverages a network of high value-adding affiliates in consulting and industrial excellence, and leading partners across multiple sectors to provide you with the most comprehensive services and solutions in an ever-changing environment.

Maritime sector tlimagazine.com 37

40

Old but young

Driving growth up by 250 percent – Youngs Transportation and Logistics knows the way

tlimagazine.com 41

Youngs Transportation and Logistics

Freddie Young founded Youngs Transportation and Logistics (Youngs) in 1967, and remains both the chairman and major shareholder of the company to this day. The tale of Youngs’ earlier days encompasses the traditional value of self-made, organic growth. Freddie started out with a single truck and a simple coal delivery business. That one truck soon became five, however, as Freddie gave up the physical wheel for

Mandata

Mandata is proud to be a partner in the growth and continued success of Youngs Transportation and Logistics. As their transport management system (TMS) provider of choice since 2016, we’ve been in lockstep with their growth requirements through our range of scalable solutions.

Louisa Ridgway, Business Development and Strategy Manager at Youngs, commented, “Through seamless integration with our clients’ systems, Mandata’s software saves our clients time and effort when making bookings. Their satnav tool allows our employees to locate our trucks at any time, allowing us to give our clients instant, accurate ETA information. Together, these features go a long way in enhancing customer satisfaction and ensuring return business for us.”

Transportation and Logistics 42

Youngs

There are no shortcuts to success.

But there is always a more cost-effective route.

Mandata’s powerful range of Transport Management Software products is leading the way in helping thousands of hauliers across the country to ...

Maximise profitability of every mile with map-based planning capabilities.

Increase cash flow with invoicing on delivery and seamless integration with major accounting software solutions.

Build customer confidence with total transparency of consignment progression.

Avoid costly human error by having a single point of entry for all haulage work, no more duplication or key errors.

Have a real-time view of the entire operation, with our deep pallet network system integration.

Grow your business with software that helps you to deliver.

Mandata.co.uk

the metaphorical one, driving the business towards further growth. His continued involvement at the head of the enterprise is a unique selling point in itself, as he continues to drive the values of reliability, commitment, and trust.

The coal business carried Youngs through the 1970s, until Freddie a fresh opportunity presented itself in an unlikely way. As Paul Pavitt, Managing Director, recalls: “Freddie

was standing in the pub one night and he overheard a lady saying how she urgently needed to move some cargo from Dagenham Storage’s warehouses. He interjected, offered his trucks, and it was a deal. He moved the cargo for her, she paid him – a lot more than he’d earn in a day shifting coal – and that was that. From there, Youngs moved into freight forwarding, and what has become a vital pillar of our business.”

Youngs Transportation and Logistics 44

Youngs continued to develop through the following decades, transitioning across to haulage, and by the 1980s, extending its reach into Europe. Rob Hollyman, Managing Director, joined Youngs in 1985. It wasn’t long before the company was at its peak of international output.

“Under Rob and Freddie’s leadership, Youngs became a huge player within the industry,” Paul

The company has achieved growth of 250 percent over the last five years, despite the impact of the Covid-19 pandemic 46

“ “ “ “

continues. “At its height, the company was sending between 45 and 55 trailers to Italy every week. Rob had worked for another company called International Express and when it ceased to trade, he took the business that he had previously controlled, being the Italian contracts, and brought them directly to Youngs, having always used us for his deliveries and collections. The service grew greatly in a short space of time, particularly in Rome and Milan.”

The European arm remained a core market for Youngs until the millennium when, facing increased competition and undercutting from European competitors, the company started to look elsewhere. When Paul joined the business in 2010, he somewhat changed the direction: “By 2016 we had regressed from the European market all together. It was nothing to do with Brexit, the European arm just wasn’t giving

us the return we had once enjoyed – at this point we were only sending two trailers to Italy and two to Spain per week. We were covering some of the haulages internally for our European department, which meant the warehouse and transport sides were both subsidising them. When I applied the real costs, the margin completely eroded, and I decided to shut the department down.

