ものづくり補助金により作成

Supported by a special government Grant

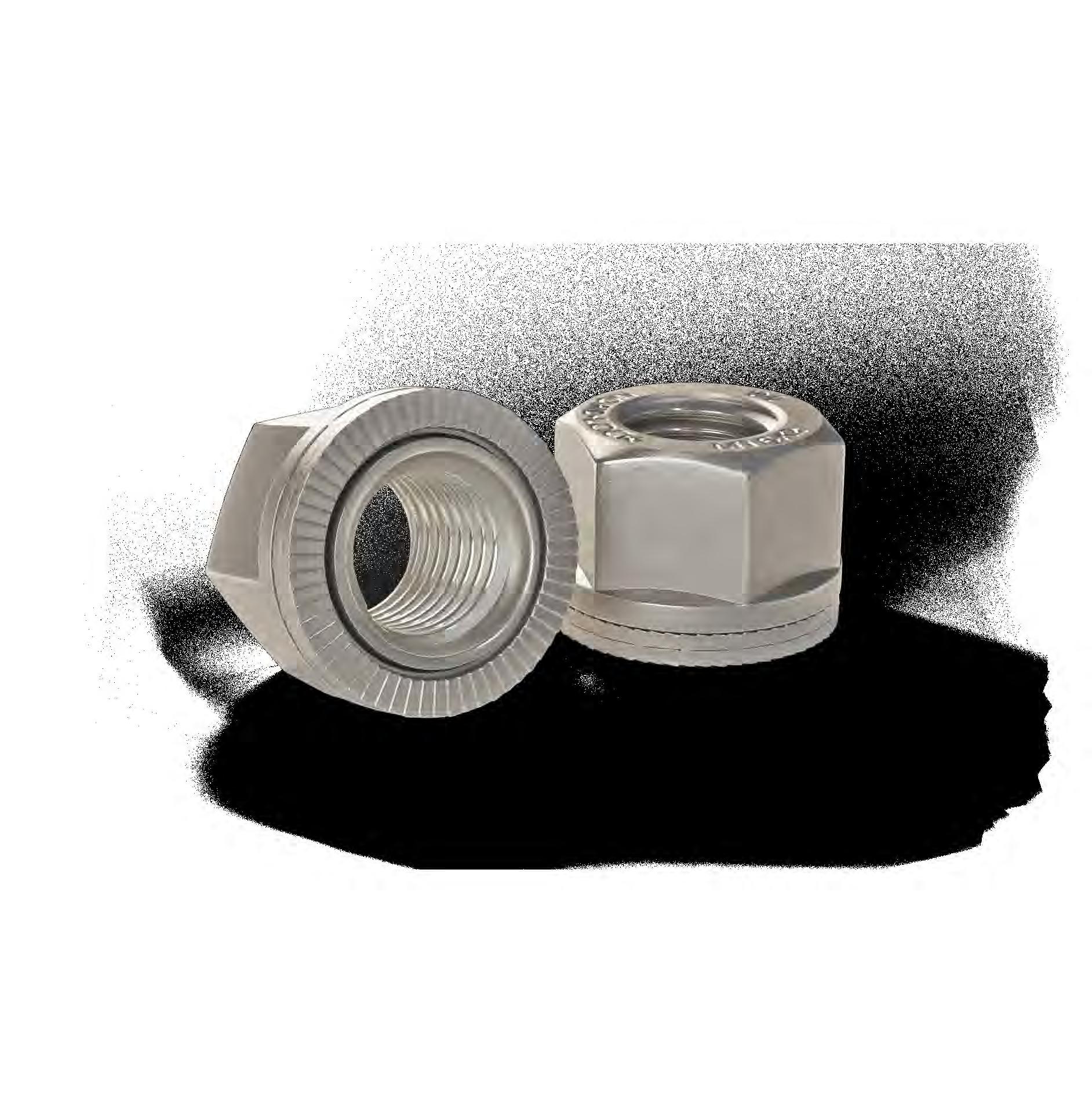

ISO 16130 Proven to provide optimum locking performance

Easy to install and remove with standard power or hand tools

Available in most fastener designs, sizes and materials

PLEASE SHARE YOUR APPLICATIONS WITH US SO WE MAY BE YOUR SOLUTION PROVIDER

Scan this CODE to see the “PLB v2”website

SCAN QR CODE TO VISIT THE PLB v2 WEBSITE

European Partner Güde GmbH

www.guede.net

Phone: +49 2391 91 90 0

Email: sales@guede.net

Address: Dieselstraße 8, D-58840 Plettenberg

NISSEI CO., LTD.

2022 Torisawa, Tomihama-machi, Otsuki-shi, Yamanashi, Japan 409-0502. Email: plb_bolt@nisseiweb.co.jp

USA Partner

MS Manufacturing Solutions, 620 East Bigelow Street, Upper Sandusky, Ohio 43351

Michael Shutt – PLB v2 System USA Program Manager Phone: 419-460-1101 Email: shuttm@aol.com

Publisher

Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Rachel King rachel@torque-expo.com

Sales Manager – UK Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

UK Sales Manager – Tools

Lloyd Ramsdale lloyd@torque-expo.com

Circulation

Tracy Howell tracy@torque-expo.com

Head of Production Luke Wikner luke@torque-expo.com

Designers

Dan Bennett

Victoria Arellano

Head of Marketing

Shona Hayes shona@torque-expo.com

Published by

Stag Publications Ltd

18 Alban Park

Hatfield Road

St Albans

Herts AL4 0JJ

tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-expo.com Web: www.torque-expo.com

Disclaimer

Although the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in

06 GUEST EDITOR 08 NEWS

12 COVER PROFILE > YUYAO ALFIRSTE THE CHINA FASTENER BUSINESS TELLS TORQUE ABOUT MARKET EVOLUTION, BROADENING PRODUCTION BASES AND INVESTMENTS…

14 WOMEN IN FASTENERS & TOOLS > KERRY GARNER, BON PRECISION ENGINEERING

16 FOCUS > RENEWABLES – FASTENERS & TOOLS

20 TOOLS MADE IN GERMANY > FEATURING CAS, BOSCH, WITTE AND NWS

28 FOCUS > RAIL FASTENERS

34 INTERVIEW > SUPPLY CHAIN PLANNING SPECIALIST SLIMSTOCK ON PEOPLE AND PROCESSES WORKING TOGETHER

37 NORM FASTENERS > …ON THE CRUCIAL ROLE OF FASTENERS IN LIGHTWEIGHT EV DESIGN

40 BUILDING & CONSTRUCTION > ETAs AND ACCREDITATION

53 TERRITORY FOCUS > ITALY

62 SHOW REVIEW > TORQUE-EXPO 2024

74 INTERVIEW > OPTIMAS ON RE-SHORING

76 SPOTLIGHT > DÖERKEN

80 SHOW PREVIEW > INNOTRANS 2024

83 SPOTLIGHT > FERDINAND GROSS

84 SHOW PREVIEW > INTERNATIONAL FASTENER EXPO 2024

To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code...

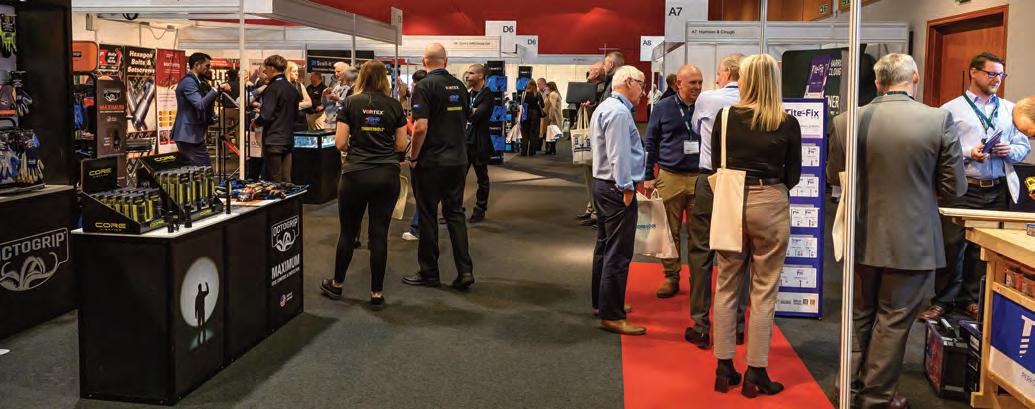

The doors recently closed on Torque-Expo 2024. Prior to the show, we had been wondering how it was going to compare with our previous show in 2022. A natural question you might argue, but the 2022 edition occupied a pretty unique position in history: It was one of the first opportunities to bring the industry back together post Covid lockdowns. At that point there was a big appetite to get back face-to-face with customers and peers after a difficult and enforced absence behind closed doors and Perspex screens.

But would that appetite remain, two years on?

Happily, the answer was yes and Torque-Expo 2024 recorded growth in visitor numbers compared with 2022, hinting that – in fact – the appetite for the industry to meet had increased, even compared with those initial unusual postlockdown times. So, why is that?

