HV (EN 14399-4) delivered as set: bolts + nuts + washer in 1 box

HR (EN 14399-3) delivered as assembly in 1 box

SB (EN 15048) in zinc plated and hot-dip galvanised (iso-fit)

TÜV Rheinland certified

40 brands. 400 tools. 1 battery pack.

CAS. The multi-brand battery system.

More than 40 powerful manufacturers have joined forces so that tools, battery packs, and chargers are 100% compatible with each other. CAS battery packs are developed in Germany and perform well even in the most demanding applications thanks to leading battery pack technology.

Publisher

Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Rachel King rachel@torque-expo.com

Deputy Editor Simon Yuen simon@torque-expo.com

Sales Manager – UK Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

UK Sales Manager – Tools

Lloyd Ramsdale lloyd@torque-expo.com

Circulation

Tracy Howell tracy@torque-expo.com

Head of Production Luke Wikner luke@torque-expo.com

Designers

Dan Bennett Victoria Arellano

Head of Marketing Shona Hayes shona@torque-expo.com

Published by

Stag Publications Ltd

18 Alban Park

Hatfield Road

St Albans

Herts AL4 0JJ

tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-expo.com

Web: www.torque-expo.com

Disclaimer

Although the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or of Stag Publications Ltd.

06 GUEST EDITOR 08 NEWS

14 COVER PROFILE > AMBROVIT

16 WOMEN IN FASTENERS & TOOLS > SOME OF THE LADIES FROM BRIGHTON BEST INTERNATIONAL (UK)

19 SHOW REVIEW > GOEBEL WORLD RIVETING CONGRESS

22 FOCUS > C-PARTS, LOGISTICS & KANBAN FEATURING FERDINAND GROSS, FABORY AND PGB EUROPE

28 INTERVIEW > JRP

32 INTERVIEW > BÜLTE

34 FOCUS > AUTOMOTIVE FASTENERS & TOOLS

40 FOCUS > SURFACE TREATMENT & COATINGS – NOF COATINGS, OWLETT-JATON, HENKEL

46 FOCUS > PRODUCTION LINE TOOLS

52 SHOW REVIEW > LIGHTWEIGHT METAL DAYS

56 SPOTLIGHT > BRIGHTON BEST INTERNATIONAL

60 BUILDING & CONSTRUCTION > ADHESIVES, TAPES, SEALANTS & FILLERS

63 INTERVIEW > NORD-LOCK GROUP

66 SHOW PREVIEW > BAU 2025

70 FOCUS > BATTERY TECHNOLOGY & SMART TOOLS

73 SHOW REVIEW > IHT X TITE

74 SPOTLIGHT > HEICO

76 SPOTLIGHT > GROWERMETAL

78 SHOW REVIEW > TAIWAN HARDWARE SHOW

80 TORQUE RISING STARS

To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code...

This issue we’ve been fortunate to get our foot in the door with some big-name execs in the fastener and fixing industries and use up some of their valuable time to glean some insights into the market. That’s not a boast (OK it is a little bit), but it’s also to flag up some of the genuinely valuable inside knowledge that can be found within this humble magazine.

Our Guest Editor, Ian Doherty, Owlett-Jaton CEO and BIAFD Chairman, shares his perspective on CBAM, a huge issue that is affecting, or will affect, the entire industry, from importers to distributors, manufacturers and the end user (likely in cost terms). It’s well worth digging into his knowledgeable appraisal of the situation.

Deeper into this issue, we speak with NordLock Group’s new CEO Daniel Westberg. He reveals a little about the future direction of this global giant under his stewardship and some of the sustainability strides Nord-Lock Group is making with SBTi.

Elsewhere we have Bülte Managing Director Fanny Bülte on similarly crux topics like digitalisation and the challenge of combining company heritage with forward-thinking innovation.

And there’s a lot more besides, from other top execs and also up-and-coming names in the fastener and tool industries. Technically, it took a few weeks to put this magazine together, but – in one sense – it has been decades in the making, featuring insights and knowledge that have been garnered by individual interviewees over decades and decades in the trade. Thanks to all for allowing us to share their acumen with our readers.

Jonathon Harker Editor

jonathon@torque-expo.com

As part of our commitment to the environment, Torque

www.achill-fasteners.com

IAN DOHERTY, CHIEF EXECUTIVE OF OWLETT-JATON, IS GUEST EDITOR OF THIS ISSUE OF TORQUE MAGAZINE

"SOME MAY BELIEVE CBAM IS SIMPLY A TRADE TARIFF, BUT I GENUINELY SEE THE NEED IF WE ARE TO LEAVE A HABITABLE PLANET TO FUTURE GENERATIONS."

Last year, in this magazine, I contended that CBAM was, in principle, a good thing. I still consider that to be the case, even in the light of the practicalities of managing the current system. 2024 has seen further evidence of the potentially catastrophic impact of climate change, with record temperatures, widespread flooding and devastating hurricanes. Any chance that the global rise in temperatures could be kept to under 1.5 °C has, in my opinion, passed. However, all that means is that it is even more important that we limit how much further global temperatures rise and the damage done to the planet. Limiting temperature rises means reducing CO2 emissions, and CBAM has its part to play in achieving that objective.

I have long held a view, perhaps slightly cynically, that people only really change their behaviour when it hits them in the wallet, if we want to limit carbon emissions, carbon must cost more!

Across Western Europe, we have seen the introduction of carbon-based taxes and emission trading schemes which add a charge for carbon emissions. I believe this is generally the right approach and over time will make carbon-intensive activities more expensive than those which have a lesser carbon footprint. The costs of carbon will have, ultimately, to be passed on to the consumer and that will raise political challenges about the cost of living. We have seen this in the UK where fuel duties, which were originally supposed to escalate annually thereby increasing the price of fuel, and encouraging the use of more efficient vehicles, have not moved since 2013 because it is politically unpopular. The emissions trading schemes currently in place in the EU and the UK both have large ‘free’ allowances available, which are planned to reduce over time, thus phasing in an increased cost of carbon on activities across Europe. Whether politicians will hold their nerve on that is another matter!

Even if we Europeans, yes I do consider the UK to be part of Europe even if it is not part of the EU, grasp the nettle of carbon pricing internally, we must ensure that does not simply result in further offshoring, hence the need for a CBAM

mechanism. There are some that may believe that CBAM is simply a trade tariff, but I genuinely see the need if we are to leave a habitable planet to future generations.

If a CBAM is to be effective I also believe it needs to cover downstream products. I realise this may be a rather unpopular view in the fastener market, but I see little value in adding carbon cost to raw materials whilst ignoring the carbon in manufactured goods. Fasteners under CN Code 7318 have had the dubious privilege of spearheading downstream products in EU CBAM. I am sure many very able people designed the mechanisms, but I suspect they were not designed with as complex a supply chain as the fastener one in mind. In spite of the best efforts of EFDA and the national distributor organisations to support importers, the end result has been chaos with few reports for fasteners being completed. The need to report actual data for Q2 2024 imports, is proving an exceptional challenge. I think it’s unlikely that current lobbying to have CN Code 7318 removed for EU CBAM will succeed, I know EFDA is lobbying hard, but if the mechanism is to work, I believe we need something much simpler, with many more defaults. Over time it may evolve and become more accurate, but at the moment I think EU CBAM is a good example of perfect being the enemy of better!

In the UK, we too have a CBAM coming, though it does seem the UK government is being rather more pragmatic about it. The charging mechanism is much simpler, with charging being related to goods entering free circulation, rather than the overly complex EU purchasing of certificates in advance approach.

The British and Irish Association of Fastener Distributors (BIAFD), of which I am Chairman, has been active in the consultation. We recognise that fasteners will have to come into scope at some point but have been lobbying that they are too complex for inclusion on launch in January 2027. We have yet to see how successful that will be, but I do hope the UK Government continues to be pragmatic about UK CBAM and learn to walk before they try and run!

Whatever happens, the fun of CBAM is going to run and run!

Aflurry of recent acquisition activity in the industry has included the significant buy out of Ferdinand Gross Group, an €80 million net sales company headquartered in LeinfeldenEchterdingen, Germany

Bossard Group signed an agreement to take over Ferdinand Gross Group, one of the leading distribution companies for fastening technology, operating in locations in Hungary and Poland as well as its Germany HQ.

The Ferdinand Gross Group is celebrating its 160th anniversary this year and employs around 260 people

For Bossard, the move further expands its market presence in Germany and Eastern Europe where it will be able to

serve customers in those regions more comprehensively, in tandem with Bossard Germany

"I am looking forward to the upcoming collaboration with our new colleagues,” said Daniel Bossard, CEO of the Bossard Group, at the time “The planned takeover of the Ferdinand Gross Group not only brings together two companies with a long tradition, but also two strong partners who represent common values and business philosophies in the spirit of ‘Proven Productivity.”

www.bossard.com/ch-de

BIAFD (British and Irish Association of Fastener Distributors) has seen record membership – up 10% on last year – and record attendance at its autumn meeting, with 105 delegates attending, approximately half the total BIAFD membership.

