Face The Future With Adaptable Automation

Reduced size, simple design, and fast availability make SOMIC a smart choice for meeting increased demands in today’s tight labor market. It can be preconfigured as both a tray packer and a wraparound packer, and upgraded as your needs change over time, bringing maximum flexibility to your Retail-Ready Packaging production. SOMIC machines will deliver consistently strong results today, tomorrow, and long into the future.

Learn more about SOMIC by calling 1.847.915.9872 or visit SOMIC.US. Follow SOMIC Packaging on Linkedin for the latest news about our machinery and our company.

PACK EXPO was a Fantastic event.

machines, followed by revealing how many installations

In our last issue, I wrote that I was anticipating an active and lively show at PACK EXPO Chicago. Not only did it turn out to be true, but the end result exceeded my expectations.

The four-day event opened on Sunday morning and despite it being a gorgeous late October day, neither the warm weather nor a full slate of NFL games could deter the crowd.

I don’t recall a minute when any of us were not engaged in a conversation with someone visiting our booth. I fully intended on walking through the other buildings at McCormick Place to see what equipment was on display. It had been four years since the last time I could do so, but I never had the chance. We were that busy.

Even though it requires hundreds of hours to prepare for a trade show like PACK EXPO, I love everything about it. You won’t find a better environment to be with people, talk about the type of equipment

SOMIC produces, and explain how it can improve someone’s current packaging situation.

Considering the state of the Packaging industry, I wasn’t surprised by the size of the crowd. Every report I read supports what I’ve been watching take place from coastto-coast. Let’s look at the Flexible Packaging market as an example.

Evaluated at $202 billion in 2020, it is projected to grow at a compound annual growth rate (CAGR) of 4%, with a market value of $267 billion by 2027. Several factors are driving the growth.

Our lives have become busier and more people are making food choices that involve packaging for small or single-size servings. The Flexible Packaging Association touts their packaging as less expensive and requiring 35% less storage space. That translates to being more costeffective because it contributes to supply chain efficiency and reduces transportation costs.

The same holds true for Corrugated Packaging. Growing CAGR at a similar percentage, this market is forecast to reach $380 billion in 2023.

So I wasn’t surprised with the conversations our team had in the booth. The top request was to explain the changeovers on our machines, followed by revealing how many installations we have in the U.S. The answer is 180, and I expect to reach 200 in the first half of 2023. The only surprise was how many first-time visitors found their way to the booth.

Retail-Ready Magazine is published by SOMIC Packaging, focusing on the Retail-Ready industry.

Based in Eagan, MN, SOMIC Packaging manufactures advanced mechatronic case-packing systems that collate, unitize and load cartons, trays, retail-ready packages, and wraparound cases.

See how SOMIC can bring new efficiencies to your packaging line.

Whether you attended PACK EXPO Chicago or not, there are two equipment-related stories in this issue that not only provide interesting perspectives and advice from SOMIC experts, but address many questions.

If you are in the process of determining which automated, endof-line packaging machine to choose for your facility, read the story about how SOMIC machines are built to be operator friendly and streamline production. It explains how our software technologies help make the process run smoothly and deliver high quality.

If you are just beginning to look at what’s available on the market, I recommend reading the story on how to customize a machine for case packing or cartoning. It talks about how we’ve removed complexity from a typically difficult equation and replaced it with simplicity.

Our sales team is here to assist and guide you through this process. We profile two of its newest members, Rosann Bagin and Stacy Schmeiser. This should provide a better idea of the 50-plus years of experience they bring to the table and what they can do to help you.

On a final note, I wish you the best of the holiday season and a happy new year. See you in 2023.

Respectfully,

Peter Fox, Chief Executive Officer

500 Lone Oak Road Suite #200 Eagan, MN 55121

+1.651.419.6050 somic-packaging.com p.fox@somic.us

Follow us on Linkedin for updated material and conversations.

I can’t wait for the next one.

“The top question was to explain the changeovers on our

we have in the U.S.”

Stacy Schmeiser Brings

Valued Packaging Sales Experience to SOMIC

Whenever a winning sports team is looking for an edge during the late stages of a season, they acquire veteran leadership to help propel them for a championship run. With business booming, that’s what SOMIC has done by adding Stacy Schmeiser as the new Western Regional Sales Manager.

With 30 years of qualified experience, he is making an immediate impact and assembling the building blocks for future success. Based in Phoenix, Stacy has carved out a unique path and was in the booth at PACK EXPO.