We had some more international visitors this time around. Back in ’22, there were likely some lingering doubts around the wisdom of global travel, so an upturn in international attendees since then is not such a surprise.

Perhaps it’s also something to do with a point some of our seminar speakers noted – increasing communication with stakeholders – particularly suppliers – to mitigate disruption.

With time pressures being what they are, a show where you can see a decent portion of the market, suppliers and potential customers is going to remain an attractive proposition, perhaps even more so in current times. With other key shows upon us and upcoming, we’ll wager continued growth in attendance as busi nesses follow through with plans for greater communi cation with stakeholders.

Jonathon Harker Editor jonathon@torque-expo.com

As part of our commitment to the environment, Torque Magazine is fully recyclable.

Scellit (UK) has expanded its presence in the UK by acquiring both Rivco Ltd and Kamtech Fasteners (ARK brand), strengthening its position as one of the leading distributors nationally of Construction Fixings, Rivets, Rivnuts and Setting Tools. This will further enhance the wide Scellit (UK)

Group brand range with names such as ARK, HUCK, FAR, RIVIT and LOBSTER.

Kidderminsterbased Rivco were established in 1994 and are a longstanding player in the UK market, bringing an existing turnover of circa £3m and a workforce of ten sales and warehouse staff.

Kamtech Fasteners, based in West Bromwich, was established in 2015 and has a customer base which perfectly aligns with that of Scellit (UK). This acquisition brings a further £1.5m of turnover and four sales and warehouse staff to the newly formed Group.

Steven Auld, the original majority shareholder of both acquired businesses, will continue with the group in his new role as Joint MD, supporting the Group’s staff and customers.

Gary Moseley, Joint MD and one of the founding shareholders of Scellit (UK), said: “We are thrilled to announce our acquisition of Rivco and Kamtech Fasteners, both businesses with excellent reputations in the UK and aligning perfectly with the existing Group. From initial discussions it was clear that this acquisition would fit in perfectly with our existing culture and help strengthen our position in the marketplace.”

“These acquisitions reinforce Scellit (UK) Group’s dedication to providing unparalleled supply at competitive prices to meet the precise needs of our customers.”

Their European partners, Scellit SAS, based at the Group's HQ in France, echo this growth vision. With established operations in Poland and Italy, it actively seeks further European acquisitions, propelling the total Group revenue beyond the current €50 million mark.

www.scellit.co.uk

OwlettJaton has achieved certification to ISO 45001:2018; Occupational Health And Safety Management System. The certification was awarded to OwlettJaton by the British Standards Institution (BSI) in February 2024.

The accreditation covers the wholesaler’s head office in Stone, Staffordshire.

ISO 45001 provides a framework to allow an organisation to proactively and continuously build and improve safety performance and culture to reduce risk. It demonstrates an organisation's commit

ment to a safe, healthy, and sustainable workplace. With a constant review and improvement process, established health and safety initiatives look to mitigate risks and improve operational performance.

Facilities and Accreditations Manager Gareth Phillips said: “Attaining this global benchmark for occupational health and safety is a major achievement for all at OwlettJaton. Health and safety is always the first point on our agenda, and this accreditation recognises the team’s hard work and dedication.”

This is OwlettJaton’s third BSI certification, alongside ISO 9001, International standard for quality and ISO 14001, International standard for environmental management. www.owlett-jaton.com

C-PARTS MANAGEMENT VIA APP

Full transparency and digital control of your entire C-Parts Kanban, even from your home office. Plus comprehensive document management of drawings and test certificates. That’s how FALCON has been impressing not only in purchasing, but also in QA and design departments for years. And with the revised FALCON app, all of its features are now in your pocket, making the tool attractive for production workers too.

We are happy to walk you through the new features! www.schrauben-gross.com/en/falcon

Ferdinand Gross GmbH & Co. KG Daimlerstr. 8, 70771 Leinfelden-Echterdingen, Germany www.schrauben-gross.com/en

ingfisher plc has announced that, after seven years as Chair of the Board, Andrew Cosslett has decided not to stand for reelection and will therefore step down from the Board of Directors at the conclusion of the Company’s AGM in June. Andrew will be succeeded by Claudia Arney, who has served as an Independent NonExecutive Director of Kingfisher since November 2018 and currently also chairs the Board’s Remuneration Committee. Her appointment will take effect at the same time.

Claudia Arney said: “Kingfisher is a fantastic business, which maintains a sharp

focus on striving to better serve its customers while delivering longterm value for all its stakeholders. I look forward to continuing to support our great management team in our mission of making home improvement accessible to everyone. Since joining the Board in 2018, I have learned a great deal about the complexities and nuance of our business and retail banners, and about our 80,000 passionate and committed colleagues in many countries. It is an honour to take on the role.”

www.kingfisher.com

European Springs, a spring manufacturer and member of the Lesjöfors Group, has announced two management changes. Stuart McSheehy will be stepping up into the role of Sales & Business Development Director for Europe as part of the Lesjöfors Group, promising to utilise his deep industry knowledge and extensive strategic expertise to lead the region’s growth initiatives.

Alongside him, Jason Wilby takes on the responsibilities of Managing Director for European Springs & Pressings, with a committed focus on pushing the boundaries of innovation and excellence and elevating customer experiences to new levels. These appointments underscore The Lesjöfors Group’s dedication to its growth ambitions and its commitment to serving its customers with excellence.

www.europeansprings.com

BUMAX ANNOUNCES NEW MASTER CANADIAN DISTRIBUTOR >

As part of an ongoing expansion into the North American market, BUMAX AB has appointed Fuller Fasteners as its master distribution partner for Canada. This milestone represents a significant step forward and the continued expansion of the company’s global footprint across key regions.

NETFORM ANNOUNCES MERGER WITH VICKERS ENGINEERING >

Netform has completed its merger with Vickers Engineering Inc., a provider of missioncritical, highly engineered metal components and assemblies serving global automotive and industrial markets. Based in New Troy, MI, Vickers has a long history of delivering quality precision machined steel and aluminium parts to leading OEM and Tier 1 customers.

EXCLUSIVE ONLINE CONVERSION TOOL FROM JRP >

Jaton Riveting Products (JRP), the riveting brand from OwlettJaton, has launched a new online comparison product finder, designed to assist customers in finding the exact JRP riveting product for their needs. The platform aims to streamline the rivet selection process, by offering sidebyside alternatives.

ATLAS COPCO LAUNCHES SMART FACTORY INNOVATION CENTRE >

Atlas Copco Tools and Industrial Assembly Solutions has demonstrated its commitment to supporting the digital transformation of the manufacturing sector by opening a new, stateoftheart Smart Factory Innovation Centre, on the i54 development near Wolverhampton. A sixfigure investment was made to reengineer the company’s existing building for the Centre.

LESJÖFORS GROUP LAUNCHES SPRING INDUSTRY ONLINE SHOP >

Making their springs available to everyone, everywhere, at any time, the Lesjofors Group, has launched an online shop offering 24/7 access to a wide range of standard stock springs. The roll out is starting in the company’s country of origin – Sweden – before progressing across Europe, America and Asia.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

WÜRTH GROUP SETS A NEW SALES RECORD >

Würth Group has closed the 2023 fiscal year with success, despite facing a number of economic and political challenges. At EUR 20.4 billion, sales were above the previous year corresponding to an increase of 2.3%, or 3.5% after adjustments to reflect currency effects.

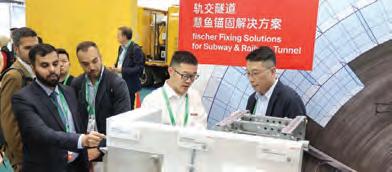

FISCHER ATTENDS THE WORLD TUNNEL CONGRESS 2024 >

The fischer Group of Companies once again attended this year’s World Tunnel Congress in Shenzhen, China. The fixing expert presented a broad range of its products and services for tunnel construction from its FIS EM Plus injection mortar and FNA II nail anchor to the fischer Castin Channel System, which have already been used in various projects around the globe.

EJOT COLORFAST CHOSEN FOR KINGSPAN’S NEW ASIAN FACTORY >

More than 120,000 EJOT Colorfast selfdrilling fasteners have helped Kingspan to create a thermally superior, visuallyappealing building envelope for its first purposebuilt manufacturing plant in Vietnam. Kingspan’s factory will manufacture its Quadcore and mineral fibre insulated panels.

ALFIRSTE’s innovative bi-metal screws are now in production

ALFIRSTE's manufacturing facility has recently expanded

The cut and thrust of the fastener sector means the worldwide market continues to evolve and among those changes is the shifting nature of China’s fastener production –no longer solely synonymous with the value end of the market but now also branching into the cutting edge high end. Torque Magazine speaks with ALFIRSTE about market evolution, broadening production bases and investments…

It’s around a year since we last spoke with Zhejiang, Chinaheadquartered fastener manufacturer ALFIRSTE. The business began life as a small workshop in 2006, but recent developments have seen it boost its already substantial production operation even further, with new factories that are helping the company adjust to the changing trading circumstances and regulations currently affecting the worldwide fastener market.

