Unleash Your Innovation. With Over 500,000 Components. What Can You Build? Scan Here To Visit Us! Issue 04 / September – October 2023

HeadOffice Unit2, StourValeRoad, Stourbridge, DY98PP THINKFASTENERS THINKRAPID 01215013903 sales@rapidfast.co.uk www.rapidfast.co.uk ManufacturingHub Unit27, LyeValleyIndustrialEstate Stourbridge, DY98HX •Volumestockistofstandardfasteners&fixings •InHouseBespokeManufacturing •ExclusiveFarEastManufacturingCapacity •NextdayNationwideDeliveries •VendorManagedSystems;JIT/KanBan •Assembly&Kitting •FullCertification;3.1,3.2&ISIR’s •Contract&Scheduleorders RAPIDINDUSTRIALFASTENERSLTD YOURCOMPLETEFASTENERSUPPLIER

Publisher Jerry Ramsdale Jerry@torque-direct.com

Editor Hayley Everett Hayley@torque-direct.com

Deputy Editor

Rachel King Rachel@torque-direct.com

Contributing Editor

Jonathon Harker Jonathon@torque-direct.com

Sales Manager – UK

Claire Warman Claire@torque-direct.com

Sales Manager – International Harry Whyte Harry.whyte@torque-direct.com

Circulation

Tracy Howell Tracy@torque-direct.com

Head of Production Luke Wikner production@torque-direct.com

Designers

Dan Bennett production@torque-direct.com

Victoria Arellano production@torque-direct.com

Published by Stag Publications Ltd 18 Alban Park Hatfield Road St Albans Herts AL4 0JJ tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-direct.com

Web: www.torque-direct.com

Disclaimer Although

INSIDE THIS ISSUE EDITOR’S COMMENT

COVER PROFILE

08 Accu – From life-changing prosthetic limbs to cutting-edge conservation technologies, discover how engineers across the globe are building tomorrow with Accu components

TECHNICAL INSIGHTS

12 Safety & security – Securing the future of urban planning and ensuring quality expertise

18 JPG Système – The current trends, challenges and opportunities facing manufacturers in the aerospace industry

40 Berdan Civata – Selecting the correct fasteners for steel construction applications

IN-DEPTH – ROAD & RAIL

22 Analysis – Evaluating the current trends and challenges facing the global road and rail transportation sectors

24 Gala Precision Engineering –Transforming efficiency and safety in railway, road and off-highway transportation

28 EJOT UK – Providing greater flexibility in tunnelling applications with anchors

30 Nord-Lock – How incidents involving trucks can be avoided through improved safety measures

32 Expo Ferroviaria – Italy’s showcase for railway technology, products and systems returns to Milan in October

PRODUCT INNOVATIONS

14 Rivets & riveting technology – Fixi and Rivit share the latest innovations from the rivets sector

SPECIAL FEATURES

36 Women in engineering – Take a look at the individuals shaping the engineering industry of today

INDUSTRY EVENTS

20 Advanced Engineering – Inspiring the future of engineering and manufacturing

34 International Fastener Expo – The fastener industry will once again return to Las Vegas for this year’s International Fastener Expo

42 Taiwan International Tools & Hardware Expo – Shaping the future of the hardware and tools manufacturing market in Taiwan’s ‘tools kingdom’

To subscribe to Torque-Direct visit: torque-direct.com/subscribe or scan this QR code...

ELECTRIC DREAMS

THE GLOBAL transportation industry has faced its fair share of challenges this past year. From the recent fuel crisis to reductions in funding for public services and a shortage of skilled engineers, it has been a turbulent time for the sector. Add to this the current electricity crisis largely resulting from the ongoing conflict between Russia and Ukraine, and progress in the area of electrification is also being hampered.

As a result, 2023 is shaping up to be a vital year for the industry as it continues to seek transparent and suitable fuel alternatives to power the world’s various road and rail transportation networks. As our In-Depth evaluation of the sector explains in more detail, the key areas to watch in this space are likely to include sustainable funding mechanisms, electric vehicles, modernisation, greater resilience, and digital innovation. On pages 2432, we hear from the fastener innovators helping to spearhead technological change in the road and rail realms and make transport safer, greener, and more efficient.

This issue also hears from the female pioneers and industry leaders currently shaping the direction of the fastener and tool industries (pages 36-28), and provides insight into the latest innovations from the rivets and riveting technology sector (pages 14-17). We also explore the crucial role safety and security fasteners will play in our future cities (page 12), evaluate the latest trends and challenges facing aerospace manufacturers (pages 18-19) and get the low-down on everything engineers need to know when selecting steel fasteners for their applications (pages 40-41).

As ever, Torque Direct previews the key industry events coming up over the next few months. On the bill for this issue is: Advanced Engineering, Ferroviaria 2023, Las Vegas’ International Fastener Expo and the Taiwan International Tools & Hardware Expo.

Hayley Everett Editor Hayley@torque-direct.com

As part of our commitment to the environment, Torque Direct is fully recyclable.

the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or of Stag Publications Ltd. Copyright Entire contents copyright © 2023 Stag Publications. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Product news

04

//////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 03

LATEST PRODUCTS > THE FASTENER & TOOL INDUSTRIES

ADVANCED PRECISION FASTENING

PANASONIC has released its new transducerised mechanical pulse tool offering high torque and advanced technology to maintain accuracy and consistency. The AccuPulse 4.0 Transducerised HT is specifically designed for advanced precision fastening with four onboard microcomputers, a builtin transducer and intelligentlymanaged torque sensing that helps manufacturers improve quality and motor control, accuracy, and data on the assembly line.

The tool’s reactionless ergonomics provide freedom of movement, error proofing and twoway wireless communication to deliver fastening accuracy and quality manufacturing.

“As manufacturers place greater importance on data to improve efficiencies and quality control, AccuPulse 4.0 Transducerised HT delivers an Industry 4.0ready pulse tool that meets the engineering requirements of today’s smart factories,” says Aziz Lokhandwala, Senior Product Manager, Assembly Tools at Panasonic Eco Systems North America. “The AccuPulse 4.0 Transducerised HT was specifically designed for higher quality, better plant safety and greater efficiencies at a lower cost of ownership. Our exclusive algorithm enables this smart tool to learn joints and overcome difficult applications to maintain accuracy and consistency.”

www.panasonic.com/us/factoryequipment-solutions

CALIBRATION CAPABILITIES

Atlas Copco Tools & Assembly Solutions has received a unique landmark approval from the UK Accreditation Service (UKAS) for the calibration of electrically powered assembly tools. The first and currently only company to have secured this type of UKAS accreditation, the industrial tool manufacturer is able to provide calibrations for electrically powered and controlled torque devices from just 0.2NM up to 2,000NM.

The wide torque range covered by the additional UKAS

accreditation includes the company’s full portfolio of electric assembly tools and any other tightening tools that are electrically powered and electronically torque controlled. These include micro torque screwdrivers for lowtorque applications such as electronics, cordless Tensor IxB assembly tools with integrated digital controllers for industrial assembly and vehicle production, and SRB HA smart battery nutrunners that provide traceable high torque bolt tightening for critical applications in the energy sector.

“Expanding the scope of our UKAS accreditation to include the calibration of electrically powered tightening tools and the related benefits in terms of cost savings, reduced downtime and quality assurance, reflects our focus on forging strategic partnerships with customers in the journey to the smart factory,” says Nicolas Van Zyl, Atlas Copco’s UK Calibration Manager. “Calibration is a key component of Atlas Copco’s ‘Smart Integrated Assembly’ concept, ensuring the accuracy and process reliability of assembly tools. Providing UKAS accredited calibrations makes a real difference for manufacturers, allowing electric assembly tools to be quickly recalibrated and put back to work on the production line straight away.” www.atlascopco.com

///////////////////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT NEWS //////////

04 torque-direct.com /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// ///////////////////////// BROADER

//////////////////////////////////////////////////// //////////////////////////////////////////////////////////////////////////////////

Tel: +44 (0)121 4397329 Fax: +44 (0)121 4397346 Unit 4, Alma Industrial Estate, Stafford Road, Wednesbury, WS10 8SX, United Kingdon The Inser t Company (UK) Limited Specialists in Threaded Inserts for Wood, Plastic and Metal Zinc Alloy Inserts Steel Inserts Brass Inserts Furniture Connectors Headed Hex Drive Steel Knock-in Barbed Expansion Countersunk Caps

DEMO DEMON SAW BLADE

Diablo Tools has introduced a new oneblade solution for maximising productivity in framing and demolition: the Demo Demon Next Generation Ultimate Framing/Demolition saw blade. Equipped with a new optimised DuraBlend Carbide for the most extreme materials, the blade offers nano grind tooth technology for precise cuts and maximum blade life.

