RANGE ROVER

From Musicals to Crime Dramas, Josh Rivera Can Do It All

EDITOR'S

From Musicals to Crime Dramas, Josh Rivera Can Do It All

EDITOR'S

whether you’ve had an olympic summer, a brat summer, fell out of a coconut tree, or went to the pink pony club, I hope it was also a restful summer. The cadence of breaking news, viral trends and political twists and turns show no signs of slowing down as we enter fall and peak election season in the U.S. I, for one, look forward to finding comfort in big sweaters, slouchy jeans and pumpkin spice-flavored anything. Cheers to a basic you-know-what fall.

Fall is always a busy and transformative time for the denim industry, from New York Fashion Week kicking off a month-long stretch of Spring/Summer 2025 runway shows to mills and fabric producers convening at Kingpins Amsterdam to discuss Spring/Summer 2026 collections. Rivet will be at both with the fall issue distributed across NYC fashion events in September and the preeminent denim event in October.

Rivet is also heading to Los Angeles this fall for the first Sourcing Journal x Rivet Sustainability LA conference on Sept. 26. With a speaker lineup that includes sustainability experts from ready-to-wear, denim, activewear, tech firms and more, the event is an opportunity to take note of the ways other companies are establishing more responsible supply chains, measuring their impact and transforming their businesses for the better.

L.A.’s denim industry has learned plenty of lessons that it can share. After a post-covid spike, L.A. laundries are adjusting to a new normal in “Local Value,” pg. 42. In “LA View” (pg. 38), designers from leading premium denim brands discuss how they approach sustainability while harnessing the West Coast lifestyle that inspires brands worldwide. In “Blue Blood” pg. 52, Nicolai Marciano, chief new business development officer for Guess Inc., shares how a partnership with a long-time supply chain partner is transforming its business.

Mills and chemical suppliers are transforming their business as well by adding creative service arms. In “To the Rescue” pg. 62, learn how they’re leveraging their expertise to help clients find solutions for their design challenges. Denim brands have long relied on trim suppliers for creative support. In “It’s in the Details” pg. 54, hear from trim manufacturers on what’s trending in zippers, labels, rivets and more. Few technologies have transformed the finishing process like laser. In “Laser Focus” pg. 58, Jeanologia CEO Enrique Silla looks back at 25 years of driving sustainability and creativity with laser innovations.

EDITORIAL

PROD

Anne

Jay Penske Chairman & CEO

Gerry Byrne Vice Chairman

George Grobar Chief Operating Officer

Sarlina See Chief Accounting Officer

Craig Perreault Chief Digital Officer

Todd Greene EVP, Business Affairs & Chief Legal Officer

Celine Perrot-Johnson EVP, Operations & Finance Paul Rainey EVP, Operations & Finance

Tom Finn EVP, Operations & Finance

Jenny Connelly EVP, Product & Engineering

Ken DelAlcazar EVP, Finance

Debashish Ghosh Managing Director, International Markets

Dan Owen EVP, GM of Strategic Industry Group

Brian Levine Senior Vice President, Revenue Operations

Brooke Jaffe Senior Vice President, Public Affairs & Strategy

David Roberson Senior Vice President, Subscriptions

Doug Bandes Senior Vice President, Partnerships PMC Live Frank McCallick Senior Vice President, Global Tax

Jessica Kadden Senior Vice President, Programmatic Sales

Judith R. Margolin Senior Vice President, Deputy General Counsel

Lauren Utecht Senior Vice President, Human Resources

Marissa O’Hare Senior Vice President, Business Development Nelson Anderson Senior Vice President, Creative

ADVERTISING Amanda

Angela Jean Velasquez

RIVET EXECUTIVE EDITOR

Footwear

Katherine Hogan Account Director, Tech

INTERNATIONAL OFFICES

Olga Kouznetsova European Director, Italy

Giulia Squeri European Director, Italy

Elisabeth Sugy Rawson European Director, France

MARKETING

William Gasperoni Vice President

Christine Staley Senior Director, Marketing and Fairchild Studio

Sara Shenasky Head of Client Activation

Barbra Leung Director, Integrated Marketing

Alexa Dorfman Senior Marketing Manager

Kayla Gaussaint Associate Integrated Manager

OPERATIONS

Ashley Faradineh Director of Operations

Rosa Stancil Media Planner

Emanuela Altimani Senior Sales Coordinator

EVENTS

Julianna Cerchio Executive Director

Joy Chernus Senior Director

Gregory Pepe Manager, Events

Elizabeth Hernandez Senior Associate, Events

Sophie Guzmán Events Coordinator

Lauren Simeone Director, Audience Development

Trish Reidy Attendee Sales Manager

EVENT PROGRAMMING

Caroline Daddario Executive Director, Head of Programming

Alice Song Senior Manager, Programming and Special Projects

Nici Catton Senior Vice President, Product Delivery

Adrian White Vice President, Associate General Counsel

Andrew Root Vice President, Digital Marketing

Andy Limpus Vice President, Executive Search & Head of Talent Acquisition

Anne Doyle Vice President, Human Resources

Ashley Snyder Vice President, Associate General Counsel

Brian Vrabel Head of Industry, CPG and Health

Constance Ejuma Vice President, SEO

Courtney Goldstein Vice President, Human Resources

Dan Feinberg Vice President, Associate General Counsel

Denise Tooman Vice President, Marketing, Strategic Solutions Group

Jamie Miles Vice President, eCommerce

James Kiernan Head of Industry, Agency Development

Jennifer Garber Head of Industry, Travel

Jerry Ruiz Vice President, Acquisitions & Operations

Joni Antonacci Vice President, Production Operations

Karen Reed Vice President, Finance

Karl Walter Vice President, Content

Katrina Barlow Vice President, Business Development

Kay Swift Vice President, Information Technology

Keir McMullen Vice President, Human Resources

Matthew Cline Head of Automotive Industry

Mike Ye Vice President, Strategic Planning & Acquisitions

Noemi Lazo Vice President, Customer Experience

Richard Han Vice President, International Sales

Scott Ginsberg Head of Industry, Performance Marketing

Sonal Jain Vice President, Associate General Counsel

Josh Rivera

13

THE ZEITGEIST

The latest movies, books and albums dropping this fall.

18

YOUNG AT HEART

How American Eagle maintains its place as Gen Z’s favorite brand.

22

FLOWER POWER

Finnish design house Marimekko gets serious about jeans.