For the second meeting running, Carbon Border Adjustment Mechanism (CBAM) was the main focus Jamie Mcleod of Crowe UK returned to the Leonardo Hinckley Island Hotel with an update on the current state of play, whilst BIAFD chair Ian Doherty and BIAFD

policy adviser Phil Matten presented a range of CBAM software solutions. Phil Matten then delivered a presentation on regulatory updates including Extended Producer Responsibility, before an economic and FX report was provided for members.

Headline sponsor EazyStock delivered a session on their services and capabilities before the day was wrapped up with the association’ s AGM.

BIAFD said those in attendance gained a better understanding of important industry issues and had the benefit of networking with another Headline sponsor EazyStock and premium sponsor Epicor supported the event

Turn to page 6 for more on CBAM from the BIAFD

Martin Dahlgren taken up the position as new Managing director for fastener manufacturer BUMAX Sweden AB. He joins the company with over 20 years of experience in management, sales, strategy, business development and international business at several global manufacturing companies.

“I am thrilled to join the global leader in fastener technology,” said Martin Dahlgren. “BUMAX is such an innovative company, whose high strength stainless steel fasteners help many companies to unlock new design capabilities, improve the performance and durability of their products, while supporting industry sustainability goals.”

bumax-fasteners.com

Home Depot has announced the passing of one of its founders, Bernard “Bernie” Marcus.

Born in 1929 in Newark, New Jersey, the son of Russian Jewish immigrants, he dreamed of a career in medicine but climbed the corporate ladder instead.

In 1978, he founded Home Depot with friend Arthur Blank and Investment banker Ken Langone, a onestop

shop for doityourselfers that didn’t exist in the retail market at the time.

The business now employs over 500,000 associates.

Bernie was Home Depot’s CEO until 1997 and served as the company’s chairman until his retirement in 2002.

In a statement, Home Depot described Bernie as “an inspiration in many ways. He was a master merchant and a genius with customer service.”

The SFS Group has acquired Pro Fastening Systems, a distributor of fasteners and sealants for the commercial and industrial construction industries. The acquisition enables SFS to expand its market presence in the Midwestern United States with Pro Fastening Systems four locations in Arlington (Illinois), Chicago (Illinois), Milwaukee (Wisconsin), and Indianapolis (Indiana).

NORM HOLDING PRESENTED AT US SUMMIT >

Norm Holding presented its project within the scope of the “SDG Innovation Accelerator for Young Professionals” at the UN Global Compact Leaders Summit in New York, which brings together leaders and pioneers in the field of sustainability on the global stage. The team representing Türkiye garnered praise for their project proposal on waste energy recovery.

GRAFTON GROUP TRADING UPDATE OCT 2024 > Building materials distributor and DIY retailer Grafton Group has issued its trading update from 1 January to 20 October 2024. Group revenue in the period was £1.82 billion, down 3.7% from the previous year. The company said a weaker euro in the current financial year slightly reduced the reported results compared to the same period last year.

JCP FIXINGS EXTENDS RANGE > JCP, OwlettJaton's speciality fixing division, have expanded their portfolio with over 30 new product lines. The heavyduty anchor portfolio now includes three new ETAapproved product ranges among many other additions. JCP products are further complemented by a variety of merchandising options suitable for retail environments.

MUNGO TAKEOVER BY INVESTORS COMPLETES >

Swiss fastening product manufacturer MUNGO Befestigungstechnik AG has been acquired by a group of investors with extensive international industrial expertise. Claude Mion is the new Chief Executive Officer. The company name and location will remain the same after the acquisition and it is still accessible through its existing contact information.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

FISCHER WINS FACTORY OF THE YEAR COMPETITION >

fischer has won the Global Excellence in Operations (GEO) Award category in the Factory of the Year competition for its production plant in Ivanovice na Hané in the Czech Republic. The win coincided with the site’s 30th anniversary.

KOELNMESSE TO LAUNCH SAUDI ARABIA EVENT IN 2025 >

Koelnmesse and dmg events have announced that they will coorganise the new International Hardware Fair Saudi Arabia which will take place annually at the Riyadh International Convention & Exhibition Center. The first edition is scheduled for June 2025 and will provide a crossindustry platform dedicated to the hardware and tool sector in Saudi Arabia.

FERVI GROUP NEW SUBSIDIARY ESTABLISHED IN CHINA >

Qingdao Fervi International Trading Co. Ltd is the latest addition to the FERVI Group. Based in Qingdao, one of China's port cities, this new subsidiary is strategically positioned to enhance logistics and streamline the Group’s gotomarket efforts, and will serve as a resource for all of the Group's companies, including Rivit, Vogel Germany, Riflex Abrasives, and Sitges SL.

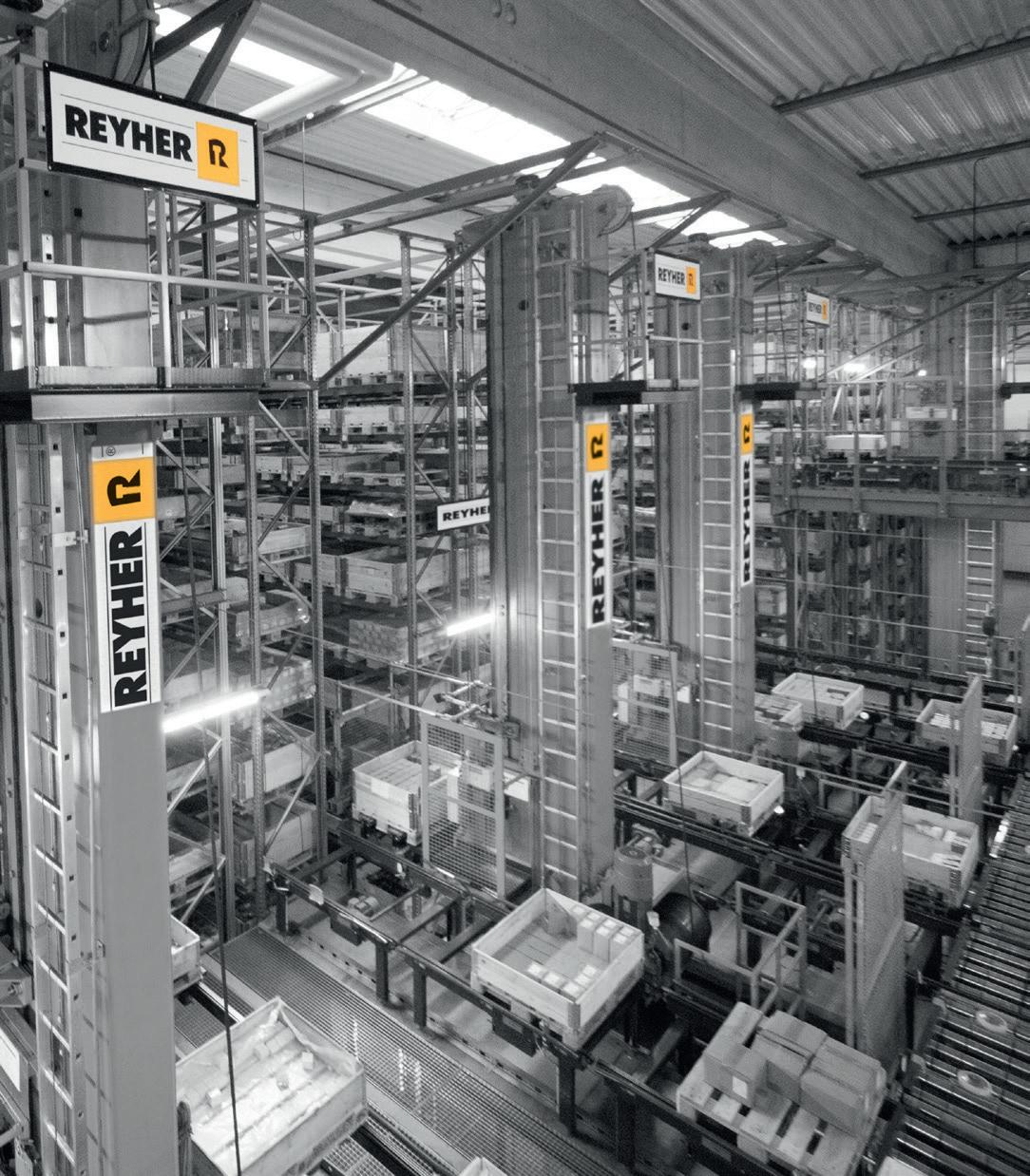

Ambrovit’s total capacity verges on 90,000 pallet spaces, including automated warehouses, operational and state-of-the-art logistics units

People at the service of quality

Last year, Ambrovit completed the implementation of its new state-of-the-art Proxima warehouse, just one of a number of sizeable investments from the company which is focused on innovation, high standards, research and anticipating market needs. Founded on family values, Ambrovit seeks strong and lasting relationships with customers and tackles challenges with enthusiasm and tenacity…

Since 1997, the Ambrovit name has been a guarantee for experts in the screw and bolt industry. The Garlascobased company has, from its beginning, demonstrated a strong devotion to work and determination to supply highquality products. Likewise, the company has, from the start, invested in stateoftheart technology.

