Sponsor Company: www.international-pharma.com Volume 14 Issue 4

Understanding Compliance Moving from Cost to Value Pre-existing Immunogenicity How Will Cell and Gene Therapies Change Our Testing Approach? Overcoming the Pitfalls of Pre-filled Syringe Filling How the Pharmaceutical Industry Can Navigate Supply Chain Disruptions and Gain Resiliency

Peer Reviewed

| | | 41 Million units 2022 INSPECTED BY: EUROPE | USA | JAPAN | BRAZIL | KOREA | TAIWAN | TURKEY | SAUDI ARABIA | RUSSIA | IRAQ | KENYA | BIELORUSSIA DEVELOPMENT CAPABILITIES Preformulation and formulation development Analytical methods Development Process Development: oral solids, conjugation, liquid and lyo formulations, complex formulations QC ANALYTICAL CAPABILITIES Method validation and transfer Full testing of small and large molecules Stability and Photostability studies ORAL CAPABILITIES icated manufacturing area for tabs, minitabs, ule, LFHC velopment: 100g to 1000g P Clinical and Commercial: 4Kg to 100Kg Annual capacity: 50 Million units DS MANUFACTURING CAPABILITIES Conjugation of ADC’s from development (10mg–5g) to clinical and commercial (20g–5 Kg) Liposomal Bulk Solutions Annual capacity: 410 Kg dditional 900 Kg by end of 2022 CYTOTOXIC STERILE CAPABILITIES 7 Filling lines working in full containment, to produce liquid and lyo vials Annual capacity: liq/lyo vials 31 Mill. units end 2022 NON-CYTOTOXIC STERILE CAPABILITIES ling lines working in full containment roduce liquid and lyo vials ual capacity liquid/lyo vials: 9 2023 17 2024 26 2025 A CDMO TECHNOLOGICALLY DEVELOPED TO MEET THE NEEDS OF INNOVATORS, WITH ITS HIGH CONTAINMENT FACILITY DESIGNED TO OFFER SERVICES FOR PRE-CLINICAL GLP, CLINICAL AND COMMERCIAL SUPPLY BROCHURE HEADQUARTER and MANUFACTURING PLANT BSP PHARMACEUTICALS S.p.A. Via Appia km 65,561 04013 Latina Scalo (LT) – Italy Phone: +39 0773 8221 Web: bsppharmaceuticals.com Mail: business.development@bsppharmaceuticals.com

DIRECTOR: Mark A. Barker

BUSINESS DEVELOPMENT: Eliza Sarfaraz eliza@senglobalcoms.com

EDITORIAL: Virginia Toteva virginia@senglobalcoms.com

DESIGN DIRECTOR: Jana Sukenikova www.fanahshapeless.com

FINANCE DEPARTMENT: Akash Sharma accounts@senglobal.com

RESEARCH & CIRCULATION: Jessica Chapman jessica@senglobalcoms.com

COVER IMAGE: iStockphoto ©

PUBLISHED BY: Senglobal Ltd. Unit 5.02, E1 Studios, 7 Whitechapel Road, E1 1DU, United Kingdom

Tel: +44 (0) 2045417569 Email: info@senglobalcoms.com www.international-pharma.com

All rights reserved. No part of this publication may be reproduced, duplicated, stored in any retrieval system or transmitted in any form by any means without prior written permission of the Publishers.

The next issue of IPI will be published in Spring 2023. ISSN No.International Pharmaceutical Industry ISSN 1755-4578.

The opinions and views expressed by the authors in this journal are not necessarily those of the Editor or the Publisher. Please note that although care is taken in the preparation of this publication, the Editor and the Publisher are not responsible for opinions, views, and inaccuracies in the articles. Great care is taken concerning artwork supplied, but the Publisher cannot be held responsible for any loss or damage incurred. This publication is protected by copyright.

2022 Senglobal Ltd./Volume 14 Issue 4 – Winter – 2022

06 Editor’s Letter

REGULATORY & MARKETPLACE

08 Understanding Compliance: Moving from Cost to Value

Throughout the life sciences sector, the key trends of globalization and digitalization are providing new opportunities for growth and innovation. However, within development facilities, quality assurance, lab systems and scientific teams are feeling the impact of these transformations. Especially as their endeavours to ensure high levels of compliance meet the growing regulatory pressure within the industry. With an increasingly digital and connected lab infrastructure, failing to navigate the challenges of global regulatory requirements can be costly. As such, any compliance and validation processes must be designed to meet the needs of multiple geographies, business activities, and functions. Here, we speak with Joshua McWilliams, Product Manager, GxP Validation Services at PerkinElmer Inc., to learn more about the rising need in the pharma industry for compliance expertise and support.

12 EU CTR: 90 Days to Go, What You Need to Know

In 90 days, the one-year transition period of the EU’s Clinical Trials Regulation (CTR) will come to a close. EU CTR aims to harmonize the clinical application process across Europe and increase transparency. The regulation envisions a faster and more streamlined submission and approval process for larger multinational studies. Soon, biopharma sponsors, contract research organizations (CROs), the European Medicines Agency (EMA), and member states will use one system to manage all trial applications and authorizations. Werner Engelbrecht at Veeva Systems explains how clinical trial sponsors and CROs can ease the transition to CTIS.

14 Brexit – Impact, Challenges, and Solutions for the Pharmaceutical Industry

Brexit has provided several challenges to the pharmaceutical industry that required robust actions and swift resolution to remain in compliance following the end of the transition phase. Focussing on the regulatory activities, Graham Donaldson at Pharmalex discusses some of the challenges faced by companies and the steps taken by the UK Regulator, the MHRA, and the UK Department of Health and Social Care, to provide solutions to marketing authorisation review and access to medicines.

16 Bad Medicine: Lessons from an Enduring Alliance Between Big Pharma and Global Policing

The challenges of tackling international crime with national law enforcement are legion. What can be done about the sale of illicit medicines? The question illustrates a familiar challenge in the world of law enforcement. John Binns at BCL Solicitors considers how Interpol’s Operation Pangea illustrates how they can be overcome in the context of the global fight against illicit medicines.

20 Driving a Vision for a Data-driven Regulatory Ecosystem

A data-driven Regulatory ecosystem has huge potential beyond the opportunity for operational improvement. Even in today’s eCTD+ world, most life sciences Regulatory teams currently still think and work in terms of documents, paragraphs and sentences when putting together collateral for marketing authorisation and variations submissions. Yet it is data, rather than pre-prepared dossiers, that is moving into central

www.international-pharma.com

INTERNATIONAL PHARMACEUTICAL INDUSTRY 1

Contents

focus now. Renato Rjavec at Amplexor discusses how regulatory and product teams will need updated data skills to deliver this vision.

22 Regulatory and Developmental Complexities Around Demonstrating Bioequivalence for a Topical Generic Product

The topical dermatology market, although niche, was estimated to be valued at approximately $20.4 billion in 20201. In a study from 2010–2015, over half of the topical drug products experienced a price increase, and the average price of topical generic drugs was 276% higher by the end of that period. This is being driven by the lack of competition among generic manufacturers, where approximately 80% of topical dermatological drug products have very few competitors or no approved generics at all. Dr. Jon Lenn and Prof. Marc Brown at MedPharm discuss the lack of generic products that can be attributed to the complexity of developing topical dermatological drug products, low market volumes, and/or the risk and expense of clinical endpoint bioequivalence (BE) studies.

26 Opportunities for The IPO of Psychadelics Companies (or, How to Change Investor's Minds)

If anyone had suggested only a few years ago that it is a realistic proposition to float a psychedelics company on any of the London markets that suggestion would likely have been met with derision. Psilocybin research is still at a relatively early stage, and, at present, only a very limited number of global regulators approve the use of psychedelics to treat mental health conditions. However, as Nigel Gordon at Fladgate LLP discusses, the “direction of travel” in the thinking about psilocybin is towards a conclusion that it may form the basis of the development of much-needed novel treatments for mental health conditions and it might well, therefore, be the case that there will be a change in the view of regulators in future.

DRUG DISCOVERY, DEVELOPMENT & DELIVERY

30 Technical Advancements in Proteomics Streamline High-throughput Workflows

Over the last two decades, significant advances in technology and new methodologies have made proteomics an extremely powerful

tool for protein scientists, biologists and clinical researchers. Scientific discoveries in proteomics largely depend on data analysis and data generation. Chris Adams at Bruker Daltonics states that using mass spectrometry (MS)-based proteomics has expanded significantly with improvements in software, data acquisition, and algorithms to provide more accessible and accurate data.

