ii

C aring for S hip M odel S

Also by Rob Napier

Reconditioning an Eighteenth-Century Ship Model: ValkeniSSe, Retourschip of 1717

Legacy of a Ship Model: Examining HMS prinCeSS royal of 1773

Caring for S hip M odel S

A Narrative of Thought and Application

by Rob Napier

© 2022 by Rob Napier. All rights reserved.

No part of this book may be reproduced in any form without written permission from the publisher.

Published and Distributed by:

SeaWatch Books LLC

2040 Milburn Ave, Suite 102 #109 Maplewood, NJ 07040

web: www.seawatchbooks.com

e-mail: info@seawatchbooks.com

ISBN 979-8-9862370-0-8

Manufactured in the United States of America

First edition, first printing, 2022

This book was set in 11-point Adobe Caslon Pro.

Contents Case Study Roster vi Foreward by Grant Walker vii Part One: Prologue 3 Part Two: Perspectives on Ship Modeling 7 Focus on Compelling Impression: Blocks 10 Part Three: Practices and Applications 21 Focus on Dehydration 34 Part Four: Case Studies 57 Addendum 161 Epilogue 167 Acknowledgments 167 Notes 169 Sources 173 Index 181

Case Study Roster

vi

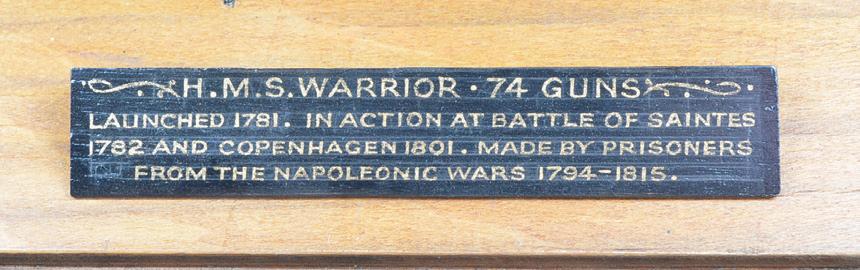

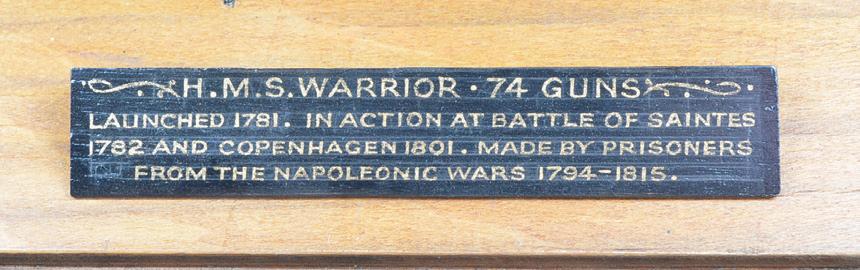

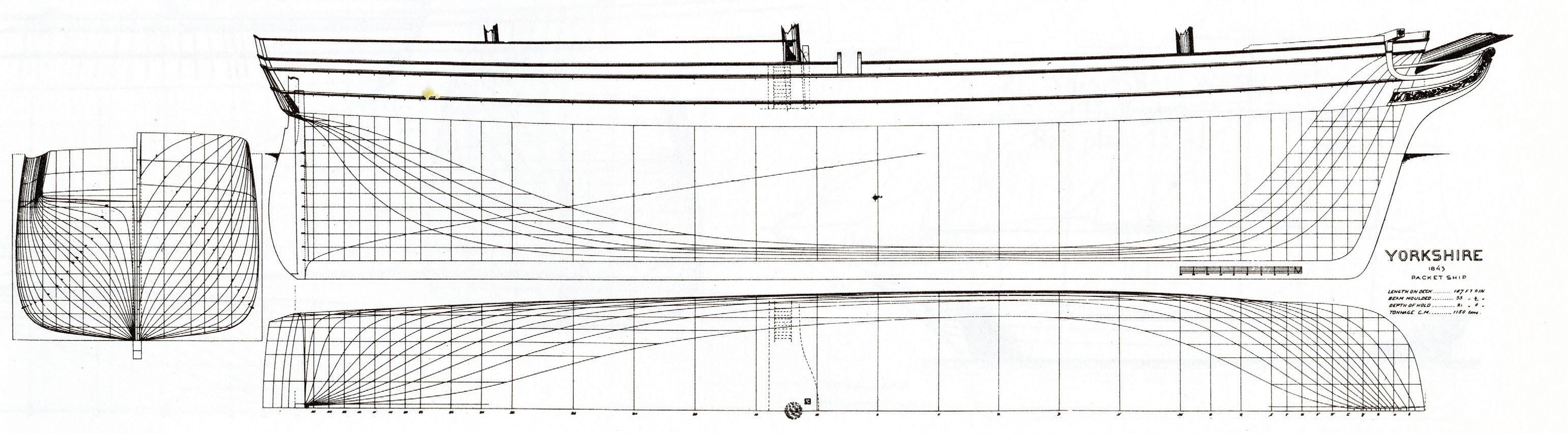

No. Vessel Name Vessel Type Date Page 1 Unidentified English fourth rate 1695 58 2 Valkenisse Dutch East Indiaman 1717 62 3 Princess Royal British second rate 1773 63 4 Warrior British third rate 1781 64 5 Constitution American frigate 1797 65 6 Unidentified French third rate about 1800 74 7 Unidentified French second rate about 1800 76 8 Andromeda British corvette 1810 81 9 Inez American merchant ship 1828 83 10 Yorkshire American packet ship 1843 86 11 Unidentified British steamship about 1865 90 12 Dunderberg American ironclad 1865 93 13 Unidentified American Down Easter about 1870 100 14 Belle American schooner yacht 1870 109 15 Panay American Down Easter 1877 110 16 Enterprise American cutter yacht 1878 114 17 Tioga American schooner yacht 1881 116 18 Corona American schooner yacht 1893 118 19 Roxana American houseboat yacht 1903 120 20 Doctor Saboia British hopper barge 1907 123 21 Unidentified American schooner yacht about 1910 124 22 Elena American schooner yacht 1911 127 23 Arizona American battleship 1916 136 24 Roseden British tramp 1918 137 25 Curacoa British light cruiser 1918 138 26 Helen Barnet Gring American merchant schooner 1919 148 27 Royal Scot British steamer 1930 149 28 Yare American sloop yacht 1936 150 29 Ocean Pearl American ketch yacht 1958 152

Foreword

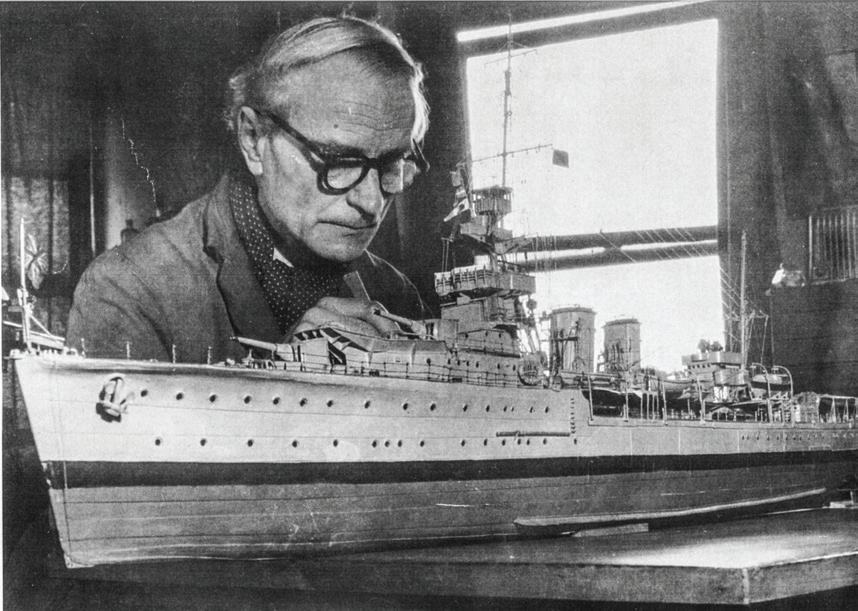

Rob Napier has been widely recognized for many years as one of the leading ship modelers in America. This book shows why, but not for the reasons I expected.

Back when I first met him in the late 1990s, I thought his reputation rested solely on the highly-prized models he had made for private owners and institutions from coast to coast. In fact, I believe I first heard about him from a local Annapolitan ship modeler-collector who invited me to his home to show off his new Rob Napier model. He was happy as a lark to have it, and it was easy to see why. Compared to the owner’s other models, this one was in a class of its own.

Later, even after I became aware of his project to refurbish the contemporary model of the Dutch East Indiaman Valkenisse of 1717 at the Museum of Fine Arts, Boston, I still thought of him as primarily a ship-model builder. He must have told me otherwise, but I still somehow saw his effort to return this timeworn model to its original appearance as an exception to his usual routine of scratch-building new models of ships and boats of all shapes and sizes. I wasn’t paying attention.

I got another glimpse of this side of Rob’s professional life the first time he gave me a private tour of the models on display in the New York Yacht Club. Until then, I had only the vaguest notion of the traditions of world-class racing yachts, and no idea whatsoever of the often-exquisite scale models that depict them. My eyes opened wide as he showed me one beautiful example after another, pointing out details that identified cer-

tain models as the work of specific modelers whom he revered. He also noted several examples of once-damaged models that he had restored to health in his role as caretaker of this unmatched collection. Aside from his infectious enthusiasm and jaw-dropping knowledge of even the tiniest details of these superb models, the thing I remember best was the respect he felt for the people who had built them with such loving care over the past one hundred and fifty years.

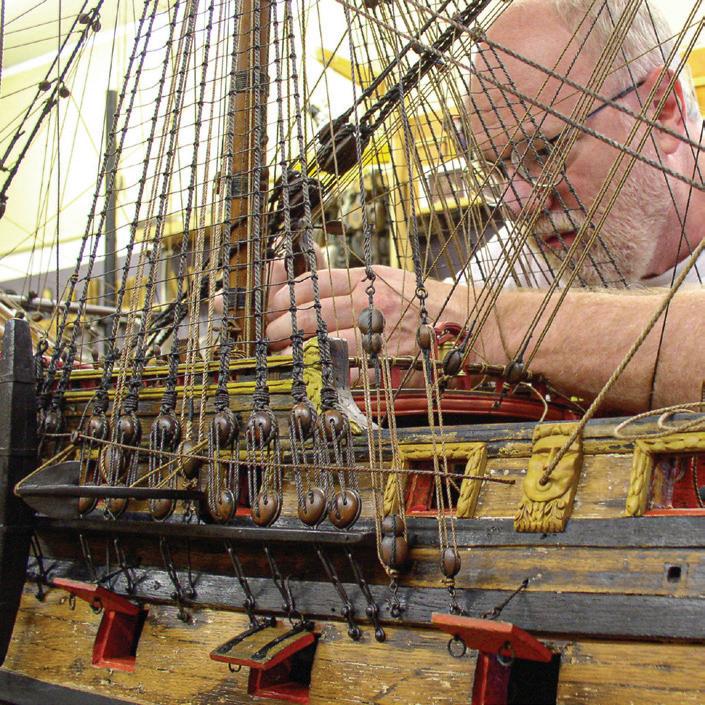

Our paths next crossed in 2004 after I noticed one day that, for no apparent reason, an ivory window sash had fallen out of the starboard quarter gallery of one of the U.S. Naval Academy Museum’s most striking dockyard models — the British three-decker Princess Royal of 1773 — and was lying on its baseboard. A few weeks later, a knee supporting an upper deck beam followed suit, coming to rest on the deck below. Concern became alarm when one end of the foremost quarterdeck beam came adrift, causing it to droop down ominously.

A look inside the model’s below-deck spaces with a surgical arthroscope revealed a shocking number of ledges, carlings, and other loose parts lying scattered about on the middle and lower gundecks. It seemed evident that, after two hundred and twenty-five years, the hide glue holding the thousands of joints together had dried out and was no longer adhesive. We had no idea when the problem started, but from the experience of the previous few months, it seemed to be getting worse. It was clear that if nothing were done to arrest the decay, this precious model would eventually fall into ruin.

Recognizing the enormity of the challenge, and with financial support provided by the Academy’s Class of 1951, we agreed to approach the world’s leading professional model makers with a job offer to save the Princess Royal. The person at the top of the list was Rob Napier, and when we contacted him, he jumped at the chance.

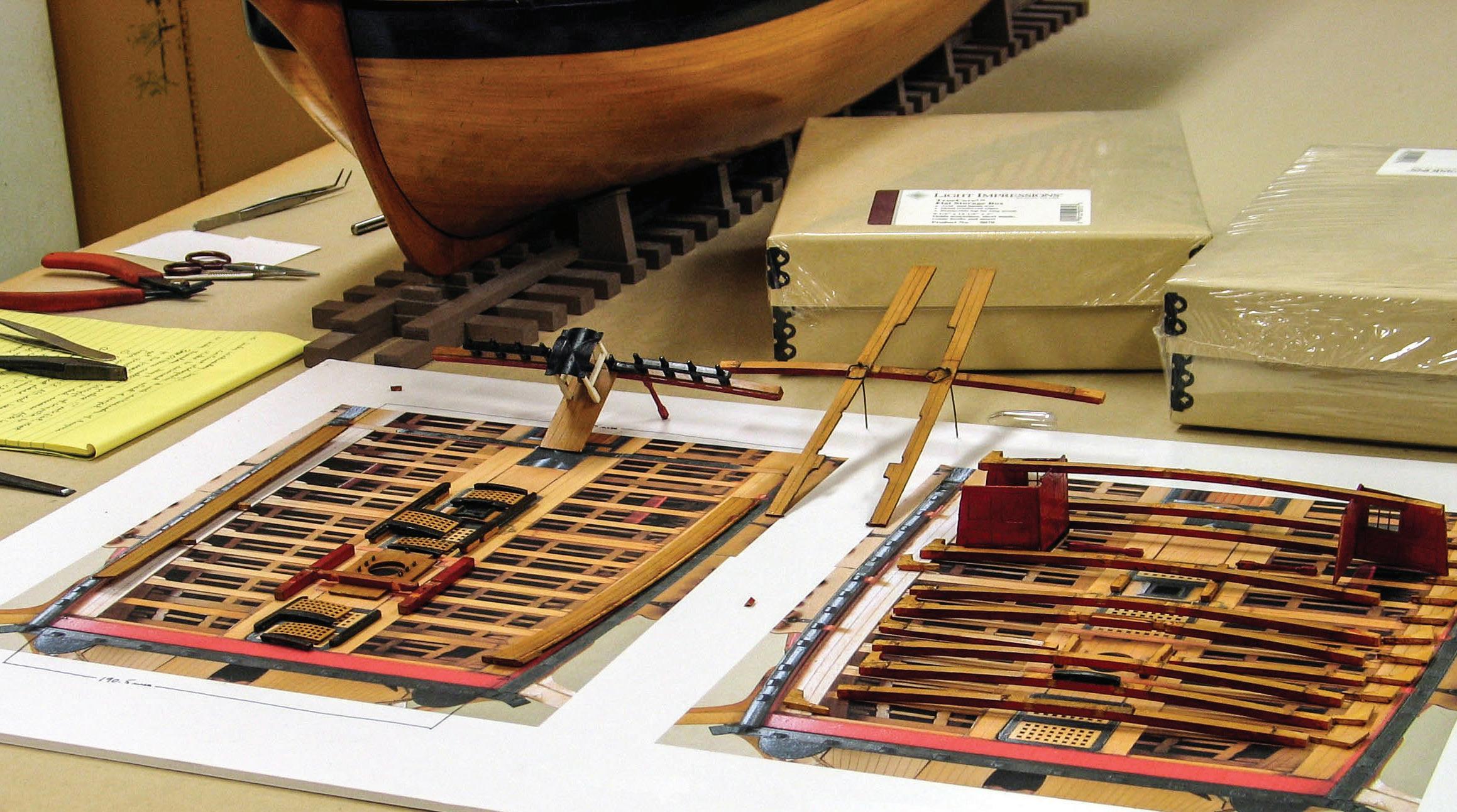

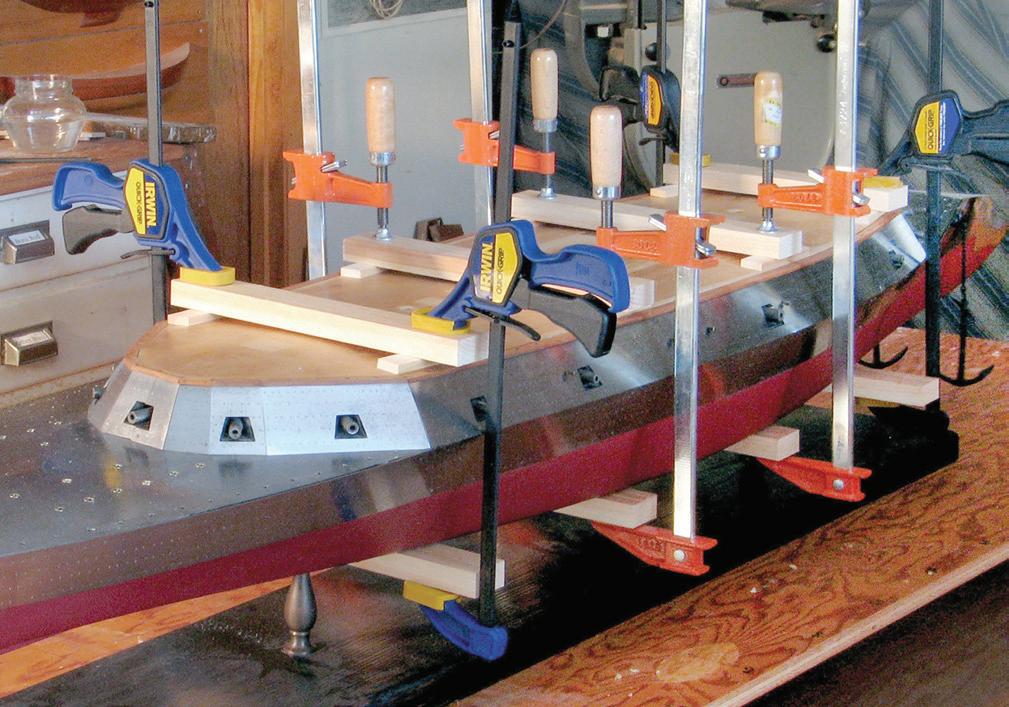

I won’t soon forget watching him in action when he came to the Academy to dismantle the model before transporting it back to his home in Newburyport, Massachusetts. His solution to keeping track of its more than three thousand parts — memory boards — was, in a word, brilliant, a remarkably simple but effective method he explains in detail in this book’s Part Three, Practices and Applications.

I was fortunate to visit him several times during the seventeen months Princess Royal was in his possession. Each time, he eagerly showed me what he was doing and explained what he was planning next to address the model’s many issues. But whatever stage he was in, he assured me that foremost among his goals was always to respect the intentions of the model’s anonymous builder(s). When he returned the refurbished Princess Royal to Annapolis, the once-ailing model looked fresh and alive, appearing like its maker(s) intended when it was brand new.

After that, I at last began to see how important his work on tattered models made by other modelers has been to him, and what a large part doing so has played

in his life. Yet it is only now, having read this fascinating narrative of his five decades as a professional modelwright (a term he coined), that I see the enormous span of his work, and the remarkable intellectual and mechanical skills he has consistently brought to realizing the vision of other modelers from times past.

In his lifetime of refurbishing fine models of every type and description, he explains how he approaches every job with the same bedrock principles, namely: Always keep respect for the original modelwright’s vision foremost. Do not try to outdo or improve upon his work, even if you are capable of doing so. Instead, do your utmost to understand and replicate what he was trying to convey about a full-scale ship or boat, real or imagined. And when assessing a model’s “quality,” ask yourself if it yields a compelling impression of the vessel it depicts, and what its maker did to achieve it.

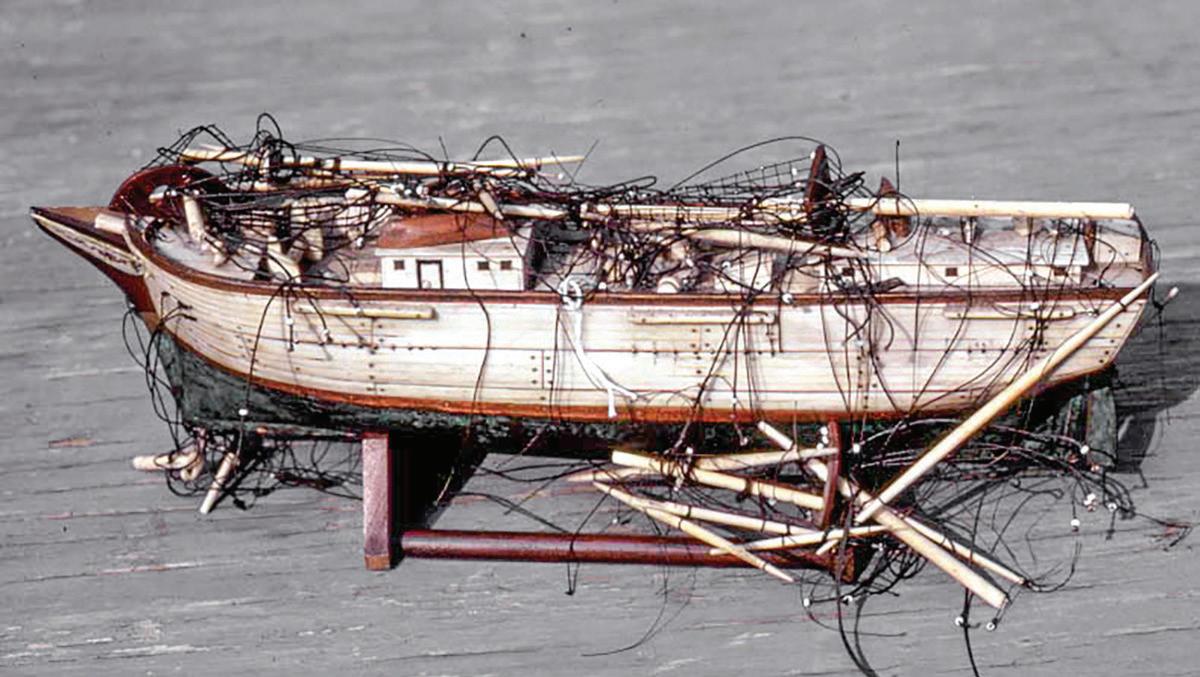

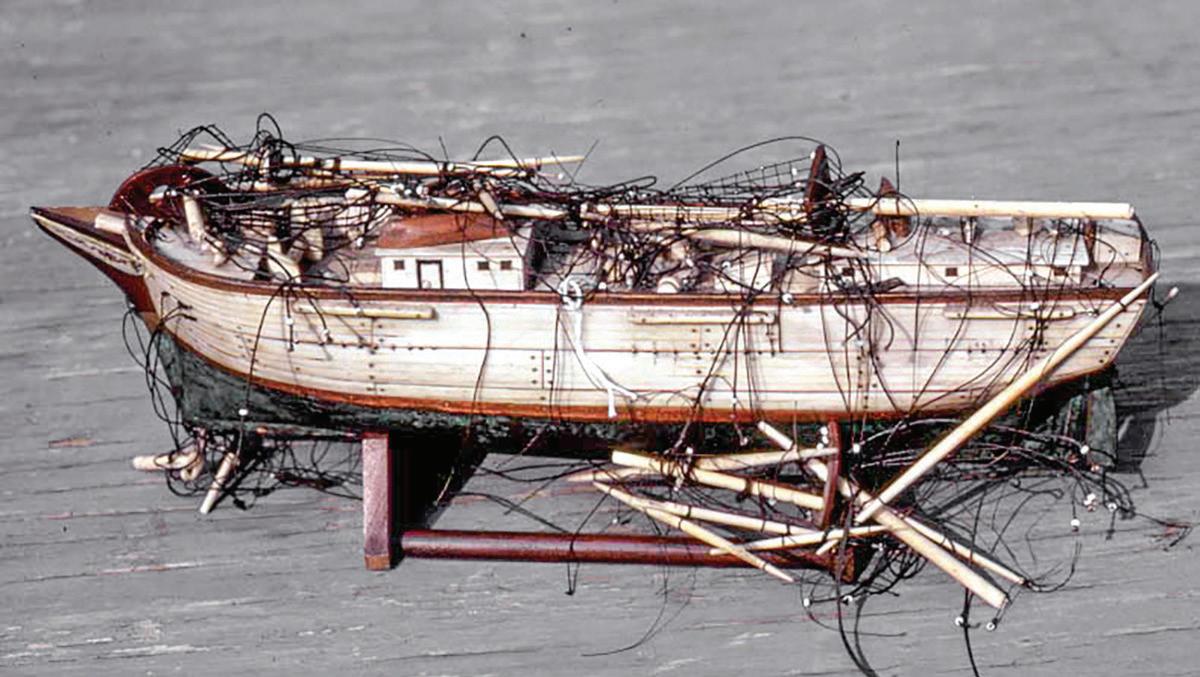

For me, reading anything Rob writes has always been a true delight. He has a dry wit that often comes through in his writing, such as the following caption he wrote for an illustration on page 21: “Infestation. Those items that look like spider webs and dead flies are spider webs and dead flies....”

