Circular Design Applications

Innovative service model and design

The first company to establish a cross-field sustainability exchange platform: Design Makes “Us” Better

“Circle Journey” hotel redesign

Value-added applications of circular material design

Establish a recycled materials knowledge platform: MINIWIZ Material Database

Tea Aroma Face Masks

Foreword Introduction Introduction of Circular Design Tools

Guidance Tools and Processes

Circular Design Applications

46 52

04 06 08

Innovative design seminars

Design exchange visits

Corporate innovation workshop

Circular design principles

Set Guidelines Leading Circular Design to Develop Ecology 16 18 22 24

Integration and innovation of circular system designs

Innovative Ward Designs - MAC Ward

Glass revival with circular design - W Spring Pool Project

Full circular design and development for products

Upgrade of all Cha Tzu Tang bottles - Camellia seed oil and toiletries

O’right ±R Project: New options for zero-carbon sustainability

25 26 32

Circular Design Promotion

Environmentally friendly, recycled modular construction materials that comply with circular designs

Pioneer project for circular buildings: 3D printers X innovations in circular material designs

RePlay: Pollution-free ocean and beach toy sets

REstone: Development and design of artificial stone materials made from discarded electronics

Transforming discarded clothing into innovative building materialsClothing fiber wood

exhibition | 2018 Are you in the loop? Circular design exhibition

exhibition | 2020 The Next Decade circular design exhibition

Awards | Circular Design Special Award, Golden Pin Awards

Select Shop | Design Pin Circular Design Exhibition

Themed Display and Sales Area

Yodex industry-academia cooperation projects for design

56 60 64 68 74 78 82

88 90 92 96 98

36 40

Table of Contents

106

Copyright Page 02 03

Design Research Institute

President Chi-Yi Chang

Chairman Tim Brown of IDEO, a world-renowned innovative design consulting firm, said, “Circular design is the next focus of the design industry. The Taiwan Design Research Institute has also noticed this trend and began promoting circular designs in 2017. It has organized several themed lectures, workshops, and circular design exchanges with developed countries, such as the Netherlands, Germany, and Japan, in order to strengthen the study and understanding of circular design processes. In 2018, the Institute organized the first “Circular design exhibition - Are you in the loop? In 2020, the Institute launched “The Next Decade circular design exhibition”, which received excellent responses.

Starting in 2019, the COVID-19 pandemic has ravaged the world. The Design Research Institute partnered with Fu Jen University Hospital and Miniwiz to develop the modularized smart ward, MAC WARD. The Institute introduced circular designs to redefine the medical space. Assembly and ward function conversion (general/ICU/quarantine/ negative pressure) can be completed within 48 hours to respond to medical needs in real time. It has revolutionized hospital wards. The construction material used for the structure of the ward is mainly antibacterial and recyclable aluminum. In the ward, recycled PP plastics are used to produce the latches. Without the use of chemical adhesives, the generation of volatile organic compounds can be reduced and the overall structure is 80% recyclable. The innovative design won the Asia Pacific Social Innovation Partnership Award, Golden Pin Design Award, iF Design Award, Good Design, and National Innovation Award, and has been officially implemented in epidemic prevention dedicated wards in New Taipei City in June 2021.

Apart from the medical industry, the Design Research Institute is also actively promoting the implementation of circular design in a diverse range of fields. For example, Cha Tzu Tang has created comprehensive, circular packaging from the production site to the consumer based on design. Circular designs have also been incorporated in the products. They aim to drive shared investment with manufacturing partners and establish a circular system. Spring Pool Glass has partnered with known tea and catering brands through the Design Research Institute to create new products, making circular, recycled glass containers into the ambassador for promoting circular economy. Circular tokens have been introduced in the business model for innovation. The

SET GUIDELINES LEADING CIRCULAR DESIGN TO DEVELOP ECOLOGY

Design Research Institute has also assisted Carrefour in planning its influential concept stores. Not only have circular design concepts been incorporated in the store space, UN SDGs have also been referenced in the stipulation of product selection principles, fulfilling the ideals of sustainable consumption. We partnered with Folio Hotel Daan Taipei to design two rooms based on circular concepts and the theme of “circular journey”. We creatively placed products from over 10 circular design brands in Taiwan in the rooms for the guests. We have also organized circular design DIY courses, which has not only increased room prices, but also attracted exposure in the media and on social media.

In addition to multiple exhibitions and diverse industry application promotion, the Golden Pin Design Award, executed by the Design Research Institute for many years, has added an Annual Special Award since 2018. Circular design is one of the focuses. The Golden Pin New Talent Design Award followed suit and added the “Circular Design Special Award” in 2020 to encourage new designers to use circular thinking and creativity when finding innovative solutions for environmental issues. Furthermore, the design display and sales channel managed by the Design Research Institute, Design Point, introduced selected products for sale in cooperation with the circular design exhibitions, allowing members of the public to support the circular economy through their actions after visiting the exhibitions.

Circular design is not only a breakthrough in perspective, it also requires innovation and revolution of materials, production processes, design, business models, and marketing. We have collected successful cases of implementation and the experiences of the Design Research Institute related to circular design in recent years, and compiled the “Circular Design Principle Guide”. We hope to provide a reference for companies who wish to introduce circular design thinking and accelerate the process for them, in order to walk the path of circular design together.

Taiwan

04 05

IntroductionAfter the Industrial Revolution, technology developed rapidly, economies grew in scale, and human life became plentiful. In the 20th century, global warming, climate anomalies, and resource scarcity worsened the living environment for humans. With the depleting resources on this Earth, the ability to create a sustainable cycle of materials has become an important issue facing all industries. In particular, with Taiwan being an island economy with limited natural resources, we have to import most of our raw materials. We have utilize every resource effectively and view resources with a global perspective. Taiwan, which is export-oriented and OEM-oriented, considers the overall sustainable development trend in the international economy and the increasing demand for supply chain sustainability of multinational companies. We must be prepared in advance.

In order to help Taiwanese corporations face the rapid changes and developments in the industry and environment with valuable and effective solutions, Taiwan Design Research Institute (TDRI) began promoting circular design in 2017. TDRI used design to introduce circular systems and help each industry implement circular innovations. The realest and deepest needs of the users are discovered to design new products, services, and systems that comply with the circular system, in order to create sustainable manufacturing and a consumer ecology.

The book will share TDRI’s processes and projects for promoting circular design. From circular design evaluation and study, exchange seminars and workshops, industry guidance, to exhibitions and promotion, we are cultivating circular design in Taiwanese industries step by step, and will promote circular ideals even further.

07 06

Introduction of Circular Design Tools

Circular design holds a significant place in industry development. When faced with cross-field and complex issues, systematic and structured design methods and tools and visualized interfaces for design tools can allow teams to have a shared language, helping teams reach a consensus and accelerating the development process.

For example, The Circular Design Guide, developed by IDEO in partnership with the Ellen MacArthur Foundation (EMF) 1, provides design-oriented entry tools and application resources for circular design. It is able to assist the agile design of circular products and services, as well as lower the knowledge threshold for the issues. The Guide increases implementation opportunities for application and new knowledge can be created through these actions (Lockton et al., 2020)2. During the design development process, the tangible card tools summarize the important information, guide thinking, and encourage external exchanges, which in turn, can inspire creativity, organization, and idea exchanges (Roy & Warren, 2019)3.

1. The Circular Design Guide: https://www.circulardesignguide.com/

2. Lockton, D., Brawley, L., Ulloa, M. A., Prindible, M., Forlano, L., Rygh, K., ... & Nissen, B. (2019). Tangible thinking: Materializing how we imagine and understand systems, experiences, and relationships.

3. Roy, R., & Warren, J. P. (2019). Card-based design tools: A review and analysis of 155 card decks for designers and designing. Design Studies, 63, 125-154.