32 Pre-existing Immunogenicity: How Will Cell and Gene Therapies Change Our Testing Approach?

When bringing a therapeutic to market, determining its potential to elicit an immune response and understanding the molecular and cellular interactions involved is essential. In some patients, it is possible that a previous exposure event to certain antigens associated with the therapeutic can prime the immune system for re-infection. Dr. McNally at BioAgilytix explains that as we move into a new era where cell and gene therapies (C>s) are frequently gaining approval for use, it is important to consider how best to approach pre-existing immunogenicity assessment for these relatively new modalities.

CLINICAL & MEDICAL RESEARCH

40

Respiratory Disease Management: A Connected Approach

Until recently, treating, monitoring and controlling respiratory conditions such as asthma centred on conventional devices, paper-based tools and appointments with a GP or asthma nurse. This approach, of course, still plays a huge role for the over 300 million people living with asthma globally. However, a deeper understanding of the greater efficiency at hand through the vastly increasing use of digital applications and the palpably mounting pressure that can be felt on healthcare bodies globally has seen a shift in the context of respiratory disease management. Sarah Sanders, Christina Philpott and Emma Dunipace at Recipe Design explain that this, in turn, is creating exciting opportunities for new MDI devices and supporting applications that enhance overall treatment capabilities and outcomes.

TECHNOLOGY

44 IP Issues Surrounding Machine Learning and AI in the Pharmaceutical Space

When it comes to protecting technical innovations, there are two broad strategies: keep it a trade secret or obtain a patent. It has long been the case that computer-implemented technologies and pharmaceutical technologies are technical fields where one or the other approach (trade secrets in the case of computers, patents in the case of pharmaceuticals) has been typically favoured. Harry Muttock, Yelena Morozova and Nicholas Fox at international IP firm Finnegan explain how in the brave new field of applying advanced computational systems to the development of pharmaceuticals, we develop a strategy which satisfies both approaches to protecting technical innovations.

48 Strategic Intellectual Property Considerations for Protecting AI Innovations in Life Sciences

Artificial intelligence (“AI”) is all around us. It allows us to unlock our smartphones with just a glance. It can customize the temperature of our home or recommend television shows based on things we enjoyed watching before. It may soon drive our cars for us. Through the combination of increasing computing power and massive amounts of data, AI has made unprecedented advances in recent years in its ability to make predictions and solve problems. As a result, AI has become a vital part of our everyday lives. And soon, the medications

2 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4 Contents

1mL & 2.25mL

Spring-free

passive safety devices for pre-filled syringes

The patient benefits of UniSafe® are:

• Passive needle shielding to help prevent needlestick injuries

• An unobscured syringe barrel for full drug visibility to create user confidence

• A large, ergonomic plunger head and a smooth finger flange, resulting in an integrated look and feel which provides reassurance

UniSafe® 1mL proven, on market, in patient use

Want to know more?

• Optional extended finger flanges for patients with strength and dexterity impairment (applicable to 1mL only)

• The same injection technique as a pre-filled syringe making it intuitive to use

• It cannot be reused or prematurely activated

Visit ompharmaservices.com/ipi-dec2022 or email pharmaservices@owenmumford.com

UniSafe® is a registered trademark of Owen Mumford Ltd ©️ 2022 OMPS/ad/ipi/ob/1122/7

INTERNATIONAL PHARMACEUTICAL INDUSTRY 3 www.international-pharma.com

we take each day also be identified and developed at least in part by AI. This article by Charles T. Collins-Chase, Kassandra M. Officer, and Xirui Zhang, examines strategic intellectual property considerations for innovative pharmaceutical and biotechnology companies that are developing AI systems or using third-party systems to enhance drug discovery, clinical trials, manufacturing, or other processes.

52 Data-driven Processes Overtake Structured Document Authoring

The strategic focus in life science technology investment is shifting from documents to data. Regulators are increasingly asking for data rather than documents, and data-focused business processes, based on a single source of truth, are bringing efficiencies right across the organization. James Kelleher at Generis describes the implications of the transition away from structured document authoring.

