17 minute read

Between Greenwashing and Profitability

What have fashion companies learned about sustainability in recent years? They seem to have arrived at the conclusion that humane working conditions and sustainable products are not only “nice-to-have” sale arguments, but also an important economic factor.

Text: Ina Köhler. Photos: Manufacturer. Illustration: Sarah Egbert Eiersholt The fashion industry is not exactly popular. Around the 24th of April, the anniversary of the Rana Plaza catastrophe in Bangladesh, a string of reports on all media channels highlighted yet again what is wrong with the industry. There are enough black sheep out there. Many companies that had been proven to produce on location – such as Benetton, Adler, NKD, and Carrefour – do not feel they are liable for the victims. As of April 2014, the trust fund had received merely 11.5 million of the promised 29 million Euros. Even politicians are getting angry; “The inhumane working and living conditions in the textile industry in African and Asian countries are no longer tolerable”, says Gerd Müller, the German development aid minister who recently invited industry representatives to a round table discussion. The conclusion of the consumer media is that the fashion industry is trying to escape responsibility and is dominated by scandals and catastrophes.

Fraudulent Labelling

The fashion industry has to adjust to the fact that consumers will scrutinise them even more closely in the future. An initiative like the Fashion Revolution Day on 24th of April 2014, which was backed by organisations such as Greenpeace, GOTS, and Oxfam, called upon consumers to turn their clothing inside-out to check where the products are being produced. A recent report about Chinese workers in Prato, who are manufacturing fashion made in Italy for Pronto Moda under unspeakable conditions, proves that a glance at the label is not enough. On the other hand, some Asian producers – such as KTC in China – are members of the Fair Wear Foundation. Is this a paradox? Actually it’s quite normal for one of the most globalised industries in the world. It is less important to question the production location than the individual commitment of the company, which may adhere to social and sustainable standards or not. Politicians and organisations like Get Changed started demanding legislative changes a long time ago. Businesses should be held responsible for compensation payments in the future. “I believe it is desirable to establish international standards, mainly because many sustainability issues are more a global than a regional problem”, says Marie Mawe, the CSR manager at Bolzano-based Ober Alp Group. “A global minimum standard would definitely help.” Progress has already been made on a regional level. An agreement regarding fire protection and building safety in Bangladesh was signed by more than 160 international corporations such as Adidas, PVH, H&M, Inditex, Mango, and Primark. The Asian country has now also introduced a minimum wage of 60 Euros per month and facilitated the formation of unions.

Notorious Industry: Rightly So?

There is certainly no lack of lip service in the form of statements and conferences. Industry congresses like the Copenhagen Fashion Summit, which was staged in April 2014 and was dedicated to sustainability issues, were attended by corporations ranging from H&M to Bottega Veneta. Unfortunately, all the good intentions often turn out to be a brief spell of greenwashing. The fact that Franca Sozzani, the editor in chief of Vogue magazine, used the occasion to postulate that fashion is one of the polluting industries in the world casts a particularly bad light on the business. But nevertheless there are ideas and efforts to make design and production processes more ecological and socially acceptable. These come from all sides such as the raw material suppliers, weavers, production companies, washers, and logistics specialists. Brands like Mammut, Schöffl, Vaude, Deuter, Odlo, and Mountain Force joined the Fair Wear Foundation as soon as 2008. Clothing suppliers such as Acne, Filippa K, Gaastra, Odd Molly, Nudie, and Kuyichi are also part of the organisation already. In Copenhagen, the Danish Fashion Institute opened a sourcing “library” focused on sustainable materials. The latter cooperates with partners like CLASS, Source4Style, and Ethical Fashion Forum. For years the fabric trade show Munich Fabric Start has been showcasing sustainably produced textiles in its Forum Eco Village and Organic Selection areas. “Both designers and buyers source and search in a highly selective manner”, says Alex Vogt, the sustainability expert of the trade show. “We discuss solution-oriented approaches that can be implemented on a large scale.” Even during the design process one can find ways to work more ecologically

“Our manufacturers need to meet high standards in terms of social, ethical, and environmental

issues.” Henrik Lindholm, Nudie Jeans

Andreas Knezovic, FTC

and use fewer resources. Many companies already use design strategies such as up-cycling and recycling; Patagonia, Puma, and Nudie Jeans are but a few examples. However, there is still no real transparency for consumers. Last but not least, companies need to keep their own houses clean too. What is the ecological assessment of their home markets? style in progress presents four companies that implement sustainability on different levels.