Ambrovit has aimed to be an undisputed leader in the screws and bolts industry, with innovation, dedication to quality and unwavering commitment to customer satisfaction.

Ambrovit's growth has been steady over the years, fuelled by its focus on innovation and adaptation to changing market needs, making it one of the leading suppliers of screws and bolts today, with an established presence in domestic and international markets.

Ambrovit's distinguishing feature is its meticulous attention to the quality of its products: The company adheres to high standards to ensure the efficacy and safety of the products it distributes. This commitment to excellence is reflected in the durability, reliability and performance of its products, earning the trust of professionals and companies worldwide. But, as behind every story of value, Ambrovit is first and foremost made up of people, whom the company trusts and values, to create a united and inclusive team. When a company is founded on family values such as reliability, openness to innovation and empathy, it can only lead to a success story, the firm says. For this reason, the company has always aimed to maintain strong and lasting relationships with its customers, with a focus on their specific needs and a commitment to providing customised solutions that exceed expectations. Thanks to this, and to the choice of quality products, Ambrovit is today a market reference for 54 countries around the world.

Technological innovation and continuous research

Ambrovit's leadership is fuelled by continuous research to stay abreast of the latest trends and emerging technologies in the screws and bolts sector, enabling the company to distribute cuttingedge solutions that anticipate market needs.

The implementation of the new Proxima warehouse, connected to the existing Orion warehouse via an impressive 26metre bridge, has created a stateoftheart logistics ecosystem, covering a total area of 24,000 m2. This forwardlooking investment represents a quantum leap in product management, greatly facilitating handling, storage and shipping.

With a total capacity verging on 90,000 pallet places, distributed between automated warehouses, operational and logistics units, and the integration of stateoftheart technolo

Ambrovit has also focused on innovation to help end users choose the products right for them

gies, Ambrovit is now able to guarantee ultrarapid shipping, delivering products within 24/48 hours. This new logistics ecosystem not only optimises internal efficiency, but also results in greater customer satisfaction. Prompt order fulfilment not only reflects the company's commitment to operational excellence, but also creates an immediate bond with the customer. Prompt deliveries have helped make Ambrovit a reliable partner, ready to meet customer needs in a timely manner, thus helping to consolidate a relationship of mutual trust.

// The implementation of the new Proxima warehouse has created a state-of-the-art logistics ecosystem, covering a total area of 24,000 m2. //

While boasting over 20 years history on the market, Ambrovit is also a company that likes to look to the future and is therefore committed to reducing its ecological footprint. All products are identified by labels that indicate their compliance with the standards of the regulations in force, making it more accessible to the customer to find fundamental information such as the conformity of products to CE marking requirements, information regarding certifications and the sorting of packaging. Another move dictated by the desire to make the company even more sustainable is the decision to equip the new Proxima warehouse with 650 photovoltaic panels that can generate enough energy to power all stages of the production chain. The company philosophy is based

Ambrovit guarantees ultra-rapid shipping, optimising internal efficiency

on the idea that efficiency can go handinhand with sustainability. Every day, the company works to prove that it is possible to combine innovation, technology and respect for the planet.

Go easy: the fastening solution within everyone's reach ‘The future is an incredible adventure’ and Ambrovit has decided to live it by anticipating market trends and offering its customers constant innovation and new ideas to optimistically look to the future. The Go Easy project was born in 2024: an activity directed at the end customer, who can conveniently choose the products that are right for them quickly and intuitively.

Three different sizes of blisters are available, containing a range of over thirty products between screws, bolts and other fastener elements. The screws available in the packaging are of various types and can also be suitable for application on different surfaces such as wood, plasterboard and chipboard. Attention to detail is essential for Ambrovit, which has designed a modern and essential packaging for this new project, with a technical drawing of the screws on the front, descriptions, sizes and areas of use in both Italian and English. On the back, on the other hand, there are detailed descriptions in nine languages to facilitate product selection.

In addition, certifications such as EN 14592 and EN 14566 complete the work, demonstrating once again the quality and rigour that characterise the company. The year 2024 has almost come to an end, amidst novelties and challenges, but at Ambrovit, preparations are already in full swing for next year's novelties, to be tackled with enthusiasm and tenacity.

Find out more at... www.ambrovit.it

Torque Magazine travelled to Brighton Best International to speak with Team Leader Kymberley Da Costa, Field Sales Representative Jessica Terry and Sales Manager Shelly-Ann Willetts

What does your day-to-day role involve?

Jessica Terry: I have recently been promoted to Field Sales Representative, I’m on the road 3 days a week and in the office 2 days. My time in the office is to write reports, plan my meetings, bring back leads and liaise with Kirsten (my dedicated liaison in the office) to grow and develop sales from my visits. Kirsten being this direct point of contact means our customers get a more seamless transaction. I’ve also been working closely with Shelly to learn from her experience, working on customer outcomes, overall development, she has helped me with how to target customers and produce results.

Kymberley Da Costa: Each day for me is different, I can go from handling a customer query which would involve pulling all the paperwork applicable to the query and requesting stock checks etc. to booking an engineer in for a site visit, to sending out enquiries to our overseas vendors and having the PO’s raised. This is why my role is so enjoyable the variety of it means there is never a dull day.

How long have you been in the industry?

Jessica Terry: I’ve been in fasteners for 14 years, it’s given me the time to build rapport and working relationships with many people across the fastener industry, it is why participating in customer visits is something I enjoy, and this has been limited at other companies I’ve worked for. Brighton Best have given me the opportunity to grow. I’ve been given support and guidance from BBI with regards to progression, this I am grateful of.

Kymberley Da Costa: Mike Churchill (Brighton Best International UK Branch Manager) has got a knack for identifying skills in people that can be developed. That's a big plus point

for our employees where it may not have recognised before at other companies. For me personally in the last six months I feel Mike has helped me develop massively into my role and continually strives to guide me to follow the correct processes. I've been in the fastener trade for 26 years at different kinds of businesses, from engineering to distribution, but I've never had the confidence that I have now working in this organisation.

Kymberley Da Costa: I started at the age of 16, so it was straight out of school. I worked at stainless steel fastener specialists for the first 15 years of my career, which obviously tied in really well with the growth in stainless steel here at Brighton Best (see page 56) because I’ve got that product knowledge and understanding.

Jessica Terry: I’m from a fastener family, from a very young age I was exposed to the fastener industry. I worked part time at a fastener company whilst at university studying to become a teacher. Whilst working in a school I was approached by a wellestablished fastener distributor and offered a sales role within the organisation, I soon realised I had missed the sales environment and this was the career path I wanted to continue on.

Kymberley Da Costa: I think I can say this for a lot of people, that once you're in fasteners, it's quite hard to leave it, because there's always something new to learn. There's no way you can know every fastener, there's usually something new to pick up or learn a new process.

What’s some of the biggest changes you’ve seen in the industry since you started?

Jessica Terry: One change that I've noticed is in purchasing. Years ago, you could lose an order if you were just a penny more expensive. Now, there are a lot more variables. It’s no longer down to price, it can be dependent on delivery time, certification, quality of the product and service.

Kymberley Da Costa: Where do I start? There have been so many, from CBAM to Russian Sanctions, it feels like the industry is forever evolving. This adds to the excitement of it all for me though, there is always something new to learn or get our heads round in order for us to continue trade and who doesn’t love a challenge? We have the best people in the best places and are able to call on all our BBI global resources to figure things out and we get it done, it’s been said now, more than once to us that other suppliers are struggling with CBAM data whereas we were ready for it and have been able to supply data upon request from our customers in a timely manner.

Brighton Best is big enough to attract people to work there, but more generally, is there an issue about appealing to the next generation and getting young people into the fastener industry?

Kymberley Da Costa: Even getting young people to see engineering as a viable career is difficult. So many kids want to be influencers and want to be on YouTube. There definitely needs to be more for younger people to make it appealing. There are some of the younger fastener companies that will utilise social media and YouTube – to show it’s not just about pieces of steel and we do this to a degree with our Ironclad range.

Jessica Terry: A lot of people would assume the fastener trade is a male dominated industry, for me this isn’t true. I was encouraged myself from a young age to work within the industry and I would do the same for my own daughter. The fastener trade is not an industry that will ever fade out, it’s fast paced and very progressive, there will always be room for young women to enter the industry and work their way up the way I have.

How are Brighton Best keeping up with the changing landscape of sales within the industry?

Jessica Terry: Facetoface contact definitely helps with a working relationship. In the fastener industry I've spoken to a lot of people over the years who say this is an element that's missing, personal approach needs to be reintroduced and I feel this is what BBI have now done by having me and ShellyAnn on the road.

I’ve personally come across Sales Reps who either know the product they are selling or know the market they are selling to, I think it’s very rare you get a Rep who can do both, I think this is where BBI are tackling this differently. Being a woman out and about in the wellestablished construction/engineering environment would seem daunting to many but growing alongside this industry it is a different landscape now to what it was 14 years ago.