28

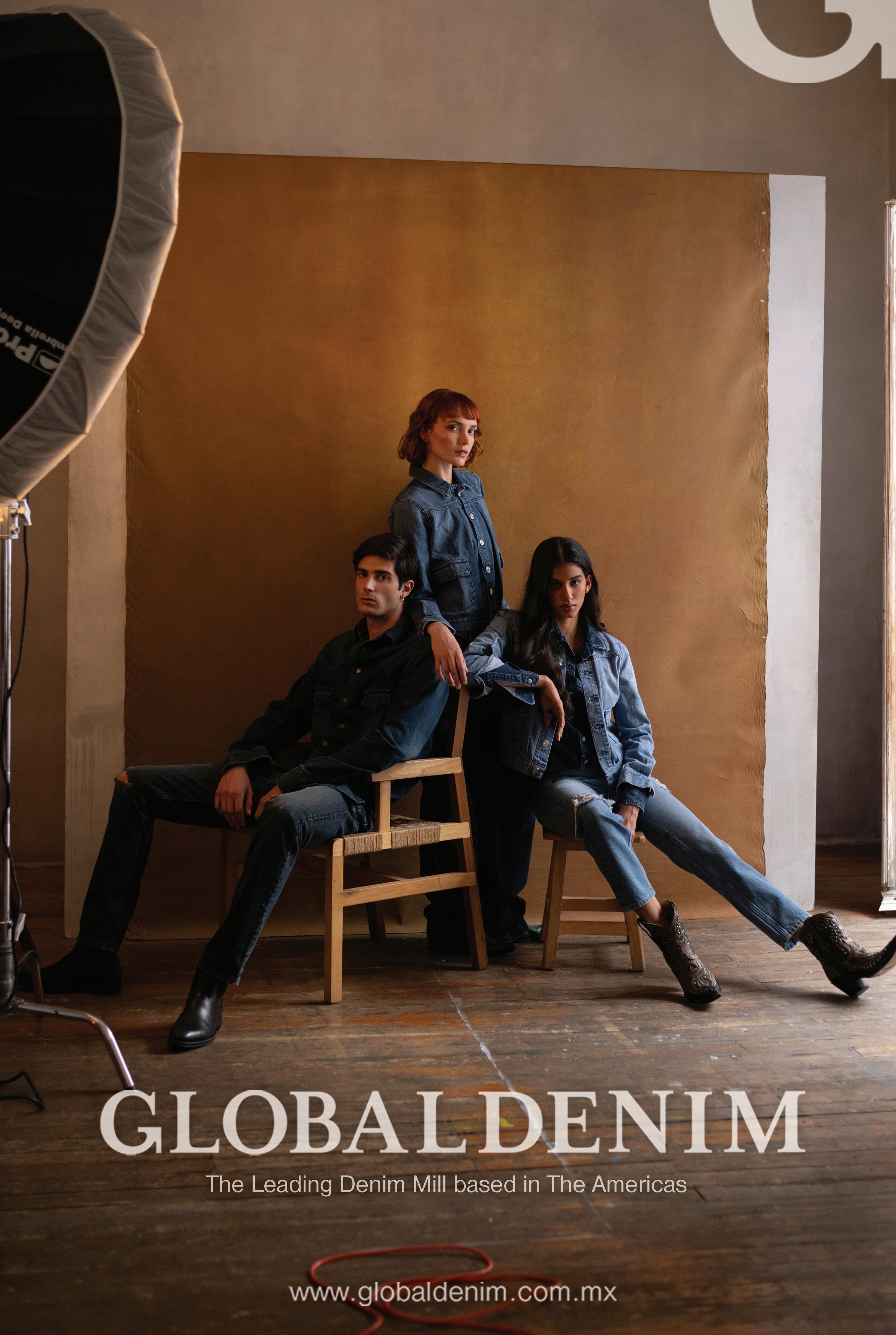

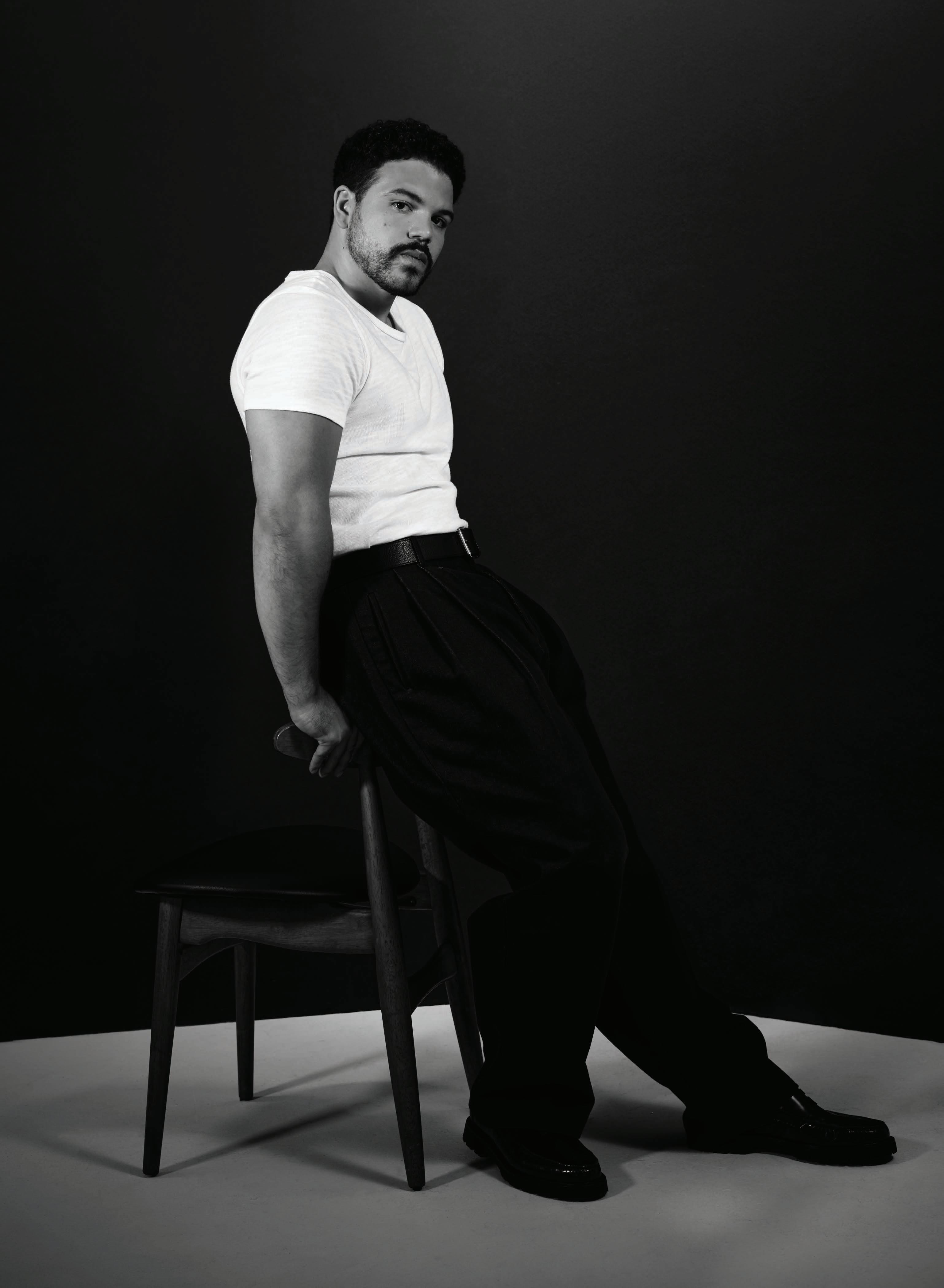

ACTOR’S STUDIO

“American Sports Story” actor Josh Rivera sports fall’s biggest fits.

38

LA VIEW

Designers and executives share what’s next in denim from the West Coast.

42

LOCAL VALUE

After the pandemicfueled spike for local production, the L.A. denim community adjusts to orders leveling off.

46

ALWAYS AHEAD

Trend forecaster

Amy Leverton reflects on her work and the industry as she builds out a new business model for Denim Dudes.

50

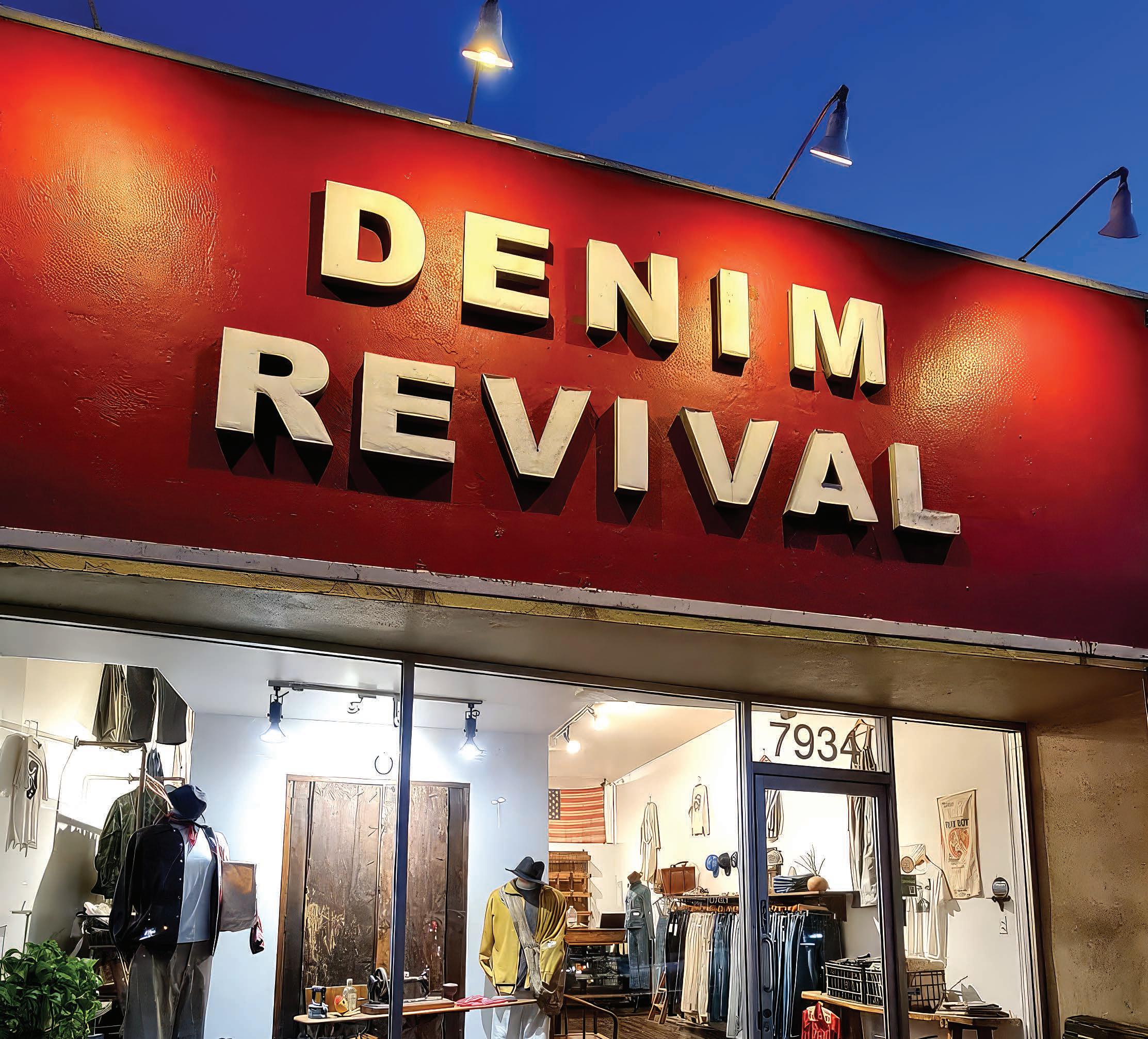

FIXER UPPER

Denim Revival helps clients maintain their favorite pairs of jeans.

52

BLUE BLOOD

Nicolai Marciano, chief new business development officer for Guess Inc., on balancing heritage and sustainability.

54

IT’S IN THE DETAILS

Trim manufacturers deliver on the market’s demand for more sustainable products.

58

LASER FOCUS

Jeanologia founder and CEO Enrique Silla looks back on 25 years of laser finishing innovation.

64

COMMON GROUND

How denim became the unofficial uniform of political changemakers.

Varsity styling clashes with deconstructed denim, quirky color combos & novelty accessories. by WWD Staff

SUSTAINABLE FABRICS REDEFINING ACTIVE LIVING

Step into the Future of Fabric at Functional Fabric Fair Fall! This exclusive sourcing destination is designed for innovators in outdoor, lifestyle, and activewear textiles, footwear, and accessories. Discover groundbreaking trims and materials that will redefine the future of performance fabrics. Be among the first to experience the latest products and technologies set to hit the market, offering an insider’s view of the trends that will define the 2025/2026 Fall and Winter seasons. Created by the industry, for the industry.

This trade-only event is available exclusively to verified designers, product developers, purchasing professionals, and materials managers. Whether you’re looking to elevate outdoor gear or enhance lifestyle apparel, this is your chance to reconnect with the industry’s best and stay ahead of the curve. Don’t miss it!