THE CIRCULAR DESIGN GUIDE

08 09

Circular design is implemented in every stage of a product or service lifecycle through “Design Thinking”. In principle, its true value is helping people understand that supporting circular design products and services does not mean a loss of quality, but is another way of realizing sustainable developments for society and the environment. Ideal circular design must successfully convey value to the consumer and effectively enter the customer perceived value. The value must be increased through innovation on different levels. Moreno et al. 4 proposed the value stream of a circular economy, which is divided into four models :

① narrowing resource flows

② cascade use

③ cycling for longer

④ slowing resource loops

The value stream is the value-adding process of converting raw materials into products. Although there have been many different circular economy models mentioned so far, they can be classified as one of two types, material-oriented or serviceoriented. Among the numerous cases, we found that the material-oriented value creation model (i.e. ASUS) can not only help companies reduce existing resource waste, but can also help the development of renewable materials and energies, supplementing the daily needs of people. On the other hand, the service-oriented value creation model (i.e. Philips lighting) can develop new business models with high-value and that can satisfy more personalized needs. According to the four value classifications for circular economies described above, the following four circular design models and related case descriptions have been compiled:

How can companies implement circular designs? When circular design principles and theories are implemented in different fields, corresponding adjustments have to be made and circular implementation methods have to be created. The current methods can be reviewed to redefine the execution methods after circular strategies are introduced. Due to differences in the characteristics and development processes of different industries, when applying circular designs, principles have been formulated to develop the tools and guiding methodology for specific industries. For example: The US sporting brand, NIKE, the Swedish houseware retailer, IKEA, the Danish pharmaceutical company, Novonordisk, and even the Greater London City Government in the UK have established corresponding methodologies and implementation strategies to develop and accelerate the introduction of circular designs.

The circular guide can be divided into three levels: 1. Establish circular design principles (theory). 2. Define practical application guidelines. 3. Propose implementation and execution methods. The results of the three levels will be used to create circular design tools for practical applications.

Narrowing Resource Flows Cascade Use Cycling for Longer

Enterprise/Unit Guide name Industry Type Guide Overview

Material Orientated Service Orientated

Provide renewable energies, materials, and recyclable materials to replace linear lifecycles.

Steadily recycle and reuse the waste of others to develop high-value products.

· Design easily recycled and remanufactured products.

· Design high-quality and more durable products.

Provide product repair services.

· Spring Pool Glass.

· Jang Chang Lumber.

· ASUS. Apple Renew Program in the US.

· Plastico plastic bag experiment project

· Truegrasses series products

· Renato Lab Taipei future project

Shikai Studio stone products

· S.Café coffee fabric

· Japan Nakadai waste disposal company

· Japan Newsed Project brand

Spain Sea2see sunglasses

· Netherlands The New Raw 3D printing

· Netherlands Fairphone smartphone

· Germany Miele appliances

· UK SARATA furniture company

Slowing Resource Loops

· Provide products and services to the change the past model of selling out products into rights of use thinking.

· Develop shared platforms to share resources and increase resource utilization.

· Netherlands Philips Lighting system

· Netherlands Bosch appliances

· Taipei Youbike shared bicycles Plan B “Park up Guting”

NIKE

Circularity Workbook : Guiding the Future of Design Sporting Goods Manufacturer

Guidelines and standards for helping industries promote sustainable supply chains.

IKEA

Circular Product Design Guide Houseware Retailer

Use design to improve the lifecycles of consumer products, invest in renewable energies at the source, and guide consumers towards a sustainable and environmentally friendly life.

Novo nordisk Circular for Zero Pharmaceutical Developer

Assist in the development of circular design guidelines for circular sustainable products, and implement corresponding optimization methods.

Major of London Designing for a Circular Economy Primer City Government

Four major principles have been proposed for constructing urban environments and buildings, and apply this to policy development.

4. Moreno, M., De los Rios, C., Rowe, Z., & Charnley, F. (2016). A conceptual framework for circular design. Sustainability, 8(9), 937; doi:10.3390/ su8090937.

Design Model

Reference Case

10 11

The design guide provides the structure and strategies for the general direction, and the application tools can guide corporations through development and operations. Take the EU-sponsored project ResCoM5 as an example, the project is based on circular resources and resource-saving manufacturing. The aim of the project is to rethink the relationships between materials, product provision, supply chains, business models and technologies, and to help manufacturers adopt the “Closed Loop model”. The 11 tools included can be applied to the different stages of product development. We have divided the purpose of use into three main categories: “Assessment, ideation, and management tools”.

Evaluation

The default purpose of the design tools will also affect the presentation of the tool. For example, the Risk & Race6 educational board game, developed by a Belgian research institution, uses a entrepreneurial perspective to simulate a circular economy business model and increase circular design concepts among participants, allowing them to apply circular concepts in their own fields. The subjects include companies interested in circular design and managers who are trying to implement corporate social responsibility through circular design. In order to promote the applications of circular design and improve the understanding of the issues among companies, the fun and approachable card game was designed. 5.

① There are many types of circular design tools, with varying purposes and user definitions. In order to help companies find an appropriate tool for corporate project applications, circular design operations will become more efficient and systematic. In addition to reducing the threshold of applications, the development of circular design tools is also using its systematic advantages to establish implementation models for circular designs in industries, further promoting the applications of circular design.

② The ultimate goal of circular design is to create value. Several of the design tools shared by TDRI are corporate development oriented. Ideal circular designs must successfully convey its value to the consumers and effectively enter customer perceived value. Therefore, tool development should deepen the discussions of buyer and user aspects. When the stakeholders of circular design can effectively integrate their resources and establish a mindful consumer culture together, circular design will also become good business.

Project ResCoM circular tools: https://www.rescoms.eu/platform-and-tools.html

6. The Risk & Race educational board game: https://riskandrace.vito.be/en

data (professional and technical information) to help circular decision-making. Define the concepts and design direction PDCA circular effects Ideation Tool Management Tool Circularity Calculator Reman Design Checklist Analytical Tool Multimethod Simulation MI:BoM Analyzer 2021©TDRI Organized Circular Pathfinder Lease or Buy - ResCoM Serious Game Upgrade Forecast Multiple Lifecycle Product Design Parts Planning Multiple Product Lifecycle Management

Tool Provide

12 13

Guidance Tools and Processes

Circular design ladder for companies: Helps companies introduce circular design thinking and establish circular design guidelines.

Assess the current stage of the company and conduct analysis and study of market trends and company needs, in order to understand the issues and opportunities faced by the company. The guidance content is based on design and is applied to the multi-aspect development of innovation in products, services, systems, settings, and business models, in order to encourage the internal implementation of circular management models and examples.

Circular Design

The company has introduced circular design in its business model and established supply chain circular guides, but has not yet achieved its net-zero emissions goal.

The company has introduced circular designs and stipulated circular design guides, but has not yet incorporated it in management strategies.

The company is using easily recycled materials but has not yet linked it to design.

The company has heard of the circular economy and is willing to join, but has not acted yet or does not know how to.

The company does not have circular awareness.

Unsure what circular economy means.

The company has become fully circular. Internationally-known companies that comply with net-zero carbon emissions. H L

Sustainability Cycle Impact

H

14 15

L

Innovative Design Seminars

In order to help companies think innovatively and accumulate momentum for innovation, TDRI is sharing design knowledge and market information through seminars. The Institute invites domestic and foreign circular design related representative companies and practical experts to share trends and provide companies with forward-thinking design concepts (circular design). TDRI is helping companies understand the latest trends in materials, production processes, business models, and practical management examples related to design and brand. We aim to use circular design strategies to improve corporate sustainable development.

TDRI partners with cross-field institutional or community units from time to time to combine resources and invite members of various industry associations to participate, in order to promote more crossindustry innovation opportunities. For example, TDRI partnered with the Sustainable & Circular Economy Development Association in 2018 to hold the “Circular Design Series Seminars”, which invited different industry and design company associations to facilitate future negotiations.

In 2019, TDRI worked with the Circular Taiwan Network to help design, plan, and organize the “1st Asia Pacific Circular Economy Roundtable”. The planning of the entire event was based on the idea “the roundtable is a part of implementing a circular economy”. It set the goal of zero waste design and complies with “design-reduction-service-recyclingremanufacturing”, in order to implement circular design principles, allowing roundtable participants to have a complete circular experience.