Standard carbide blades often cannot withstand the required cutting applications on the modern jobsite without dulling, breaking or failing when professionals need them

most. The new Demo Demon saw blade is designed to stand up to these requirements due to a new, specially formulated optimised DuraBlend Carbide that combines micron carbide with hicobalt content. This helps the blade to withstand even the most extreme cuts while also offering up to 15 times the cutting life of standard blades. The saw blade also features a triplegrind, chamfer alternate top bevel tooth geometry for ultimate tracking control to ensure finerquality cuts and longer blade life.

Accurate torque readings are vital for technicians in the field. Recognising this, Williams has released a new Digital Torque Checker capable of validating calibration of critical torque instruments right where work is being completed. The Digital Torque Checker is suited for manufacturing and assembly process control and data collection, coming in two modes of operation: track and click. The checker also features a N.I.S.T calibration certificate and is accurate to +/ 1%.

Five models of the new Digital Torque Checker are available, each featuring a range of benefits such as: LCD display, onebutton panel user interface, compact form factor for convenient mounting locations, adaptors for square drive torque instruments, and environmental protection IP40.

////////////////////////////////////////////////////////////////////////////////////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// ///////////////////////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT NEWS ////////// ////////////////////////////////////////////////////////////

www.williams-industrial.com

LATEST PRODUCTS > THE FASTENER & TOOL INDUSTRIES

NEW DIGITAL TORQUE CHECKER 06 torque-direct.com

“Diablo once again breaks new ground in saw blade technology to meet the evolving demands of professional users,” says Russel Kohl, President and CEO of Diablo/Freud Tools. “The firstofitskind Demo Demon Next Generation Ultimate Framing/Demolition saw blade is the latest example of our continued investment in advancing the industry with the best cutting solutions. Through such investment, we’ve created a specialised carbide meant to withstand the toughest materials, applied it to revolutionary blade geometry and manufactured a blade that will help professionals get up to 15 times the cutting life from their favourite cordless or corded saws.” www.diablotools.com

UNLEASH YOUR INNOVATION

Precision component supplier Accu impacts billions of people around the world. The company shares a selection of case studies from the past year demonstrating where and how its components are being used...

Behind every groundbreaking innovation and industrychanging technology, there are visionaries, brilliant minds and innovators who dare to see beyond the current landscape, challenging the norm to create something remarkable.

At the heart of these gamechanging inventions and advancements, there’s often an unsung hero; the small precision components holding everything together.

In the dynamic sphere of engineering, Accu, a global supplier of precision components, plays a vital role. With a

BUILDING TOMORROW: HOW ACCU COMPONENTS POWER GLOBAL INNOVATIONS

1. TASKA Prosthetics Industry: Prosthetics and Medical Equipment

TASKA Prosthetics, a New Zealandbased prosthetics design and manufacturing company, has emerged as a pioneering force in the field of prosthetic technology.

range of over 500,000, Accu’s components are at the heart of some of the most transformative technologies impacting billions across the globe.

These small yet mighty components stand as a testament to a powerful truth – the biggest and most impactful ideas often start small.

From lifechanging prosthetic limbs, to cuttingedge conservation technologies, discover how engineers and innovators across the globe are building tomorrow with Accu components.

Using a selection of Accu’s lightweight and durable components, TASKA has successfully engineered the world’s first waterproof, multiarticulating prosthetic hand, transforming the lives of individuals with limb differences around the world.

With a meticulous design that keeps the end user’s needs in the forefront, the TASKA Hand is a revolutionary prosthetic that empowers individuals to build confidence and develop lost abilities.

The company’s journey began with one profound experience that led to the creation of an innovative solution. After

For the HandGen2 – TASKA uses machine screws from Accu in sizes between M1.6 and M2.5, along with various general assembly hardware like pins, E-clips and circlips.

///////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 08 torque-direct.com

COVER PROFILE

“FOR US, INNOVATION HAS NEVER BEEN ABOUT CREATING A PIECE OF NEW TECHNOLOGY – IT IS ALL ABOUT DELIVERING REAL-LIFE PRACTICALITY THAT IMPROVES PEOPLE’S LIVES.”

Mat Jury, Inventor & Director, TASKA Prosthetics

founder Mat Jury suffered a mountain biking accident resulting in dual arm fractures, he gained firsthand insight into the challenges faced by people with limb differences.

Motivated by this experience, Jury applied his engineering skill to pursue a vocation with a mission – inventing a prosthetic hand that could truly make a difference.

This innovation, tailored for robustness and versatility, was built upon insights from global experts, clinicians and firsthand users to directly address the shortcomings of previous myoelectric hands on the market – which were often hindered by fragility and limited usability.

TASKA’s success lies in its meticulous sourcing of quality components, including its choice of Accu for precision fasteners and assembly hardware.

“We use Machine Screws from Accu in sizes between M1.6 and M2.5, along with various general Assembly Hardware like Pins, EClips and Circlips”, comments David Lovegrove, TASKA’s Head of Design.

These components, with highly durable and lightweight properties, play a pivotal role in the creation of the TASKA Hand, which holds an IP67 waterproof rating, allowing users to carry out everyday tasks with confidence, even in adverse conditions.

Furthermore, the integration of Accu’s antivibration solutions ensures the durability and longevity of the prosthetic hand in the face of challenging conditions.

Central to TASKA’s ethos is its designcentric approach, marked by empathydriven problemsolving and a commitment to enhancing both the functional and aesthetic aspects of prosthetic limbs.

Today, the company continues to develop new versions of the TASKA Hand with features such as improved dexterity which make it easier for users to achieve a secure grip and perform essential tasks like holding cutlery.

2. Labman Automation Industry: Robotics & Automation

Known for its cuttingedge robotics and laboratory automation, Labman Automation has been an Accu customer for several years, tapping into the company’s substantial range of fixings, fasteners and hardware to develop bespoke technology solutions.

Labman fully recognises the importance of embracing and advancing technologies, using its expertise to develop automated processes for the world’s leading companies.

From inception to manufacture, innovation is within the very DNA of Labman Automation. The team is fully committed to creating transformative productions and connected software solutions that not only integrate with existing processes, but develop and change whole industry operations for the better. Working closely with its worldwide customer base in over 50 countries, Labman produces world class automation solutions for Research & Development, labs and mass production facilities.

In partnership with Accu, Labman has created an innovative robot fighting championship, held annually at its HQ in North Yorkshire. The competition helps further the company’s efforts in recruiting talented young designers, engineers and technicians, whilst giving competitors a fun opportunity to showcase their skills.

Geared primarily towards students, but also professional combat robotics teams, this competition serves as a platform for testing their design and engineering prowess in constructing battleready robots. Drawing inspiration from the iconic TV series Robot Wars, participants unleash their creations in a specially designed bulletproof arena, striving to immobilise opponents through any means possible.

Following the success of its inaugural FightFest event in 2021, Labman joined forces with Accu to further elevate the competition. This partnership injects additional funding into the championship, with the dual objective of increasing awareness about FightFest and fostering a dynamic learning environment for

//////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 09

Labman Automation has been an Accu customer for several years, tapping into its substantial range of fixings, fasteners and hardware to develop bespoke technology solutions.

COVER PROFILE

3. Arribada Initiative Industry: Environmental & Conservation Technology

The Arribada Initiative, a notforprofit organisation, is dedicated to the development of open and accessible conservation technologies that are specifically designed to better protect our planet.

Collaborating with global conservation groups, such as National Geographic, WWF, and RSPB, Arribada works to create affordable and accessible solutions for the conservation challenges that we face today.

Led by Alasdair Davies, a dedicated conservationist, the team conducts thorough research and development to design revolutionary hardware such as timelapse cameras and marine enclosures.

Arribada’s collaborations extend to projects across the globe, including its Horizon tracking platform being used to study plastic waste movement in rivers and oceans. The organisation also aids WWF in detecting polar bears using thermal cameras in the Arctic, develop satellitebased sea turtle tags in Africa, and monitor penguin rookeries in Antarctica with timelapse cameras.

For a comprehensive understanding of animal behaviours, these innovative technologies need to be incredibly resilient to endure the extreme conditions of the natural world – much like those found in the depths of the ocean or the chilling embrace of the Antarctic winter.

Given these challenging environments, Arribada relies on Accu’s extensive range of Stainless Steel Screws, Nuts, Bolts, and Fixings to securely seal enclosures, ensuring they remain impervious to saltwater immersion and harsh conditions.

Similarly, on land, its equipment mounts and scaffolds are fortified with the same highperformance components to guarantee integrity, strength, and longlasting performance.

In fact, Arribada’s Antarctic timelapse camera stands as a remarkable testament of the longevity of these components. Whilst initially designed for a one year deployment, the position of sea ice blocked access for the team preventing a timely retrieval. Impressively enough, the timelapse camera persisted for over 3.5 years before finally being recovered, with its content intact and successfully downloaded.