Imaginative: Nudie

For many years, the Swedish brand Nudie Jeans has gradually improved processes. For example, the jeans have been made of organic cotton since 2012 and are certified with the renowned GOTS label. It’s not only the source material that counts; the production, washing, and dyeing processes also adhere to social and ecological criteria. “We are also working on ensuring fair working conditions in our supply chain”, says Henrik Lindeholm, the CSR manager of Nudie. This is guaranteed by organisations such as Fair Wear Foundation, an independent multi-stakeholder initiative that examines the rights of workers. “Our manufacturers need to meet high standards in terms of social, ethical, and environmental issues. In the best case, these are documented by global certificates such as SA80000 or ISO 14001”, Lindholm explains. Recycling is also a key topic for the Swedish company. It already uses recycled materials like wool for its collection, for instance for the sweater model Yngve. Jeans are turned into new products too: Nudie carpets are manufactured from worn and donated denims. The warp thread is made of coloured indigo yarn, while the weft thread is made of the recycled favourite pieces. The Swedish Society for Nature Conservation awarded the product the Good Environmental Re-Design label. Another idea was realised in the Nudie Jeans Repair Store in Stockholm, which was opened to the public in 2014. It offers jeans repair services free of charge and also supplies repair kits for DIY enthusiasts. There is also a 20% discount for worn and returned jeans. All these projects are advertised on the brand’s website – so the consumer can, for instance, find out which factory produced his or her particular product.

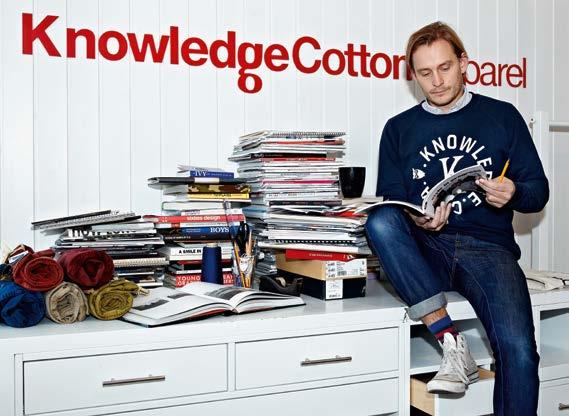

Pioneers: Knowledge Cotton Apparel

The Danish family-owned company behind Knowledge Cotton Apparel has been in the textile business for more than 40 years. In 1969, Jorgen Mørup acquired an English loom and founded his company J. Mørup Stof. He started using organic cotton as soon as the early 1990s and subsequently became the production partner for manufacturers such as Hess Natur, whereby he gained a lot of experience in terms of sustainability. "We learned a lot from that co-operation", says Mads Mørup, the founder's son, who launched his own brand in 2007. "I think the awareness of retailers and consumers has changed significantly over the last three years. Sustainability could develop into a real megatrend." Organic cotton is still an integral part of the Knowledge Cotton Apparel collection. "All our cotton products are GOTS certified", Mørup explains. The label also uses other materials such as recycled polyethylene, wool, and linen. As the men's collection has become broader and more diverse, the brand has teamed up with eight partners from the Baltic region, Portugal, Turkey, India, and China. "We cooperate very closely and intensively with our partners and our production experience is a real asset in that respect", Mørup says. The brand informs the public about its high quality standards and sustainability issues via its website. "Most consumers want their product to be manufactured in a decent manner", he explains. "Therefore, our future communication focus will be sustainability."

Under One Roof: FTC

A premium product with the entire supply chain under one roof is not commonplace in the highly competitive cashmere market. “First and foremost we want FTC to be a modern fashion brand offering excellent

value for money”, says Andreas Knezovic, the CEO of Interart of Cashmere World AG. However, he has nevertheless been committed to the fair trade philosophy right from the start. From the breeding of goats, over the combing and dyeing units, to the final production step in own knitting shops – it’s all under one roof. In Shanxi province, the company cooperates with approximately 250 farmers via a contract farming model and employs more than 300 people in its local production facilities. The existence of the aforementioned farmers is secured by contracts that guarantee the purchase of their raw material. Knezovic explains that the aim is to increase the number of goats from currently 20,000 to 100,000 by 2017. As early as 2007, FTC initiated the construction of a full-day school in the province. “It is important to me to have a clear conscience”, Knezovic says. “The fact that we control all processes makes us fairly

unique as it is.” And the label is innovative too. With the product known as Cashmere + SeaCell, a fibre developed by Smartfiber, it has secured the worldwide rights to combine those materials. The Lyocell SeaCell fibre consists of cellulose and Icelandic brown algae, which is harvested sustainably and is therefore allowed to bear the EU Ecolabel.

