“There is nothing like talking to industry people in person and showing them cutting edge, retail-ready equipment that can help their business.”

“There is nothing like talking to industry people in person and showing them cutting edge, retail-ready equipment that can help their business.”

When PMMI made the decision to cancel this year’s PACK EXPO conference on August 5, I’ll admit that one of the most disappointed people was me. Not with the decision itself, which I understand.

Nearly every major tradeshow in the U.S. has been canceled or postponed since the COVID-19 pandemic struck with a vengeance in March.

McCormick Place in Chicago, where PACK EXPO was to be held Nov. 8-11, has already canceled 140 events. In April, the convention center was converted into a makeshift alternate care facility to treat COVID, but it was dismantled in May.

The reason for my disappointment is twofold. I really enjoy exhibiting at PACK EXPO and will miss the buzz and excitement it creates. The show in Las Vegas last year was very good for us, and I was looking forward to returning to Chicago where we introduced one of our new machines in 2018. There is nothing like talking to industry people in person and showing them cutting-edge, retailready equipment that can help their business.

The other reason is we planned to show a new version of our 424 machine that exemplifies the versatility of our retail-ready

packaging system. It was ready to run blow-molded bottles in both tray-andcover and wraparound cases. This is the platform system we routinely use for flexible packages such as stand-up pouches and flowpacks.

Since we last exhibited in Chicago two years ago, SOMIC America’s business has greatly expanded. Our equipment has been discovered by a variety of industries, including cheese and dairy, coffee and confectionery, food processing, produce and retail, among others. Some like it for the simplicity and user-friendliness. Others prefer its floor-saving compact nature and automation capabilities.

Most machines are designed from the advanced SOMIC 424 mechatronic case-packaging system, which gives any manufacturer the freedom from being locked into one format or another. An additional advantage is having the flexibility to add new formats in the future. German engineering is admired worldwide, and a year ago, our parent company acquired another company – now called SOMIC Haag – as part of a growth strategy to provide additional machining capacity for our increasing business volume.

Besides manufacturing unique packaging systems for a widening

client base, our company has also grown. We’ve added more people to help provide support and hired more technicians to service our customers’ equipment. When we opened our new headquarters in suburban Minneapolis in early 2018, we quadrupled the previous amount of space. It gives us plenty of room to showcase new machines and to have parts on hand where we can provide service within 24 hours when needed.

The retail-ready packaging segment in North America is still relatively young, and the desire for more shelfready packaging will continue to grow. It’s why I thought the timing was right for this newsletter.

I hope you enjoy reading and learning more about our capabilities, our customers’ successes, and our mission to provide more end-of-line secondary packaging equipment to the marketplace. I’m also hoping to see you next September at PACK Expo in Las Vegas. Until then, I welcome your feedback or a phone call to discuss opportunities and how we can help your business.

Respectfully, Peter Fox, Sr. Vice President of Sales

Retail-Ready Magazine is published by SOMIC America, focusing on the Retail-Ready industry.

Based in Eagan, MN, SOMIC America manufactures advanced mechatronic case-packing systems that collate, unitize and load cartons, trays, retail-ready packages, and wraparound cases.

See how SOMIC can bring new efficiencies to your end-of-line packaging.

500 Lone Oak Road Suite #200 Eagan, MN 55121

+1.847.915.9872 somic.us p.fox@somic.us

Follow us on LinkedIN for updated material and conversations.

The number of SOMIC America equipment installations in North America.

The number of years the SOMIC end-of-line equipment brand has been in existence.

The number of products per minute collated by the Model 424 T2 (D) multi-purpose, retailready case packer, depending on the size of the products. The 424 T2 (D) can carton up to 35 cases in the same amount of time.

Sales in millions of U.S. dollars the global case-packing equipment market is expected to reach by 2023. The food and beverage sectors account for the maximum share of the market during this forecast period.

— Source: Allied Market Research

The number of hours each day SOMIC Parts & Service Departments in North America and Germany are available, even during the COVID-19 pandemic.

The number of products per minute that can be collated by the ReadyPack system, which case packs up to 18 packaged units per minute as a tray packer and 12 per minute as a wraparound model.