Join us at the Functional Fabric Fair Day 0 (ZERO): Sustainability Workshop! Gain valuable insights into sustainability with expert-led presentations and real-world case studies. Explore the latest updates and participate in engaging round table discussions. This workshop provides you with practical knowledge to implement on November 19th, one day before the exhibit hall opens. Don’t miss this opportunity to stay ahead in sustainable innovation!

BEETLEJUICE

BEETLEJUICE

The juice is loose. On Sept. 6, it will officially be showtime for “Beetlejuice Beetlejuice,” a sequel to the 1988 Tim Burton cult classic, “Beetlejuice.” The film stars Michael Keaton reprising his role as the infamous spirit, who is summoned once again by the Deetz family. This time, Lydia Deetz (played by Winona Ryder) and her daughter Astrid (played by “Wednesday” star Jenna Ortega) discover that the portal to the afterlife has been accidentally opened.

JOKER: FOLIE À DEUX

Moviegoers are going gaga for “Joker: Folie à Deux.” On Oct. 4, the musical sequel to 2019’s “Joker” will hit theaters. Lady Gaga stars as Harley Quinn, while Joaquin Phoenix reprises his role as Arthur Fleck, who becomes the Joker. The film continues Fleck’s story as a failed comedian whose descent into madness turns him into Gotham City’s main

villain. While imprisoned at Arkham State Hospital, he meets Quinn, the “love of his life.” Upon his release, the two embark on a doomed romantic adventure.

WICKED

Fans worldwide will be following the yellow brick road to theaters this fall.

On Nov.22, “Wicked,” the untold story of the witches of Oz, will hit the big screen. The film stars Emmy, Grammy and Tony award winner Cynthia Erivo as Elphaba, a misunderstood young woman with green skin who is on a journey to discover her true power. Joining her is Grammywinning global pop

star Ariana Grande as Glinda, a privileged and ambitious young woman who has yet to find her true heart.

PARIS HILTON, “INFINITE ICON”

Paris Hilton is solidifying her icon status with her upcoming album. On Sept. 6, the DJ and media personality will release her sophomore album titled “Infinite Icon.”

Executive produced by singer-songwriter Sia, the 12-track disc will have guest appearances from pop stars like Rina Sawayama, Meghan Trainor, Maria Becerra and more.

NELLY FURTADO, “7”

Y2K hitmaker Nelly Furtado is back in the studio and ready to reclaim her place in the spotlight. On Sept. 20, the singer-songwriter will release her seventh studio album “7,” a followup to her 2017 album, “The Ride.” The 14-track album is Furtado’s most personal to date, reflecting on four years of artistic rediscovery.

“I came to the studio lost and searching for my artistic identity. I had done a lot of reflection and self-work during my seven years outside of music, so I was bringing that growth into the studio with me.” Furtado said. “This collection of songs is so personal. It reflects my journey through heartbreak and finding my confidence as an artist again, into the pure joy and celebration you feel when you’re nurturing your passion and are part of a community.”

SHAWN MENDES, “SHAWN”

Exploring his recent travels and experiences, pop star Shawn Mendes is offering fans his most

▲ Netflix's "Territory" is a sixpart neo-western drama.

▼ Y2K icon Nelly Furtado will drop "7" on Sept. 20.

“musically intimate” and “lyrically honest” work. On Oct.18—the heartthrob’s birthday— the Grammy-nominated singer will release his fifth studio album, “Shawn.” The self-titled album was written and co-produced by Mendes, along with collaborators Scott Harris, Mike Sabath, Nate Mercereau and Eddie Benjamin. “Music really can be medicine. Two years ago, I felt like I had absolutely no idea who I was. A year ago, I couldn’t step into a studio without falling into complete panic,” Mendes said. “So, to be here right now with 12 beautiful, finished songs feels like such a gift.”

ABBOTT ELEMENTARY

School will be in session on Oct. 9 when season 4 of “Abbott Elementary,” returns on ABC. The workplace comedy, which stars Janine Teagues, Gregory Eddie and Ava Coleman, follows a group of dedicated teachers in a Philadelphia public school. Despite the odds stacked against them, the teachers are determined to help their students succeed.

Get your tissues ready. “Heartstopper” season three will be hitting screens soon, and it’s poised to be an emotional rollercoaster. On Oct. 3, the British coming-ofage series will return to Netflix, continuing the love story of Nick (played by Kit Connor) and Charlie (played by Joe Locke). This season, Charlie struggles to confess his love to Nick, while Nick grapples with his own secret.

A new six-part neowestern drama is coming to Netflix on Oct. 24. Netflix will release “Territory,” an explosive story about power, family, land and legacy starring Anna Torv as Emily Lawson, Michael Dorman as Graham Lawson and Robert Taylor as Colin Lawson. “Territory is the ultimate tale of big land, big money and all the highstakes drama that come with it,” Que Minh Luu, director of content ANZ at Netflix, said. “We’re working with some of Australia’s leading creators and crew to bring to life a version of this country we’re proud to show to our members both here at home and around the world.” ■

The must-have fashion books to have on your radar.

by Andre Claudio

CHRISTIAN SIRIANO Red Carpet Dreams

American fashion designer Christian Siriano has been turning red-carpet fantasies into reality for years, and now he’s bringing that magic to print. On Sept. 24, Rizzoli New York will release “Christian Siriano: Red Carpet Dreams,” a tome dedicated to Siriano’s continued evolution as a visionary, from his fashion that celebrates diversity, inclusion and body positivity to the craftsmanship behind each creation. “This book showcases my perspective on dressing for the new red carpet. I wanted to help transform the landscape by dressing people of all shapes, sizes, ages, genders and more so that the younger generations can see that there are no rules when it comes to clothes—if I can do it, so can you,” Siriano told Rivet.

New York After Dark

From shadowy underground haunts to prestigious galleries and clubs, “Dustin Pittman: New York After Dark” dives into the pop culture scene of New York during the ’70s and ’80s through Pittman’s lens. Reflecting on over 100,000 vibrant photographs chronicling the untamed corners of New York City’s after-hours nightlife, the book features firsthand observations and remembrances by Pittman, who photographed some of the world’s most famous fashion designers like Halston, Yves Saint Laurent and Calvin Klein. It includes an introductory essay that provides an objective view of Pittman’s work and underscores its significance as a chronicle of the music, art and fashion scene and a foreword by New York Dolls member David Johansen. The book is set to release on Sept. 3.

“Our ideas around what the red carpet should look like are dated...I hope I’ve helped contribute to an era where individuality and fantasy shine.”

DOLCE & GABBANA From the Heart to the Hands

Paying tribute to the value and tradition of handcrafted items has been an integral aspect of Dolce & Gabbana since its inception in 1985. “Dolce & Gabbana: From the Heart to the Hands” explores the Italian brand’s archival treasures for the first time. Written by Florence Müller, the book delves into the fashion house’s Italian heritage and the lasting impact of Italian culture on its most iconic and innovative collections. The book will publish on Sept.10 and follows Dolce & Gabbana’s recent exhibition in Milan of the same name.

de Givenchy and American fashion designers Oscar de la Renta, Stephen Burrows, Halston, Bill Blass and Anne Klein. What began as a restoration fundraiser for the palace turned into a culturalshifting event that left an indelible mark on the fashion industry, launched American designers as a global force and challenged the industry norms of the time. The book also features unedited excerpts from Cunningham’s private detailed diary.

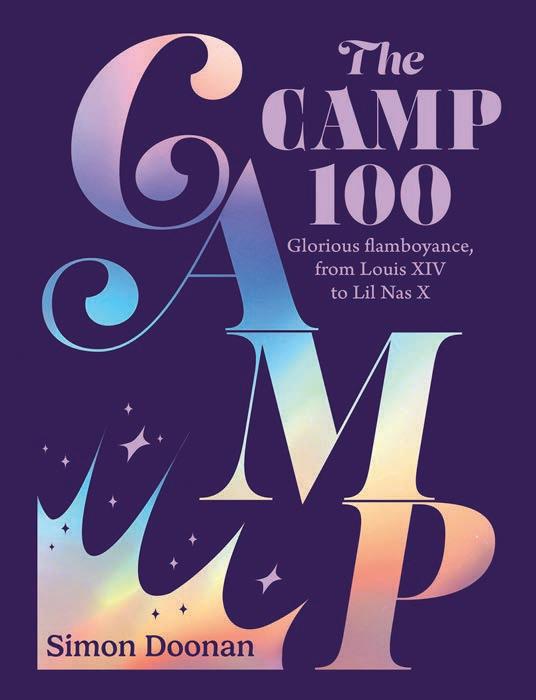

THE CAMP 100 Glorious flamboyance, from Louis XIV to Lil Nas X Camp—a style that blends old and new fashion characterized its theatricality, irony, exaggeration and kitsch—has shaped fashion houses and personal styles for centuries.

Women’s Wear Daily (WWD) is diving into Fairchild Media Group’s archives to celebrate Black designers, models and other influential figures in the fashion industry. Written by Tonya Blazio-Licorish and Tara Donaldson, the book features over 375 black-andwhite and color photographs, illustrations and original articles about the designers, models, scene-makers and stylists who have shaped the fashion landscape over the past century.

Diving deep into luxury Italian fashion designer and shoemaker Salvatore Ferragamo’s life and work, Stefania Ricci’s new book, “Salvatore Ferragamo” is poised to be a must-read for fashion lovers this fall. Available on Sept. 24, the book explores various aspects of Ferragamo’s life and work, including the wartime challenges he faced. Despite the scarcity of materials, these difficulties sparked remarkable creativity, leading him to craft shoes from unconventional materials like cork and fish skin.

The Fashion Showdown of 1973

Fashion is not always the glitz and glam it appears to be, and “The Battle of Versailles: The Fashion Showdown of 1973” highlights that. The book, written by Mark Bozek and photographed by JeanLuce Huré and the late Bill Cunningham, chronicles the dramatic 1973 face-off between French designers Yves Saint Laurent, Pierre Cardin, Emanuel Ungaro, Marc Bohan and Hubert

In “The Camp 100: Glorious Flamboyance, from Louis XIV to Lil Nas X,” author Simon Doonan explores 100 individuals, objects, art movements and more that embody this aesthetic—from The Real Housewives and Linda Evangelista to Coco Chanel and poodles.

