Supply chain The reality of additive manufacturing's impact on supply chain Formnext We preview select exhibitors & TCT Conference speakers Consumer products Jack Wolfskin, Mattel & Hasbro MAG EUROPE EDITION VOLUME 30 ISSUE 6 www.tctmagazine.com BIGGER & BETTER 3D PRINTING & ADDITIVE MANUFACTURING INTELLIGENCE SLM Solutions unveils the new NXG XII 600E with extended 1.5m axis

3d printing & additive Subscribe for FREE today myTCT.co/subscribe

EDITORIAL

HEAD OF CONTENT

Laura Griffiths e: laura.griffiths@rapidnews.com t: + 44 1244 952 389

SENIOR CONTENT PRODUCER

Samuel Davies e: samuel.davies@rapidnews.com t: + 44 1244 952 390

JUNIOR CONTENT PRODUCER

Oliver Johnson e: oliver.johnson@rapidnews.com

ADVERTISING

HEAD OF SALES TCT PORTFOLIO

Carol Cooper e: carol@rapidnews.com t: + 44 1244 952 386

SALES MANAGER TCT PORTFOLIO

Nicky Martin e: nicky.martin@rapidnews.com t: + 44 1244 952 365

SALES EXECUTIVE TCT PORTFOLIO

Andrew Cooper e: andrew.cooper@rapidnews.com t: 011 + 44 1244 952 374

SALES EXECUTIVE TCT PORTFOLIO

Kristine Baty e: kristine.baty@rapidnews.com t: 011 + 44 1244 952 341

Hamlyn Matt Clarke Rob Wood MANAGEMENT

/ PUBLISHER Duncan Wood SUBSCRIPTIONS

PRICES

Europe Print Subscription - Qualifying Criteria

- FREE

- £249 ROW - £249

North America Print Subscription - Qualifying Criteria

- FREE

& Europe - $249 ROW - $249 TCT German Language Print Subscription - Qualifying Criteria

& Europe - FREE

- €249 ROW - €249 Subscription enquiries to subscriptions@rapidnews.com Read this and back issues for FREE on Issuuwww.issuu.com/tctmagazine BPA Worldwide Membership The TCT Magazine is published bi-monthly by Rapid News Publications Ltd No. 3 Office Village, Chester Business Park, Chester, CH4 9QP, UK. t: 011 + 44 1244 680222 f: 011 + 44 1244 671074 © 2022 Rapid News Publications Ltd While every attempt has been made to ensure that the information contained within this publication is accurate, the publisher accepts no liability for information published in error, or for views expressed. All rights for The TCT Magazine are reserved. Reproduction in whole or in part without prior written permission from the publisher is strictly prohibited. ISSN 1751-0333 VOLUME 30 ISSUE 6 ... at our booth! Join us at Frankfurt, 15-18 Nov. 2022 Hall 11.1, Booth D41

PRODUCTION Sam

C.E.O.

PUBLISHED

TCT

UK & Europe

US/Canada

TCT

US/Canada

UK

UK

US/Canada

FUNCTIONAL ALUMINIUM & PLASTIC PROTOTYPES IN 1 – 4 WEEKS • Machined Aluminium Castings One Shot Casting • Rubber Plaster Mold Precision Air Set Sand • Graphite Die Casting • RIM – Reaction Injection Molding • CNC Machining & Hogouts • Painting, Finishing & Assembly AS9100 & ISO 9001 Certified • ITAR REGISTERED email: sales@armstrongrm.com For more info visit us at: ARMstrongRM.com A Strong Future Stands Behind Us!

FROM THE EDITOR

SAM DAVIES

“Apparently you’ve been with TCT for six years today!?” is the first correspondence I receive on the morning my to-do list dictates that I sit down and write this editor’s letter.

Time for some reflection, then.

“Hofstadter’s Law: It always takes longer than you expect, even when you take into account Hofstadter’s Law” is an epigraph in a book I read that evening; the last words absorbed before the book is closed and laptop flung back open.

In between, the emails come rolling in. One asks for an update on the cover story, another suggests a meeting to gauge progress on the rest of the copy. It would be the third such gathering in the last seven days. This is production week for our biggest magazine of 2022.

It is always the case that the last issue of the year is the biggest; the most arduous to put together. Some things never change. And some do, though per Hofstadter, not always as quickly as first forecast.

This issue - and my six years in AMis testament to that. Our main focus across this edition of the magazine is supply chain. Over the last six years, there has been much talk of additive manufacturing’s (AM) potential to derisk supply networks, but how much of that potential has been realised?

On page 11, we lean on expert insights and real-world case studies to explore the reality of AM’s impact on manufacturing supply chains.

Another market of ‘killer AM applications’ is consumer products, an area said to be primed for AM’s lightweighting, customisation and time-to-market benefits. From page

27, we get a feel for the impression 3D printing is having in consumer goods, featuring Hasbro, Blackland Razors, Jack Wolfskin and Mattel. Spoiler: there are increasing numbers of production applications but at mass volumes? Not quite yet.

Our cover story (P8), meanwhile, is not so much an application as a potential enabler. As you’ll read, SLM Solutions’ new NXG XII 600E already has its first order within defence, and while this market for AM is one growing quickly, it has taken until now for a machine with the productivity 12 1KW lasers offers and part size that a 1.5m Z-axis build volume promises to materialise.

For as long as I have worked in AM, and for many years before, there have been calls for more education and for more thought being applied to it. We’ve needed to teach the engineers, the future engineers, and the teachers themselves. That's still the case. We have it covered on page 47.

Once you’ve graduated from our education feature, you’ll emerge in the Chicago West Loop, inside the microfactory of a company that didn’t even exist in 2016, but is now producing hundreds of thousands of end-use parts with AM per year (P53).

From there, you’re getting a direct flight to Frankfurt – aren’t we all – to get a taste of what’s coming up at Formnext (P57), which, six years ago, was big. But not this big.

It’s in the aisles of events like Formnext where you often encounter minor grievances with regards the pace of change in the AM field. Yet, progress is being made, even if incrementally. After all, it always takes longer than you expect.

30.6 / www.tctmagazine.com / 05

from the editor

Together we lead the Additive Manufacturing Revolution

www.materials-solutions.com

BIGGER & BETTER

TOY STORY

Junior Editorial Producer Oli Johnson speaks to Hasbro and Formlabs about the Selfie Series action figure programme.

THE CUTTING EDGE

Senior Content Producer Sam Davies talks to 3DEO about the additive manufacture of affordable razor

TEACHERS

WITH ULTIMAKER

COVER STORY VOLUME 30 ISSUE 6 8 08.

SLM

capabilities

1.5m Z

47. TEACHING

51.

25.

Solutions details the

of its latest machine launch: the NXG XII 600E with 12 1KW lasers and a

axis.

THE

CREATE Education discusses the reality of implementing 3D printing in classrooms.

EDUCATION

Oli speaks to UltiMaker CEO Nadav Goshen about the first product to be launched under the new brand.

29.

33.

36. WORK AND PLAY Laura

SUPPLY CHAIN CONSUMER PRODUCTS25 11 AM adoption 78 78. DOES AM NEED MORE GOVERNMENT SUPPORT? We ask UK-based AM professionals, consultants and business leaders. EXEC Q&A THROUGH THE DOORS 21 53 21. ‘AMAZON FOR ADDITIVE’ Head of Content Laura Griffiths puts questions to MakerVerse CEO

Seibold about AM services, supply chain and lessons learned from Siemens Energy. 53. ALL ROADS LEAD TO… Sam reports

from a behind-thescenes tour

Fast Radius’

West Loop microfactory. 57. TECHNOLOGY & SPEAKER HIGHLIGHTS We preview what will be showcased on the Formnext show floor and who will present on the TCT Conference @ Formnext stage. 25 11. SUPPLY ON-DEMAND We take a look at the reality of 3D printing’s impact on supply chain with expert insights and real-world case studies. 8 EDUCATION47 39. MEET MQ The best metrology stories from TCT’s sister publication Manufacturing Quality. 43. CT-UBIQUITY Manufacturing Quality editor Tomaz van der Merwe speaks to Lumafield about its industrial CT-scanning technology. METROLOGY formnext preview 39 57

products.

KEEP COOL AND CARRY Jack Wolfskin tells TCT about how AM is providing performance enhancements on a new carry system.

takes a tour inside a Mattel innovation engineer’s home toy workshop.

Markus

back

of

Chicago

BIGGER & BETTER

(AFRL) contract awarded to Concurrent Technologies Corporation (CTC). This project has been designed to facilitate the additive manufacturing of longer parts for critical defence applications, overcoming the limits of existing powder bed additive equipment.

