THE SEAL OF COTTON CELEBRATES 5O YEARS

consumers easily discover and purchase cotton products.

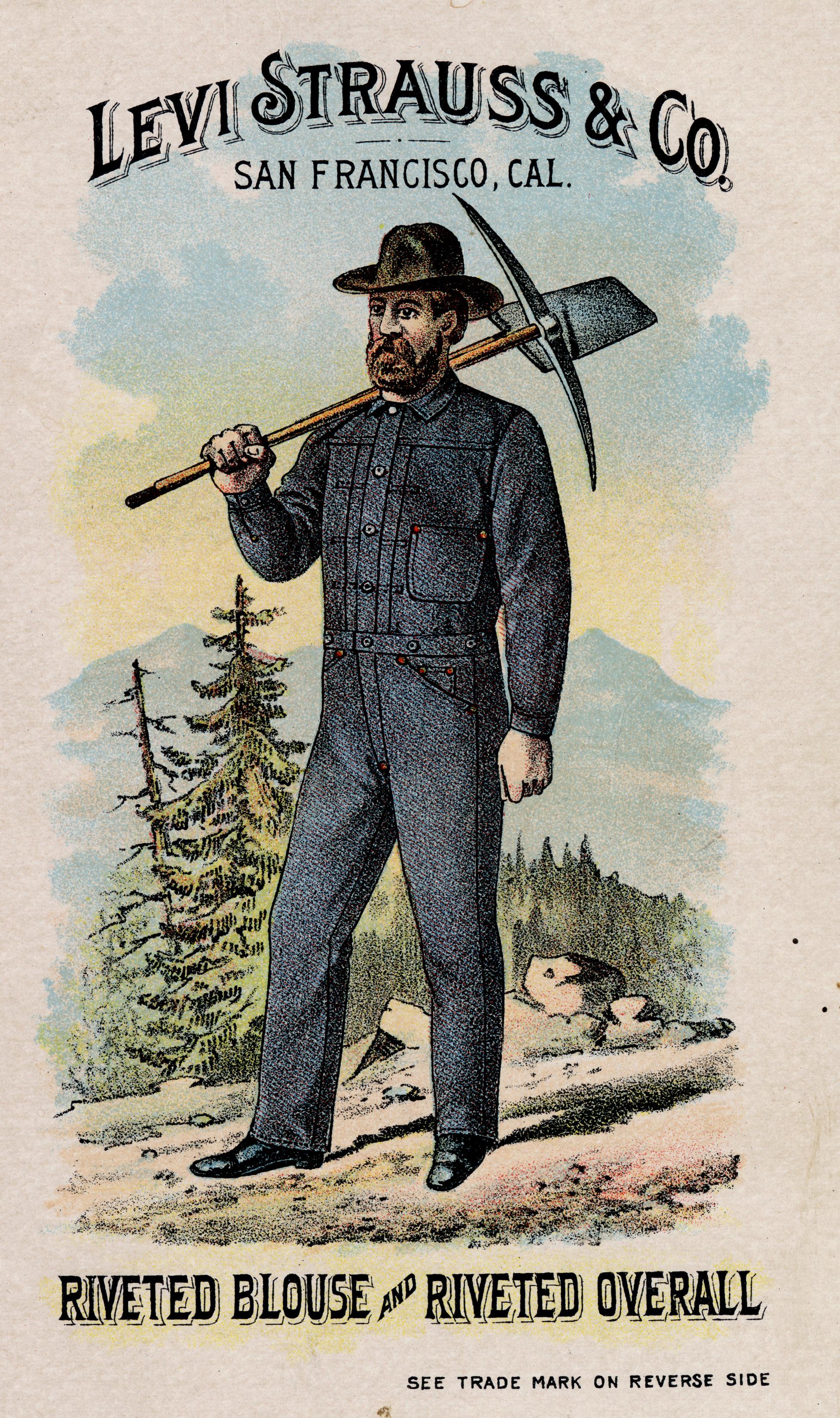

This trademark, commissioned by Cotton Incorporated, was designed by Landor Associates, the same marketing firm behind the Levi Strauss logo. The Seal established a brand identity for cotton fiber and cotton growers, raising consumer and supply chain attention toward the material.

Since its introduction in 1973, the seal’s awareness among shoppers has expanded from 18 percent to 78 percent today* courtesy of mass media marketing campaigns.

THE SEAL THROUGH THE DECADES

Cotton is the most widespread, profitable non-food crop in the world. Its production provides income for more than 250 million people worldwide and employs almost 7 percent of all labor in developing countries, which includes more than 28 million cotton farmers globally.

In jeanswear and more, cotton provides the durability, comfort and quality that shoppers are seeking. For 50 years, the Seal of Cotton has been helping

“The power of the Seal is real,” said Kim Kitchings, senior vice president of consumer marketing at Cotton Incorporated. “Cotton Incorporated has been doing consumer research for nearly three decades to gather consumer attitudes, behavior and insights. This data shows us that over the past 20 years, more than 8 out of 10 consumers are aware of the Seal and they associate it with fashion, durability, quality, comfort, trust and sustainability.”

Given the widespread familiarity with the Seal it influences shoppers’ buying choices, with 81 percent saying a brand using the Seal of Cotton logo is “trying to help me make an informed purchase decision.” Additionally, 74 percent believe that products with the Seal boast better quality than other options, and 82 percent say they can rely on products

1980s

► The Seal of Cotton is introduced.

► Cotton Incorporated launches its “True Performance” advertising campaign, using hangtags with the Seal of Cotton to identify millions of garments at retail. Cotton market share climbs to 49%, while awareness of the Seal of Cotton trademark grows to 71%.

1990s

► Procter & Gamble displays the Seal of Cotton trademark for the first time on non-textile products: Cheer, Tide and Ivory Snow.

COTTON IS “THE FABRIC OF OUR LIVES”and this iconic tagline rings even more true for cotton-rich denim garments. Cotton is woven into denim’s storied history, but it’s also part of individuals’ personal histories and the memories that happen in denim garments.

59% 77% 82%

and brands associated with the seal. Most shoppers (82 percent) also wish to see the Seal on more products, and 62 percent are even willing to pay more for Seal -baring goods.

“As a leading Gen-Z retailer of comfortable, casual clothing, cotton is an integral part of Aéropostale’s success,” said Michael DeLellis, executive vice president marketing, Aéropostale.

“Over the past 50 years, the Seal of Cotton has been a symbol of premium quality and durability, which has set the industry standard high and continues to inspire us. We look forward to the next 50 years of the logo we all know and love.”

When shopping for jeans, 49 percent of consumers say the Seal of Cotton is the logo they would most want to see on a product. Comparatively, other branding was named as the first choice by less than 10 percent of consumers, including Dri-fit (6%), Coolmax (5 %), Woolmark (5 %), Tencel (5 %) and Lycra (3%).

In addition to quality they trust, most consumers also associate the Seal of Cotton with sustainability (82 percent) and natural (90 percent). Cotton Council International (CCI) & Cotton Incorporated’s 2021 Global Sustainability Survey found that 58 percent of consumers say sustainability impacts their purchase decisions.

“For more than 50 years, the Cotton Incorporated Seal of Cotton is a signal of superior quality that is recognized around the world,” said Amy Williams, CEO of Citizens of Humanity Group, which includes Citizens of Humanity, Agolde and

Goldsign. “We congratulate Cotton Incorporated on this milestone anniversary, and importantly, on their commitment to sustainable practices within the cotton industry for the next 50 years, and beyond. As consumers around the world pay additional attention to sustainability, recycling, durability and versatile products, the Cotton Incorporated Seal will be even more important and covetable.”

2000s

► In conjunction with Cotton Council International (CCI), Cotton Incorporated develops a trade and consumer marketing campaign for India called the Cotton Gold Alliance (CGA). This marks the first time the Seal of Cotton has been used outside of the Americas for consumer promotions.

2004

AS CONSUMERS AROUND THE WORLD PAY ADDITIONAL ATTENTION TO SUSTAINABILITY, RECYCLING, DURABILITY AND VERSATILE PRODUCTS, THE COTTON INCORPORATED SEAL WILL BE EVEN MORE IMPORTANT AND COVETABLE.”

AMY WILLIAMS CEO, CITIZENS OF HUMANITY GROUP

2005

►The creation of the Natural™ trademark is developed as a part of Cotton Incorporated’s larger sustainability strategy. Building on the wide recognition of the Seal of Cotton, the trademark resonated across multiple industries, ultimately being adopted by six brands for their own green marketing efforts.

AS A LEADING GEN-Z RETAILER OF COMFORTABLE, CASUAL CLOTHING, COTTON IS AN INTEGRAL PART OF AÉROPOSTALE’S SUCCESS.”

MICHAEL DE LELLIS EXECUTIVE VICE PRESIDENT MARKETING, AÉROPOSTALE► Consumer recognition of the Seal of Cotton trademark reaches more than 80%.

AN INCREASING MAJORITY OF CONSUMERS ASSOCIATE THE SEAL OF COTTON WITH “SUSTAINABLE.”

84% CONCERNED ABOUT QUALITY

81% ONE I WOULD BE LIKELY TO PURCHASE 80% IS AUTHENTIC

79% IS TRUSTWORTHY

77% CARES ABOUT THE ENVIRONMENT

THE SEAL THROUGH THE DECADES

One reason for the positive sustainability perception is Cotton Incorporated’s longstanding work in this area. In 2006, the organization introduced its Blue Jeans Go Green™ program, which helps recycle post-consumer jeans into products such as insulation. To-date, Blue Jeans Go Green™ progam has diverted over 4 million jeans weighing more than 2,000 tons from landfills.

GROWING COTTON’S SHARE

Over the years, the Seal has also supported and promoted cotton usage within the supply chain. In the 1980s, the launch of advertising efforts such as “True Performance” and “The Fabric of Our Lives” contributed to cotton’s market share climbing to 49

TRENDS WILL COME AND GO, BUT COTTON HAS ALWAYS BEEN THE FOUNDATION OF DENIM.”