1 Replacing foam boards that are commonly used in events with doubletransparent cloth. 2 Printed designs in the venue are reproduced into souvenirs for participants, greatly reducing the disposable waste of the event. 3 Working with local teams to use discarded metal buckets, wooden boards, and other recycled materials in modular designs for display stands, which are easy to assemble, disassemble, and reuse. The suppliers can store and use the designs after the event.

16 17

Design Exchange Visits

In order to help domestic companies understand trends in circular design and implement sustainable management concepts, TDRI plans domestic and foreign design visits and exchanges from time to time. By visiting representative corporations and settings, TDRI aims to promote the cross-industry exchange of technical information and innovative partnerships between industries.

In 2018, we chose countries that have excelled in “circular issues and design innovation”, including the Netherlands, Germany, and Japan, to conduct international design interactions. Through visits to foreign companies and participation in circular forums and international events, we hope to help foreign partners understand the Taiwan’s innovations in design and promote partnership and business opportunities for international design.

International Design Exchanges with The Netherlands and Germany

The population size, land size, and trade in the Netherlands are similar to those of Taiwan. With few natural resources, it relies heavily on imports. In recent years, the Netherlands has been actively developing a “circular economy”. It is viewing the circular economy as an important strategy for transforming domestic industry developments and the driving force behind innovative industries. The government has included the sustainable ideal of “cradle to cradle” in the country's sustainable development and resource utilization strategies, in order to promote industrial sustainability and innovation. It has also formulated related promotion goals and strategies for sustainable buildings, recycling systems, circular design, administrative management, water, etc.

The Netherlands is a small country, so it specially emphasizes its role and position in the entire circular system of Europe. It encourages domestic companies, design service consultants, and neighboring countries to work together and create new economic advantages. It is also actively playing a leading role in the implementation of a circular economy in Europe by organizing circular economy international forums. The government is working with the private sector to promote public housing, public infrastructure, and other projects to establish benchmark examples.

The circular economy and circular design have created massive responses in the entire Dutch society. The study, discussion, and implementation of related projects have been implemented by companies, academic institutions, scientific research institutions and civilian groups. In the Netherlands, these efforts have formed a vibrant circular economy community. Each step has helped the Netherlands reach its sustainable development goals stipulated in its national policies. This is something Taiwan can learn from when implementing circular economy policies. Because Taiwanese corporations are actually

better positioned to implement circular principles than European countries, but do not understand marketing and exporting themselves, the deficiencies require the investment and assistance of government resources.

Another country with similar industries to Taiwan is Germany. More than 50% of small and mediumsized enterprises support Germany's economic development. The model for circular economy development in Germany is not the same as the one in the Netherlands. Most of the efforts are based on corporate management and integrating with international trends. In recent years, local German governments have used many circular designs to transform parks and repurpose idle spaces.

Compared to the small and extensive circular company and design applications of the Netherlands, the German government is less active in helping the design services industry develop and apply circular designs. It is mainly still based on the efforts of private companies, especially multinational companies, which has performed better on this issue. However, both countries have one thing in common, which is the use of idle space and factories. It has attracted large amounts of creative design related resources, in order to revitalize regional development and focus on the interactions with surrounding communities and residents.

18 19

Japan is an island nation that lacks natural resources and must depend on imports. The country is also facing the social problems of an aging society with a low birthrate. Under the developments of a sustainable country, the Japanese government introduced “The Law for Establishing the Recyclingbased Society” in 2000, and has conducted reviews and improvements every 5 years since. It has proposed “The Basic Plan for Promoting the Recycling-based Society”, in order to fully establish its sustainability goals. Japan started with the implementation of a recycling-based society, and did not focus on a circular economy like the US and Europe. Because the model for a recycling-based society is resources → products → recycled resources, economic developments have been incorporated in environmental protection, in order to create harmony between man and nature. The social benefits and economic benefits of developing a recyclingbased society have been combined into one.

Establishing a recycling-based society is the most suitable option for Japan. Due to the small land area and large population of Japan, the country mainly relies on imports for industrial raw materials and energy, which does not generally create issues during peacetime. However, when the international situation changes, resources will become scarce. The oil crisis in 1970 impacted the economic development in Japan greatly. The promotion of a recycling-based society can greatly reduce the dependence on imported resources. During its implementation of the recycling-based society, Japan is relatively focused on the development of local industries and helps cultivate and promote the developments with government or public organizations or private institutions. In addition, the Japanese government defined the industry design basis in the early stages. So, when companies are promoting new policy ideas, they understand how to utilize design and communication with the public or key partners to create market differentiation.

Overall, the circular economy value chain in Japan is led by the central government. Comprehensive implementation standards for laws and regulations has enticed companies to participate together. The role of the local governments is to help implement regional goals and provide support for its execution. With a clear vision and supporting measures, Japanese companies have started investing in the market to drive the circular industries. This is something the Taiwanese government can imitate and learn from.

“Circular economy and circular design” are cross-industry and cross-field issues. They require the government to integrate the principles from a policy perspective and to set national sustainable development goals. The government needs to establish related implementation and supporting measures, in order to drive investments and developments in Taiwan’s industry innovations and design services industry.

The establishment of a circular value chain requires the integration of material suppliers, manufacturers, purchasers, consumers, recycling providers, and design and development units to work on innovations together. The government should establish a platform for interactions and exchanges between partners, and provide related information to connect the cross-field supplies and needs, creating new value for waste through cross-field innovation.

International Design Exchanges with

20 21

Japan

Corporate Innovation Workshop

Organized to endow enterprises with self-innovation capabilities and encourage real changes to the internal thinking model of companies. TDRI matches companies with excellent, professional design teams and customizes planning workshop content according to their needs. The companies can review their management, research and development, brand, marketing, and other design related aspects with design as the core concept. Through the co-innovation of crossindustry teams, we are able to improve and elevate the creative energy and product innovation of companies.

The workshop is mainly focused on the three major aspects of “brand and communication”, “products and services”, and “operations and systems”. Starting with “brand and communication”, we will refocus the brand positioning to define product/service more accurately. Next, we discuss “products and services” to find the optimal entry point for products and services from a circular design perspective, while satisfying customer experience. Changes to the two points above are hard to realize without the support of “operations and systems”. Through the communication of co-innovation, companies can better understand the importance of optimizing internal operating systems, in order to further create an environment suitable for circular operations within the companies.

For example, Xcellent Design helped DA.AI Technology with reorganizing the value identification for the DA-AI brand, products, and settings (Humanities and Culture Hall). A clear brand value helps DA-AI's future internal designs and the design direction and market positioning of the marketing and planning team.

22 23

Circular Design Principles

Selecting Materials for Use

Adopted single materials

Adopt non-toxic materials

Adopted recycled materials

Adopt bio-materials or naturally decomposable materials

Easy-to-disassemble design

Shipping volume reduction

Packaging material reduction

Full Lifecycle (Products and Services)

Easy-to-repair (modular) design

Reusable design

Adaptive design (scalable/expandable)

Construct a circular system (service and non-one time business model)

Carbon emission minimization or carbon neutrality

Circular Design Applications Guidance Theme Categories

Integration and innovation of circular system designs

The circular design innovation industry system (internal cycle + external cycle)

Shatters traditional thinking and responds to market needs in innovative ways. It focuses on the circular integration of the entire supply chain, improves product material use, and optimizes the entire product lifecycle through the design of business service models.

Full circular design and development for products

The product system and internal material cycle

Emphasize on the safe and cyclical use of materials. Easily recycled and modularized methods are implemented for parts design to facilitate repair and extend the lifecycle of products, while ensuring recyclability.

Innovative service model and design

Breaking through the traditional method of producing one-time use objects, establishing public interest business models through service design.

By rethinking operating and business service models and by using the brand’s market potential, we create circular services with dematerialized commercial value (such as shared platforms/ servicification of products).

Value-added applications of circular material design

Product or packaging development based on circular designs

The application of environment friendly existing or newly developed materials creates product or packaging designs that incorporate circular design ideals and satisfy consumer needs.