Number of SOMIC employees worldwide (Germany and North America)

The need for retail-ready packaging options and the need to continue running standard shipping cases provided the springboard for SOMIC’s explosive launch.”

Like most other retail packaged food items, coffee has gone through many package format changes over the years.

SOMIC America has developed specific automation to keep pace with these changes, including those in the single-

Transitioning from metal to plastic cans to nonwoven pods and plastic capsules, and of course, flat-bottom vacuum brick bags and stand-up pouches, coffee has seen its share of package structures. Along with primary package changes, point-ofsale enhancements have been made, which produce a nearly endless list of packaging configurations.

Coffee packers keeping pace with these challenges can stay in front of the competition by being flexible and adapting to the constantly changing marketplace. Case-packing equipment requires retail-ready solutions that can address retailer needs, which is why SOMIC’s equipment is so significant. SOMIC America has developed specific flexible automation for the singleserve coffee capsule market with mechatronic cartoning equipment for small-format products.

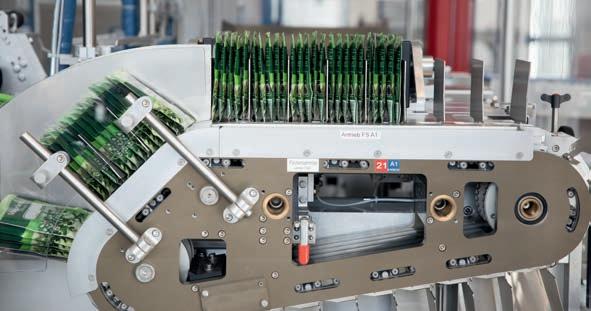

Coffee capsules provide one of the biggest challenges from a packaging equipment perspective. The capsules require special manipulation to properly orient and group for cartoning. The small capsules can be tricky to handle, and the most efficient way to pack them into a retail carton involves orienting them so they nest snugly inside. Therefore, the total solution requires precise control of the capsules, from the coffee filler to the cartoning system. Finally, the capsules are loaded into the paperboard cartons before the carts are closed and discharged from the machine.

SOMIC leverages several key equipment features that smoothly manage the capsules and keep them under control. For example, SOMIC specifically designed its systems

with a variety of vacuum belts that have capsule impressions to precisely maintain the position of each capsule. Using a product manipulator or indexing collator, the SOMIC system then rotates the capsules into the proper position for layering inside the carton prior to entering the cartoner. The capsules are appropriately grouped for each layer required and each entire layer is then picked and placed onto a second indexing collator until the number of desired layers is completed.

The pack pattern of layered capsules then indexes forward and is pushed onto a carton blank while being captured in a dynamic forming cassette. The carton is wrapped around the metal cassette, which protects the product and ensures the carton is square. After the cassette is extracted, the carton progresses to the closing station where an overhead portal closes the three sides of the wraparound carton.

While case-packing equipment for corrugated shipping cases is here to stay, the advent of retail-ready packaging has had a significant impact on the secondary packaging coffee market. The European coffee market requires retail-ready package structures, from blockbottom bags to stand-up pouches, for many different product formats. Rarely is a product on a store shelf that’s not packaged in a display tray provided at the time of packaging by the manufacturer.

Over the past decade, tray-andcover retail-ready packaging has quickly dominated the European retail market to the point that demand in the European Union for these retail-ready case packers is 80 percent/20 percent, versus the typical wraparound shipping case (the brown box). In the U.S., that demand is reversed – 80 percent wraparound cases and 20 percent retail-ready tray covers. This is rapidly changing, however, as U.S. retailers are recognizing and demanding the convenience of shelf sets incorporating efficient retailready secondary packaging.

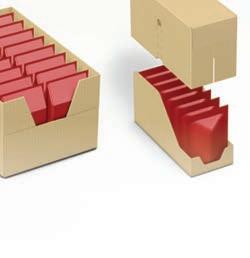

The most effective and attractive retail-ready solution consists of a two-part package that eliminates

torn and ragged packages on-shelf.

One of the two components is a display tray, typically made of a higher quality paperboard material or E-flute corrugated, which can carry high-end graphics for more effective branding. The second component is the cover, which is provided for its distribution purposes, and is often made of C- or B-flute corrugated board.