“ALFIRSTE has invested a lot of money and energy in opening factories in Thailand this year,” ALFIRSTE Sales Manager Michael Wu tells Torque Magazine. “Due to EU antidumping, orders for carbon steel are far less than they were before, but the actual demand from customers has not decreased. Therefore, we feel that setting up a factory in Thailand specifically for the production of carbon steel products can help customers and solve the problem of high tax rates.”

With a substantial amount of ALFIRSTE sales going to the European market, this is sure to be a significant move for the firm. While the investment will mean ALFIRSTE can supply those customers without being hit by the aforementioned antidumping duties, it also paves the way for expansion of the company and its reach into other markets, Wu explains: “It can allow ALFIRSTE to gain a foothold overseas and lay a solid

foundation for exploring more markets and establishing more factories in the future.”

The move is well timed, with the proportion of ALFIRSTE’s business in Europe growing even since last year, now making up more than 60% of its business. As such, ALFIRSTE has been bolstering its market presence at exhibitions in the region, including Cologne’s International Hardware Fair earlier this year.

Since it started working with the European market in 2016, ALFIRSTE has gradually developed its internal infrastructure and obtained CE certification (in 2018), the same year that ALFIRSTE opened its second factory. 2020 saw it obtain the ETA certificate and begin to produce stainless steel products.

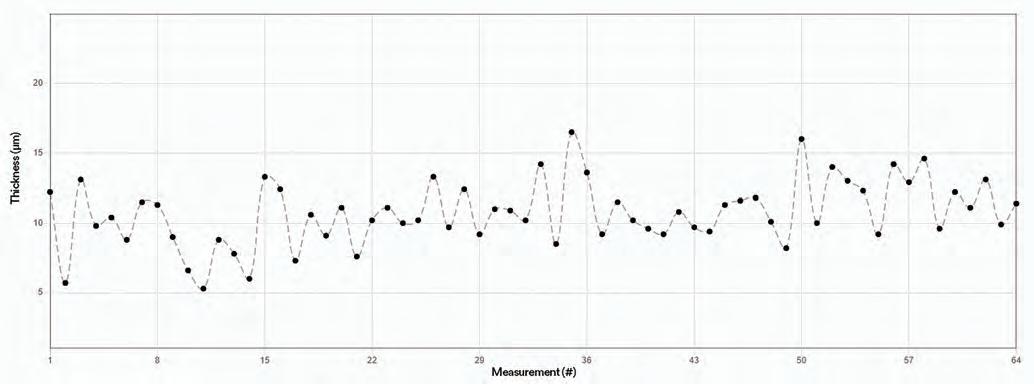

The quality focus has seen evolution of its laboratory facilities. Each production process is checked at random by quality inspectors, ensuring only quality prod¬ucts are allowed to move to the next stage. The quality department can depend on a vast array of relevant machines and instruments, from the humble calipers to salt spray test machines, Rockwell hardness machines, torque testing machines, SPECTRO spectrometer, temperature and humidity meters to metallographic specimen polishing machines, Fischerscope XRay, drilling testing machines and a metallographic microscope, among others.

While ALFIRSTE is clearly looking to expand and invest the time and money required to do so, the firm is keen to emphasise it is targeting healthy and sustainable growth. Wu explains: “Since the establishment of ALFIRSTE, we have served our customers, employees, partners and society wholeheartedly. We are deeply aware that we must adhere to some management principles and business ethics, such as integrity and respect, focus on quality, compliance with laws, cultural tolerance, supplier management, etc. These are the basis for the healthy and sustainable development of ALFIRSTE. Only by doing this well can we realise our mission, realise our vision, and inherit and demonstrate our spirit.

“In management, we judge the environmental performance of business units and individuals to promote sustainable management of corporate culture.”

Sustainable principles also extend, of course, to the environment and working ever harder and more cleverly to help reduce carbon impact. Wu adds: “In terms of production, we take the initiative to adopt cleaner production processes, including reducing raw material waste and waste generation, and using solar power to save energy. This year, FAST also actively cooperated with the EU and participated in CBAM’s investigation and selfinspection. Our company's SEE(TOTAL) is 2.770. In terms of procurement, we are using green procurement and our work is very efficient.”

ALFIRSTE’s quality lab has been boosted with investment in equipment

ALFIRSTE’s innovations points to a wider trend in the China fastener world, explains Wu: “Technological innovation promotes industrial innovation, and in the future fastener manufacturing will develop towards a trend of being more refined, higher quality and more humane. China's fastener manufacturing industry is moving towards automation, digitalisation and intelligence. ‘Made in China’ is no longer limited to the mid to lowend markets. Superior and stable quality and good cost performance will become the core advantages for Chinese companies to capture the mid to highend markets in Europe and the United States. Continuously improving the competitiveness of enterprises and entering the highend market is the direction of our efforts at ALFIRSTE.

“Original spirit, manufacture with heart” is the foundation

Readers may recall ALFIRSTE filled us in on its R&D work on bimetal screws last year, continuing its innovation investment that ALFIRSTE said was essential for its core competitiveness. Now, the bimetal screws project has born fruit, with the research and development results put into production and receiving praise from customers. Now the firm can produce long screws as well as short in the materials.

of ALFIRSTE,” says Wu. “Many products of our factory have successively obtained CE, ETA and ICC certifications, and we are still developing new products. With the economic recovery of the European Union and the United States, ALFIRSTE will seize the opportunity to meet the greatest needs of customers with products that best meet market demand.”

www.alfirste.cn 760@chinanchor.com

Kerry Garner’s career path wasn’t a straight road into the engineering sector, but her skills and experience in marketing and IT have proved beneficial in her role as Director at family firm, Bon Precision Engineering.

How did you get into the industry?

I actually stumbled into the engineering industry somewhat unexpectedly, but it turned out to be one of the best professional decisions I’ve made.

My journey into mechanical engineering began whilst I was on maternity leave from my marketing role in the IT sector when I took on a project to create a website for a fastener reseller. Before this, I had worked in marketing roles since 1995 in STEMbased industries. However, the opportunity to jump into the engineering sector felt like a natural progression, combining my expertise in marketing with a newfound interest in the world of fasteners.

Transitioning into engineering wasn’t without its challenges and I had to learn all the technical nuances. However, my background in marketing helped me bridge the gap between the technical nature of mechanical engineering and what clients need!

What does your day-to-day job involve?

As a small business, everyone must play their part. We’re a family firm; my husband John looks after our host of Star and Citizen CNC sliding head machines, and our son and nephews are also involved. Even our dog comes to work every day and oversees the important role of welcoming visitors to the building.

Marketing is my main responsibility, and it plays a vital role in attracting new customers and getting Bon Precision Engi

neering’s name into all the right places. We have an active social media presence, an online shop and an intelligently built website which I maintain and optimise daily.

I lead all the marketing initiatives, including digital campaigns, content creation, events, and advertising. Part of my daytoday role includes monitoring the performance of these initiatives and adjusting the strategies for the maximum impact.

I thrive on building strong relationships with our clients and love engaging with them to understand their needs – and also to gather their feedback to ensure we are serving them to the best of our abilities.

I enjoy connecting with industry peers, attending exhibitions, and participating in networking events. One reason Bon Precision Engineering is successful is down to the relationships the company holds, all of which help to keep me informed about industry trends, forge partnerships and identify potential business opportunities for us.

What prompted the decision to start

Bon Precision Engineering?

Redundancy, the pandemic and the realisation that John and I had made other firms very successful made us think that we’d like to be doing that for ourselves!

In March 2020, I decided my current role was not challenging enough for me, and a month later John was furloughed from an

engineering role before being made redundant. We’d discussed starting our own business for a couple of years and figured it was now or never. It was a huge leap of faith for us – but I can honestly say we have never looked back.

What are the biggest changes you have seen in the industry and company since you started?

Since I first stepped into the engineering sector, I’ve witnessed plenty of changes both within the industry and at Bon Precision Engineering.

One of the most significant shifts has been the rapid advancement of technology. The adoption of automation and integration of artificial intelligence has revolutionised how we design, manufacture and deliver engineering solutions. This evolution has enabled us to make efficiencies and improve precision in ways we couldn’t have imagined a decade ago.

Within Bon Precision Engineering specifically, I’ve seen remarkable growth and transformation. We’ve expanded our product portfolio and developed new revenue streams via our online shop, diversified our client base, and strengthened our position in the market. We’ve grown and moved to larger premises allowing us to take on more ambitious projects, increase our capacity and deliver exceptional results for our clients.

Can you share some of your career highlights and milestones so far?

Standing in our premises on our first official day of trading with a coffee in my hand, feeling both nervous and excited is one of my best career moments.

Recognition from peers and industry stakeholders has also been gratifying. We’ve been awarded ‘Best Small Manufacturing Company’ twice consecutively, and these accolades have affirmed the impact of our work and reinforced our position as leaders in the field.

Recently we have taken delivery of a brand new Star CNC machine – it’s really exciting to expand our capacity and have the capabilities to achieve more intricate components – and since technology is evolving so quickly it’s great to have new machinery with the latest whistles and bells to stay on top of it.

What is your favourite thing about the engineering sector?