“I pivoted towards getting more involved in warehousing and distribution, focusing our attention on imports and exports from China and the US,” he elaborates. “We just carried on doing what we do best and have grown on that basis to now house locations all over the country.”

Now into 2022, and Youngs with depots and warehouses within ten miles of every strategic port in UK, along with sites at Purfleet and West Thurrock in Essex, Southampton, Warrington, and Felixstowe.

Logistics tlimagazine.com 47

Youngs Transportation and

The Purfleet base services its export consolidation business, loading up to 100 containers per week, whilst West Thurrock houses all of the London distribution and imports. The others have been acquired over the years, as Paul details: “We obtained Felixstowe recently through our acquisition of Imorex Shipping Solutions Ltd. We also made the strategic purchase of North West Cargo, which operates between the Port of Liverpool and some of the ports in the South. We moved to our current site in Southampton in 2018, which is just four miles from the dock.

“What we have been able to do is create a one-stop solution for our customers’ Less than Container Load (LCL) products,” he emphasises. “Whether they have cargo in demand at our depot in Essex, or in Felixstowe, we can cover the haulage for them within a 72-hour window. It’s the quickest and most effective way to move cargo around without traversing the pallet

48

networks. Because we’re happy to take one pallet, we’re happy to take ten tons of hazardous waste. We are a general hauler; no job is too big or small.”

Separate to Youngs’ LCL services, the company also offers a Full Container Loads (FCL) sector. Initially launched as a valueadded service for customers who wanted to use Youngs for transport and warehousing, high demand heading into 2021 prompted Youngs to invest in the business, placing more trucks on the road.

“Although we only had a small customer base at the time, that base consisted of regulars who relied upon us for all their haulage,” Paul explains. “We didn’t want them shopping around because we didn’t have the resources to cover meet their needs. As a result, we moved to acquire Eldapoint’s transport division, doubling the size our FCL fleet overnight. It was what needed to be done

Bronze Mechanical Handling

We, Bronze MH, have been supplying our service and Mitsubishi forklifts to Youngs for 30 years. The business has expanded significantly in the last ten years, growing from a four-truck fleet to now operating almost 50 machines over the four depots we supply.

Our directors and management acknowledge the demands that a busy transport and logistics company require for its day-to-day activities, and understand the adverse impact that down time has on the operation of the business. Bronze MH are strategically placed to support Youngs with a maximum four-hour response in the event of a breakdown, supported by our trained engineers who carry large levels of van stock and fast-moving parts. As the Bronze MH brand is predominantly Mitsubishi, and Youngs operate a large fleet of hired Mitsubishi trucks, we are sure to have the part in stock for a first-time fix.

tlimagazine.com 49

Youngs Transportation and Logistics

50

to cope with the sheer volume of work we had to get through and to protect the best interests of our loyal customers.”

With its broad list of services, commitment to supporting its customers, immense industry knowledge and the company’s traditional, trustworthy nature, Youngs has found a recipe for success. The company has achieved growth of 250 percent over the last five years, despite the impact of the Covid-19 pandemic. “We turned over £10.5 million in 2017, then have increased this by £4 million every year since. That figure wasn’t part of a strategic plan, it’s just by sheer coincidence,” Paul exclaims. “When the pandemic hit in March 2020, we were still really busy until May, then it all stopped. We kept working through, and we’re proud to say that we did so without resorting to furlough. Then June arrived, and everything started straight back up again. Between then and 2021, we had to employ an additional 47 people in six months.”