Assembly of these components requires placing the cover over the tray or on the inside of the tray. Having the cover on the inside of the tray creates the easiest way for a retailer to open and display the inner products. A stock person simply pulls the tray walls to the sides, releasing the cover and lifting it off the tray.

The most convenient option for the retailer is a cover that doesn’t require gluing to itself, thereby becoming flat upon removal. This eliminates having to break down the distribution component. In the end, the tray-and-cover is one of the fastest shelf-stocking package structures today. According to SOMIC America, it’s also one of the most attractive display vehicles with which to market products onshelf, which is why a leading North American manufacturer of private label products for the retail and food service industries uses it.

Like all other retail food products, the coffee market will continue to evolve, and different retail segments will continue to have different needs from their suppliers. Consequently, as new packaging formats appear in the market, automated packaging machines configured to run either wraparound shipping cases or retailready display cases will provide the automation flexibility packagers will need to accommodate these emerging constructions.

As coffee packaging’s future remains unpredictable, your end-of-line packaging equipment doesn’t have to be. Capable of being reconfigured for future applications unknown at the time of a new machine installation, SOMIC equipment keeps coffee packaging in step with retail changes.

Demand in the European Union for these retail-ready case packers is 80 percent/20 percent, versus the typical wraparound shipping case (the brown box).

The tray-and-cover is one of the fastest shelf-stocking package structures today.

Attention to engineering and quality is a hallmark of German manufacturing companies. Developing universally accepted and specific case-packing solutions for various production processes was the idea Manfred Bonetsmüller realized when he saw the need for increased automation in the food industry back in 1974. His visionary approach and continuous innovation contribute to the global success of SOMIC Verpackungmaschinen GmbH & Co. KG, and its end-of-line packaging equipment today.

Headquartered in Amerang, Germany, SOMIC Verpackungmaschinen’s team of engineers designs its machines with state-of-the-art technology, passion, and technical know-how to effectively master the packaging automation challenges that come its way.

The systems combine high performance with great flexibility, precision German engineering, computerized controls and mechatronics. They incorporate a multidisciplinary branch of engineering focused on both electrical and mechanical systems, including a combination of robotics, electronics, computer, telecommunications, systems, control, and product engineering. It’s a technology that SOMIC uses to build robust equipment with added value.

CEO Patrick Bonetsmüller, who took over the position from his father and company founder, Manfred Bonetsmüller in 2015, says it’s part of what makes SOMIC competitive.

“By delivering top quality, high performance, and attention to detail, SOMIC established itself as a prominent player in the world of packaging,” Patrick Bonetsmüller says. “This can only happen with a

capable, committed team that works well together.”

Compact, economical, and versatile

Depending on customer requirements, the company’s diverse equipment portfolio offers distinct advantages. The machines, with their long service life and smooth operation, are flexible enough to run different package formats, which impresses more customers in more industries.

SOMIC has set new standards with its mechatronic machine, Series 424. The tray packer collates up to 600 products per minute, and cartons up to 35 cases per minute, in open display trays, trays with covers or wraparound cases. The 424 can be outfitted with individual format tools for varying product dimensions and case styles. The machine is available as a tray packer (Model T2), and as a wraparound system (Model W3) that collates, groups and packs products in folded cartons, wraparound shipping cases, display cases or open trays. It also acts as a cartoning system (the 232FS) which unitizes and loads products into folded cartons, open cases and tray/cover packages (cover inside or outside).

Based on the componentry of the 424 series, the compact ReadyPack model for standard applications can be configured as a tray pack or wraparound case-packing machine for one-piece paperboard packaging. If a customer initially decides on a tray packer, they can later convert the machine to a wraparound case packer. Though its dimensions are approximately 3x3 m (approximately 8x15 feet), the ReadyPack machine has the same full functionality and proven control of all SOMIC equipment. The machine accepts package formats ranging from 150 to 450 mm long and 100 to 300 mm wide and collates product in an upright display-ready manner or in a layflat configuration (with conventional shipping cases), reaching speeds up to 160 packs per minute.

The case or display tray is formed around the product while it is securely held in a forming cassette. After the tray is formed, a hood or cover is formed and applied to the tray or the wraparound case is closed.