On a more introspective note, I leave you with this eloquent observation from page 17: “The modeler who builds details no one will see is looking inward, toward his own motives for modeling. They are private, possibly even secret. He is having an assignation with his muse.” ¯

Grant Walker U.S. Naval Academy Museum, Annapolis

viii

C aring for S hip M odel S

Patience is only required for things you do not love.

— George Kaiser

Part One Prologue

Simply put, this book is about taking care of ship models. Most ship-modeling texts concern themselves with building new models. So, why am I, a life-long, full-time, ship-model professional, compelled to write about models that have already been built and that have deteriorated for one reason or another and to one degree or another? The answer is that ship-model repair, restoration, and conservation, which are distinct processes we will define in A Model Comes Through the Door in Part Two, are altogether different than building. Builders of new models tend to settle into niches that might be aligned with vessels of particular use, nationality, or era. Such builders tend to develop and occasionally perfect methods that yield the high-quality results they seek. But the person who accepts commissions to work on models built by others is forced to venture outside of his or her comfort zone.

There is a challenge in not knowing what will come through the door. Or, as the celebrated American painter Frederick Remington wrote, “The zest of the whole thing lies in not knowing the difficulties beforehand.”1 The point is that the variety and improvisational demands of repair work, especially repair work executed away from the home studio, keep the mind open.

There is a parallel in the yachting world. Many people enjoy recreational sailing. “There is nothing… half so much worth doing,” Water Rat raves in The Wind and the Willows, “as simply messing about in boats.”2 My guess, however, is that Water Rat and

his pals choose to mess about only in fine weather. If it’s too windy, too cold, too rainy, they likely stay indoors and have tea. But many sailors are driven to see how well they and their boats are able to perform in competition: they race. Racing teaches sailors to face conditions they might otherwise avoid in favor of tea or, perhaps, stronger waters. It is easy to sail in eight to twelve knots of breeze on a balmy afternoon. It is really hard to sail on a blistering day in a oneknot zephyr and make predictable headway against a contrary current. It is also risky to sail in twenty-five to thirty knots and be really safe. But the race committee fires the starting gun, and off you go, regardless. Many people disapprove of competitive learning environments, but the lessons are powerful: if you can make a sailboat perform in no wind, you are a pretty good sailor. And the reward is that you will know how to make your boat work when others don’t bother to go out.

If you want to broaden your maritime experience through the world of ship modeling, there is no better way than by accepting jobs on deteriorated models that were built by other people, in other periods, and of other traditions. Why? Because attending to the needs of other builders’ models is like learning to sail in a calm or a gale.

This project has been a long time coming. Believe it or not, my first outline for it dates to the early 1960s, when I was in high school. It was clear to me, even then, what I wanted to spend my life doing. But whenever I con-

sidered assembling a book like this, I stumbled because I wanted to include everything I knew, yet I always knew I had more to learn. I realized that I’d never learn everything I wanted to record and share, so the project languished. Repeatedly. Now, with five decades of notes in hand and my seventy-fifth birthday in the rear-view, it’s likely my experiences won’t be expanding much further. It’s now or never.

My first two books, Reconditioning an Eighteenth-Century Ship Model, ValkeniSSe, Retourschip of 1717, and Legacy of a Ship Model, Examining HMS prinCeSS royal 1773, were essentially expanded treatment reports. Each reviewed in perhaps excessive detail a substantial model project that I had done for a museum. Because they progressed more or less chronologically through a project, the books seemed to write themselves. This new book is more challenging because it offers a combination of opinions that require substantiation and experiences I think you will find interesting.

This book will, I hope, be of primary interest to two groups. The first embraces ship modelers who have built their own new models for themselves or paying clients but are considering doing repair work on models built by others. While these practitioners already know something about ships and models, they might not know about appropriate approaches to repair work, and no guide exists for this. The second group includes professional object conservators who work for non-maritime museums and other institutions that do not have a particular or broad focus on ship models but hold some in their collections. These folks are trained in the materials and processes necessary for properly caring for objects, but they may not know much about the details of how, for instance, rigging works. I have enough experience in both spheres to help the former understand something about applying conservation principles to ship models and to help the latter understand something about the maritime subjects they must occasionally address.

You are not experiencing déjà vu if some material included in the following pages seems familiar. I make no apologies for recalling content from earlier articles and editorials, mostly from my stint with the Nautical Research Journal. My explanation? Bob Friedman, publisher of my first two books, told me that getting ideas between hard covers increases their longevity.3 I cite where I’ve discussed topics earlier not out of hubris but so you may find further discussion.

I never wasn’t interested in ship models. A snapshot shows me at about seven repainting a toy dory. The last kit I built, Model Shipways’ Fair American, was complete before I finished high school in 1964.

That summer, a man watching me sail pond models at the beach where we summered on Cape Cod asked if I’d care to repair a decrepit model that had been collecting soot in his attic for years. “Yes,” I said. “Good,” he replied, “Send me a bill when you’re done.” I charged him $75, but his check was for $125. I returned it, noting: “You sent the wrong check.” He mailed it back, noting: “You sent the wrong bill.” This was my first paid job; I realized I might be on to something.

After two years at university, I enlisted in the U.S. Navy and served as a Navy journalist during two combat deployments to Vietnam aboard an attack aircraft carrier. When I separated in 1970, I wanted to continue life around the water on Cape Cod. Another fellow and I, sharing the dream of building wooden small craft, assumed the operation of a neighborhood boatyard. I realized quickly that full-size was the wrong scale for me and kept responding eagerly to folks who had old ship models that needed attention. I also found a ready market for new models. I left the boatyard to my partner and decided, in 1973, to do anything necessary to support myself with ship modeling.

By the end of the 1970s, I was writing modeling articles for the Nautical Research Journal and commuting annually from the Cape to maintain a large model collection at Forbes Trinchera Ranch in southern Colo-

4

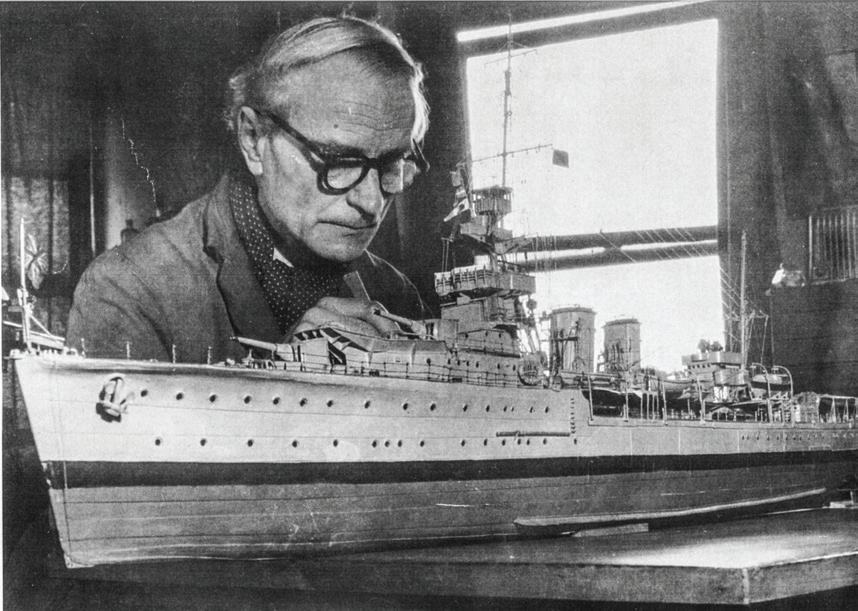

The earliest image of me working on a model made by someone else. It’s about 1953 and I’m about seven. (Photograph by Elisabeth Napier Ovans)

rado. The 1980s were spent amplifying what I’d begun. I relocated to Newburyport, Massachusetts, a community with a significant maritime heritage and better access to historical resources. In about 1990, I first worked at the Museum of Fine Arts, Boston, with academically trained conservators who dynamically reshaped how I thought about caring for ship models. During the 1990s, my schedule was filled with lecturing, emceeing national ship model conferences, judging national and regional ship model competitions, and, for five and half years, wielding the editor’s pencil of the Nautical Research Journal.

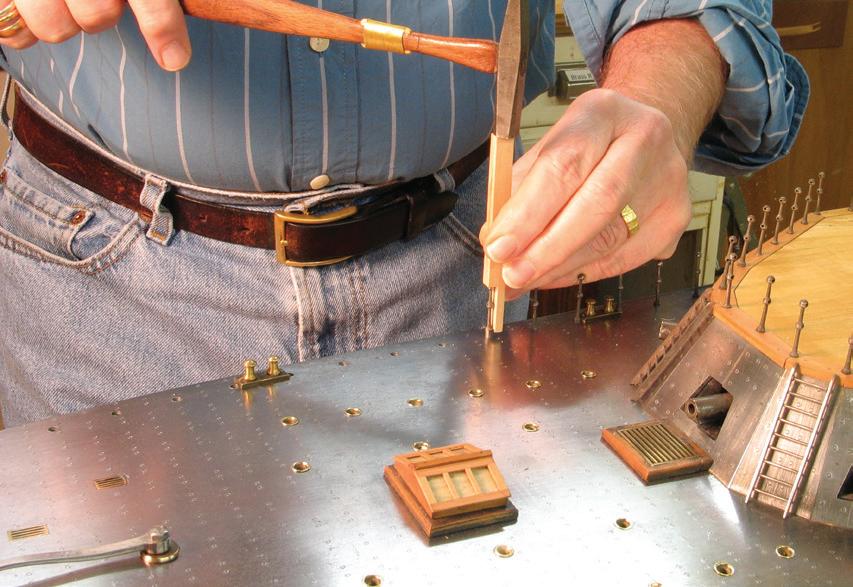

The new millennium brought new opportunities. I became lead modeler for the reinstallation of a historic collection of America’s Cup yacht models at the New York Yacht Club. That was followed by a trio of intense repair and conservation projects, each of which involved a single model and consumed more than a year’s time, for the Museum of Fine Arts, the United States Naval Academy Museum, Annapolis, and the New York Yacht Club. Several trips were made in 2008 to the Art Gallery of Ontario, Toronto, to assist with the preparation for exhibition of more than a hundred Thomson Collection models in a new gallery space designed by Frank Gehry. During this period, my first two books were published by SeaWatch Books. More recently, I was commissioned by the Mystic Seaport Museum and the Massachusetts Institute of Technology to make quality and condition, but not monetary, assessments of every model in their collections.

During the periods already highlighted, I was also engaged with hundreds of smaller building and repair projects. As of mid-April 2022, the log I keep of my work indicated that I have focused professional attention on about 3,100 models. Of these, I built 811 half-hull and 72 full-hull models; the rest, or about 2,220, were built by other modelers. I do not have a Web site, nor do I participate in any social media. With no sign on my studio door, I prefer appointments and discourage drop-ins. In almost fifty years,

I have never been without a backlog: Do I need a Web site?

In 1967, David MacAdam, an experienced trekker from my home on Cape Cod, and I were hiking in Mexico. An awkward tenderfoot, I was struggling to find a route for scrambling up and between huge, steep boulders. Not sure how to place my feet for best traction, I tried mimicking David’s every footfall, I the timid page to David’s King Wenceslas. After a while, he explained carefully that he was choosing a route for him, that I didn’t have to copy his steps, and that I should make what were literally step-bystep decisions for myself. 4 Thus, I learned there is more than one path to success.

Now, people new to ship modeling (and other, similar disciplines) seem to seek the one right way to address each component they must build or fix. But there is seldom a single, correct way. Even Queeg said there were “four ways of doing a thing aboard ship — the right way, the wrong way, the Navy way, and [his] way.”5 Maritime practices vary widely on vessels because of their eras; nationalities; regions of origin and cities within nations; size and use; and builders’, owners’, and masters’ individual preferences. And then there are traditions that defy codification. Model-building practices can vary nearly as broadly because of model design choices; builder experience levels; available materials and information; and so on. There is no single right method to construct a hull, to lay or clean a deck, to repair or belay a line.

All this is to say that, in the following, I restrict my narrative to the paths I have taken. You may elect to

5

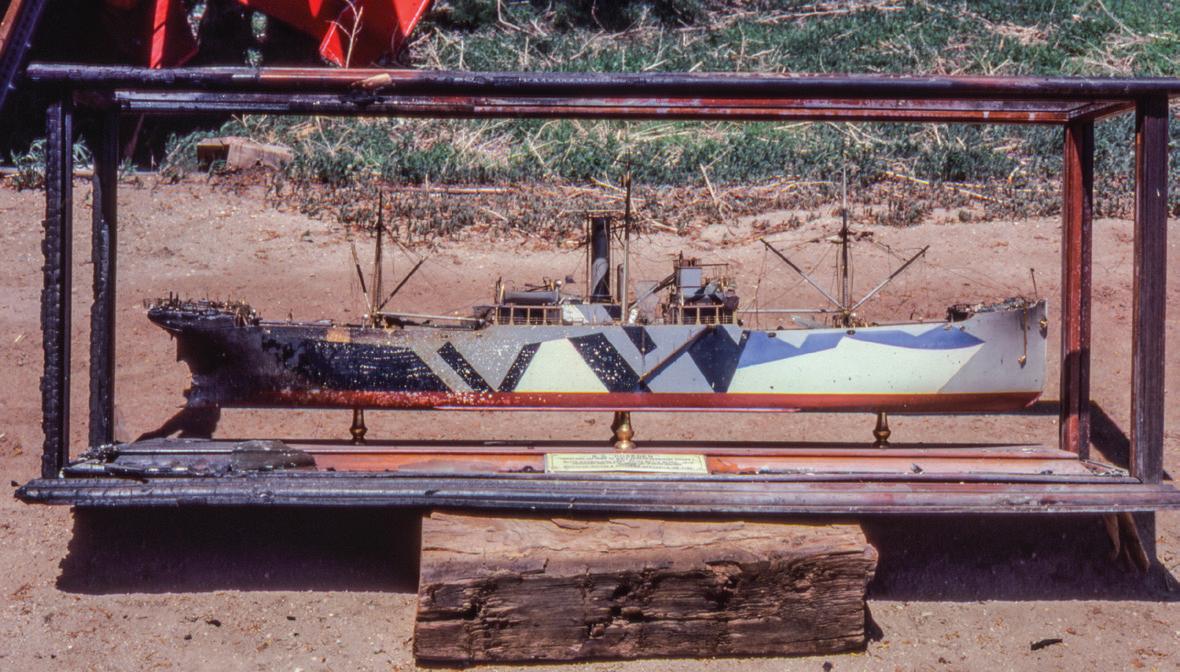

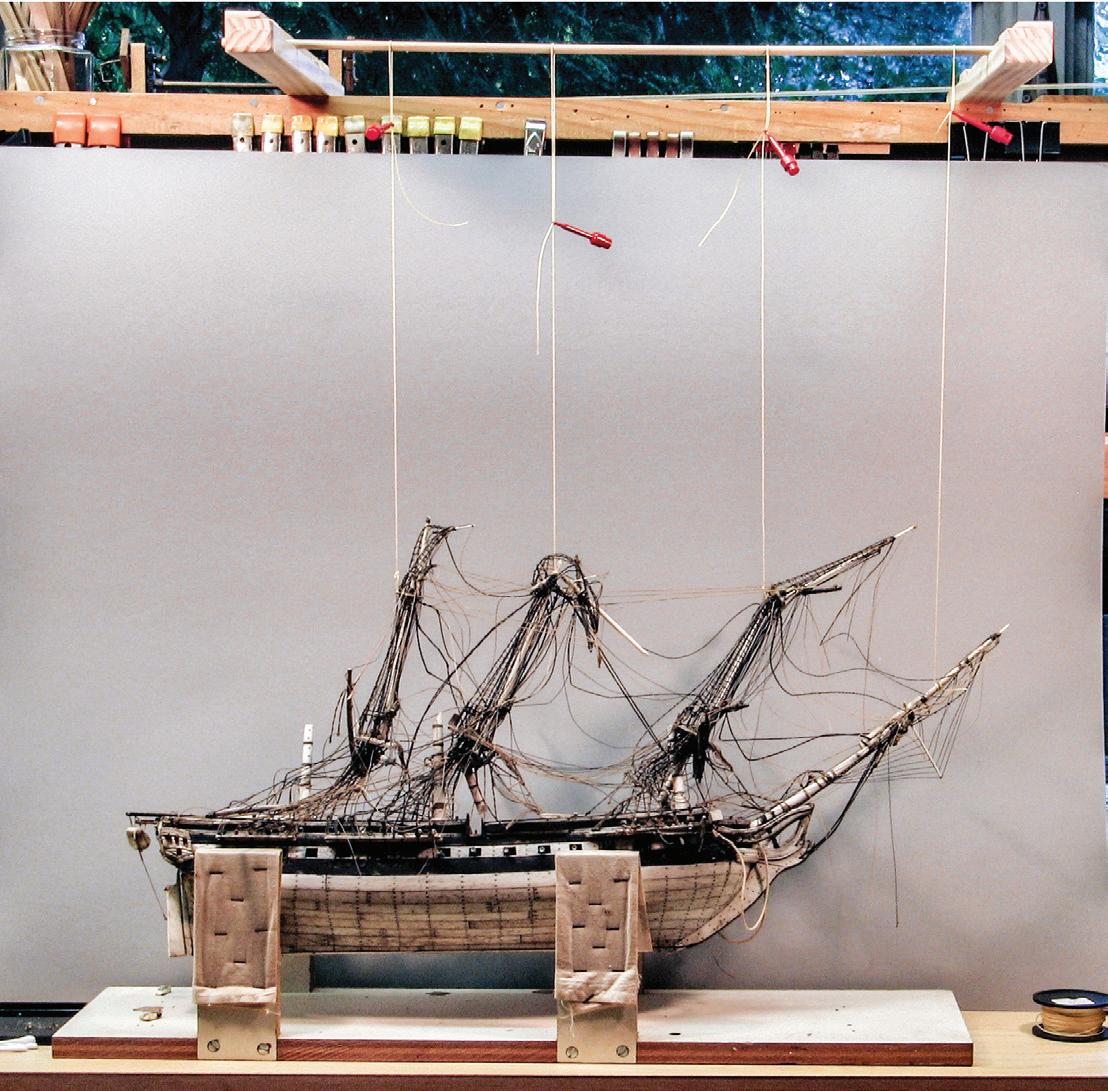

Cleaning, repairing, and rerigging this folk-art model of a late-nineteenth-century American bark was my first paid commission. (Photograph by Alice Beal Baker Hyde)

travel your own paths to the same destinations: I encourage you to do so.

Except for what I’ve gathered through observation, I learned almost everything I know about photography from two men. The first was MacAdam. He didn’t teach me how to compose, expose, or print photographs; however, in the mid-1960s, he demonstrated by example the notions that evocative photographs could be created of everyday subjects by regular people and that it’s sensible to carry the best equipment you can possibly afford. The second was Ron Testa, a Navy photographer and a shipmate with whom I served aboard the aircraft carrier. Knowingly or not, he showed me how to see subjects and manage the balances of composition and exposure. He taught me how to work in a darkroom.

Unless they are otherwise credited, I made all the images in this book. It will become quickly evident that the photographs were taken under varied and frequently terrible conditions and with a considerable range of expertise. In the Case Studies, it would be ideal to have good before and after images of each project. However, the usefulness to this book of some projects didn’t become evident until they were well underway, so I missed the before shots. And many projects left the shop too quickly to get after shots. Please be patient with these disparities and understand that they frustrate me as much as you.

While collecting material for this book, the temptation was great to comment on many topics that might be of ship-modeling interest, whether they were concerned with model care or building. I’ve worked hard to keep content relevant to model care, but some things have probably slipped through the filter. The devil takes many disguises.

Let me clarify that this book is concerned with what are considered fine-scale ship models. While I have some experience with pond models, folk-art models,

and others made for engineering purposes, they have not been the focus of my career.

With brevity in mind, I have opted to omit definitions of nautical terms that should be relatively familiar to most readers in the ship-modeling literature. I offer my apologies if some language seems obscure. Moreover, I have not included a list of sources for products because, in today’s world, company names and contact information change so unpredictably and because they are readily available on the Internet. Books mentioned in the text are included in the Sources.

Regrettably, several examples of work that would be of significant relevance in these pages had to be overlooked. Many clients prefer to keep private the material concerning objects in their collections. I respect their wishes for discretion. In almost all cases, I have acquired oral or written permission to include the models that are mentioned, discussed, and illustrated.

To avoid awkward constructions regarding gender, I have used the following conventions. Almost all the ship modelers I know and know of are men, so I refer to modelers with masculine pronouns. All the art conservators and most of the curators with whom I have worked are women, so I use feminine pronouns for that group. My clientele has been about equally divided, so I have tried to split masculine and feminine forms for them.

This book has four parts. Part One is this prologue. Part Two offers perspectives on various aspects and philosophies of the ship-modeling experience. Part Three focuses on practices and applications I have used during my career. Part Four reviews Case Studies that examine influential and interesting projects.

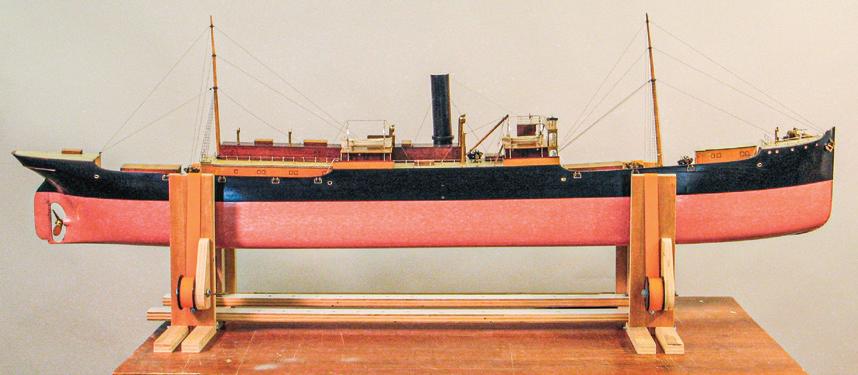

In revisiting hundreds of treatment reports for material to include here, I found a rare note I made regarding a model of an English steam-powered side-paddle tugboat: “Pre-installation review found a complete and happy model.”6 If they were all like that, I’d be out of a job! ¯

6

Part Two Perspectives on Ship Modeling

Aship model is an invitation to visit an object — not the model itself, but, specifically and hopefully, the vessel that the model portrays. Further, the invitation is to step aboard that vessel. Let me be clear, now, for those who don’t know me: I love looking at ships. Consequently, every time I see a model, I accept that invitation to visit and look, if not to step aboard. I want the model to make me feel like I am approaching a ship, and I want to be rewarded for doing so. I advance on a model until I am so myopically close that it no longer can convince me that I am looking at a ship; only then do I see the model for what it is.1 Some models are so good that even under closest scrutiny they still appear to be ships. Regrettably, at the other end of the seesaw, some models are poor enough that they never really resemble ships from any distance.