—KIM KITCHINGS

—KIM KITCHINGS

SENIOR

VICE PRESIDENTOF CONSUMER MARKETING, COTTON INCORPORATED

percent, and mill consumption of U.S. cotton reached levels not seen in 15 years. Today, cotton remains a popular fiber choice for apparel and home textiles. In addition to lifting cotton demand in the market, Cotton Incorporated undergoes research and development to discover new innovations and solutions in processing cotton so that everyone from ginners and spinners to weavers and sewers can create the best possible end product.

“Through the decades, we’ve built a foundation and helped create relevance highlighting the Seal of Cotton among all partners throughout the supply chain. Over the next 50 years, we’ll continue to ensure that cotton remains the first and best choice, with a clear emotional connection that no other fiber can claim,” noted Kitchings. “Trends will come and go, but cotton has always been the foundation of denim. It is the benchmark and there will never be a more relevant story than the success of denim with cotton as the key preferred and trusted ingredient.” ■

COTTON INCORPORATED licenses the Seal of Cotton on a royalty-free basis for qualifying products. The Seal can be used globally in a wide range of communications—including packaging, promotional programs, point-of-sale displays, interactive digital experiences and more. For more information on licensing the Seal, visit CottonWorks™ website

2006

► Cotton Incorporated launches the Blue Jeans Go Green™ denim recycling initiative.

2015

► Expansion of digital advertising and Seal of Cotton programs to work with companies such as Spotify, Buzzfeed, Amazon and Revolve to ensure consumers are surrounded by cotton messaging.

2020—PRESENT

►The Seal of Cotton is registered in nearly 70 countries with more than 950 brands There are 190 worldwide licensees.

WHEN RETAILERS & BRANDS USE THE SEAL, 4 OUT OF 5 CONSUMERS BELIEVE THAT THE BRAND IS:

FAIRCHILD MEDIA GROUP

Amanda Smith President

Michael Atmore Chief Brand Officer

James Fallon Editorial Director

ADVERTISING

Amanda Smith President, Fairchild Media Group

Hillari Lazzara Senior Vice President, Sales

Samantha Rumsky Advertising Director

Deborah Baron Advertising Director

Jennifer Petersen Advertising Director, Fashion & Luxury

Amy Macauley West Coast Director

Amanda Boyle Beauty Director

Alyssa Cohen Account Director, Finance & Tech

Katherine Hogan Account Manager, Tech

MARKETING

William Gasperoni Vice President

Caroline Daddario Executive Director, Head of Programming

Christine Staley Senior Director, Marketing & Fairchild Studio

Alice Song Senior Manager, Programming and Special Projects

Lauren Pyo Senior Manager, Marketing

Sienna Eisenhart Associate Manager, Marketing

OPERATIONS

Ashley Faradineh Director, Operations

Alaina Randazzo Digital Sales Planner

Emanuela Altimani Senior Sales Coordinator

SUMMER JAM

ITURN 40 this summer. Preliminary birthday plans include a weekend in Memphis soaking up all the Elvis Presley kitsch that Graceland offers, and singing my heart out at one of Beyoncé’s “Renaissance” tour stops. My celebration is somehow morphing into a musical milestone, but then again, I grew up on MTV—the version before “Jersey Shore,” though I’m hooked on that too, Thursday nights at 8 p.m.

Born just two years after the channel debuted, toddler Angela, according to family lore, was transfixed by Culture Club’s “Karma Chameleon” music video. In between standard kid fare like “Sesame Street” and “The Muppets”, there was Cyndi Lauper, Madonna, Michael Jackson, Whitney Houston and George Michael, whose long overdue induction into the Rock & Roll Hall of Fame will finally take place this fall.