4. Temple Cycles Industry: Bicycle Manufacturer

Temple Cycles, a Bristol based bike manufacturer, breathes new vitality into the cycling industry with its commitment to durable and timeless bicycles that are ‘Built To Last’.

Challenging the ‘throw away, upgrade’ culture commonly found in mainstream bicycle manufacturing, Temple Cycles aims to create quality bikes that are quite the opposite –simple, easily repaired and designed to become vintage.

As a matter of fact, the allure of reliable vintage bikes happens to be the source of inspiration to launch Temple Cycles, over a decade ago.

Founder Matt Mears, influenced by his Somerset cycling experiences, developed a keen fascination with vintage bikes. During his Mechanical Engineering studies, he restored bikes from the 1960s80s, admiring their resilience and pure simplicity.

Recognising the challenge of finding an allencompassing modern bike that mirrors the quality of their vintage predecessors, he aimed to create his own.

Temple Cycles officially launched in 2012, operating from its Bristol workshop, a dynamic hub for constructing, designing, and refining their bicycles.

In 2019, the brand extended its presence with the launch of a London store. Serving as a valuable extension to the workshop, this store grants inquisitive shoppers and cycling enthusiasts the opportunity to explore their offerings firsthand, testing out the bikes in person.

The brand’s design process, akin to Accu’s own commitment to quality, spans from conception through to testing.

As is to be expected for a bike that is ‘Built To Last’, component selection plays a vital role in the design process with each part being selected for its high quality and longevity. From mudguards to rack mounts installation, Temple Cycles uses a range of Accu’s Stainless Steel components throughout the assembly of its bikes.

For such a dynamic product, it is crucial that the components chosen for the bike are resilient against everyday wear and adverse weather conditions. With inherent resistance to corrosion and oxidation, A2 Stainless Steel proves to be durable and highperforming in such environments.

“Accu’s M5 Bolts are used throughout the bike assembly, from mudguard assemblies, to rack mounts and bottle cage mounts. We use Accu as we consistently get a quality product, and the delivery options are quick and reliable.” Says Dexter Robinson, Operations Manager for Temple

///////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// 10 torque-direct.com

Cycles.

Accu’s M5 Bolts are used throughout the bike assembly, from mudguard assemblies, to rack mounts and bottle cage mounts.

Arribada relies on Accu’s extensive range of stainless steel fixings to securely seal enclosures, ensuring they remain impervious to saltwater immersion and harsh conditions.