The resulting machine, SLM says, will feature the same ‘lightning fast’ speed and productivity as the standard NXG XII 600, but with the Z-axis extended to 1.5 metres.

We are a technology-focused business, and we will never stop pushing the limits of this technology.”

These were Sam O’Leary’s closing remarks a little over a year ago as he appeared on the TCT Additive Insight podcast. The SLM Solutions CEO had spent around 20 minutes detailing the capabilities of the company’s Free Float software, hinting at the possibilities the NXG XII 600 metal 3D printing system could afford, and outlining, in no uncertain terms, that there was more to come.

Since then, Morf3D, Divergent Technologies, MAN Energy Solutions, Collins Aerospace, Sintavia, and more have all placed orders of SLM’s 12-laser machine, while optics and imaging giant Nikon has moved to acquire the company. More recently than that, SLM has also secured a contract to do exactly as O’Leary said they would last August: push the limits of metal 3D printing.

In September 2022, just weeks after the Nikon news broke, SLM Solutions announced a bigger, better 12-laser metal additive manufacturing platform was under development. The first installation of its NXG XII 600E will come via a 5.2 million USD US Air Force Research Laboratory

Upon the initial announcement, details were scarce. But for a silhouetted graphic distributed on SLM social channels, there were no visuals either. Now, however, the company has publicised the first render of the system, and also revealed it expects to deliver the first unit to CTC in 2023. Additionally, SLM has said that customers who have already installed or ordered the NXG XII 600 have the option to upgrade their system to take advantage of its extended Z build envelope.

With the introduction of the NXG XII 600 series, SLM Solutions believes it is revolutionising metal additive manufacturing. Customers have been demanding the serial production of complex geometries and the faster printing of larger components, and SLM is now working to facilitate them. The NXG XII 600E, the company says, can enable such parts in hours or days instead of weeks and months, thanks to its 12 1KW lasers and 1000cm/hr print speeds.

The NXG XII 600E has been designed to be the most advanced production system on the market today. The solution features an end-to-end production workflow that includes external cool down unpacking to maximize machine uptime. This allows job-to-job turnover to be completed within one hour compared to reported “days” on competing technology. In addition, the NXG platform features SLM Open Architecture allowing maximum flexibility to tailor process parameters to optimise application results with maximum productivity using 90µm layer thickness and beyond in

08 / www.tctmagazine.com / 30.6

SLM Solutions unveils the new NXG XII 600E with extended 1.5m axis.

“It is only in close collaboration that we can push the limits of innovation.”

commonly qualified materials that include IN718, AlSi10Mg, TiAl6V4 & copper alloys. Meanwhile, support-free printing with Free Float offers ‘maximum freedom in design,’ and reduces the need for both support structures and post-processing time by up to 90%. SLM.Quality performs efficient and robust quality assurance with documentation, process qualification, and part certification with the ability to generate a quality report in as little as two clicks, fully documenting process data and validating part quality.

Driving the development of this new system was the customers’ need to produce larger components made from high-temperature materials that can withstand the extreme performance requirements in the defence, space, and aviation industries. The NXG XII 600 is considered by SLM to be the epitome of a production system in that it is 20x faster than a single-laser system and 5x faster than a quad-laser system, thus driving the lowest possible cost for end-use parts in automotive and energy sectors, in addition to the aforementioned industries.

In CTC and the AFRL, it is one of those aforementioned industries that will benefit first. CTC is an independent applied scientific research and development professional services organisation that works to design, develop, test, prototype and build solutions that ‘safeguard national security and retain US technological advantage.’ Through that endeavour, the company has turned to SLM Solutions and its NXG XII 600E system.

“We are pleased to continue our long-term partnership with SLM,” offered Edward J. Sheehan, Jr., CTC President and CEO. “SLM is clearly a leader in the additive manufacturing equipment arena, and we look forward to collaborating and expanding the possibilities of additive manufacturing for defence applications in this exciting opportunity in support of critical AFRL mission requirements.”

Concurrent Technologies has been utilising SLM technology for many years, purchasing an SLM 280HL 3D printer in 2017 as part of a 1.2m USD investment in additive manufacturing equipment. The acquisition of the 280HL machine was made after ‘an extensive research process’; leveraged to produce parts in aluminium, titanium, and stainless steel; and has clearly made an impression.

So much so, when CTC had a request for larger critical defence applications from the AFRL, SLM Solutions was top of mind. CTC is already successfully deploying its technology, and through that dynamic, has seen a company unwilling to let up when it comes to innovation. With a familiar turn of phrase, O’Leary sums up why relationships like this are key.

“We are especially pleased to be teamed with CTC, a highly regarded premier research and development organisation with an outstanding record of securing technology transition successes,” he finished. “These are the partnerships that are a testament to SLM Solutions’ ethos; it is only in close collaboration with them that we can push the limits of innovation.”

30.6 / www.tctmagazine.com / 09

COVER STORY SHOWN: 12 1KW LASERS FIRING, BUILD RATES UP TO 1000CCM/HR ABOVE: NINE HEAT EXCHANGERS BEING PRINTED IN ALSI10MG

Formnext 2022 Hall 12.0 B65 Powder Visit nlight.net/additive for more details Hall 12 | Booth D132 ...while sprinkled donuts dramatically increase team dynamics & workplace productivity. In L-PBF, donut beams greatly improve melt pool dynamics and print productivity... Donuts https://www.mitsui-kinzoku.co.jp/project/kinousei-funtai/en/index.html

SUPPLY ON-DEMAND

Griffiths and Sam Davies explore the impact of AM on supply chain.

Since 2020, the theme of supply chain has dominated additive manufacturing (AM). In turn, we’ve dedicated many column inches and conference sessions to the technology’s deployment as a solution to pandemic-related challenges, and the longer-term implications of its apparent heightened adoption. Two years later, it’s still top of mind, and with emerging use cases, data, and government involvement, it’s not showing any signs of disappearing.

At this year’s TCT 3Sixty conference, a panel of experts including the University of Bristol’s Jennifer Johns, Boston Consulting Group’s Wilderich Heising, and Equinor’s Pantea Khanshaghaghi, discussed the “transformation” that’s happening around AM in supply chain. While it was suggested that AM applications during the pandemic showed “the beginnings of a utopian ideal” where AM steps in to solve our supply chain woes, the common narrative across industry, academia, and end-users, was the cruciality of knowing when and how to implement the technology, and extending that knowledge to the right people.

“Trying to do this top down and saying, here's my catalogue of 150,000 SKUs, let's go out and start making things using 3D printing – that will break people,” Len Pannett, Supply Chain and Operations Transformation expert and author of ‘Supercharg3d: How 3D Printing Will Drive Your Supply Chain’, told TCT. “The other

part, of course, is that if you try to do it that way, the rest of the value chain won't be ready. To use an additive approach needs a different way of doing procurement, it needs a different way of doing contracting. In some cases, it needs qualification of those suppliers, as much as you would any other supplier. You also need to convince the engineering teams that the quality of what they're going to get is at least as good as going the traditional route.

“The tough nut to crack is not the engineering, it's the data side, it's how do you identify which of your 150,000 SKUs makes sense to go down this route? And that requires much more than just doing physical assessments and the assessment of physical characteristics. It means also looking at the supply chain characteristics.”

Pannett offers Deutsche Bahn up as an example of a company that has successfully demonstrated “the art of what’s possible” for AM in supply chain. Perhaps one of the most well-known adopters of AM for spare parts production, the company relies on a mix of in-house 3D printing capabilities and service providers, primarily, to produce polymer and metal components for the railway sector, from rail stops to handrail signs featuring braille. Cosmetics

giant L’Oreal is another, and is currently using HP’s Multi Jet Fusion (MJF) to create adjustable components for its packaging production line with plans to further leverage the technology via HP’s Global Production Network to “build a truly global supply chain” that will enable more localised manufacture.

“The use of additive manufacturing, notably in a hybrid configuration with other technologies, allows us to react extremely quickly to supply chain fluctuations,” Matthew Forrester, Head of Transformation & Recycling Science at L’Oreal, told TCT. “Empowered teams, deploying their intimate knowledge of manufacturing processes, integrating the specificity of our goods, and even iterating during production, is the perfect combination to create best-inclass, agile tooling.”

FITTING IN

While examples like this from major brands and manufacturers show promise, just how much is AM really being talked about with regards to supply chain outside of the AM bubble?