Originally trained in engineering, Stacy soon learned upon graduating from college that he had a knack and style suitable for a sales career. He attended the school of Industrial Technology, Engineering, and Management at the University of Wisconsin-Stout, cross-training with machine materials and understanding the mechanical aspects. He graduated in 1993 with a Bachelor of Science degree in Packaging Engineering.

“At my first job, I accompanied Sales representatives on customer calls and assisted with the presentations,” he recalled. “My manager at the time told me I had a presence and confidence in dealing with people, and that I should look at a career in sales utilizing my engineering background. From the moment after he promoted me to a sales position, I haven’t looked back.”

It was during this four-year run with the Packaging Group of Menasha Corporation that Stacy was promoted, moved to Arizona, and started to make his mark. He gained confidence by growing new business. Wanting to move into the capital equipment landscape, he accepted a larger role as an OEM sales executive at Videojet Technologies where he was responsible for managing the western U.S.

“I have resided in Arizona since 1997. I was born in Seattle and at the time, my father was in the Marine Corps. We often moved all over the western U.S. including California, Hawaii, and Washington,” he explained. “When my father retired from the military after 25 years, we moved to Wisconsin where I went to high school and the university in Stout.

“My background in the production identification industry since 2008 has been in selling various value-added technologies related to packaging production lines,” he added. “This broad experience helps me identify and qualify projects with quality organizations, and also allows me to be a more valued consultative asset to my customer base.”

Prior to joining SOMIC, Stacy worked at Syntegon, formerly known as BOSCH/Kliklok Woodman. He sold high-speed secondary and tertiary equipment including cartoners, formers and closers, and case packers.

“My strengths rest with a technical aptitude, in multitasking projects, relationship development and having the drive to succeed. Having an engineering background affords me the technical insight and aptitude to convey the technical nuances of the equipment I’m selling.

“I was looking for a dynamic company with superior technology and a strong reputation in the marketplace. After meeting with Peter Fox and the team in Minnesota and learning more about what they have to offer customers, I was convinced SOMIC was my future. My immediate goals are to develop a strong pipeline of projects and gain market share with some strategic wins.”

“I was looking for a dynamic company with superior technology and a strong reputation in the marketplace.”

Rosann Bagin Adds Passion and Sales Success to the SOMIC Team

The Green Bay Packers Hall Of Fame coach Vince Lombardi placed a high value on the team concept. He once said, “Individual commitment to a group effort: that is what makes a team work, a company work, a society work, a civilization work.”

The quote has resonated with Rosann Bagin throughout her career. An outstanding sales professional who also devotes time to a remarkable organization in her community, she is SOMIC Packaging’s new Midwest Regional Sales Manager.

It’s the first time our company has Sales representation from coastto-coast. Based near Milwaukee, Rosann joins Ryan Schumacher who handles the Eastern region, and Stacy Schmeiser who manages the Western U.S.

Rosann has over three decades of experience in the packaging industry, and finds the right valueadded automated solutions to solve customers’ challenges. Representing SOMIC provides her with the ultimate tools to continue her success.

While working at Briggs & Stratton, she attended Alverno College in Milwaukee and graduated with a degree in Business Management and Professional Communications. Rosann’s initiation into the packaging industry began with Hayssen where she was a sales representative. After doubling sales in the Northwestern U.S., her next responsibility was for West coast sales of the snack food and bakery division.

Being new to the packaging industry, Rosann recalled a rather extraordinary statement. “I was told the Packaging industry is unique and once you become part of it, it will be in your blood,” she explained. “The statement turned out to be true. Between the unending products, the projects to complete and the

advancements in technology, I find there is always a reason to be enthusiastic about what I do.”

She has found the most satisfaction in providing complex secondary packaging solutions.

“My experience in both primary and secondary packaging provides me with a unique perspective to view projects outside the box,” said Rosann. She has built an impressive client list over the years that includes many Fortune 500 companies. In her most recent position as a member of the Aagard team, she contributed to the significant growth of the company.

But it was more than just the equipment that convinced her to join SOMIC Packaging.

“An opportunity presented itself where I could join a team that has a passion for solving customers’ challenges,” she remarked.

“I now have the honor to represent a packaging company that values customer partnerships while providing innovative package designs and solutions for customers who need to automate their operations. SOMIC is more than a machine manufacturer. We aim to fulfill a long-standing consulting partnership based on mutual trust and customer goals. This made for a perfect fit.”