While advancing, I instinctively consider visual textures, scale conformity, and what story the model is telling. As an example, I used to think that the mere indication of a detail — like a windshield wiper on a warship bridge drawn as a paint line — was engaging modeling. But as my observational skills matured and I took that invitation more seriously, I wanted that wiper to resolve with an arm and a blade.

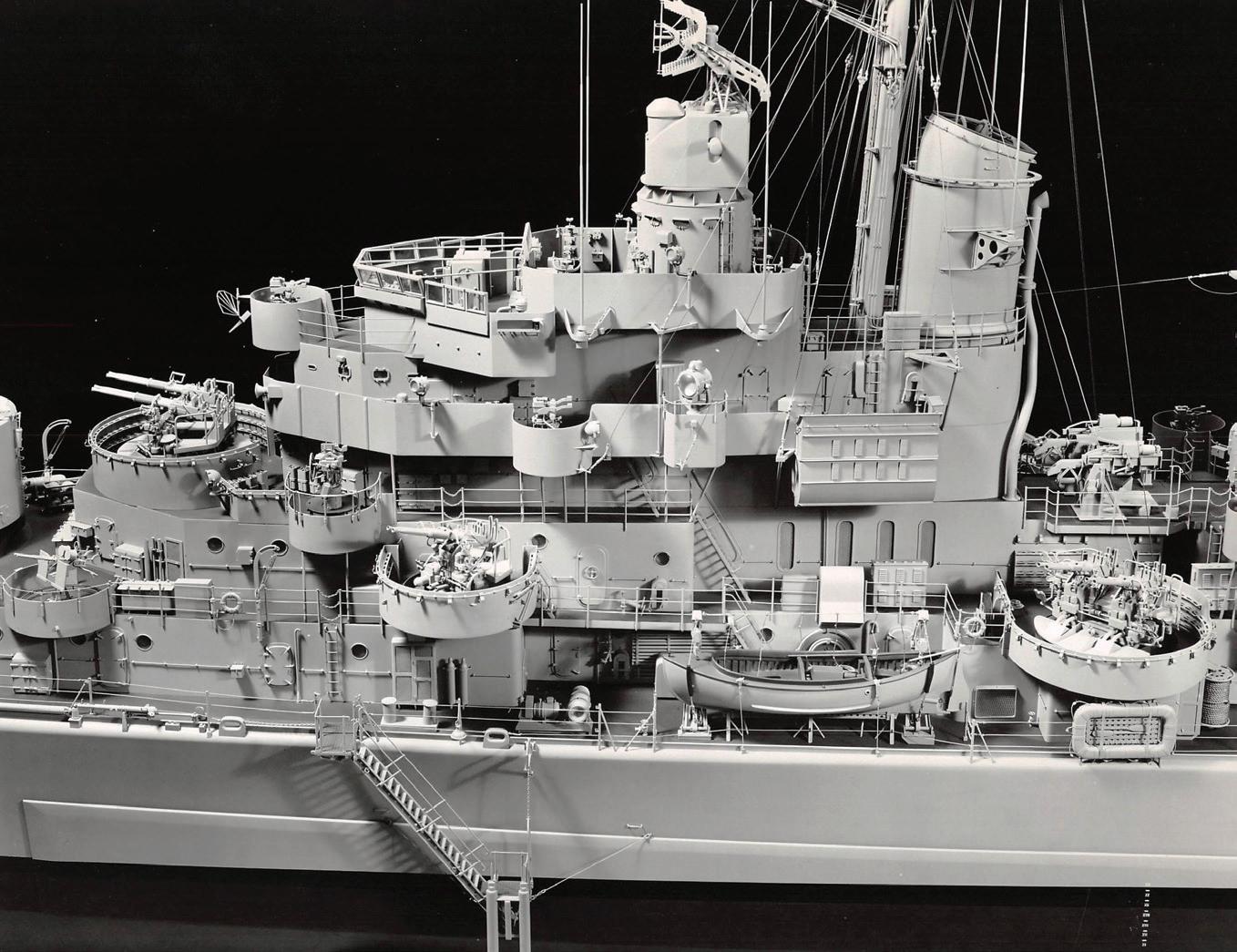

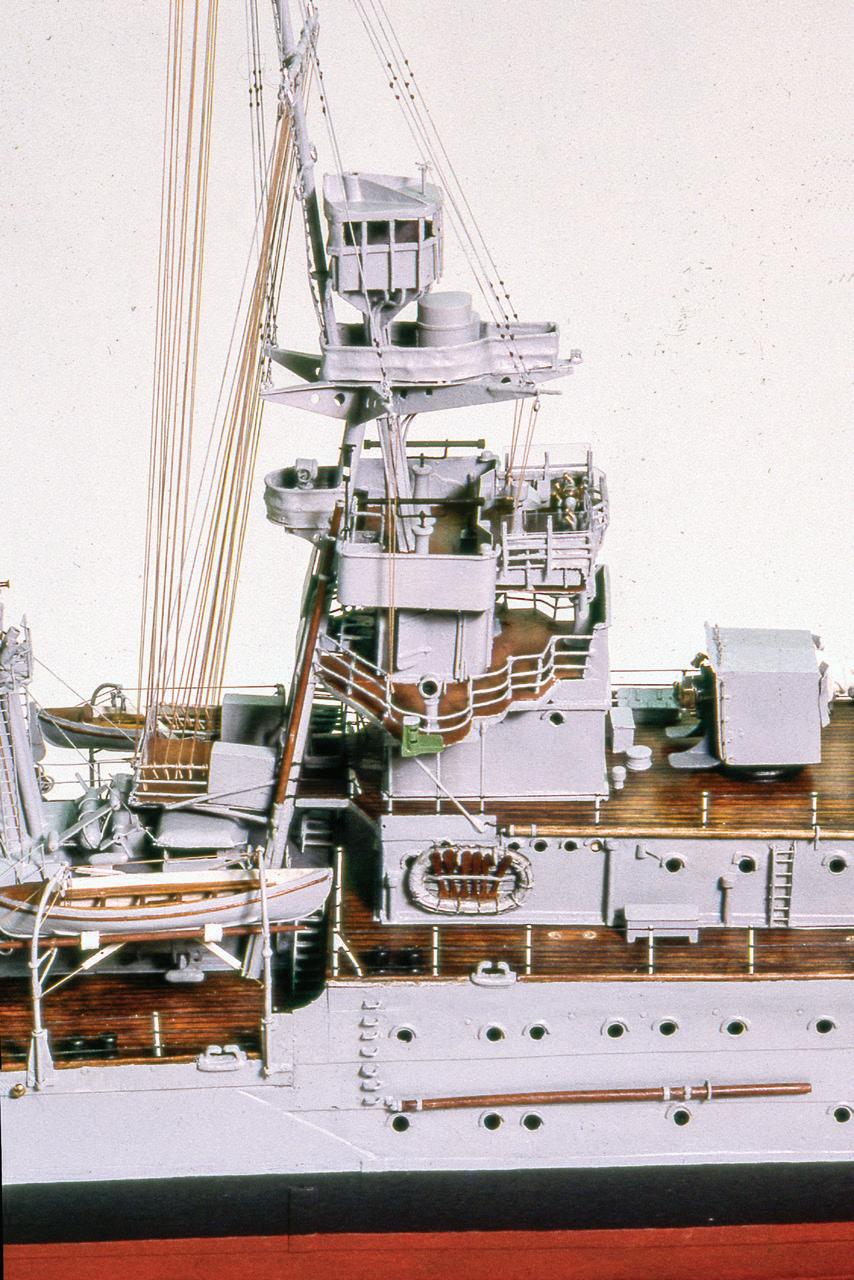

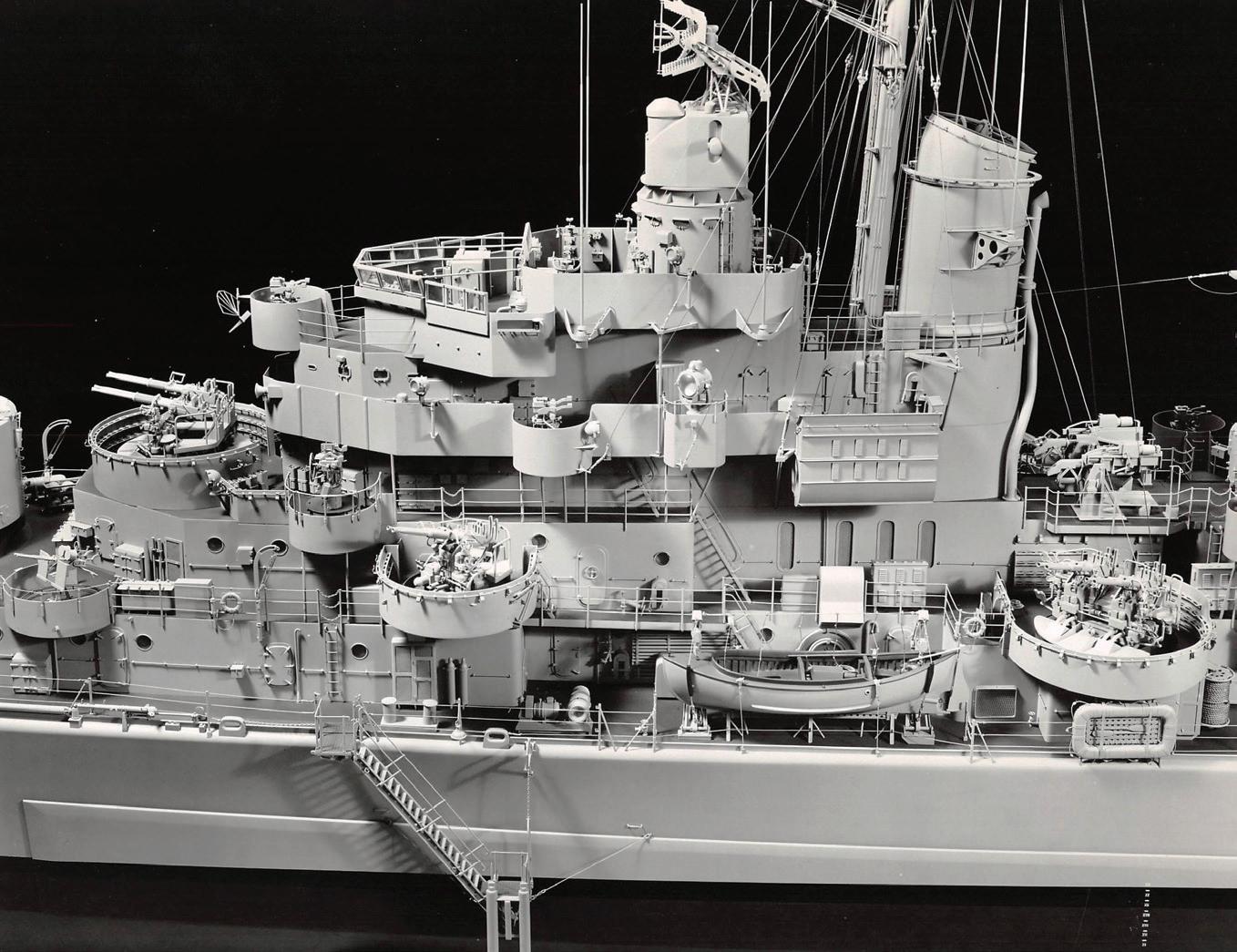

Film critic Anthony Lane wrote “Texture, not volume, is the key to the wondrous.”2 This is why models, like Bob Steinbrunn’s 1:192-scale USS Kidd (DD-661), work so well. His Kidd entices viewers with its over-

all sense of realism, but then astonishes them with the texture that they discover once they are aboard. I have approached this model until my near-sighted eyes were only a few inches from its surfaces and was still able to suspend my skepticism.

So, the paradox. While many have written about what ship models are, here I will say what they are not. Contrary to the previous concept that I want to see them as ships, the obvious must be stated and understood. Ship models are not ships.

To be successful in this foolery, the model must be only somewhat more compelling than the knowledge of the viewer. In other words, the more a viewer knows about the subject of a model, the more critical he or she will be about how well the model works.

But Are They Art?

This delivers us to the perennial question: Are ship models art? The theory I propose starts with the idea that if ship models are not art, then all models built from a common information base should be indistinguishable. Imagine you are a manufacturer who requires multisourced widgets to fit on your product. You would send the widget’s specifications to various machine shops. And you would expect the widgets you received from each shop to be identical to the

Paradox

Bob Steinbrunn’s 23-inch, 1:192-scale model of USS Kidd (DD-661). The bridge window wipers have arms and blades. (Photograph by Bob Steinbrunn)

point of being interchangeable. The widgets would be crafted.

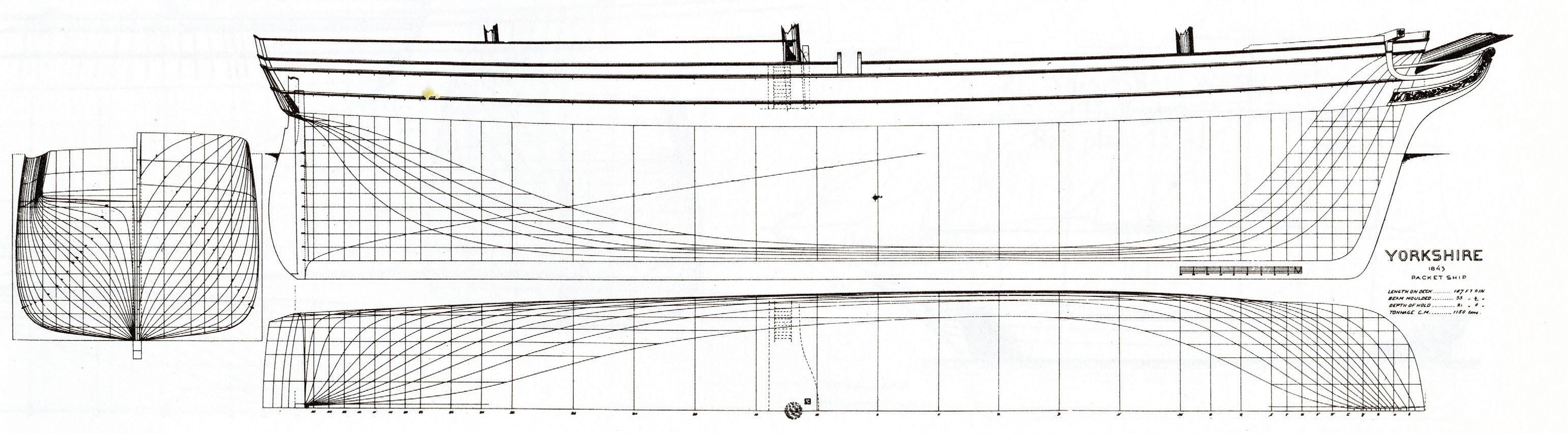

By way of contrast, I have long fancied conducting the following two-part experiment. First, I would make a packet that contained information on a single vessel; it doesn’t matter which one. The packet might contain for the vessel a set of lines and other plans, a group of photos, copies of a couple of paintings, some details about the sort of gear with which it was fitted, and a condensed history of its career. Identical packets would be distributed among a half-dozen technically proficient and recognized ship-model professionals. At the end of an agreed-upon time, say eighteen months, each modeler would emerge with a creation. If ship modeling is to be defined entirely within the realm of being a craft, like the machined widgets, then all six models should be identical, or nearly so.

For the experiment’s second part, imagine that you desire to have your portrait painted. You want to engage six artists to interpret you so you can determine whose work best captures the real you. Having unlimited resources, you are able to use your time machine to arrange to sit for, let’s say, Leonardo da Vinci, Johannes Vermeer, Mary Cassatt, John Singer Sargent, Pablo Picasso, and Andy Warhol. When you have the results, you will have six remarkable portraits of yourself to treasure. But here is the point: While each painting will be immediately recognizable as being of you, each will also be immediately recognizable as the work of its creator. The same will be true with the six ship models created from the identical information packets; there will be, say, models by Horace Boucher, Norman Ough, Joseph Wheeler Appleton, Donald McNarry, Harold Hahn, and Erik A. R. Ronnberg, Jr.

Another analogy is also germane. Artists working in any medium are continually making thousands of decisions about how finished pieces will express their messages and how these will be perceived. I know what you’re thinking: Many artists insist that their work just gushes from within them with no decision-making ef-

forts on their parts. But somewhere in their systems or psyches, ideas form and decisions are made. Otherwise, there would be no way for the artist to manage results. From here, I will focus on writing and painting because I know something about them, but I suspect that my understanding is applicable across the arts. In the 1980s, feeling jaded with ship modeling and thinking I might change fields, I enrolled in several college-level art appreciation courses. Okay, it was a mid-life crisis. From studying the work of scores of artists from across the centuries and around the world, I concluded sophomorically that all the paintings that could be painted had already been painted. There seemed to be no remaining new ways to apply paint to canvas. To test this, I took studio painting courses to learn the rudiments of color theory, brushwork, and composition. I went to work. Initially, I assumed that a new dab of paint acted only on its spot in the painting, but I discovered that a single dab of paint applied anywhere on a canvas affected the entire picture. Each new lighter or darker hue had the effect of warming or cooling, advancing or receding; brushstrokes could be smooth and slippery or coarse and arresting. Each new dab seemed to be at the center of a spherical universe and, thus, could direct a viewer in any direction the artist intended. The next dab did the same thing from the center of its own new universe. The path to epiphany was short. There is an infinity of universes; only a tiny fraction of all the paintings that can be painted have yet been painted.

Now, let’s look at another medium — one that, if you are here, you are currently engaged with: writing. In writing, the use or placement of every word and punctuation mark affects the intent of a sentence, a paragraph, or a story just like the brushed color dabs in painting. We would like to suppose the choices for color in painting and for words in writing flow spontaneously from our inner beings through the end of the brush as it touches the canvas or the pen as it touches the paper. But I do not believe they do. I believe that

8

a creative jolt arrives inside us and that we then make conscious decisions to express it. Considering this, we can acknowledge that the artistic process can be expressed as a lengthy chain of deliberate decision making that will lead to substantially different interpretations of the same subject by different artists.

The ship model is created in the same way. Each new part will alter the interpretation of the model as it already sits and of how the rest of it will be conceived and constructed. A modeler is hired or inspired to create a portrait, not of a person, but of a ship. The modeler chooses, for instance, wood and brass and line instead of paints or words. The modeler then, during the eighteen months of work (as suggested for the experiment mentioned earlier), makes thousands of decisions. Among them are scale, hull-construction technique, materials for everything, which details are to be included, which tools to take in hand, colors, presentation, and so forth. The modeler is working just like the painter or writer. In this way, ship modeling is art, indeed.

But what kind of art is it? In museums, most objects on display are accompanied by labels that provide basic information about the object. These might include the title, the maker’s name and dates, the subject matter, the materials used, and the basic form of the artwork. What would a ship model’s label say? “Ship Sooloo of 1861 by Rob Napier (active 1973-), polychrome multimedia sculpture.” “Polychrome” because the model has several colors and finishes; “multimedia” because it is made from wood, brass, linen, silk, and other things; and “sculpture” because it is unambiguously three-dimensional.

The Elusive Definition

During the early 1990s, it was my occasional pleasure to engage conversationally with Bruce Hoff. He was an accomplished ship modeler and a highly skilled analytical thinker. We were actively seeking language to replace the catchphrase “museum quality” because it had

become exhausted to the point of being meaningless. It says nothing whatsoever about quality or about what is important to museums. Although Hoff and I never found anything as succinct, we were content when we developed the following: “A high-quality scale ship model provides a compelling impression of an actual vessel within the constraints of historical accuracy.” Yes, it’s a mouthful. This expression, co-authored by Hoff and me, first appeared in print in the Nautical Research Journal. 3

The two-part definition has a subjective arm and an objective arm. Let’s look at the second first. “Historical accuracy” encompasses all the objective, or measurable, standards of technical exactness that might apply to a ship model. These embrace the obvious: hull shape and fairness; precision in fittings, rigging, and colors; lack of anachronisms; and so forth. But it also encompasses all aspects of craftsmanship because the lack of craftsmanship creates unrealistic and, therefore, historically inaccurate blemishes on a model. It’s easy to understand that paintbrush marks on a small-scale model of a large vessel are a problem of craft that would detract from historical accuracy. The phrase “historically accurate” alone effectively replaces the intention of the now-vapid “museum quality.”

But now we add “compelling impression,” our definition’s subjective arm. It allows and encourages aesthetic interpretation of a vessel that will help propel viewers to make the leap of faith that allows a model to work or to willingly suspend the disbelief that keeps a model from working. Both processes help viewers accept the invitation to visit a ship instead of a model. Compelling impression is the result of applying artistic and interpretive decision-making processes — such

9

A 32-inch (at the sheer), 1:64-scale full-hull, rigged, plankon-frame model of the 1861 American ship Sooloo (II).