AZOTH 3D USE CASE: TAKE ONE MAKE ONE

Manufacturing service provider Azoth is utilising 3D printing technologies to support its Take One Make One (TOMO) digital inventory strategy. Through TOMO, Azoth empowers its users to convert physical inventory to digital inventory and produce parts as needed without a minimum order quantity to justify up-front tooling or setup costs.

When X number of parts are taken out of inventory, the same amount are made to replace them. Azoth considers this to be the leanest supply chain possible.

The company has proved out this concept by deploying Desktop Metal’s binder jet Shop System to additively manufacture bolt placement grippers that are installed onto a robot arm to pick and place bolts on an assembly line. Using the Shop System, Azoth is

able to produce 1,400 of these end-use parts per day in 17-4PH. 3D printing is deployed because of the components’ intricate teeth design.

“These grippers are the perfect TOMO example,” commented Cody Cochran, co-founder and General Manager of Azoth. “They are more cost effective with binder jetting and can be delivered with a ten-day turnaround vs an eightweek lead time.”

30.6 / www.tctmagazine.com / 011 supply chain

Laura

Visit us at Formnext 2022 DE Frankfurt, Hall 12.0, B47

TANIOBIS

Based on our 60 years expertise in manufacturing and development of refractory metals, we have developed AMtrinsic® atomized tantalum and niobium spherical powders and their alloys for demanding additive manufacturing technologies. Our ability to adjust specific intrinsic material properties enables us to push the limits according to the requirements of your application.

AMtrinsic® spherical tantalum and niobium powders provide outstanding combinations of material properties customized for specific applications. Aligned with 3D-printing technology, AMtrinsic® powders can help overcome hurdles in various high-tech industries. The high temperature stability, excellent corrosion resistance and biocompatibility of AMtrinsic® Ta, Nb powders and their alloys deliver a perfect fit for biomedical (Ta, TNT and TNTZ), chemical (Ta, Nb, Ta-W) and aerospace (Ta-W, C103 and FS-85) applications. In addition, AMtrinsic® Nb with its prominent superconducting property found its application in superconducting industry.

TANIOBIS GmbH announces the expansion of its metal additive manufacturing powders by addition of C103 (Nb-10Hf-1Ti) and FS-85 (Nb-28Ta-10W- 1Zr) pre-alloyed powders to its product portfolio. High-temperature strength, superior creep properties and their excellent processability with AM make these alloys great candidates as structural material for various aerospace applications. Additive manufacturing offers design freedom enabling manufacturing of lightweight components with complex features e.g. rocket thruster with integrated cooling channels which is the main application of our AMtrinsic® C103 and FS-85 alloys.

Ti-Nb-Ta

C103FS-85

Ta

73 Nb

HEA

Ta-W

TNTZ

108.95

92.906 41

According to Mark Cotteleer, Managing Director - Supply Chain and Operations Consulting Deloitte, “a lot.”

“We are seeing across our client base both in the public sector and in the private sector, I would say, an upsurge in discussion,” Cotteleer told TCT. “And that has a lot to do with the fact that additive manufacturing is, in my opinion, the quintessential example of digitally distributed manufacturing. What that means is that it brings together all the interesting attributes of digital distributed manufacturing; the ability to engage in the model-based enterprise, the ability to work across the supply base and distribute production to the point of demand at the time of demand, to bring in ideas around things like digital thread and digital twin, which are very hot topics. Additive is not the only solution. There are lots of solutions and we recommend that our clients take a portfolio approach to it.”

It's true, additive is not the only solution, and sometimes, it’s not the right one either. It’s about finding that sweet spot, developing a business case, and as our TCT 3Sixty panellists agreed, choosing when to apply it, whether that’s on a permanent basis or as an emergency stop gap in times of crisis. The latter, a more temporary outlook, might sound like a negative for an industry that appears to be confidently going after supply chain, but for Cotteleer, that’s actually its USP.

“To me, that's a feature not a bug,” Cotteleer explained. “In the sense that one of the core value propositions of additive is surging production at the point of demand, geographically and in time. Can we deliver production where we need it, when we need it?”

He notes the work Deloitte carried out with America Makes during the pandemic on THE Advanced Manufacturing Crisis Production

STRATASYS USE CASE: CIRCUIT BOARD BRACKET

When Stratasys was first manufacturing its H350 Selective Absorption Fusion (SAF) 3D printers, the company ran into the same problem many other manufacturers did. A PCB Stepper Controller Board had originally been ordered from a supply chain vendor, but as COVID-19 hit, the product was discontinued.

The H350 Production Team then decided to utilise a new electronics board, which could be sourced easily, but required a mounting bracket to implement a necessary cooling

Response (AM CPR) initiative which acted as a digital stockpile of designs that could be surged into production when and where the point of need materialised. It wasn’t just about COVID-related challenges either and the collaborators ran multiple scenarios – what happens if a supplier goes down or an earthquake hits, for example? – taking into account the many players across that supply chain, from designers to regulators and so on.

In September, Deloitte issued a report in partnership with the Manufacturers Alliance looking at how traditional manufacturing supply chains are evolving to balance costs, efficiency, and resilience. While the term ‘additive manufacturing’ is referenced just once in the 26-page document, in a chart showing the biggest impact on manufacturer’s supply chains, the top three responses - shipping delays (59%), part shortages (56%) and transportation delays (56%)are key areas where the benefits of AM truly shine. Yet while additive’s value proposition as an enabler of distributed, on-demand manufacturing is evident, challenges remain.

“All of the old concerns still exist: quality, materials, cost, repeatability,” Cotteleer said. “I think what is changing is that, while the concern exists, many of the technical solutions are increasingly available so people need to be constantly revisiting the state of the art because things are changing quite rapidly. There are instances where we are seeing people quite effectively being able to distribute production, particularly at the lower end. At the higher end, with exotic materials and very expensive machines and very high-end uses, we still see, and in fact recommend, more centralised production models, but even there, you could still solve the time problem, you're just not solving the location problem.”

Interestingly, that singular nod to AM in Deloitte’s report ties into another industry trend: mergers and acquisitions. The report notes the strong M&A activity in manufacturing with 52% year-on-year growth in such deals in 2021, and suggests some instances of vertical

function. For the solution, the team looked inward and bet on the technology they were working to bring to market. With the H350 machine, they designed and printed a circuit board bracket which could secure the fan to the electronics board and then safely mount the board within the printer.

The bracket, which doesn’t require any screws or tools, is said to occupy a minimal amount of space. Stratasys can nest 132 brackets within the same build with a cost per part of 4.15 USD. The company has implemented the circuit board bracket in every H350 3D printer and has continued to apply SAF technology to its SAF systems.

“This was one of those examples that ‘ticked many of the boxes of additive manufacturing,’” Neil Hopkinson, VP of AM Technology at Stratasys, told TCT.

“The challenge arose from supply chain issues, which are becoming more frequent in manufacturing these days and the solution came from AM technology that actually allowed the team to develop an improved product with easier assembly. In this instance, it was very gratifying that SAF technology itself was the solution for a SAF product development issue. The team has since built on this and each H350 printer has 30 parts produced by SAF technology.”

30.6 / www.tctmagazine.com / 013 supply chain

“The tough nut to crack is not the engineering, it's the data side.”

FREEFORMER COMES IN A NEW SIZE

The new freeformer 750-3X is equipped with a larger part carrier for a build time that is up to 85% faster. New: freeformer 750-3X

A new key feature is the machine’s enlarged build chamber. The new freeformer 750-3X has a part carrier that is around 2.5 times larger than that of the freeformer 300-3X, which is particularly impressive given that the external dimensions are the same.

The entire system of the freeformer 750-3X – prepara tion and discharge units – has been optimised so that the design could be more compact. In terms of external appearance, the freeformer 750-3X has the same external dimensions as the freeformer 300-3X. However, the part carrier is approximately 2.5 times larger at around 750 square centimetres and is the result of several technical innovations. These include more compact and slimmer melt pressure generators for dosing and injecting, which use servo motors from AMKmotion – a company in the ARBURG family.

