NEW YORK CITY TRANSIT MUSEUM

EXISTING MUSEUM SUBWAY ENTRANCE LIGHT POLE & RAILINGS.

NEW BI-FOLD SWINGING METAL GATE WITH SIGN & HEAVY DUTY SPRING CASTER, HINGES AND PAD LOCK LATCH.

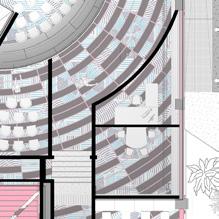

The Transit Project focused on platform barricades and transit museum entry systems within the New York City Transit network, prioritizing safety, durability, and functionality. The barricades protect historic trains while ensuring public safety, particularly for small children and visitors. Gates at the museum entrances were designed to align with the existing subway entrances in likeness and color, ensuring a cohesive design. My role included technical drafting, detailing, and coordination to meet public infrastructure and regulatory standards.

EXISTING ENTRANCE STAIRCASE.

NEW YORK CITY TRANSIT DEPARTMENT OF SUBWAYS FACILITIES PROJECT MANAGEMENT 2 BROADWAY, 14TH FLOOR, NEW YORK,NY, 10004

PROJECT LOCATION

NEW YORK CITY TRANSIT DEPARTMENT OF SUBWAYS FACILITIES PROJECT MANAGEMENT 2 BROADWAY, 14TH FLOOR,

DRAWING NAME

1 1/2" X 1 1/2" X 1/8" SQUARE METAL TUBE FRAMED AROUND.

PROJECT LOCATION

GENERAL NOTES

NOTES:

DRAWING NAME

3/4" SQUARE VERTICAL SOLID METAL RODS @ 4" O.C.

1 1/2" X 1 1/2" X 1/8" SQUARE METAL TUBE FRAMED AROUND.

3/4" SQUARE VERTICAL SOLID METAL RODS @ 4" O.C.

SCREEN PAINTED MUSEUM SIGN ON 12 GA. BENT SHEET METAL ATTACHED TO MTL. BARS.

NOTE:

PROVIDE 3 HEAVY DUTY HINGES AT BI-FOLD GATE JOINT & 3 HINGES AT EXISTING POST & PAD LOCK LATCH AT LIGHT POLE

1 1/2" X 1/8" METAL ANGLE WELDED TO FRAME AT ENDS.

12 GA. SOLID METAL BASE PANEL WELDED ON BOTH SIDES.

HEAVY DUTY GATE CASTER ANCHORED TO BASE OF GATE LEAF.

1. GATEMETAL TO BE PAINTE TO MATCH EXISTING SUBWAY ENTRANCE RAILINGS . PROVIDE RUST PROOFING PRIMER & 3 COATS OF PAINT.

EXISTING EXTERIOR BUILDING WALL.

GENERAL NOTES

NOTES:

SCREEN PAINTED MUSEUM SIGN ON 12 GA. BENT SHEET METAL ATTACHED TO MTL. BARS.

3/4" SQUARE VERTICAL SOLID METAL RODS @ 4" O.C.

NOTE:

SCREEN PAINTED MUSEUM SIGN ON 12 GA. BENT SHEET METAL ATTACHED TO MTL. BARS.

NOTE:

2. PROVIDE HEAVY DUTY SPRING CASTER BY ' PAYSON CASTERS' # 982 SIDE MOUNTED (BLACK) SPRING LOADED WITH 3" WHEEL OR APPROVED EQUAL. MOUNTED ON INNER SIDE OF GATE LEAF.

EXISTING SIDEWALK.

EXISTING MUSEUM SUBWAY ENTRANCE LIGHT POLE & RAILINGS.

3. PROVIDE SILK SCREEN PAINTED METAL PANEL MUSEUM SIGN ON EACH GATE LEAF.

1. GATEMETAL TO BE PAINTE TO MATCH EXISTING SUBWAY ENTRANCE RAILINGS . PROVIDE RUST PROOFING PRIMER & 3 COATS OF PAINT.

PROVIDE 3 HEAVY DUTY HINGES AT BI-FOLD GATE JOINT & 3 HINGES AT EXISTING POST & PAD LOCK LATCH AT LIGHT POLE

EXISTING ENTRANCE STAIRCASE

4. PROVIDE & WELD (3) HEAVY DUTY METAL GATE HINGES AT CENTER OF BI-FOLD GATES & (3) AT EXISTING POST. BY 'McMASTER - CARR' OR APPROVED EQUAL.

NEW BI-FOLD SWINGING METAL GATE WITH SIGN & HEAVY DUTY SPRING CASTER & HINGES.