① ② ③ ④ ⑤ ⑥ ⑦

① ② ③ ④ ⑤

24 25

Innovative Ward DesignsMAC Ward

Fu Jen Catholic University Hospital was newly established in recent years but the wards still lack 68 beds. In order to meet the establishment targets in a short time, traditional construction methods are not only time-consuming and noisy, and will greatly affect the daily operations of the hospital and the quality of care for patients. In 2021, with the outbreak of the COVID-19 epidemic, there was an insufficient number of isolation wards and positive and negative pressure wards could not be converted. This caused great strain during the outbreak. With the addition of insufficient major disease doctors with clinical experience, new models and digital technologies have to be introduced to reduce the medical burden.

•

•

•

Case company Fu Jen Catholic University Hospital

Partner Miniwiz Co., Ltd.

Adopted recycled materials

Easy-to-disassemble

Packaging

•

design •

material reduction

Shipping

volume reduction

Easy-to-repair

Service

Construct

(modular) design •

design / Business model •

a circular system

we must think differently. Medical institutions Circular Design Principles 27 26

President Han-Sun Chiang of Fu Jen Catholic University

In the face of the pandemic,

Assist the research and development partnership between Fu Jen Hospital and Miniwiz to implement innovative development and design of future smart wards. Design thinking and innovative designs are introduced in the usage settings for the medical field. Overall space planning and modularized ward designs are implemented. A crossfield shared platform is constructed to integrate medical furniture, digital technologies, and smart bathrooms. We aimed to create an innovative medical experience and provide the best medical solution for global epidemic prevention.

Fu Jen Hospital, located in New Taipei City, officially began operations in 2017. The innovative development office was created in the beginning to integrate clinical needs, technology, and business models, with sustainable management as the goal. Fu Jen Hospital originally had 6 negative-pressure isolation wards. If the pandemic worsens, it will not be enough. Originally, the hospital wanted to install electric doors in the intensive care unit and convert them into negative-pressure isolation wards, but the installation costs for the doors reached NT$400 thousand. Additionally, waiting for the construction permits will take 6 months, making the option unfeasible. During the initial outbreak of the pandemic, many countries in the world lacked sufficient medical resources and wards to prevent an epidemic.

In order to help hospitals convert their existing wards in real time, we designed a circular and reusable ward that can be adjusted to satisfy different use settings and needs, allowing general wards to be converted into positive or negative pressure wards within 48 hours during the pandemic. The “MAC modularized ward” that allows for the conversion to negative-pressure isolation wards was created during a design brainstorm. The name of the ward came from the original design concepts: Modular, Adaptable, and Convertible (MAC).

In order to establish a negative-pressure isolation ward, it involves more than medical, healthcare, infection control, and negative-pressure piping concerns. There are many professional and legal considerations, including how to ensure zero contact between the medical staff and the patient, isolate an infection area/clean area, plan the movement of medical staff, process the patient’s excrements, extract the air from the ward

and prevent it from entering the hospital’s air conditioning system, etc. These are all important considerations when constructing the ward.

Miniwiz is an expert in innovative material development. It introduces recycled materials in product development and uses recycled aluminum for molds of ward paneling and modules. In order to meet the high requirements of the hospital related to infection control, the entire MAC ward is airtight, antibacterial and flame proof. The design of the ward is like Legos. Each piece can be easily assembled or disassembled, and the related piping for medical devices can be easily adjusted. The design of the corners have been changed from L-shaped to R-shaped curves, making it difficult for dust to accumulate in the corners and the lack of gaps reduces infection risk within the hospital.

The ward uses sealed panels made from recycled plastics, milk bottles, saline bags, and aluminum cans. Recycled plastic bottles are spun into threads and fibers are added to create the antibacterial sound-absorbing panels and curtains. This allows the ward to transform what people used to think as waste into resources under the circular design concepts, giving new life and value to the resources. Furthermore, the MAC ward specifically uses a panel-style packaging, which makes it easy to transport, assemble, and disassemble. It can be conveniently transported to rural areas or overseas, and can be constructed in parking lots, stadiums, or in other spaces.

28 29

Guidance Focus

This is the revolution of a century for hospital wards. As the virus mutates, the needs of the ward will change, but however the pandemic evolves, the MAC ward will be the best experimental setting for the medical world. The MAC ward also verifies the value of circular design. It realizes the ideas of using local materials, local production, and recycled materials to reduce petroleum use, energy waste, and environmental pollution. It is extremely competitive in terms of quality and price. Currently, MAC wards have been constructed on the 12th floor of Fu Jen Hospital, and was officially included in the New Taipei City epidemic prevention dedicated wards in June 2021. It has also won the Asia Pacific Social Innovation Partnership Award, Golden Pin Design Award, iF Design Award, Good Design Award, National Innovation Award, and other domestic and international award.

30 31

Glass Revival with Circular Design -

Spring Pool Project

With the rise of a circular economy, glass in traditional industries may be the best recyclable material. In recent years, Spring Pool Glass has focused on materials combined with craftsmanship to promote cross-field cooperation between traditional glass works and design. The company hopes to develop new B2B cooperation business models through partnerships with different industries and brands. Spring Pool Glass believes that circular concepts should be deeply rooted in the minds of consumers. The company aims to directly face consumers and actively communicate with the market, in order to implement a circular economy in different settings and pass on the glass craftsmanship, while working with brands in different industries to implement sustainable corporate management.

Case company Spring Pool Glass

Manufacturing

Partner PiliWu Design, Seed Spacelab, Dot Design, Joe Fang Studio

W

Circular Design Principles • Adopted single materials • Adopted recycled materials • Service design / Business model We hope that circular design can become part of everyone’s mindset and become an unique part of Taiwanese culture.

33 32

Vice President Ting-An Wu of Spring Pool Glass

Guidance Focus

Brand Design

Develop

cross-industry

Settings Applications

cooperation and value-added design

Introduce service design in settings and spaces

Business Model

Innovate new customer experiences and business models

In 1961, after the founder of Spring Pool Glass, Chun-chi Wu, was discharged from the army, he invested in the waste glass recycling industry. After experiences several economic ups and downs, his company survived every challenge. Through the continuous development of glass melting processes, they developed green building materials and established the glass tourism facilities. The Spring Pool Glass of today is focused on professional glass recycling and reprocessing, and is invested in industrial raw materials, technological building materials, arts and culture, and tourism factories.

In the past, Spring Pool Glass products could not solve the challenges of mass production, resulting in the inability to reduce costs. As an OEM company for corporate customers, Spring Pool Glass could not build brand recognition among customers in the market. Therefore, the focus of the counseling was placed on a partnership with a well-known tea brand, which not only stabilized demand and orders, but also increased product popularity and created new forms of orders.

Starting in 2020, in order to increase the public’s understanding of glass craftsmanship and enhance B2C brand management visibility, the physical space, “The Pool”, was built in Hsinchu Park to display circular design.

The expansion of setting management and business models was a new challenge for Spring

Pool. The TDRI provides counseling from two directions. The first is the design team uses circular design to combine space and product for design development, including modular furniture design with glass bricks. Spring Pool Glass worked with different lifestyle brands (JIng Sheng Yu, NINAO, and Dot Design) to develop exclusive circular glass products (take out cups, containers, cones) together. Corporate identity and design cover and create systematic visual applications (The Pool system, spatial coverage) and the glass exhibition planning in The Pool museum. It creates an unforgettable service experience, from visual enjoyment and atmosphere to product use.

The second is the partnership between Spring Pool and iNSIGHT. By exploring the commercial area around The Pool, describing customer profiles, developing biographies, and defining target demographics, we are able to evaluate whether the ideals are effectively conveyed. Meanwhile, we established a glass coin management mechanism and introduced retail chain store concepts, allowing The Pool to adopt a franchise headquarters model for the circular economy in the future. The future circular ecosystem (alliance) will use glass coins as the medium to connect the services of different brands. It will allow feedback incentives to be effectively circulated and applied in the ecosystem, increasing topicality while energizing circular actions and promoting circular economic developments.

Innovative designs are incorporated into the corporate strategies, successfully driving Spring Pool Glass’ industry transformations. The Pool has also become a core setting for driving transformations in the glass industry of Hsinchu, injecting new energy into glass industry innovations and sustainable developments.