The entire system, comprising the preparation and discharge units, has been pressure-optimised and is therefore tai lored to the conditions of additive manufacturing. When improving the melt pressure generators, the primary focus was on repetition accuracy (i.e. producing droplets of the same size) and cost reduction; the latter was achieved through hardware adjustments. These improvements

also allowed the three discharge units to be made more compact and arranged closer together. Compared to the freeformer 300-3X, they have a "streamlined" design. The innovations in the area of control extend to the "pro duction control" sectors, with intuitive operation such as overviews of the job status and production as well as the "intelligent start-up sequence" for production prepa ration. In addition, other new features include reduced material dwell time in the cylinder and parallel dosing, resulting in a reduced build time, as well as optimised and enhanced slicing in terms of the construction strategy for lattice structures (support structures) and break-away support. This all contributes to improvements in process stability, part quality and build time optimisation. The freeformer 750-3X therefore bridges the gap between pure prototyping and economical small series production: this new system reduces the build time by up to 85%!

i

Further information: www.arburg.com

Advertorial 2022

ARBURG GmbH + Co KG Arthur-Hehl-Strasse 72290 Lossburg, Germany

Tel.: +49 7446 33-0 www.arburg.co.uk contact@arburg.com

integration can be seen as a tool for achieving supply chain resilience. For instance, earlier this year, aerospace and defence manufacturer Safran, which recently opened a new dedicated 3D printing campus, completed its acquisition of metal AM powder supplier Aubert & Duval, bringing its supply of metal powders inhouse. It’s an extreme example, and bringing AM into your supply chain doesn’t necessarily mean investing in an entire company or bringing in expensive hardware. Advanced manufacturing service providers can offer an alternative route to sourcing parts ondemand, and Pannett suggests that finding a supplier to produce products with the right quality and with the right QA processes already in place as a “very easy, quick win.”

Joshua Parker, US 3D Printing Supply Chain Manager for Hubs, fittingly the subject of another major AM acquisition which saw the distributed 3D printing network merge into the Protolabs family in 2021, manages a network of 3D printing suppliers across the U.S. The Hubs network allows users to upload designs, instantly receive quotes and send their files for production via 3D printing, CNC machining, injection moulding, and sheet metal fabrication. To date, the service has manufactured over 6 million parts, and as part of its annual 3D Printing Trend Report, this year spotlighted more robust supply

chains and localised on-demand manufacture as one of the most important AM trends for 2022.

“As additive becomes more of a low volume production solution, there has been increased interest with customers using technologies like SLS and HP’s MJF to either provide a shortterm production solution or to switch to 3D printing altogether,” Parker told TCT. “We have seen a lot of success in the EV sector, especially with companies that are highly iterative and innovative and want to stay nimble with their design. With the increased lead times of going overseas for moulds, 3D printing provides a quick alternative while tooling is being created.”

AM FORWARD & SUPPLY CHAIN

“We believe the initiative is a bold step forward for additive manufacturing, particularly if it revitalises the US supply chain by enabling more companies to take advantage of the intrinsic benefits of AM. Our hope is the programme helps the many small and medium-sized businesses working to unlock new business opportunities and scale sustainable production with AM.”

“Public-private initiatives like the recently announced ‘AM Forward’ initiative will help to address DoD’s sustainment and readiness challenges head on. Strengthening US supply chains, by encouraging small and medium sized manufacturers across the United States to adopt metal additive technology will create a nationwide network of qualified additive manufacturing suppliers.”

“We're at an undeniable inflection point — bringing digital manufacturing to U.S. businesses will be a critical component to the success of the American economy both now and into the future. The administration's acknowledgment of 3D printing to boost the economy is a solid step forward and a proof point that digital manufacturing is critical in addressing our ongoing supply chain challenges and beyond.”

“I think it's still early and I think a lot of people I work with are still wondering what that means. But I think, if anything, it could chart a path towards additive manufacturing playing a more significant role in supply chain resilience. And if there's anything that the last 36 months has taught us, it's that there's vulnerability there and additive can play a role.”

30.6 / www.tctmagazine.com / 015 supply chain

AM INDUSTRY WEIGHS IN ON THE AM FORWARD INITIATIVE DESIGNED

THE

TO SUPPORT US-BASED SUPPLIERS’ ADOPTION OF AM CAPABILITIES.

DIDIER DELTORT | PRESIDENT, PERSONALIZATION AND 3D PRINTING | HP

LAUREN TUBESING | DIRECTOR OF OPERATIONS, MILITARY PROGRAMS | GE ADDITIVE

ELLEN KULLMAN | CHAIR OF THE BOARD OF DIRECTORS | CARBON

JOSH MARTIN | CO-FOUNDER & CEO | FORTIFY

“The more we can get AM in front of supply chain decision makers, the better.”

Signi cant Cost Savingson Additive Tool Partnership between ermwood and General Atomics e Details Using a ermwood LSAM 1020, the tool was printed from ABS (20% Carbon Fiber Filled) in 16 hours. e nal part weighing 1,190 lbs was machined in 32 hours. Cost Savings of around $50,000 vs traditional methods Total lead time for the part decreased from 6-8 weeks to less than 2 weeks by utilizing the powerful LSAM system. e Results • Cost Reduction: 2-3 times • Faster Development: 3-4 times • Production Capable Tool • Vacuum Integrity • Suitable for Large, Deep 3D Geometries, Backup Structures & Vacuum Piping www.thermwood.com 800-533-6901 MADE IN USA Scan QR code to view a video of the LSAM and General Atomics process. Nov 15th-18th Booth 11.0-D61 Join us at

PRACTICE WHAT YOU PRINT

If 3D printing is the silver bullet in supply chain resilience, are 3D printer manufacturers taking note?

Megan Liu, Supply Chain Engineer at Formlabs, works within the global sourcing team, looking after supply chain for pretty much every aspect of Formlabs products. In fact, several Formlabs machines feature a range of components manufactured with its own printers.

“We, I think, definitely understand that there is a good application for 3D printing in supply chains,” Liu explained. “At the same time, most of our printer is not made out of a 3D printed material so there are definitely limitations on 3D printing parts for production. I think the best use cases are really small parts, in terms of geometry, things that nest well in our printers.

“I joined Formlabs because I am super interested in how we can use 3D printing in all different types of

industries. It's super exciting for me to see Formlabs practising what we preach.”

The sourcing team’s job is essentially to find suppliers to make and deliver parts to its contract manufacturer on time. When Formlabs launched its Form Wash L and Form Cure L systems during the pandemic, for example, the team was able to mitigate supply chain issues and material delays by ramping up print production from its materials production facility in Ohio and Somerville HQ.

“Something that has been super exciting to see is, and I know this is kind of a buzzword, but we are able to decentralise our supply chain a little bit by using 3D printing,” Liu said. “If we are ever short on components or things like that, we can use a 3D printer right at the spot to print components to keep production going.”

In addition to a shift in customer applications, which now go beyond prototyping to tooling or production parts on the Fuse and Form 3L, and extend to even more industries, Liu says the last few years have also produced more awareness and interest in the technology.

“I think a lot of things probably have contributed to that extra interest,” Liu said. “I think the technology has improved and grown a lot over the last couple of years, but then also COVID with all the supply chain issues that brought was also definitely a wake-up call for a lot of people who are relying on traditional manufacturing methods.”

If the wake-up call was missed the first time around, the announcement this past Spring around the Biden Administration’s AM Forward initiative should ring a little louder. The initiative was setup to support the adoption of AM amongst SMEs, with large

additive approach needs a different way of doing procurement.”

FAST RADIUS USE CASE: STREAMLINING SPARE PARTS

As 3D printing continues to mature, and applying the technology for productiongrade parts becomes more of a reality, Husqvarna has aligned with Fast Radius to implement an advanced manufacturing approach.

The outdoor product manufacturer has worked with Fast Radius to identify parts that could be produced at scale with Carbon Digital Light Synthesis and HP Multi Jet Fusion technology, before establishing a Production Part

Approval Process (PPAP) that included UV resistance, chemical resistance, and dayslong cycle tests, as well as an evaluation of real-world performance. Once parts pass the PPAP, designs and production specifications are stored digitally in the Fast Radius Virtual Warehouse, eliminating a lot of the supply chain costs associated with warehousing, minimum order quantities, material waste and part obsolescence.

From this virtual warehouse, parts can be downloaded, produced and shipped in a matter of days, while also affording Husqvarna and its customers the peace

of mind that products will never be out of stock again. The reduction or elimination of material waste and part obsolescence is also supporting Husqvarna’s ‘Sustainovate’ sustainability programme, in which the company has outlined CO2 reduction targets for the year 2035.

“For Husqvarna, storing parts in the Virtual Warehouse has allowed them to avoid inventory holding cost, scrap at end of life, and has enabled better customer support by eliminating the need to discontinue production of certain spare part SKUs,” Matt Schroeder, Product Manager at Fast Radius, told TCT.

30.6 / www.tctmagazine.com / 017

“An

supply chain

Print tons of innovative designs on the Sapphire XC 1MZ

Part of an advanced and integrated metal additive manufacturing solution that includes print preparation software, hardware, and quality assurance software, Sapphire XC 1MZ is a production-level metal laser powder bed fusion printer that enables the highest levels of quality, innovation, and unprecedented scale and productivity with its eight 1 kW lasers and build volume of 600 mm Ø by 1000 mm z-height.