A B

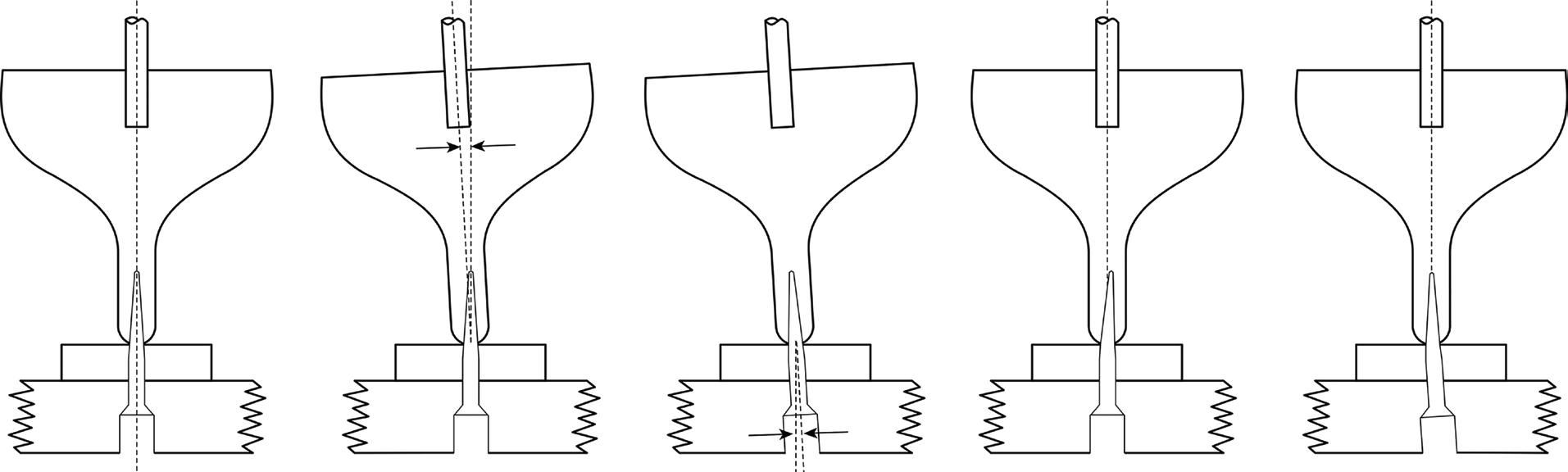

Focus on Compelling Impression: Blocks

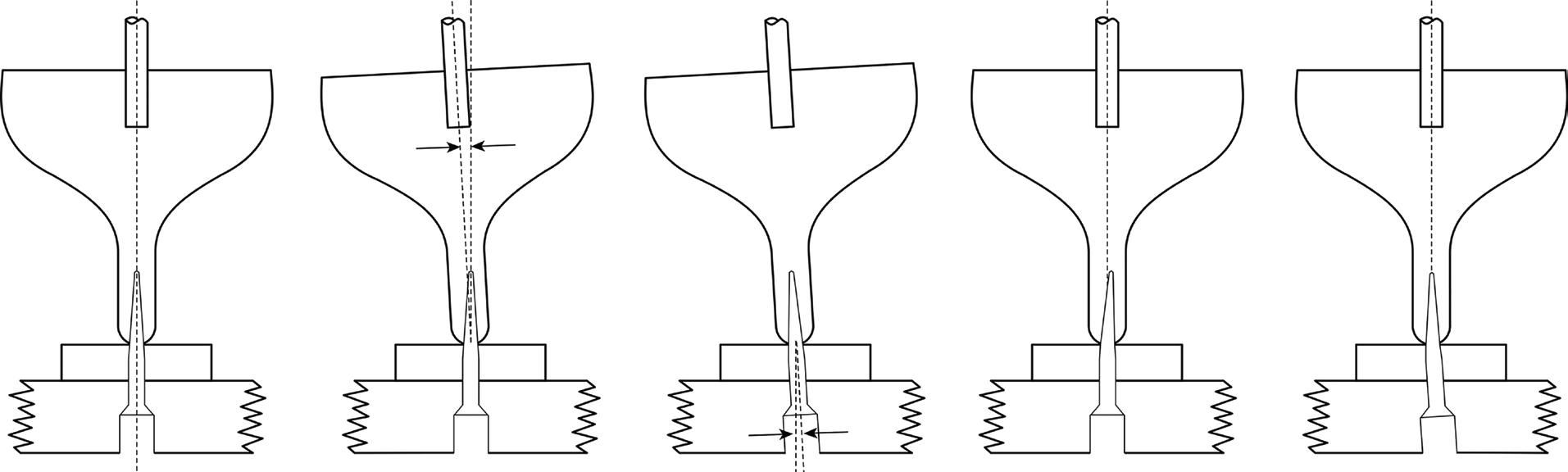

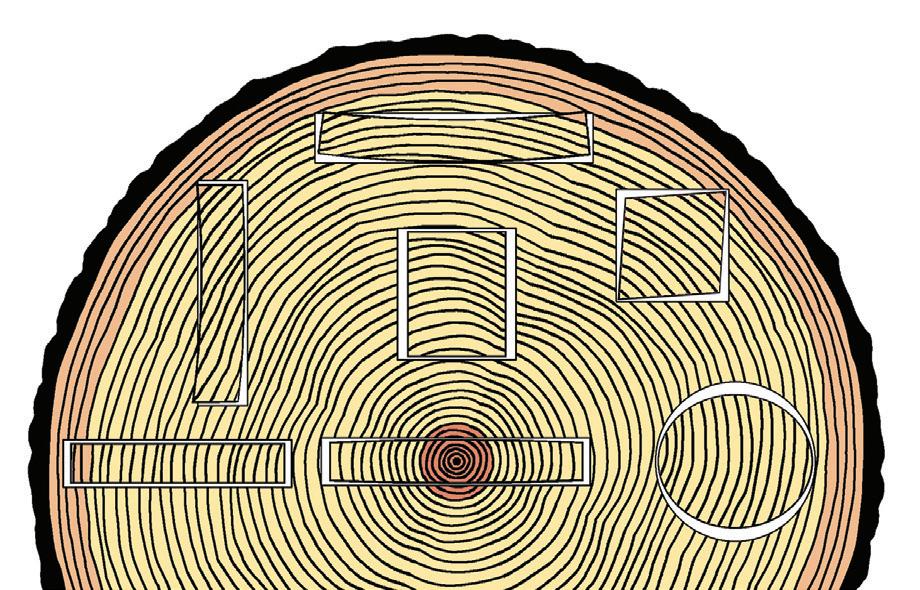

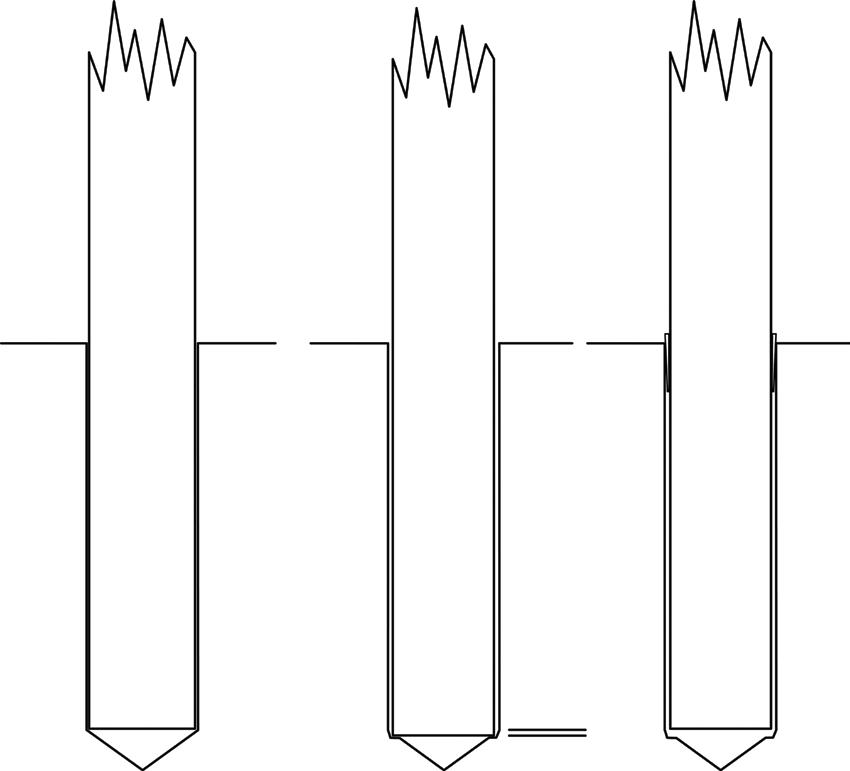

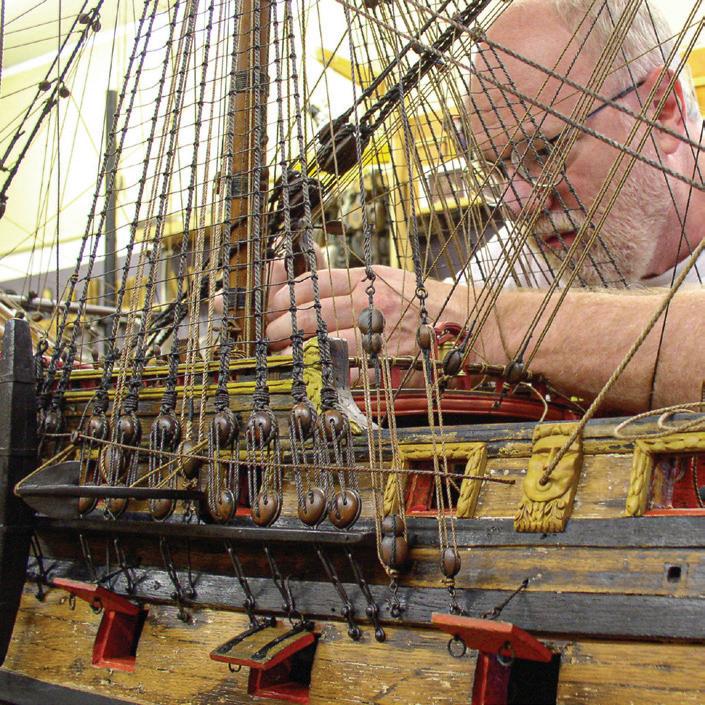

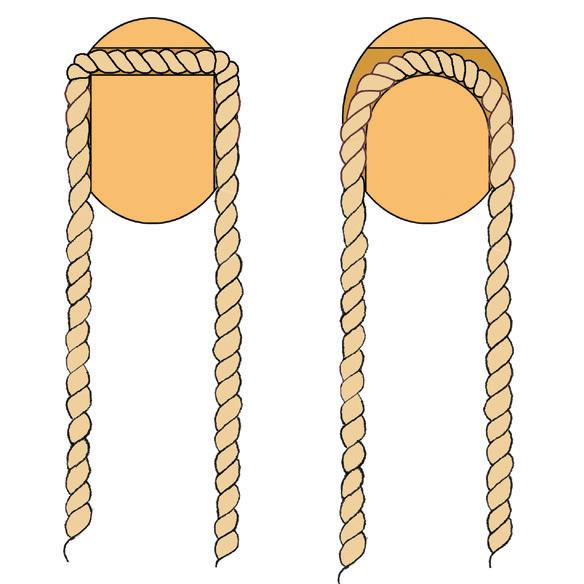

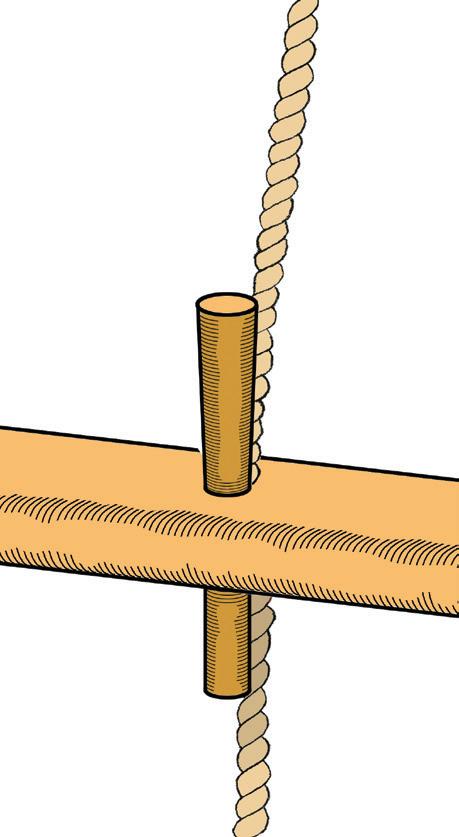

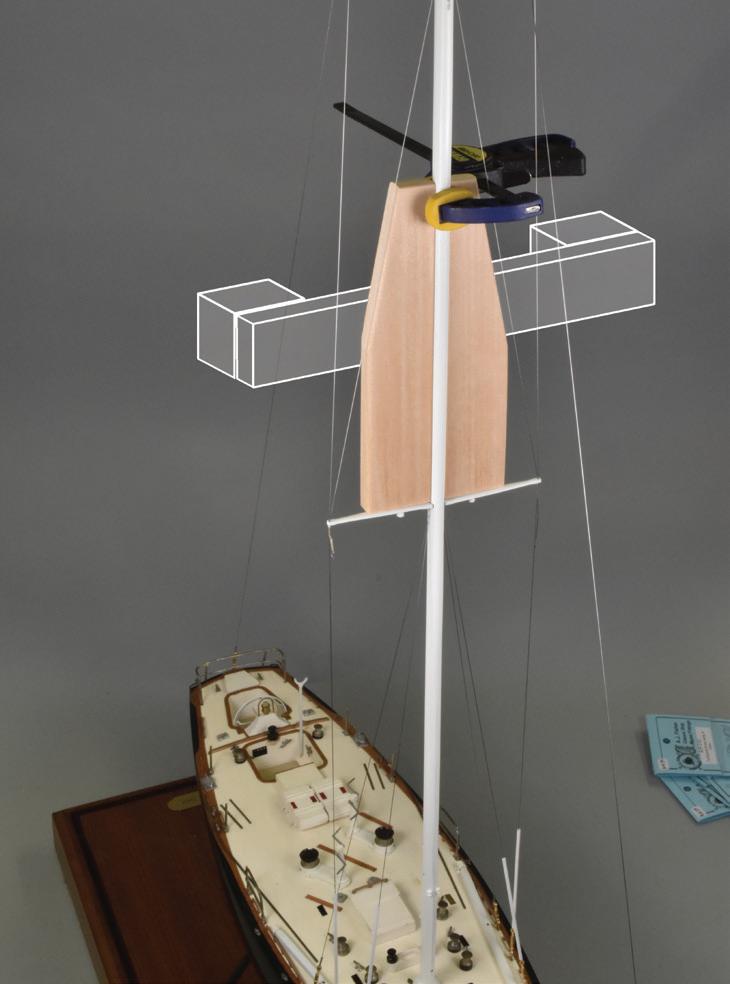

To observe the concept of “compelling impression,” one could choose from among dozens of shipboard systems. More than any, though, blocks fascinate me. They were the only labor-saving machinery used in rigging for centuries. Their utility has not changed, and their refinement continues to evolve. With a name as prosaic as “block,” they are sculpturally sophisticated. How can a few blocks speak for the quality of an entire model? Many veteran model viewers agree there is one feature on models they notice first; it differs for each person. The first things I see on a model, assuming it’s of a square-rigger, are the ends of the lower yards — they are closest to me in a display case. They are frequently fitted with a cluster of blocks. If these blocks and their associated gear are well-crafted, I am immediately engaged, but if they are crude, I struggle to observe the rest of the model objectively. (You can determine what you notice first by paying attention to where your eyes settle first on models new to you; it will take hundreds of models.)

A and B. Are you more likely to invest additional time in the 18-inch folkart model of an American ship (A) or the Rogers Collection dockyard model of a British 36-gun frigate of about 1800 (B)? (Photograph B courtesy United States Naval Academy Museum)

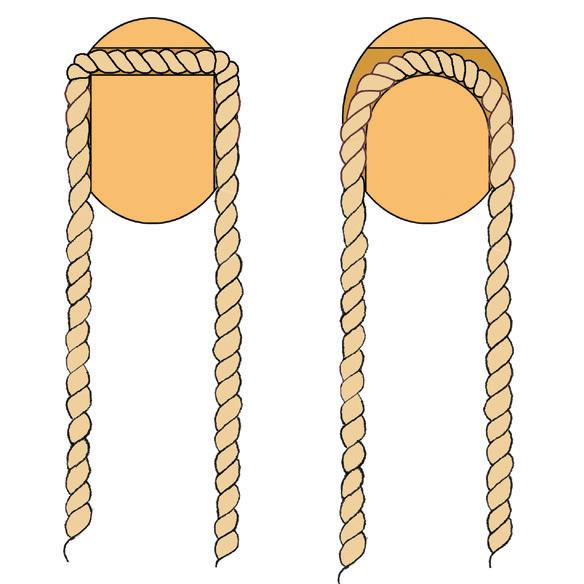

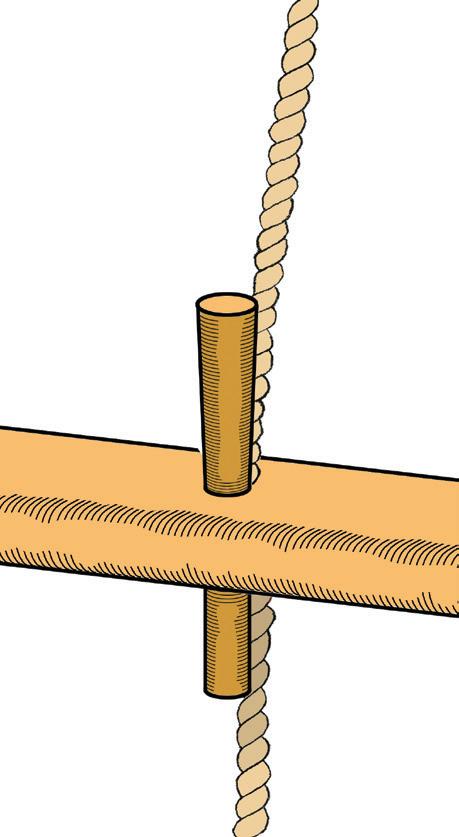

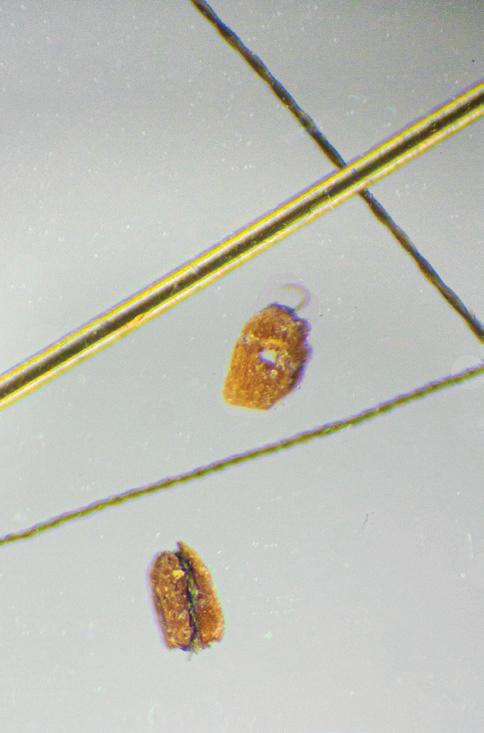

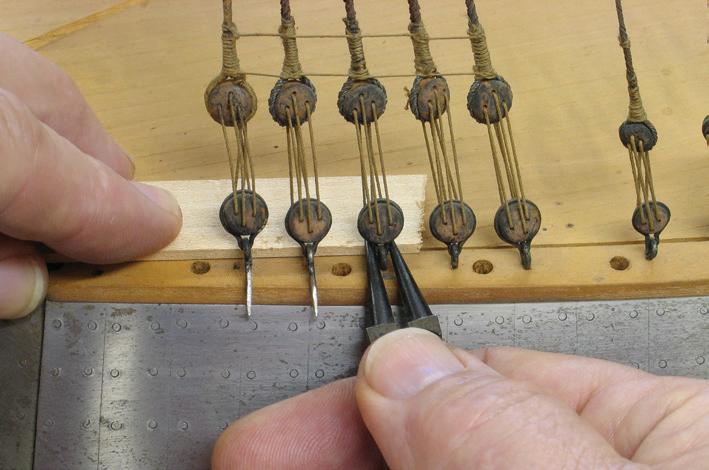

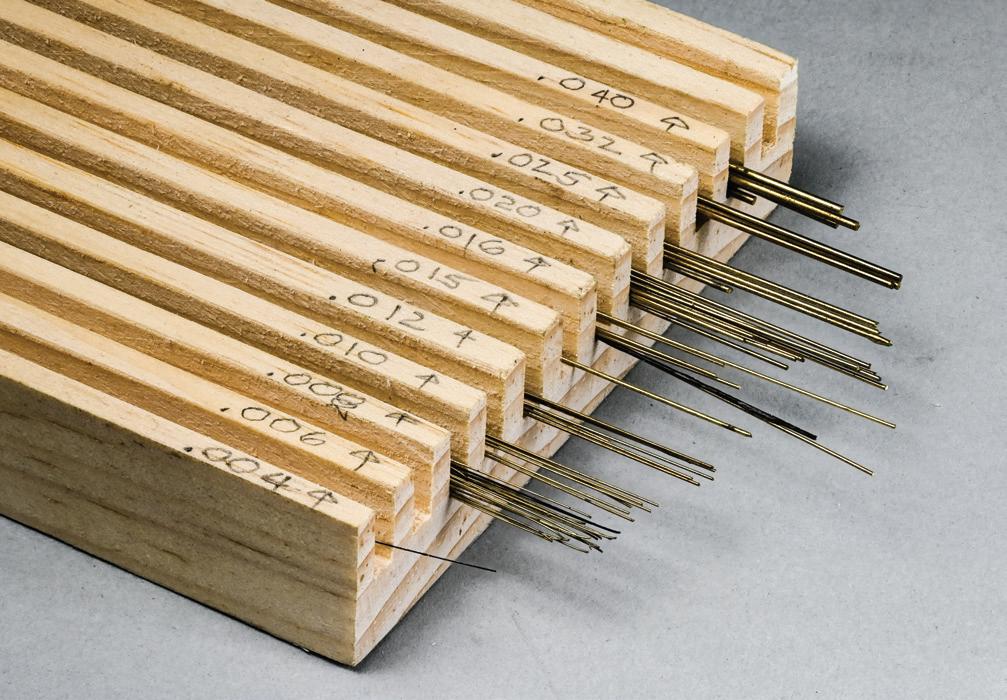

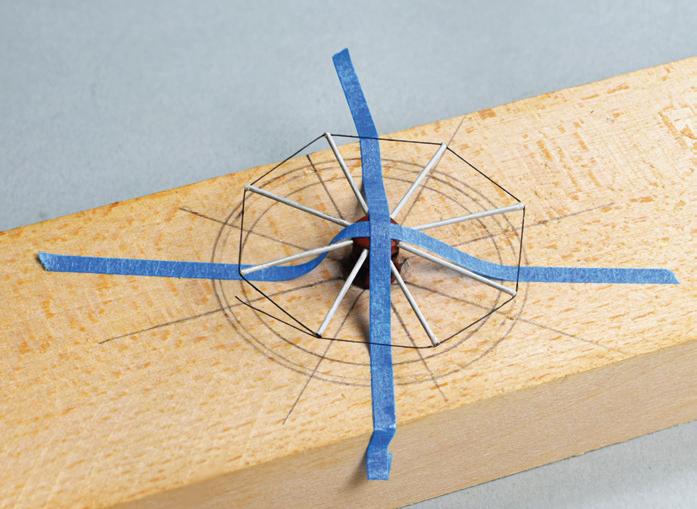

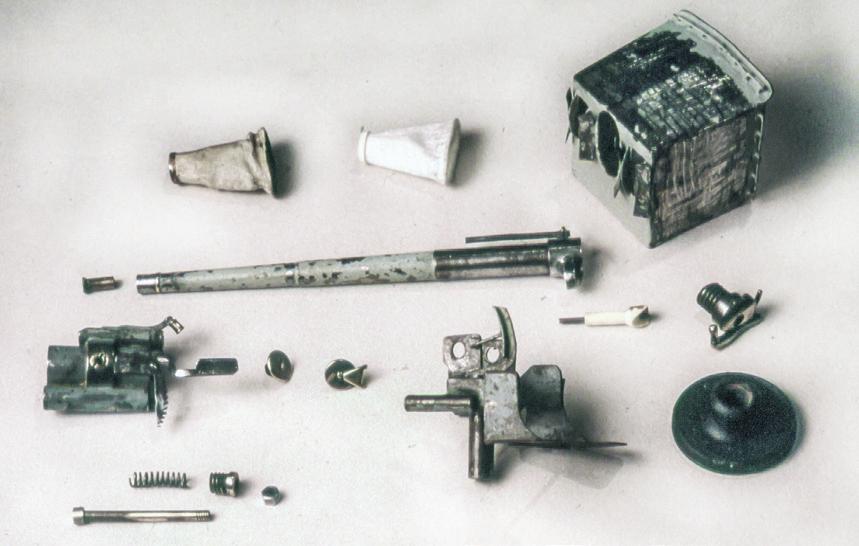

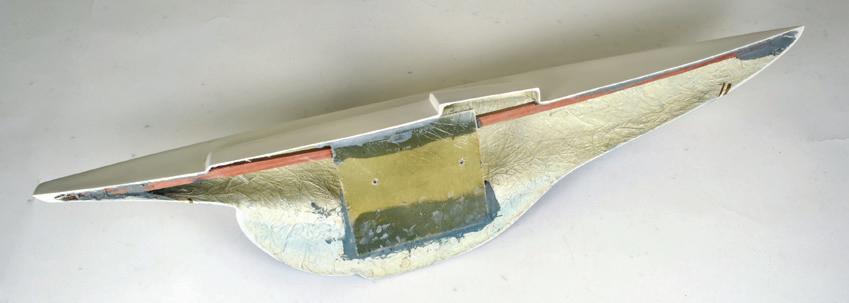

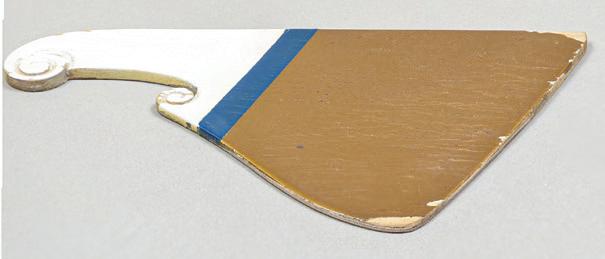

C. To establish perspective, consider a real, 3-inch, weathered block with a single-piece wooden shell, steel sheave, canvas-covered rope strop, and a nicely wrought steel hook. Blocks of this type were ubiquitous on sailing vessels. Next to it are six compelling nineteenth-century model blocks. They are built just like the real block except for canvas on the strops.