I know it’s a cliché, but I love how every day is different. We’ve made precisionturned components for everything from jetpack suits to sheep shearing equipment – what other industry can boast that?

Ultimately, what I love most about the engineering sector is the opportunity to make a positive difference in the world, for example, we recently engineered components for a company that makes highend prosthetic limbs – and to know you’ve played a small part in making someone’s life better is a real buzz.

What do you think needs to be done to encourage more women to get involved in the fastener/engineering/manufacturing industries?

Introducing girls to STEM subjects at an early age is crucial for sparking their interest and confidence in pursuing careers in engineering and manufacturing.

I have previously volunteered at events for young people with a passion for STEM, encouraging them to make slime, build junk models, engage in activities such as virtual reality experiences, and get involved in innovative engineering projects to reduce space debris. It’s learning through play at an early age that can ignite an interest in our industry.

Offering flexible work arrangements and parental leave policies can also help support women’s career progression in engineering and manufacturing industries. Providing support for worklife balance is essential for attracting female talent and promoting diversity in manufacturing and engineering.

www.bonprecision.co.uk

As the usage of solar panels has increased, so too has the demands on the fixings, fastenings and tools needed to safely build and install them. Rivit, fischer and Gesipa are three such companies ready to provide solutions to meet the specific requirements of this growing sector.

Rivit gtreriv-photovoltaic panels

Rivit offers a range of targeted and continuously expanding solutions dedicated to the fixing of photovoltaic panels, to meet the needs of the sustainable energy sector.

With more than 50 years of experience in fastening systems, Rivit has developed a range of specific solutions for the photovoltaic sector that includes consumables such as blind rivets, rivet nuts, bushings for panel ballasts, special screws and tools for their installation. Thanks to the company’s experience, continuous research, development and innovation, Rivit solutions dedicated to photovoltaics can guarantee extreme effectiveness and reliability, but also impermeability, durability, high resistance to weathering and ease of installation. The Italybased company is also able to provide customers with ad hoc solutions, created on request for any specific needs of the sector.

Popular consumables include blind rivets such as the Gtreriv, with its neoprene gasket ideal for trapezoidal sheet metal and sandwich panels, and the Lockriv for wide hole diameter tolerance. Also worth mentioning are rivet nuts such as Tubriv and Jackriv, both of which are ideal for the installation of photovoltaic systems on various types of coverages and roofs, and the Rivlock breakstem bolts, for assemblies

requiring a strong seal and high resistance to mechanical stress, especially for fastening parts subject to high vibration.

The company’s bestselling fastening tools are the batteryoperated riveting machines of the 700 Series and especially the RIV720, for the power of brushless motors and longlife batteries that allow easy and durable fastening even on roofs and in the absence of compressed air, with the convenience of transport and storage provided by the practical carrying case with all accessories. Among the hydropneumatic riveting machines, for indoor work, you can instead use the tools of the 500 Series, light and handy riveting machines. Finally, there is also the possibility of relying on an efficient manual tool such as the RIV7, designed specifically for the photovoltaic sector.

Thanks to the wide range offered and to the expertise of its staff, Rivit is already a valued partner for several customers in Italy and abroad, to whom it offers a valuable consulting service on fixing solutions for specialised fields such as photovoltaics. Producers of photovoltaic panels and installers who are still unfamiliar with Rivit’s solutions can contact their local agents or the company’s sales office for targeted advice.

www.rivit.it

Solar energy is a steady source of readily available, renewable and sustainable energy. It’s a trend that’s becoming increasingly popular in the building and living sectors. In order to fasten solar panel systems to roofs and facades, the fixing specialist fischer offers solar and facade systems, as well as the accompanying services to ensure the success of a project. The company will be showcasing its latest products at the Intersolar Europe trade fair between 1921 June, 2024.

fischer will be displaying its innovative system solutions for fastening photovoltaic modules (PV modules) to roofs and facades in hall A5, where the fixing expert will be presenting its solar systems with which installers can master various fastening situations while installing solar panels on roofs, from smaller installations around the home to largescale industrial facilities. Reallife exhibits at fischer’s booth demonstrate the systems’ application on roofs with tile, fibre cement, standing seam and trapezoidal sheet metal covers. Rails, roof hooks, brackets, stud screws and other accessories form ideal system solutions for solar engineers and suppliers of PV modules and systems. Clever designs and technical ingenuities enable a flexible range of applications as well as quick and simple installation without the need for specialist tools or major alterations to the roof. Another advantage is the high quality of the products, which guarantee lasting safety and functionality of the installation throughout its entire lifespan.

Additional wall exhibits demonstrate how fischer facade systems can be used to create lasting and secure solar facades. Among the products being shown are the new PV clips for positioning on the edge or the centre of the field along with the FSMN M8 R connector, with advantages including simple application,

sophisticated technology and costeffectiveness. Minimal joints are required between the PV modules, resulting in a uniform surface when combined with concealed fastenings. Restraintfree installation and loadoptimised designs ensure a technically sound implementation. Thanks to simple and flexible installation on various substrates and substructures, PV systems are particularly costeffective and userfriendly to implement.

Horizontal ATK 103 PV clasp profiles used together with vertical carrier profiles will also be exhibited. PV modules can be hooked into the open Cprofile of these horizontal elements with premounted clasps attached to the back. Premounting the clasps with special screws that precisely fit the horizontal profile enables quick progress on the construction site. With its substructures for PV modules, fischer facilitates the construction of an aesthetically appealing and safe structure with a sustainable energy source.

fischer also offers the new SOLARPANELFIX software as part of its fischer FiXperience Suite for planning and calculating installation systems for solar panels.

At an additional consultation counter, the fixing specialist will be speaking to visitors about its comprehensive range of services for planning and installing solar panel systems on roofs and facades. Support options include planning and design as well as onsite support until the project’s successful completion. Impressive example projects meanwhile demonstrate the company’s extensive expertise in implementing solar facades around the world.

See fischer’s solar and facade systems at the event over on booth A5.413.

www.fischer.group/en

The high quality SMART insulation plugs from pgb are the perfect combination of plug and expansion nail in one handy product. “ “

The high quality SMART insulation plugs from pgb are the perfect combination of plug and expansion nail in one handy product. The plastic insulation plug prevents thermal bridges and is ideal for use in hollow and solid building materials.

ETA assessed

The insulation fixings are an ETA assessed fixing with high load-bearing capacity for a wide range of building materials.

Our insulation fixings are suitable for fixing thermal insulation on almost all building materials. The plugs are approved for use in concrete (usage category A), solid masonry (B), hollow/perforated bricks (C), lightweight concrete (D), en aerated concrete (E).

The insulation fixings can be combined with the extra 90mm insulation disc (IWP 90) or the extra 140mm insulation disc (IWP 140) for the installation of soft insulation.

We breathe fasteners®

When you think of solar panels, what comes to mind? Sunlight, clean energy and perhaps the complex engineering behind the technology itself? But have you ever thought about what holds it all together – such as blind rivets? Probably not. Yet, these unsung heroes, especially ones like GESIPA’s SolarGrip, play a crucial role in the manufacturing and installation process of solar panels.

When you look at a solar panel, you see sleek, shiny surfaces soaking up sunlight. But beneath that smooth exterior lies a network of components meticulously assembled to harness the sun’s energy. Rivets are the connection that holds these components together, quite literally.

In solar panel manufacturing, blind rivets are used to fasten together various layers of the panel. Whether it’s securing the photovoltaic cells, attaching the frame, or connecting the mounting brackets, rivets provide the structural integrity that ensures the panel functions optimally for years to come.

// In solar panel manufacturing, blind rivets are used to fasten together various layers of the panel. //

Why are rivets the goto choice for solar panel assembly? The answer lies in their reliability and durability. Rivets create a permanent bond between components, ensuring they stay in place even in the harshest of conditions.

Solar panels are constantly exposed to the elements: rain, wind, hail and even extreme temperatures. Blind rivets like the GESIPA® SolarGrip provides a secure connection that can withstand these challenges without loosening over time.

Rivets not only play a crucial role in manufacturing solar panels but also in their installation. When it comes to mounting solar panels onto sheet roofs or other structures, efficiency is key. Rivets offer a fast and reliable way to secure panels in place, allowing for quick and hasslefree installation.

SolarGrip blind rivets meet specific system and quality requirements, guaranteeing water tightness, long service life, and the highest economic efficiency. With millions of successful installations, GESIPA’s SolarGrip blind rivets have proven their reliability and effectiveness in practice time and time again.

A fast and precise riveting process, in addition to the splashproof properties of the riveting points, produces a durable and secure connection. Another advantage is its excellent hole filling capability. This means that, since the rivet body is deformed radially while the rivet is being installed, you can compensate for borehole inaccuracies, centre offset and differences in diameter, thus allowing you to create a tight connection with zero clearance. The SolarGrip blind rivet also allows you to cover a large clamping area with just one rivet.

Other advantages include:

ETAApproval applied for ETA13/0255

Matching grip range for many solar applications

Ideal for working on trapezoid panel roofs

SolarSeal coating for 4.8mm rivets

Riveting of sponge rubber or EPDM washers possible www.gesipa.de

AMPShare is the multibrand battery system for trade and industry professionals. With just one shared battery system, users can effortlessly switch between pro tools and brands – no more compatibility concerns or the need for multiple battery sets.

