ARN - 303- Building Construction - IV

Professor: Ram Sateesh Pasupuleti

NAME: Muskan Aanand (19110016)

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

Sismo Building Technology

Sismo (patented) Building Technology is an insulating shuttering kit for a whole building unit based on a three-dimensional lattice made of galvanized steel wire and EPS panels

Structural Stay-in-Place Formwork System (Coffor)

Insulating Concrete Forms (ICF)

These are formwork systems which are left in the structure after concreting and act as insulation.

Monolithic Insulated Concrete System (MICS)

It is a patented structural stay in place formwork system to build loadbearing monolithic concrete wall structures based on shear wall concept

Lost-in-Place Formwork System

– Plaswall Panel System

Lost-in-Place Formwork system

– Plasmolite Wall Panels

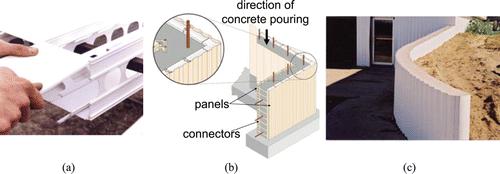

Stay-In-Place PVC Wall Forms

Plaswall Panel System is a lost in place formwork (patented system of M/s FTS Buildtech Pvt Ltd), where two fiber cement boards (FCB) of 6mm thickness each are bonded through HIMI (High Impact Molded Inserts) spacers

This is a prefinished wall formwork from M/s Novel Assembler Pvt Ltd comprising of rigid PolyVinyl Chloride (PVC) based polymer components that serve as a permanent stayin-place durable finished form-work for concrete walls.

Permanent Wall Form (PVC)

Monolithic Insulated Concrete System (MICS) is a patented system of M/s Maiwir Ecotech Pvt Ltd It is a formwork system for reinforced concrete made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors and roofs.

Plasmolite Panels are lost in place formwork system (patented system of M/s FTS Buildtech Pvt. Ltd), where two fibre cement boards (FCB) of 6 mm thickness are bonded together through High Impact Molded Inserts (HIMI) spacers

“Permanent Wall form” of M/s Kalzen Realty Pvt. Ltd is an innovative permanent structural walling system consisting of rigid Poly-Vinyl Chloride (PVC) formwork that serve as a stay in place finished form-work for concrete walls.

WHY SIP?

After concrete pouring and hardening this type of formwork systems remain in place as an integral part of the structure and contribute to the structural integrity ,durability and even aesthetics of concrete elements.

Stay in place formwork systems are quicker requiring less manpower and machines. These are used to form loadbearing walls, eliminating need for columns and beams. With the use of stay in place formwork, need for separate formwork is eliminated. It brings overall economy and speed in construction.

NAME: Muskan Aanand (19110016) Page No:

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

ARN - 303- Building Construction - IV

Date: 23-09-2021

The formwork is composed of two filtering grids comprising of rib meshes made of galvanized plain steel GP sheets with herringbone mesh pattern Riblet. Reinforced by C profile GP sheet vertical stiffener, these grids are further connected by articulated horizontal ms rebound loops in one direction and cold rolled closed annealed plate GP horizontal connectors in other directions. After the erection of formwork panels in alignment over strip foundation, closing of corners edges of doors and windows frames rebar positioning concrete of required greatest pod inside the panels either using pump bucket or with Chauvel loader. The inside and outside walls are finished with cement plaster of suitable grade The Coffer system brings a unique technology called a structure stainless formwork system. Compared to the conventional there is a time saving of 50 to 60 percent. Coffer

It is an insulating shuttering kit made in a factory for whole building based on a three-dimensional lattice made of high-tensile galvanized steel wires. At the exterior side of the lattice, a high-density fire-resistant grade of expanded polystyrene panels is inserted which transforms the lattice into a closed structure that can be filled with concrete. Other materials like mineral board can also be used depending upon the requirement and cost economy The steel bars also act as a and anchoring for the finished materials and it holds reinforcement bars in place during concreting. The panels are erected on foundation using dowel bars and exterior surface is finished with cement plaster of appropriate grade. EPS base stay in place formwork system has high heat resistant property and brings down energy consumption required during winter and summe and cooling

