HOW BURLOAK’S EARLY BELIEF IN ADDITIVE PAID OFF Laura speaks to Samuel, Son & Co.’s CEO Colin Osborne (CO) about Burloak Technologies' expansion, certification & scaling AM. TCT: When Burloak’s acquisition by Samuel was confirmed, you commented, "our early belief in the transformative potential of AM is paying off.” Why were you confident in the technology so early on? CO: I come from an engineering and metallurgy background and have spent my life in manufacturing – car parts, air parts, every sort of manufacturing you can think of. I joined Samuel in 2015. At 165 years old, and with 15 different businesses, Samuel is very uniquely positioned to identify opportunities for manufacturing innovation because we make so many different things. We manufacture everything from tubing for engines to pressure vessels, to extrusions for solar panels and service about 15,000 customers ranging from big OEMs like Boeing or Tesla or GM, to mom-and-pop machine shops. The common theme in all that we do is metal. When we first started looking at additive manufacturing, we realized that we could produce innovative metal parts that can't be produced any other way. We realized that we could produce parts 70% lighter and two times stronger. And we saw that it [could] completely disrupt the supply chain. We certainly didn't have all the answers, but I think we had a high degree of confidence that this was going to become a mainstream process just like casting or forming or extruding.

excellent facility in Canada that provides end-to-end additive solutions for many customers, adding a second facility in California helps us expand our footprint so we can serve even more customers. It also allows us to address any sensitivity due to the nature of the work we’re doing, which requires production take place in the country where the customer is located. This obviously includes defence-related work, which is extremely proprietary and requires compliance with ITAR and government requirements that isn’t conducive to going across borders. Between these drivers, controlled goods legislation and NIST legislation, we knew that for most of our U.S. customers, we would eventually have to produce incountry. From a growth perspective, in addition to having an economy as big as Canada’s, California is also a major hub for space and aerospace. Now we have existing and prospective customers only a two-tothree-hour drive from our facility that we can engage with. TCT: You’ve spoken about challenges around scaling AM. How is Burloak addressing those obstacles?

TCT: You opened a second AM facility last summer. Can you talk about the growth that led to this milestone?

CO: What's neat to me about Burloak and Samuel is our ability to help customers scale. You may have this incredible technology leader that can go from blue sky concept to proof of a commercially viable product but when they need to go from a prototype to producing 2,000 or 5,000 units a month, they don’t know how to do that.

CO: As you keep expanding and winning new customers, you have to expand your capabilities. While we have an

I think people underestimate the difficulty of going from small scale to large scale. The beauty of our partnerships with

042 / www.tctmagazine.com / VOL 8 ISSUE 2

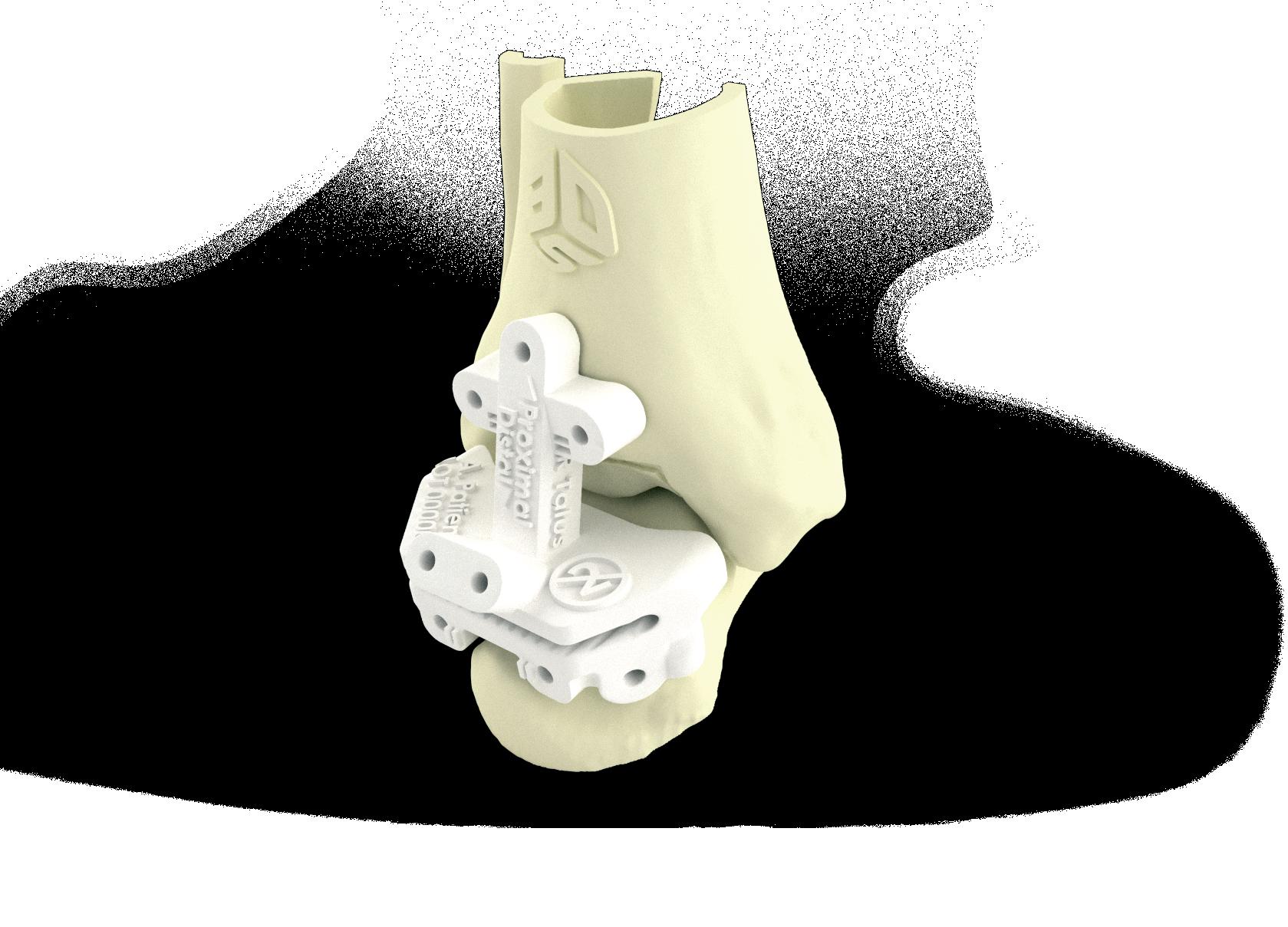

SHOWN: SAMUEL, SON & CO. CEO COLIN OSBORNE