The pathway to printing your most ambitious designs starts with Velo3D.

Without Compromise

Velo3D and Sapphire, are registered trademarks of Velo3D, Inc. Without Compromise is a trademark of Velo3D, Inc. All Rights Reserved © Velo3D, Inc.

Contact us today for a consultation Visit us at Formnext Booth 12.0-D01

THE NEXT-GENERATION OF 3D METAL PRINTERS - SAPPHIRE XC 1MZ

manufacturers like Siemens Energy, Honeywell, Lockheed Martin, GE Aviation and Raytheon, all long-time users of the technology, committing to purchasing additively produced parts from smaller US-based suppliers, providing training, and engaging in common standards development and certification for additive products. It’s a bold move, and emphasises the recognition of additive and distributed, localised manufacturing as tools to achieve supply chain resilience, something which Deloitte shares a confidence in.

SPEAKING SUPPLY CHAIN

From each of these conversations, it's increasingly clear that AM’s success in supply chain also relies on sharing these wins and having conversations with the people that can make change happen. Those already working in or using AM will be aware of the benefits of on-demand and decentralisation, and Pannett argues AM companies should be putting themselves in front of supply chain professionals in order to see progress.

“I think the more that we can do to get the AM community in front of supply chain decision makers, the better,” Pannett said. “Those events where the supply chain guys are going to be exposed to new ideas, those are the ones that, I think, if we're going to really peak in our sales, have to be included in the roster.”

Cotteleer said: “We are very bullish on the concept of distributed digital manufacturing and I think that it will continue to be important for supply chain and operations leaders to stay on top of, and develop strategies for how to deploy these technologies in support of cost, quality, resilience, flexibility, agility – fill in the buzzword – because this, to me, is the way the world is going, and if you're not incorporating these into your strategies, you're very likely falling behind.”

Having those conversations means being able speak the right language, to understand the needs of those operating along supply chains, and communicating where the benefits of AM, which may be lesser known outside of the industry, come into play.

“Words matter and I think this is a general challenge in the additive and advanced manufacturing space,” Cotteleer said. “And I'll point no further than the use of terms like digital thread and digital twin, which are crucial for the support of additive manufacturing. We often find ourselves at the beginning of a project or discussion, literally saying, ‘when we use these words,’ fill in the blank, ‘here's what we mean,’ because different people can ascribe different meanings to those words.”

Speaking from a service provider perspective,

Parker adds that it’s important to put that message across early in the procurement process: “Education and familiarity is the main reason we see a lack of adoption. Our Sales and Engineering teams do a great job working with the customer to understand their needs and help companies steer their design towards the final manufacturing method. If you don’t consider 3D printing as a production method during design, it can be more difficult to change the manufacturing method later in the product design cycle.”

That also means educating the right people, not just the engineers who will ultimately be using the technology but personnel along that value chain who need to understand the benefits in order to recognise where and why additive fits, or if it simply doesn’t.

“It's definitely a lot of engineering [people] right now, they're probably the most aware of this technology. [...] When we talk to people in supply chain, they're talking to us about printing spare parts and components and I think that definitely makes a lot of sense," Liu concluded, adding that there is an element of curbing expectations and a learning curve around what 3D printing can currently do in terms of spare parts. "That's, I think, where the knowledge gap starts to show a little bit because I think they're really hoping that 3D printing can solve all their problems in terms of aftermarket parts, spare parts, and things like that. I think maybe there needs to be a little bit more education in terms of the interim. Even though you potentially can't use 3D printing for this grand solution, there are definitely ways in which 3D printing can help aid in that transition, keeping all this excess stock to printing when you need.”

30.6 / www.tctmagazine.com / 019

supply chain

“This is the way the world is going.”

look at our

to performance

the

is improving

robustness

operating

process reliability

to

gas

Melt

your

Find your flexible solution for industrial metal 3D printing! Visit us at Formnext in Frankfurt! November 15-18th, hall 12.0, booth D81

Have a

TruPrint 3000. In addition

increase with fullfield Multilaser option, the focus of

TruPrint 3000

process

and various

scenarios. High

due

newly developed

flow and high part quality are proven with

Pool Monitoring. The 3D printer can be tailored to

production process needs. More information www.trumpf.com/s/truprint-3000

'AMAZON FOR ADDITIVE'

Q: You spent the past seven years as VP Additive at Siemens Energy. Tell us about how MakerVerse came about.

Siemens Energy has gotten really deep and really good [at] metal powder bed fusion for high temperature applications for gas turbines. This was the real sweet spot. When I left, early 2022, there were more than 200 people now working on additive and the company overall has more than 50 metal powder bed fusion printers installed in our global Siemens Energy network. […] There is the saying ‘when you have a hammer, then everything looks like a nail’ and what happened at Siemens Energy, we looked at every potential component like a metal powder bed fusion, hightemperature AM component. The reason Siemens initially started to think about MakerVerse was that there was a need for a second pillar in the strategy. To fulfil a few requirements, it should give Siemens Energy access to a whole array of different additive manufacturing technologies and materials that the company didn't have in its own very deep footprint. Number two, it should do that at industrial-grade quality so that Siemens Energy really could take prototypes all the way to a certified spare part. And number three, it should support specifically the on-demand nature of nonplannable prototypes, of unsteady spare parts. And with those three requirements, one-stop shop, industrial grade quality and on-demand manufacturing, the idea was created to turn this into a digital platform model. It's intended to be something like the Amazon for industrial 3D printing.

Q: We understand MakerVerse aims to offer a ‘full technological service spectrum’. Which specific technologies/ services will that include?

This is an always evolving story. If you go to our platform today, you will find on the metal side, metal powder bed fusion, and on the polymer side, you will find selective laser sintering, HP’s Multi Jet Fusion and FDM technology. Then there's of course a different set of materials below each of those four technologies and our operations team is continuously working on expanding the technology and materials portfolio. […] We will broaden our scope step by step. Currently we are an additive manufacturing platform

but we believe that this needs to be integrated with conventional technologies like CNC machining, so over the next weeks and months we will also broaden the technology focus beyond additive to also include conventional technologies so MakerVerse is a true one-stop shop for both additive and conventional requirements.

Q: We’re talking a lot in this issue about how AM can bring agility to supply chains. How does MakerVerse fit in? There are two very fundamental different use cases [for AM]. One is, you design a new part, taking into account the design possibilities that additive offers and then you can think about all these topics like performance improvement, weight reduction. So, you start a new project, you design a new component for a new product. Then you can, from the very beginning, design for additive and then you also need to think about industrialisation of this part in terms of qualification of the entire process: machines, powders, printing processes, post-processing. The second category is that you have an existing part, you have an existing supply chain, and you want to mitigate your supply chain risks by, for instance, reducing lead times by nearshoring production through additive manufacturing, and then usually your design is an existing design that has been sourced from wherever, and rather than improve the design of the part, you want to mitigate the supply chain situation. The big challenge that I see still for additive here is cost because the original design wasn't designed for additive. So, you usually face higher product costs and you need to trade these higher product costs with the effects you gain on lead times or on not having a part at all, because of supply chain disruptions. And

yet, in the second case of supply chain resilience, you still need to make sure that when you convert a conventional part to an additive part, you meet certain properties in terms of material.

What a digital platform like MakerVerse can offer for the first category, the design iterations, it can offer you super-fast access to different technologies and materials,

30.6 / www.tctmagazine.com / 021 EXECUTIVE Q&A

Laura

Griffiths speaks to MakerVerse CEO & Managing Director Markus Seibold about AM services, supply chain, and lessons learned from Siemens Energy.

SHOWN: MAKERVERSE CEO MARKUS SEIBOLD

Pushing Additive M A nufA cturing to its Li M its Parts as large as 1 meter, wall structures as thin as a hair, lowest surface roughnesses, highest electrical conductivity? Cumbustion chamber* 1000 mm heights Finest tungston wall structure 100 µm thickness Heat exchanger** 100 mm diameter *by courtesy of Launcher **by courtesy of Conflux tell us your story and we find your cutting-edge solution tailored to your needs - open new fields of application with a reliable partner! Welcome to the world of Additive Manufacturing Customized Machines Welcome to AM c M An company We are ready to connect: amcm@amcm.com www.amcm.com tAL k to us At the 15 th - 18 th n ovember 2022 h all: 11.1, Booth: c 51

and it can really help you to accelerate development speeds, that's the classical use case. When it comes to the second use case, of on-demand, supply chain needs, […] for every technology/material we offer on our platform, we have multiple suppliers behind each technology/ material combination. So when you have an on-demand situation, that you need certain parts that run in your supply chains, quickly, on-demand, in unsteady quantities, MakerVerse as a digital platform has the advantage of always having, at any point in time, multiple suppliers qualified for this material/ technology combination so we can react super quickly.