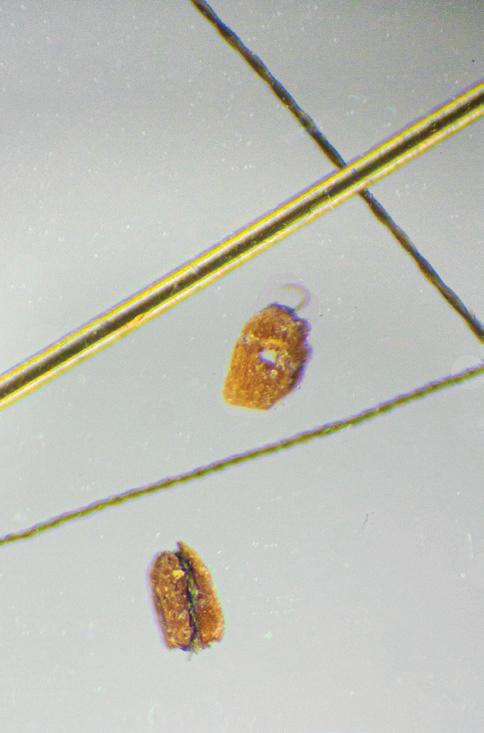

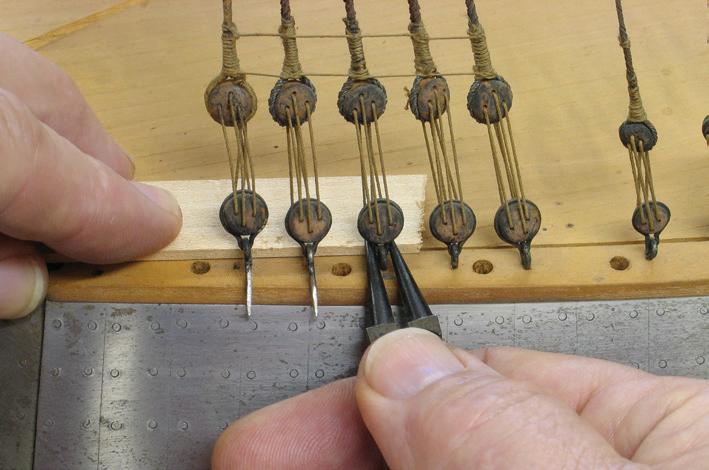

D. Forty old and new model blocks. In the upper left are two rope-stropped examples from the previous image (C). To their right is a group of nine metal blocks; all are brass or plated brass from early twentieth-century builders’ models except the two to the lower left in the group. The single with the perforated shell is a white metal casting by Vincent Castello from 1970. The seven wooden blocks in the upper right are my work. The large fiddle and single and the small ebony double have single-piece shells; the other four are built up of pearwood or boxwood with separate cheeks, fillers, sheaves, internal strops, and pins. The late Jim Shoesmith

made the two white blocks with one-piece shells and silver-painted internal strops. The three wire-hooked doubles in the center are synthetic ivory from a 1922 builder’s model. The central fiddle is antique bone from the early nineteenth century. The two white, unstropped blocks are new ivory. The row of four blocks in the bottom left are from folk-art models (the black one is leather!). In the lower right are ten twentieth-century commercially available wooden and Britannia metal single and double samples with and without strops. Which of these forty examples give compelling impressions of actual gear?

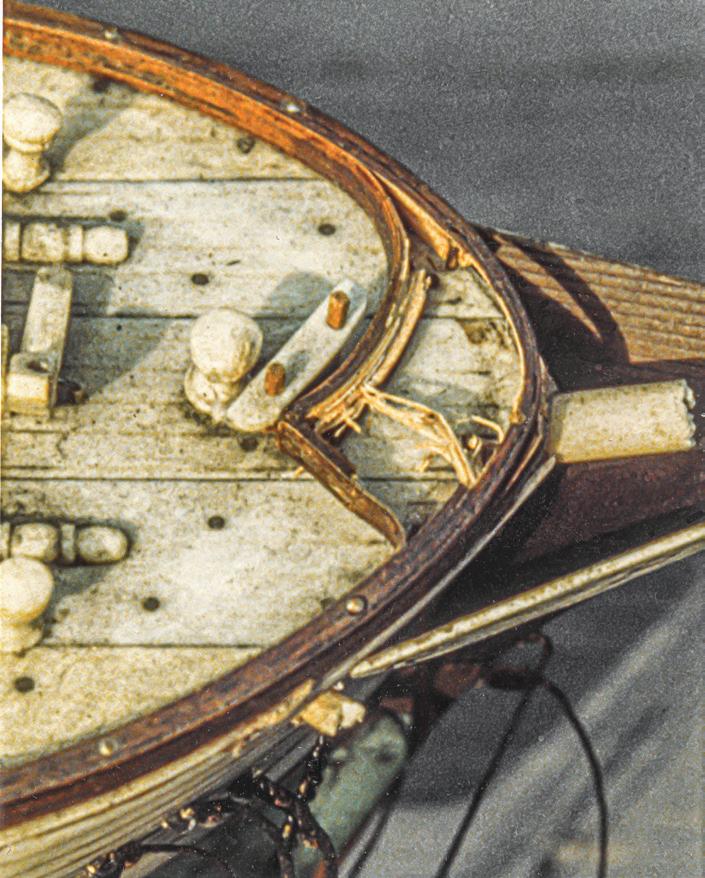

E. Nine boxwood blocks. The four on the left are from a model custom built by the H. E. Boucher Manufacturing Co. in about 1915. They are appropriately flat and elliptical, have well-sculpted sheaves, and strops flattened into grooves in the surfaces of the shells. The five to the right are much chunkier, have unfaired, sharp-edged sheave holes, and unrefined wire strops. These five were marketed to hobbyists by Boucher in a 1934 catalog as “the type used on fine ship models for which the Boucher organization has been famous for nearly thirty years.” Differences between the two styles are clear. The largest block here is about 3/16 inch long. Note the lovely faux wire-rope splices on the pendants of the two blocks in the upper left.

F. A page from the 1934 Boucher catalog. The five chunky blocks to the right in the previous image (E) are what you received if you purchased from this catalog.

10

E F D C

as weathering and placing models in dioramas — to amplify a model beyond being a mere assemblage of parts. Generally, the smaller the scale of the model or the larger the prototype vessel, the more crucial this sort of interpretation is. This is because the larger the scale, the more nearly a model is like a ship and less like a model and vice versa.

One could argue that it is more important and more difficult to teach inexperienced modelers how to tell if their model yields a compelling impression than it is to teach them how to put the thing together. If they are only interested in being satisfied with the latter, then the former is even tougher.

Each winter, starting in 2009, I conduct a day-long seminar for the USS Constitution Model Shipwright Guild. The gathering is open to the guild’s entire membership, but it serves primarily as a mandatory refresher for the judges for the guild’s annual competition. The seminar is built around interpreting the above definition of a high-quality scale model. I never developed the syllabus for publication.

It is important to recognize that neither arm of our definition considers how a model was made. There is no assessment of whether entire models or components of them are built from scratch, built from kits, or built by teams of modelers. The main thing is the appearance of the finished model. The ends justify the means.

Teamwork

Please consider the notion that a ship model can be built by a team of modelers. To do this, though, we must acknowledge first that ship modeling today is principally a domain inhabited by individuals working alone. Models are built by and credited to solo practitioners. They write books, speak at conferences, and record videos about their work; they win the awards in competitions. However, suppose a team of modelers was formed to construct a single model? The adage “two heads are better than one” comes

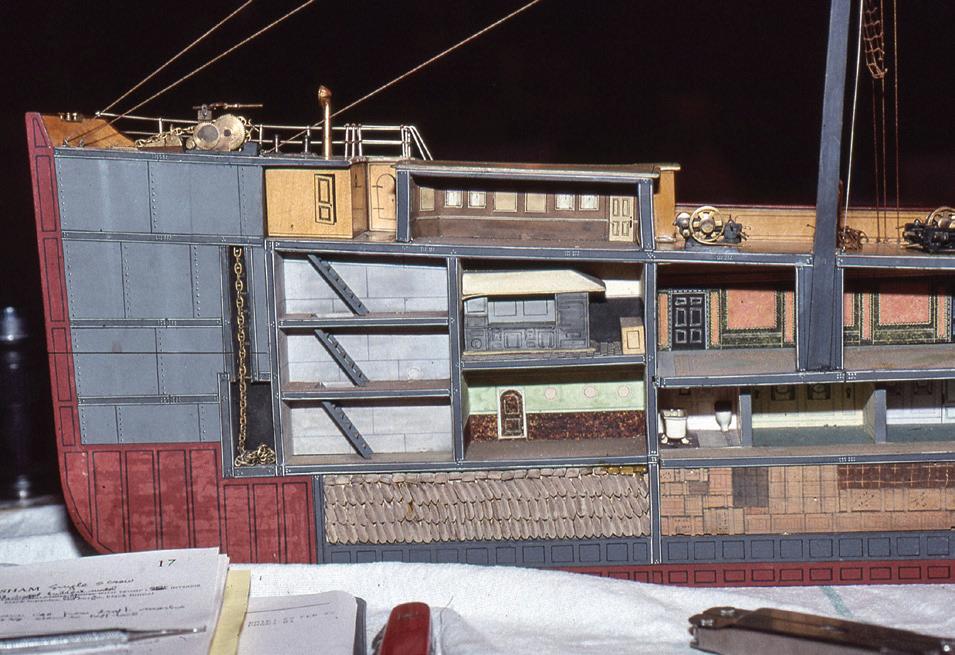

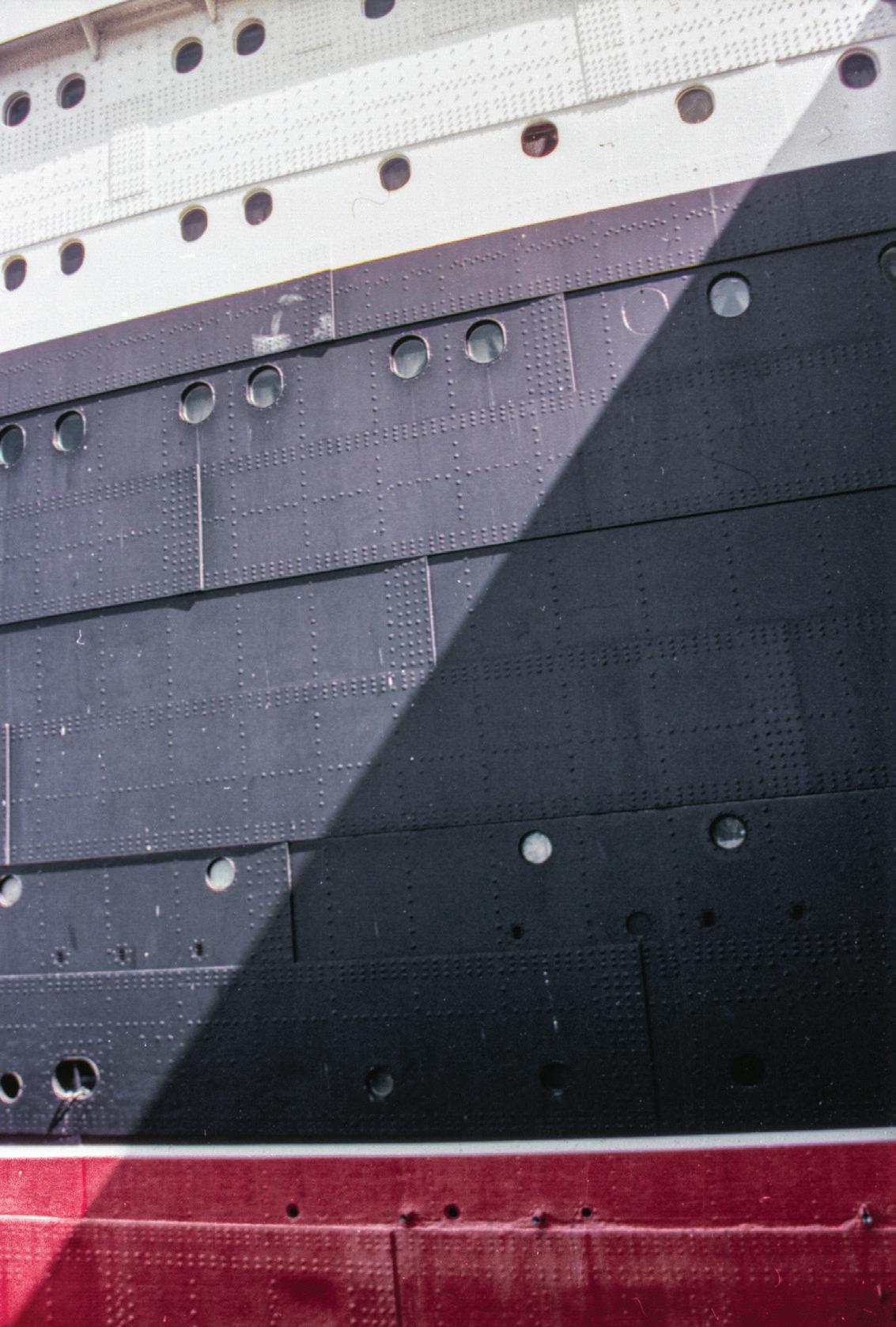

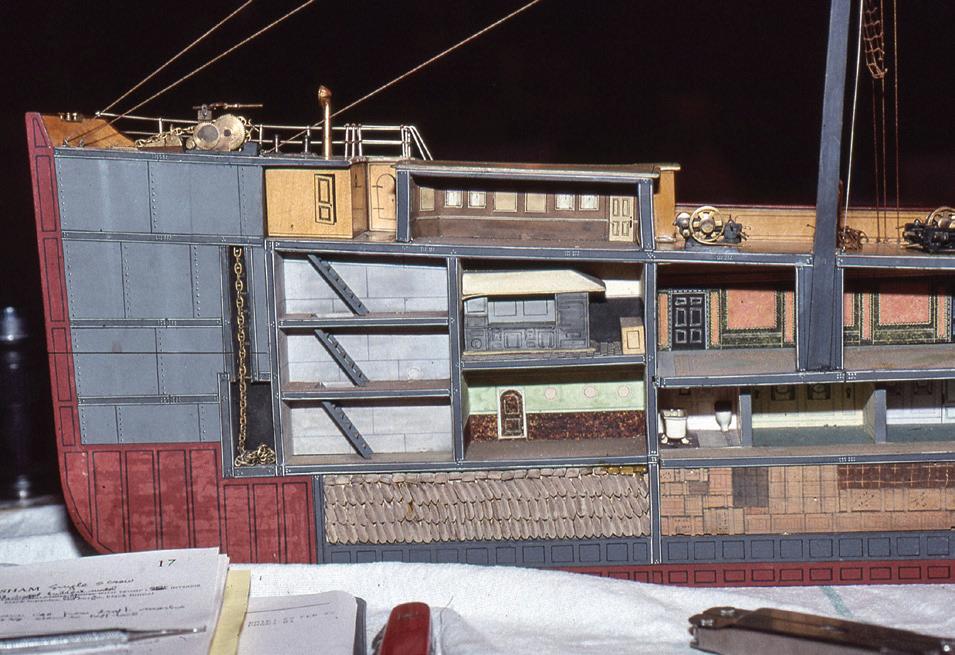

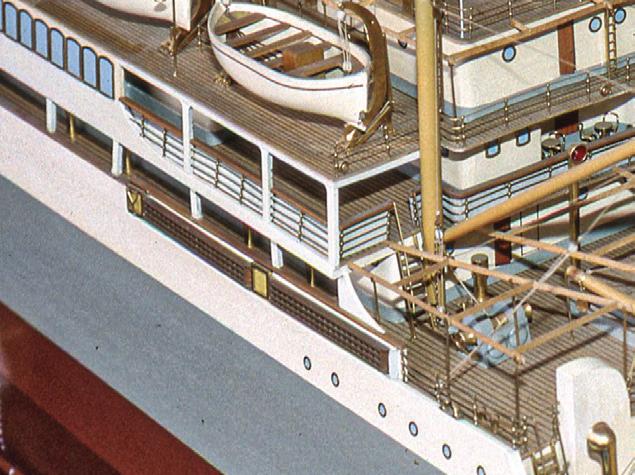

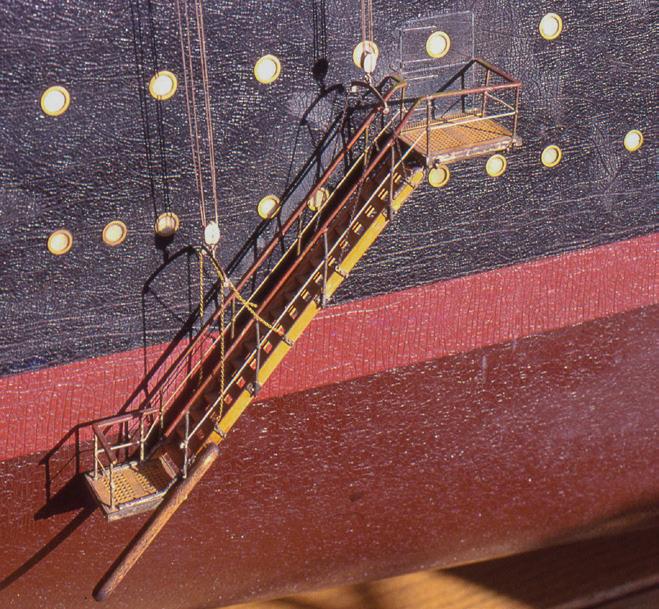

to mind. The proposition should not sound even remotely outlandish because the models that we position at the pinnacle of virtuosity were built by teams. Think of the complex seventeenth- and eighteenth-century European dockyard models of elaborate warships, nineteenth- and twentieth-century shipping office or builders’ models of steamers, and, of course, the mid-twentieth-century Gibbs & Cox models of American warships. There are no models of any similarly complex vessels being built today, by any individual, anywhere, that compare with these spectacular achievements.

We should encourage groups of two or more modelers to pool their skills and other resources.

Well-organized collaborations might yield some incredibly synergistic results. For instance, for a model sailing ship, one contributor might focus on framing, another on miniature carving, another on rigging hardware, and another on creating cordage. Or for a steel warship the foci might be hull plating, fine painting, open gun mounts, or aircraft.

If the goal is to produce better ship models, does it matter how many people work on a project? I maintain that it does not. One drawback to my thesis is that, if we agree that the work of individual ship modelers is as consistent and identifiable as that of other artists, it would be tough for all hands working on a team to match their “styles” to produce a visually cohesive model. However, if modelers are not encouraged to work together, how will we ever be able to produce re-

11

The 135-inch, 1:48-scale model of USS Juneau (CL-119) by Gibbs & Cox. This model is four times the scale of Bob Steinbrunn's USS Kidd on page 7. In other words, Kidd’s 26-foot motor whaleboat is one quarter the length of Juneau’s. (Photograph courtesy Naval Surface Warfare Center, Carderock Division)

sults that match the team efforts of previous generations?

Ship-model competitions in America and elsewhere encourage modeling excellence and offer rewards for it. Little effort would be needed to include categories for models built by groups. Team entries would certainly advance the purpose of any event.4

Longevity

Earlier, I said that model quality doesn’t depend on how a model was made, but that isn’t the whole story. My guess is that most modelers assume, or at least hope, that their creations will last far into the future. They want their efforts to be appreciated by their grandchildren, private collectors, or museum visitors. The U.S. Navy, in its “Specifications for Construction of ⅛” = 1’ Scale or Smaller Technical and Exhibition Models of Naval Vessels,” states that builders must design models so they will “last one hundred years before deterioration is visible.”5 This is a long time. Imagine your house not needing major repairs until it hit the century mark.

Such a remote goal demands that models be constructed with materials and techniques that will ensure survival. Unfortunately, success in this mission requires great forethought that is not generally observable in the short term.

If you want your model to last, to grow long in the tooth, you must render it strong. I have worked on hundreds of models — old, new, good, bad, large, small, simple, and complex — and report here with certainty that materials used in ship models are continually striving toward self-destruction.

Further, it is naïve to expect that a model will survive simply because it is strongly built. It must also be built so it can be repaired. The person in all of time who will care most for your model is you. And you have the edge. Because you built the model, you know how it went together and how to get it apart to reduce the

invasiveness of repairs. You can help the next person charged with caring for your effort — hopefully, there will be one. Make it possible to remove deck houses, to open shackles, to lift coils of line from belaying pins, and to adjust the tension of rigging components. The key here is to make these things as true-to-life as possible so their operation on a model can be understood. Realism is the common denominator, the universal solvent.

To withstand the withering vicissitudes of time, ship models must endure handling, cleaning, merchandizing, grandchildren, cocktail parties, and the cat. It seems probable that many will succumb. In the end, a model may survive because of the care taken of it rather than the care that was taken in building it. However, if the latter isn’t attended to, the model is likely to fail far sooner.

Achieving modeling results that are historically correct and visually satisfying is difficult enough. Add to the mix the challenge of making a model that will last a hundred years, and the extent of the cumulative challenge to the modeler is increased several-fold.

Many modelers intend that their models will speak as documents of their original research into some arcane aspect of maritime history, for instance how a particular vessel appeared at a particular moment. If we accept this idea, then concerns for model longevity become more important. Of what value is a research document if its author outlives it?6

Respect

Every ship model was, in the beginning, created by what I have come to identify as its “original modelwright.” The phrase could describe an individual working alone. Or, as suggested earlier, it could identify a team of modelers working collectively. You may be an original modelwright! A model exists solely as an expression of the original modelwright. It continues to exist solely because of the care that is taken of it by

12

others, and those others must strive to understand the original modelwright.

Thus, the rule that guides me is: Respect the work of the original modelwright. His, her, or their work, or so-called “hand,” should be protected or preserved when possible and emulated when necessary. Never erase or damage signatures or other markings left by the original modelwright; they contribute to the model’s significance as a document. These rules are true regardless of how good a model is, how well it was built, how well it has been cared for, or how well it tells its story. Art critic Calvin Tompkins wrote that the “whole responsibility is to [the] artist. Not to the dealer, not to the owner, not to the public, but to the artist.”7 I’m pretty sure this is how you would like to have your model treated later, when you are no longer able to tend to it.

When a client brings into my shop a model by a still-active modeler, I suggest that, if possible, the modeler be given the opportunity to work on the piece. This is most respectful to the model and its builder. And, as mentioned, the builder will be most qualified to do the work.

Permit me a pair of clarifying anecdotes. In the early 1980s, I built a model on speculation of a Herreshoff New York 30. Happily, it sold quickly. Months later, I learned through the grapevine that, despite adequate crating, the model had been damaged during transportation to its new home several hundred miles away. For repairs, the buyer took the model to someone else who was near enough to me that it would have been simple to bring the model right to me. I was upset that I was denied the opportunity to repair my own piece, to make it right for the buyer. On the flipside, when I moved to Newburyport in 1986, I introduced myself to Ed Piel, a well-known local modeler (who we’ll visit in Part Four in the Case Study 13 for the Unidentified Down Easter). I said that I hoped he wouldn’t consider my move to his city an infringement on his turf. He graciously replied that I was welcome

to hang my shingle and asked only one thing. If, as seemed likely, people brought to me models made by him, I would send those people to him. This was more than reasonable. Sticking to that request for more than thirty years helped build and maintain good community relations.8

A Model Comes Through the Door

In conversation with the client, whether individual or institutional, I discuss a model’s condition, losses, quality, and needs. I learn the client’s goals for the model and propose treatments. These can vary widely from simply dusting the model and perhaps fixing a broken piece of rigging to completely disassembling and rebuilding the model.