“This book comes at a pivotal time for both WWD and the broader fashion industry,” said Amanda Smith, president of Fairchild Media Group. “’Black in Fashion’ celebrates the vibrant legacy and ongoing impact of Black talent in fashion. We are proud to contribute to the enduring narrative of diversity and innovation that defines our industry.” The book comes out Sept. 3. ■

fueled by the raw emotions of his breakup, Omar Apollo’s sophomore album “God Said No” takes fans through an emotional journey of heartbreak, self-discovery and resilience. → In June, the pop star released his highly anticipated “God Said No,” the heartthrob’s most personal work to date. The album title reflects a conversation Apollo had with a friend about surrendering to the challenges the universe presents, embodying the notion of allowing pain to take its natural course. The title is also a play on the Spanish phrase “Lo que será, será,” which roughly translates to “What will be, will be.”

“I’m not going to lie, I wasn’t in a good place to be writing an album, but the situation was so circumstantial I thought, ‘why not write this pain until it's gone,’” Apollo told Rivet. “It took eight long months of back-to-back work [to finish ‘God Said No’], although some songs were written two years ago.”

Apollo’s 14-track album features heartfelt songs like “How,” “Dispose of Me,” “While U Can” and “Empty.” However, while each track delves into a deep emotion, Apollo revealed that the most challenging song to write was “Glow.”

“I’ve been ignorant, I can be like that. We don’t conversate, we just burn our backs. Lying on a star, we still stay intact. You're my only one, I can promise that. If we go to hell, you can hold my hand, brace yourself, water

pulls the sand. Before you leave, give me one more dance,” the song expresses, highlighting Apollo’s vulnerability.

Despite the emotional toll of writing the album and reliving his breakup, the singer said he enjoyed the process, particularly collaborating with producer and songwriter Teo Halm.

“Teo Halm is a genius to me. I’ve always enjoyed making music with him, even when it doesn’t come out,” Apollo said. “I’ve [also] been making music with Blake Slatkin since 2018, so it felt good to work with someone I started with. Mustafa [who’s featured on the song ‘Plane Trees’] is my best friend, so sometimes I forget we’re both artists. Making music with him is a bonus in our friendship—he’ll always be in my life.”

These collaborative efforts not only enhanced the creative process but also contributed to the album's success.

“God Said No” debuted at number 56 on the U.S. Billboard 200 and number 14 on the Top Rock & Alternative Albums chart, with 10,000 pure album sales and 16,000 album-equivalent units. This marks Apollo's highest-charting album yet.

“This album has really become a time capsule for me, proof that [my breakup] happened,” Apollo said.

To celebrate the album and its success, the 27-year-old singer is embarking on the U.S. leg of his world tour. After kicking off earlier this summer in Melbourne, the tour will now visit U.S. cities like Philadelphia, Houston, New York and Boston, among others.

“I feel like for the first time I’m giving this album and tour a proper representation through dance, lights and visuals,” Apollo said.

“I’m excited to perform at the Hollywood Bowl, Indiana, and Red Rocks—those are going to be special. Chicago and Texas always show crazy love, and I remember Atlanta being really loud too, which I’m [really excited for].”

While on tour, Apollo expressed that connecting with his fans is one thing he is looking forward to the most.

“I’ve been getting really long messages [from fans] that I enjoy reading,” he said. “I love hearing them break down songs or tell me specific lyrics that stuck with them. They’re still stuck to me.” ■

THIS ALBUM HAS REALLY BECOME A TIME CAPSULE FOR ME, PROOF THAT [MY BREAKUP] HAPPENED.”

What is your favorite denim brand? Varsity Los Angeles.

What's your favorite thing to do when you're not making music? Eat.

What’s one thing you must bring on tour with you? Disha Hot, my hot sauce brand that I recently relaunched.

What are you looking for in your next partner?

I don’t need a man.

How does fashion influence your music or vice versa? Through visuals and shows.

What fashion trend are you currently obsessing over? Ballerina shoes.

What’s something you always do while touring? I read and watch TV on my iPad. Probably going to play spades or bring a video game, too.

What advice would you give someone currently going through a breakup? Don’t get into another relationship, just be sad. Give yourself five years.

What keeps you up at night? A lotta shit that doesn’t matter.

AAS SUSTAINABILITY becomes less of a want and more of a need for consumers, the fashion industry is exploring innovative ways to enhance its eco-friendly practices and find alternatives to conventional materials. The denim sector in particular is leading this shift, with Panther Denim playing a key role.

Since 1986, Panther Denim has been committed to producing stylish denim that balances sustainability and comfort. Now, nearly 40 years later, the Chinabased manufacturer continues to uphold this mission with its latest innovation, Planet Indigo.

In October, Panther Denim will introduce Planet Indigo, a collection offering a sustainable alternative to conventional denim. Developed in partnership with Shuise Dyeing House, this project combines traditional dyeing techniques with modern sustainability practices to engage both consumers and denim communities, according to Tim Huesemann, sales director at Panther Denim.

Shuise Dyeing House, established in 2010 in Nantong, China, plays a crucial role in preserving local dyeing traditions. Its expertise in dye resources and techniques, particularly its revival of the native Nantong indigo plant through the Wu Indigo Comes Back Home project, reflects a deep commitment to both culture and environmental sustainability, Huesemann added.

“Planet Indigo is designed as an ethical and sustainable denim option, utilizing dye extraction techniques that are part of China’s intangible cultural heritage,” he said. “This collaboration with Shuise Dyeing House illustrates the intersection of heritage and technology, showcasing how traditional methods can address global sustainability challenges. Such partnerships foster innovative solutions and contribute to the long-term transformation of the textile industry.”

Indigo dyeing is a practice with deep historical roots, intertwining art and science across multiple disciplines.

In fact, natural indigo has been used for thousands of years, with its cultural significance evident in various myths and traditions. China has a long history of plant dyeing, from the Paleolithic Age to the sophisticated dyeing departments established in the Zhou, Qin, Tang, Song, Ming and Qing Dynasties, Huesemann explained.

The term “藍 lán,” or blue in English, refers to the dye plant cultivated in China for over 4,000 years, and ancient texts like “The Book of Songs” highlight its deep cultural integration.

“Historically, indigo dye was a cornerstone of textile coloration until synthetic dyes began to dominate,” Huesemann said. “Although synthetic dyes offered convenience, they also contributed to significant environmental pollution. As awareness of these environmental impacts grows, there is a renewed interest in natural dyes, including indigo, for their lower ecological footprint and aesthetic value.”

“HISTORICALLY, INDIGO DYE WAS A CORNERSTONE OF TEXTILE COLORATION UNTIL SYNTHETIC DYES BEGAN TO DOMINATE.”

TIM HUESEMANN , sales director, Panther Denim

Planet Indigo aligns with this shift by focusing on natural indigo and sustainable production processes. This approach not only reduces water contamination and energy consumption but also minimizes other pollutants associated with synthetic dyes. By leveraging traditional dyeing techniques within a modern framework, Planet Indigo supports a more environmentally friendly textile industry.

Heritage-based projects like Planet Indigo highlight the importance of integrating traditional knowledge with contemporary practices. They offer sustainable solutions that transcend a one-size-fitsall approach, addressing both climate impacts and economic barriers. Such projects earn

trust and foster meaningful participation across the textile sector, transforming conventional production methods and challenging existing attitudes.

“Planet Indigo represents a significant step toward sustainable fashion by bridging the gap between tradition and innovation. By embracing heritage dyeing techniques and modern sustainability practices, it not only offers a viable alternative to conventional denim but also contributes to a broader movement toward environmentally responsible textiles,” Huesemann said.

“This project underscores the value of meaningful collaborations and the potential of heritage-based approaches to drive industry-wide change.”■

american eagle outfitters inc. knows what lane it is driving in.→The retailer’s ability to track and pivot into emerging trends and categories helps make its American Eagle (AE) brand the No. 1 jeans line for its targeted core customer between ages 15 to 25. A wide assortment of fits and washes that nod to past eras, coupled with comfort-driven fabrics have made AE denim a staple in closets for back-to-school, while denim accessories, co-branded collections and licensed gear keeps consumers coming back for more. → “As a leading jeans brand, we are so excited to be in a denim cycle right now,” said Renee Heim, AE’s chief product officer. → Heim joined American Eagle as senior vice president for women’s apparel and accessories in January 2021. Her background in product and merchandising in past leadership roles at Vineyard Vines and J.Crew gives her the expertise to create a new denim experience for consumers through product and storytelling. → Here, Heim sheds light on AE’s latest strategies for denim, fabrications and the back-to-school season.

Rivet: The company has been driving growth in the American Eagle brand by going deeper in casualwear. What are some of the casual dressing options or extensions that you’ve invested in to complete a denim outfit?

Renee Heim: American Eagle launched its “Live Your Life” brand platform in late July, empowering customers to go out and do the things they love in the clothes that make them happy. As a leading jeans brand, we are so excited to be in a denim cycle right now. We are leveraging denim to inspire a full lifestyle, seeing success with pieces that support year-round wear, like our women’s Dreamy Drape collection. This reflects the social casual fashion trend we’re seeing now.

We’re blending street, social and runway influences to create easier fits with bottoms that complement casual tops. For women, this means incorporating femme details like ruffles and bows. For men, we’re offering wider, boxier tops and standout prints. We interpret these trends through AE’s unique fabrications, using soft, stretch fabrics that provide comfort without sacrificing style.

Rivet: Who is your core American Eagle customer and targeted age range?

RH: AE is the No. 1 jeans brand for 15-to-25-year-olds, the No. 1 jeans brand for women overall, and the No. 2 jeans destination across all demographics.