Despite an increase in size, when it comes to employees, Paul hopes to preserve Youngs’ familiar approach. “I don’t sit in an ivory tower,” he insists. “Just two years ago, I was still conducting every interview for any new hires. I’m immensely proud of the 330 people we employ nationally, at least 300 of them by face and name. As a company, we host annual meetings with our driving and warehouse staff, for which we hire out a venue and provide drinks and refreshments. It’s a platform for an open and frank conversation: anyone can bring grievances, positives, or new ideas to the meeting, and we’ll discuss it as a team.”

www.ytgroup.com

It’s an ethos that’s set to continue. Youngs remains committed to investing in the best possible fleet, and a partnership with DAF is set to bring in an additional 45 new trucks for 2023. But the company is also putting its money towards in its people. As Paul puts it: “We are reinvesting in training, we are reinvesting in equipment, we are reinvesting in staff.” ■ Youngs Transportation and Logistics tlimagazine.com 51

Electrifying moves

Restore Harrow Green takes an energy-saving, technological approach to business relocation

Restore Harrow Green takes an energy-saving, technological approach to business relocation

52

Restore Harrow Green has been helping organizations change and grow for over 30 years. Its commitment to remain the leading business relocation company in the UK has seen it expand its portfolio of services to match the growing needs of its customers. Its new facility in Cambridge is a good example of its strategy in action.

“The life science world has been very much on my radar for several years and Cambridge is its epicenter in the UK,” says Toby Swain, Restore Harrow Green Operations Director. “It was about Christmas 2020 when we got the site up and running, had the mezzanine infrastructures in place and increased usable storage space by about a third. We officially opened in March 2021.”

Harrow Green tlimagazine.com 53

Restore

Restore Harrow Green has invested heavily in providing the capabilities needed by customers in life sciences, pharmaceuticals and other areas with specialist and niche requirements. It has trucks specially equipped for transport of sensitive items, such as artefacts and materials from heritage museums, libraries, pharmaceutical

companies and laboratories, for example. It uses five redundant mines for temperature and humiditycontrolled storage and has two controlled-atmosphere converted aircraft hangers, selected for their very high vaulted ceilings and the additional security afforded by being on an RAF base.

Restore Harrow Green will be celebrating its 40th anniversary in 2023. It was privately owned until 2012 when it was acquired by Restore PLC, which describes itself as the UK’s leading provider of integrated information and data management services, secure technology recycling, and commercial relocation solutions.

“Ninety-five percent of our market at Restore Harrow Green is about moving offices and businesses. While we specialize in laboratories, pharmaceuticals and life sciences, co-working and flexible ‘nearhome’ working spaces and in niche segments like libraries, art galleries

54

and museums, we also offer a range of other specialist storage solutions,” Toby explains. “It’s quite a broad business and we have the largest market share in the UK for commercial moving.”

The company employs around 450 people and operates a fleet of 130 vehicles from nine facilities across Great Britain, including eight in England and one in Scotland. A lot of its trucks have bespoke equipment, such as built-in generators and inverters, to run freezers, fridges and ambient temperature control equipment for the transport of sensitive items, from vaccines to vulnerable manuscripts and supervaluable works of art.

The investment in capabilities and capacity, even during the pandemic, has paid dividends in competitive advantage. “Things returned pretty much back to normal for us quite quickly. We found that a lot of our competitors didn’t have the resources that we had access to,

Shell SHELL FLEET SOLUTIONS: ACCELERATE TO ZERO

Decarbonisation is a critical goal for fleets everywhere, and owners and operators need the ability to transition to low- and zerocarbon solutions while remaining competitive. At Shell Fleet Solutions, we’re committed to helping our customers, like Restore, to operate productively and more sustainably. This is why earlier this year, we launched our Accelerate to Zero (A2Z) programme, which combines expert consultancy services and end-to-end mobility solutions, to create a tailored roadmap designed to meet each fleet’s specific decarbonisation needs. Offering a range of e-mobility, consultancy and datadriven solutions like Shell Telematics, our A2Z programme helps fleets to advance sustainability goals, drive emissions reduction and accelerate to zero sooner.

Restore Harrow Green tlimagazine.com 55

across the Restore Group, and were struggling to re-engage with customers. They lost staff and made redundancies, but we actually grew our payroll by the end of 2020,” Toby says. “After a period of uncertainty in 2021, which hampered the business slightly, we are looking at what may turn out to be a record year for us. We learned a lot during Covid and gained a lot of efficiencies during that period.”