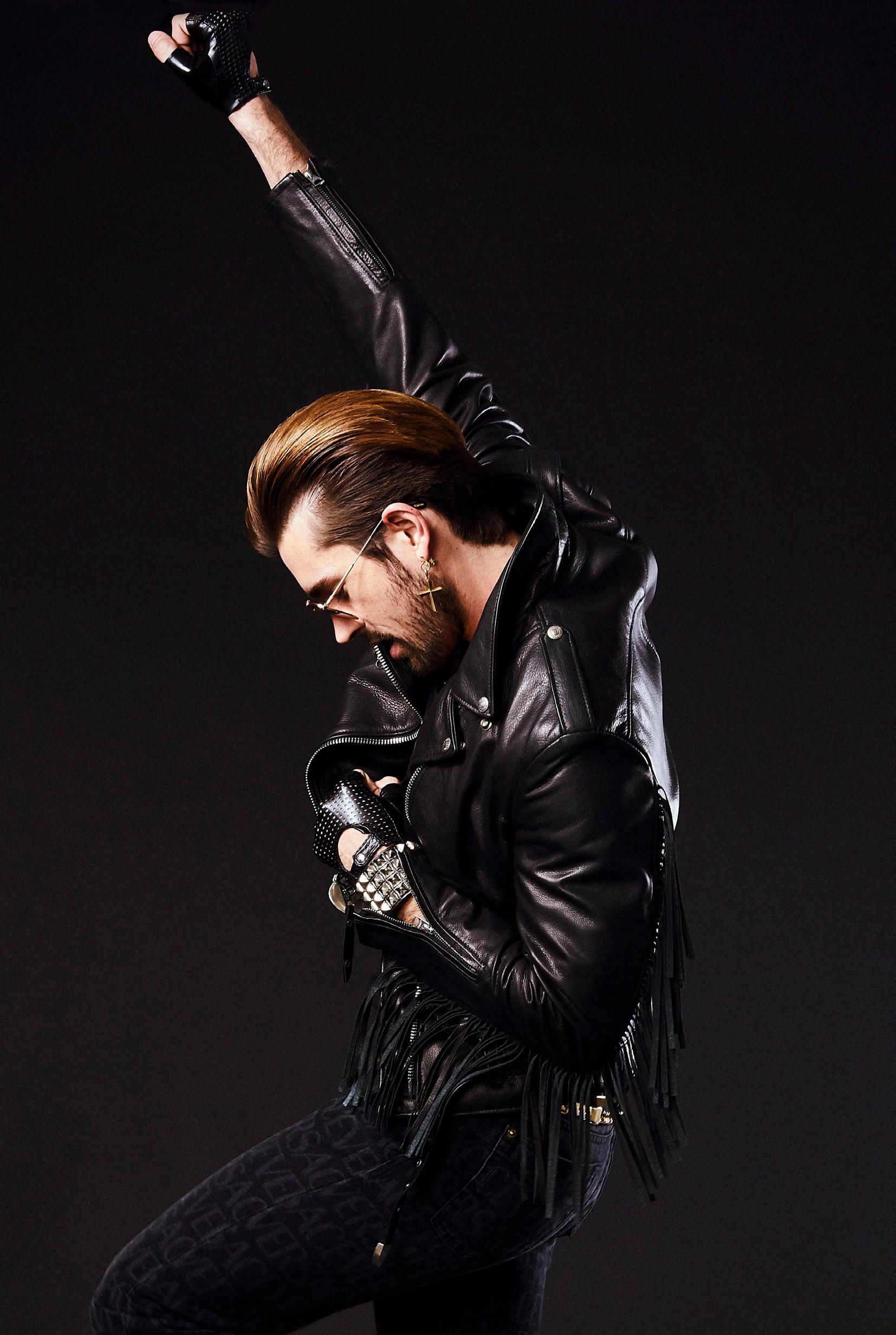

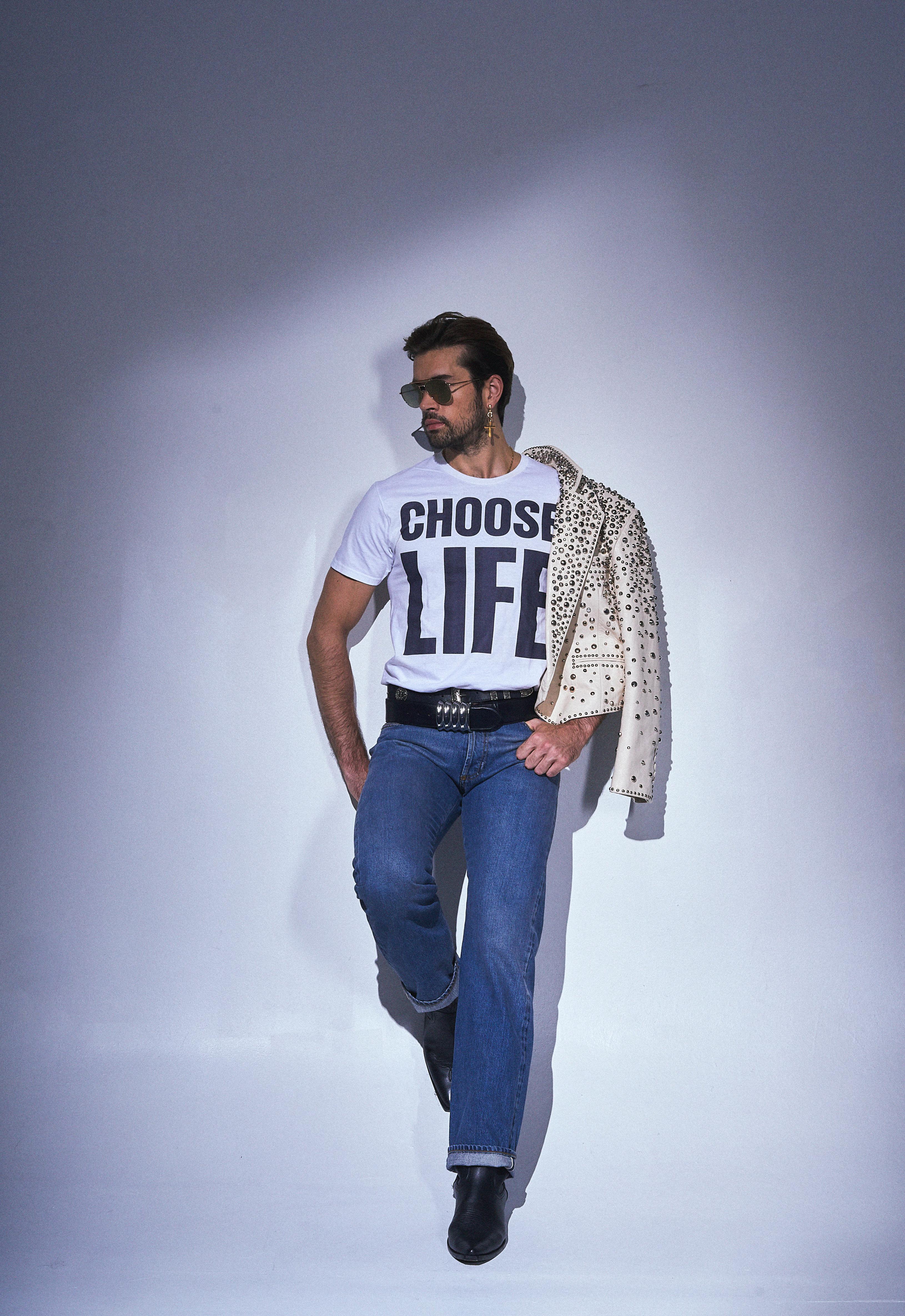

Indeed, there’s something nostalgic in the air that’s once again bringing icons like George Michael back into the cultural zeitgeist, including Rivet’s fashion editorial. Aptly titled “George,” the story (pg. 48) pays homage to his signature double-denim stage looks and the iconic ensemble from his 1987 “Faith” music video that made wearing a black leather motorcycle jacket atop Levi’s 501 jeans a worldwide style sensation.

Instantly symbolic of rebellious cool, the outfit has become ingrained in music, fashion and pop culture history. Style-wise, it’s a look that Brooklyn hipsters and Parisian bohemians still replicate by mixing new and vintage garments.

PENSKE MEDIA CORPORATION

RIVET IS OWNED AND PUBLISHED BY PENSKE MEDIA CORPORATION

Jay Penske Chairman & CEO

Gerry Byrne Vice Chairman

George Grobar Chief Operating Officer

Sarlina See Chief Accounting Officer

Craig Perreault Chief Digital Officer

Todd Greene EVP, Business Affairs & Chief Legal Officer

Paul Rainey EVP, Operations & Finance

Tom Finn EVP, Operations & Finance

Jenny Connelly EVP, Product & Engineering

Debashish Ghosh Managing Director, International Markets

Dan Owen EVP, GM of Strategic Industry Group

David Roberson Senior Vice President, Subscriptions

Jessica Kadden Senior Vice President, Programmatic Sales

Judith R. Margolin Senior Vice President, Deputy General Counsel

Ken DelAlcazar Senior Vice President, Finance

Lauren Utecht Senior Vice President, Human Resources

Marissa O’Hare Senior Vice President, Business Development

Nelson Anderson Senior Vice President, Creative

Rachel Terrace Senior Vice President, Licensing & Brand Development

Adrian White Vice President, Associate General Counsel

Anne Doyle Vice President, Human Resources

Brian Levine Vice President, Revenue Operations

Brian Vrabel Head of Industry, CPG and Health

Brooke Jaffe Vice President, Public Affairs & Strategy

Cassy Hough Head of Industry, Technology

Constance Ejuma Vice President, SEO

Courtney Goldstein Vice President, Human Resources

Dan Feinberg Vice President, Associate General Counsel

Doug Bandes Head of Live Event Partnerships

Ellen Dealy Vice President, Audience Marketing & Special Projects

Frank McCallick Vice President, Global Tax

Gabriel Koen Vice President, Technology

Jamie Miles Vice President, eCommerce

Jennifer Garber Head of Industry, Travel

Jerry Ruiz Vice President, Acquisitions & Operations

Joni Antonacci Vice President, Production Operations

Karen Reed Vice President, Finance

Katrina Barlow Vice President, Business Development

Kay Swift Vice President, Information Technology

Keir McMullen Vice President, Human Resources

Matthew Cline Head of Automotive Industry

Mike Ye Vice President, Strategic Planning & Acquisitions

Nici Catton Vice President, Product Delivery

Noemi Lazo Vice President, Customer Experience & Marketing Operations

Richard Han Vice President, International Sales

Scott Ginsberg Head of Industry, Performance Marketing

Sonal Jain Vice President, Associate General Counsel

That’s great news for the 501, which turned 150 years old on May 20, 2023. Worn by 1870s West Coast miners, 1960s hippies and modern reggaetón sensation Bad Bunny at this year’s Grammys, the 501 is a long-running moneymaker for the storied San Francisco brand. 501 revenues this year are expected to approach $800 million, nearly 70 percent higher than pre-pandemic numbers. In “The Archetype” (pg. 32), we dissect how the 501 became the blueprint for the modern jean. In “Time Traveler” (pg. 42), we look back at the style’s defining moments and reminisce with denim heads on what the jean stands for in the industry.

Though it’s easy (and fun) to get lost in denim’s vaunted past, we would be remiss to overlook the ways the supply chain is pushing forward. In “Dark Art” (pg. 24) we examine the color-lasting technologies brands are using to keep dark indigo and black washes as fresh as day one. In “Dirty Talk” (pg. 26), we look at how brands can sustainably reinvent the dirty-looking washes synonymous with Y2K denim. We cool off in “Jeans in Heat” (pg. 20), which looks at the fiber technologies and unique weaves making jeans a comfortable choice even when temperatures are rising.

The innovation and newness engulfing the denim market give me faith, faith, faith that jeans will be cool and covetable another century-and-a-half from now.

THE RIVETING LIST

STYLE AND SUBSTANCE

With backing by some of Europe’s leading innovation VC’s, Belgium label HNST is setting its sights on the United States. The brand has undergone a visual rebranding rooted in “elevated simplicity.” Saks Fifth Avenue picked up the men’s collection this spring and it will add women’s in the fall.

The classic fits and vintage-inspired fabrics that have landed HNST in stores in Belgium, Italy, Germany, France, the Netherlands, Spain, Portugal, and Japan are the focal point in HNST’s efforts to gain

share in the U.S. premium denim market. The company offers core fits—relaxed, relaxed tapered, straight and slim tapered for men; mom, dad, straight, high rise loose and balloon for women—in indigo, black and ecru retailing for up to $195.

The jeans are 100 percent circular and made with low impact washes—a mere footnote in its rebranding—but an integral part of the HNST’s story. “We want to give [consumers] a more sustainable and circular way of buying clothes without them initially knowing it,” said Martijn Swolfs, HNST CEO.

ANGELA VELASQUEZFRIEND CIRCLE

Triarchy launched its first fully recyclable denim collection. The five-piece women’s collection, called “Cellsius: Designing with the Earth in Mind,” was produced under Ellen MacArthur Foundation’s Jeans Redesign guidelines, ensuring the garments consider circularity from production to the end of the product lifecycle. The collection spans relaxed jeans, a jacket, a sleeveless tunic dress, shorts and a vest— each designed with a vintage aesthetic.

Triarchy teamed with the Karachi, Pakistan-based denim manufacturer, AGI Denim, for the first time to develop the collection. The 100 percent cellulosic denim used throughout the collection comprises 70 percent organic cotton, 9 percent Circulose, and 21 percent viscose from sustainably managed forests. No synthetic fibers were used.

“The common goal for this project was bringing together a group of industry leaders to try and tackle end of life and recyclability in the denim space. AGI was able to take all the ingredients from all partners and create the final product that surpasses all our expectations,” said Adam Taubenfligel, Triarchy co-founder and creative director. AV

SUSTAINING FARMERS

Plant-based dyes and organic cotton are the main drivers of sustainability for the new Levi’s WellThread collection. The Spring/Summer 2023 men’s and women’s collection uses fabrics spun with organic cotton sourced from Levi’s WellThread Transitional Cotton program. Launched in 2020, the program works with small shareholder farmers in India as they transition their fields to a production system

that sustains the health of soils, ecosystems and local communities. The brand supports the farmers during this transition by committing to purchase their transitional cotton crop, which reduces their financial risk during the shift to organic farming.

The S/S ’23 collection also sees the addition of the plant-based black pigment, BioBlack TX by Nature Coatings. The black pigment comes from upcycled wood waste that otherwise would be burned or landfilled and serves as a replacement for petroleum-derived carbon black, which relies on the combustion of fossil fuels.

Style-wise, the collection zeroes in on classic silhouettes with long-lasting appeal. For women, the assortment includes the Baggy Dad, a loose and relaxed-fitting jean, and the Type II Trucker, a boxy silhouette with denim-covered snaps. New additions include the ’80s Mom Shorts and a slim denim shirt with denim-covered snaps. Men’s fits for the assortment include the 551Z and 502 in denim, the Loose Chino Crop in printed denim, and the Vintage Trucker jacket. AV

BLING RING

Frame’s capsule collection with British Vogue fashion director, Julia Sarr-Jamois, includes an $11,995 pair of jeans.

The lavish offering shows how denim brands are cooking up attention-grabbing pieces to create a halo effect for their whole collections. Boasting more than 50,000 iridescent chocolate brown Swarovski crystals, the low-slung, straight leg jean is “the most luxurious denim currently on the market,” according to Frame. The pièce de resistance took 120 hours to make.

The limited-edition, 19-piece capsule collection is inspired by Sarr-Jamois’ eclectic style, featuring bold colors, earthy textures and tie-dye prints. A range of artisanal crochet pieces keeps the holiday vibe going. It includes a crochet string bikini, halter mini dress, bucket hat, earrings, and a handmade beaded tote. A pair of camouflage print cargo pants nods to the ongoing utility trend. AV

BOSSY PANTS

A new boss is entering the denim fray. Hugo Boss announced it is expanding its portfolio with Hugo Blue, a line dedicated to denim. The brand’s aesthetic will be inspired by street culture and embrace a relaxed approach to dressing.

Denim will be at the core of the men’s and women’s collection when it arrives in stores in February 2024. The denim range will be complemented by jersey, knitwear, outerwear pieces and accessories. Some

unisex styles will also be available.