First- or one-time private clients will probably want to have a model restored. Institutional clients, such as museums or holders of large collections, will probably want cleaning and repairs. If they also want major work, they will likely call it “conservation,” not “restoration.”

Most models need cleaning (processes are discussed in Cleaning in Part Three,). And most models need at least some work beyond cleaning. Something will be loose, broken, or missing. If tasks are few, simple, and noninvasive, I call it “repair” work. But many models need more significant treatment. So, it is the difference between “restoration” and “conservation” that I’d like to bring to your attention.

In the museum world, according to the American Institute for Conservation, to restore a “cultural property” (an object that has “artistic, historic, scientific, religious, or social significance”) is to return it “to a known or assumed state” that is, as career conservator Sherry Phillips further clarifies, dictated by evidence presented by the object. Restoration often involves “the addition of non-original material.”9 Conspicuously, this definition does not license alterations to the nature or detail of the original object. For us, it

13

implies and encourages respect for the original modelwright.

But most ship modelers, both amateur and professional, are far from strict about this usage. Regrettably, they use “restoration” to label any more or less large-scale undertaking on a model. And, although “restoration” implies deeper immersion than “repair,” there are no limits in the craft world on any facet of “restoration;” the horizon for clarification is open and vast: nothing is sacred. Usage of “restoration” is so entrenched, yet vague, in the ship-modeling community that it is all but hopeless, today, to restrict its meaning to the museum professional’s considerably more cautious interpretation.

Let’s construct an example. A client presents a twohundred-year-old model of a square-rigger that lacks, say, a set of steps to connect the main deck with the quarterdeck. Such steps were common and necessary on real ships. Many modelers would see an opportunity to make the model more accurate by adding steps, and they would consider the addition part of their restoration. But museum professionals will search for evidence — glue footprints, fastener holes, paint gaps, and the like — that steps had been fitted originally on that model. If there is no evidence, they would not add steps, and the addition of steps would not be restoration; it would be disrespect. They listen to evidence provided by the object and, by doing so, they respect the original modelwright.

Museum and independent specialists called “conservators” employ another practice. This is “conservation,” and it is somewhat more complex. The Institute for Conservation defines it as a process “devoted to the preservation of cultural property for the future.” In turn, it defines “preservation” as “the protection of cultural property through activities that minimize chemical and physical deterioration and damage and that prevent loss of informational content.”10 While working with several conservators over the course of thirty-five years, two aspects of conservation grew clear.

To me, the less imperative aspect involves being educated in the chemistry of objects. All conservators with whom I’ve spent time apply a solid knowledge of how materials, adhesives, and finishes react with one another. While I attend to what we might call the shippy aspects of model jobs at museums, conservators prescribe the limits of materials and processes that will be appropriate to use. Chemistry is not my forte, so I welcome, appreciate, and adhere to conservators’ input.

Now, the aspect of conservation more important to me is that everything that has become part of an object becomes a part of that object’s story — its “informational content.” What does this mean to us as ship modelers?

Let’s say a client presents that same square-rigger already fitted with the steps. By close examination of fit, finish, and materials, the conservator can see that the steps are not original gear. A previous hand was not “restoring” the steps because there is no evidence the steps were original. But the conservator, accepting the entire object, will leave those steps aboard because everything, original and new, contributes to the model’s overall story. In this example, someone built a model, but left off the steps. Who knows why? But then, a century later, someone added steps because they would “improve” the model. The conservator recognizes that even errors by previous hands become part of and relate a model’s history. So, the conservator acts conservatively and alters as little as possible. The conservator preserves and stabilizes but doesn’t correct. As Phillips explained, the conservator “leaves [her] ego at the door.”11 This can be interpreted to mean that the ego of the piece is more important than the ego of the conservator and that the piece should speak louder than its custodians.

Another hypothesis bears consideration. That same square-rigger is presented. There are no steps, but clear evidence indicates they had been fitted originally. Notches in the quarterdeck rail show wood slivers em-

14

bedded in old, dried glue, and there are nail holes in the deck. There were steps! Now the conservator has license to build and install new, replacement steps. This is proper restoration, dictated by the model and respecting the original modelwright.

These differences will not be appreciated by all clients, but they will be by some. Thus, it is important to be able distinguish various approaches to treatment.

With full disclosure in mind, I must declare that, when starting out, I didn’t know about, let alone apply, any conservational theories. Several models fell victim to my early heavy-handedness, and I assure you there are a couple of jobs I wish I could undo. Fortunately, I gradually developed a lighter touch and learned to respect the models and their builders. I approached a fork in my path and left the amateurs’ version of restoration at that fork. I now avoid almost entirely the use of “restoration” in favor of other words.

Never Upgrade the Model

For another perspective, I should add that before learning about professional conservation, I had, from time to time, people assisting me with repair work. To help guide them, I had independently developed what is an effective working corollary to the policy of respecting the original modelwright. This is: Never upgrade a model. I explained that when it’s apparent an original modeler made a mistake — installed a blatant anachronism, say — the error must be preserved. (Conservators consider removal of original work, even if it is wrong, among the most scandalous taboos.) Further, it’s important to match original workmanship. If it is fine, then repairs must be fine. If a model was made crudely, then, ironically, high-quality repairs must be crude. I told my colleagues that a model builder creates a world, an environment, and a story. It’s incumbent on us to understand and enter that domain, to attempt to be the original modelwright. The availability of modern research, materials,

and tools does not justify the violation of an artist’s intentions and craftsmanship. The goal is not to correct the original modelwright, but to re-invigorate him. If a person repairing a model wants to make a “better” model, he or she should build an entirely new one.

Two Debates

A pair of debates seems always to be on-going about ship-model work. To understand the first, imagine an old but historically relevant plank-on-frame model that has been severely damaged and is missing quite a bit of its structure. The model is going to be rebuilt for a museum exhibition. The question is: Should replacement work be executed so it blends inconspicuously with the old model, thus making the model appear whole? Or should new work be made to contrast with the model’s original fabric so viewers can make no mistake about what portions of the model are new and old? My response is to make the model appear whole. This is because inexperienced viewers will likely not care about and will be confused by the visual evidence of the rebuilding. They will see it as a part of the portrait of the ship. Conversely, informed viewers who care about the rebuilding will be able to distinguish between original fabric and new work no matter how well it’s made to blend in. I would only support the idea of contrasting work if the museum’s story is primarily about rebuilding the model.

For the second debate, it’s important to know that, within most old models, one can find debris of one sort or another. There may be dust, shavings, bits of woodworking or rigging, evidence of infestation by rodents or insects, and more. What is to be done with these things? Items that are recognizable as having been fitted to the finished model, but, for one reason or another, came adrift and were tossed below for safe keeping, may be reinstalled externally with confidence.

15

Shavings, dust, and scraps, however, seem to have no value. Curators and conservators do not like to discard anything because everything may contribute someday to the model’s story, even if its language isn’t yet known. One policy is to leave everything in situ that cannot be reinstalled confidently. The thinking is that the model is the best place to keep material against a time when as-yet undeveloped analytical processes may reveal more than is possible today. This policy avoids the need to archive things separately from the model — the model is the file cabinet. Another policy is to remove as much debris as possible. The advantages are that the model will look better, that some buried items may surface that might not have been noticed, and that the debris can be studied later without reinvading the model. The model also profits environmentally because impacted dust can retain moisture, which is usually debilitating, and because the more that air circulates, the healthier the model’s fabric will be. The only inconvenience is that a filing system and space are required to catalog and store removed three-dimensional materials.

A Few Perspectives on the Arcane

The remaining eight sections of Part Two are musings. They are not directly related to ship-model building or repair. However, I suspect that, from conversations I’ve had through the years, these topics burble occasionally to the surface of many modelers’ minds in one form or another. This seems to happen when they are engaged in lengthy, repetitive tasks that occupy the hands but that leave room for thought. I hope that their inclusion here will help solitary modelers feel less isolated; in an obscure way, we share a common work space.

Profoundly Handmade

Seventeenth- and eighteenth-century British Navy Board models, which we revere, were made before

the advent of steam power and electricity. Modelers operated spectacularly with manual frame saws, chisels, knives, bow and pump drills, planes, gravers, scrapers, and hand or pole lathes. And they labored with no electric lighting to enable work in dimly lit rooms or on gloomy days, which there were plenty of in England. This was before the refinement, in the nineteenth century and later, of the modern circular saw, band saw, power sander, and drill press, not to mention the incomparable engine lathe. When those earlier ship modelers first saw a circular saw, I’ll bet they cried, “Hot damn! Gotta get me one o’ those!” They immediately recognized a tool that could be adapted, with effort, to their tasks; that could make their work easier, faster, and more precise. I’ll bet few condemned the device for its lack of being traditional.

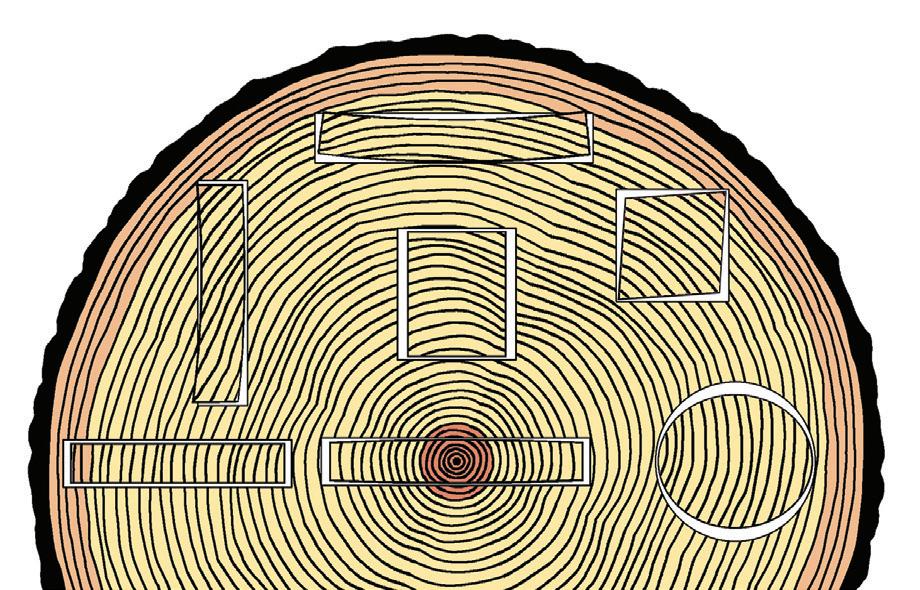

We take our electric, circular-motion tools so absolutely for granted that we forget they were once technologically advanced. Imagine building a complex plankon-frame model and all you have is a hand-powered frame or jeweler’s saw, scrapers, and planes. Ripping a hundred feet of dimensioned boxwood decking (by candlelight!) suddenly becomes daunting. To prepare a board, you must handsaw and plane it to consistent thickness; scribe off a plank; handsaw that to width; then scrape it smooth. The planks had to be identical, and they were, to tolerances we have trouble attaining with the Preac-brand table saw. If we think of our work today as being handmade, even with our power tools, then we must think of the master seventeenth- and eighteenth-century modelwrights’ work, who literally worked with their hands, as being profoundly handmade.

Nowadays there are those who think innovations like photo-etching, 3D printing, and other computer-based techniques should be rejected chiefly because they are not traditional. There is no reason to suppose that ship modeling has evolved to its ultimate phase. So, let’s look back from the future per -

16

spective of, say, the twenty-fourth century. By then, the technologies of table saws and computers will be relatively the same age. They will have been around always, and modelers will be using both without qualms. Why? Because computers make production of ship-model components easier, faster, and more precise — exactly like the table saw. This will occur regardless of how we label or shun today’s breakthroughs. With the present era’s exponential increases in developing technology, there will be even newer methods about which we haven’t yet imagined a glimmer. 12

Personally, I favor working with wood, brass, and natural fiber line. I just like the stuff; I grew up with it. But progress is important. We should not make blanket rejections of technology simply because some processes may not yet be proven.13 If we do not experiment with new ways to solve old problems, we would not be human; we’d still be living in caves, perhaps under rocks. The obvious fact is that if we do not experiment, we will never discover what will work to create models that will last a hundred years.

Tryst

Over time, I’ve asked many ship modelers why they install features that will never see the light of day inside their models. I suspected there must be some deep-rooted reason, some drive, that those modelers were reluctant to articulate. But they seemed to guard their reasons. Their pat answer felt too flip: “Because I can.” This didn’t tell me anything; it didn’t sit well. I felt like my question hadn’t been given any real thought. Then, during a model repair trip to Long Island’s North Fork in 2011, the answer came to me in the small hours of the morning. It is this: Ship modeling is solitary, and, as such, trends generally inward. A modeler really doesn’t want to admit his feelings, whether he can express them or not, any more than someone wants to admit an affair of the

heart that occurs outside established boundaries. The modeler who builds details no one will see is looking inward, toward his own motives for modeling. They are private, possibly even secret. He is having an assignation with his muse.

Spirit

My eyes opened briefly to see the barber intently trimming my beard and mustache. It was 2008, the first time in perhaps thirty years I was getting my hair cut by an unfamiliar barber in another country. It was a highly recommended, old-world-style shop. Three efficient barbers were working, six men were waiting. It’s a risky business. How do I tell him what I want; will it turn out okay? The barber was completely focused. Only inches from my face, his eyes didn’t blink when mine opened. I was glad of that. Right then, I wondered if I look at ship models with that barber’s intensity. It might be harder to understand what I wondered next. Does a ship model perceive me looking at it? Does it feel my concentration? Does it know if my hands are steady? Does it enjoy my attention? Can it tell if my tools are doing the right things? If so, is it grateful; if not, is it resentful? Can it remember? If I mess it up, can it affect the effort of future hands? Does it understand I am trying to help it? Does it feel refreshed when I’m done?

I know I’m anthropomorphizing an inanimate object. However, from experience at sea, I have come to believe that some vessels have genuine presence, that they have spirits. They seem to enjoy being the vessels they are, or not, and comport themselves accordingly. Why not models? Do some models see me like I saw that that barber?

The Orbit of Pluto

Everyone knows the Law of Lost Parts: A lost part is always found in the last place one looks. But there is an

17

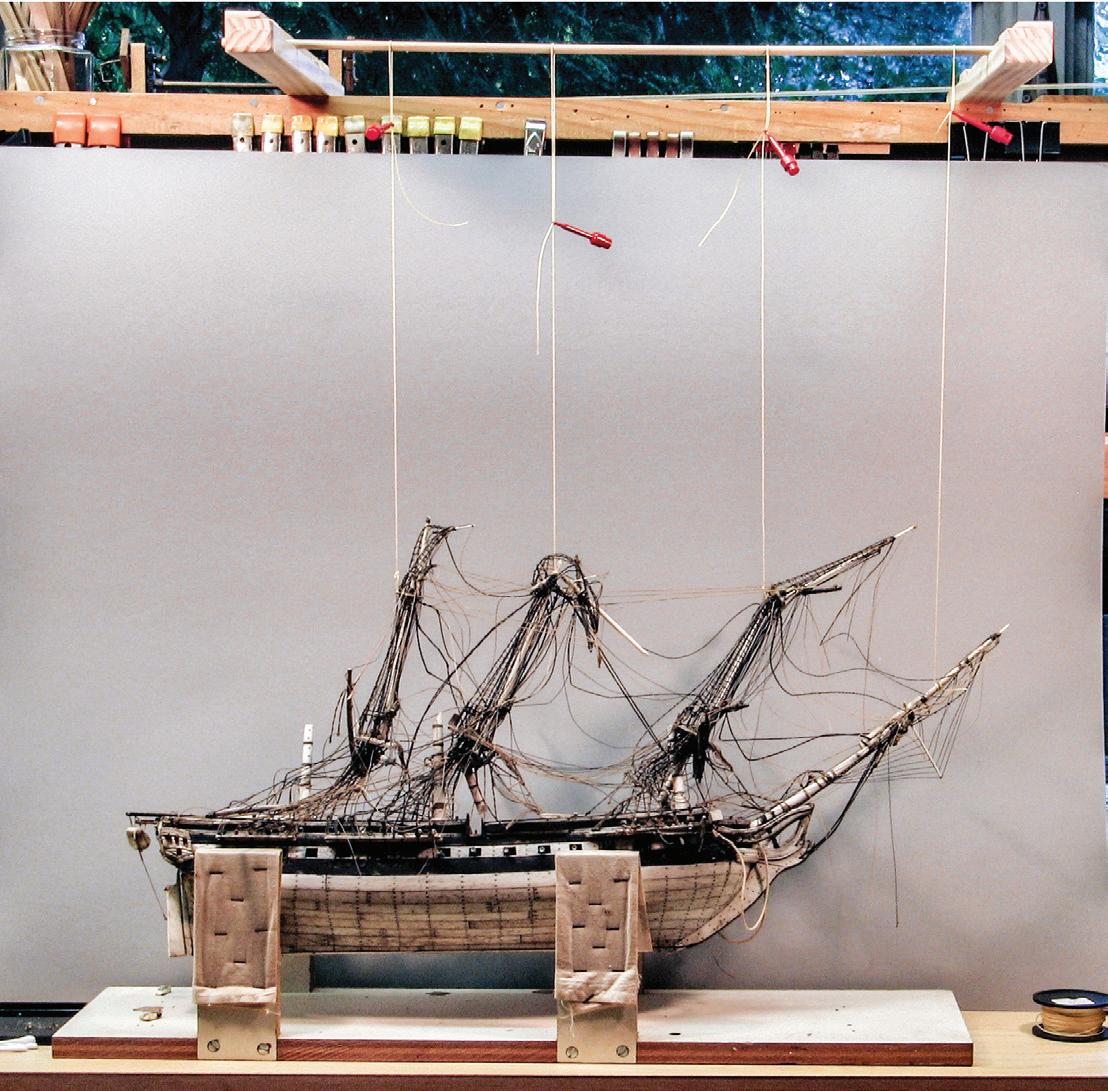

Does this large model of an eighteenth-century warship perceive that I am peering into it with the same concentration as that barber had when he looked at me?

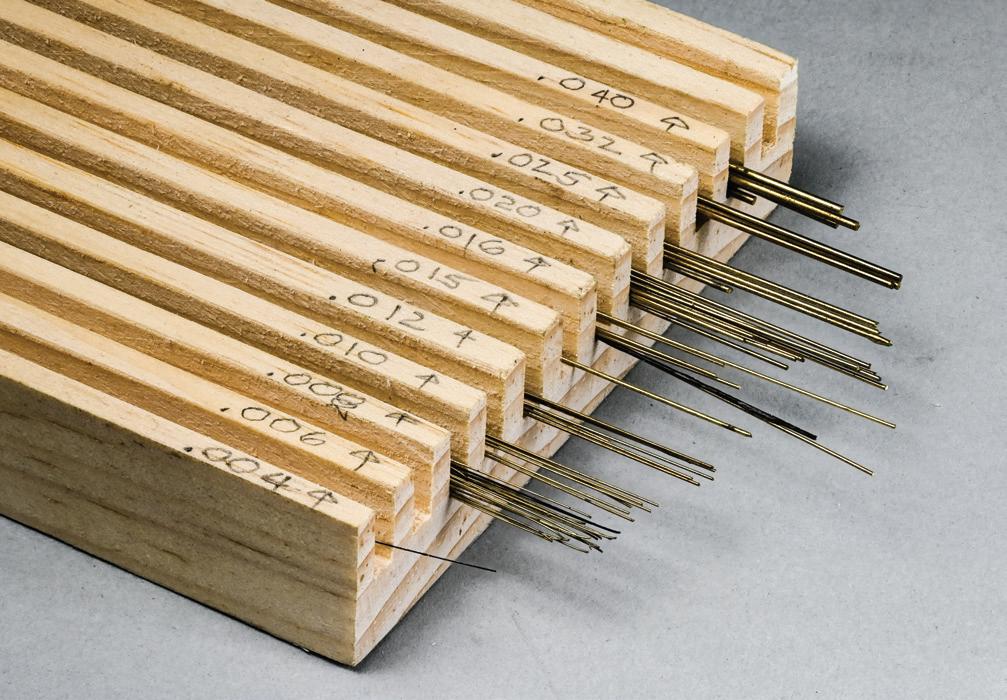

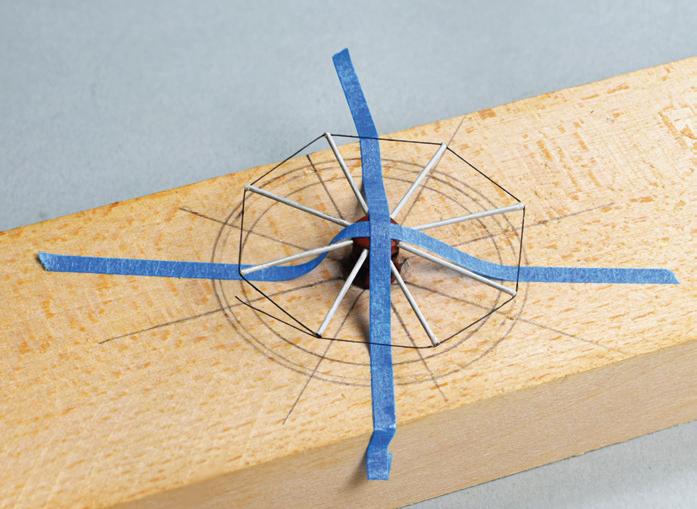

obscure First Corollary: The smaller a lost part is, the more likely it will be found in the last place one can look. In 2014, a ferocious deadline to finish a model was looming, and I was making the gang of blocks. They were built up with separate cheeks, fillers, pins, sheaves, and internal metal strops. The largest was 5/16 inch long, and the average time spent on each was considerable. One popped out of my grasp, fell to the floor. I searched the area on hands and knees with a flashlight to produce raking light to amplify the block’s shadow and make it more visible. No luck. I spent more time searching than it finally took to make a replacement. Some modelers say that such parts are sucked into the black hole of the Milky Way. I, however, believe they enter the Belt of Missing Parts just beyond poor little Pluto’s orbit. And the proof was that block. If it had been sucked into a black hole, it would have been gone forever. But, lo, more than a year later it reappeared in a cabinet, at least 10 feet from where I had been sitting. This happens frequently enough that I have formulated the Law of Lost Parts, Second Corollary: The time required to locate a vanished part is inversely proportional to the part’s mass yet directly proportional to the part’s building time, these factored against the time spent searching prior to the realization that, yes dammit, you’ll have to remake the part anyway.

The Zone

When doing repetitive model work, I sometimes find myself in the Zone. The work is flowing, thanks to experience, practice, and muscle memory. I think about the actual moves I am making — holding the pencil so it marks properly, moving the knife so it cuts the right bevel, snaping the end of a wooden strip without tearing — things like this. But I think not only about processes, I am also mentally verbalizing them in phrases or sentences. There are two side effects. First, I’m pleased that I can convert action into language

spontaneously. Second, if I want to save the language, I must write it down immediately, and that might take me out of the Zone.

The Zone embraces me in another way when I’m concentrating on something numbing, like rattling down shrouds. At the start, I find myself totaling the number of times I’ll have to repeat a task, in this case tying clove hitches. Then, in my head, I serially recalculate the percentage of the job I’ve finished so far. Eventually, the numbers fade — the Zone takes over. I usually resurface at about the 90-percent mark, then figure percentages down to the finish.