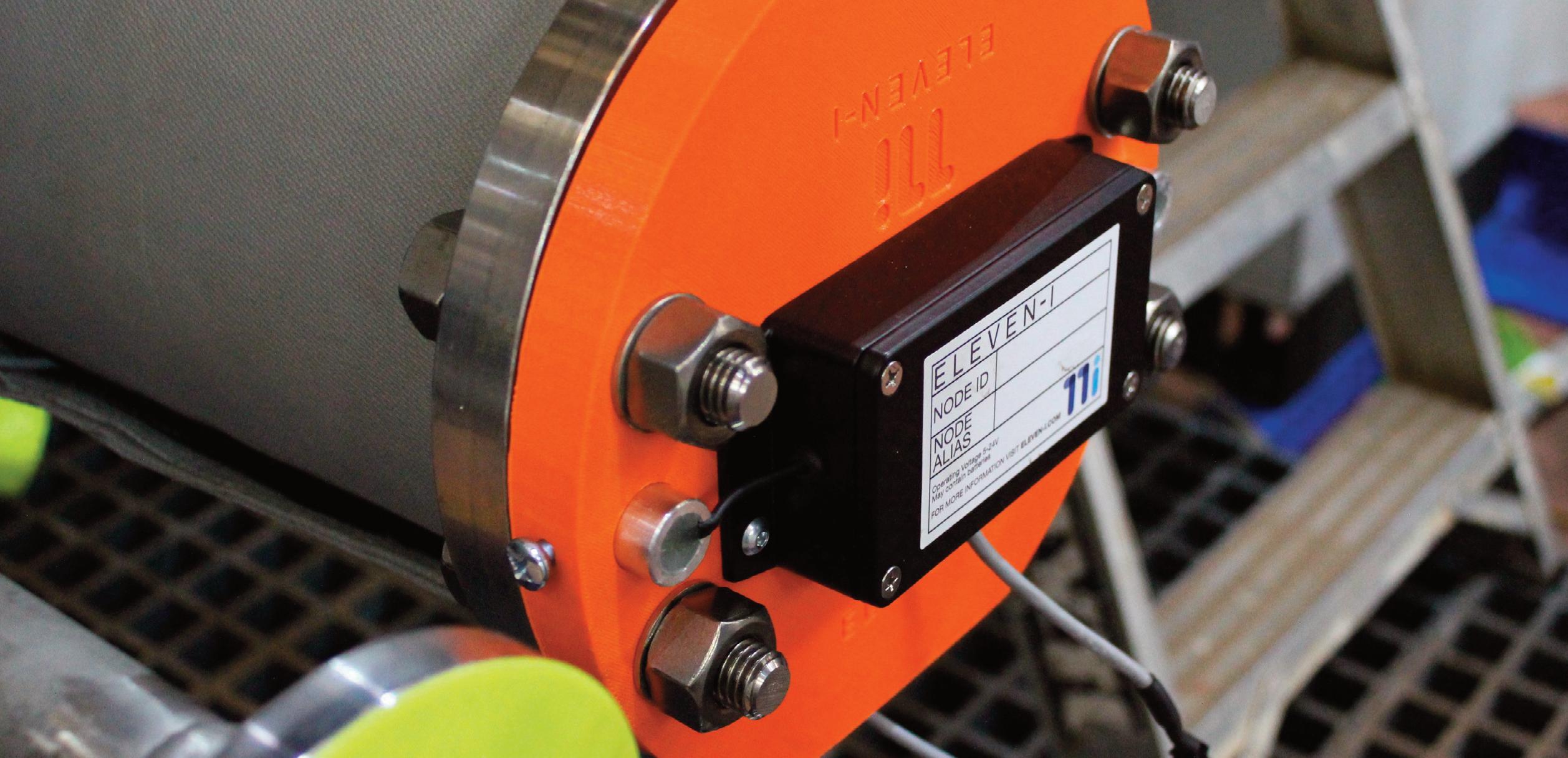

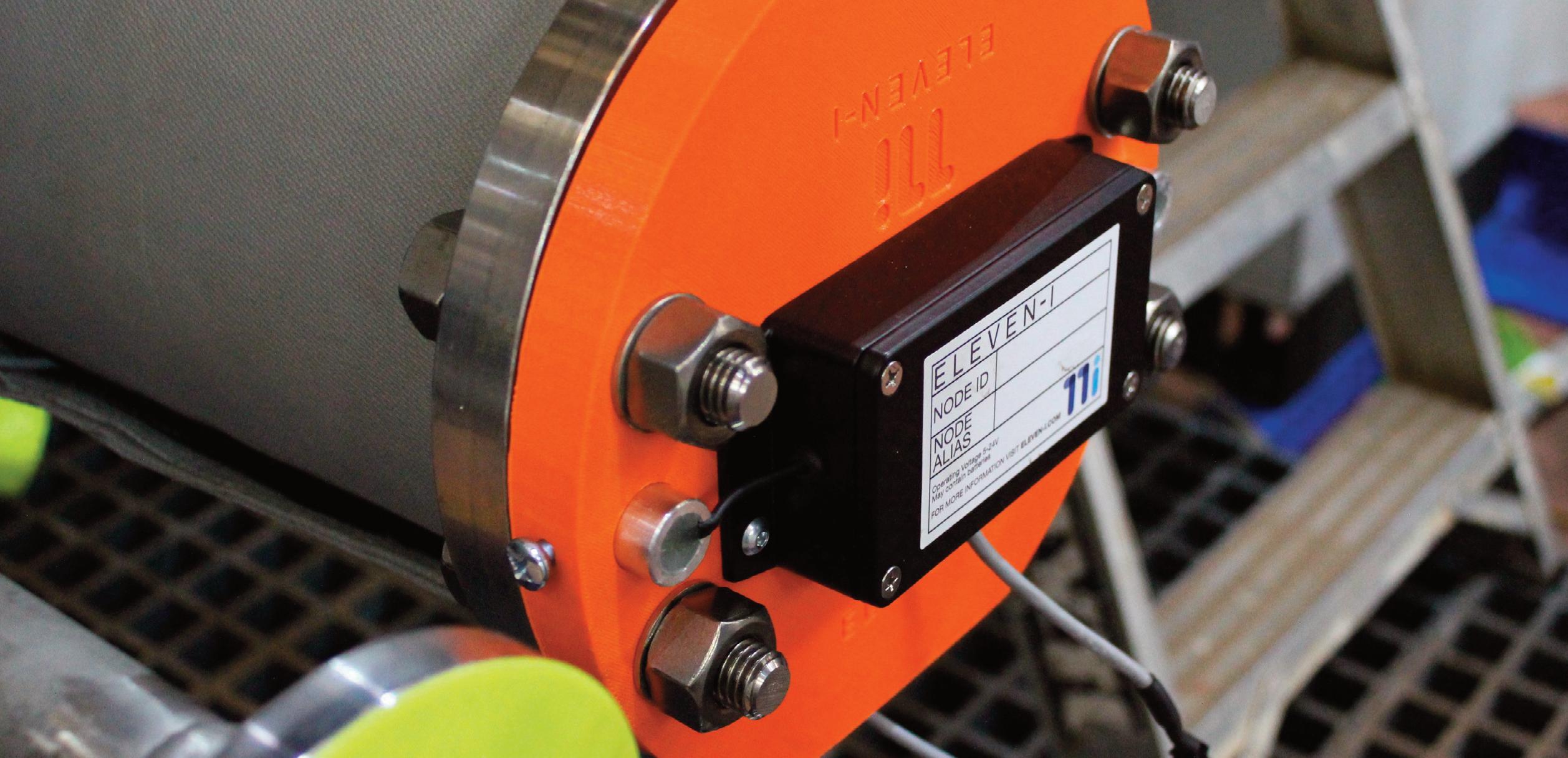

5. Eleven-I Industry: Energy & Environmental Asset Monitoring

Wind energy has rapidly emerged as a pivotal player in the global quest for sustainable power sources. As wind turbine installations continue to expand, the efficiency of maintenance operations becomes paramount. A groundbreaking solution is on the horizon with Eleveni, and its revolutionary technology that’s set to transform wind turbine maintenance.

Eleveni redefines the landscape of wind turbine upkeep through its innovative approach. Traditional maintenance methods often involve timeconsuming manual inspections and costly downtime. However, Eleveni harnesses the power of cuttingedge technologies such as sensor nodes and predictive analytics software to streamline and enhance maintenance procedures.

By continuously collecting data from sensors embedded within the turbines, Eleveni’s systems can detect early signs of wear and tear, as well as potential malfunctions. This datadriven approach enables maintenance teams to intervene proactively, preventing costly breakdowns and minimising operational disruptions.

Eleveni uses Accu for all of its fixings, particularly M4 to M6 Stainless Steel Screws in a range of head and drive types, plus the Hex Nuts and Locking Nuts to go with them. The company firmly believes that developing strong working relationships with suppliers is key to success, particularly in maintaining these links as they grow.

One of the key advantages of Eleveni choosing Accu for its component needs is the ability to maintain a lean supply chain, keeping stockholding to a minimum to avoid tying up capital on the shelf. This perfectly suits its business model, as devel

oping specially designed bespoke asset monitoring technology typically means highly targeted smallscale production.

Eleveni stands at the forefront of a new era in wind turbine maintenance. Through the integration of its analytics software and sensor technology, the business is not only enhancing operational efficiency for its customers, but also contributing directly to the sustainability of the entire wind energy sector. As the world races to meet its renewable energy goals, these innovations from Eleveni are catalysts for progress, revolutionising the way we harness and develop the technology to create clean and abundant wind power.

www.accu.co.uk

////////////////////////////////////////////////////////////////////////////////////////////////////////////////

torque-direct.com 11

Eleven-i’s systems can detect early signs of wear and tear, as well as potential malfunctions.

“ELEVEN-I USES ACCU FOR ALL OF ITS FIXINGS, PARTICULARLY M4 TO M6 STAINLESS STEEL SCREWS IN A RANGE OF HEAD AND DRIVE TYPES, PLUS THE HEX NUTS AND LOCKING NUTS TO GO WITH THEM.”

SECURING FUTURE CITIES

5 reasons why security fixings are vital for the future of urban planning

As cities grow, the need for robust security measures becomes increasingly critical. Security fixings and fasteners play a crucial role in ensuring the safety and longevity of urban infrastructure. Antitheft and antitamper security fastener specialist Hafren Fasteners has listed five ways in which these types of fasteners will be of importance for our future cities.

PROTECTING CRITICAL INFRASTRUCTURE

Security fixings offer a proactive approach to safeguarding essential components. Tamperresistant screws, bolts, and nuts make it significantly harder for unauthorised individuals to gain access to critical infrastructure components, preventing potential disruptions, damage or even sabotage. Urban planners can incorporate security fixings to bolster the resilience of critical infrastructure and ensure uninterrupted services.

IMPROVING PUBLIC SAFERY

Security fixings play an important role in securing public spaces, street furniture and amenities. Tamperproof fasteners can help to minimise the risk of vandalism, theft or intentional damage to public installations such as benches, street signs, lighting fixtures and public art. In addition to enhancing public safety, security fasteners can also help to create a sense of security in urban environments.

MITIGATING RISK

Modern cities face everevolving threats, such as terrorism and criminal activities. Security fixings can help to counteract these risks by offering enhanced protection against unauthorised access, tampering and forced entry. Utilising advanced fastening systems that are resistant to manipulation, urban planners can reduce vulnerabilities in highrisk areas like government building transportation systems and sensitive installations. Strengthening security measures can help to deter potential attackers and safeguard the wellbeing of citizens.

SAFEGUARDING SENSITIVE INFORMATION

In the digital age, safeguarding sensitive information and data is of the utmost importance. Security fixings play a vital role in protecting equipment that holds confidential or sensitive information, such as data centres, control rooms and communication networks. Temperresistant fasteners can be used to secure cabinets, racks and enclosures that house critical technology infrastructure in order to ensure that sensitive information remains protected from unauthorised access. Robust security fixings can provide an added layer of defence against data breaches and potential disruptions to essential services.

FUTURE-PROOFING

For successful sustainable urban planning, environmental considerations must be considered alongside social and economic resilience. By integrating security fixings into urban infrastructure, planners can extend the lifecycle of assets and reduce maintenance costs. Tamperproof fasteners also minimise the need for frequent repairs or replacements, resulting in longterm cost savings. Secure urban environments foster economic growth, attracting businesses, residents and toourists who value safety and security.

As cities continue to evolve and face new challenges, Hafren says security fixings will play a crucial role in ensuring the safety, resilience and sustainability of urban environments. Tamperresistant fasteners are essential for protecting critical infrastructure, enhancing public safety and mitigating risks.

www.hafrenfasteners.com

///////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////

12 torque-direct.com TECHNICAL INSIGHTS SAFETY & SECURITY APPLICATIONS

Hafren's security fasteners save time and money when fixing applications that require a firm hold

”SECURITY FIXINGS CAN HELP TO COUNTERACT THESE RISKS BY OFFERING ENHANCED PROTECTION AGAINST UNAUTHORISED ACCESS, TAMPERING AND FORCED ENTRY.“

LANFRANCO: SELF-LOCKING SAFETY

French selflocking safety systems manufacturer J. Lanfranco has added more capabilities and equipment to its quality department that it claims ensures the same level of quality expertise as private laboratories. The company is compliant to standards NF EN ISO 8982, NF EN ISO 35062, NF EN ISO 2320 and NF E250352.

The latest investments guarantee the company’s safety fasteners are designed to meet the highest standards in the railway, mining, nuclear, aeronautical and petrochemical sectors. One of the machines that the company has invested in includes the Automatica, a new measuring bench capable of performing torque and tension tests from M5M39 thanks to a fourway sensor and inthread coefficient. The level of precision offered by the bench allows J. Lanfranco to measure the performance of its surface treatments and Filmogene.

Another investment made by the firm includes the ZEISS binocular machine, which is equipped with a magnification capacity of 1,000x and integrated measuring software that enables the company to directly control the protection thicknesses of its fasteners. This destructive test enables the company to ensure that its products comply with the strictest constraints.

The improvements have allowed J. Lanfranco to strengthen its expertise as a manufacturer of safety fasteners, and remain a major player in the global safety fastener industry. www.lanfranco.fr

”THE LATEST INVESTMENTS GUARANTEE THE COMPANY’S SAFETY FASTENERS MEET THE HIGHEST STANDARDS ACROSS MULTIPLE INDUSTRIES.“

////////////////////////////////////////////////////////////////////////////////////////////////////////////////

torque-direct.com 13

The Automatica measuring bench

RIVETS & RIVETING TECHNOLOGY

KEEP THE PACE

RIV730 and RIV740 are suitable for rivet nuts up to M12. Flexibility, ease of use and a powerful brushless engine are among the key features of the new product range.

NEW TOOL RANGES

The RIV710 battery tool for blind rivets from Ø2.4 up to Ø4.8 mm is equipped with a powerful and reliable brushless motor and longlasting battery, making simplicity and reliability its strong point. The tool offers customers a valueadded solution capable of covering a wide range of applications for rivets in all major alloys and steels, featuring a marked nozzle for easy rivet matching and an end cone made of steel for greater strength and durability.