An American initiative is used in Europe America Africa and Southeast Asia. Insulated concrete forms ICF system comprises a panel of two walls of selfextinguishing expanded polystyrene EPS of density 24 kilograms per cube meter separated by a nominal distance of 150 millimeters by hard plastic tiles. The forms are open-ended hollow polystyrene blocks that fit tightly together to form a shuttering system. These are assembled at the site to hold reinforced concrete. The concrete of the desired grade is poured into the hollow space to form a continuous wall, when hardened the wall supports the structural loads from floors and roofs and shuttering provides thermal insulation. Reinforcement, as required from the design, is also placed. The Upper and lower surfaces of the polystyrene panels are castellated and the vertical mating surface of our tongue and grooved to

NAME : Shreyes Gupta (1911

Muskan Aanand (19110016) g

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Date: 23-09-2021

Images From BTMPC manuals and videos

Stay in Place PVC Wall Form is a typr of SIP which is already in use in Australia and Canada . The technique involves using rigid poly-vinyl chloride (PVC) based polymer components serve as a permanent stay-in-place finished formwork for concrete walls. The formwork System being used acts as pre-finished walls requiring no plaster and can be constructed instantly.

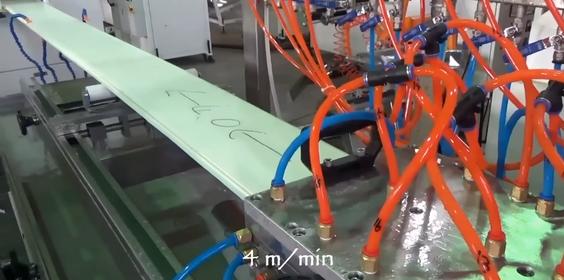

EXTRUSION OF PANELS

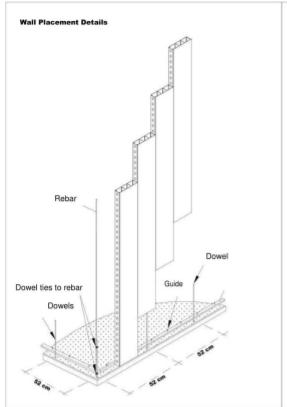

ERECTION OF PANELS

Each wall component cut with automated cutting saw.

Course begins with box connector, and placing two adjacent pannels.

The box connector slid down between the two panels and is located over the foundation dowel.

Checking of correct component, proper pieces and correct alignment.

Basic Frame Starter

Jointer Connector Jointer Panel

Bracing done at top and bottom, components screwed, and assembly plumbed.

Erection continued sequentially, according to drawing layout

Katta Sheetal (19110011) 3 way Connector Azteca Frame

NAME: Muskan Aanand (19110016) Page No: 2

ARN - 303- Building Construction - IV

Date: 24-09-2021

Main Panel Connector Connector Panel

AZTECA FRAME STARTER 11

Main Panel Connector Connector Panel

AZTECA FRAME STARTER 11

of spacing of horizontal bars

The horizontal bars are lapped with the previous bars

At the first corner, the hooked horizontal bars are installed from both directions

Horizontal hooked bars are installed at the ends of straight walls prior to installing the next corner and are installed at intersections after erecting a sufficient length of wall.

are properly installed and that the Novel System components are located, aligned and plumbed

A highly workable, free-flowing concrete mix has to be used for the pouring

The concrete specified shall be highly workable, free flowing mix 13 poured from the top into the cavities using a small hose to go down at least 1.5 to 2m into the cavities for directly pumping the concrete from ready mixed concrete truck

For small building construction, concrete can be poured manually using a funnel.

Concrete mix directly poured from ready mixed concrete truck

There is no need to use vibrator because gravitational pressure acts to selfcompact the concrete inside the water tight cavities when selfcompacting concrete is used.

Filling the panels with concrete shall be done in three layers of 1m height with an interval of 1 hour between each layer

NAME: Muskan Aanand (19110016) Page No:3

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

ARN - 303- Building Construction - IV

Date: 24-09-2021

Images From BTMPC manuals and videos

STAY IN PLACE : PVC WALL FORM

NAME: Muskan Aanand (19110016)

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

Testing of samples by RDH Building Engineering Ltd, USA

These tests were performed by constructing a wall of 1994 mm x 2032 mm using light weight EPS by Plasti-Fab Advantage ICF as formwork for the steel reinforced 150 mm thick concrete A 584 mm x 584 mm fixed window was installed within the wall assembly.