Restore Harrow Green took a deliberate decision to focus, during lockdowns, on providing services to ‘business critical activities’ supporting the NHS. The fact that Ford Motor Company was among them may prompt a query, but Toby is quick to explain why.

“Ford consolidated engineering space in order to produce ventilators as part of the Ventilator Challenge UK consortium,” he says. “We also did a lot of work for a large pharmaceutical company involved in vaccine production, and for its suppliers. We moved a lot of furniture to and from hospitals and into care homes. We delivered furniture and equipment to three Nightingale Hospitals, and PPE and

56

essential equipment to NHS hospitals and clinics, for both medical and facilities management.”

Moving forward, Restore Harrow Green is maintaining a strong investment strategy and is now very much focused on environmental and social governance. It has a target to be Net Zero by 2035 and is already implementing the strategy in its vehicle fleet.

“Rising prices of supplies, of fuel especially, has been difficult for many businesses to manage,” says Toby. The company has taken a number of measures to control costs and environmental impact. “We have partnered with Shell to provide us with fuel. To compensate for carbon from our fleet operations, we give back to Shell and they invest in projects to protect and enhance natural ecosystems that capture CO2 emissions, benefit local communities and improve biodiversity.”

Twelve vehicles in the company’s fleet are already electric, but this predominately includes smaller vehicles, such as vans and cars. Restore Harrow Green would like to go zero-carbon with its heavy trucks, but doing so comes with its challenges: an electric HGV costs five times as much as an Internal Combustion Engine (ICE) equivalent. The company is investigating the potential for hydrogen and other alternative fuels.

“We have signed up to Climate 100, which is a commitment to have our entire fleet, up to 3.5 tonners, entirely electric by 2030. I think we will be there well before then,” Toby confirms. “We have partnered with a provider with the aim of having electric charging points on sites across the whole Restore group.”

Additionally, telematics technology in all trucks, running on a platform called Shell Telematics, focuses on driver behaviors and helps them to find the most efficient delivery routes. The company has also invested in a program to equip each vehicle with six to eight onboard cameras, to give 360 vision.

“We sell this as an added value service to our customers. Some of the loads can be very valuable indeed,” Toby says. “Being able to

live stream vehicles from the moment they leave their property to the minute they deliver has been very well received, in life sciences, especially.”

As a vision for the future, it is pretty hard to beat. ■

www.harrowgreen.com

Above: Toby Swain, Restore Harrow Green Operations Director

Restore Harrow Green tlimagazine.com 57

Driving success

Two ways data and market trends are fuelling BM2 Freight’s success

BM2 Freight Services Inc (BM2 Freight) was founded in Covington, Kentucky. In the spring of 2008, three motivated salesmen, Kevin Ball, and brothers, Jeff and Matthew Mason, decided to go out on their own and build a freight brokerage business from the ground up. Their mission was to become the leading customer-oriented strategic broker in North America. “They decided to create a company that provides best in class service, treats its employees very well, and services customers to the highest level,” shares Peter Katai, BM2 Freight’s Vice President of Sales.

We learn from Peter about the ways in which BM2 Freight has made itself a pioneering freight business, and a one-stop shop in today’s world of transportation. “Although we started in Kentucky, we now have two outside offices located in Chicago and Nashville, as well as a Canadian operation,” he says. “We service the larger freight forwarders in our industry domestically, with food and beverage, retail, chemical, manufacturing, and packaging split into smaller verticals.

“Last year, we turned over about a 120-million-dollar revenue, with the Kentucky and the Chicago offices being particularly successful,” Peter reveals. “Although the Nashville office is smaller and opened during the pandemic in 2020, it is a growing market

with a lot of young talent. We believe it’s going to be a great office in the future.”