5. GRIND SMOOTH ALL METAL EDGES & CORNERS AS REQUIRED.

2. PROVIDE HEAVY DUTY SPRING CASTER BY ' PAYSON CASTERS' # 982 SIDE MOUNTED (BLACK) SPRING LOADED WITH 3" WHEEL OR APPROVED EQUAL. MOUNTED ON INNER SIDE OF GATE LEAF.

3. PROVIDE SILK SCREEN PAINTED METAL PANEL MUSEUM SIGN ON EACH GATE LEAF.

6. PROVIDE A EXTRA HEAVY-DUTY GATE FLIP LATCH FOR METAL GATE BY 'ALISE' #MS3001-B MATTE BLACK OR APPROVED EQUAL. VERIFY

1 1/2" X 1/8" METAL ANGLE WELDED TO FRAME AT ENDS.

PROVIDE 3 HEAVY DUTY HINGES AT BI-FOLD GATE JOINT & 3 HINGES AT EXISTING POST & PAD LOCK LATCH AT LIGHT POLE

12 GA. SOLID METAL BASE PANEL WELDED ON BOTH SIDES.

1 1/2" X 1/8" METAL ANGLE WELDED TO FRAME AT ENDS.

EXISTING SIDEWALK.

12 GA. SOLID METAL BASE PANEL WELDED ON BOTH SIDES.

HEAVY DUTY GATE CASTER ANCHORED TO BASE OF GATE LEAF.

EXISTING SIDEWALK.

4. PROVIDE & WELD (3) HEAVY DUTY METAL GATE HINGES AT CENTER OF BI-FOLD GATES & (3) AT EXISTING POST. BY 'McMASTER - CARR' OR APPROVED EQUAL.

7. PROVIDE 'MASTERLOCK' EXTERIOR WEATHERPROOF GATE PAD LOCK OR APPROVED EQUAL. VERIFY

PAD LOCK LATCH ON METAL SHIM.

8. PROVIDE GATE OPEN POSITION STOPPER OR ANCHOR & HOLD IN-PLACE MECHANISM, VERIFY.

5. GRIND SMOOTH ALL METAL EDGES & CORNERS AS REQUIRED.

6. PROVIDE A EXTRA HEAVY-DUTY GATE FLIP LATCH FOR METAL GATE BY 'ALISE' #MS3001-B MATTE BLACK OR APPROVED EQUAL. VERIFY

7. PROVIDE 'MASTERLOCK' EXTERIOR WEATHERPROOF GATE PAD LOCK OR APPROVED EQUAL. VERIFY

HEAVY DUTY GATE CASTER ANCHORED TO BASE OF GATE LEAF.

8. PROVIDE GATE OPEN POSITION STOPPER OR ANCHOR & HOLD IN-PLACE MECHANISM, VERIFY.

EXISTING EXTERIOR BUILDING WALL.

EXISTING MUSEUM SUBWAY ENTRANCE LIGHT POLE & RAILINGS.

NEW BI-FOLD SWINGING METAL GATE WITH SPICKS AT TOP & SIGN ATTACHED TO EXISTING POLE & POSTS.

PAD LOCK LATCH ON METAL SHIM.

REMOVE POST CAP & EXTEND 4"X 4" EXISTING METAL POST ℄

STYLE THERMOPLASTIC TUBING HANDRAIL SYSTEM

THERMOPLASTIC RAILING (TYP.)

MOUNTING W/ THERMOPLASTIC DIP-COATING SYSTEM W/ 3/4" NON-SLIP BASE PAD AT (TYP.)

STATION PLATFORM FLOOR

1. PARKED SUBWAY CART

1. 2" Ø MALIBU STYLE THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

2.1"X 3/4" NEOPRENE STRIP WITH/ADHESIVE-DARK GRAY (TYP.)

EXISTING SUBWAY PLATFORM 6" 3'-6"

3. 1" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING

4. ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL W/ 3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

SECTION - BARRICADE

2"Ø MALIBU STYLE THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

05

1. 2" Ø MALIBU STYLE

THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

2.1"X 3/4" NEOPRENE STRIP WITH/ADHESIVE-DARK GRAY (TYP.)

3. 1" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING

4. ALUMINUM MOUNTING

STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL W/ 3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

SECTION - BARRICADE 01 1" = 1'-0"

EXISTING SUBWAY PLATFORM

℄

2" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING (TYP.)

ELEVATION-

BARRICADE

1" = 1'-0"

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

4"X4" X 3 8" NON-SLIP RUBBER PAD W/ ADHESIVE MOUNTING TO BASE PLATE(TYPE.)

DETAIL- BARRICADE BASE 6" = 1'-0"

1" Ø THERMOPLASTIC TUBING TO RAILING (TYP.)

ALUMINUM MOUNTING

STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL W/ 3/4" NON-SLIP RUBBER BASE PAD AT BOTTOM (TYP.)