Holistic: Salewa

The Ober Alp Group, headquartered in Bolzano, combines such diverse brands as Salewa, Dynafit, Pomoca, and Wild Country under one roof. An international multi-brand CSR team deals with the various sustainability aspects: product, social standards for employees on location and staff of suppliers, and consistent environmental management. In 2013, Salewa and Dynafit became members of the Fair Wear Foundation. The significance of this becomes even clearer when one learns that 65 percent of all Salewa products come from Asia; the three most important supplier countries are China, Vietnam, and Indonesia. “At Salewa we take social and labour standards very seriously, which means we continually work on creating healthy and fair working conditions and it is our long-term aim to have transparency throughout our entire supply chain”, says Maria Mawe, the company’s CSR manager. “All suppliers have to sign our code of conduct agreement and we visit all production sites on a regular basis. We are a member of the Fair Wear Foundation to ensure independent and professional monitoring of the working conditions and we strive to meet the foundation’s strict stand

Marie Mawe, Ober Alp Group (Salewa) ards on a daily basis. Currently the costumer cannot trace his product back to the factory, but it is our declared aim to provide such transparency.” Salewa wants the individual to be the centre of attention. The company shows social commitment by backing projects in Bolivia and Nepal. This commitment also extends to its own shores. The new headquarter in Bolzano – which the company moved into in 2011 – took sustainable criteria into account during the construction process, boasts a photovoltaic energy system, and received the Klimahaus Award for its exemplary overall energy concept. “Salewa’s focus is on ensuring that our entire business activities are sustainable and social, and we want to improve these aspects continually”, Marie Mawe explains.

„I think the awareness of retailers and consumers has changed significantly over the last three years. Sustainability could develop into a real mega

trend.“ Mads Mørup, Knowledge Cotton Apparel

Hang On, He’s Just Saving the World

Naturally, Jochen Zeitz doesn’t take things that lightly. However, while chatting with the current supervisory board member and sustainability officer of Kering (the parent company of various luxury brands such as Gucci, Brioni, Saint Laurent, and Boucheron, as well as sport and lifestyle brands such as Puma and Volcom) about exactly this topic, one does get the impression that achieving sustainability could be quite simple.

Interview: Dörte Welti. Photo: David Crookes

Jochen Zeitz, how deeply do sustainability and ecology need to be entrenched in a company?

If you really want to make a difference, then sustainability and all important ecological aspects need to be embedded in all divisions of a company. I am referring to both strategic and operative measures. It is not enough to merely focus on the operational side by doing a little bit here and there. It is necessary to have a strategy that the company implements beyond its supply chain.

You are committed to ensuring that businesses - not only those from the textile and fashion industries - publish a life cycle assessment. What exactly do you have in mind?

By the time a product is introduced to the market and can be bought and used by the consumers, the manufacturer has used water, land, and air, as well as producing waste and pollutants such as carbon dioxide. These elements must be measured against each other and then transparently translated into a monetary value. As a result, we obtain a life cycle assessment whose fundamentals are the same for everyone and that can be reported just like the financial figures at the end of the year. It would be an environmental footprint in Euros and Cents, so to speak.

How can one comprehensibly compare a ton of carbon with a litre of water?

Criteria and calculation approaches to solve this problem already exist. Kering plans to publish its first life cycle assessment in 2016. Nature is our cap

Jochen Zeitz is upbeat about the future. One of his aims is that every company - no matter how large or small - publishes a standardised life cycle assessment. style in progress 414

"My wish is that we finally manage to introduce a general standard. And if that standard becomes enshrined in law, then everyone can build - and has to build - on the same foundation. However, that takes time. What you don’t measure - or what you don’t express in values and numbers - will not be taken into account, or you start trying to improve the wrong things. In that case, the life cycle assessment would remain an abstract concept." Jochen Zeitz

ital, which means that we need to measure it in the same way we value all other corporate assets. However, it will take time until a standardisation at industry level is achieved.