My mother, a music major at university, encouraged me to listen to classical music; popular music had no place in our home. I didn’t question this: It was what it was. I realized only lately that this was beneficial in a way I’d never considered. Mother recognized I was fervent about ship models, and I suspect she understood how much effort and time they would require. She knew that classical music also required enormous effort and concentration to compose and perform, especially when compared to pop music. Perhaps seeing classical music and ship modeling in parallel, she may have understood that listening to the former offered the appropriate environment for creating the latter. I didn’t learn hard facts about classical music, but I absorbed its moods, complexities, and power. Long compositions helped me focus on lengthy problem solving in ship-model work.

Later, when I turned pro, each ten-hour workshop day was filled with music — classical, jazz, rock, in that order — but now I prefer just the steady whirr of a fan. I’ve asked other modelers about the Zone. Bob Steinbrunn refers to the Zone as the “alpha state,” and says that “all great artists” feel a “flash of irritation” when they are dragged “back to full awareness” by interruptions. Joel Sanborn “can’t listen to music with lyrics…music needs to be background ‘noise’. Opera is okay if it is in Italian or German.” David

18

Antscherl says he meditates once he’s “achieved the muscle-memory rhythm” and listens “to classical/baroque music to help time pass enjoyably.” Clay Feldman “used to listen to NPR,” but now has “de-zoned altogether” with “no more radio at all.” Bob Filipowski suggests that the Zone has a “dark side” where he is so focused he forgets about nearby fragile objects and occasionally breaks them. “That brings [him] back to reality quickly.”14 Some modelers relieve long Zone sessions by rewarding themselves with other tasks. My preference is to just steam through to the finish — I like the Zone.

Autodidact

When people ask how I learned my trade, it pleases me to reply that I am an autodidact. But is this entirely true? Granted, no schools offer formal curricula for researching, building, and caring for historically accurate and significant ship models. (However, in recent decades, brief ship-model conservation workshops have been offered by a couple of European institutions.) Nonetheless, there are other ways to learn. For instance, I have retained a perfect mental video of watching, when I was sixteen, New York modeler Don Peterson’s hands manipulate a miniature plane to shape a grab rail for a yacht model’s deckhouse. Whenever I work with trained conservators, I absorb everything possible. These generous folks didn’t know they were teaching me, but I was learning from them. I’ve read countless books and studied other people’s models, old and new. I let them all teach me about ship modeling. I’ve spent thousands of hours at the workbench, often making mistakes and redoing things. Does this mean I am self-taught?

For more than twenty years, the Forbes Trinchera Ranch collection was in my care. I was assisted there on many annual trips by Racket Shreve, a fellow modeler and marine artist. We received from the client no guidance whatever on what we were to do. Racket

compared us with a M.A.S.H. unit. We worked in the ill-equipped field, triaged the collection’s needs incessantly, and did what we could in a hurry to keep models intact. I always hoped the owners would take a more active rôle. Had they, though, we would never have learned as much as we did. This was on-the-job training by the models themselves. Was I self-taught, or did I let the models teach me?

Sometimes I find myself not liking a model I’m working on. But I know that, through the effort of the work, the model will teach me something; I will learn from it, and I will like it more because there is something of me in it. If I don’t learn something positive from the model, I haven’t put enough of myself into it.

Anxiety

Anxiety affects my ship modeling. After fifty years, how can this be? Suppose I am building a set of fittings for a model and consider them finished well enough to move on. I start thinking about the next task and that it will be challenging for any of several reasons I’d prefer to avoid. So, rather than advance, I take shelter by retreating to the earlier project — by adding another level of detail, say. There are two results. First, the model gets better. Second, I have delayed the inevitable. But soon I can stall no longer, even if that next step does seem too difficult, complicated, or scary.

Now, when avoiding a task for these reasons, I must remember “fear is the mind-killer.”15 This central message from Frank Herbert’s Dune is that anxiety prevents one from thinking through a problem to the point of solution or action. It is key to finding success. So, what do I do when I don’t know what to do, or how to search for a new approach, process, or outlook?

Another venerable maxim becomes operable: Do something, even if it’s wrong. The paralysis of inaction can be cured by taking a first step, even if I’m not sure it’s on the right path. For instance, a wing transom for a large wooden vessel’s frame incorporates complex geom-

19

etry that is particularly tricky to visualize, to pin down in space. The timber usually curves and tapers in a couple of directions and abuts neighboring timbers without the convenience of right angles. I can’t visualize how to start. Finally, I draw what I hope is a likely line on a piece of wood and cut it. I will know immediately, by whether I can picture the following step, if I have discovered the correct first step. If I’m not sure, the second cut cinches it, even if it tells me I need to restart, and I know I will succeed. If the path is altogether wrong, I recall the lesson of a friend from my Navy days: “If you try something three times and it still doesn’t work, try something else.”16

You may think I’m nuts for assessing problem solving this way, but there it is. It has prodded me to deeper levels of accomplishment consistently for fifty years. There must be something to it.

About Money

It is inevitable that, during the question-and-answer period following every talk I present to lay audiences, the subject of how much I charge for my work will arise. My policy is to say either how long a project took or how much it cost overall. But I never reveal both because people want to do the math to learn my hourly rate. When asked directly, I say that it’s business between my client and me. My observation is that clients don’t care what my hourly rate is; during my career, I may have been asked only three times. Clients are only interested in the bottom line.

Amateurs boast about how long projects take them as if longer is better. Professionals boast about how quickly they do projects because they need to keep hours down.

My work is divided into three areas: half-model building, model repair and conservation, and full-hull model building. The list inversely orders profitability. In the early 1970s, I sometimes worked for as little as $2 an hour, and I could make a profit at that on some projects. And there is no doubt that full-hull model building, which requires thousands of hours, will generate a lower hourly income, on average, than shorter projects simply because, for full-hulls, the hours can really pile up.

I know roughly what academically trained, independent conservators charge (and get, judging from their backlogs). Not being an accredited conservator, I do not bring their level of expertise to the bench. Thus, I have always kept my rates lower.

Incidentally, it’s ironic that the security of an extended backlog erases the joy of spontaneity. I always know what I’ll be doing next week, next year, and the knowledge is debilitating.

In the 1970s, I had a mentor who did exclusive yacht designing. When I asked him about charging for custom work, he counseled firmly: “Never give a client anything to complain about except the price.” This was terrific advice for a young practitioner. And I heeded it. But as I have wandered into my seniority, I find it increasingly difficult to meet deadlines. ¯

20

Part Three Practices and Applications

Why Are They Here?

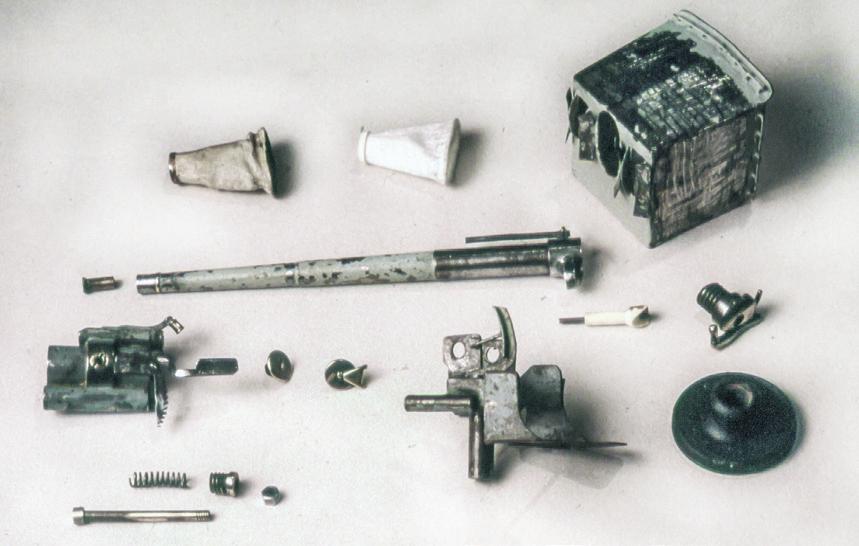

What brings ship models to my shop? Models suffer many woes that can be sorted into two basic categories. Let’s call them external and internal issues. External issues might be considered those things that happen to models. They are generally severe. Models are damaged by poor handling; by careless viewers; by passersby; by heat, smoke, and fire; by objects falling on them; by falling on the floor; and so on. Such catastrophes and more are easily understood, and the results are obvious.

One client called to say he was sending a small, bone prisoner-of-war model for repair; it travelled across the country in a paper mailing envelope; do I need to describe it? The upper masts and rigging of an-

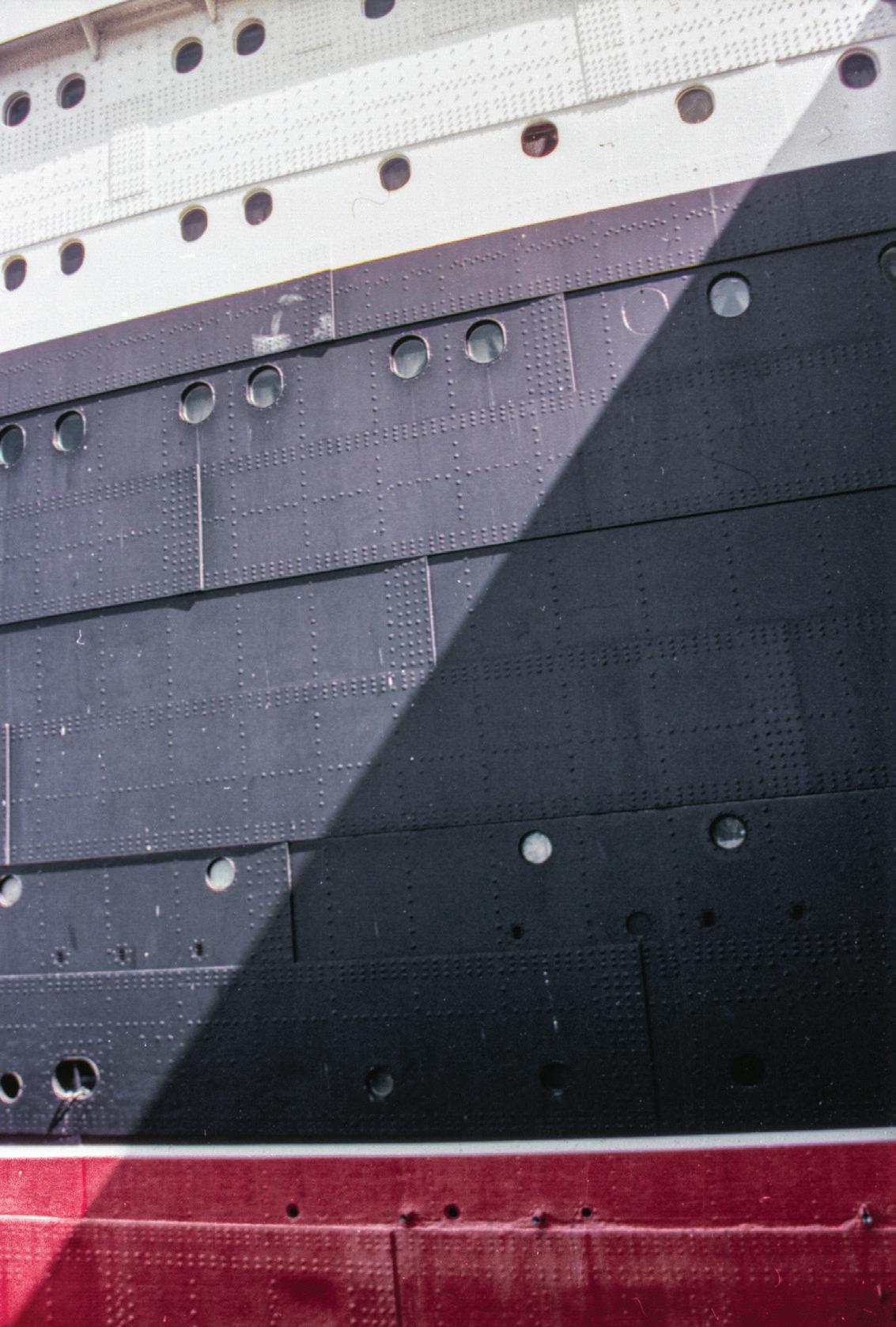

other bone model had been crushed by a customs agent who reached zealously into a shipping carton before looking to see what was there. I’ve rebuilt more than one steering wheel that shattered when someone at a cocktail party saw it and said, “Look at that! I wonder if it works”: nope. A collection of large models suffered a fire; models that weren’t charred were covered with smoke residue. One of the first models I built was swept off a mantel, thus one of my earliest professional jobs was rebuilding my own work. Another model and its display case were mauled by airline baggage handlers. And another, “professionally” packed and shipped to me for minor repairs, arrived with its brass mast bent into a double-S curve and penetrating the carton top; all the rigging was destroyed. The first time I saw one 11-foot builder’s model of a British liner, it was covered