When it comes to the company’s uniqueness, Peter highlights that BM2 Freight chooses to think outside the box. The business, which specializes in moving complex shipments, has been able to diversify into several sectors owing to its wide-ranging expertise. “We’ve worked into verticals, such as fresh and perishable food, which has enabled us to refine our temperature control operation,” he notes. “Additionally, we have adapted to put tent tails on the back of the vehicles to make sure our drivers are able to monitor their environment. Despite this being a small percentage of our business, we have put in extra care. Our expedite business is really where we’ve become more specialized, and is about 20 percent of what we do in total. This has been a fantastic avenue for us, as we have seen our connections with clients lead to other opportunities in the industry.”

In addition to these industries, BM2 Freight offers a drop trailer service as well, which, according to Peter, is uncommon for a broker. “We do business with large food and beverage, automotive and retail companies where we provide them with trailer-dedicated runs. Our goal is to offer tailored solutions for our customers so that the shipment process is as easy as possible.”

forward

58

“ “

In my opinion, the food and beverage sector is one area of our business that will thrive, because of the return on investment it’s set to provide BM2 Freight tlimagazine.com 59

“ “

Peter then goes on to discuss recent projects that have brought the company great success. He highlights that this year, BM2 Freight has been working closely with three large beverage companies. Partnerships like these have served the company’s growth excellently, and are challenging it to broaden its horizons. “For these two, we are dropping trailers at specific sites, which is one of the traits that separates us from the competition,” he says. “We have also recently won a half-million-dollar contract from a large retailer that we will be executing over the next four weeks. The biggest challenge we’ve seen right now is that in an industry like this, sometimes experienced businesses have a difficult time operating because they are confident in their ways. However, for us, we are open to adapting, and we see the current state as a good market to learn. We are hiring more salespeople as well to keep the pipeline active, and to make sure that we have opportunities lined up for next year.”

Peter is keen to share that moving forward, the company has a goal to achieve a turnover of more than 500 million within the next five years. To reach this, he says that the business will be growing organically. His strategy will be to buttress the company culture and ensure the team consists of the best in the industry.

“There’s a massive market out there that we feel offers so much room for growth, and we want to continue to bring in talented people to help us take that on,” he emphasizes. “We are establishing a mentor program to assist with this journey. What we’re doing is looking more closely at the market so that we can move in the direction of where the trends are. We are paying attention to what’s happening with the trucking sector for

BM2 Freight Services named as a Top Workplace in the Greater Cincinnati and Northern Kentucky area

60

example, and how it is being influenced by the economy. In response, we then take that information and look into areas we can focus on. This then filters across the rest of our team according to the expertise and skills our leadership group can offer, and we then share that with the rest of the team. In my opinion, the food and beverage sector is one area of our business that will thrive, because of the return on investment it’s set to provide.”

Peter drives home his point about the importance of the company’s people by closing our conversation on the ethos that continues to fuel the business. “Since the beginning of our work, we have been determined to improve our culture from within. That comes down to our four core values, which are: win the day, be professional, excellence only, and trust the process. I feel that at the end of the day, to ensure that these remain true, our leadership team, myself included, has to stay accountable for our actions. This means we must make ourselves present and available for our staff every day.

“On the flip side, we also try to stay fun and engaging. We like to host sales contests, and we have company outings. We have three company events a year: a summer event, and a holiday outing, as well as a golf outing for our sport fanatics. We also organize lunches once a month because we want to encourage an environment where everyone here feels appreciated.

“Finally, we have implemented a few bonus and commission programs to ensure our financial commission programs are very transparent,” Peter concludes. “This is where technology is becoming more significant within our work. We have introduced a new TMS system, so our employees know exactly how much money they are making, and how much commission they will receive. We feel we have been very open with our employees, and as long as we continue with this culture of honesty, while keeping an open mind as to how we can improve, we will continue to get better every day.” ■ www.bm2freight.com

BM2 Freight at the Council of Supply Chain Management and Planning Conference, Nashville, 2022

tlimagazine.com 61 BM2 Freight

Manufacturing with purpose

How TVS Interfleet is driving a new era of industrial and commercial vehicles

62