Hugo Blue will launch with four collections per year and have the same opening prices as the existing Hugo brand line. Products will be available worldwide in Hugo retail stores and on its website. Wholesale and e-commerce partners will also carry the brand. The order season for the first Hugo Blue collection begins in June.

A full-throttle rollout and a shop concept dedicated to the younger target group will support Hugo Blue’s launch, as well as a new bold blue logo design. AV

ARTISAN APPRECIATION

AG launched the Chimayó collection, a special collaboration with Irvin and Lisa Trujillo, seventh-generation weavers in New Mexico. Inspired by Northern New Mexico’s landscapes and the Rió Grande river, the collection offers “extremely limited” men’s and women’s jean jackets with traditional handcrafted Chimayó woven paneling at the back.

AG tapped the award-winning husband-and-wife team to boil, process, spin and dye the yarn from Churro sheep, a breed that arrived in New Mexico with Francisco Vázquez de Coronado’s expedition in 1540. AG said the “hardy sheep” are known for their silky, lustrous wool. The Trujillos then weaved the colorful yarns into designs that pay homage to New Mexico’s history in sheepherding, spinning and weaving.

“The collection honors the heritage

and labor-intensive process, making for a truly special offering. Vibrant colors and geometric shapes appear to dance, conveying a motion that celebrates the traditional craft, one that is centuries old and passed down through generations,” the brand stated.

The black and indigo jackets are made with 100 percent cotton and are assembled in the U.S. AV

KEEPING UP WITH THE JONESES

Sustainable denim is coming soon from Jones New York. Authentic Brands Group announced that it has entered a long-term partnership with sustainable denim manufacturer, Noize Jeans, for its Jones New York brand. Through the partnership, Noize Jeans will design, produce and distribute men’s bottoms, jackets and denim for the brand.

The goal is to produce denim garments that stays true to Jones New York’s classic yet modern aesthetic while delivering comfort and fabrics that are built to last. The new assortment is expected to roll out across key department stores, specialty retailers and online in North America starting this fall.

“Noize Jeans’ expertise in the jeans space is second to none, and we are pleased to partner with them on the expansion of Jones New York’s men’s apparel offerings with uniquely designed lifestyle apparel product,” said Joseph N. Zarro, Authentic Brands Group executive vice president of luxe and classic brands. AV

ITALIAN JOB

Candiani Denim tapped a group of sustainable leaders to help evolve its patented Coreva technology into a full-fledge apparel brand. Called Coreva Design, the brand will offer jeans made exclusively with the Italian mill’s natural and biodegradable stretch denim fabrics when it launches for Spring/Summer 2024.

Candiani is rolling out a series of capsule collections ahead of the official launch, beginning with a four-piece line made with Quid, a Verona, Italy-based tailoring workshop, and Orange Fiber, a producer of yarn derived from citrus waste.

The collection is designed by model Gabriela Giovanardi and consists of four gender- and size-inclusive pieces inspired by vintage pieces from her personal wardrobe. It includes workwear-inspired overalls, cargo pants, a boxy shirt and a sweatshirt. All fabrics contain Coreva and Orange Fiber and are dyed with mineral pigments.

Candiani introduced Coreva in 2020 as an alternative to synthetic yarns. The technology uses the elastic properties of a plant material derived from natural rubber to create the same level stretch and comfort that plastic provides. AV

GLITZ AND GLAM

Swarovski crystals and dramatic cutouts are part of 7 For All Mankind’s capsule collection with Italian fashion journalist and stylist Anna Dello Russo. The Los Angeles premium denim brand teamed with Dello Russo for the limited-edition collection of haute denim inspired by the glamorous style that captivates her 2.6 million Instagram followers.

Celebrating “high-octane fashion,” the collection’s hero styles include a cropped denim Trucker jacket and a bodycon dress made with “luxe stretch denim.” Jeans include 7 For All Mankind’s signature fits, the HW slim kick and relaxed bootcut jeans. Each piece features white crystals and circular cutouts.

“We combined 7 For All Mankind’s 20 years of denim expertise with my signature touch of glamour to create something really special,” Dello Russo said in a statement.

Other items include an embellished shirt, a cropped top, slouchy denim shorts and a white tank top.

“She is incredibly talented, full of ideas and a contagious energy,” Francesca Toninato, 7 For All Mankind Global CEO, said about Dello Russo. “Our world of refined premium denim has been given a new fashion touch—one that embodies Anna’s innate glamour and haute couture edge. We are very proud to launch this sophisticated, disruptive aesthetic within the denim market.” —AV

BEAR ESSENTIALS

Buddy Lee, the iconic mascot that starred in Lee’s advertisements from the 1920s to the 1960s, and again in the 1990s, is the focal point of a new collaboration. The Kontoor Brands-owned heritage brand announced a partnership with Medicom Toy, the Japanese creator of Be@rbrick dolls.

The Lee x Be@rbrick collaboration offers three iterations of a Buddy Lee doll that embodies the mascot’s mischievous

attitude. The figurine is available in the 1000%, a Be@rbrick doll that stands over two feet tall. Smaller 400% and 100% sizes dolls are available as a duo. Each doll wears a denim overall and hat inspired by heritage Lee designs. The collectibles cost $800 for the large one and $200 for the set.

“This collaboration feels like the perfect mesh of two global icons,” said Joe Broyles, Lee VP of global collaborations. “The figurines are a new iteration of Buddy and will be great additions for denim fans and Be@ rbrick collectors.”

An apparel collection accompanies the dolls. It consists of three T-shirts and a denim jacket. Each tee features a different design of patches or screen-printed imagery of Buddy Lee and his Be@rbrick counterpart. The denim jacket is based on the Lee Rider jacket and boasts an oversized fit and vintage wash with sewn-on patches of Buddy Lee.

“We love how the accompanying tees and jacket bring a wearable connection to these collectibles,” Broyles added. AV

SMART HOME

Ikea launched the first iteration of what will be an annual home accessories collection dedicated to traditional craftmanship.

Called “Mavinn,” the line features 20 handmade items from seven social businesses located across Asia. These partners—Saitex, Spun, Doi Tung, Classical Handmade Products, Ramesh Flowers, Industree P.T. and Rangsutra—provide long-term job opportunities for people from vulnerable groups, Ikea said.

The collection includes baskets, rugs, a lampshade, an apron, bags, cushion covers and a wall organizer and was made with cotton, over-run materials from denim production and natural fibers. “Most” materials were sourced locally in Bangladesh, India, Thailand and Vietnam, where Ikea’s partners are located.

“One of our goals with this collection has been to create a diverse collection of handcrafted items that someone who enjoys walking at a local crafts market would like,” said Maria Vinka, Ikea designer. “We have a beautiful collection with handcrafted items, a natural appearance with contrasts using embroidery and colorful splashes. That is something I think our customers will really appreciate.”

CHELSEA DOBROSIELSKIBETTER BASICS

Lands’ End is the latest brand to add Recover’s high-quality, low-impact recycled cotton fiber to its ingredient matrix.

The brand bowed a line of women’s jeans made with the Spanish materials innovation company’s branded fiber. The comfort stretch jeans are made with fabrics comprised of 52 percent cotton, 20 percent Recover recycled cotton, 27 percent polyester and one percent spandex.

The recycled cotton is from textile waste, significantly reducing the carbon and water footprint of the new apparel produced with it. Lands’ End highlights the sustainable benefits of using Recover in the collection’s product descriptions, calling attention to how using “just 20 percent of Recover recycled cotton fiber to make just one pair of jeans will save enough water to amount to 23 showers or one year of drinking water.” The jeans are also dyed with liquid indigo that requires less indigo than traditional indigo, the company stated.

The collection spans straight, straight ankle, cropped flare, wide-leg, boyfriend and bootcut fits. The jeans have contoured, no-gap backs and are offered in a dark rinse wash. Jeans are finished with a faux leather back patch made with apple skin. AV ●

DESIGNER CHAT

BY ANDRE CLAUDIOLOOSE FITS, skate culture and a variety of rises are the main players in Fall/Winter 2023-2024 collections. With sustainability and comfort at the top of consumers’ lists, brands are paying closer attention to the ingredients in the fabrics they source and their impact on the environment. Here, designers and executives from leading brands discuss what’s next for jeans and how they stay inspired.

On F/W 23-24 trends: We are seeing a resurgence of vintage prep, bringing back bold stripes and preppy silhouettes. The ’90s are back in a big way with very loose-fitting jeans, tighter tops and lots of textured knits. Lastly, in a post-covid world, comfortable sophistication is everywhere, from elevated sweats to long driving coats, shackets and layers that go from day to night.

On balancing sustainability and design: Sustainability is part of our vernacular. We do not consider any fabric or item to be created without an ecostory. In fact, 95 percent of our line is sustainable.

FIVE DESIGNERS AND EXECS DISCUSS WHAT’S NEXT IN DENIM FOR FALL/WINTER 2023-2024.◄ CAROLIN LOOSE CARVE DESIGNS DESIGN DIRECTOR CARVE DESIGNS

On what I want to see more of from the denim industry: Better dyeing processes, less water usage and repurposing denim more frequently and efficiently.

On finding inspiration: Maybe the question should be what doesn’t inspire me because everything can and does. How to hone that in through the Carve brand filter is more nuanced. The outdoors, exploring new cities and looking at what people wear in their everyday lives are key things that inspire me. Additionally, seeing how capable women are inspires me to design for them every day.

▲

UWE KIPPSCHNIEDER & JOHANNA CZEPALLA CLOSED DENIM DESIGNERS/DEVELOPERS

On F/W 23-24 trends, Uwe Kippschnieder: The easiness of the late ’90s is one of the key drivers for denim at the moment, including loose silhouettes, wide legs, dropped waistlines and a long-slung rise. Back pockets are getting even bigger, and worker details are still important.

For men, the new Closed fit Springdale is one of our styles trending the most. It’s an easy skate cut with a wider leg and a casual, laid-back attitude. Our Blomberg style—a single-pleated chino hybrid silhouette—is also doing well.