Produced with a leading battery technology, AMPShare batteries offer extreme power, extended runtimes and outstanding durability. Compatible with the entire Bosch Professional 18V system and all brands in the multitool alliance, they ensure consistent performance across your tools.

Thanks to an evergrowing list of professional partner brands, the AMPShare battery alliance puts a world of application possibilities into end user hands. This is the fastest, easiest and most costeffective way to build up your 18V tool bag, says the alliance.

“With over 80 million batteries sold and a fastgrowing alliance, AMPShare is the 18V battery system you can build on.”

www.ampshare.com

“MADE

arkets are currently reorienting themselves, there are gaps in the supply chains, price developments are difficult to calculate and companies are once again concentrating on production and warehousing in their own country. Current economic developments in Europe and worldwide show that ‘Made in Germany’ can prove to be important and extremely helpful in the future.

“The ‘Made in Germany’ mark offers security and a certain level of transparency. It is important to put quality features in the foreground in order to create trust and assert oneself in the market,” says Michael Adam, authorised representative and marketing manager of NWS Germany Production W. Nöthen e.K. The NWS Pliers range is completely made in Germany.

Almost all NWS products and even the brand logo are marked ‘Made in Germany’: “We only carry a few products that do not come from Germany. ‘Made in Germany’ is a flagship for

our products and a commitment to quality that we not only use but also live by. With our slogan “Function, Quality + Design” we support this idea by producing highquality products, equipping the tools with useful functions and providing them with a distinctive design.”

“Made in Germany” could also play an important role in competition in the German market, Michael Adam adds: “In addition to the many international tools that are increasingly coming onto our market with German brand names and a wide variety of qualities, the “champions” are often difficult to recognise. It can only be a good thing if a label like ‘Made in Germany’ explains where the product comes from, that it has a high quality image and that the user will enjoy it in the long term.”

www.nws-tools.de

When nine power tool manufacturers launched the cross-brand battery alliance CAS in the summer of 2018, acting on Metabo's initiative, they laid the cornerstone for a success story. In the sixth year after the founding, this simple and winning idea has permanently changed the power tool industry…

When you hear the term innovation in conjunction with power tools, you automatically think of new technology. However, new approaches can bring lasting change to the industry even without new technology. The first multibrand battery system CAS (Cordless Alliance System) has shown in recent years how to make such a change.

The world’s first crossbrand cooperation for battery pack technology has brought new freedom to professional users in the trades and industry in two different ways: thanks to the CAS, they can not only work without cords, but can also use tools from a wide range of different brands. When the alliance, initiated by Metabo, was introduced in the summer of 2018, nine manufacturers were involved with around 110 cordless tools in their portfolios. Five years later, the alliance encompasses 40 brands and 400 tools. This growth proves the extent to which the CAS has transformed the market. A large number of imitators also indicates how simple, and at the same time compellng, this idea was. In the years since the alliance’s founding, a variety of power tool manufacturers have followed CAS’ example and founded their own cooperations. There’s nothing like the original, however, and CAS remains by far the largest of the alliances. It is also the most international. While it only included German manufacturers at its founding, CAS partners now come from Switzerland, Spain, Poland, Denmark, Italy, France, the Netherlands and even the USA today. Five new partners will be joining the CAS over just the next three months.

“Since the start, CAS has been consistently pursuing its goal to be an alliance of the best – especially the best specialists,” says Thomas Zeller, Head of the CAS Partner Programme at Metabo. That is why its partners include a large number of manufacturers focused specifically on individual target audiences and trades. Instead of having a portfolio that contains every common power tool, they offer users solutions to solve tradespecific tasks. “The more precisely a power tool is tailored to the typical challenges of a specific area, the greater the boost in productivity it can offer to tradesmen,” Zeller says. “Here’s an example to illustrate: a typical power tool manufacturer might have one tool for setting rivets in its product portfolio. Our CAS partner Gesipa, which specialises in sheet metal processing, offers seven different cordless models. Mafell offers its core target audience of carpenters seven different types of saws alone. The list of CAS specialists with very deep product ranges goes on and on; today, we cover not only all common power tool classes, but also specialised solutions for all trades along with our partners,” Zeller explains.

And CAS’s range of tools continues to grow. Its partners ensure this by continuously developing new tools based on the common battery technology. When it joined the alliance in 2021, Scangrip had six cordless lights. Today, it has 22. Metabo itself had around 70 tools when the alliance was founded in 2018 – today its product portfolio includes 150 cordless tools and devices.

Fon

“CAS is based on Metabo’s battery pack technology,” says Bernd Fleischmann, who is responsible for global development as the Chief Technical Officer (CTO) at Metabo’s parent Koki Holdings Group. “In the past, we have been driving the battery sector forward by making huge leaps in development and premiering new products on the world stage. We are continuing down this same path, and of course we provide all of our new products and developments to our CAS partners. For tradesmen and CAS partner companies, CAS means always

having the latest and best battery and charger technology available. As the technology provider, Metabo specifically ensures this. We will be launching another new technology on the market this year to open up new horizons for batteryoperated power tools for us and our CAS partners.”

Collaboration within the CAS association now goes beyond using common battery pack technology, says Peter Vullinghs, Managing Director of Metabo and Koki Holdings Europe: “Although we are part of a large, international group today, we have retained many of the qualities and the approach of a midsized company. This allows us to quickly take up new developments in fundamental technologies, perfect them for use in power tools, and in this way advance technological progress. In addition, however, we know and understand the challenges of our midsized CAS partners. Because of this, the CAS is a partnership among equals. Over the years, we have engaged in a range of projects where CAS partners collaborate and benefit from one another’s knowledge and experience,” Vullinghs explains. This collaboration is about more than technical innovation: “At Metabo, we developed the MetaBox years ago alongside a specialist as a transportation solution for our tools and accessories. Today, 13 partners use it for their own needs.”

CAS partners work together in the marketing area as well. Since the first CAS stand in 2022 at the Cologne Hardware Trade Fair, the alliance has participated in different exhibitions each year – for instance at the stand of the partner with the largest presence at the individual event. In its sixth year, the CAS also got a visual makeover. The brand image was revised, and CAS now has a clearer and fresher look. In addition to marketing considerations, there was another happy and simple reason for the relaunch: the new brand image shows the (very large number of) CAS brands much more clearly now.

www.cordless-alliance-system.com

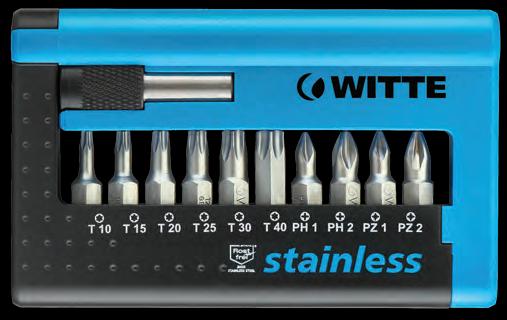

WITTE Tools specialises in the manufacture of high-quality bits and screwdrivers. The longestablished business offers a broad range of products as well as a private label service…

Based in Hagen, North RhineWestphalia, WITTE Tools is part of the KIRCHHOFF Group, which traces its origins back to Stephan Witte, a company founded in Iserlohn in 1785 to manufacture sewing needles. The group, which has been wholly owned by the Kirchhoff family for four generations, today consists of four divisions – WITTE Tools, KIRCHHOFF Automotive, KIRCHHOFF Ecotec and KIRCHHOFF Mobility – and has a turnover of €3 billion with more than 13,000 employees worldwide.

From the company’s beginnings with the production of needles, the production of screwdriver blades developed in 1949. today, WITTE Tools specialises in screwdriver series, bits and bit ranges and is one of the leading German manufacturers of screwdriving tools in the premium segment. The tool specialist supplies its products with all salespromoting elements such as individual and set packaging, counter dispensers and pallet displays to partners from trade, commerce and industry worldwide.

A particular focus is on the private label customer sector. Under the WITTE Inside 360° development concept, WITTE Tools offers a diverse selection programme depending on the desired degree of differentiation of the brand. This ranges from the development or expansion of the company’s own tool range to individualised, specially developed product solutions and includes branding, handle design, color design, material selection and the targeted design of specific product features.

The range includes stainless steel screwdriving tools that prevent stainless steel screws from rusting: These are pitched as an ideal choice when used outdoors, e.g. in aerospace, solar panel installation, food processing, medical technology and the pharmaceutical industry. Bits and screwdrivers made of highly tempered, very corrosion and rustresistant stainless steel are ideal for use in damp environments, outdoors or in areas with aggressive chemicals.

WITTE’s product range also include Precise PRO WITTRON® ESD screwdrivers for electronics. The ESD (ElectroStatic Discharge) precision screwdrivers with fastturning zone have been specially developed to protect sensitive electronic components from damage caused by static electricity. Even a small electrostatic discharge in integrated circuits (ICs), which can occur when touching a component, can damage or completely destroy an IC. The twocomponent handles of PRO WITTRON® ESD screwdrivers are made of a defined electrically conductive material that ensures safe dissipation of the electrostatic charge.