Q: Who is currently using MakerVerse?

I can't share names but I can share applications that I think are quite interesting. One category we are currently seeing is development projects. Heat exchangers being one example where companies are currently developing and designing different designs for heat exchangers, trying to see how much they can push the engineering limits in terms of wall thicknesses, cooling hole sizes in the internal structures and they want [quotations] for different designs quickly, they want to know how fast it is until you can really have hardware so that they can test this. […] Another customer category that I see now emerging is potential spare parts on-demand. So, it’s parts that are not necessarily designed for additive from the get go, this is a legacy part and in most of the cases actually,

that are prospectively interested in converting these legacy spare parts to 3D printed spare parts. A third category is production aids, grippers for robots and certain toolings or jigs and fixtures.

Q: Siemens is arguably one of the biggest industrial users of AM. What lessons were you able to learn there about adopting the technology?

I spent quite a bit of time in the past years reflecting with the team on what were certain hurdles and what were success factors for Siemens Energy because I believe our global teams have really done a fantastic job of being super effective and focused on driving additive into serial production. […] I think an already very commonly accepted success factor is that you need to stop trying to quote the same designs that you optimised for turning, milling, injection moulding, and hope that additive can make those parts cheap - it just doesn't work. Usually when you try to copy the same design, and make it by additive, additive is at a cost disadvantage. It's all about design for additive. At Siemens Energy, for instance, you can build internal cooling channels into parts that you could never cast, you could build combustion system components that allow you to better mix air and fuel in a way that you reduce emissions.

In a corporation like Siemens Energy,

thing and big companies have a lot of responsibility for the end product. It's very hard to introduce a new method of manufacture and design because you have no long-term proven experience. So, it's actually really difficult for an engineering-driven business to say, 'I'll put an additive component on my car, on my plane, on my gas turbine,' because you just don't know how this material or how this part will behave over time. So, you need a certain risk culture. This doesn't mean that you go just completely crazy and put parts you don’t understand on engines, but you need openness on the level of the famous middle management in terms of product owners, component owners, part owners. […] So, you need this risk culture on the mid-level so that you incentivize additive, look at it, and push it against real component applications.

Listen to the interview in full on the Additive Insight podcast: mytct.co/AIPodMakerverse

[Editor: Answers have been edited for brevity and clarity.]

30.6 / www.tctmagazine.com / 023

EXECUTIVE Q&A

•

•

•

•

addiblast.com Make your existing better. Make the new possible.

www.

Still waiting for the revolution in additive? The wait is over. Visit us at Formnext 2022:

Get hands on with our toughest, fastest-in hand SLS nylon copolymer parts

Experience the quality of SLA parts that print twice as fast and remain stable and strong for years

Be stunned by large 1:1 scale molds printed at up to 10 times the usual speed at a fraction of the cost

Booth #D11, Hall 11.1 Nov 15-18, 2022 | Messe Frankfurt, Germany

Find out why the world’s most demanding industries turn to us to produce one million complex metal parts a year FormNext:

© notice. 3D Systems and the 3D Systems logo are registered trademarks of 3D Systems, Inc.

A BATCH OF FACES PRINTED USING SLA

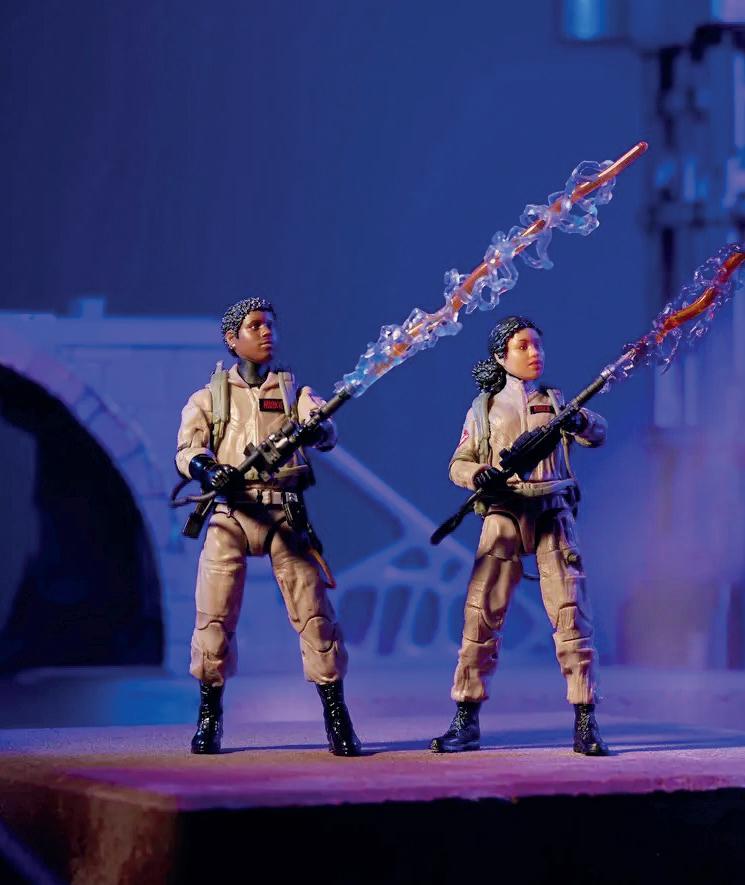

This summer, Hasbro announced the Selfie Series, a new product range which allows customers to have their face 3D printed onto the body of a sixinch action figure; a Stormtrooper, Spider-Man, a Ghostbuster, a Power Ranger, amongst several others.

The production process starts by taking a scan of the customer’s face through the Hasbro Pulse mobile app, where they can also select their preferred action figure and hair colour. The information is then sent to the Hasbro print factory and queued up for 3D printing. Multiple customised heads are printed at the same time on a single build

plate, using Formlabs stereolithography (SLA) technology. The heads are then assembled with a standard off-the-shelf action figure body, before finally being shipped to the customer.

The IPs that Hasbro works with are some of the most beloved in the world of pop culture. To create a product that would be well-received by fans, selecting the right 3D printing process for this range of action figures was crucial. The toy company has been using 3D printing since 1995, primarily for rapid prototyping, and began using Formlabs printers in 2014. According to Hasbro, as it saw 3D printing cross over from being a prototypecentric technology, it had the dream of developing something with the technology that was truly innovative, hence the idea of mass customisation.

Gary Rowe, Global Head of Business Development at Formlabs, told TCT: “Many companies turn to SLA 3D printing for the strength and resolution of the prints, and Hasbro had used Formlabs SLA 3D printers for prototyping in the past. When seeking the right solution for the Selfie Series,

Hasbro selected the Form 3 SLA 3D printer that would provide the high resolution and accuracy needed to create life-like faces of Hasbro’s fans, with a smooth finish that would also be durable. In addition to the quality of the prints, the Form 3 worked well with the resin created for the manufacturing of these action figures.”

Mass customisation enabled by 3D printing allows for the commercialisation of products that are unique to the customer. The audiences the Selfie Series are targeted towards - Star Wars fans, Marvel fans, Power Rangers fans and more - often embrace the opportunity to dress up as their favourite characters at fan conventions and premieres, so Hasbro believes the market is there for products that invite fans to put their face onto their favourite characters too.

Patrick Marr, Sr Director of Model Development at Hasbro, spoke to TCT about the implementation of mass customisation in Hasbro products: “Our fans continue to look for new ways to engage with our brands and see becoming their favourite action figure as the ultimate expression. 3D printing has allowed us to offer that experience at scale in a quality that was never possible before. We see utilising 3D printing as opening

30.6 / www.tctmagazine.com / 025

Oliver Johnson speaks to Hasbro about its new range of customisable 3D printed action figures, the Selfie Series.