Rosann’s commitments extend far beyond the sales world. Along with her family, she dedicates time to volunteering for a cause near and dear to her heart, Special Spaces. The national organization creates dream bedroom makeovers for dependent children ages 2-19 who have cancer and are within one year of treatment.

“Our goal at Special Spaces Wisconsin is to provide the kids with a safe place to recover, heal, sleep and play. And make it a very special space just to be a kid.”

"I find there is always a reason to be enthusiastic about what I do.”

A triumphant return to PACK EXPO Chicago

PACK EXPO Chicago was held at McCormick Place for the first time since 2018 and the pent-up demand was evident. Show management reported over 44,000 people attended the four-day show that was held October 23-26. Most of the time, the overpasses linking the North and South convention halls with the West pavilion – and where our booth was located in the Lakeside building – resembled a Chicago expressway during rush hour. Many of those attendees gravitated to our booth.

Maybe it was the colorful video board on display at the top of our booth that caught people’s attention. It ran non-stop, demonstrating the capabilities of our equipment. You could see it from half a football field away. Or maybe it was because the Packaging industry landscape has changed dramatically over the past four years, and attendees recognize SOMIC as a leading source for the innovations they seek.

“The

Peter Fox, Chief Executive Officer for SOMIC

SOMIC Innovations Match The Energy Of This Growing Industry

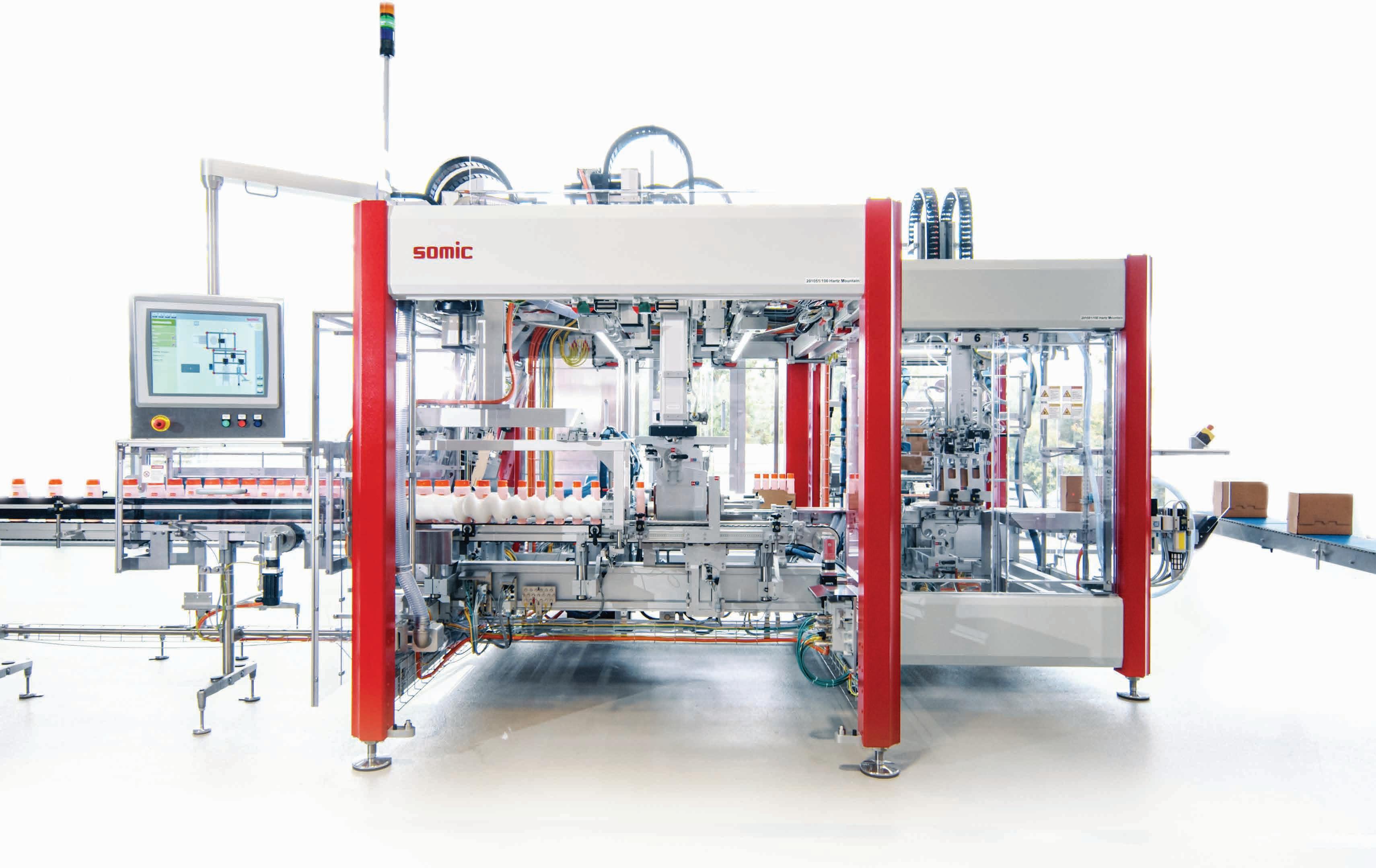

According to PMMI’s State of the Industry U.S. Packaging Machine report, the Packaging machinery market grew 40% from $10.8 billion in 2019 to over $15 billion in 2022. This remarkable growth brought an invigorating energy to the show. At times, every member of our team was engaged in a conversation with visitors and others were waiting their turn to learn more. We demonstrated an automated 424 W-3 case packer system and it generated a significant amount of interest and questions.

Our shelf display was another center of attention. People learned that SOMIC machines can accommodate nearly any size package, and do so affordably at varying speeds and with a small, space-saving footprint. Mark your calendars now and plan on joining us September 11-13, 2023 for PACK EXPO Las Vegas. You won’t want to miss visiting with us at this show.

Wraparound Packer SOMIC 424 W3 for single-component packaging

Produces up to 25 cases per minute Simple. You won't find a more efficient automated case packaging system. Smooth. Our newest technology ensures consistent, trouble-free operation. Space-Saving. Make the most of your floor space with a compact footprint design that assures a user-friendly experience.

STREAMLINING PRODUCTION WITH OPERATOR-FRIENDLY PACKAGING EQUIPMENT

We know there is a lot of pressure on most production departments to deliver products within a strict timeframe. That’s why we encourage machine operators in the food packaging segment to become familiar with their end-of-line equipment and learn its finer points in order to achieve the best production line performance.