The PRO ESD line with a largevolume triangular round shape and threecomponent handle is suitable for higher torques. The relatively soft plastic on the edges optimises the padding of the palms and increases slip resistance.

A wide range of bits characterised by high quality and durability increases productivity and reduces costs. Coatings such as TiN or diamond make bits easier to grip and more corrosionresistant at the same time. With bits up to 600 mm long, hardtoreach screws can be loosened and tightened easily and precisely, e.g. when servicing agricultural machinery.

WITTE Tools is certified to ISO 9001, 14001, 45001 and 50001. Readers interested in investigating WITTE’s 360° WITTE INSIDE PRIVATE LABEL proposal for their next Screwdriver or Bit project, or in potentially distributing WITTE tools in the UK can contact the company via:

marketing@wittetools.com

Download the WITTE Tools catalogue for screwdrivers and bits:

It's how to achieve streamlined installation processes.

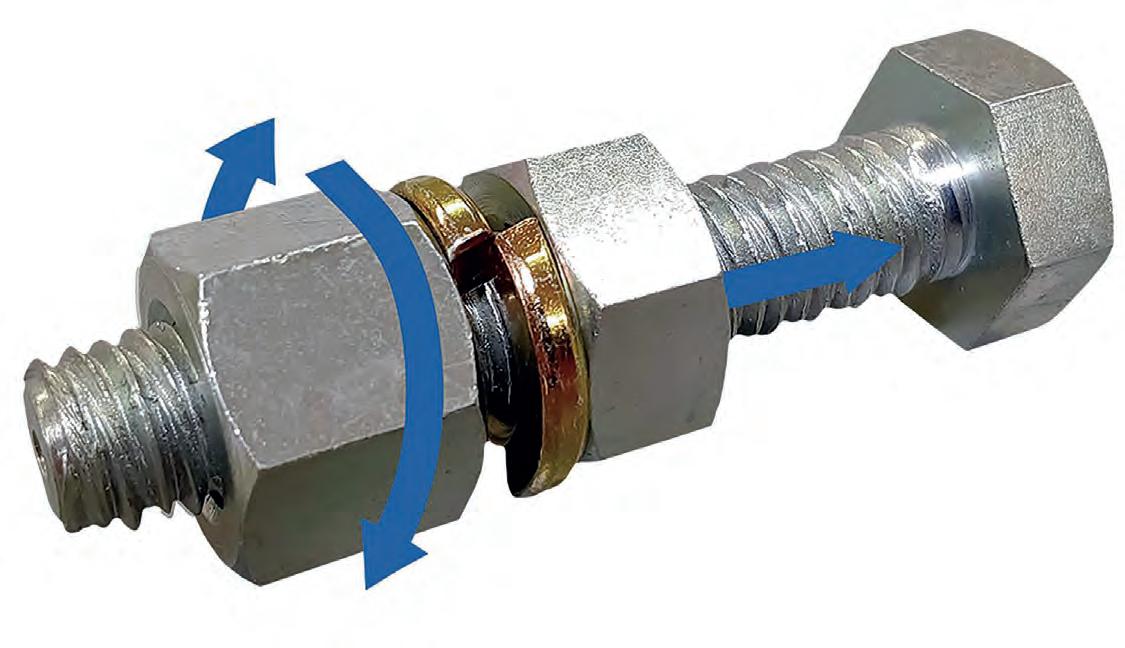

That’s why we are introducing the Nord-Lock® Combi Nut. This product reduces the number of parts your operators have to deal with by combining our world-famous washers with a nut. The result? A faster, safer way to get the job done.

Safety, integrity and reliability are crucial for the fasteners and other items used in the rail sector. We look at some of the organisations meeting these strict demands via technology and innovation.

In the realm of railways, every component is crucial in maintaining the integrity of the railroad system. Growermetal, renowned for its precision washers and parts, addresses the rail sector by combining its 70yearlong expertise in washer design with the inhouse manufacturing system. Through investments in cuttingedge technologies, the fastener company delivers solutions that exceed industry standards, developing parts on customers’ drawings and integrating the range with branded designs. In this process, attention is given to the conditions of rail operations, subjected to constant vibrations and heavy loads. To meet the requirements of the industry and prevent bolts from loosening or failing, the fastener firm has developed a complete line of safety washers and coiled spring washers in different designs, materials and dimensions, which can be combined with surface treatments and coatings for improved performance.

Growermetal’s range for railway tracks includes:

Single, double and triplecoiled spring washers: widely used in railway applications, these spring washers allow the absorption of dynamic loads caused by train transit. The version with ribbed bearing surface combined with a peculiar geometry, provides the parts with a great fastening performance avoiding any risk of cracking. In addition, Growermetal manufactures spring washers according to the UIC 8643 standard, meeting the request of the European markets. Targeted for the US market, single coil springs are in accordance with the American Railroad Engineering Association standard (A.R.E.A. 1967) completing the railway portfolio.

Conical elastic Contact and Sperrkant washers: these ribbed washers are designed to create an elastic preload in a boltedjoint connection, reducing the risk of unwanted loosening. For this, conical Contact and Sperrkant elastic washers are particularly suitable for electromechanical applications subjected to temperature variation and requiring vibration resistance.

Conical elastic washers for bolts: used to prevent loosening of assemblies by the elastic compensation of expansion and contraction and the elimination of play.

Flat washers for bolts: ideal for broader uses, they prevent surface damage from nuts and bolts and provide a greater loadbearing surface.

“Around Ideas” is the Growermetal motto: an approach that inspires continuous research and innovation. In the last five years, this attitude has led to the creation of exclusive designs, like Grower TenKeep®

Introduced in 2019, this flat washer has knurls of different geometry on the two surfaces, maximising the performance against loosening of the bolted joints while avoiding damage during the tightening or untightening procedures.

Furthermore, the range is supplied with the zinc flake coating Delta Protekt® KL120, which guarantees a corrosionresistant performance of 1,000 hours minimum in neutral salt spray (NSS) tests according to ISO 9227. Zincflake coatings are particularly suitable for railways applications even in environments with presence of water and humidity, such as in railway tunnels, as they provide outstanding quality with a complete line of base and top coats available. During the coating process no hydrogen is produced and thus there is no danger of any embrittlement due to the application process, ensuring protection against corrosion.

These coatings are performed by Growermetal inhouse on a fully automatic coating line specifically designed for washers and railway springs, to guarantee the highest quality of the coating itself and the maximum performance of the product during its use.

Trade shows are a great opportunity to discover the complete range of rail solutions offered by Growermetal. Among the next events, there will be InnoTrans, the world’s leading trade show for transport and rail technology which takes place every two years in Berlin. From 2427 September, visitors will have the opportunity to discover the madeinItaly product line of the company at booth 415 hall 8.2 of the Berlin Exhibition Grounds.

The participation is significant for Growermetal’s next evolution, as it represents an opportunity to get in touch with participants from all over the world and discover the latest technologies and trends for the sector. As InnoTrans approaches, Growermetal’s commitment to innovation stays strong, setting the stage for groundbreaking developments in railway solutions. www.growermetal.com

Fixings and fasteners are amongst the world’s most widely used commodities, found in a broad range of applications from flagship construction projects through to complex manufacturing machines. Here, Mark Dorrington, Business Development Director at Harrison & Clough, outlines the role they play in safety critical industries and the importance of specifications and certifications.

Harrison & Clough (H&C) is proud of its straighttalking Yorkshire heritage that goes back more than 65 years. Over this time, the company has supplied billions of fixings and fasteners to traditional industries, such as the construction industry, through to providing specialist parts for innovative solar PV installations needed to deliver the UK’s latest carbon reduction targets.

It may come as a surprise however that between 5% and 10% of H&C’s fixings and fasteners are used to grow and maintain the UK’s rail infrastructure. This safetycritical industry relies on both ‘offtheshelf ’ products and specific ‘madetoorder’ pieces, designed and manufactured to detailed specifications required to meet specific needs.

Working with our network of qualityassured manufacturers, we produce products that are either used directly on the railways or taken in a ‘natural’ state by specialised distributors who then have them coated, patched or drilled to suit specific applications.

Utilising our global supply chain, we work to seamlessly deliver accredited products to specialist distributors and then onto the rail network. In all cases, however, fixings and fasteners are manufac tured to meet strict specifications, ensuring they are made to the highest standards required for safetycritical applications.

Harrison & Clough fixings can be found across the UK rail industry.

To ensure that all fasteners are produced to our high stan

Fixings and fasteners are manufactured to the highest standards required for the rail industry.

dards, Harrison & Clough use Approved and ISO Certified manufacturers. This helps ensure that all goods are manufactured to strict quality control criteria with regular inspection plans – tested by specially designed and audited inspection equipment. As well as independent audits, H&C also undertakes regular quality inspections to ensure they meet the standards required.