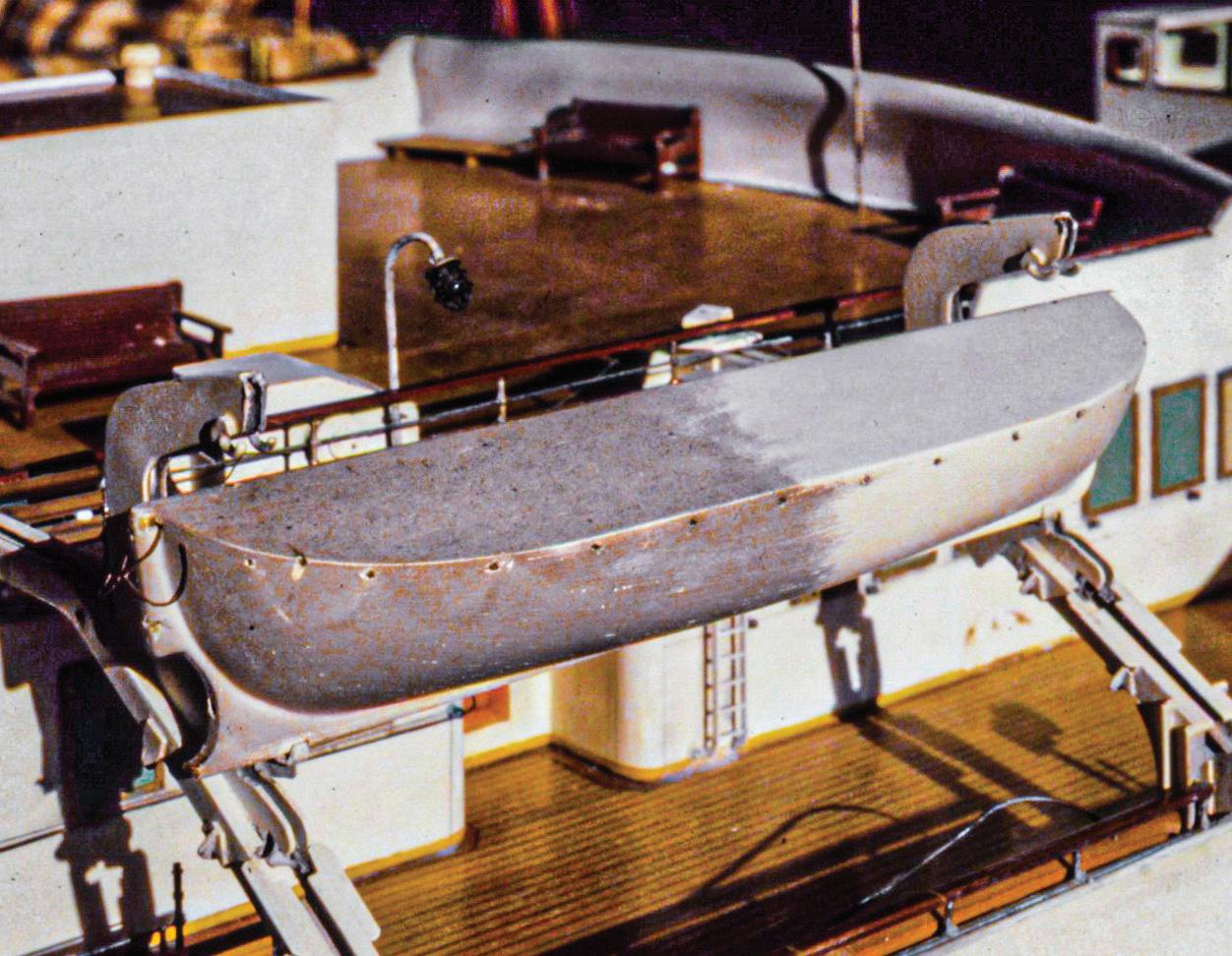

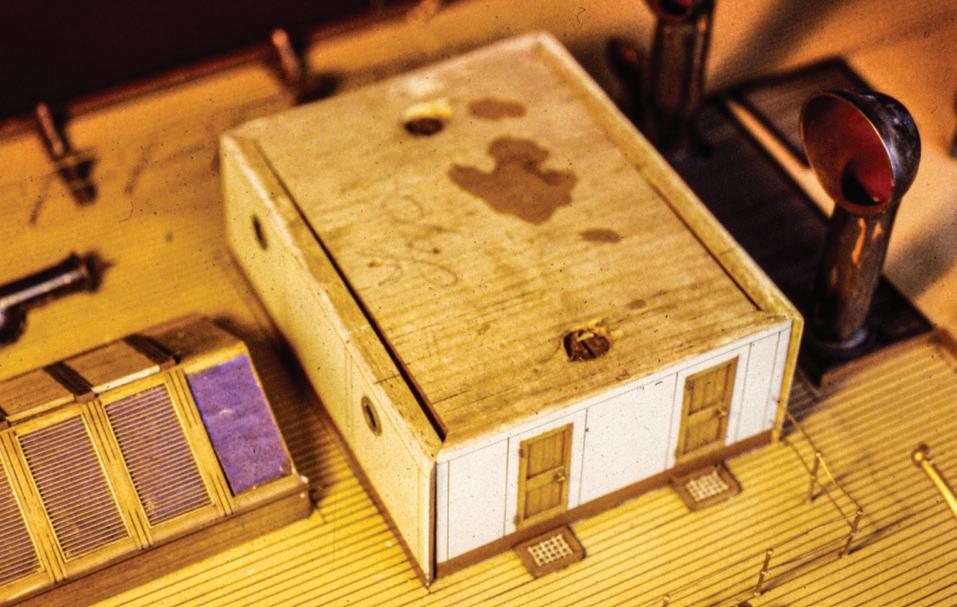

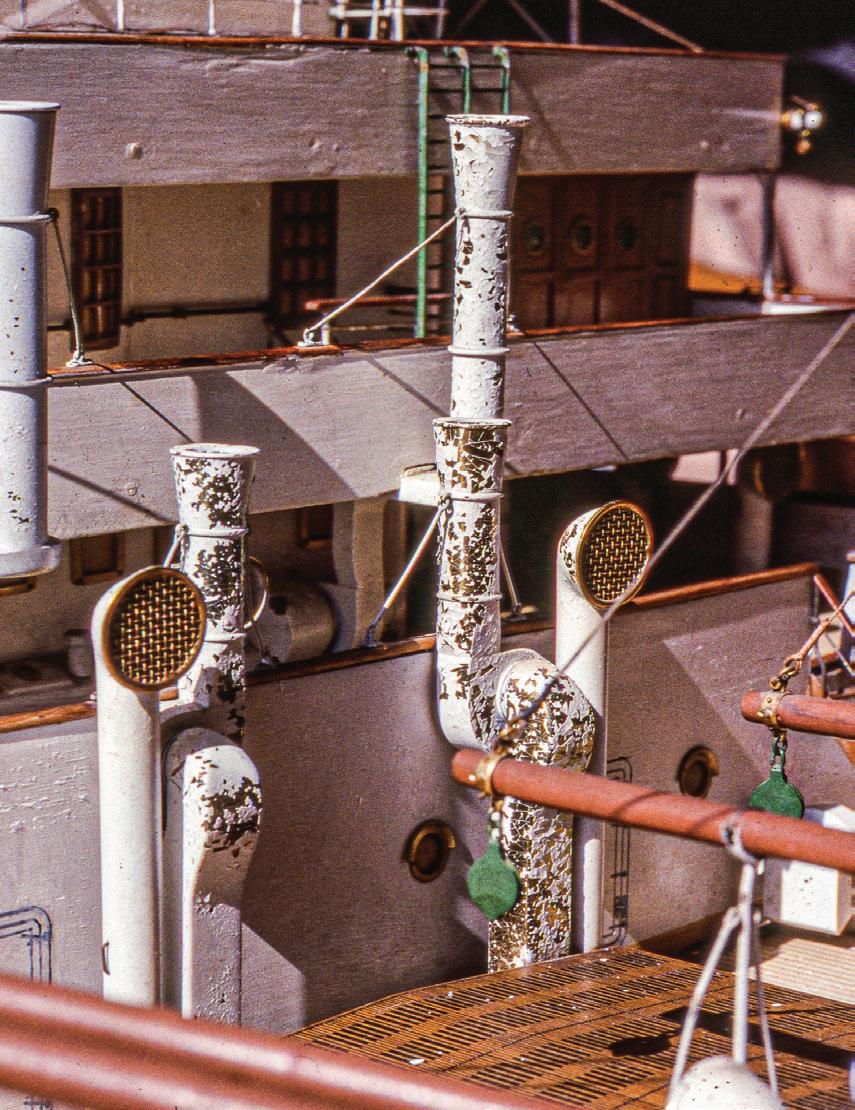

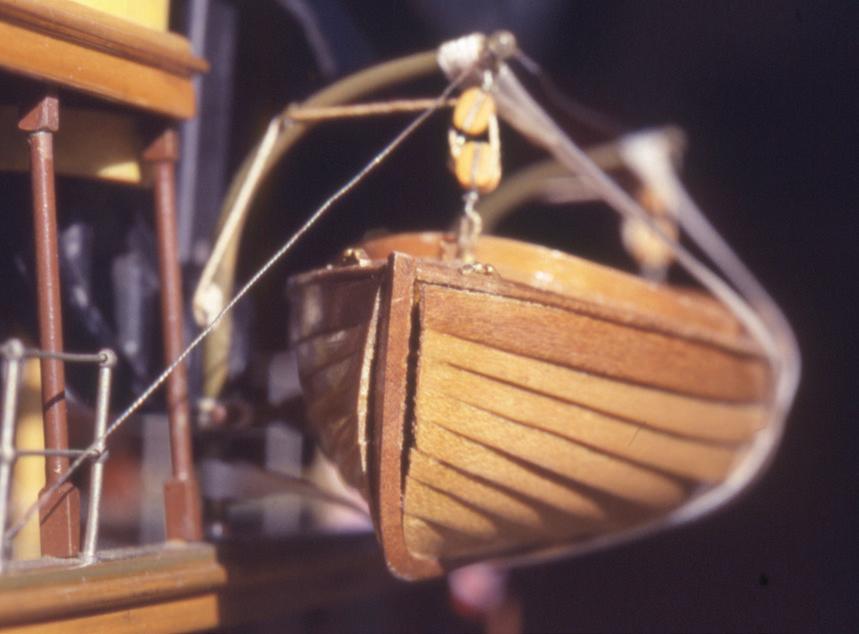

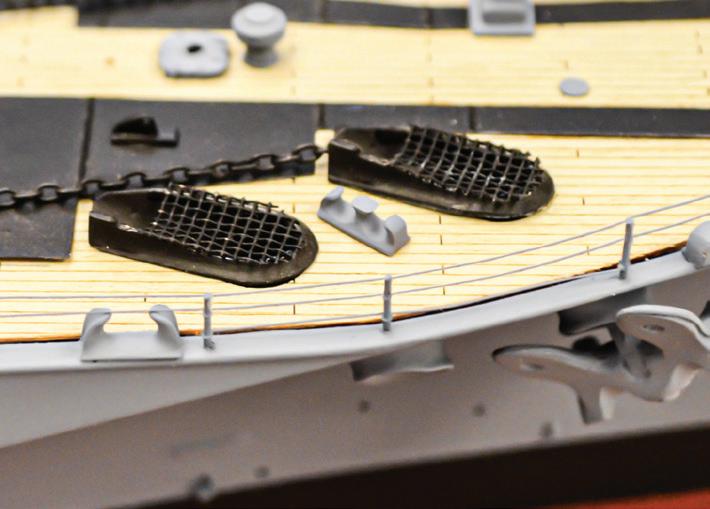

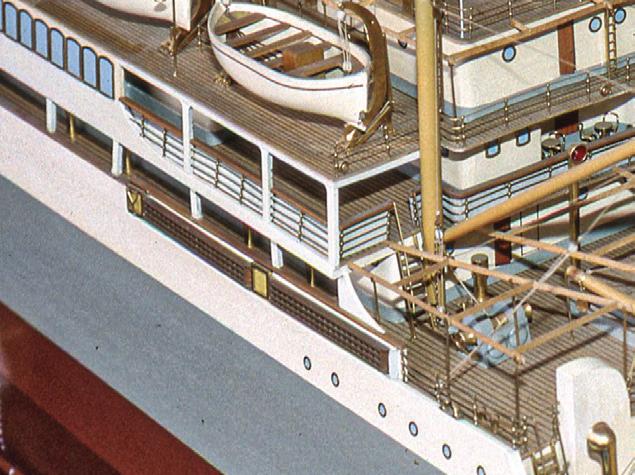

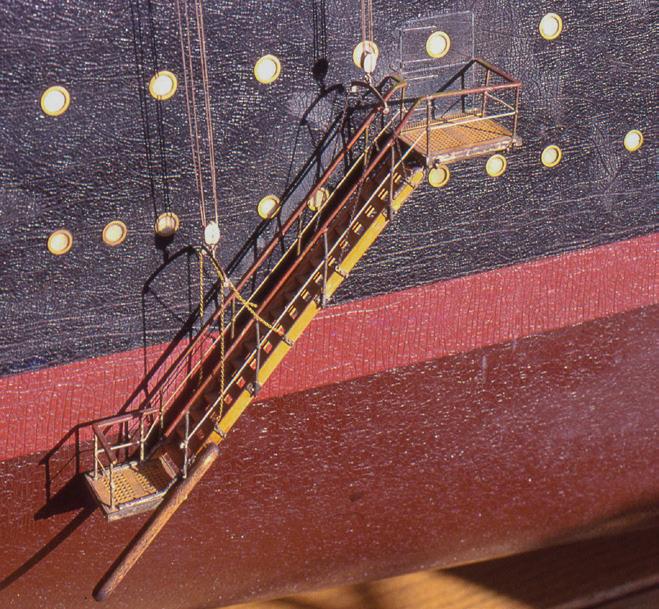

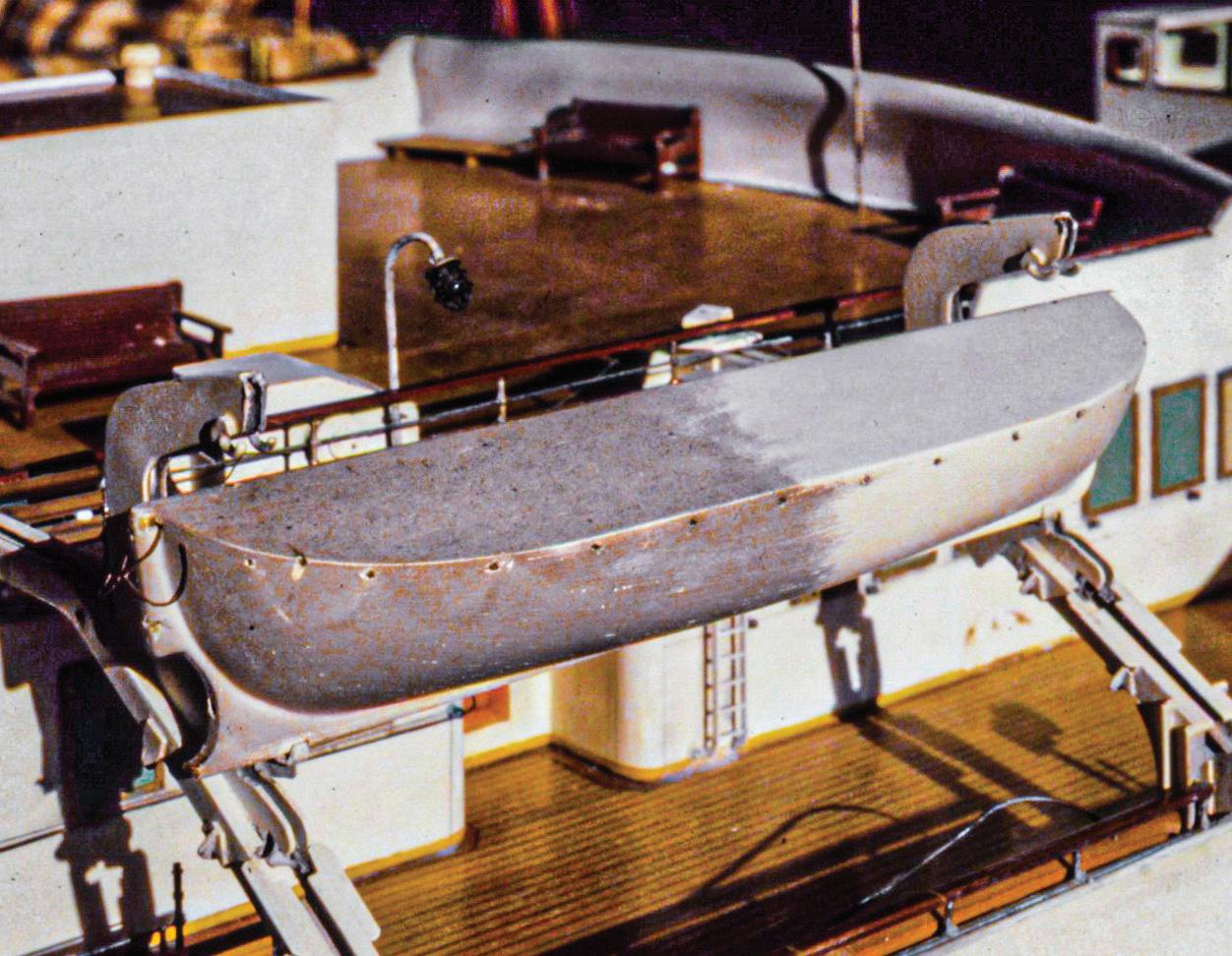

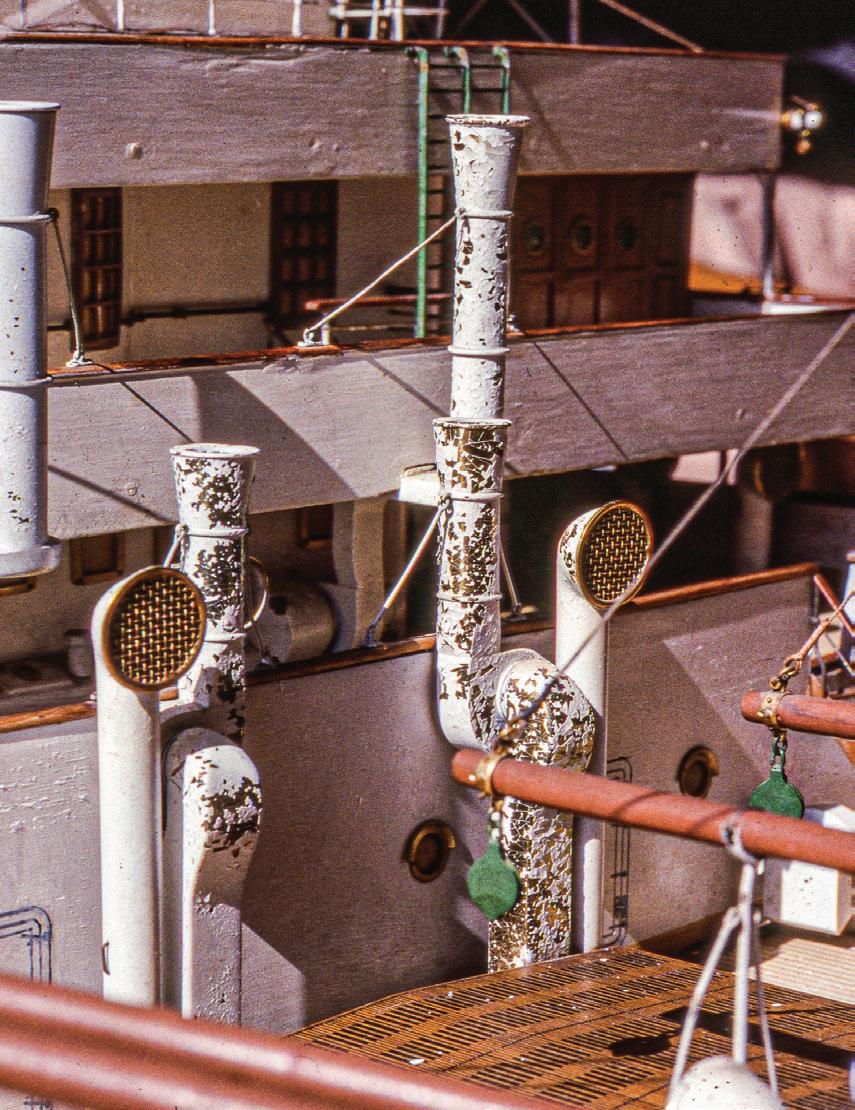

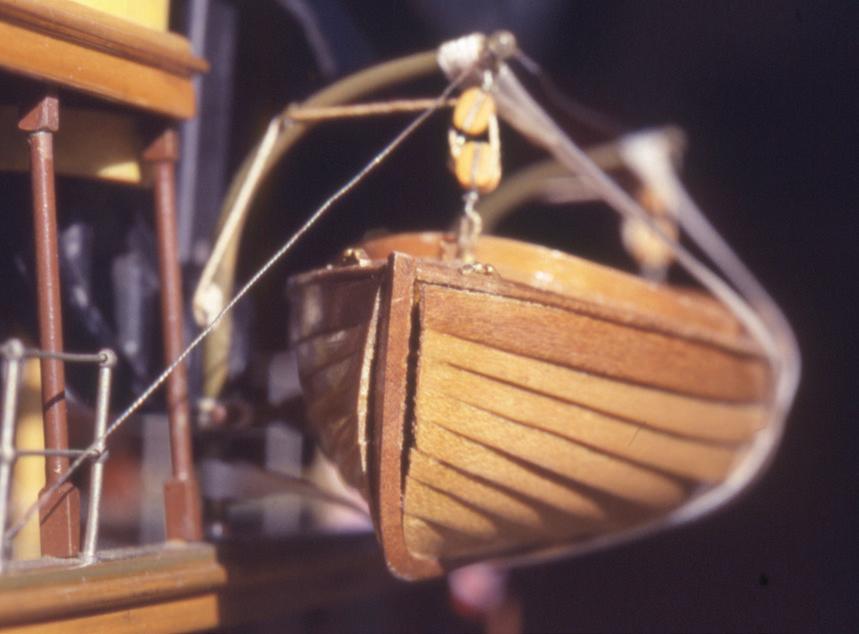

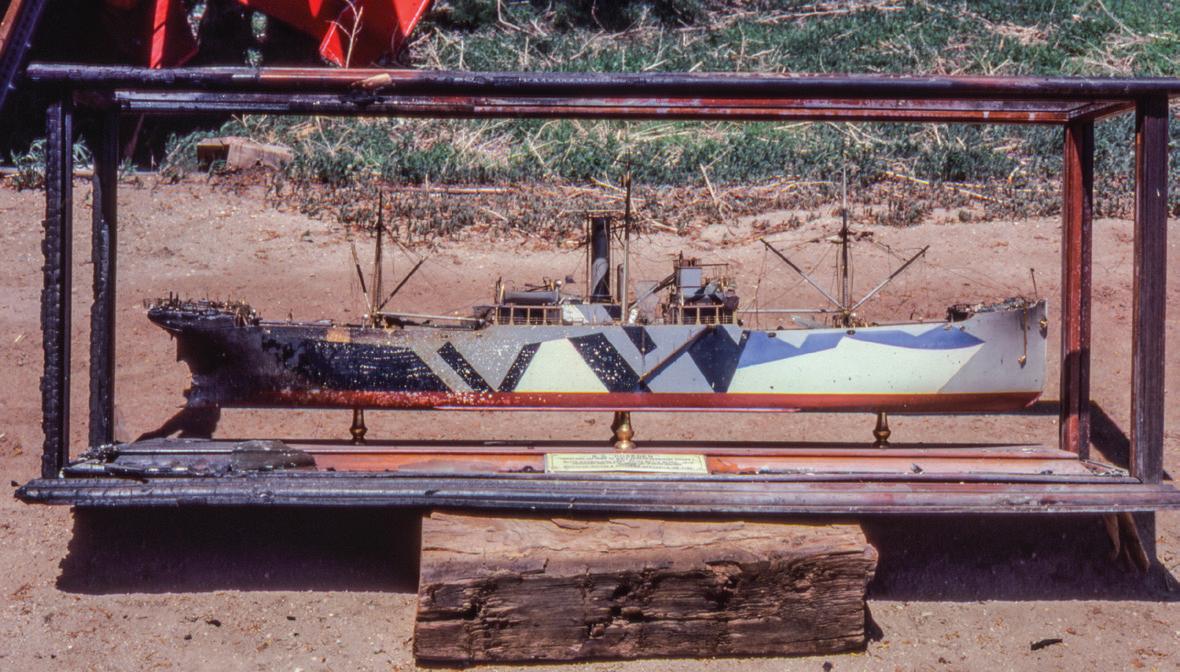

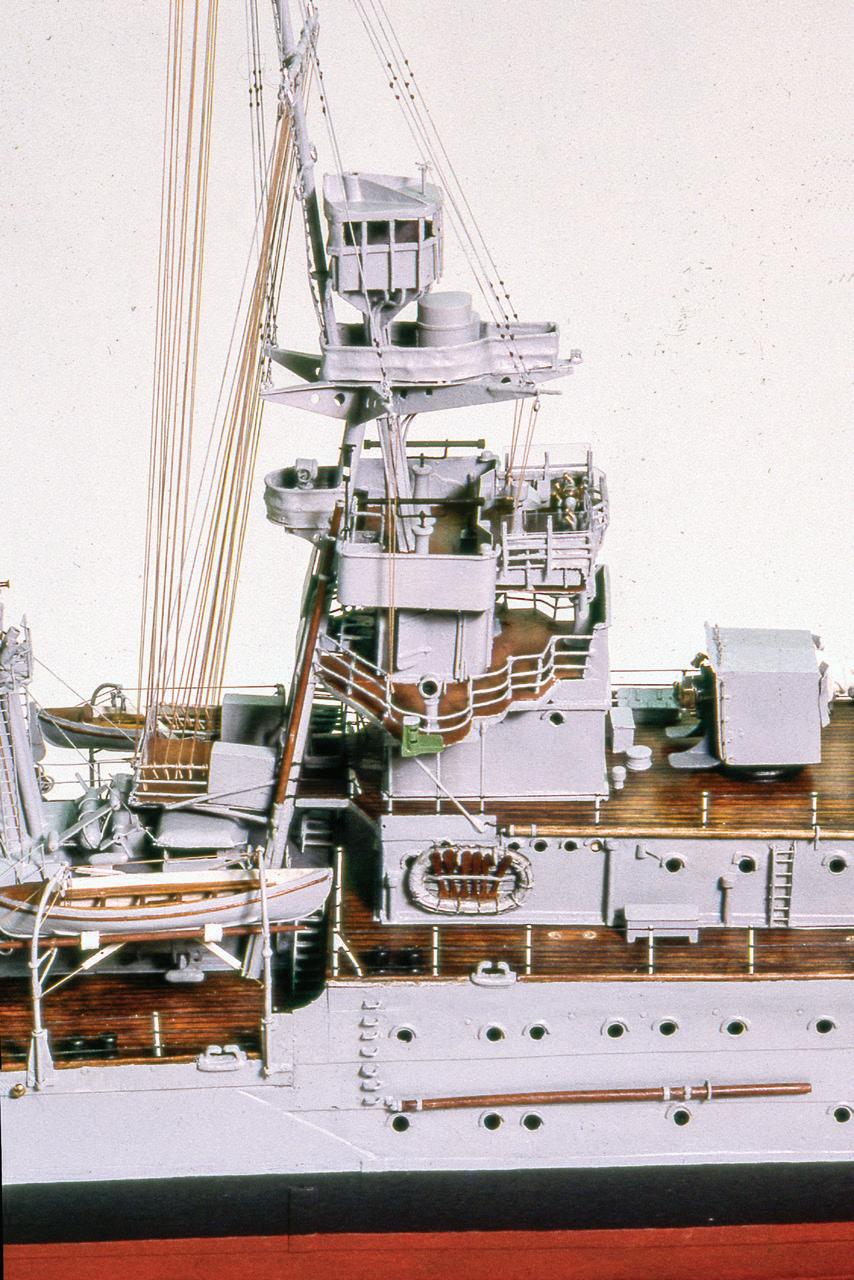

Far left. Smoke damage. The lifeboat’s uncleaned aft end shows how smoke residue completely enveloped this 142inch, 1:48-scale builder’s model of the Royal Mail Line’s short-lived 1948 twin-screw turbine ship Magdalena Center. The port bridge bulwark was slashed by a shard of 3/8inch glass falling from a shattered case. Detail from the 138inch, 1:48-scale builder’s model of the New Zealand Shipping Company’s 1929 twin-screw passenger liner Rangitiki.

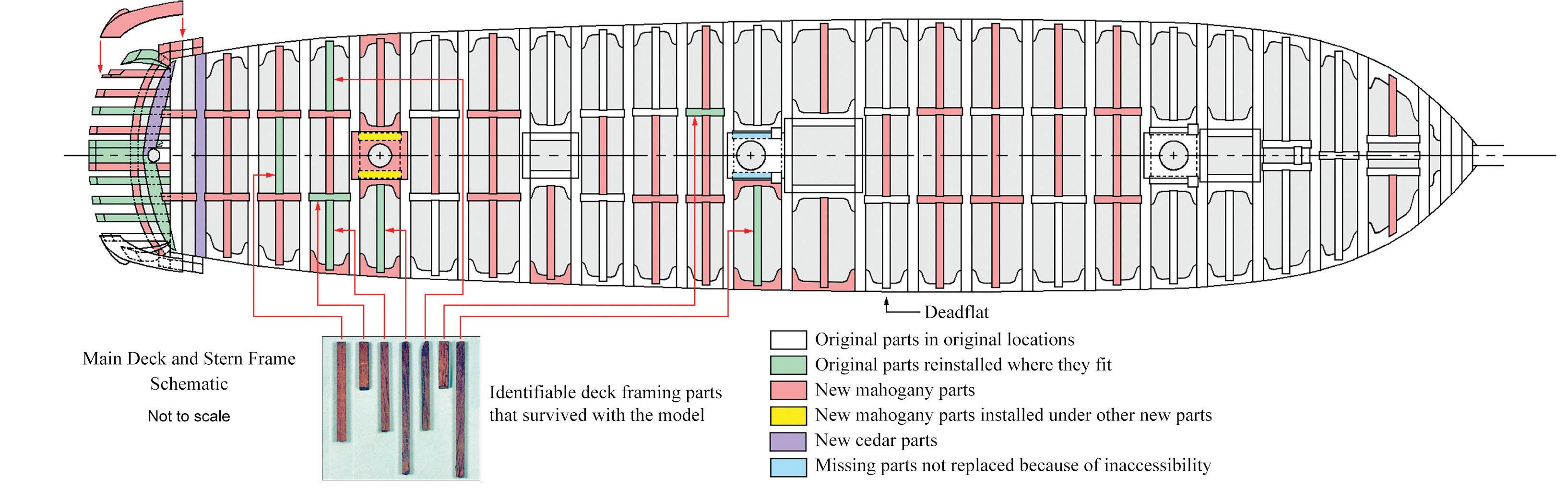

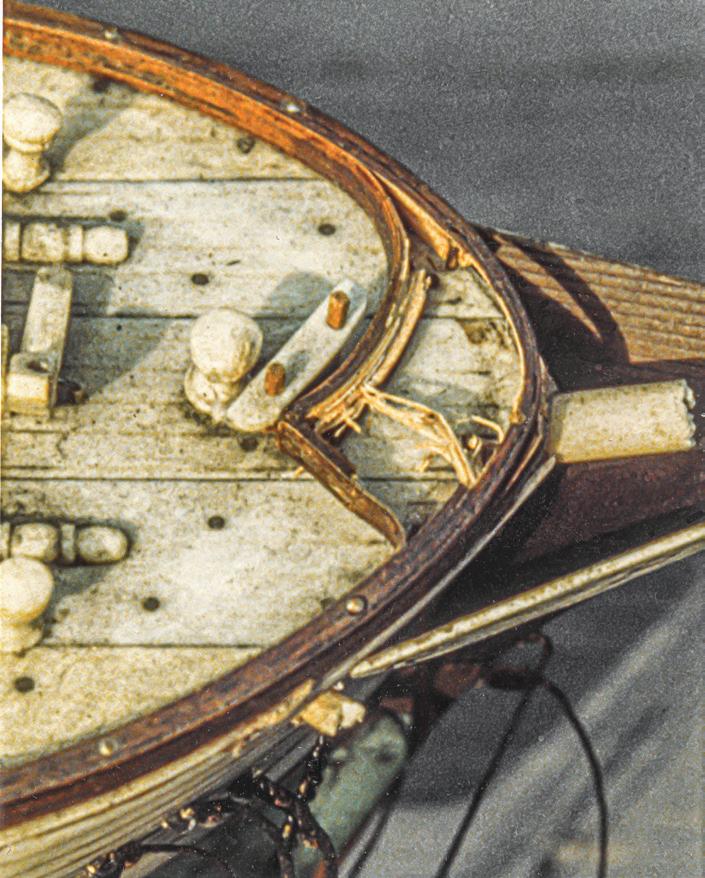

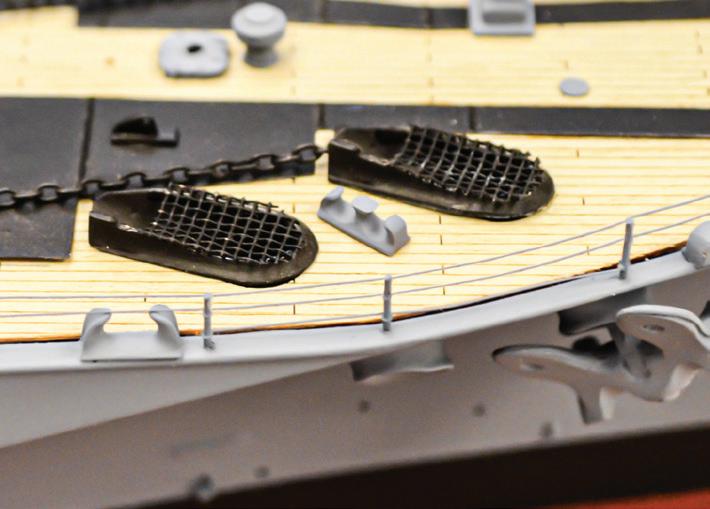

Left. A foam-like drop of melted acoustic ceiling tile grips a bent lifeline stanchion, and one ivoroid (or other early synthetic ivory) block has partially melted in its wire strop. Parts are from the 121-inch, 1:48-scale builder’s model of the British India Steam Navigation Company’s 1922 twin-screw passenger steamer Mulbera