1 minute read

Shape the future

from TCT Europe 31.3

by TCT Magazine

We are shaping the future of manufacturing and product development

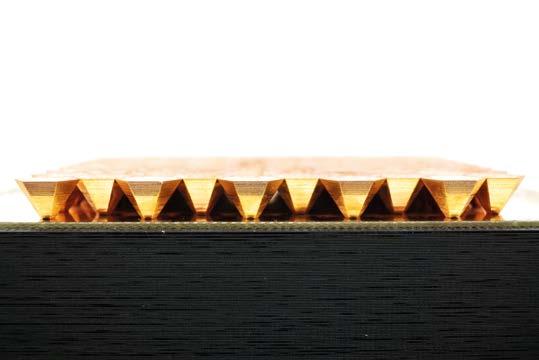

Transforming Manufacturing: The Power of the UltiMaker 3D Printing Ecosystem with Briggs Automotive Company.

Briggs Automotive Company (BAC) is a British sports car manufacturer best known for the Mono model, a single-seater road-legal supercar.

BAC has successfully integrated 3D printing into the production of the Mono R Supercar by harnessing the full potential of the Ultimaker Ecosystem to produce high-quality parts.

The UltiMaker 3D Printing Ecosystem has benefited BAC in some of the following ways:

• Enabled fast and inexpensive production of highly customisable parts

• Optimised supply chain management through the UltiMaker Digital Factory

• Enhanced design flexibility and geometric complexity

• Accelerated design iteration cycles and reduced time-to-market

Vist UltiMaker at TCT3Sixty

Unlimited application potential

The power of the S Series lies in its versatility. Explore new 3D printing applications using the widest choice of materials on the market. These printers enable rapid iterations and customisations making them the perfect desktop 3D printers for manufacturing and product development.

Andrea Gasperini will be taking the stage to show how the UltiMaker 3D Printing Ecosystem can benefit manufacturers. You will also find out more about how BAC harnessed the UltiMaker 3D printing platform to its full potential.

Location: TCT Introducing Stage

Date: Wednesday 7th June at 1 pm - 1:30 pm

08. THE CUTTING EDGE SLM Solutions details the additive manufacture, postprocessing and inspection of a liquid rocket engine capable of reaching the Kármán line.

11. NIGHT & DAY

Sidus Space tell Sam Davies about its use of 3D printing in the design of a lightweight satellite set to launch off SpaceX’s Transporter-9.

12. A FLYING START

We look at GE Aerospace’s success with AM, application by application.

15. SPACE BOUND

Oli Johnson speaks to MIT about its application of 3D printing for satellite sensors.

17. ENABLING WAAM IN MANUFACTURING AIRCRAFT LANDING GEAR

Cranfield University shares its findings after carrying out a feasibility and reliability study on 3D printed aircraft landing gear.

21. THE COST PER-PART CHALLENGE

AM experts give their perspective on how users can overcome their cost-per-part headaches.

25. STEP BY STEP

Production 21 11

Evolve Additive Solutions explains the benefits of its recently launched Production Assessment Program.

METals

27. PARTS THE PLAY

Sam explores the technologies and business models of several metal AM firms coming to market with proprietary processes.

30. RENISHAW IS READY

As the company celebrated 50 years of engineering, Laura Griffiths sat down with Director of AM Louise Callanan to discuss collaboration, productivity and ‘applying innovation.’

32

32. 23 REASONS TO ATTEND

We round up all the things to look forward to at this year’s TCT 3Sixty, including exhibitor highlights, conference sessions, and networking opportunities.

EXEC Q&A 38

38. LEAPS AND BOUNDS

We speak to UK-based Evove, a company using binder jet additive manufacturing to advance filtration membrane technologies.