Kymberley Da Costa: I’ve noticed that change myself, when first starting out in the trade, the hierarchy of many organisations were predominantly male, it’s empowering to see so many women in positions of authority these days, an example of this being our Sales Manager, ShellyAnn. I think it’s becoming a more common than it used to be. There are definitely more women attending our industry trade shows and meetings. Another way we are keeping up with changes is our webshop, now this isn’t a new function for BBI but its being used more frequently. Our customers have 24 hour access to our live inventory and pricing, this gives them the advantage

of placing enquiring/placing orders at a time that is convenient for them. Our certification is also available FOC using the web portal. Big changes in the industry that have affected many recently would be the introduction of CBAM submissions, this is something that hasn’t phased us at BBI, we deal with carefully selected vendors worldwide who are able to provide us this data and in turn we can pass this onto our customers. We hear of the changes coming in to focus for the fastener trade and act quickly enabling us to pass on this benefit to our customers.

What’s your favourite thing about the faster industry?

Kymberley Da Costa: You can learn something new all the time. That's a huge plus for me. You never get bored. There's always something new and you're always busy. The second one for me is customers, because I've been in the industry so long and get to speak to many customers I feel I have got great working relationships with them, you get to know a bit about them and their family… and it's nice to have that, it allows you to ask the cheekier questions when negotiating!

Jessica Terry: I agree with Kym with regards to there always being something new to learn. Coming from The Black Country the fastener and steel trade has a deep routed history in which my family have been a part of and I am proud to continue this legacy.

Welcome back – how does it feel to be returning to BBI? Thank you. I would say it feels like I never left but our internal system has been upgraded and had a facelift so I’m still reacquainting myself a little. But it’s good to be back!

What new skills/experience have you acquired over this last year to bring back with you to the business?

I’ve been introduced to another tier of the distribution chain, different product ranges, different industries and ultimately the other side of the industry; I’ve been with BBI a long time so it could be said that I am institutionalised; seeing the other side of the coin has given me a different outlook, a different vantage point so to speak.

What will your role within BBI and day-to-day activities consist of moving forward?

Similar to previous but focused more on increasing sales further to take us to the next level. The plan is to increase sales in 2025 to our highest turnover to date – using various avenues to achieve this. We will have more of a presence in front of customers than we have ever had previously, with myself and Jess visiting customers on a weekly basis. We’re increasing mill direct orders and partnering with distributors heavily – storing annual usages so the customer can maintain stock and price; allowing them to take advantage of our purchasing power. We are increasing our stainless range on a weekly basis which is largely at the forefront right now for the sales team. Moving forward a few months; we have Stuttgart’s Fastener Fair Global and planned visits to Ireland and Scotland also.

It’s an exciting year ahead for BBI with the 100-year anniversary in 2025 – any exciting plans you can share?

There is a lot in the pipeline at the moment but it’s a big year for us as a company – but as far as the UK; We plan on organising a Supplier Open Day at BBI UK premises to celebrate –inviting customers to tour our warehouses, meet their account manager, see how we operate, have lunch etc. we haven’t done an event like this since we moved to this building over 16 years ago so I think it’s long overdue and 100 years it’s a perfect way to celebrate.

www.brightonbest.co.uk

In September, the Goebel Group hosted the inaugural World Riveting Congress 2024 in Erkrath near Düsseldorf, where invited guests were able to discover the latest in blind rivets and riveting machines – along with a few other surprises

The World Riveting Congress 2024 (WRC2024) was held from 2627 September near Düsseldorf. The event was hosted by the Goebel Group, which invited buyers, dealers, designers and industrial customers from all over the world to discover the latest developments in blind rivets and riveting machines.

With participants and representatives from 19 countries, the WRC2024 had a strong international presence among its several hundred guests. Highlights of the event at the Group's premises included 12 specialist presentations in German and English on the latest trends and innovations in the industry –plus an exclusive company tour where guests saw the company’s new production facility.

“Shall we do it again?” The crowd responds YES!

The tour offered insights into modern production “Made in Germany”, which sets high standards in quality and precision. Participants followed the entire production process, from material selection to finishing, with Goebel Group experts providing technical details and answering questions.

Of course there was fun to be had as well, with food trucks and espresso vehicles providing culinary delights as well as a special opening ceremony at the Alte Seifenfabrik in Düsseldorf, which provided the setting for stimulating discussions and networking in a festive atmosphere.

The threeday event concluded on September 28 with the WRC2024 Golf Cup, where golfloving participants once again had the opportunity to network in a relaxed atmosphere and bring the event to a sporting close.

Seminars and celebrations: The World Riveting Congress shared knowledge and networking in a festival atmosphere

With its successful organisation and comprehensive programme, the WRC2024 was a complete success, but also set new standards for future specialist congresses. With exciting innovations, interesting presentations, insight into blind rivet production and an international audience, this event is sure to be remembered by many of those who attended.

www.goebel-group.com

Advancements and improved efficiency can come from many different areas, Ferdinand Gross is banking on artificial intelligence as one method to enhance its C-parts management as it takes the next step in the digitalisation process.

The future of Cparts management is closely tied to the use of artificial intelligence. For Ferdinand Gross, leveraging AI opens up new opportunities to free up resources, enabling higher quality throughout the supply chain.

Modern Cparts management has been highly digitalised for years. From Kanban systems with automated order triggering (e.g., via RFID, Bluetooth, or weightbased smart bins) to comprehensive eKanban solutions like Ferdinand Gross’s FALCON software, the entire Cparts management process can now be digitally monitored and controlled. AI builds on these developments to further enhance efficiency, quality, and supply chain safety.

To make repetitive data entry tasks more efficient and free up resources, Cparts providers are testing AI in order processing and quote generation. “Every year, we handle millions of quote requests, a massive volume that we can now process faster and more accurately with AI. This gives our sales team more time to focus on personalised advice,” said Thomas Erb, CEO of Ferdinand Gross.

The potential becomes even more compelling when procurement is included. While traditional procurement planning relied solely on historical data, AI now enables dynamic, realtime demand planning. By analysing current market developments, opportunities and bottlenecks can be quickly identified, and appropriate action can be taken. “With AIsupported planning we can provide our customers with realtime, optimised offers in terms of timing and quantities. The interaction between procurement and sales will be taken to a new level,” emphasised Thomas Erb. This realtime effect creates cost advantages while increasing supply chain security.

AI also has great potential in optimising Kanban systems. Whether it’s selecting the right container system, determining the optimal order trigger, or setting the best delivery rhythm, AI can continuously analyse data to further improve the Kanban system to fit best the customer needs.

For Ferdinand Gross, AI also offers new perspectives in eKanban. The FALCON software is set to be enhanced with additional features such as a simulation tool which could allow customers to run different production scenarios and determine the resulting Cparts requirements.

Beyond specific efficiency and cost advantages, AI serves an even more fundamental purpose: “AI helps us become more resilient,” added Erb. “In recent years, we have seen how quickly supply chains can come under pressure due to external shocks like pandemics, geopolitical crises, or regulatory changes. Lead times or prices can suddenly double. AI helps us evaluate parameters, better anticipate situations, or at least make the best decisions under time pressure.”

The Strategic Impact of AI in C-Parts Management

In summary, AI offers both strategic and operational opportunities for Cparts management. It allows employees to automate repetitive tasks and focus on relationships with customers and suppliers, creating true "High Quality Connections," as they are called at Ferdinand Gross. For customers, AI means more efficient Kanban solutions with enhanced supply chain security and improved service quality.

www.schrauben-gross.com

About Ferdinand Gross

Ferdinand Gross is one of the leading suppliers of fastening technology. Founded in 1864 and based near Stuttgart, the company is a leader in C-parts management, flexible kanban systems, standard and drawing parts and application technology.

We are celebrating 160 Years of High Quality Connections

C-PARTS MANAGEMENT VIA APP

Full transparency and digital control of your entire C-Parts Kanban, even from your home office. Plus comprehensive document management of drawings and test certificates. That’s how FALCON has been impressing not only in purchasing, but also in QA and design departments for years. And with the revised FALCON app, all of its features are now in your pocket, making the tool attractive for production workers too.

We are happy to walk you through the new features! www.schrauben-gross.com/en/falcon

Ferdinand Gross GmbH & Co. KG Daimlerstr. 8, 70771 Leinfelden-Echterdingen, Germany www.schrauben-gross.com/en

Fabory is a comprehensive, full-service company, with over 400,000 products, deep market knowledge and extensive expertise in supply chain solutions. MyFabory Insights is a digital solution the firm has developed to help lighten the load for production teams, making inventory management simpler with real-time insights to help keep things smooth…

In the fastpaced manufacturing industry, efficient inventory management is essential for seamless production and cost control. Production teams face challenges such as unexpected stockouts, labourintensive tracking, and costly downtime. Fabory’s MyFabory Insights, combined with advanced digital tools like Fabory Logic RFID, Optical Recognition, and Weight Scale solutions, provides realtime transparency, automation, and precise control, helping teams minimise disruptions and maintain operational flow.