MANUFACTURING

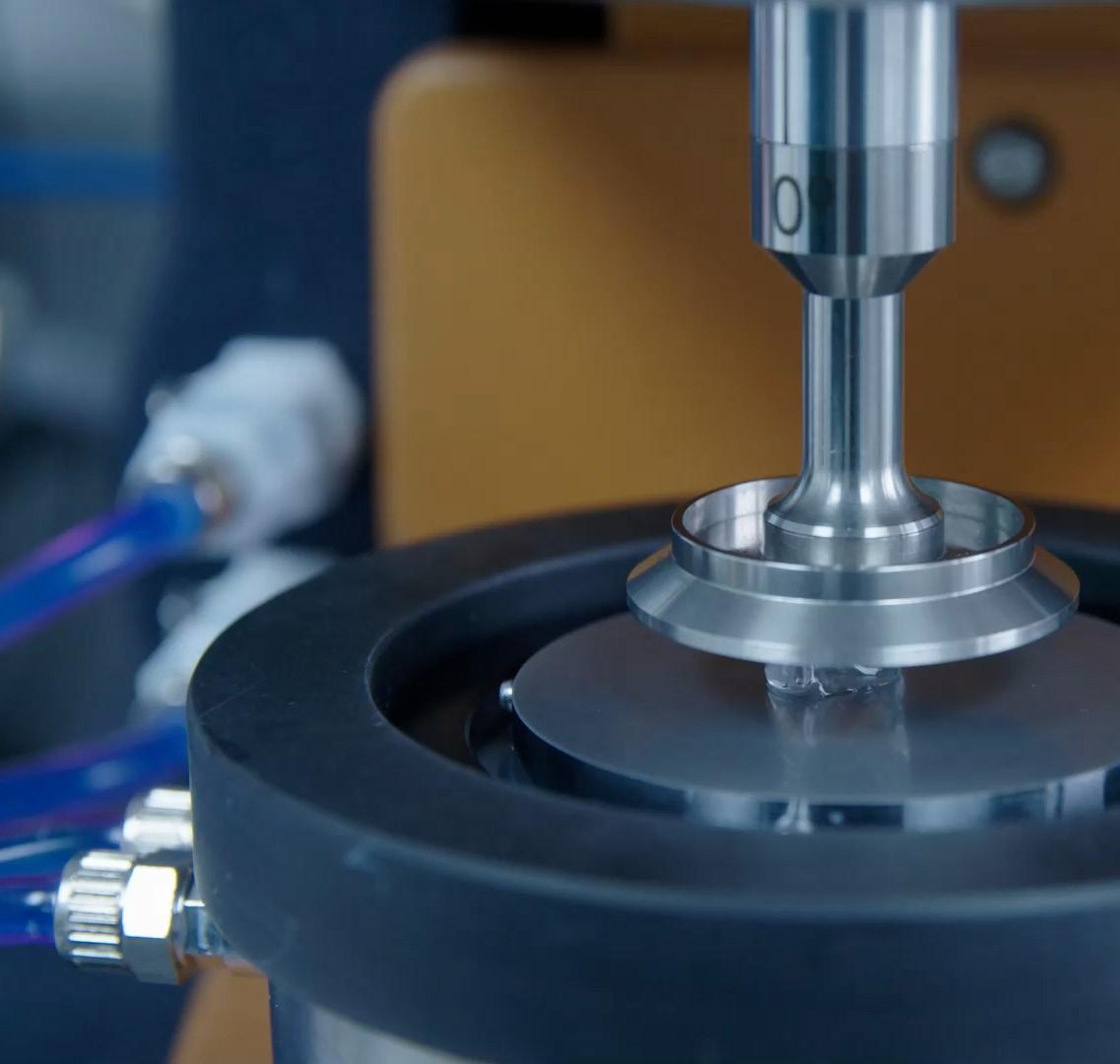

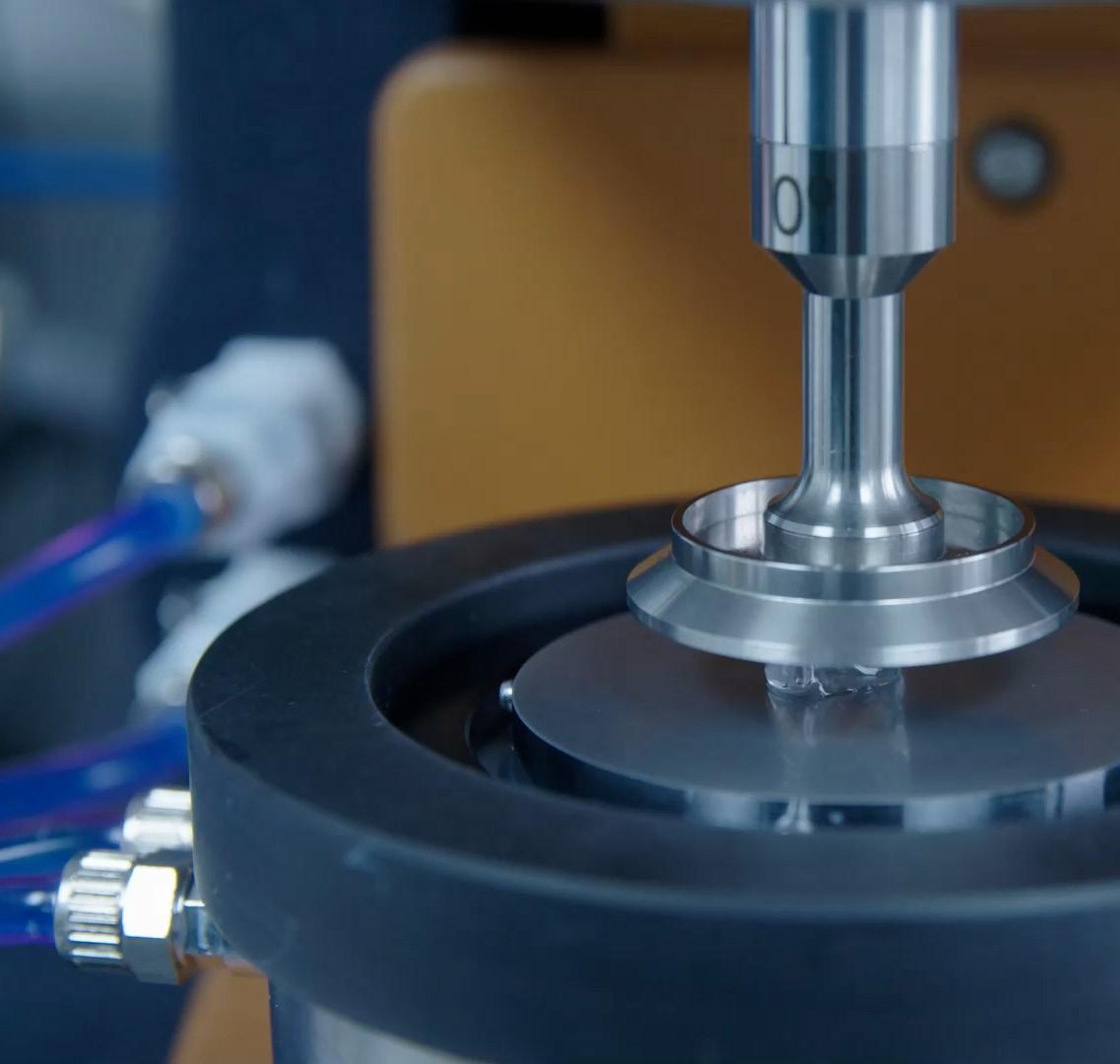

54 Pharmaceutical Tablet Coating –Achieving Perfect Coating Uniformity

Tablets are the most important oral dosage form in the pharmaceutical industry. Pharmaceutical film coating, a thin film made from one or more polymers that can fulfil a variety of functions is applied to the tablet. Most of the coating processes are performed for drug release modification, drug stability improvement against light or moisture and taste masking. Furthermore, patient compliance issues play an important role, as swallowability improvement or a simpler identification due to a different colour. Tobias Borgers at L.B. Bohle explains why coating represents an important process step in the pharmaceutical industry.

58 The Challenges of Increased Complexity in API Development and Manufacture

There is no getting away from it: the small molecule drugs now entering and travelling through the clinical pipeline are becoming more complex. This increasing complexity poses a variety of challenges that pharmaceutical and biotech companies will need to overcome. Giovanna Libralon at Lonza Small Molecules talks about the molecule itself and that it may be that, as an integral part of the way it is designed to hit the target, it includes features and moieties that are difficult to make.

PACKAGING

68 What’s Next for Pharmaceutical Serialisation?

Supply chains for pharmaceutical products are exceptionally complex, with medicines and ingredients often crossing the borders of many countries before reaching the end consumer. Bart Vansteenkiste at Domino explains that to protect patient health and safety, serialisation and track and trace requirements have become standard for pharmaceutical products worldwide. Legislations include the EU’s Falsified Medicine Directive (FMD) and the US Drug Supply Chain Security Act (DSCSA), which both necessitate serialisation and government reporting for prescription pharmaceutical products.

70 Overcoming the Pitfalls of Pre-filled Syringe Filling

The international pre-filled syringe market was worth $3.6 billion in 2021 and is predicted to increase in value to $6.5 billion by 2030, growing at a CAGR of 7.1% throughout the forecast period. One of the key drivers for this projected growth has been a major change

in the choice of injectable delivery formats following the COVID-19 pandemic. Michael Isele at Recipharm explores the pitfalls of filling and packaging in pre-filled syringe formats, from sterile integrity requirements to packaging challenges, such as kitting, explaining how these challenges can be addressed.

HEALTH OUTCOMES

72 Artificial Intelligence is a Core Pillar in the Evolution of Digital Health and Patient-centric Solutions

The US Food & Drug Administration has stated that digital technology is driving a revolution in healthcare. The lines between healthcare delivery and clinical research are blurring as the patient becomes a key partner and focus. We see a rapid expansion in the use of mobile and patient-centric devices, exponential growth in the volume and diversity of life sciences data and acceleration in the use of data-dependent computation to gain insight and automate, loosely called artificial intelligence (AI). Michael Phillips and Gerard Quinn at ICON discuss Artificial intelligence as a core pillar in the evolution of digital health and patient-centric solutions.

LOGISTICS & SUPPLY CHAIN MANAGEMENT

74 How the Pharmaceutical Industry Can Navigate Supply Chain Disruptions and Gain Resiliency

Every pharmaceutical shipment is valuable, some to the tune of millions of dollars. The distribution and safety of pharmaceutical products have a very direct impact on medical outcomes. Therefore, manufacturers, distributors, shippers, logistics service providers, and retailers need deeper levels of insight and greater visibility into the supply chain now more than ever. Alex Guillen at Tive explores how real-time tracking of pharmaceutical shipments accelerates their distribution and examines the common challenges in distribution, including compliance issues, and how real-time data, combined with customised tracking alerts, can empower supply chain leaders to overcome obstacles and realise insights that will drive proactive management decisions.

4 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Contents

wel-screen

Contract services firms are becoming increasingly sophisticated and embedded in the drug development ecosystem. Contract development and manufacturing organisations are the pharma industry’s special forces unit: a highly specialised team that functions behind the scenes, doing difficult tasks in high-pressure situations.

Pharma companies have turned the corner in terms of their appetite to outsource development. The scale and scope of outsourcing have changed markedly. In the early 2000s, instead of one-off project transactions, there has been a move to longterm strategic partnerships between the contractors and their clients. Particularly in the biotech sector, CDMOs are often seamlessly integrated with any inhouse development and manufacturing departments. Many small and virtual pharma companies, those that consist of only a few employees and few, if any, facilities, could not exist without CDMOs.

Over the last five to eight years, there has been a rise in organisations that aim to be ‘one-stop shops’ for anything from early-stage research to manufacturing. The integration between development and manufacturing is valuable even to big pharma companies because it greatly reduces the tech transfer and scale-up risk.

The pandemic marked a turning point for the relationship between CDMOs and pharma companies. Pre-2020, pharma companies usually outsourced services on a project-by-project basis. Long-term partnerships were rare; around 80% lasted no longer than a few years. During the pandemic, CDMOs suddenly became a huge source of additional research and manufacturing capacity, though it remains unclear whether this will translate to more strategic collaborations in the long run.

The relationship has become more integrated and broader, with increasing use of [contract research, development, and manufacturing

Editorial Advisory Board

organisation, CRDMO] companies from the early phases through to the complete life cycle. Partnerships have shifted from transactional to strategic. This requires that CRDMOs have developed technologies, manufacturing capacities and proven quality systems, as well as experience and expertise.

Speed and competency are the two major components when it comes to making decisions around outsourcing. The advantage of CROs and CDMOs is that you can look globally for the precise competencies that you need. It’s difficult to build this, especially if you’re a small company in one location.’

The outsourcing market for biological products – sugars, proteins, nucleic acids or even whole cells and tissues – is growing at 10–15% per year, compared with 6–7% growth in small-molecule drug compounds. While new chemical entities remain the largest segment of the CDMO market. Biologics have been riding a wave over the last few decades and are certainly part of the change the market has experienced.

However, the fastest growth is happening in entirely new classes of treatment: RNA therapeutics, protein degraders, cyclopeptides, antibody-drug conjugates and gene therapy. They are highly outsourced because normally they’re very small, so for every individual pharma player it rarely makes sense to invest in building a whole plant.