Johanna Czepalla: For women, we still see a shift from high waists to a lower waistline due to the Y2K trend, but now, with a simple and elevated straight leg. For women, denim skirts are getting super important, both short and full-length.

On balancing sustainability and design, U.K.: Sustainability has always been relevant for Closed, especially our denim. Many of our partners are worldrenowned for their sustainable denim innovations, from eco-friendly materials to low impact washing techniques. In fact, we developed Closed’s eco-denim line, A Better Blue, with our partners in 2018 to save water, chemicals and electricity. Additionally, we always aim to create long-lasting pieces. For the design process that means constantly seeking innovations, new techniques and new qualities. Every season, we question ourselves to see whether certain processes are still needed or can be improved. That implies looking at our existing styles and qualities.

On what I want to see more of from the denim industry, J.C.: The most important point is that the denim industry is becoming more transparent. Brands, fabric mills, manufacturers

and laundries are constantly working together. A shift is already happening, but there is still plenty of room for improvement.

On finding inspiration, J.C.: Traveling is always an inspiration—especially after the lockdowns—because you can see different cities and catch their vibes. I guess that’s one of the reasons why we were inspired by the young and cool skateboarding vibe of the ’90s for our fall/winter collections. This carefree and laid-back attitude, self-expression and individuality almost embody an antifashion that has become fashion.

BACK POCKETS ARE GETTING EVEN BIGGER, AND WORKER DETAILS ARE STILL IMPORTANT.”

—UWE KIPPSCHNEIDER

THE ’90S ARE BACK IN A BIG WAY WITH VERY LOOSE-FITTING JEANS...”

—CAROLIN LOOSE

MARK PETERS NYDJ, DIRECTOR OF CONSUMER EXPERIENCE ESTELLE DAHAN NYDJ,

VP OF DESIGNER AND CREATIVE DIRECTOR

On F/W 23-24 trends, Mark Peters: We will emphasize tailored and flattering bottom silhouettes for the fall and winter seasons, including wide leg, high waist straight and slim fits. Cargo details will be a prominent trend this year that we will showcase throughout the collection.

Additionally, we just launched our new seamless jeans, Le Silhouette jean, with a compression fit that smooths every curve without outseams to achieve a

second skin look and flawless silhouette. Le Silhouette jean will be available in several slim fits throughout the year. Our key trend fabrics will be faux leather, velveteen and corduroy. The collection’s palette will feature rich jewel tones and traditional favorites like gray. We will also introduce a lightweight denim capsule with high-rise, wide-leg pants and denim shirts for the holidays.

On balancing sustainability and design, Estelle Dahan: We factor in sustainability when we decide on the quality and textures of the fabrics we use for the season, always prioritizing sustainable fabrics and materials produced with sustainable practices. We also strongly consider the most sustainable resources and methods used in the dyeing process, which helps reduce water consumption.

On what I want to see more of from the denim industry, M.P.: It would be nice to see more sustainable production methods and eco-friendly fabrics in the industry. I also believe that recycling materials will gain more traction as the industry considers an uptick in circularity and overall carbon footprint reduction.

On finding inspiration, E.D.: Women’s lifestyles and curves are always top of mind at NYDJ, especially when

considering new denim technologies. Her lifestyle and activities are important factors since style, fit and comfort are at the forefront of our design ethics. Whether she’s running errands, gardening or going out with the family or for date night, our sophisticated, classic and diverse woman is our muse that we keep in mind with every design. We start the design process every season by choosing a specific global location or travel destination that inspires the look and feel we want the collection to capture. From there, we create mood boards and source inspirational elements from that area, influencing our silhouettes, design details, prints, fabrics and textures.

ROB SZENYERIAMERICAN EAGLE OUTFITTERS, SVP, MERCHANDISING MEN’S AND AE77

On F/W 23-24 trends: We are excited about several trends, including higher rises, wider leg shapes, classic fits, straight legs, workwear details and gender-inclusive sizing. Gender-inclusive sizing is an important aspect of AE77, a premium denim brand from American Eagle for men and women inspired by the convergence of artistic vision and a planet-first mindset.

OUR KEY TREND FABRICS WILL BE FAUX LEATHER, VELVETEEN AND CORDUROY.”

—MARK PETERSNYDJ

CÜNEYT YAVUZ, MAVI CEO

On F/W 23-24 trends: We are in the age of denim on denim—an era where denim is used across all categories, including jackets, overshirts, vests and skirts. Trend highlights for F/W 23-24 include utility and workwear, featured in our new denim cargos, jackets and shirts with oversized pockets, and modernized in our non-denim cargo twills with carpenter details.

For women, we launched Recycled Blue, a new jeans collection that incorporates Tencel with Refibra technology. The technology gives a second life to pre- and post-consumer cotton textiles—which would otherwise be sent to landfills or incinerated—by upcycling them. The closed-loop process uses 95 percent less water to produce than conventional cotton, resulting in jeans that have a vintage look with a soft hand.

For men, we debuted the London fit, highlighting the loose tapered trend.

A new chino fit with a more universal appeal, Milton, reflects the casual smart trend, while utility and workwear are also found in men’s in the new Sam cargo style. Additionally, our Steve Athletic fit returns with expanded comfort fabrics and wash options.

On balancing sustainability and design: Drawing from our belief that the best denim is sustainable denim, we aim to inspire the industry with innovative products with low environmental impact by embracing the circular economy model. We recognize that every step and action we take will bring about massive transformations, which is why we focus on every aspect of the value chain, from the farmer to the end consumer. We start with responsible raw material sourcing and production, invest heavily in research and development and product development processes and identify innovation partnerships to shape the future of sustainable fashion. ●

On balancing sustainability and design: In 2020, we launched our Real Good label, which is apparel and jeans made with sustainability and the planet top of mind. Our Real Good jeans are sustainably manufactured and made in factories and mills that meet our Water Leadership Program—a program launched in 2017 that sets expectations for our factories on wastewater, water reduction, water recycling and chemical management standards. Additionally, the AE77 collection is focused on sustainable practices and reducing environmental impact. We use organic cotton, green chemistry, responsibly sourced trims and components and traceable practices.

On what I want to see more of from the denim industry: A return to more authentic details in classic jeans that never go out of style. At American Eagle, we love to reinvent iconic styles through the evolution of fabric and wash. Like our approach, I think you’ll also see more brands utilizing sustainable practices.

On finding inspiration: We are a brand rooted in authenticity and inspired by heritage, and we believe it’s important to keep the vintage details from the 1950s and ’60s alive through modern styling and shapes. We are all about innovation and discovering new ideas that we can apply to our broad assortment to create the best and most comfortable jeans possible.

WE ARE IN THE AGE OF DENIN ON DENIM—AN ERA WHERE DENIM IS USED ACROSS CATEGORIES.”

—CÜNEYT YAVUZ

SUMMER FARE

BRANDS, RETAILERS AND CONSUMERS

LOOK BEYOND THE BASIC 5-POCKET JEAN TO BUILD OUT A DENIM WARDROBE.

BY VICKI M. YOUNG

BY VICKI M. YOUNG

WHEN THE DECADE-LONG grip that skinny jeans had on consumers was finally released during the pandemic, it created an opportunity for brands to bring forward classic but forgotten fits. Consumers eased back into staples like bootcut, slim and straight, while Gen Z found novelty and newness in wide and slouchy styles.►This cadence of fresh denim is trickling beyond the basic 5-pocket jean this summer, allowing consumers to better express their personal style. ► Interest in Y2K-era fashion is kindling demand for denim miniskirts and maxiskirts in both indigo and Barbiecore pops of pink. Jean shirts and dresses are a mainstay in the Western trend. Denim blazers à la Giorgio Armani and Saint Laurent speak to consumers pursuing the “quiet luxury” aesthetic spurred by HBO’s family drama “Succession.” Meanwhile, jean jackets have become the go-to item in Taylor Swift and Harry Style fandoms to DIY with patches and embellishments that nod to their songs or eras.

Underpinning the various ways that fashion is embracing denim is its versatility. That quality is especially important to consumers who are increasingly thinking about the cost per wear of the garments they purchase.

“Denim is one of the most diverse materials in the fashion business and can be dressed up and down. It stretches from workwear to skate to street to luxury and that is reflected in the way the styles in denim appear and how the material is being applied and treated,” said Herbert Hofmann, Highsnobiety vice president, creative and buying. “It’s a durable and easy-to-wear material so customers like its comfort and usually also the price point.”

Known for having a pulse on what’s next in fashion, Hofmann said Highsnobiety is anticipating a shift away from Y2K. The Berlin-based e-tailer is betting on denim shirting and shorts to fill the summer gap.

“We haven’t seen styles like cut jeans with fringes last summer so much, but this season will be its big return,” he said. “Let’s see if people want to buy it already cut or make their own at home from an old long pair like [past generations.]”

He added that Highsnobiety did “bigger buys” on denim and its variations the past two seasons, but then pulled back slightly this season because the company wanted to “move on from the Y2K wave.” Still, examples of the Y2K’s influence on denim include looks from Glenn Marten, the creative director of Diesel. Hofmann noted that the Italian denim brand is translating the creativity it puts into its jeans to other items like swimwear with denim prints and motifs. “They also put a lot of work and layers into their denim caps,” he said.

Other brands on Highsnobiety’s radar include Acne Studio, which Hofmann said is using an “overly cute cat print” to push the denim trend forward, and Prada, which “did a great job with making shirts, dresses and shorts chic.”

Fashion statements are made with denim in Good American’s collection. The brand’s soft stretch indigo midi and mini dresses are made from compression stretch denim that smooths, sculpts, and shapes curves. Jean shorts are another major category this season for Good American, especially ’90-inspired styles that are shredded, ripped and have raw hems.

Lower rises and coordinates permeate AG’s collection this spring and summer. “Undertones of Y2K” is driving demand for AG’s Remy skirt, a low-slung mini inspired by the aughts, said John Rossell, AG Jeans’ head of marketing and creative.