As manufacturing demands grow, digital solutions have become crucial for effective inventory management, delivering the speed and precision often absent in traditional methods. To address these limitations, Fabory offers a comprehensive suite of digital solutions, including RFID, Optical Recognition, and Weight Scales, which continuously generate valuable, realtime data on stock levels, usage trends, and ordering needs. All data generated by these technologies is seamlessly integrated into MyFabory Insights, creating a centralised dashboard for production teams to view, analyse, and act on essential inventory insights. This powerful integration allows production teams to monitor stock levels accurately, respond proactively, and optimise resources.

“At Fabory, we’ve developed digital solutions to lighten the load for production teams, making inventory management simpler and delivering realtime insights that keep things running smoothly,” says Paul Green, Solutions Engineer at Fabory UK.

“With MyFabory Insights, teams can see all the data from our RFID, Optical, and Weight Scale tools in one easytouse dashboard. It means they can make quick, confident decisions, knowing they’ve got the latest information at their fingertips.”

MyFabory Insights, powered by Fabory’s suite of digital solutions, provides production teams with a userfriendly dashboard for visibility and control over inventory. The platform includes features such as Fabory’s VMI Monitor, which updates stock data every 15 minutes, ensuring realtime accuracy. This integration empowers production teams to track inventory seamlessly and make informed decisions to keep production running smoothly.

Fabory’s MyFabory Insights, combined with VMI/CMI Monitors and advanced digital tools, offers capabilities specifically designed to tackle inventory management challenges, including:

Real-time

Access: Enables instant inventory views, ensuring essential parts are always available.

Automated Alerts: Provides proactive restocking notifications for uninterrupted production.

Custom Reporting: Tailored reports reveal usage trends and support datadriven planning.

Together, these tools streamline processes, minimise downtime, and enhance productivity, enabling teams to focus on innovation and operational improvements.

By integrating RFID, Optical Recognition, and Weight Scale data into MyFabory Insights, production teams can shift their focus from timeintensive inventory management to highpriority projects and innovation. This automation and access to precise, centralised data empower teams to make quicker, databacked decisions, reducing downtime and improving productivity. Ultimately, Fabory’s digital solutions help production teams optimise operations and drive continuous improvement.

Fabory sets a new standard for datadriven inventory management. Schedule a personalised demo to explore how these tools can enhance your processes, improve productivity, and support operational excellence. Discover more on Fabory’s website or by contacting us at contactus@fabory.com.

www.fabory.com/en_GB

pgb-Europe is consistently evolving and growing its logistics operations with the use of advanced automation and a planned expansion just some of the current developments

For three generations, pgbEurope has specialised in fasteners: from small screws to Europeancertified structural bolts and seismically approved anchors, maintaining a constant stock of around 30,000 items. These products are primarily distributed under the brand names PGBFASTENERS, PFS, HAPAX, and SMART.

Founded in 1956 under the name PennoitGrootaert – later abbreviated to pgb – the company has grown into an international player with a central logistic centre in Belgium, a production facility in Poland, a sales organisation in France

// Since pgb-Europe moved to its current headquarters in Melle in 1997, its warehouse and logistic processes have constantly evolved. //

A modern WMS is at the core of pgb-Europe’s logisitic processes

and the Netherlands, and a sourcing hub in Shanghai.

Since pgbEurope moved to its current headquarters in Melle in 1997, its warehouse and logistic processes have constantly evolved. From the start it was a paperless warehouse with small aisle trucks. Nowadays it is steered by a modern WMS and automatic order picking.

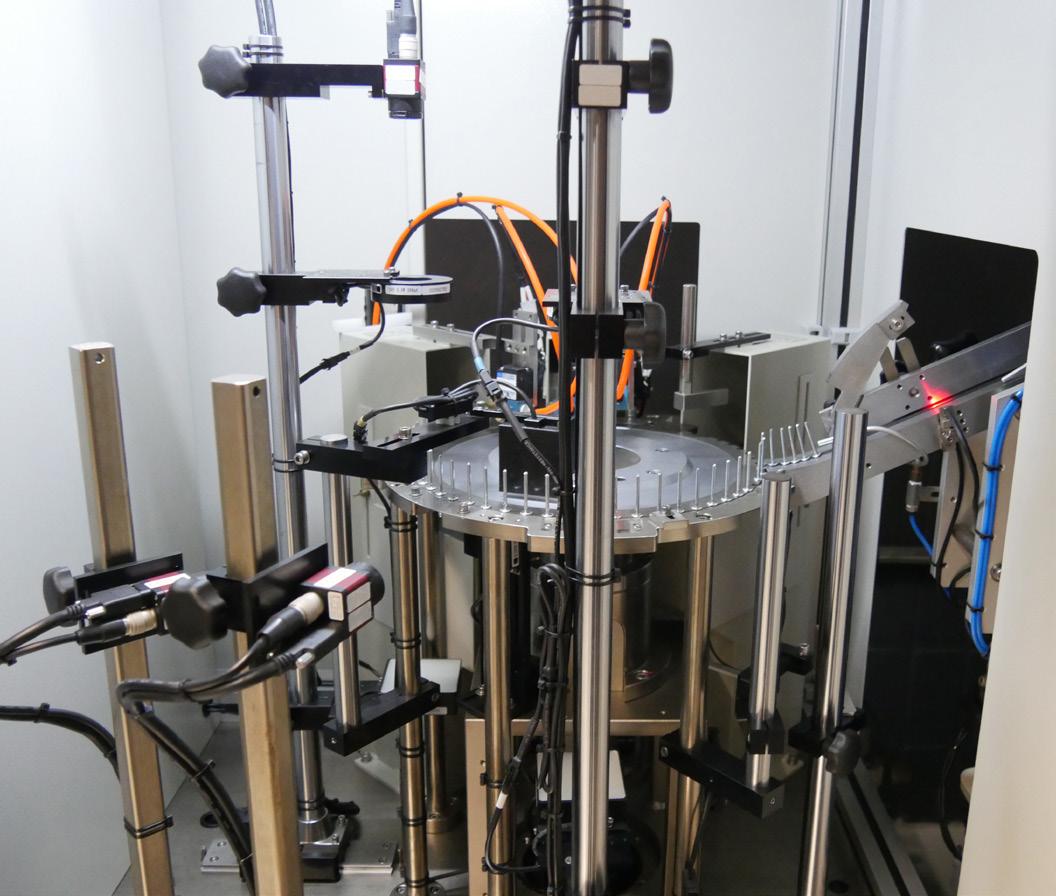

“Our warehouse is the aorta of our organisation, and we are heavily investing in advanced automation (Dynaman WMS) and efficiency. In our highbay pallet warehouse, goods are stored with automatic cranes, and multiple AGVs (Automated Guided Vehicles) handle internal transport. The WMS system is seamlessly connected to our ERP system S/4H. In that way we can ensure that each step is traceable, allowing us to map the entire product chain,” explains Johannes Heye, Managing director pgbEurope.

“Every year, we now process over 1,000 incoming containers and ship 18,000 tons of goods to customers across Europe. This naturally requires a wellstructured system to keep everything organised, but at the same time, we always operate with a customercentric approach to add extra value.

“Currently, construction is ongoing for a new automated shuttle warehouse with 40,000 storage locations (OSR – Order Storage and Retrieval) from Knapp. This internal upgrade represents a new level of toptier logistics technology. The system uses small autonomous shuttles that quickly move

across different rack levels. Products are stored in plastic totes or remain in outer boxes, which are transported by shuttles to and from storage locations and work/pick stations.

“The significant difference from our current miniload system is that this system operates much faster and more efficiently than the older cranes. Additionally, we can process full outer boxes directly without manual handling, and robots will assist with (de)palletising. This will drastically increase our processing speed, enabling us to more than double the number of pick lines per day. Furthermore, it will offer a more ergonomic way of working for our warehouse employees by eliminating the manual handling of heavy outer boxes." pgbEurope also successfully acquired two adjacent plots and will be carrying out further expansions of the logistics centre in the short term. In early 2025, a new shipping area with four loading docks will be constructed, along with additional offices and meeting rooms on the upper floors. Once this phase is complete, a second automated pallet warehouse will also be built, providing an additional 12,000 pallet spaces by end of 2026.

With an ambitious entrepreneurship combined with high quality products and likewise service level way, pgb strives to be amongst the best in the sector.

www.pgb-europe.com

// Every year, we now process over 1,000 incoming containers and ship 18,000 tons of goods to customers across Europe. //

Creating a new brand from scratch is a daunting prospect, but Owlett-Jaton’s JRP has made a big impact in just five years. Torque Magazine quizzes Technical Support Specialist

Warren Keeley on the beginnings and future of Jaton Riveting Products…

From day one

Warren Keeley: My role is purely technical support. I was brought in initially to help develop the brand.

I’d owned a company for over 30 years. After selling the business, Tony Williams (OwlettJaton Sales Director) who I’ve known for over 30 years saw the news on LinkedIn and got in touch. OwlettJaton is a big organisation and they’ve obviously got all the contacts and know where to go to buy product from, but they were looking for some extra expertise on a new rivet brand. That’s where I came in.