This broad appeal is due to our ability to quickly pivot into emerging trends and categories, offering a wide range of styles that accommodate multiple generations. While our Gen Z customer might drive trends through platforms like TikTok, we offer something for everyone, like moms and young professionals who appreciate balance, variety, and more elevated dressing, which can be found within the brand’s AE77 collection.

Rivet: What is the proportion between men’s and women’s in the overall assortment mix?

RH: Our assortment mix is approximately 65 percent women to 35 percent men. Denim plays a more significant role in our women’s business, particularly with women embracing new styles, like wider-leg silhouettes. For our AE guy, we’re iterating on various pants and casual bottoms to keep up with evolving trends, and to ensure men are choosing AE when they’re in the market for new jeans.

Rivet: What are some key fabrications and finishes for men’s and women’s denim?

RH: For women, our styles are focusing on a more classic, heritage look in line with trends, while still maintaining AE jeans’ foundation of

comfort and stretch for a modern approach to denim. Men’s trends are leaning into cleaner, more traditional washes with straight fits. Our fabrication still reflects a super-soft feel, offering the look of rigid denim with a touch of stretch in all the right places.

This shift requires significant innovation to maintain comfort and style. We’ve introduced our Strigid denim, which combines stretch in essential areas like the waistband and backside with a rigid front for a classic look with modern comfort. And, our Dreamy Drape fabric has been a customer favorite, featuring soft, lightweight denim with a wide leg for a cool, slouchy fit.

Our EasyFlex fabrication for men offers the rigid denim look with the comfort of stretch, making traditional denim styles more wearable.

Rivet: Y2K has been a big trend in denim. Any thoughts on what might be the next decade that will drive denim trends?

RH: We’re seeing an eclectic mix right now, blending influences from the ’70s, ’90s, and 2000s. Trends from the ’70s reflect silhouettes that are getting lower and looser, while more neutral and block-inspired patterns nod to the early aughts. This eclectic influence of past generations allows us to keep our offerings diverse and interesting.

Rivet: What is AE’s strategy for licensed collections and collaborations?

RH: AE has always been at the forefront of culture, and our licensed collections, like those with Mickey Mouse and Peanuts, resonate because they speak to the optimism and nostalgia of our customers. Our recent success with the Peanuts collections and the hit series “The Summer I Turned Pretty” demonstrate the range and relevance of our collaborations, showcasing how

by Vicki M.

▲ AE is focused on head-to-toe denim styling.

◄ Jacksonville Jaguars quarterback Trevor Lawrence stars in AE’s fall campaign.

▼ New fits and washes are on deck for the back-to-school season.

we create connections across generations. These products and partnerships keep the conversation going with our customers, complement our core assortment, and provide the opportunity to add newness and excitement.

Rivet: This summer, American Eagle and Aerie released their first collaboration. How was the collection received by customers?

RH: The AE x Aerie A Match Made in Denim collaboration was very well received. It demonstrates the power of how our brands are better together and appeals to a broader range of consumers. We know our best customers shop across brands, and we’re always looking for ways to innovate by giving customers a reason to explore all of our brands.

Rivet: Western trends gained a lot of buzz this year. Has it affected AE?

RH: The Western trend was significant, especially with cultural moments—like Beyoncé’s album launch—instantly influencing fashion. We approached the

Western trend with a subtle touch, inspiring customers to express their individuality, whether that’s through simple touches or bold statements. We offer pieces like cowboy boots, Western-inspired jewelry, and a variety of denim, providing versatility in styling and excitement for the consumer who’s all-in on the trend and the one who prefers to dabble around the edges. We even had some fun showcasing this trend within our Peanuts collection, offering Western-inspired pajamas and crew socks featuring a yeehawready Snoopy.

Rivet: Other brands have reported success with denim tops, dresses, skirts—items besides traditional 5-pocket jeans. Has that filtered down yet to the younger customer? What about denim accessories?

RH: We are all about providing our customers the head-to-toe denim styles they’re craving. When denim is trending, we make sure every category has a denim option, from tube tops to jackets. Denim accessories like boho bags, hair scrunchies, and earrings are

also popular. This comprehensive approach helps us stay relevant and appeal to our denim-loving customers.

Rivet: What is AE’s approach for back-to-school this year?

RH: It’s a good mix of both core AE basics and statement pieces. What’s interesting is that when a fashion item hits TikTok and gains popularity, it often becomes a core piece in our assortment. AE has consistently been on the forefront of fashion trends and having the ability to pivot quickly has set us up with a strong foundation for when the back-to-school season approaches. Our collections celebrate individuality and living your life in your favorite AE styles, reflecting our spirit of innovation and adaptability.

Rivet: Tell me about AE’s fall collection.

RH: This fall and beyond, we’re excited about newer fits like the stovepipe, which comes in classic, cuffed, and a variety of washes. The emerging barrel fit has been an incredible opportunity for us. We’re seeing a lot of fun, fresh trends for women, with styles emphasizing puddling around the shoe. After the success of the cargo pants trend last year, we’ve tapped into some of our favorite denim silhouettes, such as Dreamy Drape, to extend our bottoms styles beyond jeans.

For men, athletic fits, bootcut, and straight jeans featuring our EasyFlex fabrication are crucial, offering guys the authentic denim look they want with just enough flex for all-day comfort. It’s all about versatility of product. We have something for the high-trend consumer, as well as those who might be interested in more classic fits. For women and men, we’re really leaning into full outfitting, ensuring customers know how to wear our products from head to toe. AE jeans can stand alone. However, we’re [also] providing really great tops and accessories that our customers can relate to and live their life in.■

marimekko’s signature prints have added vibrancy to apparel, accessories and home décor for more than 70 years. Now the Finnish lifestyle brand has its eyes on denim, using sustainable laser technology to apply its beloved Unikko print to jeans and shirts. Comprising five versatile color washes, three jeans fits and one shirt, Marimekko Maridenim marks the brand’s foray into denim, promising high-quality craftsmanship and sustainable practices and Marimekko’s signature flair. Additionally, the collection follows the Jeans Redesign guidelines by the Ellen MacArthur Foundation, which sets the industry standard for responsible and circular denim production.

Though denim is new territory for the brand, Rebekka Bay, creative director for Marimekko, said it is a natural extension as it has a strong link to the brand and design philosophy.

“In the 1960s, Marimekko introduced the iconic Tasaraita (even stripe) products designed by Annika Rimala who was inspired by the increasing popularity of denim jeans at the time and designed the products as companions to them. Therefore, in a way, this product launch has been a long time coming,” she said.

Here, Bay shares the creative process behind Marimekko Maridenim and how it carries on the brand’s tradition for bold and playful designs.

Rivet: How does denim fit in with the brand’s aesthetic, and how are you incorporating Marimekko signatures into the collection?

Rivet: Why is it the righttime for Marimekko to launch denim?

Rebekka Bay: While Marimekko has a long history that provides us with an unparalleled source of inspiration, we are also constantly looking for new ways to respond to our customers’ needs and to surprise our audiences. As a print house, venturing into a new product category with Marimekko Maridenim gives us virtually infinite opportunities with denim and, at the same time, it feels like the most natural continuity to Marimekko’s lifestyle offering.

RB: Marimekko Maridenim feels like a natural part of Marimekko and almost like the missing piece as high-quality denim is a wardrobe staple and essential in styling. Whether you are dressing up or dressing down, denim fits every occasion, and it is also the perfect styling companion to Marimekko’s renowned bold prints and colors.

When it comes to Marimekko signatures, Marimekko Maridenim presented us with the opportunity to extend our art of printmaking into a new canvas by lasermarking the denim products with our patterns, starting with our most famous pattern, Unikko that is celebrating its 60th anniversary this year.

MARIMEKKO’S LONG TERM AMBITION IS TO LEAVE NO BURDEN FOR COMING GENERATIONS.”

Rivet: How did you decide on the fits?

RB: Marimekko Maridenim jeans come in three fits: straight, wide and barrel. We chose the fits with three different individual attitudes in mind, so all our customers can find the fit they like and complements their wardrobe the best—whether it is the classic straight fit, a more relaxed barrel fit or a full, flared leg for special occasions. To complete the assortment, we also designed the Maridenim Vaihde denim shirt that can be worn either as a relaxed fit or a straight silhouette. The Vaihde shirt can be used as a shirt or a jacket, depending on the season, and it matches all the Maridenim bottoms.

Rivet: Why did you decide to follow Ellen MacArthur’s Jean Redesign guidelines?

RB: Marimekko’s long term ambition is to leave no burden for coming generations. We believe that, in the future, timeless and high-quality products will be made in balance with the environment, in line with the principles of

the circular economy. We are committed to continuously driving innovation in technologies, materials and business models through collaborations to push the industry forward and to reach our ambitious vision of leaving no trace. As we entered a new product category, we wanted to set high circularity and sustainability goals for the products and decided to follow the Ellen MacArthur Jeans Redesign guidelines as the foundation is the world’s leading network on circularity. The guidelines are reflected in Marimekko Maridenim through, for example, the material choices and high quality of the products, so they can be used for a long time and more easily recycled at the end of their lifecycle.

Rivet: Were there any challenges following the guidelines?

RB: I would not say it was a challenging aspect per se, but we spent a lot of time researching and finding the right partners, who understood our vision in developing this category.

Rivet: How do you envision Marimekko Maridenim evolving in future seasons?

RB: Marimekko Maridenim is part of our continuous collection and each year we will launch new fits and complementing styles, new colors and new patterns, to complement the core assortment. I can reveal that for the Spring/ Summer 2025 collection we are adding a new pattern to Maridenim. ■

atelier founder maria

wants the denim industry to stop and smell the roses—literally and figuratively. → The Amsterdam-based creative studio supports brands in technical design, visual merchandising and sustainable solutions including projects involving upcycling, recycling and natural dyeing. Through workshops, AMK helps designers with creating base fit blocks, size grading and sewing instruction. The studio also welcomes students and other groups to learn how to mend, repair and dye denim. → The atelier is a hybrid of Gunnarsson’s own experiences. Though a slow fashion designer at heart, she has years of experience at commercial brands and understands the business of making and selling jeans.