01 02 03

34 35

Manufacturing Due to the decline of the camellia seed oil industry in Taiwan and the sustainability issues facing the agricultural industry, Cha Tzu Tang hopes to use the power of its brand to incorporate the land, culture, and art of Taiwan into its products, creating new value for camellia seed oil culture. In terms of product design and planning, the company hopes to connect its brand mission with craftsmanship and sustainable development, adding visibility and practicality to its ideals, aesthetics, and creativity and becoming the best promoter for the land. Case company Cha Tzu Tang Partner Hwa-Hsia Glass, Spring Pool Glass, PiliWu Design Upgrade of All Cha Tzu Tang BottlesCamellia Seed Oil and Toiletries CEO Wen-hao Chao of Cha Tzu Tang Thank you to Taiwan Design Research Institute for the support and assistance! On the long journey of this brand, we wish great things for Cha Tzu Tang, no matter where the road leads. • Adopted single materials • Adopt non-toxic materials • Adopted recycled materials • Packaging material reduction • Reusable design Circular Design Principles 37 36

Guidance

Focus

Incorporate circular sustainability concepts in the core of Cha Tzu Tang’s brand management, and conduct the planning of new bottle designs. With design as the basis, the company is creating fully circular packaging for manufacturing to the consumer side. It is working with PiliWu Design, Miniwiz, REnato lab, and other organizations on research and development, helping Spring Pool Glass, Hwa-Hsia Glass, and other manufacturers to establish circular partnership models.

Cha Tzu Tang was established in 2004 and is dedicated to developing the Taiwanese camellia seed oil culture. Currently, the company owns 3 camellia tree farms in Taiwan that use environmentally friendly methods to cultivate the land and plant new trees. A new series of products is being developed based on the camellia seed, in order to create new value of the camellia seed oil culture. By connecting the three main missions of “passing on camellia seed oil culture”, “promoting craftsmanship”, and “implementing sustainable development”, the company’s brand purpose is to convey the beauty of the land and realizing good things.

In order to effectively implement a circular economy, Cha Tzu Tang began its sustainability journey in the 17th year of its establishment, fully upgrading all bottles for different products. The company upholds the design thinking of “formed by nature and refined by humans”. It uses delicate designs and craftsmanship to pay tribute to nature.

Camellia seed oil

The designs of the new bottles focus on elevating the content and refining the details. The sustainable, recycled glass of Spring Pool Glass is incorporated into the new bottle designs. The bottles are manufactured using Hwa-Hsia Glass’

century of experience and are designed by PiliWu Design. The rounded bottles are based on the organic lines found in nature and are made to fit in the palm of the hand, providing convenience for daily use. The dark brown bottle creates a delicate beauty through the contrast of glossy and matte surfaces and the thin and thick glass. It organically reflects different lights and shadows.

Toiletries

Plastic content has been reduced by 44% compared to the previous generation of products and recycled rPET plastics have been introduced, achieving 100% recyclability. The bottles with no repeated curves and reflected light corresponds to different plant extraction scenarios. Printing processes have been increased to reduce the use of plastic labels. Each detail is in line with nature and offers a better option for the land.

Cha Tzu Tang hopes to connect the upstream, midstream, and downstream of the industry with “value” through bottle design, rising above the traditional thinking of a manufacturing supply chain and exceeding production limits. Apart from production volume, visibility and practicality is added to the ideals, aesthetics, and creativity, realizing the sustainability principles of being good to the land.

The launch of the camellia seed oil in early 2021 and the launch of toiletries at the end of the year completed the upgrades to all product bottles. The three brand missions of “passing on camellia seed oil culture”, “promoting craftsmanship”, and “implementing sustainable development” is connected through bottle design, representing the land and culture of Taiwan behind the camellia seed oil industry.

38 39

O’right ±R Project: New Options for Zero-carbon sustainability

Design thinking should be elevated to the ecological level. Respect for all things should be increased and the burden on the body and environment should be reduced.

Let us use circular design to make the world a better place.

Founder and Chairman Steven Ko of O’right

O’right was dedicated to developing professional salon channels. In 2016, it began entering the counter retail space, creating exceptional management performance. However, the retail consumer market still requires further expansion in order to improve overall brand performance and popularity. O’right, with its brand services established in the international market, is actively planning the brand experience flagship store (Yongkang Store) based on circular designs, in order to fully display O’right’s circular model (green factory, product, supply chain, CSR, etc.) in the store.

• Adopted recycled materials

Case company

O'right International Corporation

Circular Design Principles

• Adopt bio-materials or naturally decomposable materials

• Service design / Business model

• Construct a circular system

Manufacturing

41 40

Guidance

With the assistance of TDRI from a design strategy perspective, O’right established its flagship store based on circular design concepts and formulated its own brand style. It fully represented O’right’s incorporation of circular economy concepts in products, production, raw materials, and factory construction. Experiences for the five senses were integrated in the flagship store through spatial design and the use of environmentally friendly materials, allowing the consumer to better understand the O’right brand with the green flagship store, thereby driving consumption and enhancing brand image.

O’right was established in 2002 and formulated its green mission in 2006. From the implementation of green concepts in products and services to the care for the environment and social welfare, O’right upholds its core values of “green, sustainability, and innovation”. It became the first cosmetics company in the world to be certified as a zero-carbon company in 2020, and continues to provide sustainable zero-carbon solutions for life.

For many years, O’right has complied with the 6 major zerocarbon directions of sustainable commitment, green services, carbon management, green production, green products, and green impact, implementing green ideals in its actions. O’right provides environmentally friendly green products, established a green headquarters that utilizes renewable energies, implements green logistics that reduces carbon footprint, and effectively conducts carbon reducing green actions. It will continue to accumulate green influence for the world and move towards the goal of zero carbon. The green cycle will enrich every corner of the Earth. Let us protect the beauty of the world together and embrace a zero-carbon future.

O’right has never been just a hair products and cosmetics company. It is a brand that serves mankind, society, and the Earth. It continues to provide innovative services and creates environmentally friendly consumption models, providing a better and sustainable lifestyle.

Focus 43 42

After establishing the first flagship store in Yongkang Street in Taipei based on circular designs in 2017, O’right has replicated the store and expanded its presence gradually. In response to climate change and the post-epidemic era, O’right will continue to uphold circular sustainability concepts and is dedicated to providing zeroenvironmental impact and zero-carbon products. It has remodeled the Yongkang flagship ship store in Taipei and introduced the ±R Project.

A GMP certified food-grade filling machine, “±R machine”, was introduced in the Yongkang flagship ship in Taiwan. It can fill “R-Bottles” made from 100% post-consumer recycled (PCR) plastic materials. The machine is capable of sterilizing the bottles with 100℃ steam and fill the bottles with shampoo through a pneumatically sealed, automated nitrogen process. The filling process is dust free, non-polluting, and completely automatic, satisfying the legal and safety concerns of the public related to no-packaging retail stores.

By using the novel “refill” technology, the ±R Project is able to implement “reuse” for the bottles, thereby “reducing” the generation of new plastic waste. The “+” and “-” represent the harmony between zero-waste and nature, defining a new green consumption model. Through the 3 R’s, O’right “responds” to the silent cries of nature to regain the balance between nature and man. It “respects” the existence of all things and provides opportunities to “revive” ecosystems and all living things.

The company’s sustainable ingenuity is not only reflected in all its products. It is also fully integrated into the entire store. The sign for the

store uses RePET environmentally friendly material, which is made from 2,058 recycled plastic bottles. The material is able to provide the performance advantages of plastics and wood and is also 100% recycled. O’right hopes to provide an immersive “zero carbon consumption and living” experience to the customers of the Yongkang flagship store. The experience aims to instill respect for all things in the customers’ lives, increase the respect for nature, and reduce the burden on the body and the environment.

O’right has implemented its circular and sustainable ideals and innovative designs in its products, services, and experiences, and throughout its company operations in all retail channels for the consumers. The company has won the Golden Pin Design Award, the Good Design Gold Award in Japan, the Red Dot award in Germany, the Global Sustainability Cosmetics Award in Paris, France, and multiple CSR awards. It has formed its brand value through excellent design strategies and created a benchmark for domestic and foreign circular sustainability.