These new modalities require a completely different set of equipment and expertise than traditional drug molecules or even biologics. Moreover, the new modalities market encompasses so many different technologies, it would be nearly impossible for a single company to develop expertise in all of them – and bear all the financial risk for drug failure. But with the help of specialist CDMOs, firms can dip in and out of different therapeutic fields.

Multiple interconnected factors continue to drive growth in outsourcing services. Pharma

firms’ efforts to maximise value for shareholders, aspects of cost and technological advancements. Large firms want to reduce their assets and costs while emerging companies want to hit milestones as quickly and efficiently as possible, ‘even if it means failure’. The average number of drug approvals by the US Food and Drug Administration almost doubled between 2011 and 2021 compared with the previous decade, and that increase is associated with more demand for outsourcing and more opportunities for deeper integration into the pharmaceutical ecosystem.

Drugs featuring complex molecules and substances require investment in new technologies, a decision that may be more easily made by a specialist CRDMO than a pharma company. CRDMO companies will continue to evolve in the next few years, investing in cutting-edge science and technologies to enable innovation, such as targeted protein degradation and photoredox chemistry.

More generally, the pharmaceutical industry has understood that specialist companies can often be more productive than internal resources in the R&D process. Specialist CROs often see many projects across several targets and therapeutic areas, whereas employees working in a small or large pharmaceutical company may focus on a particular area. The CDMO market will continue to grow over the next five to 15 years.

Virginia Toteva, Editorial Manager – IPI

Deborah

Diana L. Anderson, Ph.D president and CEO of D. Anderson & Company

Franz Buchholzer, Director Regulatory Operations worldwide, PharmaNet development Group

Francis Crawley. Executive Director of the Good Clinical Practice Alliance – Europe (GCPA) and a World Health Organization (WHO) Expert in ethics

Rick Turner, Senior Scientific Director, Quintiles Cardiac Safety Services & Affiliate Clinical Associate Professor, University of Florida College of Pharmacy

Georg Mathis Founder and Managing Director, Appletree AG

Jagdish Unni, Vice President – Beroe Risk and Industry Delivery Lead – Healthcare, Beroe Inc.

Jeffrey Litwin, M.D., F.A.C.C. Executive Vice President and Chief Medical Officer of ERT

Jeffrey W. Sherman, Chief Medical Officer and Senior Vice President, IDM Pharma

Jim James DeSantihas, Chief Executive Officer, PharmaVigilant

Mark Goldberg, Chief Operating Officer, PAREXEL International Corporation

Maha Al-Farhan, Chair of the GCC Chapter of the ACRP

Stanley Tam, General Manager, Eurofins MEDINET

(Singapore, Shanghai)

Steve Heath, Head of EMEA – Medidata Solutions, Inc

Patrice Hugo, Chief Scientific Officer, Clearstone Central Laboratories

Heinrich Klech, Professor of Medicine, CEO and Executive Vice President, Vienna School of Clinical Research

Robert Reekie, Snr. Executive Vice President Operations, Europe, Asia-Pacific at PharmaNet Development Group

Sanjiv Kanwar, Managing Director, Polaris BioPharma Consulting

Stefan Astrom, Founder and CEO of Astrom Research International HB

T S Jaishankar, Managing Director, QUEST Life Sciences

6 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Editor's Letter

Bakhyt Sarymsakova, Head of Department of International Cooperation, National Research, Center of MCH, Astana, Kazakhstan

Catherine Lund, Vice Chairman, OnQ Consulting

A. Komlos, Principal Content Writer, Clarivate

Harnessing decades of global drug product development and commercialization, you can rely on our integrated speed solutions to simplify your supply chain, spanning the cycle from study to launch. Introducing speedsolutions™ Your bridge between life-changing therapies and patients speedtostudy™ speedtopatient™ speedtoapproval™ speedtolaunch™ PH II PH III COMMERCIALIZATION PH I Let’s talk future™ talkfuture@pci.com | pci.com Accelerating your product through development to commercialization and beyond Development & Manufacturing | Clinical Trial Services | Commercial Packaging

Regulatory & Marketplace

Understanding Compliance: Moving from Cost to Value

Throughout the life sciences sector, the key trends of globalisation and digitalisation are providing new opportunities for growth and innovation. However, within development facilities, quality assurance, lab systems and scientific teams are feeling the impact of these transformations. Especially as their endeavors to ensure high levels of compliance meet the growing regulatory pressure within the industry.

With an increasingly digital and connected lab infrastructure, failing to navigate the challenges of global regulatory requirements can be costly. As such, any compliance and validation processes must be designed to meet the needs of multiple geographies, business activities, and functions.

Taking action to identify, analyse, and reduce compliance risks requires a high level of resource and expertise. However, in a fastpaced, scientific environment, researchers are already stretched thin. This brings an added risk of slowing down productivity in even the best-run laboratories if compliance is not strategically managed.

To overcome these challenges, lab managers are increasingly turning to external partners who have expertise in qualification, requalification, risk management, and remediation. By transforming their compliance processes, scientists are then free to concentrate on research and discovery and meet the evolving demands of a more digital and connected lab.

Here, we speak with Joshua McWilliams, Product Manager, GxP Validation Services at PerkinElmer Inc., to learn more about the rising need in the pharma industry for compliance expertise and support.

Hi Josh, before we dive into compliance best practices can you tell us more about how your role drives and inspires you?

Sure. I lead the GxP Validation Service team as part of PerkinElmer’s OneSource

strategic services group. I’m inspired by how we collaborate closely with our clients so we can determine their unique needs and help them further their science while creating or maintaining safe and compliant processes.

For me, it’s exciting to see first-hand how trends and global drivers play out in the lab and affect compliance. For example, in the late 90s to early 2000s, we saw an exciting shift towards digitising labs. However, this more online route came with new challenges and required a different level of validation. As more labs move towards advanced digitalisation and cloud-based data management, they need to look at compliance in a more collaborative and connected way and share information securely and accurately.

Lab managers and scientists are experts in their field but finding dedicated compliance expertise in-house can be a real challenge. I started my career as a bench chemist, so I know all too well how difficult it can be to manage your own time in the lab let alone handle compliance needs. This direct insight

allows me to help labs define the difficult and non-core compliance tasks that are getting in the way of their vital research and key scientific tasks.

Ultimately, the biggest driver for me and my team is to give time back to science, so researchers and lab professionals can focus on discovering better therapeutic candidates vs. getting bogged down in compliance execution and monitoring.

What do you consider to be the top best practice approach for compliance or a framework to work from?

Industry best practice involves following a risk-based approach for patient safety and quality. We work to GAMP 5 guidelines, which build in quality checks throughout the entire production process and enable us to meet the unique needs of a company and particularly its computerised systems.

The first step is creating a comprehensive requirements document, which includes how a

8 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

system is supposed to operate and its intended uses. A validation plan can then be drawn up that should outline the strategy – which policies and procedures will be followed, any functional configuration specifications and design specifications as needed.

Lab instrument qualification historically would have meant simply purchasing, installing and bringing the new piece of equipment into service. Today’s regulatory requirements mean that planning and development should occur before purchase to ensure the instrument is fit-for-purpose. After which, qualification continues with Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ). This isn’t just a question of verifying the vendor’s hardware and software qualifications. Everything should be checked against the requirements document for its specific use at the manufacturing site. Documents such as standard operating procedures also need to be created, and staff must be trained to follow them for all instrument usage, including administration and calibration as well as operation.

Ideally, validated instrumentation needs to be maintained across multiple sites and lab spaces by a team of specialised onsite validation experts. Here, a multivendor approach can save precious lab time, by harmonising protocols under a single Universal Operational Qualification framework. Allowing lab managers to streamline processes across all major models of laboratory instrumentation and scientists to concentrate on research and discovery.

Nowadays, regulators are probing how data is generated, reported, archived, and retrieved. Therefore, data integrity should play an essential role throughout the validation process. For example, regulations such as FDA 21 CFR Part 11 must be built into the requirements, to ensure the security of electronic records. Data relating to

formulations, clinical trials and any other sensitive areas must be tightly controlled.

Compliance is a continual process: thorough documentation must be kept dayto-day to provide evidence that the policies and procedures set out in the validation plan are being carried out to meet the validation requirements. Centralised monitoring and continual improvements enable labs to pursue science with integrity and help keep staff and lab inspection ready.

When it comes to the conversation around compliance pressures in the modern-day pharma lab, where are the gaps in people’s knowledge and understanding?

Within labs, there is often a lack of deep compliance knowledge. Although lab teams will be trained on compliance steps for individual instruments and tasks, they may not have a wider knowledge of compliance systems and processes as well as trends or new regulations that are evolving. There is also a challenge for facility IT teams, who may not have a real-time or full understanding of the specific compliance needs within highly regulated industries like pharma or food. Labs that don’t have the expertise or procedures in place to prove their increasingly connected data is accurate and their instruments are fit-for-purpose may risk non-compliance which slows their R&D cycles.