She weaves her love for nature into many of the projects that she takes on. In 2023 she partnered with Cone Denim to create Wander, a capsule collection of ’80s-inspired gorpcore constructions made with the mill’s mental health awareness selvedge denim. The collection highlighted the therapeutic benefits of spending time in nature. This year, she regrouped with Cone for The City Farmers Project, a year-long initiative that will have Gunnarsson design contemporary denim workwear for six young farmers working on a biological farm on the edge of Amsterdam. The AMK team will visit the farmers to learn about their work and see how it’s reflected in the aging of their garments. Each season will be documented on film and through interviews.

Gunnarsson likens her designs to “social fashion” or fashion that the wearer feels strongly connected with. Many of the people who join her repair workshops share this sentiment with garments they’ve inherited or had for a long time. Others, she said, are students who are buying new and cheap clothing because they don’t have the money to invest in quality pieces, but they have a sustainable mindset and want to change how they consume fashion.

by Angela Velasquez

Born and raised on a farm in Sweden, Gunnarsson said she learned early how to “create what she needed” and to mend and repair clothing. At 16, she moved to Stockholm to study fashion and garment technology, learning patternmaking by cutting jeans apart and piecing them together. Her graduation collection? Upcycled denim. “I realized that denim has so many different details and shapes, so the love story started there,” she said. Meanwhile, side jobs as a salesperson and visual merchandiser for denim retailers exposed Gunnarsson to the trials and tribulations of finding perfectfitting jeans. “I was working in a fitting room with a lot of people and families coming in to buy their jeans and I learned so much about bodies and what kind of brands fit certain personalities and body types,” she said.

An internship at Levi’s Vintage in Amsterdam turned into a fulltime job as a garment technologist for the premium label. “I went straight into a very dreamy situation after school to work in a premium department of Levi’s, LVC where there were amazing people. I got to work with very talented and creative people from design, product development and marketing. It was very fun and crazy,” she said.

I CHOSE TO

MY

AMK ATELIER ON MY CHARACTERISTICS AND VALUES.”

◄ AMK Atelier promotes mending, repair and upcycling.

◄ ◄ Maria Gunnarsson, AMK Atelier founder.

▼ Gunnarsson invites students and brands to workshops at the atelier.

When Levi’s moved its global offices to San Francisco, Gunnarsson made the transition to a much smaller but just as ambitious label, Kings of Indigo, in 2014. She said working for the Dutch brand was eye opening as it allowed her to see the industry outside of the Levi’s bubble where there was the flexibility and budget to be creative. As the “queen of product” at Kings of Indigo for five years, she had to be hands-on with materials and production, in the factories and at the wash houses and sewing rooms in Tunisia. She also worked directly with mills like Calik Denim in Turkey to innovate fabrics. “Kings of Indigo is where I got to be really nerdy,” she said.

Gunnarsson launched AMK Atelier in 2017 as a side hustle and creative outlet to explore denim design outside the traditional seasonal cycle of a brand. Two years later, it became her fulltime job focused on three pillars: bespoke collections, consulting and education. “I chose to build my company AMK Atelier on my characteristics and values,” she said.

As a coach to designers, she sees how the pressure to get products onto the market quickly before perfecting the fit or understanding the technical aspects of the fabric affects returns and overproduction.

“I always compare it to cooking— you have to make sure that your fridge is full of good ingredients,” she said about executing a successful and sustainable garment. “The knowledge gap and sometimes naiveness from brands to go on without taking time to really think of the best options is a waste of time. We can’t do that anymore,” she said. It is for this reason that Gunnarsson plans to grow the educational element of her business through more consulting. The personal connection of coaching and the ability to spread knowledge is the only way to make a bigger sustainable impact, she said.

“For me, it’s not about the riches. I feel rich by filling the days with work that fulfills me and that really makes it quite a nice experience to have this atelier. I have been lucky to build the brand AMK Atelier on what I am good at,” she said. ■

SSOORTY IS RENOWNED for innovative approaches to sustainable production. Here, Eda Dikmen, senior marketing and communications manager at Soorty, discusses the mill’s latest efforts.

RIVET: How does Soorty aim to achieve net-zero GHG emissions across the value chain by 2050?

Eda Dikmen: Soorty is proud to announce the validation of our near-term and net-zero greenhouse gas emission reduction targets by the Science Based Targets initiative. This aligns with the 1.5°C ambition and represents the highest level of commitment within the SBTi framework. This landmark pledge reflects our dedication to environmental stewardship and sustainable practices, despite the challenges faced by the developing world, particularly in mapping scope 3 emissions.

Additionally, our recently launched Soorty Sustainable Cotton Research Hub will serve as a pilot farm, R&D hub and education center to empower sustainable fashion and provide insights and advancements. We are also a strategic innovation partner with The LYCRA Company and an early adopter of ShapeSync technology, which offers an invisible, customizable fit and shaping solution.

What does Soorty’s Regenagri Initiative (SRI) in Pakistan aim to achieve?

E.D.: Following our success with the Soorty Organic Cotton Initiative (SOCI), SRI is our continued engagement with farmers, now focusing on transitioning to regenerative cotton. Partnering with Regenagri, this initiative aims to enhance land

health and community prosperity, providing a direct source of material for Soorty fabrics. Our transformative journey began in April 2023, collaborating with 1,100 small-scale farmers over 5,000 acres. It emphasizes improving soil health and biodiversity, tracking the social and environmental good that embodies each of our bales.

How has joining the Circulose Supplier Network (CSN) boosted your circular efforts?

E.D.: Second Life, our traceable denim-to-denim recycled cotton products range, marks a significant milestone in our circularity journey. We collect, sort and repurpose old denim that would otherwise end up in landfills, then transform it into high-quality, durable products that meet the highest environmental and social standards.

The initiative is now expanding. We’re preparing to launch a collaboration that will demonstrate how supply chain partners and brands can unite toward shared goals. We hope this sets a new benchmark for sustainability and transparency in the industry, empowering consumers to make informed purchasing decisions.

As a trusted partner for Circulose®, our CSN membership proves that Soorty is a trusted supplier in the region, which has proven to be beneficial. We also use

“WE HOPE [TO SET] A NEW BENCHMARK FOR SUSTAINABILITY AND TRANSPARENCY IN THE INDUSTRY.”

EDA DIKMEN senior marketing and communications manager, Soorty

Haelixa’s innovative DNA marker at early stages of production, allowing our garments to be tracked and verified throughout their lifecycles.

What are some of the latest trend concepts and proprietary collections Soorty has created?

E.D.: Earth is designed for mindful doers who seek moments outdoors and wear versatile, functional, adaptive clothes. The concept combines fabrics with high-stretch performance that maintain their fit, brush-back options for winter warmth and materials designed with circularity in mind, such as Second Life™, SOCI, Ecovero™ and Circulose®.

Classic offers timeless denim allure. Some fabrics are inspired by classics, refined with sustainable fibers and added comfort, while others are suited for everyday wear. We feature 2x1 and 3x1 RHT workwear options, bi-stretches with authentic character and a range of slub definitions.

Drip, for the young and cool, offers a mix of colors, constructions and silhouettes. This concept includes fabrics with special weave designs and textures, coating stories from glittery disco looks to leatherlike appearances, as well as a dark, inky color story utilizing Earthcolors® by Archroma, Tencel™ Modal fiber with Indigo Color technology and Bioblack TX by Nature Coatings.

How is Soorty using AI beyond conceptual design?

E.D.: We are now implementing AI across our practices, from tracking data in our Cotton R&D Hub to enhancing efficiency and innovation in our production setup. Digital innovation showcases the synergy between craftsmanship and cutting-edge technology to remain at the forefront of sustainable and innovative denim production. ■

Soorty leads as the first in Pakistan with SBTi-validated Near Term & Net Zero GHG Reduction Targets.

Learn how we do it.

for fans of Josh Rivera, be it from his musical theater days in “West Side Story,” his role as the moral, sound Sejanus in the latest “Hunger Games” or his much-beloved relationship

with actress Rachel Zegler, the actor is about to show a whole new side of himself.→The 29-year-old, who is easy-going, charming and light in person, takes on the role of Aaron Hernandez, the New England Patriots tight end who was convicted of murder in 2013 and

took his own life in 2017 while in prison, in the FX series “American Sports Story: Aaron Hernandez.” The transformation is unlike anything he’s ever done before.

“I like to be lighthearted, and I like to make a lot of jokes. I consider myself a good-humored person, but there’s a degree of sensitivity I obviously have to approach this with that I might not with other projects,” Rivera says. “With ‘The Hunger Games,’ there’s a little bit of levity there, even considering the subject matter, and ‘West Side Story’ was more of a celebration, whereas this is an analytical lens of the relationships or lack thereof, brain damage, sexuality, societal culpability. There’s a lot of things that go into it.”

Rivera was asked to audition for the role by Nina Jacobson, who produced the “Hunger Games” movies; before learning of the project, his knowledge of Hernandez’s life was minimal.

“But the more I learned about it, the more I felt really passionate about the story. As an actor, anything dealing with density and complexity and analyzing your own personality and the layers in personality, that kind of complexity is something that I always crave,” Rivera says. “The more that I learned, the more that I was really, really motivated to get the part.”

Rivera wasn’t in touch with anyone who knew Hernandez in preparation for the role but rather relied heavily on the Boston Globe podcast “Gladiator: Aaron Hernandez and Football Inc.” Physically, he embarked on a three-month transformation to go from his “Hunger Games” physique, which was the leanest he’d ever been, to playing a professional football player.

“Oh my gosh. I worked out so much,” Rivera says. “FX was really generous; they hooked me up with a trainer, and we worked out four to five times a week, and then I had a football boot camp. I mean, it was tough. I started at 187 pounds and when we started [shooting] three months later, I think I was 215.”

◄ ◄ PREVIOUS

9DCC JEANS, LEE SHIRT, DIESEL LEATHER JACKET.