Barth Lothar, Director of International Sales at SOMIC, says the packaging process is just as important for smooth production on the line as case palletizing and product delivery.

“Packaging machinery must be operatorfriendly. We believe it should function intuitively to help food production lines perform reliably,” said Lothar. “We build automatic carton forming and packaging systems to handle the product gently. If the machine operator can easily use these systems, the better the workflow and the faster and smoother the throughput.”

He explained that line operators should have a say when it comes to equipment selection. “Our customers often buy more than once from us because the operating personnel are satisfied with the machines. When they try our equipment, they stay with SOMIC."

"We incorporate reliability and superior performance into each system we design."

Barth Lothar, Director of International Sales at SOMIC

Friendly format changes

Over the course of time, we have refined our commitment to streamlining end-of-line packaging equipment performance. Lothar said SOMIC’s software-based technologies work in tandem with the equipment to ensure consistent package quality.

“Line operators especially like the easy format changes on our machines. Changes must be simple to perform. In some cases, format changes on our machines can be handled using quick-change disconnects and locking systems, which eliminates production downtime. When we change the processing spectrum of our machines in the field, the simplest option is pre-programming. You can also set additional format parameters using our remote maintenance function.”

Customers who request different changeparts for an existing machine can install them via SOMIC’s QuickChange system, which requires no tooling. Easy-open format change levers are manually released by the operator, who securely inserts a new part and locks the levers. A red/ green signal incorporated within the machine’s digital position controls indicates whether the adjustment positions are correct and if the format change is complete.

For more complex changes, Lothar said a SOMIC project manager is available to fully supervise and support comprehensive machine commissions.

“When a full conversion is required, our retrofitting department can be there to guide the project from start to finish. Our highly experienced mechanical engineers are trained specifically for making adjustments to sophisticated case-packing equipment, for retrofits, and for expanded formats. We manufacture the changeparts according to customer directives and communicate with the customer throughout the process, even if they integrate the parts into the line themselves.”

Lothar also said that new changeparts aren’t always required for a retrofit, but it depends on the application.

“Using our documentation, we determine exactly which assemblies may be affected by a change. For example, if a customer wants to start case-packing or cartoning a new product grouping, everything may still fit well on the lamella chain conveyor but a change may be needed on the machine’s push-off comb device or on the carton feeder. We consider the processed carton spectrum and all of the guides in relation to each product/package format, so the machine has the flexibility the customer needs.”