These knowledge gaps are compounded as teams are unable to fully understand the benefits that investing in rigorous validation methodology can bring. Our OneSource validation and compliance team utilises industry best practices, keeping up with changing regulations on a daily basis. One recent trend we see is the regulatory focus on data integrity. However, accurate and

reliable data has always been the foundation of successful basic research, it just takes on different meanings and needs around security, sharing and validation in cloudbased environments.

What are the key challenges labs face when navigating today’s compliance environment?

One of the biggest challenges is ensuring that lab efficiency does not suffer at the hands of compliance. Events such as the purchase of new equipment, company acquisitions, relocations, and audit findings can all contribute to increased validation needs and workloads and need to be proactively vs. reactively factored in. Plus, the increased focus on Computer Systems Validation (CSV) and data integrity is driving a need for larger validation budgets and resources.

Like data integrity, CSV is a broad concept that affects virtually every dimension of pre-clinical research and drug discovery. Departments such as IT will be needed to help with the configurations, permissions, and necessary settings. Without a dedicated validation team, general lab or IT resources may not have the appropriate skill set or bandwidth and can become overwhelmed. Furthermore, as the industry looks to adopt new digital tools and innovations like eValidation, staying current with the latest software versions may require additional validation to be completed.

It’s important to understand the impact that updates can have on your validated systems. As such, it’s clear that CSV is an ongoing process, not a one-time activity. It will extend all the way through to the eventual decommissioning of the given instrument or application. Its time-consuming nature may require outsourcing and expert assistance to keep the process on track.

INTERNATIONAL PHARMACEUTICAL INDUSTRY 9 www.international-pharma.com

While compliance endeavours can seem daunting, they are ultimately critical to the scientific integrity of the pharmaceutical industry and, down the line, to the safety and well-being of patients. Companies can achieve the most effective regulatory defensible position for computerised instrument and analysis systems using a standardised delivery framework. This requires compliance and scientific expertise.

By partnering with a third-party expert, lab teams can receive unbiased recommendations from specialists that engage with the needs and demands of regulatory compliance all day, every day.

Integrating successful validation and QC procedures into the lab results in more streamlined and efficient workflows. Furthermore, external solutions help put both data integrity and the closely associated CSV on sustainable trajectories.

Lab managers may want to avoid investing more in-house or with a compliance service provider, but the costs of non-compliance are often much greater. Strategically partnering with an expert supplier can be more cost-effective and enables labs to stay focused on their core R&D activities.

From your point of view, what do you think the future of compliance looks like for pharma and life science labs?

I think we’ll continue to see the trend of incorporating digital tools for cloud-based

data capture, visualisation and sharing that is part of Pharma 4.0, as well as further validation of enterprise systems versus stand-alone equipment. Labs are starting to move data to the cloud, and with that comes the regulatory focus on validating to intended use and following a risk-based management approach.

I’m also expecting to see an increasing number of companies choosing strategic partnerships to understand and overcome the latest compliance needs and challenges. External service providers can leverage learnings and insight from across the industry. As such, they can help streamline lab workflows and boost scientific productivity with data integrity assessment and methods to establish quality control procedures that support reliable research data. With an experienced partner, you're not just getting the resource to do the work. You're also getting the breadth of experience across all professional services to support you through the continued digital revolution.

Josh McWilliams is GxP Validation Services Product Manager for PerkinElmer's OneSource strategic services and has 25 years of experience working in the pharma industry. Josh currently oversees the development of the OneSource GxP Validation Services product roadmap, as well as product innovation and oversight, including; Stand-alone and Enterprise Computer Systems Validations, Data Integrity projects, Method Validation, Process Validation and CQV. Before joining OneSource, Josh developed his skills and experience working as a senior scientist at Watson Laboratories and as a validation specialist at PPD.

10 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

Josh McWilliams

How can strategic approaches to outsourcing help support labs looking to meet their compliance demands while also enabling scientific innovation?

DropControl minimizes the spontaneous dropping of ophthalmic preparations

—

The newest developments of eye drop solutions are focused on non-water based solutions, which require a different design of the eye dropper to prevent unintended dropping.

Our solution is an insert into our existing eye dropper, which controls the flow of water-free eye drop solutions.

The DropControl fits our existing dropper bottle system A, E and F.

INTERNATIONAL PHARMACEUTICAL INDUSTRY 11 www.international-pharma.com gerresheimer.com

Pharmapack | February 1 – 2, 2023 | Paris, France | Hall 7.2, booth B60/B64

EU CTR: Final Countdown, What You Need to Know

The end of the transition period is imminent. How can clinical trial sponsors and CROs ease the transition to CTIS?

Soon, the one-year transition period of the EU’s Clinical Trials Regulation (CTR) will come to a close. EU CTR aims to harmonise the clinical application process across Europe and increase transparency. The regulation envisions a faster and more streamlined submission and approval process for larger multinational studies. Soon, biopharma sponsors, contract research organisations (CROs), the European Medicines Agency (EMA), and member states will use one system to manage all trial applications and authorisations.

Sponsors and CROs have spent the transition period learning how to navigate

the Clinical Trials Information System (CTIS) for their study registration and approval activities, which will be a mandatory requirement from 31st January 2023. Having a common regulatory approach across the European Union will boost regional competitiveness. Patients are set to benefit from improved transparency of trial data, as data submitted within applications will be made public, making it easier for patients to identify and participate in ongoing trials.

To date, almost 100 studies have already been submitted under the new regulation, with Veeva customers accounting for at least half of these. The initial feedback from sponsors and CROs alike is that it is challenging to remain efficient while complying with legal responsibilities. Companies have had to improve communication, collaboration, and alignment across diverse global study stakeholders and departments.

Rethinking Our Approach to People, Processes, and Data

In its present format, the backbone technology of CTIS is not easy to integrate. Sponsors and CROs are collating data in their own technology environments. Each document in a study submission needs to be individually isolated and manually uploaded to the CTIS portal. Process timelines are getting longer, as companies spend more time collecting data points and information while managing translations and redactions. Once the submission has been made, companies often find they have a small window to respond to questions and requests for further information from the EMA.

How should companies address these challenges? Those that have successfully navigated the new process first had to attain internal alignment. This meant acknowledging that the old way of interacting with regulatory authorities was no longer

12 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

Regulatory & Marketplace

Checklist

Are you ready? Your EU CTR Checklist

Processes: Review and re-define for tighter timelines

Review processes for ethics committee submission, health authority interaction, and clinical trial disclosure

Define new processes for document redaction, translations, and data collection

Determine approach for upload to CTIS (who, what, when) and regulatory tracking

sufficient and mapping out which internal stakeholders should be brought into the process, and when. Some created new roles to reflect the new reality, including managing translations or uploads to the portal. Others have redefined the RACI framework for clinical and regulatory study leads to maximise efficiency. All agree that technology plays a crucial role in improving collaboration across diverse stakeholders by making it easier to search for and extract data quickly, as well as draw on internal expertise during submission.

Without a doubt, managing high volumes of data and documents in the new process is very challenging. Few companies like their current approach of collecting data using internal tools, like spreadsheets. Nor do they think the current cross-functional efforts to complete reviews, quality checks, and translations are sustainable. Eventually, the industry expects further enhancements, such as integration with CTIS.

However, any sponsor or CRO submitting an application faces disclosure risks for two types of information: protected personal data (PPD, with privacy protection under GDPR) and commercially confidential information (CCI). The redaction effort required to make documents available for public consumption is significant, complex, and dynamic as redacted passages can change over time.

For the industry, CCI and PPD are serious pain points – perhaps the most acutely felt. And while there is consensus that automation could alleviate the redaction effort, there is a high barrier to entry before technology can offer more than just tactical support to human oversight and interventions. There are multiple languages in play, metadata to

Define clear RACI and ownership mapping

Reduce redaction and mitigate user errors by updating forms and templates

People: Build alignment across your entire R&D organisation

Coordinate closely with regulatory, quality, safety, and disclosure teams

Include affiliates, as well as CRO partners

Offer end-user system training for all relevant functions

Data & Systems: Future-proof your technology environment

Review current technology landscape, existing capabilities, and future requirements

Identify interim solutions until data formats and document requirements are determined by the EMA/CTIS team

Visit the EMA/CTIS website for guidance (e.g. document naming), training material, and CTIS revision notes

Contact a Veeva expert to support with Vault system evaluation, capabilities, and recommended configurations

remove, and significant coordination effort, to name just a few hurdles.