Other key features of the RIV710 include a bright LED indicating the operation of the tool, an easily removable container for nails and an ergonomic handle made of soft rubber. The tool is suited to applications such as general tanks, carpentry, building materials, corrugated panels, insulated roofing, plastics, batteries, cabinets and switchboards, among others.

Rivit is reinforcing its global presence on the fasteners and tools market with a double approach: from one side the company intends to “keep the pace” on the Italian market where the brand is wellknown and appreciated, while from the other it aims to “increase presence and share in Europe and overseas countries” where there are many interesting opportunities.

First, let’s deep dive into the Rivit strategy in Italy. The core business of blind rivets, rivet nuts and related tools is going to be boosted by the introduction of new tools, a new important distribution partnership with PEM/Haeger for selfclinching fasteners, and a partnership with the etailer “Mister Worker” with a new physical point of sales on top of the web platform. This strategy will consolidate the Rivit brand on traditional core business while opening up more opportunities both in the industrial and retail channels. This will consolidate a multichannel Rivit approach in Italy that is furtherly enhanced by the synergies with the sister companies FERVI and RIFLEX.

Concerning the markets outside of Italy, Rivit is actively working on a selected network of business partners on the main GEOs. USA is among the most important markets for Rivit, especially for the automotive market, together with Germany, France and the Nordics. The East and Far East are the areas where Rivit’s growth is typically more consistent. Industrial automation is for sure the market segment with the highest potential, as a result of the skilled worker shortage that began with the pandemic and the need to increase automated solutions with big data to improve efficiency during the manufacturing process.

As part of this strategy, Rivit is increasing its battery tools offer with a brand new range of products for blind rivets and rivet nuts. The new RIV710 and and RIV720 are designed to cover the needs of the blind rivet market up to 6.4, while

The RIV720, while equipped with the same powerful and reliable brushless motor and battery, is designed for blind rivets from Ø2.4 up to Ø6.4 mm. Additional features include a knurled ring nut on the end cone that can be loosened and tightened by hand and a robust start button integrated into the main body. As well as the applications met by the RIV710, the RIV720 can also be used within solar panels and roof brackets of variable thicknesses. In regards to packaging, the tool comes equipped with a new practical and durable case with an extensive array of accessories, including two batteries. www.rivit.it

”USA IS AMONG THE MOST IMPORTANT MARKETS FOR RIVIT, ESPECIALLY FOR THE AUTOMOTIVE MARKET.“

PRODUCT

//////////

INNOVATIONS

14 torque-direct.com

Rivit’s Head of Product Marketing & Development Marco Mallegni provides an overview of the company’s growth strategy and how it is increasing its battery tools offering

/////////////////////////////////////////////////////////////////////////////////////////////////////

The new range comes equipped with a new practical and durable case

Metal anchoring for concrete. Advanced. Approved. Available.

The demands of fixing into uncracked and cracked concrete are wide and varied. Which is why EJOT’s range of solutions are equally varied, from the temporary fastening of facade scaffolding and cladding to the anchoring of structural elements such as railings, steel stairs, facade components. The high quality of EJOT and LIEBIG anchoring products ensures safety and high load-bearing capacity values – promoting confidence in design and specification.

Call EJOT UK: 01977 687040 EJOT online: ejot.co.uk LIEBIG online: liebig.co.uk SUBSCRIBE

LATEST NEWS IN FASTENERS & TOOLS Want to stay up to date with the latest features, products and developments? Get our magazine delivered to your door or inbox Scan this QR code to visit the online subscription page www.torque-direct.com

MADE

BY EJOT WORLDWIDE

FOR THE

DIVERSIFICATION BREEDS SUCCESS

Fasteners specialist FIXI Group discusses how diversifying its product portfolio is opening up new markets

Since 1984, FIXI Group has manufactured and supplied a wide range of fasteners and fastening technologies to the metal sheet, solid parts and plastic component industries. Serving hundreds of customers in Europe and overseas, the group has continuously improved its services and range of products to offer more customerorientated solutions in these industries.

Historically, the core of FIXI’s business has focused on metal sheet working fasteners such as blind rivets, rivet nuts, and selfclinching and welding fasteners. Now, the company is undertaking several initiatives to introduce new lines of fastening systems to address a variety of different industries.

SELF-ANCHORING INSERTS

Over the last few months, FIXI has developed and begun to sell its own selfanchoring insert for stone and solid surfaces, known as the IXKB Series. According to FIXI, feedback on the new range from its customers has been positive, encouraging the R&D team to further develop the product not only for the interior design industry for applications like kitchen and bathroom countertops, but also for the construction industry. To this end, the company has started a cooperation with important companies specialised in wall cladding systems to offer structures and anchors for a full solution in cladding and façade projects.

BONDING FASTENERS

Another project that FIXI’s R&D department is carrying out involves creating a new line of bonding fasteners for composites, with a full range of studs, standoffs, and nuts on different types of plates. With the new range, the company plans to compete in new emerging industries such as composites and new materials.

RIVETS & RIVETING TECHNOLOGY ///////////////////////////////////////////////////////////////////////////////////////////////////// PRODUCT INNOVATIONS //////////

16 torque-direct.com

FIXI is entering a range of new industries with its products

The R&D department is developing several new product ranges

FIXI’s core product range includes blind rivets, rivet nuts and self-clinching and welding fasteners

PNEUMATIC TOOLS

Meanwhile, FIXI has also been working on the development of an innovative pneumatic tool for installing keylocking inserts, known as Keensert. The tools is designed to provide a more efficient solution for installing such inserts compared to other commonly used manual tools.

A SUCCESSFUL START

According to FIXI, the first few months of 2023 were successful for the group, with an increase in domestic and international sales of around 10% compared to the same period in 2022. For many other markets, the group has noted some slowdowns in the European production growth, especially from typically

high sales countries such as Germany and France. However, the company considers this to be a temporary consequence of the international measures aimed at countering the inflation peak experienced in the past few months.

To best prepare itself for when sales will begin to rise again, FIXI is enlarging its stock capability with the acquisition of a new building next to its headquarters in Turin. A new warehouse spanning more than 3,200 square metres will be ready for operation from September, while a new quality department containing the latest technologies and equipment will soon be operative in a new facility as well. In total, the group’s five branches located across Italy make up more than 6,000 square metres, guaranteeing plenty of space for all its ranges of fasteners and fastening technologies. As a result, this will ensure fast deliveries for all FIXI’s existing and new customers across Europe and overseas.

www.fixi.it

//////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 17

”THE COMPANY IS UNDERTAKING SEVERAL INITIATIVES TO INTRODUCE NEW LINES OF FASTENING SYSTEMS.“

”FIXI IS ENLARGING ITS STOCK CAPABILITY WITH THE ACQUISITION OF A NEW BUILDING NEXT TO ITS HEADQUARTERS IN TURIN.“

JPG SYSTÈME

ON THE RUNWAY

JPB Système’s Grégory Chauvet shares his thoughts on the current trends, challenges and opportunities facing manufacturers within the aerospace industry

Now that we’re past the half-way point in 2023, what are your main observations so far and are they those of opportunity or challenge?

It’s probably a mixture of both. Following COVID, this year marks the first full year in which most of the industry is back at 100%. Be it for business or leisure, people are travelling again, but the pressure is on to get back to full volumes quickly and even surpass those of 2022, while struggling with an industrywide recruitment issue. To compound things further, other external factors have contributed to material shortages, which has in turn driven up costs. In fact, I would say that rising costs across the board – encompassing materials, energy prices, salaries and other expenses that are an ongoing issue for many within the whole aerospace manufacturing and supply chain. So, while we are pleased to be getting growth back on track and putting COVID in the rearview mirror, like many others, we are grappling with plenty of other concurrent challenges.

With the digitalisation of general manufacturing continuing to gather pace, is this something that you are also seeing within the aerospace sector?

I think it’s recognised that within the aerospace sector, the pace of digitalisation is somewhat slower than in other key sectors like automotive. It is of course happening, especially among large players, but there are still plenty of companies deploying older, mechanised technologies. JPB Système is ahead of the curve having begun to automate its operations some time ago. Indeed, we were one of the first companies in France to estab

lish Industry 4.0 production that increasingly deploys robots and technologies like 3D printing to advance this. We’re not seeing it as onlookers; we’re embracing it and driving it.

The benefits of automated production are even more obvious if you consider the current issue of skilled labour shortages that I mentioned previously. We would all favour employing more skilled personnel if we could, but we are nonetheless offsetting that problem if we are able to automate related areas of manufacturing processes and make ourselves less reliant upon it when it isn’t available.

What do you think manufacturers and the aerospace industry ore generally should be doing to overcome the current skill shortage issue?

We must come together as an industry to not only tackle the current recruitment challenge, but also constantly highlight our worth so that over the long term, we ensure the next generation remains enthusiastic about joining the aviation sector.