STATION PLATFORM FLOOR

2" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

THERMOPLASTIC TO RAILING

2"Ø MALIBU STYLE THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

1" Ø THERMOPLASTIC TUBING TO RAILING (TYP.)

ALUMINUM MOUNTING

STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM

PEDESTAL W/ 3/4" NON-SLIP RUBBER BASE PAD AT BOTTOM (TYP.)

ALUMINUM STANCHION DIP-COATING PEDESTAL 4"X4" X RUBBER ADHESIVE BASE PLATE(TYPE.)

THERMOPLASTIC

STATION PLATFORM FLOOR

2"Ø MALIBU STYLE THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

SCALE A-2 1"=1-0"

3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

2 BROADWAY, 14TH FLOOR, NEW YORK,NY, New York City Transit

03 DETAIL- BARRICADE 3" = 1'-0"

DEPARTMENT OF SUBWAYS FACILITIES PROJECT MANAGEMENT

1" Ø THERMOPLASTIC TUBING TO RAILING (TYP.)

PROJECT LOCATION

NEW YORK TRANSIT MUSEUM

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM

DRAWING NAME

PLATEFORM BARRICADE

PEDESTAL W/ 3/4" NON-SLIP RUBBER BASE PAD AT BOTTOM (TYP.)

GENERAL NOTES TBD

STATION PLATFORM FLOOR

AXON- BARRICADE- BASE 6" = 1'-0"

03

DETAIL- BARRICADE 3" = 1'-0"

SECTION - BARRICADE 01 1" = 1'-0" SCALE

THERMOPLASTIC DIP-COATING PEDESTAL (TYP.)

3/4" RUBBER PAD AT BOTTOM (TYP.)

PLAN- BARRICADE 1" = 1'-0" 06

1"=1-0"

1. PARKED SUBWAY CART

SECTION - BARRICADE 01 1" = 1'-0"

2.1"X 3/4" NEOPRENE STRIP WITH/ADHESIVE-DARK GRAY (TYP.)

3. 1" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING

4. ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL W/ 3/4" RUBBER BASE PAD AT BOTTOM (TYP.) EXISTING SUBWAY PLATFORM

1. 2" Ø MALIBU STYLE THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

2.1"X 3/4" NEOPRENE STRIP WITH/ADHESIVE-DARK GRAY (TYP.)

3. 1" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING

4. ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL W/ 3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

2"Ø MALIBU STYLE

THERMOPLASTIC TUBING MODULAR HANDRAIL SYSTEM (TYP.)

1" Ø THERMOPLASTIC TUBING TO RAILING (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM

PEDESTAL W/ 3/4" NON-SLIP RUBBER BASE PAD AT BOTTOM (TYP.)

02 ELEVATION- BARRICADE

MALIBU STYLE THERMOPLASTIC TUBING RAILING (TYP.)

03

DETAIL- BARRICADE 3" = 1'-0"

SCALE A-2 1"=1-0"

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

8" NON-SLIP PAD W/ ADHESIVE MOUNTING TO PLATE(TYPE.)

BASE BOTTOM MOUNTING W/ THERMOPLASTIC SYSTEM (TYP.) STYLE THERMOPLASTIC TUBING TO (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM

PEDESTAL (TYP.)

4"X4" X 3 8" NON-SLIP RUBBER PAD W/ ADHESIVE MOUNTING BASE PLATE(TYPE.)

PROJECT LOCATION

DRAWING NAME

05 DETAIL- BARRICADE BASE 6" = 1'-0"

ELEVATION- BARRICADE 1" = 1'-0"

2" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

STATION PLATFORM FLOOR

4"X4" X 3 8" NON-SLIP RUBBER PAD W/ ADHESIVE MOUNTING TO BASE PLATE(TYPE.)

ELEVATION- BARRICADE 1" = 1'-0"

06

2" Ø MALIBU STYLE THERMOPLASTIC TUBING RAILING (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

AXON- BARRICADE- BASE 6" = 1'-0"

2" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING (TYP.)

2" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING (TYP.)

AXON- BARRICADE- BASE 6" = 1'-0" 05 DETAIL- BARRICADE BASE 6" = 1'-0"

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

4"X4" X 3 8" NON-SLIP RUBBER PAD W/ ADHESIVE MOUNTING TO BASE PLATE(TYPE.)

3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

2" Ø MALIBU STYLE THERMOPLASTIC TUBING TO RAILING (TYP.)

ALUMINUM MOUNTING STANCHION W/ THERMOPLASTIC DIP-COATING SYSTEM PEDESTAL (TYP.)

3/4" RUBBER BASE PAD AT BOTTOM (TYP.)

1" = 1'-0"

SUBWAY CART

SUBWAY