A New Global Standard for Clinical Trials

The end state envisioned in the regulation is a faster, more consistent approach to clinical trials: not just for Europe but for global companies that want to sell products into the region. However, enterprise biopharma companies face more complexity than smaller sponsors (who tend to outsource to CROs). These global organisations are undertaking significant change management to harmonize their technology and processes and face the added complication of running studies under EU and non-EU regulations.

Setting an ambitious worldwide standard was never going to be easy. EU CTR challenges the industry to balance consistent processes and reporting with an excellent user experience, operational efficiency with inspection readiness. For now, companies of all sizes are focusing on ensuring their processes (including for EU and non-EU country studies) are well set up, which in turn requires significant people training.

Many will need to keep a manual approach to collecting data points for entry into CTIS for the interim period. However, their attention is turning to how software and end-to-end technology can work better to deliver on the stated aim of the regulation: accelerating innovation and research through improved efficiency.

As partners to the life sciences industry, we will need to rise to the same challenge of balancing opposing forces. Technology will get us there. But, like EU CTR, it will come in stages.

Werner Engelbrecht

Werner Engelbrecht, Senior Director Strategy at Veeva Systems, has extensive experience in the pharmaceuticals and life sciences industry, across a range of roles, with his career spanning over twenty years'. For the last twelve years, he has brought his in-depth industry knowledge to operational, and sales and account management teams at CROs (contract research organisations). In his current role as Senior Director Strategy at Veeva Systems, Werner heads up a team that is dedicated to using digital transformation to navigate the complexities of clinical trials and speed up development of new medicines.

INTERNATIONAL PHARMACEUTICAL INDUSTRY 13 www.international-pharma.com

Brexit – Impact, Challenges, and Solutions for The Pharmaceutical Industry

Brexit has provided several challenges to the pharmaceutical industry that required robust actions and swift resolution in order to remain in compliance following the end of the transition phase.

At the ‘Brexit – Impact, Challenges, and Solutions for the Pharmaceutical Industry’ Conference we heard from companies expressing their need a for a clear action plan to map out the activities, timings and responsibilities for these changes including those licencing activities, manufacturing, QP release and supply routes.

Focussing on the regulatory activities, the following are some of the challenges faced by companies and the steps taken by the UK Regulator, the MHRA, and UK Department of Health and Social Care, in order to provide solutions to marketing authorisation review and access to medicines:

Regulatory Challenges

Following Brexit, regulatory oversight in the UK has shifted from the EMA to the MHRA, for what were European procedures, with the work of the multinational agency now falling to the MHRA. One would; therefore, question capacity and anticipate resource issues.

For companies, lack of published guidance, or guidance that is published very late, has provided issues for training, compliance and updating of internal procedures. There is a continued reliance on existing EU forms and systems, and with separation of European procedures from Great Britain, there is a duplication of effort which stretches the capacity of already finite regulatory resource.

This has increased the risk of potential delays to submissions and approval in Great Britain and Northern Ireland. In addition, there is the potential for reduced supply of medicines to NI.

UK Marketing Authorisations – For Existing Products

All existing Centrally Authorised (CAP) MAs were automatically converted into UK MAs effective in Great Britain (England, Scotland

and Wales only) and were issued with a new MA number on 1 January 2021 (with a format of PL GB) unless the MHRA were otherwise advised. This was a process referred to as ‘Grandfathering’.

Companies submitted initiating sequences, with baseline data, for the new GB only grandfathered product by the end of 2021. This was a large resource burden on regulatory departments to collate these data and create a new baseline. This created a particular issue for historic products, where data may not have a readily available in CTD format, or was archived and not digitised. The MHRA took a pragmatic approach and requested companies provide as complete a dossier as possible, and that companies make all ‘reasonable endeavours’ to do so.

As a result of the implementation of the Northern Ireland Protocol, existing CAPs remain valid for marketing products in Northern Ireland. Future EU marketing Authorisations will continue to include Northern Ireland.

This has essentially created 2 parallel licences: one for the EU, including Northern Ireland, and a new separate GB only licence. Although there was no fee for the grandfathering process, as with all UK national MAs, an annual service fee is due for converted EU MAs.

Existing Nationally Authorised MAs continue as pre-Brexit and the MHRA presented options for managing MR/DC Procedures.

European Commission (EC) Decision

Reliance Procedure – ECDRP New GB MAs can follow CAP procedures, utilising the EU Reliance Route. This was effective until the end of 2022, but as a post meeting note, has now been extended by another year until the end of 2023.

Companies can wait until the product has received a positive opinion from the CHMP. The Application will be determined when the EC decision has been confirmed. The published guidance states a 67 day process thereafter to obtain a GB only MA, but in practice this is likely to be longer due to resource constraints at the MHRA to start

the procedure and any potential requests for further information.

This EU Reliance Route has been used extensively for products falling under the Centralised Licence Categorisation postBrexit.

UK/GB national variations continue to follow current EC variations regulation.

Variations to purely national MAs (PL, PLGB and PLNI) can also be presented to the MHRA under the reliance route. Companies can submit either by national only or reliance route for the Type II and Type IB variations, but Type IA variations cannot rely on the EMA decision so should be submitted to the MHRA in parallel to the EMA.

For those Type IB and Type II variations submitted according to the reliance route procedure, provided the variation is identical to that approved for the European MA, and evidence of this is included with the submission, the CAP variation approval will be taken into consideration during the assessment process.

A lower fee will be charged for reliance variations as less assessment is required. The MHRA are actively encouraging the use of reliance procedure for variations to reduce workload and speed up approval process. This will reduce divergence between the CAP MA and GB MA, which is a general concern of companies where there may be an inevitable regulatory drift between the EU and GB.

Decentralised and Mutual Recognition Reliance Procedure for New MAs

For new applications, the MHRA can use approval of Marketing Authorisations submitted via Mutual Recognition or Decentralised procedures in EU member states with a view to granting the MA in the UK or GB.

This route is called the MRDC Reliance Procedure – MRDCRP. The MAH submits the MRP/DCP MAA as usual, thereafter once approval is received the entire dossier is then submitted to the MHRA via the MHRA submissions platform. As with the EC Reliance Route, the published timelines state 67 Day Approval Timeframe.

14 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

Regulatory & Marketplace

For existing MRP or DCP products, MAHs have the choice as to how to manage their MAs;

A. Maintain a UK-wide Marketing Authorisation and retain UK(NI) (the UK in respect of Northern Ireland) as a CMS. In this case, the Authorisation will continue to be a UK-wide MA with Northern Ireland as a CMS and Great Britain aligned with, but not part of, the DCP/MRP. This is the default position and no action is needed to be taken by the MAH.

B. Request that separate MAs are issued for UK(NI) as a CMS, and Great Britain (England, Wales and Scotland)

C. Notify the UK and the RMS (reference member state) in writing that they wish to remove UK(NI) as a CMS from the DCP/ MRP and maintain a national MA in Great Britain only.

For licenses maintaining the default option ‘A’, variations may continue to be submitted and managed as part of the relevant MR/DC procedure with NI as CMS to maintain a UK wide authorisation.

The RMS will communicate the outcome of the procedure directly to the MHRA. There is a 30 day period where the MHRA can reject the RMS decision relating to those variations where CMS input is expected (primarily major Type II variations). In reality, the MHRA has communicated that they will accept RMS approval for all variation submissions, including those with UK specific product information updates.

National Licences – New MAA Routes

The MHRA have provided new types of assessment pathways in order to help expedite approvals and facilitate access for innovative medicines; these include:

1. National Procedure – which allows for a 150 day national assessment. This is for high quality MAAs. If the application includes Northern Ireland, then it must comply with EU requirements.

2. Rolling review – where the MAA is submitted in increments for preassessment, prior to the final assessment stage. This is intended to streamline development of novel medicines allowing various elements of regulatory data to be reviewed separately.

3. Innovative Licensing and Access Procedure (ILAP) – aims to accelerate

the time to market and facilitate access for innovative medicines

Northern Ireland:

The Unfettered Access Procedure (UAP) allows for MAs approved in Northern Ireland via European procedures (centralised, mutual recognition or decentralised procedures), or via the Northern Ireland National route, to be recognised by the MHRA for Great Britain (England, Scotland and Wales)

Marketing Authorisation Applications (MAAs) made through the Unfettered Access Procedure (UAP) should be agreed within 67 days of MAA validation, unless major objections are identified.

It seems likely that this strategy will take the place of the current ECDRP (although this reliance route has been extended).

It was noted that there have been over one thousand products set to ‘not marketed in Northern Ireland’. The new Northern Ireland MHRA Authorised Route (NIMAR) provides a route for the lawful supply of Prescription Only Medicines (POMs) in compliance with UK and EU rules, where there is a risk that clinical need in NI for that product cannot be met.

This supply route has been designed to ensure that people in Northern Ireland (NI) can continue to access prescription-only medicines (POMs) should clinical need be unable to be met through authorised products or any other existing regulatory routes.