It’s twofold: first, as employers we need to make the effort to attract people to the industry in the first place. From our own perspective, we often welcome students into our facility to showcase our advanced production operations and enable the potential operators and engineers of tomorrow to see for themselves the exciting and attractive workplaces the sector offers – environments that are a sometimes a million miles from their preconceptions.

Second, once they are through the door, employers need to demonstrate their commitment to new hires by supporting growth either within the role or department, but also across other areas of the company. For me, it’s an obligation to ensure our people remain permanently satisfied. That means encouraging them to acquire experience in other areas, building a stronger and more rounded set of skills so that they are energised and inspired

///////// ///////////////////////////////////////////////////////////////////////////////////////////////////////////

18 torque-direct.com TECHNICAL INSIGHTS

Gregory Chauvet, General Manager at JPB Système

as they develop and learn, rather than remain in one lane for the whole time they are with us.

Fundamentally, it’s about always proving to your employees that they are valued. I think the fact that at JPB Système, we were able to ride out the COVID 19 pandemic with zero reduction in headcount, underscores that.

What advice can you offer to other manufacturers to help them navigate this tough sector?

I think it’s about exploring ways to diversify one’s product portfolio, while inbuilding innovation within that solutions offering. In our instance, despite a longstanding heritage as a supplier to aerospace engine manufactures, we continue to look at how we take appropriate products into other relevant sectors like rail or energy where there may be similar application needs. Beyond existing products for new markets, we have already diversified as a company to provide entirely new advanced nonsector specific solutions for the wider manufacturing industry, evidenced by our KeyProd production monitoring solution. I would always say customer satisfaction and quality are paramount. After all, a technologically advanced product that meets the customers’ needs is of little use if you fail to hit delivery times or there are failure issues. Companies that can successfully address that collective mix stand a farbetter chance of not only keeping their existing customers but winning new ones to futureproof business.

www.jpb-systeme.com

//////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 19

”WE WERE ONE OF THE FIRST COMPANIES IN FRANCE TO ESTABLISH INDUSTRY 4.0 PRODUCTION THAT INCREASINGLY DEPLOYS ROBOTS AND TECHNOLOGIES LIKE 3D PRINTING.“

JPB Systeme was one of the first companies in France to establish Industry 4.0 production

ADVANCED ENGINEERING

REBRANDING WITH A FUTURE FOCUS

Now in its 14th year, Advanced Engineering will once again take place at the NEC in Birmingham between 12 November. The show returns this year with a fresh and futurefocused rebrand, removing the previous show zones from its exhibition floor and introducing a main stage for the event’s wellattended forums.

“Making these challenges wasn’t any easy or a quick decision,” says Alison Willis, Director of Easyfairs, the organiser of Advanced Engineering. “We spoke to over 200 exhibitors, visitors and speakers to make sure that any changes made were futureproof and reflective of all stakeholders. We realised that many of the issues that our exhibitors and visitors are facing align, no matter what sector they’re from. Take sustainability as an exam

ple – we wanted to make sure that our floor plan gave attendees the best opportunity of sharing ideas and solutions to challenges like this.”

Originally starting out as a specific aerospace event 14 years ago, Advanced Engineering has since expanded greatly. “2023 felt like the right time to break down the walls that separated our exhibitors to fully encourage collaboration across industries and to prepare the show for a new era of manufacturing and engineering,” Willis adds.

To ensure that visitors and exhibitors can still easily find relevant contacts, exhibitors at the show will now be categorised by the services, products and solutions they offer. Companies will be able to highlight all of the sectors they work in, removing any limitations created by the specific show zones. In addition to encouraging visitors from the show’s established sectors, Advanced Engineering now hopes to attract visitors from newer sectors such as marine, security, rail, energy, sports and leisure, and medical.

The exhibition floor was previously divided into several different zones covering composites, automotive, aerospace and connected manufacturing. Now, the longestablished composite zone will remain while the other zones will be removed. These sectors will still retain a strong presence at the event, though, with the industryspecific forums remaining. There will also be a main central stage on the exhibition floor where discussions about key challenges in the engineering sector will take place.

This year will see the show welcome back a full speaker programme with representatives from some of the leading companies in UK manufacturing. Attendees will be able to access the talks free of charge, totalling around 50 ours of free CPD accredited learning. Previous speakers have hailed from leading firms such as Jaguar Land Rover, Make UK, RollsRoyce and Airbus.

www.advancedengineeringuk.com

////////// INDUSTRY EVENTS > SHOW PREVIEW 20 torque-direct.com

Advanced Engineering returns to the NEC in November with an overhauled exhibition floor plan. Torque Direct previews what attendees can expect from this year’s event

”2023 FELT LIKE THE RIGHT TIME TO BREAK DOWN THE WALLS THAT SEPARATED OUR EXHIBITORS TO FULLY ENCOURAGE COLLABORATION ACROSS INDUSTRIES AND TO PREPARE THE SHOW FOR A NEW ERA OF MANUFACTURING AND ENGINEERING“

/////////////////////////////////////////////////////////////////////////////////////

SMART FACTORY AND SUSTAINABILITY

Aimed at supporting manufacturers and Tier 1 suppliers in the transition to fully automated operations, Atlas Copco Tools & Industrial Assembly Solutions is doubling its footprint at this year’s Advanced Engineering show. The smart tooling and industrial assembly solutions specialist will be showcasing its Smart Factory philosophy during the event.

Central to Atlas Copco’s ‘Smart Integrated Assembly’ is the goal of eliminating costly rework and material wastage, in pursuit of sustainable manufacturing. Advanced Engineering will see Atlas Copco feature ‘Avantguard’, its latest generation errorproofing software. The webbased solution provides ultimate flexibility, with the software able to run on any device with any operating system, that integrates with existing customer IT infrastructure.

Atlas Copco’s ‘Smart Integrated Assembly’ is designed to wirelessly connect all digital tools throughout the factory, harnessing the latest 5G connectivity on selected tool models in order to optimise production, improve quality, reduce costs and energy consumption. Utilising its customisable ‘ToolsControl’ solution removes the need for separate controllers for each tool on the production line. Atlas Copco’s innovative software creates a single environment for connecting every tool in the factory to the client’s MES (Manufacturing Execution System), which delivers significant reductions in hardware costs and floor space.

Complementing the assembly solutions being showcased will be ISRA VISION, part of the Atlas Copco group, that provides inspection systems which identify possible problems and defects at different stages of the production process, enabling manufacturers to further improve their quality assurance.

“As a strategic partner to manufacturers, Atlas Copco is fully committed to improving production efficiency by harnessing realtime data insights and hyper flexibility, as part of a smart manufacturing ecosystem,” says James McAllister, General Manager, Atlas Copco Tools & Industrial Assembly Solutions. “We are looking forward to demonstrating Smart Integrated Assembly with the ToolsControl ‘controller anywhere’ concept, as well as a comprehensive range of Smart connected solutions, including 5G and realtime software, to enable factbased decision making that will revolutionise production line design into a full Smart Factory.”

Atlas Copco’s stand will also feature a racing car in recognition of the company’s partnership with Red Bull Ford Powertrains, for the development of a new engine for 2026. Atlas Copco is providing Red Bull Ford Powertrains with a range of tightening technologies designed to boost innovation, enhance productivity and increase quality within the assembly process. Its Tensor IxB series of assembly tools with builtin controllers will revolutionise production line operation, providing improved

productivity and agility in the smart factory environment, while its Tools Talk 2 tool programming software will streamline the assembly line through simultaneous configuration of multiple power controllers and virtual tool stations from a single platform. Atlas Copco will also supply Red Bull Powertrains with ToolsNet8 data collection software and STR digital smart wrench, which will be used to disassemble the engines after use.

www.atlascopcogroup.com

INVESTING IN THE FUTURE

European Springs, a UK manufacturer and supplier of pressings, springs and wire forms, has invested a substantial £500,000 in its production capabilities, highlighting its dedication to precision and quality. The latest addition to its arsenal is a renowned Bruderer stamping press machine, known for its exceptional precision and efficiency. The machine integrates seamlessly with the company’s stateoftheart CNC machinery, solidifying its position as a leader in the manufacturing sector.

Bruderer machines have earned a distinguished reputation throughout the manufacturing sector, particularly in metal stamping and forming processes. These specialised stamping presses use for the shape or cut metal and other materials with precision dies and tooling, and are known for their precision, rapid cycle times and productivity.