SHOWN:

SHOWN: SELFIE SERIES GHOSTBUSTERS ACTION FIGURES

consumer products

SHOWN: HAIR PIECES BEING PREPARED FOR 3D PRINTING

We are dedicated to providing an excellent service – from rapid quote to on-time delivery – producing high-quality components at the right price. · Stereolithography · Selective Laser Sintering · Vacuum Casting · Two Shot and Over-moulding · Silicone Components · Silicone Tooling · Reaction Injection Moulding · Water Clear Lenses · Traditional Model Making · Model Finishing RAPID PROTOTYPING info@amtech-rp.co.ukwww.amtech-rp.co.uk(0191) 454 1900 Print today. Parts tomorrow. Make metal with the Rapidia System. Hall 12.0, #E122 Meet us at 1201 Franklin St. Vancouver, BC V6A 1L2 Canada +1 604 267-0199 info@rapidia.com Office-friendly No loose powder or solvents, small footprint Design freedom Fast sintering of thick parts, solid infill. Evaporative support and water-bonding, unlimited geometry Rapid turnaround Printer to sinter, no debinding www.rapidia.com Hall 12.1 - C129 arkema.com Unlocking the next revolution. Learn more about this system by contacting us at https://quantica3d.com/ Combine up to 7 functional materials in a single print

many future opportunities for our fans.

Leveraging the technology allows us to deliver products faster, create custom products, and then continue to evolve that platform by offering new features.”

The material that Hasbro chose had to be able to create figures that were highly detailed, to accurately replicate the consumer’s face, but also durable enough for everyday wear and tear. Formlabs assisted in the process of deciding on a material that could be available in a variety of skin tones and hair colours, which ultimately led to the creation of a new resin, based on its Tough 1500 material, specifically for this application. Rowe shared how Formlabs worked closely with Hasbro to meet quality assurance and safety testing standards required for commercial products in the toy industry. While the hair pieces for the figures are currently not personalised, these are also manufactured using the same SLA technology.

Marr added: “Hasbro Selfie Series is really our first consumer-directed product that utilises 3D printing in the mass customisation space. The product was driven by leveraging our 25-year knowledge in 3D printing to bring an experience and product to market that sets the bar on personalisation and quality. We spent about two years developing the scanning, printing, and production process

to ensure we could offer an amazing customer experience.”

An important aspect of the production for Hasbro was the ability to match the quality of its collector figure lines. Hasbro action figures have been a staple for collectors for decades, and the company wanted the Selfie Series to match the quality that fans have been used to.

Rowe spoke about the future for Formlabs and Hasbro, and for mass customisation, saying: “Selfie Series is an example of how Formlabs 3D printing solutions can deliver mass customisation to consumers. Hasbro

has understood this potential innovation and created this first application of mass customisation to foster engagement with its customers. 3D printing will continue to advance in end-use-parts and mass customised products as complimentary technologies such as scanning technology and material development increase the quality, speed, and applications. Consumer demand for personalised products will also rise in tandem with this technological development to make 3D printing a more sought-after approach for delivering new products that strengthen brand awareness and loyalty.”

Emphasising Hasbro's ambitions for future personalised products, Marr added: “We look at Hasbro Selfie Series as just the first expression in this space, and we want to continue developing and expanding our engagement with our fans. Again, it is really the perfect flexible platform that allows us to leverage ideas from some of the company’s amazing talent.”

30.6 / www.tctmagazine.com / 027

“Selfie Series is an example of how Formlabs 3D printing solutions can deliver mass customisation to consumers.” SHOWN: SELFIE SERIES ACTION FIGURES

ON A

3 BUILD PLATE consumer products

SHOWN:

SELFIE SERIES FACES

FORM

Nexa3D, a global leader in ultrafast polymer 3D printing will be exhibiting its full range of photopolymer and thermoplastic additive manufacturing solutions at this year’s Formnext at Hall 11.1, stand E31.

Nexa3D’s patented Lubricant Sublayer Photocuring (LSPc) technology offers orders of magnitude faster print speeds and lower total cost of ownership compared to traditional stereolithography and DLP processes. Its wide range of ultrafast printers span from the desktop to the factory floor, and include the XiP Desktop 3D Printer, the NXE Pro Series Industrial Printers, the NXD Dental 3D Printer, and the QLS 820 powder bed fusion platform for serial production.

Its desktop resin 3D printer, the XiP offers a large, 4.8L build volume and print speeds of up to 18cm per hour, resulting in significantly greater throughput than other professional desktop 3D printers. Powered by Nexa3D patented LSPc™ Technology, the XiP’s key features include:

• Self-lubricating Everlast™ Membrane delivering enhanced part quality at superior speed

• Generous 4.8L build volume (190 x 115 x 210 mm)

• Modular, 4K resolution mono LCD and advanced UV light engine delivering

uniform and consistent prints

• Open materials platform for ultimate accessibility

• Quick-change resin system for easily swapping resins

• Sleek industrial design with robust components made from recyclable aluminum

Nexa3D’s flagship industrial 3D printer, the NXE 400Pro series is used by hundreds of customers worldwide to produce functional parts and production components for a variety of industrial applications. Its 17L build volume and unrivaled print speed enables exponential productivity gains on the production floor. The NXE Pro series printer features include:

• Precision and high speed enabled by the patented LSPc™ Technology printing up to 6.5x faster than other SLA or DLP technologies

• Large, versatile build volume of 17L, measuring 10.8 x 6.1 x 15.7 inch (275x x 155 x 400 mm)

• Robust, high-performance materials portfolio of validated resin as well

as an open platform for the ultimate freedom of resin selection. Currently validated materials include a variety of modeling and functional resins, with both rigid and elastomeric properties.

• Edge-to-edge uniformity and accuracy with 4K resolution enables partto-part consistency across the full build without light diffusion near part edges.

Nexa3D’s newest industrial 3D printer, the QLS 820 is built for highest throughput manufacturing applications. This thermoplastic, powderbased technology can print 8L per hour at up to 20% job density, making it the industry’s leading powderbased technology for serial production.

The QLS 820 printer features include:

• Highest throughput in its class printing up to 8 liters/hour and delivering an average 20% build density.

• Automation-ready architecture with Siemens PLC factory

unit for optimal printer utilization and minimal down time.

• Open platform with inert, high-temperature capabilities you have an abundant material choice and build parameters, including production temperatures up to 230°C.

Nexa3D will be demonstrating all printers during Formnext and visitors can stop by the company’s stand at Hall 11.1

| Stand E31 for live prints narrated in both English and German. Additional information can also be found at nexa3d.com.

ADVERTISEMENT FEATURE

Sam Davies speaks to 3DEO about its role in the development of Blackland Razor’s TCT Award-winning Era razor.

THE CUTTING EDGE

It’s not very often that you have a consumer product that has a price point that can compete.”

3DEO President Matt Sand is reflecting on a TCT Award-winning project: The Blackland Razor Era double-edge safety razor, the company’s first mass-market offering. It was enabled by 3DEO’s metal additive manufacturing (AM) technology.

The razor, 3DEO and Blackland Razor believe, is the most advanced of its kind on the market. At a point-of-purchase cost of under 100 USD, it is up to three times less expensive than prior Blackland Razor products, but with no compromise on the quality.

“When we set out to create the Era, we didn’t choose metal 3D printing as a gimmick to get cheap attention,” Shane Swartzlander, founder and Chief Innovator at Blackland Razors, writes on his company’s website. “We chose it because this production method allows us the flexibility to design a razor with features that cannot be machined. Without a doubt, the Era is a razor unlike any other due to its 3D printed stainless steel structure.”

3DEO’s Intelligent Layer technology was leveraged to

additively manufacture the top cap of the safety razor, as well as five varying open combs and five varying safety bar base plates. The technology works by spreading a thin layer of metal powder before a proprietary spray technology deposits a binder agent across the entire layer, indiscriminate of part location. Then, a bank of CNC micro endmills cut the predetermined internal geometry of each part across that layer, with these steps repeated until parts are fully formed.

The intelligence of the technology comes from the process’ capacity to work on many layers at the same and choose when to cut – for example, the CNC endmills could be programmed to cut every tenth layer for speed or surface finish purposes. Once parts have been built with

Intelligent Layering, they are put through a sintering furnace with the help of robotic automation and then sent for post-processing. The Blackland Razor Era parts were finish-machined on Hass DM2 vertical mills with custom tooling and bead blasted, before inspection and shipping.

Through leveraging this workflow, Blackland is said to have enjoyed ‘much faster development and first article times’ than conventional methods. Per 3DEO, first article parts were delivered to Blackland Razors across 11 SKUs within four weeks of purchase orders. The 11 SKUs represent the 11 variations of printed parts across the top cap, open combs and base plates.

Initially, Blackland had come to 3DEO with the hope of launching a single 3D printed product.