44 45

It is difficult to convert the promotion of sustainability and sales of sustainable products into substantial data Hard to reach a consensus among internal corporate personnel It is difficult to spread sustainability concepts from the management level to the general employees. Existing supply chains cannot support the

Difficulties in quantifying/qualifying the benefits of sustainability

01 02 03 04 Case company Presicarre Corporation Partner 3+2 Design Studio, iNSIGHT, Impact Hub Taipei Circular Design Principles • Easy-to-repair (modular) design • Service design / Business model The first company to establish a crossfield sustainability exchange platform: Design Makes “Us” Better Director of Corporate Social Responsibility and Communication/ CEO of the Foundation/Company Spokesperson Xiao-Zhen Su of Carrefour The impact concept store continues to evolve, and the product range and services continue to be adjusted. Most small producers have a limited supply and cannot achieve the same stability in supply like bigger companies, making it difficult for them to enter larger retail spaces.

Retail Channels 47 46

sales of sustainable products It is difficult to convince retail channels to adopt a green supply chain. Developments of the issue are hard to be noticed by external consumers For consumers, price is more important than value.

Carrefour is willing to take the risk and has established the impact concept store to provide a stage for all. This is the goal of making “us” better.

First, Carrefour introduced sustainable concepts, then actively influenced its midstream and upstream suppliers, and even indirectly impact other related industries. The project was planned accordingly to convey its ideals, classify services, position products, formulate in-store routes, and generate the atmosphere of the store. Although the case is based on retail channels, the development process can still be applied for companies looking to fulfill their sustainability goals.

01 Conveying value through ideals

When the impact concept store was given the tasks of product sales, ideal tours, and event planning, it was not only the decision-making level that determined the future service direction. The service staff and consumers were also asked to provide their thoughts. The case had multiple internal stakeholders of Carrefour participate in internal workshops. The requirements of key missions were identified and the personnel related to decision-making, planning, and onsite service were found. Together, they decided the primary ideals of the Carrefour impact concept store.

02 Creating the atmosphere

When consumers are shopping, they should be able to easily understand the product ideals and Carrefour’s sustainable goals and developments. When designing the space, SDG 11 “Sustainable Cities and Communities” and the “WHO Global Agingfriendly Cities: A Guide” were referenced as the basis for the friendly space design. Circular design principles were also implemented as the design strategy for the space.

03 Product selection

SDG 2 Zero Hunger and SDG 12 Sustainable Consumption and Production were referenced to stipulate the five major product selection principles, which include support social enterprises, local procurement, purchase sustainability, natural products, and minimal packaging, in order to comply with product selection for sustainable consumption. The principles provide a basis for customers shopping, staff introductions, product selection, and for the suppliers.

Currently, the Carrefour impact concept stores include the Chongqing Store, Neili Store, Qingpu Store, National Palace Museum Southern Branch Store, and Nangang Store. In the future, more impact concept stores will be established in Taiwan.

We hope to achieve balanced development between society, the economy, and environment according to the Sustainable Development Goals (SDGs) announced by the United Nations in 2015.

Carrefour has responded to the development of SDGs by the UN. Starting in 1999, Carrefour’s slogan was “every day is cheap in Carrefour”. After the food safety crisis, the slogan was changed to “everyone deserves better” in 2008. A series of transformations were implemented after the new core value was adopted. In response to the UN SDGs, Carrefour impact concept stores abandoned the traditional channel management and service models. It entered the Taipei NPO village in July 2019 and established the first Carrefour Impact concept store. The company aims to implement sustainable developments in daily life and create a better future for the next generation.

The impact concept stores are important management indicators for Carrefour. As a leader in the food industry, the company has introduced sustainable developments and established an example for innovative service models. It hopes to use the spread of physical stores to act as a training site for potential employees around Taiwan. Carrefour will convey its sustainable ideas to all its seed employees and develop sustainable products with its suppliers, helping create a better future for society. It is a socially responsible sales channel with a mission.

49 48

Guidance Focus

① Selecting key alliance partners

Food related supply chain companies were invited through the innovative business strategies for farmers workshop to understand the new trends and development requirements of the industry, as well as potential partnerships.

②

Setting stage goals for the alliance

Carrefour is one of the few companies in Taiwan with sustainable development goals. It must consider new problems when developing new service models. TDRI has helped Carrefour set goals for different stages of development.

③

Identify the restrictions of alliance development issues

In order to lower the barrier to entry for companies introducing new developments, in addition to conducting extensive interviews with internal personnel of the company, the 3+2 Design Studio team and iNSIGHT were invited to visit the impact concept store and talk with the frontline sales staff and internal team. They offered suggestions based on design thinking and design aesthetics

④ Introduce issues through design

Working with iNSIGHT, design thinking was used to help the company convey its sustainable ideals and values internally and externally. Working with 3+2 Design Studio, compliance with sustainable development and elderly friendly principles was ensured and circular design concepts were introduced. The product selection principles were set by TDRI to make product categorization more logical and representative of sustainable consumption.

The internal corporate impact Its partnership has expanded and impacted 224 stores (including Welcome, which was acquired in 2021, and Jasons) and 11,000 internal employees.

External impact of channel

Help Carrefour establish a service model with sustainable development at its core, and adopt Carrefour Impact concept stores as important internal indicators for the company.

In the future, established impact concept stores will become employee training sites for introducing sustainable developments, which will train the important managers in various stores.

Carrefour will solve issues such as reducing plastics in packaging and production waste through its channel impact and partnerships with suppliers who wish to invest in sustainable developments.

Since the opening of Carrefour Impact concept stores in January 2021, the concepts have been expanded to 5 stores in 6 months, including the Chongqing Store, Neihu Store, Nangang Store, National Palace Museum Southern Branch Store, and Qingpu Store, saving around one third of the time needed for new store opening and reaching a service satisfaction rate of 90%.

1 2

Establish

Establish Sustainable Impacts for the Settings

Sustainability Knowledge for Employees Realize Sustainable Implementation for the Environment

50 51

“Circle Journey” Hotel Redesign

Folio Hotel was the dormitory of the Cooperative Bank. Through the redesign and remodeling by the group, its service life was extended. The “Circle Journey” project uses the space of a hotel and designer brands to create a circular experience. On this platform, consumers can experience circular designs and get to know the recycled goods of Taiwan, creating beauty in the detailed designs.

With the tourism industry being impacted by the pandemic, being able to redeploy in the post-pandemic market is currently the biggest challenge facing domestic hotel companies. Especially with the dwindling numbers of foreign travelers, being able to use design to create innovative solutions has become an important approach. In the past, when hotel companies introduce green or sustainable circular solutions, they often find that it is difficult to conduct quantitative assessments, qualitative benefit assessments, or that there is a lack of methods, leading to difficulties in creating an understanding among management, the formation of stereotypes related to sustainability and circular concepts among consumers, and a lack of results of equal value to investments.

Partner

Rock

Hotel, tourism and lifestyle industries

Case company Folio Hotel

Rising Co., Ltd. 2 by Wu&Chen

Manager Gang-Ling Chang of Folio Hotel

53 52

Circular Design Principles • Adopted recycled materials • Service design / Business model

The breakdown of a hotel's product and service system by the hotel industry provides companies and other related suppliers with more brand value and circular economy models. It creates immersive display modules, encourages other tourism industries and lifestyle industries to follow suit, and expands the impact of applications.

Folio Hotel is an example of the circular reuse of old buildings. The company remodeled the Cooperative Bank dormitory, while maintaining the original facade and retaining the style of old buildings in Taipei, which conforms with the design of surrounding buildings. The hotel often partnered with different art events and performances, infusing the energy and diversity of art into the space.

During the year when the pandemic ravaged global tourism, it was the perfect opportunity for Taiwan to incorporate the circular economy concepts in the industry’s DNA through design thinking and strategies. In the “Circle Journey” project, the challenge was to incorporate circular design into everyday life. The well-known Folio Hotel in Taipei was chosen as the site for demonstration, with 2 circular experience rooms being built. Designs based on the five senses were adopted for the space remodel, service design, and circular product selection.