Attendees at Advanced Engineering can find out more about the new capabilities enabled by the acquisition of the Bruderer machine during the show.

www.europeansprings.com

torque-direct.com 21

Atlas Copco’s Smart Integrated Assembly line

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////

The Bruderer machine will enhance component precision and quality

THE FUTURE IS ELECTRIC

This in-depth feature looks at the current trends and challenges facing the global road and rail transportation sectors, within which fasteners play a crucial role in regards to safety, innovation, and enabling technological advances

The global transportation industry has undergone a turbulent few years. Against the backdrop of the recent fuel crisis, the industry has faced problems regarding funding, the efficiency and fairness of fuel taxes, and the need to seek transparent and sustainable fuel alternatives. Furthermore, the growing share of electric vehicles (EVs) and the development of the charging infrastructure needed to support this has been hampered somewhat by the current electricity crisis largely as a result of the ongoing conflict in Ukraine.

Aside from these issues, the transport sector is also facing a talent crunch of skilled engineers and specialists who are depended upon to provide the technological advancements required by the industry to become more efficient, sustainable, and safe.

Multinational professional services provider Deloitte has identified five key trends that will influence the road and rail industries throughout 2023 and beyond: Sustainable funding mechanisms, EVs, modernisation of transportation systems, more resilient transportation networks, and digital and technology innovation.

As a result, 2023 is shaping up to be a vital year for the industry with the added issues of ongoing staff shortages and strikes, the increasing effects of climate change, and evolving passenger demands. Let’s dive deeper into the crucial role that fasteners play in both the road transport and rail sectors, and how innovative fastener solutions are helping to spearhead to technological advancements in these industries.

FASTENERS FOR RAIL

Rail fastenings are used to secure rails into chairs or directly to sleepers in order to facilitate an effective transfer of force between the train and track, prevent the longitudinal movements of rails and dampen the noise and vibration emanating

////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH ROAD & RAIL – ANALYSIS 22 torque-direct.com

”THE TRANSPORT SECTOR IS ALSO FACING A TALENT CRUNCH OF SKILLED ENGINEERS AND SPECIALISTS WHO ARE DEPENDED UPON TO PROVIDE THE TECHNOLOGICAL ADVANCEMENTS.“

from them. These types of fastening systems are specifically designed to limit the rail’s ability to rotate around its outer edge, assist in maintaining track gauge, and prevent creeping.

There are several different types of rail fastenings. Fish plates are used to keep the rail line properly aligned to ensure continuity of the rails and allow for expansion and contraction due to changes in temperature. Spikes, meanwhile, serve the purpose of holding the rails to the wooden sleeper, and should possess significant strength for holding the rails in position. They should also be easy to fix and replace to ensure straightforward and convenient maintenance. Elsewhere, bolts are used to fasten fish plates to the rails at every rail joint, fix sleepers to girders, and attach chairs and bearing plates to wooden sleepers. Comprised of cast iron, chairs are deployed to hold the bullheaded and doubleheaded rails in the desired position, while keys small and tapered wooden or steel pieces – are used to connect the rails to chairs on metal sleepers. Additionally, bearing plates are placed between the flatfooted rails and timber sleepers on a track, and are comprised of cast iron, wrought iron or steel.

When selecting which of these fasteners to use, engineers must consider several different factors:

Permissable speeds

Category of the track

Loads emanating from the acceleration/deceleration of trains

Track geometry

Vehicular axle loads

Electrical insulation

Underlying formation and structures supporting the track

The form of track construction

FASTENERS FOR ROAD

When it comes to the road sector, there are many different types of applications for which fasteners are crucial. Bolts, nuts, screws, spacers and springs are used in practically every car component, and it is estimated that there are some 64,000 different fastener designs used throughout the automotive industry.

Metal fasteners, commonly iron or aluminium alloy, are used to position and fasten heavy items, engine parts and suspension components, while plastic fasteners such as connectors, pins, spacers and washers offer a lightweight solution to fastening together various materials for a wide range of car applications. In addition to securing the vital internal components of vehicles, fasteners also play a key role in numerous other vehicle applications, such as storage compartments on buses, seating fixings, soft trim fastenings for interiors, cab fixings for trucks, body panel fixings, and fastenings used in vehicle conversions, to name a but few.

Aside from the vehicles themselves, fasteners are also key to ensuring our road infrastructure is safe and secure. Heavy duty stud bolts, hex nuts, ground screws and other large fasteners are crucial in securing structures such as overhead gantries, roadside signs, tunnels, communication towers and other heavy structures that need to be held up safely in the vicinity of people. High quality fasteners provide a safe and secure foundation for highway and infrastructure applications that keep our freight and transport networks functioning effectively.

In this indepth feature, we hear from the fastener and fixing companies offering new and established fastening and fixing systems to the road and rail sectors to ensure better safety, reliability and security.

//////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 23

”HIGH QUALITY FASTENERS PROVIDE A SAFE AND SECURE FOUNDATION FOR HIGHWAY AND INFRASTRUCTURE APPLICATIONS THAT KEEP OUR FREIGHT AND TRANSPORT NETWORKS FUNCTIONING EFFECTIVELY.“

Coil springs are used in gangway couplers, break heads and engine spring exhaust valves

TRANSFORMING EFFICIENCY & SAFETY

Transportation is crucial for connecting people, facilitating commerce, and driving global economic growth. The railway and road industries are vital components of this transportation network, continuously striving to improve infrastructure, enhance safety measures, and promote sustainability. At GALA Group, we take great pride in being a leading provider of precisionengineered components that are revolutionising performance standards in transportation systems. With a strong focus on pushing the technological boundaries, we are actively shaping the future of transportation.

Recognising the pivotal role of transportation in our society, we understand the significance of excellence and innovation. Through our stateoftheart manufacturing facilities, we are at the forefront of transforming efficiency, reliability, and safety across various sectors, including railways, roads and offhighway applications.

ENSURING SAFETY AND RELIABILITY

Safety and reliability are paramount in railway systems. We specialise in providing a wide range of components tailored specifically for railway applications. Our product offerings include Disc Springs – DIN 2093 Std, High Tensile Fasteners and Studs, Gallock WedgeLock Washers, and Coil Springs. These meticulously engineered products are designed to withstand the rigorous forces and vibrations encountered in railway systems. Our hightensile fasteners and studs create strong and reliable connections, contributing to the overall safety and dependability of the Track Fastening system, protecting both passengers and cargo. Our products have been thoroughly tested and approved by leading OEMs in Germany, Japan, USA, Denmark and France.

////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH ROAD

24 torque-direct.com

& RAIL

GALA Group shares how it is transforming efficiency and safety in railway, road and off-highway transportation

”WHETHER IT’S THE TRANSMISSION SYSTEMS, FUEL INJECTION SYSTEM PARTS, BRAKES, OR SEAT RECLINING SYSTEMS, OUR COMPONENTS PLAY A VITAL ROLE.“

Disc springs provide reliable and consistent load distribution

One of our key offerings is Disc Springs, designed to provide reliable and consistent load distribution in the bogies and coaches of semispeed and highspeed trains. These springs efficiently absorb and distribute forces, ensuring stability and minimising the risk of component failure. With their ability to withstand heavy loads and resist fatigue, Disc Springs play a crucial role in maintaining the safety and dependability of railway infrastructure.

To enhance the integrity and stability of bolted connections, we utilise Gallock WedgeLock Washers in various applications such as traction motors, traction push rods, control arm bushes, outer bearing caps, gear box assemblies, and compressortofan fittings. These washers feature a unique design that creates a wedging action, effectively countering vibrations and dynamic forces. By maintaining optimal tension and preventing loosening, they ensure longterm reliability and prevent the risk of accidents or failures caused by loosened connections. Gallock Wedge Lock Washers provide an additional layer of safety, contributing to the overall stability of railway systems.

Coil Springs, meanwhile, are used in gangway couplers and for break heads and engine spring exhaust valves to provide suspension and cushioning in diesel locomotives and metros, ensuring a comfortable and smooth ride for passengers. These springs are carefully designed to absorb dynamic loads, vibrations and shocks, reducing the impact on rolling stock and enhancing passenger comfort. By minimising wear and tear on train components and ensuring a stable and comfortable travel experience. Coil springs play a significant role in maintaining the safety, reliability and passenger satisfaction in railway systems.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////

”WE SPECIALISE IN PROVIDING A WIDE RANGE OF COMPONENTS TAILORED SPECIFICALLY FOR RAILWAY APPLICATIONS.“

Fastening system for ballast-less track

torque-direct.com 25

Traction motor of locomotive

ENHANCING STABILITY AND ENDURANCE

In the realm of the road industry, we pride ourselves on being experts in supplying durable and highperformance components that are essential for maintaining stability and withstanding the harshest operating conditions. Our wideranging product portfolio includes heavyduty washers, cushion springs, slotted disc springs, coil springs and conical springs, each designed for specific systems within vehicles.

When it comes to breaks, our slotted disc springs enable precise load distribution and controlled deflection, ensuring optimal braking performance and driver confidence. And for the seat reclining system, our spiral springs deliver consistent force, allowing for comfortable adjustments and ensuring passenger comfort during long journeys.