◄ THE FRANKIE SHOP DENIM TROUSERS, RAG & BONE T-SHIRT AND BOOTS.

Rivera knows that not only is “American Sports Story” the first look at him leading a project, but also a showcase of his range as an actor.

“What I really want in general when I think about my career trajectory, is I want to do all the different things that I can possibly do. I am watching the show back. And something that I feel, which I’ve reframed my attitude about, is whenever I watch myself, I’m like, ‘I wish I did this. I wish I did this.’ And now it feels more like ‘how exciting, I have so much room to improve, I have so many ways that I can still challenge myself,’” Rivera says. “So, I really am craving to do all different kinds of genres, whatever I can get my hands on to expand my acting repertoire.”

Rivera was born in North Carolina and spent his formative years in Boulder, Colo; he thinks of himself as a late bloomer in the acting space, as he didn’t know he was interested until he was 18. Music was his first love and he wanted to go to school for music production but the programs were all too expensive.

“I ended up auditioning for a couple of schools for musical theater, and one of them gave me a scholarship, and it was a lot of financial help for my mom and me and everybody. So I ended up going that direction,” he explains. “It’s kind of weird. It is a lot of really random choices and situations that kind of led me to where I’m at.”

The series, the first two episodes of which drop on September 17, tells the story of Hernandez’s life from his teenage years on, as he struggled with drugs, his sexuality and the death of his father, and follows as he becomes a football star but descends into his struggles.

“I think something that the show does pretty well, particularly in the later episodes, is you kind of establish that this is a person who is well-liked and who is very talented, and who is at worst, misguided early on in his life. And then it kind of starts to escalate and escalate and escalate to the point where even the audience doesn’t know who we’re looking at, even though we kind of saw him grow up. It explains without excusing,” Rivera says. “A lot of things happened in this person’s life where it’s like, if one thing was different early on, who knows?” ■

IT IS A LOT OF REALLY RANDOM CHOICES AND SITUATIONS THAT KIND OF LED ME TO WHERE I’M AT.”

▪

SENIOR FASHION MARKET EDITOR, MEN’S: LUIS CAMPUZANO ;

GROOMER: ASHLEIGH CIUCCI ;

PHOTO ASSISTANT: ZACH REILLY ;

VISUAL MEDIA DIRECTOR: JENNA GREENE ;

PHOTO EDITOR: RYAN WILLIAMS

AAS FASHION-RELATED regulations across the globe tighten, the denim industry is ramping up its initiatives to enhance sustainability, improve transparency and reduce environmental impact throughout the entire manufacturing process. Looking to be at the forefront of change is Brazilian-based denim mill Vicunha, which has introduced new and extensive water conservation initiatives.

Here, German Alejandro, chief marketing officer at Vicunha, discusses the mill’s strategies for tackling water challenges and its alignment with the United Nation’s Sustainable Development Goals.

RIVET: What are the main water challenges that Brazil faces, and how is Vicunha addressing them?

German Alejandro: Vicunha faces a unique challenge compared to many companies: water scarcity. For the past 56 years, we have been addressing this issue in the regions where our factories are located in Brazil. Our primary focus has been on reducing water extraction from stressed reservoirs. Annually, we collect and reuse over 100 million liters of rainwater at our facilities in Northeast Brazil.

Additionally, we employ reverse osmosis technology to produce water for boilers, cutting waste by 3.1 million liters per month. We have also introduced technologies to minimize water use in dyeing processes and use natural starches in yarn preparation, which aids in the biological treatment of effluents.

A notable initiative is our Vicunha Water Footprint project, which is turning the tide on water usage in Brazil. This project measures the water impact throughout the entire life cycle of a pair of jeans—from cotton planting to the final consumer— enabling the production chain to identify inefficiencies and adopt more sustainable practices.

“SINCE ITS INCEPTION, VICUNHA HAS BEEN DEDICATED TO IMPROVING ITS PROCESSES FOR GREATER EFFICIENCY AND SUSTAINABILITY.”

GERMAN ALEJANDRO chief marketing officer, Vicunha

What is Vicunha’s overarching strategy regarding water, and how are you aligned with the UN’s Sustainable Development Goals (SDGs)?

G.A.: We committed to the UN Global Compact in 2020 and pledged to support several goals, including UN SDG 6, which focuses on drinking water and sanitation. By 2030, we aim to improve water use efficiency by reducing consumption in our manufacturing processes and eliminating the use of surface

water sources in Ceará. We are already seeing positive results, having saved over 300 million liters of water combined in 2022 and 2023.

What other water-saving initiatives does Vicunha plan to implement in the future?

G.A.: In early 2024, we launched the VSA project, a cutting-edge water and sewage treatment facility that uses only reclaimed water in our manufacturing process. Looking ahead, we’re planning a new similar effluent

treatment plant within two years. With a $20,000 million investment, this facility will produce 150,000 cubic meters of reclaimed water per hour, enough to fully supply our factory and sell the surplus to other companies, significantly reducing our water footprint in the fashion industry.

How is Vicunha innovating with raw materials?

G.A.: Vicunha has consistently focused on enhancing efficiency and sustainability. Our Regen line uses local, traceable cotton grown exclusively with rainwater. With its success and great acceptance, we plan to increase regenerative cotton fabric production by 15 percent by 2025. Also, our Less Water and Recycle classifications achieve up to 95 percent water savings and 90 percent chemical reduction, using more recycled and fewer virgin materials. In 2023, we used 9,000 tons of recycled cotton from our production. ■

OUR NUMBERS

OVER 100 MILLION LITERS of rainwater annually captured and utilized at our manufacturing units

UP TO 95% OF WATER USAGE REDUCTION in the production of several fabrics in our portfolio

OVER 9,000 TONS of reused and recycled cotton consumed in our production process

From continuously reducing and recycling to consciously using raw materials and resources, we are committed to building a permanently sustainable future

Scan to learn more about our sustainability goals, journey and achievements

as the birthplace of premium denim, creativity merging with responsibility is a common goal for many Los Angeles-based denim brands. They’re redefining what it means to be premium with a focus on longevity, sustainable fibers and intentional production practices. They’re also leaning on local design and washhouse talent to elevate denim fashion and push it beyond the basic 5-pocket jean.→These efforts are reflected in brands’ Spring/ Summer 2025 collections. Here, designers and executives from leading denim brands share their vision for the upcoming season and what they believe makes denim a uniquely L.A. product.

◄ ◄ AG sources from Italian and Japanese denim mills.

▲ Icon Denim recently launched an organic cotton collection.

◄ Citizens of Humanity is scaling its use of regenerative cotton.

Adam Taubenfligel co-founder and creative director

On S/S ’25: This is a collection that focuses on the fine lines of denim excellence. We bring silhouettes to life in familiar ways but with unexpected detailing—jeans and jackets with western-inspired seam lines and darts; bowlegged jeans in rich, dark washes and tailored jackets with hot pants are just a few of the highlights of this irreverent collection.

• On sustainability: We don’t make anything at Triarchy unless it falls within our very strict responsibility lens. We are the only brand to offer plastic-free stretch denim across our entire core collection, and we only work with sustainable washing machinery and organic or regenerative cotton. Our actions and practices are vetted and published by a third-party auditor to ensure we aren’t contributing to greenwashing and making sure we can consistently deliver denim with a clear conscience.

• On inspiration: I would say that travel remains my biggest source of inspiration when creating new collections for Triarchy. I am always drawn to timeless design, as I would never want to make anything that you wouldn’t want to wear in five- or 10-years’ time. I find that walking the streets of Paris or London allows for a window into timeless fashion.

• On premium denim: Premium denim is denim that is not made like fast fashion, and that hopefully is made with responsibility in mind. I don’t think a brand should be able to call itself premium if its manufacturing practices are irresponsible, regardless of price point or market standing.

On L.A.: I think denim and L.A. are synonymous, and they always will be. Los Angeles will forever influence our washes and aesthetics. When I see a light blue pair of jeans, it makes me think of sunshine and who in the world doesn’t love sunshine? For this reason alone, the influence L.A. has on Triarchy translates globally.

Jen Kim senior design director

On S/S ’25: We are excited and confident about the success of two new fits that we introduced for Fall/Winter ’24—Brinley, a mid-rise straight leg, and Hattie, a high-rise barrel—that we wanted to continue the momentum for S/S ’25 and build those fit blocks in cropped versions. Additionally, we are launching two new short fits: the Halle, a high-rise relaxed short, and a new high-rise Bermuda [short] called the Hattie short that takes inspiration from our barrel jean.

• On sustainability: AG has worked hard over the years to implement sustainable practices in our design and manufacturing by using laser technology, recycled water [and more]. This practice continues each season, and we strive to do better season after season.

On inspiration: For spring, we were inspired by the vast shoreline of the West Coast and vintage naval uniforms. We found inspiration in vintage deck pants and jackets, as well as the Fleet Week episode from “Sex and the City.” You’ll find mariner-inspired details sprinkled throughout the collection. For summer, we continue down the coast to Baja to seek refuge. We found inspiration in the sunbaked surfaces and vibrant colors of the region.

Getting out of the office and traveling is one of the best ways to get inspired. It’s great to get out of your comfort zone and be somewhere else, breathe new air and see new things. People watching and seeing how people put looks together is so inspiring.

• On premium denim: Premium denim is about craftsmanship, innovative washes and fit. It all begins with a cloth, and AG partners with the best denim mills in the world. Many of our fabrics are sourced from the finest Italian and Japanese mills. Couple that with our founders’ extensive manufacturing knowledge and our passion for fit, and you have a superior standard of denim that distinguishes itself from commercial denim.

• On L.A.: L.A.’s laid-back lifestyle mixed with a vibrant arts and entertainment scene leads to designs that are effortless and relaxed. This way of dressing lends itself to denim and is sought after across the globe. I have designed for many brands that have tried to capture the relaxed spirit of California.