The two guestrooms were based on the themes of “green energy” and “energy conservation”. One room was named the “Livingreen Room”, which was based on green energy and was decorated with discarded flowers and native Taiwanese plants from florists, demonstrating the cyclical and perpetual nature of life. The other room, “Hiddenspace Room”, was based on energy conservation. The lighting design extends the natural colors of the room, highlighting the serene but lively energy of the lands. The themed rooms used products from 13 circular design brands in Taiwan, helping visitors understand circular design by leading them on the “Circle Journey”. By supporting circular product brands and integrating the designs of hotel space and service experience, circular designs are introduced in real settings for testing and cross-field cooperation. The results of the demonstrations are continuously promoted and copied to maintain the developments of the hotel industry.

When the COVID-19 pandemic began in 2020, the idle space and resources in hotels were used to test the marketability of circular hotel models. Through the themed short but intensive circular life experience, the room prices were increased by more than 3.5 times during the pandemic, and were shared by lifestyle media and internet personalities. In the past, the true value of circular sustainability has been often underestimated. The development of complete process designs and the linking of cross-field, cross-brand companies will become important approaches for expanding circular impacts in the future.

Guidance Focus 54 55

Establish

We transformed pollution into sustainable solutions for a zero-waste future. Environmental protection should not only be moral blackmailing. We are transforming people’s ideas of garbage through technology.

CEO and Founder Arthur Huang of Miniwiz

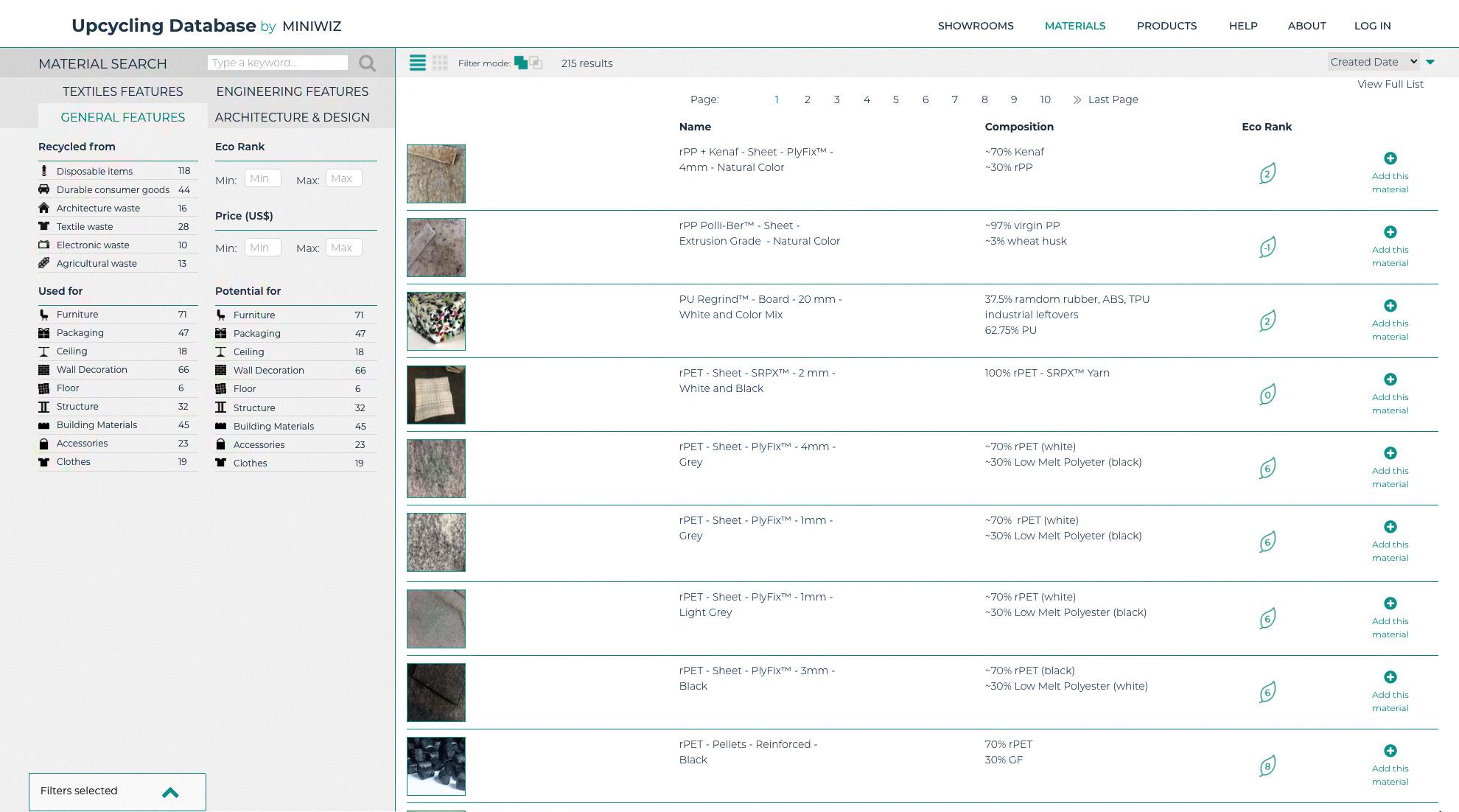

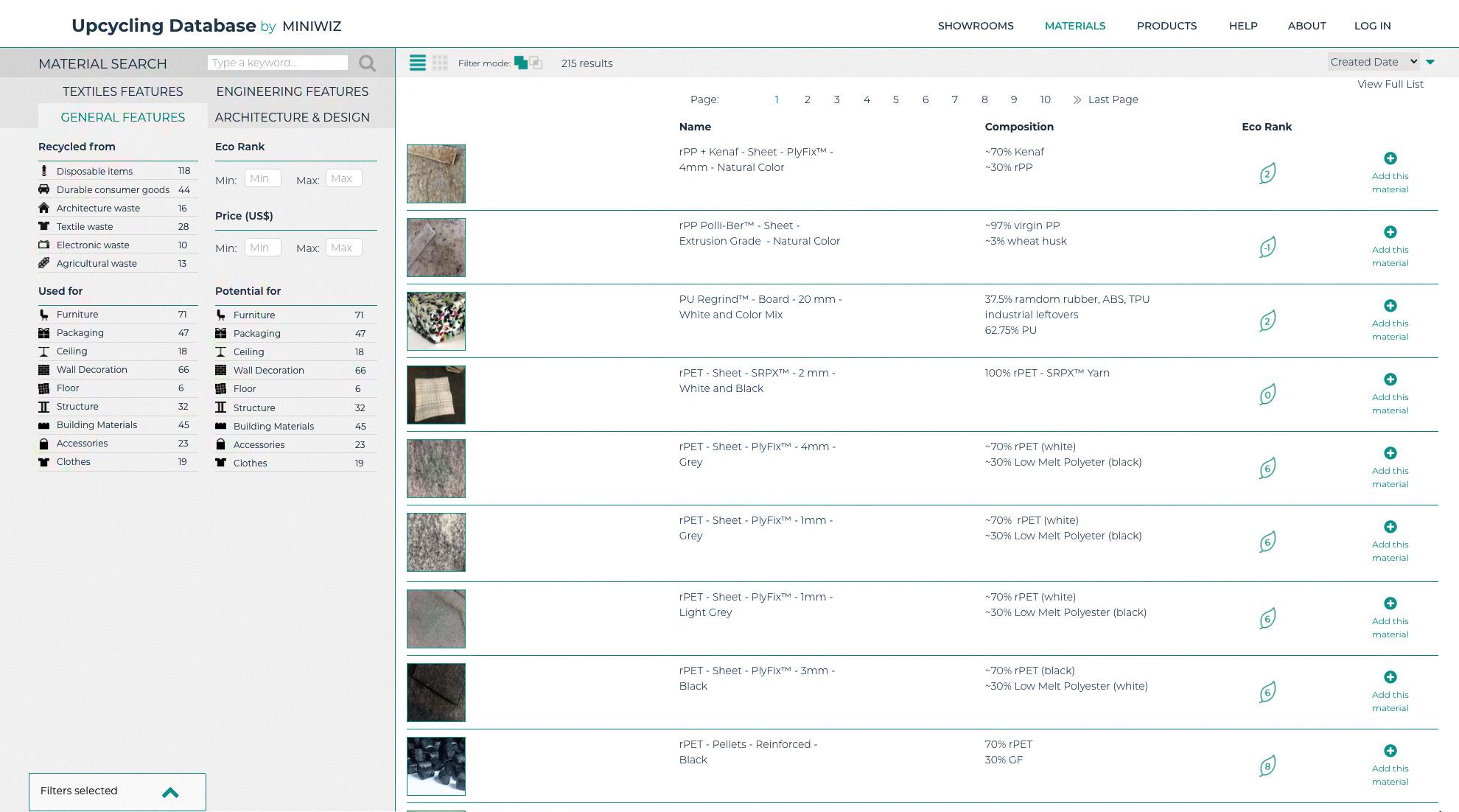

Taiwan has a good recycling system but there is an informational discrepancy between supply and demand. We lack a material flow database, which results in waste becoming garbage. This means large amounts of landfilling and incineration are required instead of industrial waste recycling, generating social and environmental costs. Recycling companies do not know how to respond to industrial needs and how to transform recyclable waste into value-added materials.

companies do not know how to help designers by conveying the characteristics of recycled materials to designers. Designers do not know where to get recycled materials. Designers lack the knowledge related to recycled materials and information on processing units.