“We’ve also seen the excitement around our new Alanna cropped jacket that pairs back to the Remy skirt. It’s a fresh, sans-collar take on the Trucker that ac-

centuates the neckline and is really playful and versatile, changing the mood depending on the choice of top paired underneath,” he said. Both styles are offered in AG’s Vapor Wash cleaning process that combines laser, nanobubble and ozone technology to save water and energy and eliminate chemicals.

The brand’s new relaxed slim short, the Becke, is also getting a warm reception from consumers. “The low-rise trend is likely to thank for that,” Rossell said. “It’s no surprise that it’s a current customer favorite since it’s so easy to dress up or down with a tank or a button-up shirt.”

He added that white denim and lighter colors have also been popular this season, especially for pieces like the Robyn Trucker jacket. “Customers love the feminine fit as it pairs easily with jeans, shorts, skirts and dresses,” Rossell said.

Betty Madden, Lee’s global vice president of design, said denim skirts are having a big moment this season, especially those that are midi-length and have a late ’90s feel. The brand taps into that nostalgia with a split denim midi skirt and the Rider shirt dress.

“Both have a touch of stretch and that worn-in feel in a lighter-weight denim,” she said. “They’re great options that you can wear just about anywhere.”

Other options offered by Lee are the short Union-All—a summer-friendly take on the heritage style from 1913—and the short Bib Overall in lighter fabrics. The latter is available in an ecru carpenter version and a shredded indigo version

Unfinished hems added a bohemian feel to Carve Designs’ denim assortment. The brand’s organic cotton denim cutoff skirt is “perfect for running errands or grabbing lunch—a must have for the warmer months,” said Jennifer Hinton, Carve co-founder.

Hudson expects to see growth in more leg-barring categories. “As the weather warms, we find that women are coming to Hudson in search of more than the traditional jean and jean short and we have adapted to this demand by growing our short, dress and skirt assortment,” said Ben Taverniti, Hudson Jeans’ design and creative director.

A key item is the Freya Shaker short, a new style that offers a wider leg than what Hudson has done before. He said Hudson’s high-rise reconstructed skirt has been a top seller, and the brand continues to offer the style in new washes each season.

The utility trend is being adapted by non-jean categories as well. The brand introduced a reconstructed cargo dress in indigo. Taverniti said Hudson’s cargo styles “continue to be incredibly popular.”

While Hudson leans into the ongoing demand for pink with two jean styles, it also paid attention to interest in clay, a tangerine orange hue, and classic white.

Also showing a robust lineup of white denim this season is Lucky Brand. “White denim has been a seasonal fashion staple for decades, but this season it’s taking on a fresh new twist, inspired by the ’90s and Y2K nostalgia,” said Tamara Reynolds, Lucky Brand’s vice president of denim.

Reynolds said the trend is about embracing the carefree spirit of the ’90s and the unbridled energy of the Y2K era. “With a focus on inclusivity and gender-neutral fashion, this new take is about embracing the freedom to wear what you want, how you want—that’s the beauty of a white canvas,” she said. ●

PREVIOUS PAGES: GOOD

AMERICAN DRESS (LEFT), DIESEL TOP (RIGHT); THIS PAGE: AG JEANS

“DENIM IS ONE OF THE MOST DIVERSE MATERIALS IN THE FASHION BUSINESS AND CAN BE DRESSED UP AND DOWN.”

—HERBERT HOFMANN, HIGHSNOBIETY

HEAT

JEANS IN

FIBER TECHNOLOGIES AND ENGINEERED WEAVES ARE KEEPING CONSUMERS COOL IN DENIM THIS SUMMER.

BY ALEX HARRELL

BY ALEX HARRELL

THE FIRST DAY of summer is June 21, but seasonal jeans have been on the minds of brands and retailers for months. ► In April, Good American bowed “weightless denim,” a collection of ultra-soft and airy jumpsuits, jeans, shirts and shorts made with cotton and lyocell. The brand describes the collection as their lightest jeans yet. Madewell’s “summer denim drop” in May offered wide-leg cotton and Tencel jeans, lowslung cargos made with hemp, Tencel and cotton, and white and ecru denim for a light and bright look. More recently, direct-to-consumer brand Mott & Bow has been touting 10 oz. soft twill denim jeans for men as the “jeans for 90-degree heat.” ► Demand for bottoms that can be worn comfortably during sweltering summer months—or even better, year-round—has never been greater. Consumers’ growing awareness of technical fabrics and their desire to do more with less, coupled with record-breaking high temperatures have put a spotlight on garments that seamlessly fit into their lives no matter the season. ► However, fabric weight, fiber composition and the weave of the fabric all play a large role in what makes a jean warm-weather friendly.

gram. Lycra Dual Comfort creates comfortable, soft stretch fabrics with durable shape retention and cool comfort by transporting moisture to the outside of the fabric. These performance attributes come from Lycra T400 Ecomade, a stretch fiber that contains 50 percent recycled content.

“It’s quite an important fiber technology that the majority of the brands put in their fiber matrix,” said Ebru Ozaydin, The Lycra Company’s strategic marketing director of denim and ready-to-wear. “It’s a good option to replace virgin materials.”

Lycra’s Coolmax technology is synonymous with cooling performance, but the addition of Ecomade versions further complements the denim industry’s focus on circularity. The moisture-wicking technology is made with 100 percent post-consumer waste like recycled PET bottles in one version and 100 percent pre-consumer textile waste in another.

The latter is made from factory floor scraps or unused fibers, resulting in chips

NATURAL COMFORT

Cotton’s inherent breathability makes it the natural choice for hot days. Cotton Incorporated’s CottonWorks program highlights the ways is helps the wearer keep cool.

“Who wants to wear 16 oz. denim in the summertime? There are all kinds of really great things you can do with lighter weight constructions in denim that isn’t necessarily your traditional 3x1 right-hand twill,” said Yvonne Johnson, director of product development for Cotton Incorporated.

Cotton Incorporated’s TransDry technology is a patented, moisture management application that allows fabrics to wick perspiration while maintaining the comfort of cotton. Its Natural Stretch concept is a mechanical stretch technology designed for 100 percent cotton woven fabrics to provide comfortable stretch and softness without the use of any synthetic spandex.

“This is the sweet spot—cotton can perform just like any other fiber,” said Ryan Vulcan, Cotton Incorporated’s associate director of corporate communications.

“When you talk about the marketability of different products, we often see [that] cotton is always the comparison. You want to be like cotton. And why is that? Because we’re the brand standard.”

“People don’t want to wear synthetic things in the summertime, especially when it sticks to the body,” said Tuncay Kılıçkan, Lenzing Fibers head of global business development, denim.

The same cooling properties that make Lenzing’s Tencel popular in the home textile category also make it a popular choice for jeans. The lyocell cellulosic fibers absorb moisture to help the wearer feel cool and dry. “Tencel has a cooling effect naturally and it has twice as much absorbency of moisture compared to cotton,” Kılıçkan said.

Tencel is a common blending partner, but denim mills are growing their use of the fiber as an alternative to virgin cotton. In some cases, they’re making 100 percent Tencel fabrics. Lenzing presented Zero Cotton and Zero Virgin Cotton fabrics from 15 global mills including Bossa, DNM, Iskur, Saitex and more at Kingpins Amsterdam in April. While zero

cotton denim was a niche concept a few years ago, Kılıçkan said it should soon be scalable and accessible.

Lighter fabrics with a soft drape are always a core part of Soorty’s collection for the spring and summer seasons. Looser constructions with open weaves feel lighter, while natural fibers offer water absorption properties and quick drying times.

Achieving lightweight fabrics and maintaining denim’s unique character are challenging, however.

“If we develop lightweight denims with very fine yarns, we don’t usually get the washed, worn-in effects. We prefer to keep the authenticity and look of jeans, and here the challenge starts,” said Alper Cataloglu, Soorty’s senior product development manager. “It’s never easy to develop lighter-weight fabrics while keeping the same visuals as an authentic pair of jeans.”

Enter synthetics. Cataloglu said most of the time Soorty uses synthetic fiber cooling technologies in fabrics because the cooling performance does not get affected by wash processes.

“We do work on sustainable options on all developments; for synthetic fibers, we try to shift to recycled material bases,” he said. “On the other hand, we try to reduce the use of synthetic fibers and replace them with man-made cellulosic fiber options such as Tencel, viscose or even recycled versions of them.”

CIRCULAR COMFORT

Pakistani mill Siddiqsons experiments with yarn twists to make softer fabrics and use more open weaves and cotton products for the summer season. “Everybody wants something a little bit lighter and more comfortable and more flowing during the summer months. If you go back to the old fashion, even the Japanese denim, they’re pretty open constructions,” said Scott Gress, Siddiqsons president of North American sales and marketing.

Siddiqsons also utilizes Lycra Dual Comfort technology for moisture management and shape retention.

The Lycra Company is working to change the negative perception of synthetics by upgrading proven technologies with recycled ingredients through its Ecomade pro-

that use 29 percent lower emissions compared to chips used to make virgin fibers, Ozaydin said.

Naveena Denim Mills is meeting consumer demand for sustainable performance by using Coolmax Ecomade with pre-consumer textile waste.

“For spring and summer, we are working on innovative technologies that keep end-users cool and comfortable without sacrificing the denim look they look for,” said Berke Aydemir, Naveena Denim Mills’ head of R&D and technical sales. “Designed specifically for use during these months, these fabrics are lighter, mixed with smart fibers or have temperature regulation or moisture-wicking properties”

Aydemir added that the Pakistani mill is also using “creative engineering and weaving solutions” to offer lighter and more breathable fabrics. The mill’s Edges collection addresses the market’s demand for looser and drapey jeans.

WE DRAW INSPIRATION FROM NATURE AND THE QUALITY OF MATERIALS GROWN IN THEIR NATURAL HABITAT, JUST AS CASHMERE THRIVES IN COLDER CLIMATES.”