“With this new development, we are addressing customers who expect

they’ll have additional needs in the future and want to switch from manual to automatic packaging functions,” says Stefan Julinek, Sales Director at SOMIC Verpackungsmachinen.

The ReadyPack is the answer for those wanting a modular, high-tech system that can handle rigid or flexible primary packaging with an attractive return-on-investment. The cover applicator may be installed as a standalone unit or may be integrated into existing case-packing equipment to apply easily removable covers to produce retail-ready packaging. “The machine is a reasonably priced supplementary model suitable for test runs, short-term projects and temporary or special market introduction,” Bonetsmüller adds.

The U.S. shredded cheese market is a leading end user of the standup pouch format for which SOMIC’s flexible machines are designed. In fact, interest in retail-ready secondary packaging has never been higher than it is today, says SOMIC America’s Peter Fox, Vice President of Sales. Fox says in the U.S., the move to the packaging structure is in part due to Walmart’s push to eliminate pegboard displays in the dairy case.

The packaging format is also lighter in weight and has superior shelf impact. “It has also found its way into the chunk cheese and other areas of non-pegged items,” Fox says. “The two-piece retail-ready package allows the producer to use different materials for the display vehicle, typically a tray with retail graphics.”

The cover, or hood, can be lower-cost brown kraft corrugated, like that commonly used for standard shipping cases. That way, producers can invest in tray graphics and package substrates with maximum shelf impact and still reign in material costs.

The spirit of partnership at SOMIC guides the planning and commissioning of machines and our competent, reliable service worldwide. Visitors and customers are welcomed by the company’s family-run, team-centric atmosphere, friendly interactions, and supportive philosophy. SOMIC’s goals also include providing customers with exceptional service, from machine assembly to online operation assistance. They also offer personal advice by phone or on-site. “Our technicians handle processes from installation and inspections to test runs, regular maintenance, and quality control,” Julinek adds.

Remote diagnostics help to troubleshoot problems and often solve existing production issues directly. “We know the conditions and requirements on the production floor, and as a specialist in tertiary packaging, we provide customers with comprehensive advice,” Bonetsmüller emphasizes. “That’s what the name SOMIC and the reputation of our well-trained workforce stand for.”

To see how SOMIC can bring new efficiencies to your end-of-line packaging, call +1.847.915.9872 or visit Somic.us.

Packaging machines for single-component packaging, multi-component packaging, and modular packaging.

OH SNAP! ® Pickling Co. made a wise decision by installing a pair of new SOMIC highspeed, end-of-line machines for retail-ready packaging. The first of the popular Model 424 W3 wraparound case packers has begun the collation and case-packing of nearly 2 million single-serve pouches a week, a rate company President Ryan M. Downs expects to far exceed by this time next year.

That’s important, because the Appleton, WI-based division of progressive food producer GLK Foods wants its pickles to go where no others have gone before. Formed in 2015, OH SNAP! produces fresh refrigerated, portion-packed, brine-less pickled vegetables such as cucumbers, carrots, green beans, snap peas, and jalapeños. GLK is the largest producer of sauerkraut in the U.S., so it was looking to expand the success of its fermentation process for kraut to other products.

Its efforts were fruitful, er, veggie-ful, as the OH SNAP! products, in their handy stand-up, tear-open pouches, quickly won over consumers for their convenience, freshness, crunch, and tasty flavors. In fact, the pickles’ initial foray into the market led to impressive results. So, the company introduced more pickle varieties and other pickled products, such as carrot sticks, snap peas, and string beans, which were all eagerly accepted. While that’s good news, it can also present a challenge. They caught on so fast with such great demand in a short amount of time that the company couldn’t pack them fast enough.

Last year, demand was such that management decided to construct a new manufacturing plant in nearby Little Chute to accommodate the business’ fast-paced growth. The nearly 70,000 square-foot facility

began brining product in March, just as the COVID-19 pandemic was starting to spread in the U.S. Still, demand remains strong; the company is running three shifts around-theclock, six days a week.