So, I was pretty much there from the start with JRP. I came in as a Technical Consultant and put the technical specs together, put the range together and I was involved in things like the logo design.

OwlettJaton’s premise was to develop something along the same kind of business model as they had with JCP (Jaton Construction Products). Starting from scratch, I said it’d take around 18 months. We were doing factory audits in October 2019, selecting our chosen partners, and then Amy Baker (Head of Marketing) and her team then came in. I worked with them to produce the catalogue, packaging…

Then we launched on the day of the first Covid lockdown! I was doing branch training but we had to stop because everyone was getting sent home.

What was it like to help guide something from the beginning into a big brand?

It was brilliant because starting a new brand with the support of a multimillionpound business behind you was great. It’s been, personally, really satisfying. You can watch an embryo of the brand develop and I was extremely confident it was going to take off, because I thought we got the right mix of product. Initially we only launched hand tools to support the range, but we got to see prototype battery tools while we were doing the factory audits, so that was in the pipeline. But you have to walk before you can run. You need to establish sales before you start trying to get them to spend any more money. Effectively, every addition I proposed got backed, with no questions. I’ve dealt with quite a lot of CEOs, but OwlettJaton’s Ian Doherty always has a lot to say. He’s the best Chief Exec I’ve ever had the pleasure to work with and for.

It was a big investment, putting the stock in and everything else, and then it has just exploded. Within about six months we were already adding new ranges.

OwlettJaton as an organisation can get a single box of products out quickly to anywhere in the UK, and that’s a huge selling point. If you’ve got thousands of product lines and someone is ordering a range of fasteners, it is quite easy for them to add a box of JRP product to their order.

There are riveting names out there already, but having OwlettJaton behind this one is a big deal. They are so trusted by distributors. Particularly during the Covid lockdowns, that trust counted for a lot and JRP snowballed during those Covid years.

Now we’ve got 1,300 lines of JRP. It’s huge. They put their money where their mouth was, invested in the stock and offered a vast range to their customers.

Brand launched, now what?

We've added just over 400 lines in three years. The latest expansion of the range range is the rivet nuts. With those, we knew there were certain market sectors we could go and approach. But you've got to do it in stages.

Range extensions can be from customer feedback and distributors, and obviously if we get approached for products we don’t do, we log it on the system.

After adding 400 lines in three years, the JRP range now includes 1,300 lines

// We launched on the day of the first Covid lockdown! But ultimately JRP snowballed during those Covid years and there’s been investment in stock, offering a vast range to customers. //

JRP’s product comparison tool helps remove obstacles for new customers to start working with the brand

We’ve done branch training, and more extensive training with Area Sales Managers as they’re at the coal face. Especially since the battery tools range as that's a bit more involved. Now the brand has gone from something new in the market sector, it is five years on and we’re not the new kids on the block anymore. We're established and obviously ruffled a few feathers when we first launched. But we’ve had very positive feedback and it’s really pleasant to get that from the market.

We launched a comparison tool for JRP, for every product we sell. I spent quite a few months putting together competitor part numbers against our individual product lines, for the whole JRP range of tools, rivet nuts and rivets.

Alongside the catalogue and a variety of POS options, JRP is working on training and instruction videos, with QR code labels on product boxes to help users get the most from the products

This product comparison tool allows you to enter a competitor part number into the search field. If there's a direct equivalent to what we can offer, it gives you the corresponding JRP part number and a link to then click for information or to go and order it. Obviously it will develop further as we add products to the range. This has also highlighted just how wide the range we’re offering is, compared to competitors.

Just like any organisation, there are targets in terms of sales, with certain markers. From where I’m sitting, it has exploded, but you can’t sit on your laurels. We’re constantly reviewing market sectors.

The battery tools have been another hugely successful part of the range, they underwent a lot of market testing and were put through some worst case scenarios to see how they coped. We then went back to the factory and asked them to put a design change in to create some really good tools. The rivet nut tools are more complex than the rivet tools as they have to spin clockwise, move backwards and forwards, and then anti clockwise to set one rivet nut. In one case, we found that operators were manually changing the settings on the tool and then using it in too high or too low for setting for the application, which was causing issues where they were getting some loose nuts in applications. We adjusted the design to add a locking mechanism, so most operators can’t change the setting. That almost became a failsafe which helps with less likely tool or production issues. The settings are all visual in bright lights, so we make it as easy as possible with specific applications for an end user.

Not only does it make it really easy for supervisors, managers and owners to see if somebody on the shop floor has messed with that product, but it also aids the distributor if they've got an issue with their customer, the end user, and they know specifically what that tool was set for. You know, you've

only got to go and touch the power button and everything lights up and tells you if it's correct or incorrect, right? But not only that, it's a fantastic aid for the end user that you know they're putting work instructions for every application they've got within the factory.

We have supported the distributor in going to the end user and then setting up every single tool, at every single setting cell. And I'm now doing more and more support with distributors, looking at applications and then reengineering or helping with production issues.

We've developed things like training videos and instruction videos for the battery tooling, which we’re adding soon. There’ll be a QR code label inside the box leading to the instruction videos and they’ll have to register the tool serial number to validate the warranty.

We compare well with some of the bigger brands too, especially in terms of weight saving. When you’re working with rivet tools, 30% or so lighter tools makes a hell of a difference. It’s a major plus point. Hopefully there’s further scope to develop the battery tooling range, but that will again be marketled.

Now we've got to a point where I think the brand is firmly established, it’s a case that more of my time is working with area sales managers and distributors to help convert business. People now trust the JRP brand.

Trying to break into another market sector is about breaking habits and getting potential customers to think again as a business. It’s breaking those habitual purchasing habits.

With the additions that we’re launching, the range opens up four main sectors that we've been asked by customers to address, including electronics, rail, automotive and the agricultural sectors.

www.owlett-jaton.com

BARA will deliver the exact number of products you need. No minimum order quantity

Fanny Bülte took over the Bülte family business in summer 2023. Now, over a year on, Torque Magazine asked the new Managing Director about extending into new niches, the education challenge around plastic fasteners and their suprising versatility, as well as balancing a company’s heritage with innovation to secure future growth…

How’s business been in 2024 so far, compared to 2023?

So far, 2024 has seen mixed results in business performance across various sectors compared to 2023. Bülte has had to adapt to a slower global economic growth rate and persistent inflation, leading to cautious consumer spending and challenges in profit margins. Nonetheless, we have changed our strategies to counter these pressures, particularly with a stronger focus on productivity enhancements and efficiency gains.

It’s been over a year since you took over the reins of the family business – how’s it been so far and have there been any surprises?

Like many new leaders in this position face surprises I'm facing cultural and operational norms that have been ingrained over decades and may resist change.

Common surprises for successors in family businesses often involve adjusting to the familydriven decisionmaking culture, where traditional ways of operating can sometimes slow down the adoption of modern practices. So, it's not easy to find a balance between preserving the company’s heritage and innovating for future growth. An additional challenge is navigating the personal dynamics of the family, which may impact decisionmaking differently than in nonfamilyowned businesses.

Have there been any particular investments or projects that Bülte is currently working on?

Looking forward, we plan to continue our focus on sustainable practices and strategic growth, including participation in major industry events such as the upcoming Fastener Fair in Stuttgart in 2025, showcasing our innovations and reinforcing our longterm commitment to responsible manufacturing and global expansion.

Digitalisation has been a big topic for the industry and I think for Bülte too? I believe you brought in a new website a couple of years ago... is the process of digitalisation something that is ongoing for Bülte?

Digitalisation has indeed been a significant focus for Bülte, aligning with industry trends and the company's goals of enhancing customer accessibility and operational efficiency. We launched a redesigned website a couple of years ago, opti

mised for user experience and improved navigation with features like advanced search options and visual aids for product identification. This site update was part of a broader push towards digital integration that began during the pandemic, which also spurred the company's "zero paper" initiative to reduce paper usage and shift communications online.

Today, digitalisation remains an ongoing process for Bülte, emphasising responsive digital tools and refining the company’s web and digital presence. Continuous improvement in the digital space allows us to adapt better to market demands, particularly as clients increasingly prioritise seamless online interaction and fast access to technical product data and specifications. We also maintain our strategy to integrate customer feedback into digital updates, aiming to meet specific industry needs more effectively and ensure a robust online presence across both web and social media channels.

On the other hand, with the arrival of artificial intelligence (AI), many changes are still to come.

Bülte seems to work with a very broad range of industries. Do you regularly find new applications and markets for your ranges?

Bülte has been actively expanding its reach across industries, capitalising on its versatile plastic fastener range to meet evolving customer needs in diverse sectors. Our offerings, including nylon fasteners like washers, plugs, screws and handles, have traditionally been popular in sectors such as automotive, construction, electronics and medical technology. With a foundation of over 30,000 standard products, our unique approach also emphasises custom components tailored to client specifications, ensuring that they can meet specialised requirements in industries that demand precise, durable plastic fasteners.