—TIM HUESEMANN, PANTHER DENIMLEFT: LASER ETCHED DENIM BY COTTON INCORPORATED FABRICAST COLLECTION; BELOW: THE LYCRA COMPANY

ENGINEERED ENHANCEMENTS

Denim mills are also using their expertise in weaving and fibers to develop fabrics with moisture management and temperature-regulating properties.

Breathable natural fibers like cotton, linen and hemp are first in line in AGI Denim’s warm-weather fabrics. However, the Karachi-based B Corp also incorporates Halo technology, a weaving technique inspired by home insulation that keeps the wearer warm in cold weather and cool in hot weather.

“With the Halo technology, our yarns have innovative cross sections that help create fabric with high drape and improved comfort,” said Ali Tekin, AGI Denim R&D director. “We created air space in the core of the yarn that helps insulation. It keeps cool in warm weather conditions and allows maximum breathability.”

Creating fabrics with more air space means the garments will be looser with a more open weave. The primary method for creating a more comfortable product structure is to increase the air permeability, he added.

Abaca yarn, derived from natural leaf fiber, is used by Panther Denim to help with temperature regulation. It also possesses natural odor-resistant properties, making it an ideal choice for hot and humid weather conditions.

“The plant that produces these fibers is grown in South Asia,” said Tim Huesemann, Panther Denim director and shareholder. “We draw inspiration from nature and the quality of materials grown in their natural habitat, just as cashmere thrives in colder climates.”

That focus on the environment also led Panther to explore circular solutions. The China-based mill recently developed a cooling technology that utilizes a specialty-engineered hollow fiber made from recycled materials.

“This innovative design significantly reduces the weight of our fabrics while also providing year-round comfort, remaining cool in the summer and warm

in the winter,” Huesemann said. “We will combine this fabric with recycled cotton and biodegradable elastane, as we always strive to provide a variety of sustainable options that cater to the diverse needs of our customers.”

Twin Dragon Marketing Inc.’s (TDMI) solution for seasonless denim is Atmos, a fabric that utilizes a Japanese hollow fiber that cools the wearer by allowing airflow and forming a thermal barrier that shields it from the outside heat. “The approximate 30 percent hollowness helps to keep the wearer airy in the summer by allowing air to flow while also creating a thermal barrier from warmer outside temps,” said Stephanie Poon, TDMI director of marketing and merchandising.

The fiber is made from 100 percent recycled polyester and can be blended with other eco-friendly fibers like lyocell to create sustainable jeans. Atmos fabrics also don’t need to be made with looser or open weaves due to the nature of the hollow fiber. Poon said the construction of the fiber facilitates a spongy and soft feel, rendering denim that looks substantial but feels light to the touch.

“We are on a journey to create fabrics that have not just functionality but longevity across many seasons,” Poon said. ●

FIBER AND DYE INNOVATIONS ARE HELPING JEANS

BY ANGELADARK

as a living fabric that gains character with wear. Fades are a form of currency among denim heads. Vintage denim’s worn-in appearance is what makes it covetable to collectors and is the impetus behind the wash and finishing technologies brands use to

There is consumer demand for jeans that retain their

When workplaces started to reopen in 2021, employees returned dressed in jeans, albeit in looser and more relaxed fits than their pre-pandemic skinnies. Denim’s inherent versatility reflected their new hybrid work schedules. Cut to two years later, more CEOs are backtracking on remote working and traditional corporate culture is crawling back. Jeans are part of the workplace landscape but faded and distressed styles are not.

Instead, consumers are turning to dark indigo and black jeans as alternatives to traditional slacks. The clean and polished bottoms are dressed-up with blouses, blazers and sport jackets. The dark denim trend is being perpetuated on the runway as well with designers like Maison Kitsune, Schiaparelli and Loro Piana using dark indigo denim as a palette cleanser from the harsh-look-

“There’s a decent number of people who [enjoy wearing] their denim with a clean or rinse look, and they are happy with it. Therefore, the worn-in look is not their style. They like a more dress-up look,” said Tuncay Kılıçkan, Lenzing’s head of global business development for denim. “It’s a borderline between formal and sportswear—a different interpretation of wearing sneakers

There’s also the customer that wants their purchases to look new for as long as possible. If they’re spending $200 on a black jean, they expect it to look like the black jean even after laundry day.

“Consumers are increasingly looking for more sustainable and timeless jeans that preserve their colors and quality,” said Cüneyt Yavuz, Mavi’s CEO. “The desire for clean and simple jeans and the need for styles that consumers can easily combine to create different looks are the among the factors that drive the demand for dark wash and black denim.”

Launching this fall, Mavi’s Pro Dark Tech, features a technology that preserves the dark indigo color. “In every wash cycle at home, denim generally changes in tone and gains a more personal look with different effects depending on how often and where it is worn,” Yavuz said. “The colorfastness technology of Pro Dark Tech ensures that the color of the denim is not affected by use and care.”

The line is designed exclusively for men and offers jeans and denim jackets made with recycled polyester and BCI cotton for a head-to-toe look. Pro Dark Tech builds on Mavi’s existing dark denim offerings like Double Black, a range of men’s and women’s black denim jeans, jackets, shorts and skirt that have ranked among the brand’s most popular styles.

Black denim, in general, is pitched by mills and brands as being seasonless. Both black and gray denim have claimed a large share in recent spring and summer seasons.

Mavi also touts the sustainable benefits of its Pro Dark Tech collection. “Since they undergo fewer washing processes due to their dark colors, these products consume less water and energy during production. And the long-lasting color translates into longer-lasting products for the customer,” Yavuz said.

Color-fast fabrics decrease apparel production costs, as they do not need a washing. “A quick rinse is enough,”

JEANS RETAIN THEIR OFFICE-FRIENDLY LOOK.

ART

said Berke Aydemir, Naveena Denim Mills’ head of R&D and technical sales.

The Pakistani mill launched Solido, a collection of black and “indigo-looking” navy fabrics to its line this year. Naveena uses a special dye technique that guarantees no color change after 20-plus home laundering with excellent color fastness. The fabrics are available as a rigid 100 percent cotton construction and a comfort stretch with one percent elastane.

“We observe that there is an increasing audience for smart casual looks, which include vintage looks but also no-fade,” Aydemir said. “We had very good reactions and follow-up from many clients.”

There’s a science behind denim with long-lasting color, and the chemistry is increasingly sustainable.

Chemical manufacturer Archroma’s Stay Dark system provides better fastness for black and navy shades compared to regular black denim or indigo-based denim fabrics. Stay Dark enhances fabric color Wresistance to repeated home laundering and provides “significant” life cycle savings in energy and CO2 emissions during consumer use. The product has received the Cradle to Cradle Products Innovation Institute’s gold level material health certificate.

Sustainability is part of Lenzing’s messaging for Tencel Modal with Indigo technology, a product that adds indigo pigment during the finer production process. It won the ITMF Innovation Award in 2022.

Used by Gap, NYDJ, NA-KD, Otto and more, Kılıçkan said the fiber is a solution to the typical rubbing fastness of conventional indigo. It also eliminates the need for further dyeing, which saves on chemicals, water and energy.

Though Tencel Modal with Indigo technology is a solution for long-lasting color, the color is not permanent. Kılıçkan said it can be washed down with ozone, chemical bleach, enzyme and other processes, meaning brands can put their creative touch on jeans and it will last.

“The advantage is the final look of the product is stable against domestic home laundry whereas conventional jeans carry on discharging indigo which results with a different look than the one of the purchase,” he said.

Lenzing Modal and Repreve recycled polyester are key ingredients in NYDJ’s IndigoLast and BlackLast product lines that retain color for at least 30 home laundries, though Estelle Dahan, NYDJ’s VP of design, said that’s on the conservative side. “We suggest machine washing the jeans in cold water, which traps the dye inside the fabric. This, in turn, helps prevent color bleeding,” she said.

“Our consumers tend to lean toward a very classic, sophisticated look,” she said. “Because of this preference, they appreciate the no-fading benefit of our IndigoLast and BlackLast denim. I would say there’s a high demand for [no-fade jeans].”

BlackLast launched in July 2020; IndigoLast followed in January 2023. The product lines achieve their color fastness because both components are fiber dyed before they are spun together. This fiber dye is more resistant to color fading.

Both offer a variety of fits spanning slim bootcut, skinny, straight and more. The dye technology is even applied to a few footwear styles with denim uppers.

The collections, Dahan said, appeal to NYDJ’s consumers who “may want jeans that look both clean and sophisticated for the office, paired with a blazer and flats; or dressier jeans for evening, paired with a trendy top and heels.”

“This denim collection with lasting color intensity can go either way, depending on the outfit pairings,” she added. “Plus, it’s really a day-to-night option due to the wearability of its eco-friendly, soft fabric.” ●

THE SUSTAINABLE WAYS TO ACHIEVE

BY ANGELA

DIRTY

ACHIEVE Y2K-INSPIRED DIRTY WASHES. VELASQUEZ

TALK

► Whether you call it “vintage tint” like New Jersey-based BPD Washhouse, “dirty look” like Italian chemical company Officina39, or “dirty, smokey or trashed” like Turkey’s Isko, it’s safe to say that gritty, apocalyptic washes are back. ► Blumarine, R13, Foo and Foo, Acne Studios and Diesel are among the brands to inject dirty-looking denim into their recent collections. Defined by its earthy tint, vintage fades and dull appearance, the edgy look fits in with Gen Z-oriented trends from Y2K and grunge to moto. The wash is at home on items that haven’t been popular in nearly 20 years, including low-slung jeans and midriffbaring miniskirts. ► “These types of washes were extremely in vogue in the 2000s, especially with Italian brands such as Diesel,” said Alice Tonello, R&D and marketing manager for Italian machinery company Tonello.► She said Diesel developed two models with this type of wash, the 736 with a reddish look, which was dirtied using wall dyes, such as ferrous oxide, and the 738, a second style with an intense orange color. “Later [Diesel] switched to using mineral pigments, and later, even to this day, colored mineral pigments to achieve the same effect,” Tonello said. “This wash made the fortune of brands such as Diesel.”