Installation of the end-of-line SOMIC packaging machines couldn’t have been better timed. “We first heard about SOMIC through John Bartmann, our corrugated sales representative at Packaging Corporation of America,” recalls Downs, a fourth-generation GLK owner. “He introduced us to Peter Fox [SOMIC’s Senior Vice President of Sales] in 2016,” recalled Downs. “I remember thinking, if the OH SNAP! line did the volume to support the purchase of one SOMIC machine, we would have really created something special. We’ll soon be purchasing our third machine.”

“Before purchasing our SOMIC machines, we looked at two or three other solutions to be sure nothing was missed. None was as compelling as the SOMIC offering,” Downs mentions. “We love the simplicity of its design, its compact nature, and the references we received could not have been more glowing. We learned that start-up would be very quick, and it indeed has been..”

The SOMIC 424 W3 wraparound case packers are flexible, high-performing systems that use decentralized servo drives. To satisfy distribution to retailers such as grocery, big box, and convenience stores – plus vending and hospitality outlets – throughout North America, and widening the channel to include Europe, OH SNAP! plans to operate the machines to collate and case pack up to 160 pouches per minute. The pouches are available in formats of 6-, 12-, and 18-count display cartons.

Both machines were onstream as the company expanded from 68 employees to 94 for the annual, six-week Wisconsin cucumber harvest in July, Downs says. “We’re planning to add another 40,000 square feet to our facility to accommodate the brand’s additional growth. By the time the expansion is completed next summer, I expect us to far exceed what we are currently producing.”

We love the simplicity of its design, its compact nature, and the references we received could not have been more glowing.”

Ryan M. Downs, President

With SOMIC, the future of Retail-Ready Packaging is maximum flexibility. That’s because every single and multi-component packaging machine can be adjusted for a variety of products, arrangements, and packaging types. When different case-packing formats are required, they can be quickly adapted to meet the new requirements. SOMIC machines will deliver consistent results today, tomorrow, and long into the future.

To see how SOMIC can bring new efficiencies to your end-of-line packaging, call +1.847.915.9872 or visit Somic.us.

Why wonder about the future when it could be running in your factory?

“That shipping box is now responsible for being the final marketing tool at the most critical point in the product life in sales –consumer presentation.”

Retail-ready packaging isn’t just a trend or a fad. It’s becoming part of the daily shopping experience across a huge range of products in the retail environment. Brand owners are consequently searching for packaging options that facilitate shipping container handling at the retail level. Retailers say the way a product is presented plays a big part in sales. Adding retail-ready packaging greatly improves their shelf visibility.

To retailers, shelf-ready packages increase both supply chain and in-store efficiency because they’re easy to open and eliminate the need to unpack their contents. In fact, they’re so user-friendly, Walmart even invented its own term for them: PDQ – pretty darn quick. And Peter Fox, Senior Vice President of Sales for SOMIC America Inc., Eagan, MN, knows them, and the equipment used to produce them, well.

Fox says the advent of the Europeanstyle grocery model, which is focused on rapid product stocking of such display-ready or retail-ready shipping cases, is what triggered the switch in the U.S. “With European grocery chains such as Lidl and Aldi making significant inroads in the U.S., the pressure to deliver will continue. The trend toward more retail-ready packaging is a reality. Equipment producers who are prepared to meet these retailers’ needs with flexible, end-of-line packaging equipment will have a distinct advantage over their competitors who remain chained to that little brown box.”

That brown box today is truly moving beyond the utilitarian protective shipping vehicle into a

significant marketing tool, optimized for efficient stocking and sale, Fox says. “Considering the amount invested into the development of retail packaged food products — the marketing, the primary packaging and the production — isn’t that last presentation to the consumer at the store level worth the final follow through?”

Shining on the shelf

Thus, the conventional brown box has been promoted to readymerchandised, he explains. “That shipping box is now responsible for being the final marketing tool at the most critical point in the product life in sales – consumer presentation. This transformed shipping case must be easy to open and place on a shelf while being visually appealing. After all, 90 percent of buying decisions are made at this point in the product distribution cycle. It’s truly the big ‘point-of-sale’ moment. It’s the last opportunity a marketer has to outperform the competitor who decided the ‘good enough’ approach would be, well, just ‘good enough.’”