In recent years, we have leveraged our expertise to expand further into niche markets. For instance, the company’s flexible approach to production allows it to work with customers on specialised solutions using a variety of materials beyond polyamide, enhancing its appeal across different applications. This adaptability has allowed Bülte to maintain a strong presence in Europe while positioning itself for growth in new regions, especially with its digitalisation push to streamline customer

experiences and access to product information and prototypes. This commitment to responsive service and quality manufacturing enables us to continuously explore new applications, adapting our product line to meet the unique challenges of each industry it serves and expanding our foothold in both existing and emerging markets.

When it comes to plastic fasteners or fixings, is there an education challenge for your customers e.g. they aren’t always aware of how versatile and appropriate plastic can be for their projects?

Yes, there is often an educational element involved in helping customers fully appreciate the versatility and strengths of plastic fasteners. Many clients, especially those traditionally accustomed to metal components, may have initial reservations about plastic fasteners' durability, strength, or suitability for specific applications. For Bülte, part of the challenge is addressing misconceptions by demonstrating how advanced plastic materials can offer numerous benefits, like corrosion resistance, lightweight properties and adaptability, which can outperform metals in certain contexts.

Plastic fasteners are particularly advantageous in applications requiring low weight, chemical resistance and nonconductive properties, which makes them ideal for sectors such as electronics, medical devices, and automotive parts. However, potential customers may not always realise that plastics can be engineered for high tensile strength, impact resistance and temperature endurance, providing reliable alternatives in demanding environments.

Bülte actively educates clients through technical resources, custom solutions and material guidance to align plastic fastener choices with specific project needs. For instance, the company offers custom component design in various plastic materials beyond polyamide, which helps clients explore applications they may not have considered feasible with plastic. Through these efforts, we aim to shift perceptions and help customers see plastic fasteners not just as costsaving alternatives but as highperformance components in their own right.

big is the custom side compared with the standards side, for

The balance between custom and standard parts is a key part of Bülte’s operations, reflecting a commitment to versatility and client responsiveness. We offer a wide array of standard fasteners, particularly through our expansive online catalogue, which includes over 30,000 technical plastic items that adhere

// There is often an educational element involved in helping customers fully appreciate the versatility and strengths of plastic fasteners. //

to established industry standards like DIN, ISO, and NFE. This standardised range helps to meet the baseline needs of a variety of industries, from automotive to electronics and beyond.

On the custom side, Bülte’s specialised service for bespoke plastic fasteners is significant. Custom solutions involve designing unique components that cater to clients’ specific requirements, often going beyond what standard fasteners can achieve. The custom offerings include fasteners in diverse materials beyond nylon, such as PTFE and PVDF, which can fulfil unique mechanical or environmental requirements. Our tailored parts not only add value in terms of functionality but also allow customers to optimise parts for weight, corrosion resistance and design integration. With a strong focus on custom offering, we remain a flexible partner for businesses across multiple sectors, enhancing our adaptability and growth in both established and emerging markets.

Sustainability is another of the big topics facing the fastener industry, in what kind of ways is Bülte addressing things like driving down carbon emissions and trying to use more environmental materials?

Bülte is actively addressing sustainability challenges through a range of strategies focused on minimising environmental impact. For instance, the company is exploring new materials that could lower emissions, such as recycled plastics and bioplastics, which can help in reducing reliance on traditional petroleumbased polymers. This shift aligns with broader industry efforts to improve the environmental footprint of plastic components, particularly in highdemand sectors like automotive and construction.

We also support sustainability by optimising our production processes. Through waste reduction initiatives and streamlined manufacturing practices, the company has taken steps to cut down on carbon emissions while improving energy efficiency. Our focus on customisation allows us to create tailored solutions for clients, which can minimise material use and further decrease environmental impact. Additionally, we have recently enhanced our logistics to reduce transportation emissions, which includes consolidating shipments and improving supply chain efficiencies

These initiatives reflect Bülte’s commitment to sustainable production and materials innovation, contributing to a more environmentally responsible manufacturing approach within the plastic fastener industry.

www.bulte.com

NORMA Group has been awarded a major contract to equip a new platform for small to medium electric passenger cars with lightweight tubes for the battery thermal management system. The customer’s vehicle platform encompasses several car models and targets to enable efficient city mobility. The contract is worth more than €30 million. Starting in December 2026, NORMA Group will deliver around 1.4 million tubes to the customer per year.

CEO Guido Grandi said: “Largescale production and availability of small and medium electric vehicles will be a main driver for the transition towards a lowemission, more climatefriendly mobility. This contract proves that with our engineering expertise, our standardised quality management and our global manufacturing footprint we are the right partner for leading car manufacturers as they broaden and scale up their portfolio of batteryelectric vehicles.”

The tubes are made of thermoplastic elastomer, a light and flexible material. With its material and design quality, a TP Flex tube significantly reduces the pressure drop of the fluid that flows through it. The tube is therefore well suited for use in the thermal management systems of electric vehicles where it is particular challenging to keep the pressure in the cooling circuit evenly high.

Carolin Wolfsdörfer, President Mobility & New Energy at NORMA Group, said: “Our joining technology can be used in all kinds of vehicles. With our engineering capacities, we are able to offer tailormade solutions according to the customers’ requirements. Specifically in electric vehicles, car manufacturers focus on lightweight components as the total weight of a vehicle influences the amount of energy needed to move it. A lighter electric vehicle requires a less powerful drive or offers a higher range.”

The tubes will be manufactured at NORMA Group’s plant in Subotica, Serbia. For the contract, the company will invest in new ergonomic assembly lines.

According to a fresh report from Allied Market Research, the automotive fastener market was valued at $34.2 billion in 2023, and is estimated to reach $52.1 billion by 2033, growing at a CAGR of 4.4% from 2024 to 2033.

Factors such as the rise in lightweight vehicle manufacturing and growing vehicle production were cited as the two main primary factors driving the growth of global automotive fastener market. Furthermore, increasing alternatives for fasteners and rising material costs are two important factors hampering the growth of the global automotive fastener/ connector market. Moreover, innovations in manufacturing technologies is providing an opportunity for the growth of the global automotive fastener business.

By material, the stainless steel segment dominated the global automotive fastener market in 2023, commonly used in applications where corrosion resistance is critical. The aluminium segment, however, is expected to grow at an increasing rate with the material offering a strength and reduced weight balance, making such fasteners increasingly relevant to the motor market.

By product type, the threaded segment dominated the 2023 automotive market, according to the report. The rise in the manufacturing of EVs is among the factors creating

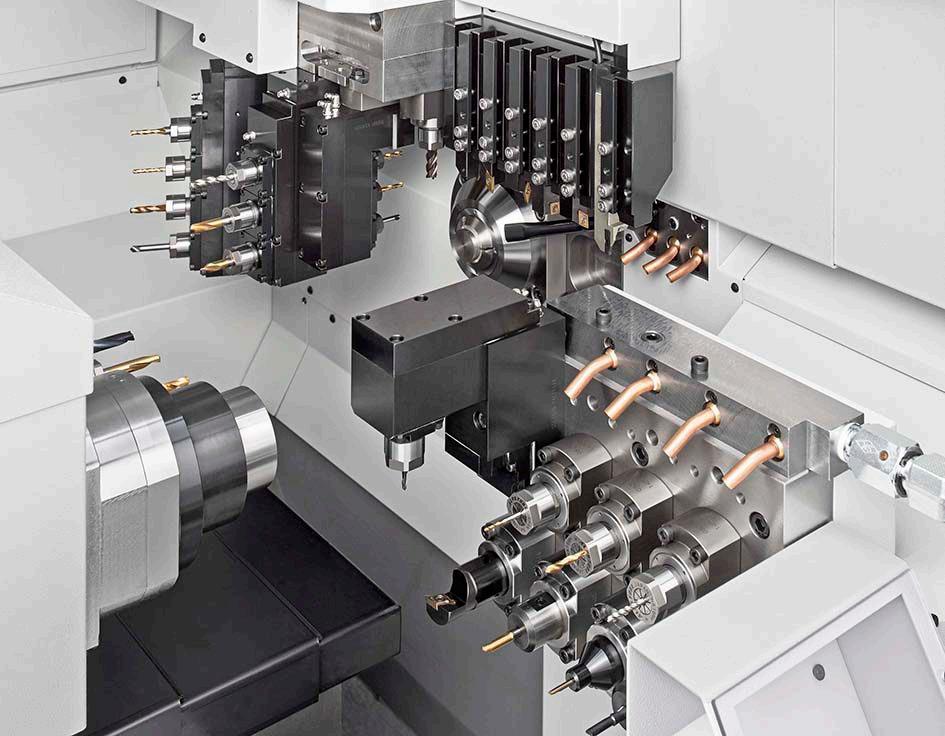

The everacquisitive Atlas Copco Group unveiled one of its latest in early November, which is set to becomes part of the Group’s Motor Vehicle Industry Tools and Assembly Systems division within the Industrial Technique Business Area.

Michigan, USAset Air Way Automation, a supplier of automated bolt feeding solutions to the automative and general industries, has become part of Atlas Copco Group.

Air Way has 98 employees and during 2023 the company had revenues of approximately US$35 million (370 MSEK).