Convenience and Case Blank Reloading/Carton Forming Capability

SOMIC’s series of end-of-line packaging machines feature an easyto-use Human Machine Interface (HMI) on the control panel. Lothar said it provides intuitive preset sequences and menu navigation for stored package dimensions and format parts settings.

“We can remotely connect to the machine’s control panel in maintenance mode and update the program’s product and carton presentation formats.”

The operating controls also feature a graphic display of the production process. Standard tasks can be learned and executed quickly with the help of the HMI display, and operators can readily access production logs on the display screen. Text displays in the local language ensure that operators understand everything necessary to run the machine.

"The operating panels are equipped with 20 different languages that accommodate customers located in a wide range of countries," points out Lothar. "This is standard on all SOMIC equipment.”

Daily operation in a production plant also requires re-feeding the carton blank magazine with a fresh batch of new cartons. Depending on the machine model, magazine belt length, and carton thickness, the magazines on SOMIC machines can hold from 400 to more than 1,000

carton blanks. This is sufficient for at least 30 minutes or more of running time.

Because most line operators don’t have time to constantly watch cartons move through a magazine, a light indicator and the HMI display alert operators when the magazine is slowly emptying. Optional powerful LED lights can also be provided to visually signal the various operating states, even at a great distance.

SOMIC machines also can provide options for the carton-forming sequence, including an integrated indicator that checks when the carton contains the proper number of products. The product count is displayed on the operator panel and by the outfeed checkweigher. Optical sensors can also check the contour of the product-filled carton, immediately alerting operating personnel if something is wrong.

A good working relationship

Lothar says each packaging plant employee has different functions and requirements when contributing to the packaging process. SOMIC equipment offers the option of creating and managing user groups on the operator panel. Individual authorizations can be stored for each machine user, allowing users to handle their respective assigned actions.

"This is part of our standard. The equipment features statistical functions that check operating production times and raw material consumption, and efficiency evaluations are also available. Customers often want this data, which helps us as we evaluate and develop new equipment," he remarked. He indicated that SOMIC is constantly innovating with these and other equipment solutions to streamline customer workflows and extend equipment life.

“We want to provide our customers with machines they can work with and depend on. We incorporate reliability and superior performance into each system we design. That is part of our commitment to the food, pharmaceutical, and other industries we’ve served for more than 45 years.”

EQUIPMENT OPTIONS:

• Case erector

• Product loading system

• Tape or glue system to close the box

• Conveyor systems to connect all this equipment together

Selecting a case-packing or cartoning machine to improve your production line can be challenging. Depending on your product and process, it requires careful planning, communication, and cooperation. That's why it is essential to research these machines for the best results and understand all tasks involved when evaluating equipment that will suit your product and production line. We understand and design our caseand carton-packing systems to work optimally with the product, package, and production line in mind.

“We start at the user's site and their precisely defined packaging system requirements,” notes Josef Bliemel, Director of Systems Engineering at SOMIC. “Our goal is to leave nothing to chance. A few important considerations the customer should think about include:

At what speeds should the equipment be able to run?

What are the important performance characteristics, safety features and accuracies they want?

What are their space requirements, and the number of product/package changeovers the new equipment should accommodate?”

A machinery inventor, Bliemel has filed numerous SOMIC machine patents.

He said there are some key points to consider when ordering a new end-ofline packaging system.

Continue on page 14

THE KEY FACTORS DEFINING YOUR PACKAGING SYSTEM REQUIREMENTS:

• At what speeds should the equipment be able to run?

• What are the important performance characteristics, safety features and accuracies desired?

• What are the facility space requirements?

• What are the number of product/ package changeovers the new equipment should accommodate?

• What are the case or carton blank specifications?

• What are the packaging materials' thickness, style, and other configuration details?

• How will the package be handled, folded, and erected?

• How will it be loaded and closed?

• What is the carton feeding behavior into and out of the machine?

“Our goal is to find what’s right for each customer’s specifications.”Josef Bliemel, Director of Systems Engineering at SOMIC

“We start with the case or carton blank specifications, examining every one very closely, evaluating the packaging material, its thickness, style, and other configuration details. We also look at how the package will be handled, folded, and erected, where the folding tabs should be positioned, and how it will be loaded, and closed. Next, we evaluate the carton feeding behavior into and out of the machine.”