Having a broad range of products and specialist knowledge has helped H&C grow to be preferred suppliers for distributors supplying UK railway companies, whether for maintenance, repair or overhaul (MRO contracts).

The products are manufactured to such a broad spectrum of specifications that H&C fixings can be found across the rail industry whether rolling stock, freight, signalling, power generation or track refurbishment.

As well as full traceability and certification, access to products and reliability of delivery are important factors when choosing a supplier. With large scale 108,000ft2 of warehousing in the UK, H&C also holds stock to ensure it’s available when or where needed. By holding stock and working with specialist rail distributors we help reduce the operating costs of client held inventory, while ensuring continuity of material supply that is critical to production output as well as MRO and OEM operations.

H&C works closely with customers to analyse and develop stock profiles, tailoring them to deliver their safety critical requirements and uses the latest technologies and best practice in their manufacture. With H&C’s support and expertise, the small but important role of fixings and fasteners can help reduce total costs, improve operational efficiency and maintain regulatory compliance across the UK’s rail industry.

www.harclo.com

On the face of it, building the Kienlesberg bridge was a reallife mission impossible. After all, how can you successfully bring together two completely opposing concepts?

Located in Ulm, between the southern German cities of Stuttgart and Munich, the Kienlesberg bridge was to become a beautiful example of filigree architecture.

Stretching 270 metres in a smooth curve, this work of art was to feature specially fitted vantage points. Here, pedestrians and cyclists could pause to behold the historic city below them, and the Gothic style Minster church, which boasts the world’s tallest steeple.

At the same time, however, everything had to be about rules and reliability, safety and sturdiness. Requiring over 2,500 tons of steel, this construction had to be robust enough to support two train tracks.

Moreover, with a bustling Deutsche Bahn intersection below, the bridge meant complying with strict and uncompromising safety regulations. The rules governed everything from

electrical cables to train tracks. Despite the seemingly impossible nature of the challenge, the solution came in the form of a combination of two products. This included glassfibre reinforced plastics (GRP) from CTS (Composite Technologie Systeme GmbH), and special washers from the NordLock Xseries bolt securing system.

There are two main reasons why NordLock products were a perfect fit for this project. Severe vibration from rattling carriages on a highspeed train can lead to bolt loosening, but not when used with NordLock Xseries washers. The wedgeeffect underneath the bolt head and nut mean the washers cannot loosen unintentionally.

CTS found NordLock washers to be highly reliable as they also passed Deutsche Bahn’s strict safety tests. CTS could now guarantee that their product – fitted using NordLock washers – could withstand the vibration.

www.nord-lock.com

// Stretching 270 metres in a smooth curve, this work of art was to feature specially fitted vantage points. //

Various challenges have been thrust upon fastener distribution businesses of late, and there’s little sign of this stopping in the near future. Torque Magazine speaks with Ciaran Lumsden, Business Development Manager at Slimstock, the supply chain planning specialist, about how technology, people, and processes have to work together for any form of supply chain success…

The frailty of the supply chain has been brought into focus in the last few years and now there’s the ongoing situation in the Red Sea... have you seen more awareness of potential supply chain issues among customers over the last few years?

As new disruptions emerge, people need more help than ever to navigate these sorts of challenges. It’s not that a single instance of something has happened, but rather it’s an accumulation of things that have occurred over many years.

We talk about two types of volatility: there’s supply side volatility, like the Red Sea situation, and demand side. We started with Brexit, then there were product shortages, container price fluctuations, and container availability issues. All of these contributed to long lead times.

For most people, the idea of returning to normal seems like wishful thinking. Instead, ongoing supply chain challenges highlight the crucial role of companies like Slimstock. In this context, adaptability and resilience are key.

And it’s not just these events, there’s also things like legislation, the Russian sanctions, CBAM, for companies to deal with...

No company can predict these things, but what we try to do is give customers as much visibility and agility as possible. So, when something does occur, they can react quickly to mitigate the risk as much as possible.

Reshoring and onshoring are seen as ways to mitigate these challenges. Does that kind of solution fit with what Slimstock does?

It’s going back to that point about visibility and the simulation of what could happen if you change how your supply chain works. Companies must be able to quickly explore the impact of reshoring, onshoring, or offshoring. For example, how will this impact the lead time? What about the impact on costs?

This is linked to the demand side challenges, where the increase in cost of living, wages, consumer spending and inflation means that consumers are more aware of price changes. So, if you decide to onshore and your prices increase, will you see a reduction in demand, which then means it’s not worth it? Do you take a hit on your own margin, which is already under pressure from inflation?

It’s a hard balance for businesses to strike. But for our customers, we help weigh up the best course of action to deliver their business goals.

Can you just give us an overview for people who may not be aware of Slimstock and what it can do?

Slimstock celebrated its 30th year last year. As a privately owned business, we are driven by a passion to help businesses create more agile and resilient supply chains. Our primary focus is on supply chain planning and S&OP.

Today, we support over 1,500 customers across the world to make better supply chain decisions. As a global operation, we offer the scale and expertise to deliver combined with local intimacy that ensures local teams work with local people. For this reason, we successfully deliver 150+ digital supply chain transformations every year with customers across every industry ranging from privatelyowned companies to Fortune 500 organisations.

Each industry has its nuances, but great supply chain principles are universal. We also see common challenges across all sectors: Are they challenged by volatile lead times? Are they impacted by disruptive supply chain events? Is the complexity increased to a point where spreadsheets create more problems than they resolve?

We are here to help these businesses navigate their supply chain challenges and deliver tangible performance improvements. This is both in terms of customer experience and profitability but also sustainability and eliminating all forms of waste.

We achieve this by empowering people and processes throughout the supply chain with our AIpowered supply chain planning platform. But we are far more than just a technology company. We believe in equipping supply chain teams and business leaders with the knowledge, insight, and visibility to make informed, datadriven decisions.

We do that through things like our Slimstock Academy, which offers a range of courses and development programmes to upskill supply chain teams. We also look at how a business’s process works. Can it be improved? What can we automate? And where can we finetune supply chain workflows?

It is a fundamental belief at Slimstock that technology, people, and processes have to work together for any form of supply chain success.

Our customers include wholesalers, retailers and manufacturers. By developing our platform in close collaboration with our customers, we go to great lengths to ensure they benefit from the latest supply chain innovations. Some of your readers might know of Toolstream or Cromwell Tools, which have been customers of Slimstock for some time.

// Today, we support over 1,500 customers across the world to make better supply chain decisions. //

In what ways can Slimstock help businesses?

Our approach centres on efficiency. By automating the automatable and forecasting predictable events, we can help planning teams free up time to tackle unexpected challenges like sudden spikes in demand. More importantly, by minimising mundane work, we can eliminate firefighting so our customers can dedicate more energy to delivering strategic goals.

From a workload perspective, customers see around a 5080% reduction the planning workload. By automating routine supply chain workflows, our platform does a huge amount of the heavy lifting.

Our system automates a range of workflows, such as detecting seasonal patterns, using machine learning to understand customer behaviour and catch any unusual activity, and autonomously optimising stock levels. Our customers love it because it lets them focus on what really matters.

Reliability of supply is a big thing in the fastener industry, including being able to deliver for projects to avoid delays, etc. Is that something Slimstock is primed to help with?

Availability of products ultimately makes or breaks a business, especially in this industry. Customer expectations are extremely high. After all, stockouts quickly result in costly delays. We appreciate the importance of delivering an industryleading standard of service.

But on the other hand, fastener companies typically offer vast assortments. Therefore, working capital constraints have to be taken into account. By providing robust insights, we help businesses balance this trade off to prioritise their working capital investment in the products that matter most. Ultimately, it’s about investing money into right stock at the right time.

We’ve mentioned sustainability, and CBAM. It’s a more important factor now and more end users are demanding sustainable supply chains. So, does Slimstock have any impact on the sustainability side of things?

Looking at it from a waste and obsolete stock perspective, the benefits are clear for everyone involved. The push for sustainability resonates with businesses committed to making a positive impact, as well as those whose performance is directly influenced by minimizing obsolete stock and waste.

Optimising container space, for instance, allows us to consolidate orders, ensuring high availability while ultimately reducing our overall shipping frequency. Likewise, eliminating planning errors, optimising replenishment, and rationalising assortment policies all translate to a significant reduction in carbon emissions.

Other than awareness of supply chain volatility, are there any big trends that you’re seeing?