Marianne McDonald creative director

On S/S ’25: For spring, we’ve been experimenting with ready-to-wear styles like trousers, vests and shirting in fluid denim fabrications that feel effortless and sophisticated. Also, we continue to be inspired by vintage styles, and you’ll see new silhouettes that feel both boyish and sexy at the same time. We have been gravitating toward lived-in washes in beautiful indigos and destructed denim in easy, relaxed silhouettes and stone-washed denim in neutral colors.

• On sustainability : We are continuously implementing sustainable technologies and processes into our apparel making. We are thrilled to have seen incredible success thus far with our regenerative cotton program, which began to roll out within our collections earlier this past spring. Currently, we are on track to procure a total of 4 million pounds of regenerative cotton. We look forward to the continued growth and success of this program year after year and bringing others (such as additional farmers, mills, brands, and retailers) along the journey with us to regeneration.

• On inspiration: At Citizens, we’ve always been excited by the narrative power of fashion and this season, ready-to-wear from the late 90s and reworked vintage are some of the elements that we’ve been drawn to. This takes shape in the form of fluid silhouettes, patch and repair, as well as relaxed utility styles that push the boundaries of everyday dressing.

WASHES AND FIT.” Jen Kim, AG Jeans

• On premium denim: For me, premium denim is something that is defined not by the price of one’s jeans, but rather by the values behind the brand and the platform it provides to be in service to the world. Without these elements, it becomes just another piece of clothing. For us at Citizens, we believe that premium denim begins with craftsmanship and a dedication to design and is firmly rooted in what we can do for the environment and the communities that surround us.

• On L.A.: There’s something distinct about the way people dress on the West Coast. Jeans are often the mainstay of one’s closet and there is a real connection between style and culture. L.A. embodies this unique point of view because of the mild climate and the deeply creative spirit embedded in the city. I think this translates to markets outside of L.A. because it brings an effortlessness to everyday dressing that feels authentic and cool.

Jack Burns design director

On S/S ’25: We’re offering alternative fits for men. We want to go out to the guy who is a little more interested in something unusual. This season, we’re debuting a high-rise fit for men; I think guys are looking for something

that’s a little more tailored or refined in the top block, and we love a wider, baggier fit in the legs. We [also] have some other pieces; the Fusion jean is the one I wear quite a bit. It’s very generous through the leg, more like a vintage Silver Tab look. And we’re expanding immensely into ready-to-wear.

• On sustainability: We’re focusing on our regenerative cotton. We are partnering very closely with farmers in America and paying a premium for cotton that’s grown with regenerative practice, to build our own materials. Normally, the focus is on recycling or finishing, but this is literally from the ground up. For spring, regenerative is our focus with the denim line. Most of our base [fabrics] are regenerative, and we’re going to be transitioning, hopefully to 100 percent, in the next year or so.

• On inspiration: I love shopping, and I have a really hard time finding clothes that I want to wear in the men’s market. So to me, it really started from a place of ‘oh, these things don’t exist, and I need them to exist because I want to wear them.’ It was very personal. We do this in women’s as well—what can’t you find that you really need? You go out to any store and it’s like, ‘Oh my God, there’s so much stuff,’ and you feel guilty as a designer sometimes contributing to more stuff, so, for me, the inspiration was really, let’s create honest clothes…that people are going to wear for a very long time and really cherish, and what items can’t they buy from anyone else that they need?

• On premium denim: [A lot of it is about] the fabric. We use fabric from Candiani and Kaihara. It must be good 3x1. We don’t like stretch denim. It must be rich; it must have a beautiful wash and feel really good. It must fit well and last a long time. I think people should be buying [fewer] clothes, so my mission in my career is to design clothes that have a lot of integrity, that are going to last for a long time and people won’t feel the need to replace them so rapidly.

AGOLDE

On inspiration: EB Denim has a few great core silhouettes that I wanted to base this collection off. The whole theme of the collection is rooted in the TWA Hotel [at JFK airport]; that was the inspiration for the collection. I fell in love with the architecture and the curvature and the silhouettes and colors of everything. I also just intuitively think, what do I want to be wearing? Listening to my body, what feels good? What shapes and silhouettes are flattering on my body and designing into that.

• On premium denim: I think it’s all about the quality of materials—the rivets, how intricate the washes look, the whiskers’ look, the integrity of the denim itself. Also, the fit is really important. All those things combined— plus design—create premium denim.

◄ EB Denim is working with Artistic Milliners.

▲ Agolde’s factories and wash house are located in L.A.

▼ Triarchy offers plastic-free stretch denim.

Marianne McDonald, Citizens of Humanity

On L.A.: L.A. exports so much of its culture already—every luxury brand in Europe wants to participate in L.A. There’s so much heritage in terms of the denim industry in L.A. We have our wash house there, which is incredible. It’s one of the most amazing facilities I’ve ever been to. We have our own factories, as well, in L.A. The garment industry in L.A. is really inspiring. As a New Yorker who moved there, I never thought of L.A. as a garment manufacturing hub, and when I finally did live and work in L.A., the garment industry there is so impressive— it’s so much more impressive than New York.

Elena Bonvicini founder and creative director

On S/S ’25: We have the Frederic Jean, which is this bowed-shaped horseshoe, and I wanted to expand upon that. So, we have a few new introductions of different barrel legs, more of our low-rise baggy jean, which has done so well for us. We are also introducing a fresh take on a flare. I wanted a palette cleanser, too, because a lot of what EB Denim has been is great novelty denim ideas. I wanted to start introducing more wearable pieces that a girl can put on and feel comfortable and cool and can elevate the look without being too overstated. It’s kind of like a palette cleanser, in a way, for us.

• On sustainability: Sustainability is always in the back of my mind. It’s a tough balance between being a profitable and growing business, while also trying to be as sustainable as possible, while still offering customers a reasonable price point. All these things must come into consideration.

We have just recently moved our production to Artistic Milliners in Pakistan, and they check every single box of sustainability. It was a hard decision to move my production from L.A. because it’s right around the corner and I have visibility, but in terms of longevity of the business, I thought it was a great long-term decision. I love that factory, and I love the people who work there, and I think they’re doing amazing things in sustainability and ethics in the industry.

• On L.A.: When you think of denim, you think of L.A., just because the culture here is so laid back. It’s so easy to throw on a pair of jeans and a T-shirt. You’re right next to the beach, and it’s [a lot of] cut off shorts and everything like that. It just breathes denim, so I definitely feel like there’s a lot of great influence and inspiration when it comes to the aesthetic of a pair of great jeans and a tank top or a T-shirt here.

Lucio Mauro founder

On S/S ’25: Our collection is a perfect blend of classic elegance and contemporary comfort. Our denim pieces in refined white are the highlight of the collection, enriched with vibrant yellow accessories that create a striking contrast. This collection captures the essence of a bygone era, recalling the elegance of the past while adapting it to the needs and tastes of modern fashion.

• On sustainability: Sustainability is a cornerstone of our collections. We use ecofriendly materials and sustainable production methods to minimize our environmental impact. Additionally, we ensure fair labor practices throughout our supply chain, reinforcing our commitment to ethical fashion.

• On inspiration: The inspiration for this collection came from a desire to blend timeless elegance with modern comfort. We looked to the sophistication of past decades and reinterpreted it for today’s fashionforward consumers. Regularly, we draw inspiration from various sources, including art, culture and global fashion trends. By observing how people mix and match styles in everyday life, we ensure our designs remain relevant and inspiring.

• On L.A.: L.A.’s vibrant culture and diverse fashion scene greatly influence our design choices. The city’s blend of laid-back and sophisticated styles inspires us to create pieces that reflect this unique vibe. Our designs translate well into global markets by offering adaptable pieces that can be styled for various occasions and climates, appealing to a broad audience.

• On premium denim: For us, premium denim combines exceptional quality, timeless style and sustainable production. It involves producing items that stand the test of time. Premium denim should offer versatility and comfort, making it a staple in any wardrobe while being responsibly produced. ■

“made in the usa” is a rallying cry that has grown ever louder since the Covid-19 pandemic ground global supply chains to a halt, cutting off American brands from their offshore partners. Over the ensuing years, challenges persisted, with production slowdowns and logistical hiccups prompting U.S. brands to reexamine the sourcing status quo—and revisit the idea of manufacturing stateside. →The concept is far from new for many denim and apparel labels who have long viewed the U.S., and Los Angeles in particular, as home base. Downtown, L.A. and the communities that surround it are home to thousands of mills, dyehouses and garment factories responsible for 83 percent of the country’s apparel production.→But even with buzzwords like “onshoring” on the tongues of many, the reality on the ground reflects a much more nuanced state of affairs for manufacturers.→Elvia Anaya, administrative specialist at Omni Laundry, told Rivet that the upsides of producing in L.A. are readily apparent. “The benefit to doing business in L.A. is the turnaround time,” she said, “and the creativity level is one-of-akind. We have had many customers come to us and are amazed to see their ideas come alive.”

Still, the six-year-old laundry’s business has decreased in recent years, and that unfortunate trend is continuing into 2024. According to Anaya, while brands are still interested in making denim in L.A., other apparel sourcing hubs, like Italy, are pulling market share away from SoCal makers.

Today, Omni provides a variety of services, from wet processing to dry processing like handsanding and whiskering, as well as several dye techniques. While it used to offer novelty washes, like tie-dye, those techniques have fallen by the wayside as brands streamline their offerings.

“For overdyes we are processing 60 percent direct dyes and 40 percent reactive dyes,” Anaya said. She noted that “direct dye takes an additional discharge process to lighten certain areas and seems very popular these days and keeps us busy.”

Omni also operates a small development sewing line for sampling and limited-production runs.

The ebb and flow of demand is being felt across the sector with inflation lingering and consumer confidence on a tentative upswing. But Pakistan-based Artistic Milliners’ recently acquired L.A. wash and finishing facility, Star

Fades International (SFI), is in a period of flow, according to Katie Tague, vice president of global marketing and sales.