Optimal Variant Choices

Purchasing packaging machinery is a substantial investment for most businesses. It’s why SOMIC's project specialists jointly consult with the customer to finalize the wish list before preparing the machine. Requirements are determined for all carton/case dimensions. Many factors are considered, such as the proper sealing adhesive placement, how many different product groupings could go inside the package, and others before a 3D construction model is created and prototypes are tested.

"Only an optimally-designed carton will allow the machine to function at peak efficiency,” says Bliemel, pointing to an example of a recent dairy application. SOMIC optimized the cartoning process for a product without compromising the quality of the intricate carton design. "We often create carton samples on our board plotter to test how the package will behave inside a machine. It's always easier to hold a sample in your hand and test it."

Discussing the development of the package with SOMIC's project engineers, the dairy raised questions about operating costs, maintenance considerations, unplanned production downtime, and much more before a variant was finally approved.

“Like other customers, the dairy approached the initial machine design with the future in mind, so we took a large format margin into account,” Bliemel points out. "Equipment investors should also remember to ask about operator friendliness and possible unplanned production downtime."

He further explained how SOMIC uses these and many other points, customer requests, regulations, and

standards when building suitable case-packing or cartoning systems.

“We adjust for these factors as needed,” he continues. “We build the machine to also help streamline package palletizing, shipping and handling, and product presentation at retail. Every machine design and application is different. Our goal is to find what’s right for each customer’s specifications.”

Factory Acceptance Testing and other Helpful Solutions

After the machine order is assembled, clarified and placed, the next in-depth collaboration between SOMIC and the customer is an extensive Factory Acceptance Test (FAT). "We conduct this test at our plant before delivering the machine,” said Bliemel. “All U.S. FATs are now conducted at our facility in Minnesota.”

SOMIC can also arrange for an online FAT if the customer cannot be present. Such online communication was handy during the difficult travel regulations in the last two COVID-19 pandemic years. Depending on customer requests, a FAT usually takes one or two days. Our personnel and the customer closely inspect the machine together under real production conditions with the actual products to be packaged.

After commissioning, the machine is shipped to the customer’s production facility. The installation process typically takes three to 10 days, depending on the system's complexity. After installation, we provide operator training on all procedures, from switching on the machine and reloading the carton blanks to changing the format parts. Making part changes is explained in detail and demonstrated to the machine operators.

“As with the equipment evaluations pre-purchase, it’s wise to have plenty of questions ready at this time,” says Bliemel. “We specifically address any and all employees’ questions.”

He explained how the SOMIC team also presents operators with images or animated graphics to easier understand the process. The easyto-use Human Machine Interface (HMI) provides relevant information, such as the intervals between

maintenance tasks, which operators can quickly access. There is also a plan recommending machine maintenance.

The operating panel stores all product format-change programs for quickly made minor changes. The touchscreen incorporates stepby-step information with easy-toread numbering (see changeparts explanation in the related article in this issue).

“Operators can use the instructions to create a precise sequence plan and make quick changes when installing a new part,” said Bliemel. “This is handy, as food manufacturers must respond quickly to changes in the marketplace and consumer demands for additional package formats.”

We also assist plant personnel and machine operators after the machine begins running at the plant. Quick support is available for fault diagnostics and remote maintenance. In addition, the customer can call in our equipment specialists to provide any further customer assistance.

“Remote support works in about 80 percent of the cases,” Bliemel added. “To maintain IT security, we offer customer-specific access requirements for remote maintenance.”

Our after-sales team also assists with any additional changes. If a new format calls for a more significant machine retrofit, the Retrofit Team will produce new changeparts the customer or SOMIC personnel can easily install if needed.

“Collaborating not only benefits our customer, but it also improves our machines’ performance and our services,” Bliemel summed up. “It also helps reduce customer costs, streamline our design and ordering processes, and inspire us to design more machine innovations.”

Begin the buying process with the SOMIC Packaging Buyer’s Guide. Download the PDF.

“Collaborating not only benefits our customer, but it also improves our machines’ performance and our services.”Josef Bliemel, Director of Systems Engineering at SOMIC

500 Lone Oak Road Suite #200 Eagan, MN 55121 1.847.915.9872 somic-packaging.com

Your search for the right equipment begins with this guide.

Download the SOMIC Buyer’s Guide. Purchasing packaging machines is a big investment. We want to ensure that you have everything you need to make the best decision. We’ve created a Buyer’s Guide to help you identify the most important criteria for selecting the right end-of-line equipment. It also contains information about your available options.

Learn more by calling 1.847.915.9872 or visit somic-packaging.com.