“Instead of launching one product, with us, [they were] able to launch ten different variations [plus the top cap],” Sand told TCT. “There was a lot more development effort on our side, but the cost comparison – it didn’t cost Shane anything. We didn’t charge him anything to launch it [but] he would have been in for hundreds of thousands of dollars across all those products

30.6 / www.tctmagazine.com / 029

SHOWN: THE ERA RAZOR WITH 3D PRINTED COMB AND TOP CAP consumer products

“It's a highly functional design that's enabled specifically by 3D printing.”

3D Prints - SLA 3D Prints - Carbon 3D Vacuum casting Production ready assemblies Two shot and over-moulding CNC machining Finishing Low volume production Water clear parts CAD design for prototypes Prototype packaging Digital and screen printing 01223 836837 info@compfab.co.ukw ww.compfab.co.uk We o er a full range of prototyping services. Whether you need best resolution 3D prints, industry leading quality presentation models or a low volume production run, we have it covered. Highest Quality 3D Prints To Fully Finished Product Aheadd® Aluminium powders Specifically designed and optimized for Additive Manufacturing Aheadd® CP1 High conductivity & productivity Aheadd® HT1 High temperature & strength The solution of choice for: n Aerospace n Automotive/Motorsport n Defense n Transportation n Semiconductor Courtesy Volum-e, designed by Gen3d Courtesy GMP Expanding the boundaries of your application Aheadd® aheadd@constellium.com

[through conventional manufacture].” “If I were to launch this product with traditional manufacturing, I would have to pair it down to one to two options and it would cost three times as much to develop,” commented Swartzlander.

That conventional cost projection, which 3DEO calculates could have been up to 400,000 USD, is 50-70% more than Blackland Razors had to invest with Intelligent Layering. Not only that, but the companies were able to implement geometries that are not possible, or too expensive, to CNC machine.

One such example can be found on the Era’s base plate where the collaborators were able to create a deep overhang on the base plate that supports and clamps the blade as close to the cutting edge as possible. This is said to make the blade ‘extremely rigid’ while ensuring users can enjoy a ‘stable, repeatable shave’ similar to the performance of a single-edge razor. The same features also facilitate unobstructed lather flow, meaning there is little-to-no clogging even when cutting through multiple-day beards.

3DEO also points out that the teeth on each open comb baseplate would add 20-30% to the part cost via CNC, but the price of additively manufacturing the baseplates with Intelligent Layering doesn’t scale with geometric complexity.

“It’s a highly functional design that’s enabled specifically by 3D printing,” Sand says of the overhang/undercut feature. “That design means that you’d never clog your razor again as you’re shaving, you just keep shaving right on through.”

It isn’t the only design feature enabled by 3DEO’s Intelligent Layering technology.

“And then there’s the top cap,” Sand continues. “A razor blade sits on it and it’s pretty important that it be flat. If it’s not flat, you’re going to run into potential safety issues with the product. The dimensional accuracy and the tight tolerances we can hold with our technology are such that I think we were uniquely positioned with our patented technology to hit the specifications.”

After months of back and forth to land at the final design, hit the specifications 3DEO did. In the additive manufacture of the Era components, 3DEO leveraged precipitation-hardening stainless steel with a hardness value of 312HV (34 HRC), and is said to have achieved a tensile strength of 1000 MPa, elongation of 6%, and an as-

sintered density of 99.5%.

To get there, there was much design work and several iterations, where tolerances and surface finishes for the correct feel were surveyed before the Era went through user testing. At the end of all that, Blackland Razors took the Era to market at a price of 75 USD – nearly 250 USD less than its Blackbird Titanium razor – with units manufactured on-demand month by month.

At that price point, 3DEO believes it has taken a significant step: a metal 3D printed consumer product at a fairly affordable price. It is cause for optimism.

“I don’t see it competing in true mass quantities yet, but with that, 3DEO and a lot of other companies like 3DEO in the ecosystem are all working in concert to lower the cost structure, so they can one day compete,” Sand finishes. “I think it’s inevitable, especially when it comes to lower and medium volume products, especially when it comes to products with high degrees of variation like mass customisation on one extreme, but

also products like Blackland where there are ten different SKUs. And based on demand, they want to vary what’s produced across those ten different SKUs. Those will all play into 3D printing’s wheelhouse.

“I think it’s only a matter of time before the cost curve comes down to the point where it's going to be a question of, ‘can I justify traditional manufacturing when I get all these benefits with additive for maybe a slight premium in the price point?’”

30.6 / www.tctmagazine.com / 031

SHOWN: THE ERA IS AVAILABLE WITH VARIOUS BASE PLATES & COMBS

WATCH THIS SPACE: Submissions for TCT Awards 2023 are now open at tctawards.com consumer products

SHOWN: 3D PRINTED WITH INTELLIGENT LAYERING TECHNOLOGY

Let’s grow together.

Metal Additive Manufacturing is an innovative, smart, and sustainable technology that enables new business models Thanks to our solutions and all the exclusive related services, you can grow your business with greater efficiency and creativity. Do you want to try it?

15-18 November Frankfurt, Germany Stand E81 - Hall 12.0 Visit us at

KEEP COOL AND CARRY

How 3D printing is providing enhanced comfort on Jack Wolfskin’s 40 litre 3D Aerorise Carry System.

In Northern Italy, the autumn sun beats down, casting a shadow high up against a massive grey cliff face. The view from the country’s largest lake below is just a tiny spec. You have to squint to see it. But as the hands stretch to grip and the lower limbs find whatever foothold they can, you can just about spot some movement.

Magdalen Hamel is two days into her weeklong vacation at Lake Garda, where she is living the dream of any climber by scaling the mountains that overlook a body of water some 32 miles long and 10 miles wide. It is a spectacle she is taking in at every belay station on her multi-stage climb, an ascent in which she is debuting the first Jack Wolfskin product produced with the help of additive manufacturing (AM) technology.

As she recuperates from that climb, Hamel is back at the hotel, with headphones in ears and the 3D Aerorise 40 Carry System by her feet, answering questions for TCT Magazine.

We are nearly two years on from when Jack Wolfskin received the first samples of Carbon’s Digital Light Synthesis technology. The round, latticed pucks would soon evolve into ergonomically shaped pads that support the lumbar and shoulder areas on the back of a carry system that is now available for purchase.

“I think it was end of 2020 [when we started to use 3D printing] and close cooperation [with OECHSLER, a Carbon Production Network partner] started in ’21,” Hamel, Category Manager, Equipment at Jack Wolfskin, tells TCT. “It was our Innovation Manager that had the contact with Carbon and gave us the first sample. With

this first touch, we were addicted, because we can combine so many material properties with only one material, which [translates] into using less materials. On a common carrier system, to get that comfort we need a lot of different degrees of hardness and more firm or soft foams, EVAs, spacer mesh and the air mesh. And with only one material,

we can [now] create an even better performance because it doesn’t collapse.”

Per OECHSLER’s Senior VP of Global Product & Technology Development Matthias Weißkopf, the service manufacturer expects AM to ‘significantly change the design of outdoor equipment and sporting goods in the coming years.’ Jack Wolfskin believes with the 3D Aerorise 40, it's leading the way on the former, while joining several other household names in leveraging 3D printing within the latter.

For the development of the 3D Aerorise 40 Carry System, the outdoor apparel company implemented a body mapping process which considered how the weight of the backpack needed to be distributed. The optimum distribution of weight and pressure, in addition to forming the ideal ergonomic shape, was important to ensure sufficient air circulation to enable cooling.

Printing four parts per build, Jack Wolfskin is putting the latticed pads into series production via OECHSLER, with the 3D Aerorise 40 already available via pre-sale. The four pads have replaced traditional foaming layers that cover the entire back panel and harness an open grid structure lattice that boasts thousands of rod-shaped struts. These struts have different vertical and horizontal strengths, with zonal cushioning offering different

www.tctmagazine.com / 033

WITH 3D PRINTED LUMBAR AND SHOULDER PADS

SHOWN: JACK WOLFSKIN’S 3D AERORISE 40 CARRY SYSTEM

“With this first touch, we were addicted.”

consumer products

WORDS: SAM DAVIES

We are ceramic 3D printing. THE ANSWER TO CERAMIC DIGITAL MASS PRODUCTION CERAFAB SYSTEM S65 FORMNEXT BOOTH D39HALL 11.1 INDUSTRIALMEDICALAEROSPACE Need higher performance for laser powder based fusion? Visit us at Formnext in Frankfurt, Nov. 15-18, Hall 12.0, #E08 Lasers • Beam Steering • Controllers & Software • Sub-Systems Tested For Performance & Reliability Firefly, the next generation 3-axis scan head with multi-head machine capability, automated scan field calibration, precise process monitoring, and simplified installation, engineered specifically for LPBF.