I think S&OP, Sales and Operation Planning, is emerging as hot board room topic. It’s a recognition that a supply chain is not unique in a business – it shouldn’t be disconnected. Previously, I think businesses could get away with keeping supply chain management and sales and operations siloed. But we’re now in a world where everyone has to work together to ensure that we’re getting the best results possible. S&OP is something that we support our customers with. It’s part of what we do, both from a solution point of view and also from helping establish a robust S&OP process in a business.

www.slimstock.com

UMUT INCE R&D AND ENGINEERING DIRECTOR, NORM FASTENERS

UMUT INCE R&D AND ENGINEERING DIRECTOR, NORM FASTENERS

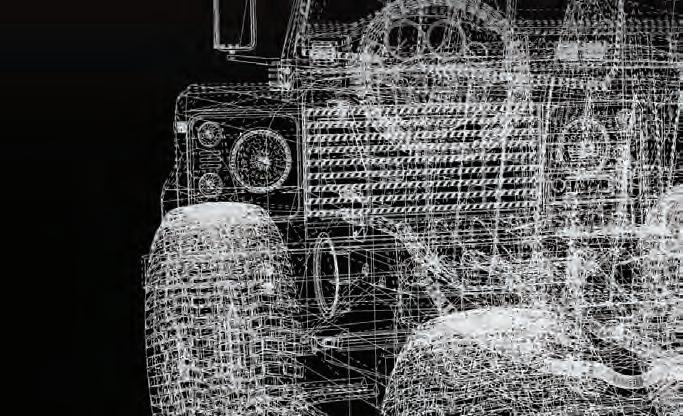

In the dynamic landscape of electric vehicles (EVs), every gram matters. As the automotive industry shifts towards electrification, optimising weight becomes paramount for enhancing efficiency, extending range and ultimately, improving performance. In this pursuit, fasteners emerge as unsung heroes, playing a pivotal role in ensuring the structural integrity and safety of lightweight EV designs.

Fasteners, such as bolts, nuts and screws, are the backbone of vehicle assembly, holding together critical components ranging from battery enclosures to chassis structures. However, in the context of EVs, where reducing weight is essential for maximising energy efficiency, the significance of fasteners transcends mere mechanical connectivity. Lightweight materials like aluminium, carbon fibre and high-strength steel are increasingly replacing traditional steel in EV construction. While these materials offer remarkable weight savings, they also present unique challenges in terms of joining and fastening due to their differing properties and characteristics.

Moreover, the design of fasteners themselves is evolving to meet the demands of lightweight construction. Especially geometrical optimisation using Computer-Aided Engineering (CAE) is a powerful tool in the design and development of lightweight fasteners for EV. This approach involves leveraging computational simulations to refine the

GET IN TOUCH...

www.normfasteners.com

info@normfasteners.com

LinkedIn: norm-fasteners

geometry of fasteners, maximising their strengthto-weight ratio and ensuring optimal performance under various loading conditions. Geometrical optimisation using CAE empowers engineers to push the boundaries of lightweight design for fasteners in vehicles. By leveraging advanced simulation techniques, such as topology optimisation, parameterized design, FEA, material modeling, and multi-physics simulation, engineers can design fasteners that are not only lighter but also stronger, more reliable, and better suited to meet the demanding requirements of vehicle applications.

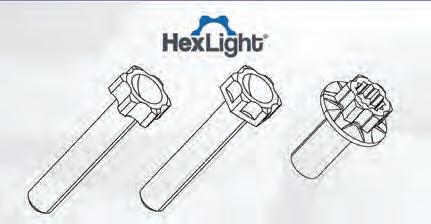

In accordance with automotive trends, Norm Fasteners offers lightweight products to OEM companies as a design partner. There are limitations that OEM companies take into consideration to adapting weight-reduced products to their production lines. We can evaluate these limitations under three main headings: operability, cost efficiency and weight reduction ratio. For companies that do not want to change the currently used standard hexagonal bits, topologically optimised weight-reduced products such as HexLight® are offered at Norm Fasteners with similar costs. There is also the ExtremeLight™ product with a special head design for situations where the weight reduction ratio is more important. In addition to design solutions, it is also possible to achieve higher weight reduction by reducing the diameter with ultra-high-strength bolts that can also be combined with the mentioned designs.

In conclusion, efficiency in the world of EVs requires optimising every component, including fasteners. These essential elements enable lightweight design and play a crucial role in the pursuit of sustainable transportation as industry moves towards electrification.

norelem is expanding its product lines and increasing safety with Indexing locking bolts and positioning bushings with condition sensors.

Norelem has added locking bolts and positioning bushings with condition sensors to its extensive line of products with condition sensors. Condition sensors are used to give a constant visualisation of the “health status” of facilities and equipment, and detect signs of abnormalities, reducing material losses and significantly increasing process reliability. With these new, intelligent products, norelem continues to stake its claim as the market pioneer.

The new products aim is to enhance manufacturing processes delivering stability, precision and reliability. Products with condition sensors support and position monitoring functionality, such as the norelem locking bolts and positioning bushings, offering a clear advantage.

For locking bolts with condition sensors, the sensor is integrated within the handle of the bolt and is connected to the central machine with a threecore PVC cable. This setup enables the sensor to accurately detect the bolt’s status (locked or pulled) and relay the information to the central machine, facilitating actuationdependent process control. As a result, the length, height and positioning of moving components can be finely adjusted, enhancing precision. norelem’s locking pins are available in both steel and stainlesssteel variants.

The positioning bushings with condition sensors have a variably adjustable sensor on the bushing. On the models specifically designed for a condition sensor, the user can easily mount a standard inductive sensor with 3mm diameter. The inductive sensor detects the signal and transmits it to the machine control system. The control system then knows not to start the production cycle until all operating or detent elements are in the correct position. Such electronic condition monitoring is instrumental in format adjustments for packaging machines and aids various other manufacturing processes.

In addition to locking pins and positioning bushings, norelem has developed springloaded thrust pieces with condition sensors, and stainlesssteel condition sensors with holders for toggle clamps.

www.norelem.co.uk

NordLock has a long tradition of innovating new products, starting in 1982 when it introduced wedgelocking technology. This new way of securing bolted connections broke new ground in the bolting industry. And now, more than four decades later, the company is adding the CE marking to its securing washers.

Although the washers are the same, made from the same highquality materials and rigorous production process, adding the CE marking innovates the securing washers significantly. Manufacturers within the wider construction industry can add an extra layer of compliance, meet highquality standards in terms of safety and compliance, through choosing NordLock washers. They’re also reassured that the washers have been thoroughly inspected from a safety perspective.

“We are thrilled to introduce CE marking for our wedgelocking washers, reinforcing our commitment to delivering

excellence in engineering and design. This achievement demonstrates our dedication to compliance and safety, providing our customers with a competitive edge in their operations,” says Graham Souter, Vice President and head of the NordLock Business Unit.

The fact that no other manufacturer of securing washers offers CEmarked products at this time speaks of the laborious efforts involved in obtaining the certification. Demonstrating that NordLock materials meet the specified quality requirements, to harmonise with the Assessment and Verification of Constancy of Performance (AVCP) and succeeding with the other steps on the journey towards the CE marking has been a multiyear process. NordLock’s team of engineers and product specialists have worked tirelessly to get this high recognition of quality.

JCP has added three new high-performance ETA-approved anchors to its already broad range

JCP Construction Products, the specialist fixings division of OwlettJaton, offers an impressive range of ETAapproved fixings. To expand its offering further, it has added three new ranges of highperformance ETAapproved anchors.

Specifying ETAapproved anchors demonstrates a commitment to quality and safety. They represent the pinnacle of performance in construction fastening solutions. With their superior features and benefits, these fixings are the preferred choice for engineers and contractors seeking reliable solutions for their projects.

Manufactured from A4316 stainless steel and alloy steel, a range of selftapping pan head ankerbolts suitable for use in cracked and noncracked concrete have been added to their extensive ankerbolt range. ETA (ETAG 0016) approved, they offer a fire resistance loading and are suitable for use both indoors and out.

The pan head gives a wider bearing area to give greater contact with the fixture, whilst the undercutting action provides a positive anchorage with no expansion forces. In addition, two ranges of multipleuse dropin anchors have

been added to their heavyduty anchor range. These deformationcontrolled zincplated anchors are suitable for multiple uses in nonstructural applications in concrete. Suitable for use in cracked and noncracked concrete, they are perfect for suspending services with threaded rods or bolts or fixing a permanent set socket to allow a fixture to be removed, amongst other uses.

The specific design provides the flexibility of using the anchor for applications with limited embedment depths, such as precast and prestressed hollow core slabs. The internal thread is suitable for bolts or threaded studs.

Available in both lipped and nonlipped, they are ETA (ETAG 0016) and CE approved and offer fire resistance loading. The lipped version ensures the anchor is set flush, thus avoiding overdrilling.

JCP offers over 250 ETAapproved lines with new ranges and line additions consistently added. To download the catalogue or to get technical data and data sheets, please visit...

www.jcpfixings.co.uk/product-category/heavy-dutyanchors

CELO has revealed it now has official approval for its FORCE ONE Direct Impact Fixing System by the European Technical Assessment (ETA) board.

The ETA approval highlights the high standard of performance and security embedded within the FORCE ONE gas nailing system. By utilising CELO’s extensive system, which includes nailing accessories, XHA nails, and the FORCE ONE gas nailer, construction professionals can trust in the integrity of their installations, streamline their workflow and save time and money compared to traditional installation methods.

The ETA assessment confirms the technical applicability and suitability of the FORCE ONE system for various applications. CELO’s XHA nails, meanwhile, are designed to integrate with the FORCE ONE gas nailer, offers strength, durability and precision.

CELO says: “The ETA approval guarantees that our direct impact fixing system meets strict regulations, providing peace of mind to professionals and minimising risks on the job site.”