MHRA International Collaborations

The MHRA are extending their collaborations with international Health Authorities. Two examples are:

Project Orbis

One of the MHRA’s main priorities is to accelerate access to medicines in the UK in the aftermath of Brexit and they have implemented a framework for concurrent submission and review of oncology products.

This initiative aims to deliver faster patient access to innovative cancer treatments with potential benefits over existing therapies. Whilst coordinated by the FDA. it is open to MHRA, Australia (TGA), Canada (Health Canada), Singapore (HAS), Switzerland (Swissmedic) and Brazil (ANVISA), with each country remaining fully independent on their final regulatory decision.

Access Consortium

(Previously Known as ACSS)

The Access Consortium (Previously known as ACSS), is a further work-sharing initiative between MHRA, TGA (Australia), Health Canada, HAS (Singapore) and Swissmedic. Not all authorities have to be included and those who are, will maintain their own sovereign decision based on the recommendation in the Assessment Reports.

Currently, this pathway can offer Applicant’s three separate routes of authorisation:

1. New Active Substance Work Sharing Initiative (NASWSI)

2. Biosimilar Work Sharing Initiative (BSWSI)

3. Generic Medicines Work Sharing Initiative (GMWSI)

Approval by one Authority does not guarantee approval by all.

In conclusion, the steps taken by the MHRA to create new and innovative licencing options, and to expand collaborations with international partners, are in an endeavour to mitigate the effects of leaving the European regulatory network.

INTERNATIONAL PHARMACEUTICAL INDUSTRY 15 www.international-pharma.com

Graham Donaldson

Graham Donaldson is Director, Regulatory Affairs at PharmaLex UK. Graham has over 17 years of regulatory consultancy experience and leads PharmaLex’s UK and Ireland Centre of Excellence Service Delivery Area.

Bad Medicine: Lessons from an Enduring Alliance between Big Pharma and Global Policing

The challenges of tackling international crime with national law enforcement are legion. John Binns, partner in the Financial Crime team at BCL Solicitors considers how Interpol’s Operation Pangea illustrates how they can be overcome, in the context of the global fight against illicit medicines.

A World of Problems

What can be done about the sale of illicit medicines? The question illustrates a familiar challenge in the world of law enforcement, in that a problem we as consumers and taxpayers can see as straightforwardly needing tough and enduring action is made harder to solve by two fundamental features of the landscape.

The first of these is legal complexity. The trade in counterfeit and otherwise illicit medicines can be categorised in various ways from a legal perspective, broadly depending on the nature of the harms that are involved. Even where the law clearly provides remedies against conduct, which may result from a combination of civil and criminal law, the overlapping provisions and procedures can be unhelpful.

Controlled Drugs

In the UK, and indeed in most jurisdictions, the starting point for tackling many illicit sales of pharmaceutical products will be controlled drugs offences. The Single Convention on Narcotic Drugs 1961 provides the international framework, while the Misuse of Drugs Act 1971 and its schedules set the domestic framework for prohibited acts and the classification of various substances, with various regulations made under it providing the detailed rules. Where the actions of an illicit trader in medicines constitute prohibit actions under that legislation and are not covered, or insufficiently covered, by licences granted under those regulations, criminal investigation and prosecution may be both possible and appropriate.

Counterfeit Medicines

With respect to counterfeit medicines, these may breach intellectual property

laws, specifically in connection with the infringement of patents (under the Copyright Designs and Patents Act 1988) and the unauthorised use of trademarks (under the Trade Marks Act 1994), which can be enforced using either civil law routes, litigation in the High Court) or criminal law (prosecution in the magistrates’ courts or Crown Court.

Significantly, the availability of these two routes of enforcement does not entirely depend on who is doing the enforcing. Increasingly, private companies opt to bring private prosecutions in UK criminal courts against those identified as breaching criminal provisions of intellectual property law. While civil litigation may result in substantial damages and payment of costs by the losing party, and involve the lower evidential standard of civil proceedings, ‘the balance of probabilities’, as opposed to the criminal standard of ‘beyond reasonable doubt’, there is substantial deterrent value in obtaining a criminal conviction, with all that implies in terms of the offender’s reputation and, if and insofar as individuals rather than corporate defendants can be proved responsible, the threat of imprisonment.

Proceeds of Crime

A significant factor in the growth of private prosecutions in the UK has been the availability of confiscation procedures under the Proceeds of Crime Act 2002 (POCA), under which a convicted defendant can be ordered to pay sums that are equivalent to their benefit from criminal conduct, which in many cases are far in excess of their actual profits from the activity.

Meanwhile, state agencies – including, in the pharmaceutical conduct, the Medicines and Healthcare products Regulatory Agency (MHRA), can now use different provisions of POCA to pursue the proceeds of unlawful conduct (whether that conduct took place in- or outside the UK) without a criminal conviction. Recent changes to those provisions enable a relatively easy route to summary freezing and forfeiture of such proceeds in the magistrates’ courts where they are represented by funds in bank or building society accounts, which the MHRA have used to pursue alleged proceeds of online sales of prescription-only medicines.

The provisions of POCA relating to money laundering may also be engaged where there are proceeds of conduct that breaches UK law, or overseas conduct that would do so if it occurred here. In a pharmaceutical context, this has proven problematic in the context of sales of medicinal cannabis, which are, at least arguably, ‘criminal conduct’ for these purposes.

Consumer Protection

As well as the societal harms that underpin controlled drugs legislation, and the protection for private rights afforded by intellectual property laws, the sale of illicit drugs can engage various laws aimed at protecting the consumer from deception or various other forms of unfair trading. The Fraud Act 2006 prohibits, among other things, the use of active deception (or, in some circumstances, the failure to disclose relevant information) as a means to extract a gain from someone, while the Consumer Protection from Unfair Trading Regulations 2008 (CPUTR), generally enforced in the UK by trading standards departments of local councils, contain specific prohibitions on, among other things, selling medicines based on untrue claims as to their efficacy.

On top of all of that, there are specific provisions that establish bespoke regimes for medicines, including natural and homeopathic remedies, under the Human Medicines Regulations 2012 (the HMRs). Significantly, having previously derived many of these specific rules from EU law, post-Brexit, the UK government can make, amend, and repeal regulations under the Medicines and Medical Devices Act 2021 (the MMDA), which also establishes a civil penalty regime for offences involving medical devices.

Picking Up the Pieces

The second fundamental, and often unhelpful, feature of the law enforcement landscape is the contrast between its international nature and the significance of national borders – a challenge that the MHRA has also taken an effective lead in this sector in overcoming. As is increasingly obvious, the nature of financial crime, of which illicit medicine sales are a prime example, is global, which positively demands that

16 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

INTERNATIONAL PHARMACEUTICAL INDUSTRY 17 www.international-pharma.com CUT THE WASTE! Visit us at Pharmapack 2023. 1 - 2 February, 2023 Paris Expo, Porte de Versailles, France Booth J50 www.liveoresearch.com/en/cutthewaste

local, national, and regional agencies join forces to share information and coordinate enforcement efforts.

A Joined-up Approach

We do not, and indeed may never, have such a thing as a global police force. Instead, the role of Interpol is to help coordinate the efforts of national and supranational law enforcement agencies. Since 2006, the MHRA has worked with Interpol and various other agencies, including the EU’s Europol, to tackle illicit medicines and medical devices. This includes concerted days or weeks of action against suspected offenders and their assets, which are then publicly announced, most recently this summer. Under the surface, the work to produce this undeniably impressive feat is essentially about tackling those twin challenges of legal complexity and working across national borders. Among other things, this will necessarily involve consideration of data protection and procedural rights for suspects and others involved.

Importantly, the agencies involved are not limited to public-sector regulators and law enforcement. They also include private companies, whose financial interests of course are engaged in a big way, insofar as counterfeit medicines breach their intellectual property rights. Indeed, more broadly, the profits and reputation of the pharmaceutical sector generally are put at risk by those who sell medicines in breach of the rules. Involving them therefore makes sense on a principled basis, and doubtless helps with resourcing the work of agencies that may not otherwise be wallowing in money.

A Global Template?

So, is there anything in Operation Pangea that might point the way for other efforts to tackle financial crime? Are there other industries that might similarly be incentivised to cooperate with and fund law enforcement in this way, other categories of crime that require similar international coordination? Could, for example, the financial sector be brought into international efforts to combat frauds on covid support schemes, or offending that involves crypto assets, or sanctions evasion?

Such comparisons make for interesting thought experiments, with some instructive results. The immediate impact of bounce back loans, controversially handed out with minimal due diligence to businesses at the peak of the pandemic, has been on lending banks, but the government guarantees have made them squarely a public sector problem. The UK’s response, so far, has been at a national level, perhaps assuming such crimes do not cross borders – but is this right? Are we doing enough to involve the financial regulators, or to work internationally, on crypto- and sanctions crime?