In addition to these components, we offer damper and pressure springs with critical index and E1 and E2 parameters. These specialised springs are designed to uphold the integrity of road infrastructure and vehicles; smooth riding comfort and meet stringent performance requirements. For heavyduty applications, our conical springs provide reliable suspension support, even under heavy loads, contributing to stability and control.

Whether it’s the transmission systems, fuel injection system parts, brakes, or seat reclining systems, our components play a vital role. They are specifically engineered to absorb load forces, provide shock absorption and dampening, and ensure reliable force transmission. In essence, they significantly contribute to the overall performance and safety of vehicles on the road.

Through our contributions to the railway, road and offhighway sectors, we aim to enhance performance, safety and sustainability in transportation systems. We actively collaborate with industry partners to develop innovative solutions that address the evolving needs of modern transportation. GALA’s expertise positions the group as a driving force in propelling technological advancements and shaping the future of transportation, while actively contributing to the global connectivity and trade that drive our modern world.

www.galagroup.com

26 torque-direct.com ////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH

”TO ENHANCE THE INTEGRITY AND STABILITY OF BOLTED CONNECTIONS, WE UTILISE GALLOCK WEDGE-LOCK WASHERS“

ROAD & RAIL

Axel counting sensor

Bogie mounted braking system

Gallock Wedge-lock washers are designed to counter vibrations and dynamic forces

Gangway coupler

WE ARE EXHIBITING In-House Manufacturing Localise your fastener supply through our UK cold-form manufacturing facilities support@optimas.com www.international.optimas.com Reduce Your Total Cost of Ownership Consolidate your vendor base and partner with Optimas for all your fastener and component requirements Come and see us at our stand K110

FLEXIBILITY IN TUNNELLING

Heavy duty ‘post installation’ anchors are ideal for providing secure attachments in tunnel construction projects and schemes to refurbish or upgrade existing tunnels. From brackets for cabling, lighting, signage and traffic signals to ventilation equipment and overhead catenary systems in rail projects, the varied requirements of tunnel projects mean castingin all of the required anchors at the design stage is not feasible.

Shallow concrete depth, spacing restrictions and close edge distances, which are very typical challenges in construction projects, have routinely been major hurdles to cost effective anchoring because these scenarios often require the need for custommade anchors with high unit costs and lengthy lead times.

The LIEBIG Superplus BLS modular anchor from EJOT, however, is redefining the possibilities. As this is a selfundercutting anchor, it requires no special setting tool during installation, but most importantly it offers excellent performance characteristics with a relatively small hole diameter.

This means the anchor is particularly effective for applications where only a shallow embedment depth is possible, or where there is a need to either anchor at reduced spacings or close to the edge of the concrete – with potential cost savings because baseplates can be smaller than usual.

Hence why postinstallation anchors are important in tunnel construction. Unfortunately, however, the technical limitations of the vast majority of standard range anchors do not necessarily provide engineers or contractors with an easy or costeffective solution.

The Superplus BLS also enables two embedment depths per anchor diameter. This gives greater flexibility to the designer, as it enables the necessary embedment depth to be achieved to satisfy the design criteria without a need to change baseplate design.

By increasing the anchor length, as defined by both the effective embedment depth and thickness of the member to be fastened, a greater volume of concrete can be activated by the

////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH ROAD & RAIL 28 torque-direct.com

EJOT

UK’s anchoring systems specialist Paul Papworth explains how a modular post-installation anchor can provide greater flexibility in tunnelling applications

”THE ANCHOR IS PARTICULARLY EFFECTIVE FOR APPLICATIONS WHERE ONLY A SHALLOW EMBEDMENT DEPTH IS POSSIBLE.“

Tunnel catenary systems are the kind of applications ideally suited to Superplus BLS

The cone of influence has an impact on the spaces permissible between anchors and how close they can be used to the edge of the concrete

CONE OF INFLUENCE

anchor, increasing the concrete capacity and thus the tensile resistance of the anchorage.

This anchor’s versatility comes from the way it utilises a larger cone of influence, given its deeper embedment in the

concrete. Increased embedment depth equals increase cone volume, which in turn leads to increased cone surface area and increased tensile resistance.

Crucially, this larger cone of influence impacts on the spaces permissible between anchors and how close they can be used to the edge of the concrete. Using anchors at closer spacings is beneficial in applications such as tunnel ventilation fans and overhead catenary supports where the position of the support may be close to the edge of a precast tunnel segment.

The modular design of Superplus BLS adds to its flexibility due to the bespoke lengths of the main threaded bolt and simple adjustments to the distance sleeve, which relates directly to the base plate thickness, can be made by EJOT at our Yorkshire factory with relative ease.

www.liebig.co.uk/ejot

CUSTOMISABLE FOR BESPOKE LENGHTS

Superplus BLS anchor can be easily customised without the lengthy lead times or high costs usually associated with bespoke solutions

//////////////////////////////////////////////////////////////////////////////////////////////////////////////// torque-direct.com 29

”THE MODULAR DESIGN OF SUPERPLUS BLS ADDS TO ITS FLEXIBILITY DUE TO THE BESPOKE LENGTHS OF THE MAIN THREADED BOLT AND SIMPLE ADJUSTMENTS TO THE DISTANCE SLEEVE.“

Using Superplus BLS closer to the edge of concrete and at closer spacings can deliver many benefits

DRIVING TRUCK SAFETY

through improved safety measures

Few traffic safety topics are more earnestly discussed in Germany than the need for modern safety systems on trucks. Figures from previous years published by the German Federal Statistical Office have noted thousands of accidents involving trucks and cyclists, with a significant number of these leading to fatalities. Many f these incidents were caused by trucks not being able to see cyclists when turning.

As a result, demands to ban trucks completely from German cities are on the rise, while pressure is growing on the government to take action. An EUwide regulation on extended truck safety systems is already under discussion but is not expected to become law before 2024.

Taking the initiative with truck safety

One company looking to get ahead of the new legislation is EDEKA Südbayern, one of the largest food retailers in Germany. Four years ago, the company developed a turning assistant with an integrated camera that eliminates the ‘blind spot’ for the truck driver, allowing them to see cyclists and pedestrians more easily.

“After several fatal road accidents involving trucks in the region, I conducted research and found out that there were no corresponding safety solutions on the market,” says Anton Klott, the company’s Technical Director. “Our trucks drive through all big cities in this region and turning is always a dangerous manoeuvre. I decided to develop the solution myself, and two months later, we had the first turning assistant on the road.”

Today, the system is distributed externally by a partner in the truck market and has so far been installed in more than 2,000 vehicles belonging to other companies.

“We are a food retailer that loves safety,” continues Klott. “These accidents have dramatic consequences, also for the truck drivers. Statistics show that 80% of all drivers involved in a fatal accident suffer long term stress and are unable to continue working. Police and other first responders also need psychological support to cope with these incidents.”

EDEKA Südbayern has a fleet of around 300 trucks and 475 truck drivers covering the entire southern part of Germany. The turning assistant is just one part of the firm’s vision of creating safer trucks, with other important safety features including a reversing assistant that can initiate an automatic brake, ultrasonic rear sensors, and side flashing lights.

No more loose nuts

Alongside these additional safety measures, EDEKA Südbayern also looked at how it could fix a crucial safety issue with loosening wheel nuts in its trucks by working with bolt specialist NordLock.

“We used to have big problems with loosening wheel bolts,” explains Klott. “Sometimes they were not properly derusted, sometimes the driver forgot to retighten them. Alternative solutions were always complicated. For example, the driver had to check regularly that certain indicators on the wheel

////////// /////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////// IN-DEPTH ROAD & RAIL 30 torque-direct.com

Nord-Lock's wheel nuts are suited for both on and off-road vehicles

German food retailer EDEKA Südbayern demonstrates how incidents involving trucks and vulnerable road users can be avoided

”TRUCK SAFETY IS HIGH ON THE PUBLIC AGENDA IN GERMANY, AND EDEKA SÜDBAYERN HAS PROVEN THAT THIS DOESN’T NEED TO BE AN EXPENSIVE UNDERTAKING.“

nuts pointed in the right direction. That’s all history now. The wheel nut solution from NordLock is a perfect system that increases safety.”

“Accidents due to loosening wheel nuts can be tragic and also very negative for a transport company’s public image,” says Stephen Gruber, Sales Engineer at NordLock. “That’s why more and more companies use NordLock to eliminate these kinds of accidents.”

Truck safety is high on the public agenda in Germany, and EDEKA Südbayern has proven that this doesn’t need to be an expensive undertaking: “All our security attributes only account for about 1% of the total truck acquisition cost,” explains Klott.

A technical approach

The loosening of wheel nuts is the main reason for wheel detachment – a problem that occurs mre often than you might think. According to the Department of Transport, in the UK alone there are up to 400 wheel detachments from heavy trucks every year, while the USA’s National Transportation Safety Board claims detached wheels result in around 20 accidents per week.