The interpretation of what a life cycle assessment is still varies greatly from company to company. How can it be standardised?

We need to introduce qualitatively and quantitatively measurable values for the elements we all use, no matter whether we produce shoes, cars, or candy. It is good that people have started thinking about life cycle assessments and that, for a start, every party is doing what they think is best. At least that means that talking is turning into action. However, things do need to be optimised. I did the same in the past; I just jumped straight into an idea. Over time, one finds out what is important and what isn’t. It can happen that a company finds out that an element in a new supply chain doesn’t work under ecological conditions. For example, if a manufacturer uses too much water at one location, then that’s where something needs to change. Smaller companies can draw from the experiences of larger corporations; there’s no need to reinvent the wheel each time. My wish is that we finally manage to introduce a general standard. And if that standard becomes enshrined in law, then everyone can build - and has to build - on the same foundation. However, that takes time. What you don’t measure - or what you don’t express in values and numbers - will not be taken into account, or you start trying to improve the wrong things. In that case, the life cycle assessment would remain an abstract concept.

Do you think that sustainability really is a factor in the pur chase decision of customers, especially luxury customers? What measures could lead to a sensitisation of customers?

You need to make the topic brand-relevant and implement it in an interesting and exciting manner. Luxury brands are often about quality, tradition, and history. If one implements that consistently and uses the right arguments, one automatically operates sustainably. One has to ask oneself where the brand’s competitive edge is and what makes it particularly interesting for the customers. After that, you just need to put it into practice.

What about the so-called lowcost suppliers? Will it be possi ble to persuade those suppliers to participate in your idea of a life cycle assessment?

Just look at the American market. Look what is happening on the food market over there, for instance. For the last few years, whole-food markets have been on the rise. They offer local produce, work within fair trade rules, and sell organically grown goods. That would have been considered impossible five years ago. Then there’s the very attractive Tesla electric car. There are a few examples of that sort. The opportunities are countless, but it is vital to tackle the topic in an innovative and confident manner. Debates help and, in the long term, lead to movement. For example, the United States are currently discussing the sugar level in soft drinks. It is controversial, but that is positive from a general point of view. We need more such disputes in all areas.

How realistic is it that companies take responsibility before the world runs out of steam?

I hope that we, as in our generation, will still see that happen. We have to act swiftly; we cannot afford to wait until something happens. I am convinced of what I’m doing and I enjoy it too. I believe you can achieve something as long as you act with conviction and see what is possible.

You travel a lot. That’s part of your work and your manifold commitments. What do you do to improve your personal life cycle assessment?

I do as much as possible. Above all, I balance out my life cycle assessment with my activities. In 2008, I founded the Zeitz Foundation, which is a non-profit organisation that is committed to the “long run”. It doesn’t support projects that have an impact from just recently to now, but projects that are effective in the long term. In Rivas in Costa Rica, for example, we are funding the construction of biological gardens that purify wastewater and produce clean water. The residents and the environment need both desperately. However, we do not only build such gardens, we also sensitise and educate the residents and ensure that the systems work in the long run. Then there’s the Segera Retreat on the Laikipia Plateau in Kenya, which is also the location of the Zeitz Foundation’s headquarters. It is our aim to preserve the entire 20,000 hectares of land, as well as everything that grows and lives on it. We also conduct research to learn more about the ecological balance of nature during interaction with humans. In the Segera Retreat, we implement a sustainable lifestyle that our guests can consciously experience and contribute to.

Life Cycle Assessment - Is it Zeitzgeist?

The plans of the large corporations may be impressive; and possibly they should be perceived as impressive too. And one might be inclined to say that smaller companies don’t have the funds to follow suit. How can such smaller industry players improve the ecological balance? The central question is how business in general can change the world. Jochen Zeitz teamed up with British businessman Richard Branson for what they call “Mission Plan B”. On the basis of an agenda with twelve key points, they highlight what is necessary to make entrepreneurship profitable, as well as interesting and effective when it comes to making the world a better place. They make it clear that a conscious entrepreneurial attitude and a consistent pursuit of goals can make a huge difference. The platform www.bteam. org constantly informs its readers about the progress, achieved goals, and inspiring implementations in both large and small companies all over the globe. Learning from others is definitely a step in the right direction.