Air Tightness Test in accordance with ASTM E283

When tested to the standard of ASTM E283 at a pressure differential of 75 Pa, the specimen, as prepared, achieved an Air Leakage Rate per fixed area (qA) of less than 0.0039 L/s.m2.

Water Ingress Resistance Test in accordance with ASTM E331

When tested to the standard of ASTM E331, no water ingress resistance was observed through the specimen at differential pressures of 150, 300, 700, 1400 & 5000Pa

Engineering Evaluation of Logix ICF Water Vapour Transmission

Test by Intertek Testing Services NA Ltd., USA

Intertek has conducted an engineering evaluation of Logix Insulated Concrete Forms Ltd, on Logix ICF to determine if the Logix ICF meets the 2005 National Building Code as a vapour barrier The analysis showed that Logix ICF meete the water permeance requirements and can be installed without a vapour barrier

Page No: 4

ARN - 303- Building Construction - IV

Date: 24-09-2021

STAY

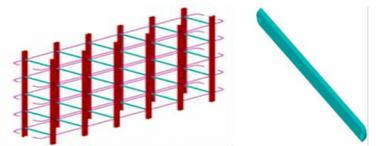

The formwork system comprises of two filtering grids made of rib mesh reinforced by vertical stiffeners called ‘C’ channel which is made up of galvanized sheet having zinc coating .The grids are connected by rebar which acts as horizontal stiffeners and connector which act as a shear link

The vertical steel channels and horizontal steel bars act as steel reinforcement for load bearing wall. The connectors help to fold the formwork for easy transportation. Concrete is poured into these gaps between ribmehses The panels are prefabricated which when arrive on the construction site are installed and ready for concreting. The Formwork System is generally used for residential buildings upto G+4 storey, Industrial buildings, Underground Tanks, Water retaining structures, Storm water drains, Compound walls etc. and also as shuttering material for slabs

'C’ Channel ReBar

These panels shall be used for slab shuttering but may also be used as shuttering option for RCC wall having thickness of more than 350mm.

ib Mesh

Standard double panel

Insulated double panel Fibre cement double panel

Insulated Double panel –These panels shall have an integrated insulation on the exterior side The insulated material shall be of polystyrene or polyurethane of required thickness as per design. Used for main walls in structures

These shall have inbuilt steel and not require extra reinforcement. shall be of fixed size and need to be cut on site for openings etc but there are also Customized double panels from the factory that shall have required cutting for openings as per drawing and no need to cut on site. These panels shall be used for load bearing walls, retaining walls and shear walls.

NAME: Muskan Aanand (19110016) Page No:5

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

These panels shall have its interior face as fibre cement board which has smooth surface and avoid plastering of walls. These panels may be used for water retaining structures.

ARN - 303- Building Construction - IV

Date: 24-09-2021

C'

MANUFACTURING PROCESS FLOW CHART

Marketing PPC Panel Designer Plant store, Issue of raw material Production of Components

Production of Single panerls

Assembly Machine

Production of Double panels

Quality check Packing and Dispatch

studs and scews

Single coffer panels

Horizontal steel C profile and scaffholding

NAME: Muskan Aanand (19110016) Page No: 6

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

ARN - 303- Building Construction - IV

Date: 24-09-2021

Images From BTMPC manuals and videos

Coffer panels on pallets Steel wire Rib lathe Construction tools and vertical sawLAYOUT AND BLOCKING 1.

TEMPORARY PLACEMENT

The Structural formwork panels shall be fitted over projecting vertical reinforcing starter bars. On a provisional basis, each panel shall be positioned vertically with the help of c channel of wooden battens or metal bars. Then, the small left over gaps after placing all panels is adjusted by cutting a panel with a vertical saw and is fixed in accordance with the width of that gap

The angle panels shall preferably be fixed as follows:

CLOSING THE EDGES OF OPENINGS

Once the panels are correctly stabilized, reinforcement bars shall be installed Details of the reinforcement elements in the angles and around the openings shall be the same as for traditional walls of reinforced concrete. Vertical bars and horizontal bars in U-shape, shall be placed in the angles and openings- bound together and tied by a steel wire

BENDING THE PANEL ON SITE

a. On the inside with a batten of panel placed vertically all the way up the angle. This batten shall be bounded around the stiffening sections of Formwork panels of the angle b. On the outside right angle accessories are used as braces fixed on the angle panels . they are either screwed or tied.