All these supply chain and retailer packaging demands may seem to add unnecessary costs. But Fox asserts that instead, “they’re creating a new opportunity to let products shine on the shelf. Retailers are looking for a rapid pallet-to-shelf display case that’s easy to stock while providing a superior shelf presence,” he points out. “There are so many new graphics and material capabilities available today for display packaging that the chances to dominate onshelf are limitless. Using multiple secondary packaging components provide marketers with ways to invest in the display tray with retailquality graphics and branding.”

Sturdy E-flute corrugated or paperboard display trays maximize shelf appearance while further enhancing and reinforcing product branding, he adds. “A separate cover or hood made of natural kraft corrugated material delivers the shipping protection products need and an upscale display-tray look,” Fox notes. “The stocking clerk simply pops the cover off and places the product filled tray on-shelf, with absolutely no cutting or tearing necessary. This prevents potential damage to the products inside, and provides a perfectly clean, consistent high-quality display every time.”

Fox cites several real-world examples of packaging conversions currently taking place that include products historically displayed on pegboards. “Retailers are looking for a rapid pallet-to-shelf display case. They recognize the opportunity to save on the labor-intensive process of uncasing and stocking individual packages on pegs — it’s an obvious first step in converting to shelfready packaging. Products include packaged cheese from sliced flowpacks to pouches of shredded cheese. This trend continues with bagged candies in stand-up pouches, as well as vertical form/fill/seal bags.”

Manufacturing such retail-ready packaging requires versatile end-of-line secondary packaging equipment that’s flexible enough to run both multi-component shelfready packaging, as well as standard shipping cases for channels that do not require point-of-purchase packaging.

“Having the manufacturing flexibility to run multiple case formats prevents future retailer demands from obsoleting existing equipment,” Fox points out. “One example of this type of flexible system is the compact SOMIC 424 Mechatronic case-packaging system. This advanced system prevents the manufacturer from being locked into one format or the other. Additionally, future retailer-specific ready designs of display trays can be added as new formats when the need arises. SOMIC equipment can also pack products in any orientation in a carton, tray, or case. All of this gives the producer a competitive advantage.”

The availability of exciting new varieties, along with the appetite for protein-rich foods, has more U.S. consumers saying “cheese, please!” According to a report published by Allied Market Research, the U.S. cheese market generated $34.39 billion in 2019, and is estimated to reach $45.49 billion by 2027, registering a compound annual growth rate of 5.3% from 2020 to 2027.

The U.S. cheese market is a perfect match for SOMIC’s packaging equipment capabilities, says Peter Fox,

Senior Vice President of Sales for SOMIC America. “This market was being challenged by retailers to provide retail-ready solutions to replace traditional pegboard displays. It was this particular industry, the need for retail-ready packaging options, and the need for packagers to continue running standard shipping cases that provided the impetus for SOMIC’s explosive equipment launch. The SOMIC 424 multi-functional case-packing system is the right system, introduced at the right time, in the right market.”

SOMIC America’s case- and tray-packing equipment became so popular, the surge in equipment demand and sales plus the need for further customer service and spare parts support led to the relocation last year to a new corporate headquarters site in Eagan, MN. “We have quadrupled our space requirements and have room for future growth,” he says. “In recent months, we have also strengthened our service support team. And when our showroom is completed, we will be demonstrating different types of machines.”

“In addition to the cheese market, SOMIC is a strong U.S. player in the broader packaged food market, the confection industry, the coffee capsule cartoning business, and the snack market,” Fox continues. “We have well over 100 U.S. installations and we are continuing to grow at an annual rate of over 25 percent. We also have a larger spare parts inventory, thanks to our expansive warehouse, as well as a production space capable of running Factory Acceptance Tests for new machines. Today, SOMIC America has seven service technicians throughout the U.S. and a full support staff in Eagan.”

Driving this growth is SOMIC’s ability to provide a nearly endless array of retail-ready packaging options, with the tray-and-hood being prevalent choices and a key factor in dairy packaging. “SOMIC America has launched an equipment methodology built on our 424 machine platform, incorporating an internal modular design, based on functional groups common to case-packing applications,” Fox explains. “These functional groups can be mixed and matched to satisfy a wide variety of end-ofline packaging needs. From standard wraparound case-packing to trayand-hood retail-ready case-packing and everything in between, SOMIC focused on providing a specific machine that could provide both on this versatile platform.”