Though trendy, Paolo Gnutti, CEO of PG and the creative director of Isko Luxury by PG, likens the existence of dirty denim to the first appearance of chino pants in the mid 1800s when an English army officer in India was trying to hide in the dust. To dye the chinos, the officer mixed spices and coffee to create shades that went from sand to ochre, according to Gnutti.

Similarly, the first industrial dirty effect in the 2000s involved the use of natural pumice stones from mountainous Greek or Turkish quarries and dye pigments. “This kind of technique, unfortunately, had a high environmental impact on residual sludge and chemicals that are difficult to remove and dispose,” he said.

“Back in the 2000s the aesthetic results were much more important than their potentially unsustainable consequences,” said Andrea Venier, Officina39 managing director, adding that the level of awareness among suppliers, brands and consumers was “totally different from what data and technology allow us to do now.”

Several methods were used to achieve the dirty look at the height of their popularity in the early 2000s.

“The traditional way that brands achieved the look back in the 2000s was by exhaustion, adding direct dyestuffs together with salt, increasing the temperature of the water up to 50-60ºC, and running the machine for 10-15 minutes,” said Amor Cardona, member of Jeanologia’s BrainBox team. “After this time, bath water with remaining dyestuff and salt was drained. Then, rinses were done to eliminate the chemical products remaining on garments.”

Other times the garments were sanded by hand and then treated with pumice stone to get the stone effect. Chlorine and permanganate were used for bleaching and localized corrosion. Finally, pigments or reactive dyes were used for over-dyeing or even double-dye processes.

What they all have in common, according to Ivan Manzaneda, Isko’s R&D lead, is their environmental impact, “starting

from the huge amount of water consumption to finish one garment, to the hazardous chemicals or the total number of compounds needed in the whole process.”

“In general, these industrial processes were characterized by the use of products that were chemically hazardous to the environment or that were difficult to dispose of,” Venier said.

The human impact of these techniques is not to be overlooked. The high number of steps, risky chemical applications and manual operations puts workers in danger. Potassium permanganate and sanding processes result in “considerable harm” to the workers who handle it, he said. Meanwhile, poor management of toxic substances poses a risk of water pollution, potentially affecting many more people and aquatic life.

“Denim manufacturers are increasingly moving toward sustainability,” Gnutti added. “However, the fact remains that in terms of washing, there are still some limitations in the look of a 100 percent sustainable wash. There’s a long road ahead, but it is the right one and the denim sector is constantly working to improve it day by day, season by season.”

SUSTAINABLE ALTERNATIVES

Dirty denim is shedding its reputation, however. Brands can replace many traditional processes by eliminating stones, certain chemicals and local applications, and reducing the total water to finish a garment. Some manual applications and steps are also reducing the impact on workers.

THE DENIM INDUSTRY has made strides in cleaning up its wasteful ways, but one fashion trend is dragging it back to its dirtier past.

Gnutti said innovation in the last decade has revolutionized the market by almost completely replacing natural pumice stone with various types of synthetic stones made of rubber or recycled plastic. Depending on the weight and type of fabric, he said alternative materials can fully replace natural stone in terms of the final look.

“Today this type of effect can be done more responsibly by using direct dyes or colored mineral pigments directly in the bath. It is done at lower temperatures and is very short, 5-10 minutes maximum,” Tonello said.

Brands can also achieve the look through atomization with Tonello’s Core system, a misting finishing process garment that allows maximum dye optimization and significant water savings. “This automatic system, operated entirely by the machine, can produce a fine mist inside the washing machine drum, resulting in uniform or contrasting effects on the

garments,” she said.

Jeanologia’s eFlow technology, which uses nanobubbles of air instead of using water as a transport of the dyestuffs to the garments, is another way to apply dyestuff. The technology uses minimal quantity of water, product and energy with zero discharge, achieving savings 95 percent of water, 90 percent of chemicals and 40 percent of energy.

“With eFlow no residue is obtained, neither of contaminated water nor of chemicals, obtaining the same result as with tinted or dirty by exhaustion but in an environmentally friendly and efficient way, saving costs to the industry,” Cardona said.

“With eFlow no residue is obtained, neither of contaminated water nor of chemicals, obtaining the same result as with tinted or dirty by exhaustion but in an environmentally friendly and efficient way, saving costs to the industry,” Cardona said. Isko’s mineral dyes are one option, he

added. “They are created with natural dyestuffs—not oil-based or synthetics— coming right from the earth.” In addition, by working with suppliers that have a recycling water system like Isko’s Creative Room Hub in London, Manzaneda said they can develop 100 percent of their garments using recycled water, reducing the waste in the development stage.

Soko’s Easy Wave dyeing method is another solution, according to Matteo Urbini, managing director of the Italian chemical company. “Pigments and resins previously used were more complicated to get treated,” he said.

Easy Wave is a dyeing auxiliary that creates a look like cold pigment dyeing without using any pigments and without the inconvenience of using pigments. The look is a surface dyeing with lighter seams, a good hand feel and good fastness.

Officina39’s goal is to match the dirty vintage looks of the 2000s with ethical, honest, transparent, and socially responsible alternatives.

The company utilizes Aqualess Mission, its combination of technologies allowing garment laundry processes to use 75 percent less water. Aqualess Aged is used in combination with Aqualess Activator to create the stone effect and replace the pumice stone treatment. Oz-One Powder and Ind/J Remover are applied locally to replace the use of potassium permanganate and chlorine on denim and obtain a bleached and distressed vintage look in an eco-friendly way.

Officina39’s One Step Process can combine several of these processes at the same time, saving time, energy, space and water. “That means that a raw garment enters the machine and a garment with a basic vintage effect comes out ready to be dried, already treated, bleached and softened,” Venier said.

For over-dyeing Officina39 uses Recycrom Dirty, a patented dyestuff derived from textile waste, which the company claims is one of the most sustainable dye technologies currently available on the market.

FADE IN

Interest in vintage-looking denim and Y2K styling—from both brands and consumers—is behind the resurgence of dirty washes. The grungy effect is brand new to Gen Z consumers who’ve unearthed wide, boot cut, flare fits and more in their post-pandemic quest to ditch skinny jeans. However, full-on dirty tints are still an extreme in the mainstream market, said Bill Curtin, BPD Washhouse owner. He said the look is “still a few seasons away” from being a full-blown trend.

“Certain customers who have a younger consumer target or more grunge aesthetic to their range have requested development around these dirty and trashed looks,” said Melissa Clement, Isko head of product development.

Tonello added that the effect has always been in fashion from the 2000s onward. “It has never been the star but has always maintained its slice in the collections of many brands,” she said. “Even today it is still used with more or less intensity— sometimes even without being so clearly discernible.”

The wash underscores consumers’ unwavering fascination with nostalgic fashion. Venier said “recreating the worn and yellowed parts that characterize a naturally used garment” is “really on trend now.”

“But today, the interest is also in being able to achieve this kind of bleached, distressed and worn look, while impacting as little as possible,” he said. “Our task is precisely to meet this need.” ●

THERE’S A LONG ROAD AHEAD, BUT IT IS THE RIGHT ONE AND THE DENIM SECTOR IS CONSTANTLY WORKING TO IMPROVE IT DAY BY DAY, SEASON BY SEASON.”

—PAOLO GNUTTI, PG DENIM

SOORTY LOOKS TO A HUMAN/AI— INTEGRATED FUTURE

While so many in the fashion industry are afraid of artificial intelligence, denim mill Soorty embraces it. The company recently presented a 50-piece collection of AI-generated garments at Kingpins called HumIAn. Here, Ebru Debbag, executive director, global sales and marketing, discusses how AI and humans can work together to improve the denim space, and how each side can improve the other.

RIVET: What role do you see AI playing in the industry?

Ebru Debbag: We will see more implementations of AI tools in our industry—not only designing collections but mirroring manufacturing processes, funneling consumer data into the supply chain, and waste reduction through curated product solutions enabling pre-sample market testing. We will use AI further to enhance our sustainable infrastructure for our customers’ specific needs and wants.

We were extremely pleased to launch our innovative AIgenerated denim collection in collaboration with trend forecaster and designer Volker Kettenis to emphasize the human value of working together with artificial intelligence. Industry stakeholders’ reactions were genuinely curious and excited. HumAIn unlocks undiscovered potentials, bringing forth purpose-driven designs made with responsible tools and takes consumers closer to a more sustainable future. The result showed the denim handprint and some pieces with loosely defined AI-imagined “boundaries.”

How is Soorty using technologies and sustainable alternatives to redesign products more responsibly?

E.D.: Our 3-pillar approach uses circular raw materials and our uniquely defined processes supported by infrastructure to seek sustainable alternatives— both in what is available and yet to be discovered. Our conceptual approach provides solutions to modern day challenges. For example, our Longevity

concept ensures longer use of jeans achieved with intentional selection of raw materials as well as unique design. Our third and foremost pillar is our people—not only our workforce but all stakeholders. We work in partnership with our supply chain, academia, our customers as well as the final customer. Most technology is available for all the industry, but how we implement it gives us the competitive edge.

How does Soorty’s “Design for Circularity” annual openhouse events bring circularity information and supplier connections to brands?

E.D.: We hold two SpaceD events annually and each event is themed around an innovative aspect of circularity with our stakeholders. Soorty is a vertical denim and jeans operation at scale, and our unique supply chain integrated circular design process brings all stakeholders together. Our business is complex and constantly evolving, thus

there is rarely time enough at trade shows and customer meetings to dive deep into the hard work behind ideas. Design for a purpose demands a collaborative approach. We must not only build the right content, but also dialogue with stakeholders so that circular design and manufacturing can become a collaborative effort and be reflected at the product level at scale. SpaceD events offer the time for attention to technicality and aesthetics to enjoy and learn about denim and jeans.

What are some of your latest CSR initiatives?

E.D.: Soorty’s strength lies in giving back and developing with its communities. There are multiple CSR projects on gender sensitivity, inclusivity, diversity and empowerment, with concentration on female workers and people with disabilities. Through the PRISM project, we