Once done, the The verticality of all the pnels fixed shall be checked using a plumb line or level.

NAME: Muskan Aanand (19110016) Page No:7

Katta Sheetal (19110011)

STAY IN PLACE

ARN - 303- Building Construction - IV

Date: 24-09-2021

The opening for windows shall be done using a rotary saw Rims of doors and windows shall be closed preferably with wooden boards/rib lath/preframes the width of which shall be equal to thickness of the panel. Then the openings of edges are closed with panels.

On the outside, traditional hydraulic or sprayed façade coating shall be used. On the inside, normal plaster, panels of wood, tile, marble etc shall be usedThe ideal number of coats is two, namely the undercoat followed by a finishing coat. The total thickness of two coat plaster shall not normally exceed 20mm where - Back coat, both for internal and external shall be 10 to 12 mm thick and Finishing coat shall be 3 to 8 mm thick.

The electric and plumbing ducts etc shall be placed inside the ducts. For connectors, small openings shall be made.

The pouring should be done with plastic concrete and can be poured using plump ,bucket or chauvel loader. The pouring shall be monitored at the jointing points, reveals and zones containing reinforcement bars. In coffer system , it is possible to pour at the walls and slab at the same time. This will ensure a monolithic structure of excellent quality

Slab & outer wall connection

Slab & Inner wall connection

NAME: Muskan Aanand (19110016) Page No:8

Single coffor panels are used for slabs. Reinforcement of slabs is placed on the coffor panels. .

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

ARN - 303- Building Construction - IV

Date: 23-09-2021

Sketches are hand - Drawn.

7. ELECTRIC AND PLUMBING DUCTS

NAME: Muskan Aanand (19110016)

Katta Sheetal (19110011)

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

Test 1: Lateral capacity of the panels with concrete Details of Test: Size of panels: 2.2 m x 3.0 m, thickness : 160 mm and no of panels used = 2

Grade of concrete: M20

Test result; Breaking load 8.512 MT

Maximum deflection: 62 mm

Test 2: Axial and Buckling capacity of the panels with concrete Details of Test:

Size of panels: 05 m x 30 m, thickness 160 mm and no of panels used = 2 Concrete grade : M20

Test Result: Maximum load per cylinder given: 263 MT Total load applied per cylinder: 1052 MT

Maximum deflection observed: 187 mm

Test 1: Compressive Strength on Hardened Concrete Cubes Details of Test: Material description: Concrete cube (150 x 150 x 150mm) Concrete grade M20 for 28 days strength Concrete grade: M25 for 7 days & 28 days strength Concrete grade M30 for 28 days strength

Test 2: Compressive strength of Concrete cubes & Concrete panel (after 7 days & 28 days), Flexural strength of Concrete beam & concrete panel (after 7 days & 28 days), Shear strength of panel (after 28 days), Deflection of panel (after 28 days), Water absorption (after 28 days) and Modulus of Elasticity of Cylinder (after 28 days)

Page No: 9

ARN - 303- Building Construction - IV

Date: 24-09-2021

Images From BTMPC manuals and videos

COFFOR CONSTRUCTION SYSTEM

Already in use in Canada & Australia, the plant manufactured rigid poly-vinyl chloride (PVC) based polymer components serve as a permanent stay-in-place finished form-work for concrete walls The formwork System being used acts as pre-finished walls requiring no plaster and can be constructed instantly

This System is suitable for residential and commercial buildings of any height from low rise to high rise In order to achieve speedier construction, strength and resource efficiency, the composite structure with PreEngineered Steel Structural System as structural members is being used in the present project.

TECHNOLOGY : PVC Stay In Place Formwork System

"The Light House Projects (LHPs) showcase the best of new-age alternate global technologies, materials and processes in the construction sector for the first time in the country at such a large scale They are being constructed under GHTC-India which envisages to provide an ecosystem for adoption of innovative technologies in the housing construction sector in a holistic manner

NAME: Muskan Aanand (19110016) Page No: 10

Katta Sheetal (19110011) STAY IN PLACE

Amasa Pranay (19110002)

Shreyes Gupta (19110025)

ARN - 303- Building Construction - IV

Date: 24-09-2021

Images From BTMPC manuals and videos