Based on the engineering of both electrical and mechanical systems, mechatronics (also known as mechatronic engineering) combines robotics, electronics, computer, telecommunications, systems, control, and product engineering to produce a design solution. SOMIC embraced

the opportunity to combine advanced computer technology with the mechanical requirements for its end-of-line case-packing systems.

“Leveraging computer hardware and significant software developments have provided us with the tools necessary to minimize the mechanical components required in a flexible, multifunctional 424 case-packing/ platform,” Fox says. “Launched in 2010, the platform has been the key driver behind SOMIC’s growth in Europe and around the world. Combined with our plug and play functional groups, all within a compact frame, this configuration brings it all together to meet our customers’ varied retail-ready packaging format requirements.”

The mechanical equation to the 424 primarily includes a decentralized servo motor control that provides both precision and programmable motion, controlled through a Human Machine Interface (HMI). “In the dairy industry, many of the cheese packages contain ‘living’ products that vary in size and shape, which increases the need for a precision machine to be able to handle the variations,” Fox explains. “The mechatronic structure of the SOMIC 424 offers these advantages.”

The ability to provide customized solutions is essential in today’s fastpaced production arena. That’s why SOMIC America offers the SOMIC 424 with the Rockwell Automation platform. This is a customized solution for North America, since the standard control platform of the SOMIC 424 is a Schneider-Elau decentralized system, Fox points out. “SOMIC is driven to be a dominant player in this market. In order for us to achieve this goal, a secondary Rockwell platform was required.”

Adapting the Rockwell platform was a team effort, Fox reports. “We worked closely with Rockwell to develop a platform in which we could operate the 424 in the same fashion as our Schneider platform. The look and feel had to be the same. It was an arduous effort, but the result was well worth it. Furthermore, it was a learning experience for both the SOMIC controls group and the Rockwell team.”

Fox says that SOMIC describes its customized machines as uniquely configured standards. “All of our customers want to provide a unique format to the market, and this is especially true when it comes to retail-ready. Our customers are looking for a non-commodity solution – a competitive advantage. Many of these formats are developed by our customers, which we tweak to perform in a production environment. We allow our customers to determine what package is best for their market – and we have the flexibility to run it on the 424.” The compact 424 T2(D) machine configuration was developed specifically for the U.S. market because it can run retail-ready packages (tray and cover) as well as standard wraparound corrugated cases, he says. “Like the other 424 models, the T2(D) also provides long-term flexibility for forward-thinking customers.”

The debut of the larger-capacity SOMIC-Flexx III, introduced to North America in 2018, proved to be overwhelmingly positive. A new dimension in the SOMIC lineup that provides maximum flexibility for a wide variety of formats, the SOMIC-Flexx III is a large footprint machine created to address requests from retail chains looking for upright, two-part corrugated packaging. “The SOMIC-Flex III is intended to take multi-purpose, retail-ready packaging machinery to the next level,” Fox says. The system packs primary containers in a flat, nested position and in standing display orientation. It also functions with both single and multi-component packaging.

To stay on the cutting edge of the latest dairy packaging technologies, SOMIC America continues to develop new format configurations for dairy producers, and especially for the cheese business, Fox sums up. “Our customers continue to work toward the optimization of retail-ready formats and see this as a competitive advantage in the marketplace. Our European experience with retail-ready, especially the trayand-hood designs, puts SOMIC miles ahead of our competitors in the U.S.”

Learn more about SOMIC’s systems by visiting somic.us.

500 Lone Oak Road Suite #200 Eagan, MN 55121 1.847.915.9872 / somic.us

First Lastname Title 12345 Address St. City, ST 12345

Save time and floor space with the SOMIC ReadyPack. A reduced size, simple design, and fast availability make it a smart choice for standard case and packaging tasks. It can be preconfigured as both a tray packer and a wraparound packer, and upgraded as your needs change over time. These features, and more, make the SOMIC ReadyPack an excellent investment now and in the future.

To see how SOMIC can bring new efficiencies to your endof-line packaging, call +1.847.915.9872 or visit Somic.us.

You don’t need a big and complex machine to get better results.