“This acquisition complements one of our recent acquisitions and will further strengthen Industrial Technique’s offering in the area of automation,” said Henrik Elmin, Business Area President for Industrial Technique.

The purchase price was not disclosed.

high demand for threaded segment, while the nonthreaded segment is also expected to grow at a significant rate in the global automotive fastener/connector market. Typically, to the nonthreaded fasteners such as clips, rivets, and snapfit designs being lighter in weight and aligning with the industry’s focus on fuel efficiency and electric vehicle design, asserts the report, adding that. The nonthreaded segment also helps in reducing manufacturing time and cost.

As expected, the AsiaPacific region dominated the global automotive fastener/connector market in 2023 thanks to the region’s large automotive manufacturing industry, especially in countries such as China, Japan, and South Korea. Meanwhile, the same region is growing at a significant rate due to factors such as rising middle class, urbanisation and infrastructure development.

The report provides a detailed analysis of key players in the global automotive fastener market. These players have adopted different strategies including new product launches and contracts to increase their market share and maintain dominant shares in different regions.

www.alliedmarketresearch.com

JohnDow Industries has added three new items to its product lines

JohnDow Industries (JDI), supplier and distributor to the automotive aftermarket, has announced three new cuttingedge products within its Service Equipment and Dynamic product lines.

Alongside the JDI Manual Extractor & Discharge Pump (JDI150DE) is a Mobile Tool Cart, designed to keep essential tools organised and within reach. The cart features locking swivel casters for easy maneuverability and a durable black powdercoat finish. With over three feet of width and nearly two feet of depth, it provides ample storage space, including a twosided pegboard for additional tool organisation.

(DY-DPA-30R, DY-WHA-30R, DY-TPMS-24)

To streamline the service process, Dynamic now offers three new comprehensive cabinet assortments, each designed to minimise bay downtime and enhance part accessibility. These wallmountable cabinets include:

Oil Drain Plug & Gasket Cabinet Assortment (DYDPA30R): 247 pieces, including 30 popular drain plugs and gaskets.

Wheel Nut & Stud Cabinet Assortment (DYWHA30R): 152 pieces, featuring 30 commonly used wheel nuts and studs.

TPMS Service Kit & Valve Replacement Cabinet Assortment (DYTPMS24): 44 pieces, offering 24 essential TPMS service kits and valve replacements.

“For 40 years, our customers have been the singlemost important driver on determining what we bring to market,” says Robert Christy, President of JDI. “And we have set the precedent for high quality when it comes to service equipment and parts. Every new product goes through rigorous testing and engineering to ensure every product we bring to market qualifies for these standards so when customers are looking at the number of options on the market today, they don’t even have to question their choice when buying a product with the JDI sticker on it; they know that sticker represents longevity.”

Headquartered at Barberton, Ohio USA, JohnDow Industries has served the automotive aftermarket for more than 40 years.

JohnDow.com

// FOR 40 YEARS, OUR CUSTOMERS HAVE BEEN THE SINGLE-MOST IMPORTANT DRIVER ON DETERMINING WHAT WE BRING TO MARKET. //

FSP MANAGER NORM FASTENERS

IGET IN TOUCH... www.normfasteners.com

FSP@normfasteners.com

LinkedIn: norm-fasteners

n a dynamic and ever-changing global market, as business leaders, we emphasise “efficiency” as often as we say “good morning”. Inefficient processes and procedures lead to value loss, posing significant risks even for major brands. For instance, while top companies in the S&P index used to stay on the list for 30-35 years in the 1970s, they now only last 15-20 years due to rapid changes (PERRY, 2021). The term “productivity” was first used by Dr. George Bauer in 1556, in his book ‘De re Metallica’. Even after almost 500 years, the drive to improve productivity remains just as strong. The Full Service Provider (FSP) Business Model is crucial to the concepts of productivity and efficiency.

In the automotive industry, pioneers like Karl Benz, Ferdinand Porsche and Henry Ford originally built their cars by hand, but this method was slow. Henry Ford’s serial production revolutionised the industry, though it faced high rework costs due to supply chain issues. Kiichiro Toyoda’s lean production improved efficiency and reduced costs, but wasn’t entirely sustainable due to resource limitations. This led to specialisation and modular production methods, introducing terms like Full Service Supplier (FSS), Full Service Provider (FSP), and Full Service Vehicle (FSV).

For more efficient and detailed processes, I recommend you to review the theses we have written:

“Case Study on the Establishing Conceptual Design of Management Organization and C-Parts Management in FSP Company” (TUNALI,2023)

“Implementing Analytic Hierarchy Process Method for Supplier Selection in Fasteners Industry”

(OZKAN,2024)

As Norm FSP, we define our business model as “a partnership and service model that manages every step in bringing two products together, from design to sustainable mass production, to enhance efficiency.” We are managing the world’s biggest commercial vehicle programs and next gen Electric Vehicle Programs” by providing our business partners with efficient and sustainable solutions from idea to final product.

In addition to our in-house production capabilities, our primary responsibility at Norm FSP is to provide comprehensive support to our business partners. Our engineers prioritise design, cost and complexity reduction, while our quality teams ensure compliance with standards and supply chain teams guarantee timely delivery, all aimed at enhancing value and efficiency for our business partners through our FSP Teams.

// A partnership and service model that manages every step in bringing two products together, from design to sustainable mass production, to enhance efficiency. //

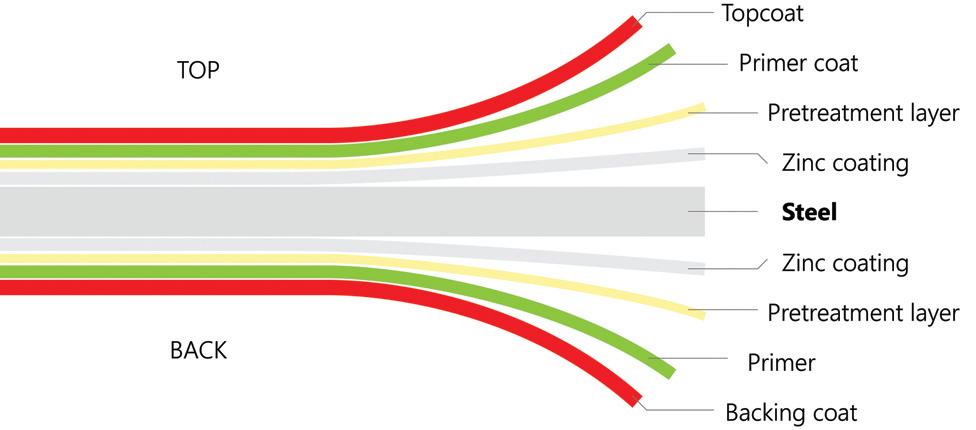

NOF Metal Coatings has an environmentally friendly PFAS-free topcoat range that provides customers with a more eco-conscious product but also stays ahead of increasing regulation for the sector

PFAS, or poly (or per) fluoroalkyl substances are coming under increasing scrutiny due to their longlasting presence in the environment. A possible European ban on PFASs might come into force as early as 2027 for specific industrial segments.

Apart from PTFE, a fluoropolymer currently classified as a “polymer of low concern” by the OECD, NOF Metal Coatings do not use any other PFAS in its products.

Regardless of the potential restrictions imposed by environmental authorities on PTFE, the group took this new regulation as an opportunity to develop a new PFASfree topcoat range generation with worldwide availability.

PFAS free PLUS® Series

The objectives of these developments were to be able to offer customers a new range of more environmentally friendly products, while guaranteeing the same tribological performance as the current PLUS® range.

PLUS® XL 2 Silver: COF 0.06 – 0.09 (ISO 16047)

PLUS® VLh 2 Silver: COF 0.09 – 0.14 (ISO 16047)

PLUS® ML 2 Silver: COF 0.10 – 0.16 (ISO 16047)

// All three new PFAS-free topcoats will include fluorescent pigments for ease of positive identification – a feature unique to NOF Metal Coatings Group topcoats. //

Applied on top of NOF Metal Coating’s GEOMET® waterborne zinc flake basecoats, the PFASfree alternatives to PLUS® XL, PLUS® VLh, and PLUS® ML meet or exceed the global OEM requirements and specifications while providing outstanding tribological properties including:

Multitightening and highspeed tightening

Compatibility with various mating substrates (ecoat, aluminium, zinc, and steel)

Stick slip avoidance

Behaviour in loosening tests (including at high temperature – PLUS® VLh 2 Silver and PLUS® ML 2 Silver)

To offer customers the best products on the market, the company have taken this opportunity to enhance the aesthetics of the products in this new range by adding aluminium pigments to be able to obtain a uniform silver colour. This enhancement improves the visual appearance of assemblies where fasteners are visible by customers.

In addition to the improved aesthetics, all three new PFASfree topcoats will include fluorescent pigments for ease of positive identification – a feature unique to NOF Metal Coatings Group topcoats.

In the group’s R&D laboratories, teams are continuing to work on PFASfree coatings and GEOBLACK® systems, with the addition of black topcoats to the PFASfree PLUS® range to be ready soon.