Conflicts of Interest

We should take care, of course, not to celebrate the contribution of the international pharmaceutical industry to law enforcement without recognising that it is, at least to a large extent, the result of self-interest. Indeed, it might reasonably be asked whether agencies like Interpol and Europol might even be shortchanged by the deal, putting public resources into enforcing laws that are largely in place to protect intellectual property rights that might

just as easily be protected by civil litigation, or even by private firms bringing their own prosecutions. In addition to that, might the alliance of national law enforcement agencies (LEAs) and private firms lead to an unhealthy conflict of interests, insofar as private firms, even reputable multinationals, are not above committing offences themselves, including breaches of competition law and the payment of bribes, for example, from time to time?

In the UK, a comparison with the financial services industry is particularly apposite: thanks to many years of banks and other financial institutions being obliged, under yet more provisions of POCA, to gather and submit intelligence to LEAs on suspected money laundering, they have amassed the expertise and authority to enable their CEOs to sit alongside senior ministers in policymaking bodies. Even while this is happening, major banks are investigated, fined, and even prosecuted for money laundering failures by their (industry-funded) regulatory body, the Financial Conduct Authority (FCA).

The Role of Global Britain

The international nature of the problem of illicit medicines is what makes the challenge faced by the MHRA and by Operation Pangea unique. Not only must it tackle the legal complexity involved in multiple legal remedies and enforcement authorities, and the potential for conflicts of interest in public-private partnerships, but it must do so across national borders. To make matters harder, of course, it must do so in the context of a form of Brexit that has, at least potentially, decisively broken from EU regulatory norms, including in the regulation of medicines and the protection of rights

18 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

in the context of criminal investigation. Among other things, that has necessitated a new, somewhat hollowed-out relationship between domestic LEAs and Europol, and doubtless created numerous hurdles behind the scenes of Pangea’s operations.

Despite all that, the overwhelming logic of converging interests between national law enforcement and international pharmaceutical firms means that the impetus for continuing, strengthening, and deepening the activities of Pangea will surely endure; indeed, there may be potential for offshoots using the same approach. With many jurisdictions now beginning to embrace a more sensible regulatory approach to medicinal uses of cannabis, for example, there are commonalities of interest between national LEAs in regulating the borders between the various jurisdictions and tackling parties that may seek to exploit differences and gaps in these nascent frameworks. As the development and rollout of covid vaccines and treatments continue to expand, the need to police unlicensed or unsafe alternatives, particularly in the developing world, is ever clearer. And, of course, the alarming societal harms

associated with sales of opioids diverted from legitimate supply chains, online or otherwise, continues to present a challenge that cries out for international cooperation, including in tracking and seizing their proceeds.

The approach of the UK to these issues is not necessarily perfect. Cannabis, even in a medicinal context, remains the province of the Home Office rather than the MHRA, with a licensing regime in its infancy and too little thought given to a joined-up approach between the regulatory and law enforcement approaches. Scant attention is paid to fake covid treatments, save for isolated examples of trading standards prosecutions under CPUTRs for so-called cures. UK LEAs’ attempts to tackle UK proceeds of illicit sales overseas rarely show signs of real cooperation with their overseas counterparts. On all these fronts, there is surely the potential for the mechanisms created by Operation Pangea to assist. With decades now of experience in tackling the complexities of working with overlapping laws and across national borders, it is a cooperative endeavour that the newly styled, post-Brexit, Global Britain should continue to embrace.

John Binns

John is a partner in the Business Crime team at BCL Solicitors LLP. He has a particular focus on in confiscation, civil recovery and money laundering under the Proceeds of Crime Act 2002). He represents suspects, defendants and witnesses in cases invoking allegations of bribery and corruption, fraud, insider trading, market abuse, price-fixing, sanctions-busting and tax evasion. He has also coordinated and undertaken corporate investigations and defended clients in cases brought by BEIS, the FCA, HMRC, NCA, OFT, SFO and others. He has particular expertise in the provisions of anti-money laundering requirements in the regulated sector including pharmaceuticals & healthcare under the Money Laundering Regulations, civil recovery and confiscation of the proceeds of crime.

INTERNATIONAL PHARMACEUTICAL INDUSTRY 19

Regulatory & Marketplace

Pressure regulators Control valves Pipeline ancillaries Steam traps Special equipment STEAMING SOLUTIONS FOR ALL INDUSTRIES adca@valsteam.pt www.valsteam.com +351 236 959 060 Zona Ind. da Guia, Pav. 14 - Brejo 3105-467, Guia PBL PORTUGAL PRODUCTS MANUFACTURED IN PORTUGAL AV 001 IN EN 01.20

Driving a Vision for a Data-driven Regulatory Ecosystem

A data-driven Regulatory ecosystem has huge potential, beyond the opportunity for operational improvement. However, Regulatory and product teams will need updated data skills to deliver this vision, reports Amplexor’s Renato Rjavec.

Even in today’s eCTD+ world, most life sciences Regulatory teams currently still think and work in terms of documents, paragraphs and sentences when putting together collateral for marketing authorisation and variations submissions. Yet it is data, rather than pre-prepared dossiers, that is moving into central focus now.

That’s as stakeholders across the life sciences and healthcare ecosystem realise that a data-first approach to collecting, managing and communicating product information will be the most efficient and reliable way to maintain consistent, definitive, current and high-quality record of a product entering or on the market. One that can be interpreted and use in a wide range of use cases, by the broadest possible range of people (from regulators to clinicians, pharmacists and ultimately patients).

Professionals in a range of roles are now used to converting their particular information e.g. about the medicinal product’s clinical properties, chemical composition or information for patients in the narrative form. But are they ready to adopt new, more structured ways of dealing with such information at the source? Or is there an expectation that the Regulatory role will effectively assume the burden of data extraction and data entry assistance for them?

Adapting to a Data-centric Approach

Given that this data-centric approach will be the new reality before long, the question for existing product information managers/ regulatory teams is whether their skill sets now need to be refreshed to reflect the target new ways of working (first, data and document sets needing to be carefully aligned, then a direct flow of good data to the regulators).

So where are companies with all of this today? With the exception of very large pharma organisations with the budget and people resources to have already started exploring the wider possibilities, most companies still lack awareness both of the wider potential and of the work ahead of them in building the right capabilities.

At one level, this is about how they manage product information so that (a) it fulfils the demands of new IDMP structured data requirements, and (b) becomes sufficiently reliable to form a foundation for not only product registrations and their maintenance, but all sorts of other processes too.

On another level, the opportunity extends to leveraging reporting and analytics to smart effect – first to help users fill gaps and increase the quality of the data; then with a more strategic emphasis, even using AIassisted tools to investigate scope for process improvement (based on insights into how data is currently being managed and where recurring patterns are emerging).

Extra Layer of Quality Checks

It can be tempting to imagine that IT is going solve all of this, and that by default users will be swept along on the journey. Yet failure to adapt internal Regulatory capabilities, and to cultivate new data skills, is likely to severely compromise Regulatory Affairs’ data-based progress.

Of course, having efficient and userfriendly solutions that have been built not just with additional data fields to satisfy IDMP – but also with an appreciation for what new

20 INTERNATIONAL PHARMACEUTICAL INDUSTRY Winter 2022 Volume 14 Issue 4

Regulatory & Marketplace

data-centric process management models will mean for Life Sciences Regulatory and other teams (and for the pharma industry in general) – will be important.

But equally, the teams involved will need help in adapting to the demands of IDMP. They will need guidance, support and help with validation to ensure that the right data is being entered in the right way, and that any gaps or issues are spotted and flagged. And, given the huge weight of new responsibility that will be placed on this critical ‘source of product truth’, it also follows that an additional layer of quality checks will be needed to cement confidence in the new bank of structured data.

As teams look to use this ‘live’ data to build reports, they will need help understanding how to make the most of analytics and of pre-built dashboards, too. And as basic data interrogation becomes more commonplace and comfortable, teams will need to be

able to transition towards more advanced analytics.

Into the Realm of Data Science

For every user with a role to play in shaping the data, this work needs to be as simple and as user-friendly to achieve as possible, enabled by intuitive tools. If users are not brought along on the journey from this earliest point, anything that comes afterwards will be in vain (as the reliability of the data will be compromised from day one). Once teams are comfortable with working with data, and are confident in its quality – because they are adept at the process of capturing, enriching and managing it – Regulatory operations can start to be more ambitious in their next-level plans.

This takes them deeper into the realm of data science, as they start to harness AI-enabled tools to interrogate the data for signs of how this could be improved, and where entire data-based processes