Research and Development Services

A Recycled Materials Knowledge

Material

Case

Miniwiz

Circular Design Principles •

• Easy-to-repair

•

•

01 02

57 56

Platform MINIWIZ

Database

company

Co., Ltd.

Adopted recycled materials

(modular) design

Construct a circular system

Sustainable manufacturing production technology

03 04 Recycling

Through this project, 20 types of food packaging found in daily life in Taiwan are recycled to act as a demonstration for circular materials and designs.

The world’s first circular design materials and processing database was established, creating an open platform for “materials, designs, and production”.

By combining social design and design education, Miniwiz’s 17 years of material development experience is shared through the platform. The characteristics and processing data of recycled materials are tested and categorized, providing practical applications for designers during subsequent developments.

Provide usage settings for the design of circular materials.

The system has established a circular supply chain for waste in Taiwan, helping Taiwan become an example of a circular economy for the world.

Miniwiz was established in 2005 and is a pioneer in developing sustainable technology solutions. The company has long been dedicated to solving the problems caused by climate change and environmental pollution. It has become a leader in the industry through its many years of experience and several cases of success. ESG sustainable solutions are broadly applied to land acquisitions, concept development, project execution, marketing, and property management to form the real estate value chain, in order to fulfill the scaling goals. The core technologies of circular sustainability can upgrade and reprocess single-use plastics, metals, glass, and other waste, transforming them into modular construction materials, devices, furniture, and medical-grade materials. The Miniwiz development team has extensive implementation experience related to sustainable projects. The total surface area of applied recycled materials has reached 30,000 square meters and total carbon reduction has reached 24,000 tons. The team can effectively help strategic partners achieve their ESG goals.

The world produces around 2 billion tons of garbage each year, and this number continues to rise! The garbage problem has never been faced head on and no correct solutions have been proposed.

https://materialdb.miniwiz.com/

In response to this, Miniwiz has established a research and development lab for upgrading and reprocessing garbage called TRASHLAB. The team believes that numerous possibilities can be created with the discarded waste through recycling technologies, extending the life cycles of the materials.

With nearly 20 years of R&D experience and recycling technologies, Miniwiz has developed over 1200 sustainable materials. The results of these innovations have been compiled to create the unique Material Database, which is available to the world. Miniwiz hopes to use this platform to convey the characteristics of sustainable materials and expand the diverse applications of recycled materials. Recently, the company has been focused on implementing architecture and healthcare cross-industry projects to improve the usage rate of recycled materials. In addition to sustainable materials, the database also clearly demonstrates how Miniwiz can use recycled waste to replace single-use raw materials. The recycled materials are transformed in sustainable construction material modules and applied to buildings, interiors, and commercial spaces. Furthermore, Miniwiz has also developed a smart recyling recognition system, helping consumers become the most direct recyclers. Through this system, data related to the garbage discarded by people are collected and combined with the system, miniTRASHPRESSO, developed by Miniwiz, achieving the local, non-toxic, and low carbon reprocessing goals for single materials.

01 02 03

04 05

Focus 58 59

Guidance

Tea Aroma Face Masks

Taiwan Comfort Champ creates excellent products with the spirit of craftsmanship. We hope to establish ourselves in Taiwan and demonstrate Taiwanese quality to the world, while protecting people's health.

The COVID-19 pandemic has disrupted the world order and endangered people’s health. Taiwan Comfort Champ joined the national mask team in accordance with the national policies and tackled every challenge. It accounted for 25% of Taiwan’s production capacity. The company hopes to realize circular sustainability ideals while leading the industry. Through the design team started and recruited by TDRI, leftover tea leaves have been added to face masks, creating medicalgrade masks that give off a tea aroma. This has made wearing a face mask a fashionable and blissful action.

Case company Taiwan Comfort Champ Manufacturing Co., Ltd.

Partner Wonderful Design Studio

Circular Design Principles

• Adopted recycled materials

Manufacturing

Chairman Yong-Zhi Chen of Taiwan Comfort Champ

61 60

The product design is based on circular sustainability concepts. The leftover tea leaves or tea powder is added to the face masks, creating a mask with tea aroma.

The tea leaves are specialty teas at different levels of maturation from the different tea regions of Taiwan. We have combined teas with face masks to show the innovative thinking of Taiwan.

Taiwan Comfort Champ, which has been described as the captain of the national face mask team, has developed technical capabilities and observed the consumer market for many years. It is dedicated to solving the problems of face mask wearers and protecting more people in different countries with excellent face masks made in Taiwan. Taiwan Comfort Champ’s core value is “one face mask represents a multitude of responsibilities”.

In order to realize circular sustainability concepts, leftover tea leaves or tea powder is added to the face masks, creating a mask with tea aroma. The tea leaves are specialty teas at different levels of maturation from the different tea regions of Taiwan, forming the series of tea aroma face masks. The appearance of the masks adopted the fashionable elements of “tea camouflage”, making it stylish with any outfit. Each breath taken while wearing the mask is accompanied by a rich tea aroma, making the wearer feel as if they are in the mountains. The product was designed to introduce aromas into face masks, allowing the user to not only protect their health, but also sooth their minds with the comforting aroma of tea.

The product is expected to be launched in the fourth quarter of 2021. The projected domestic sales channels include CVS, chain cosmetics/drug stores, hypermarkets, chain bookstores, duty-free stores in airports, souvenir stores, and e-commerce channels. The international promotion strategy will target countries with existing tea drinking cultures, such as Singapore, India, and the UK. The company hopes to use this distribution method with local advertizing to add more innovative value to eastern and western tea culture.

01 02 Guidance Focus

62 63

Construction industry President Ying-Zhong Lan of Legowall Construction Materials Co., Ltd. Improving the company and brand image can help us obtain more orders and promote circular design and environmentally friendly, recycled modular construction materials.

Friendly, Recycled Modular Construction Materials

Circular Designs

the past, design was only focused on the product itself and its functions, style, color, and packaging. New design thinking is no longer just tactical thinking based on a single aspect, but is now more about overall strategy. It focuses on multiple aspects, such as business models, service innovation, consumer experience, and brand communication. Through the evolution of design, companies can now improve their brand image internally and externally. Case company Legowall Construction Materials Co., Ltd Partner GIXIA Group Co., Ltd. • Adopted single materials • Easy-to-disassemble design Circular Design Principles 65 64

Environmentally

that Comply with

In

Guidance

Focus

GIXIA has long been assisting traditional industries, R&D units of public corporations, technology industries, service industries, and chain systems manage their brand. The company has extensive cross-industry innovative design and brand consulting experience and is an expert in using the different senses to create new marketing approaches for commercialization and productization strategies. It is able to achieve high-level establishment of technical brands, broad expansions, and the cultivation of consumer brands. Through its partnership with GIXIA, Legowall Construction was able to display its brand value, in addition to its product strengths.

The Legowall management team combines its professional technologies related to construction, structures, civil engineering, materials, and automated machinery. Through 10 years of research and development, the company has solved countless problems and broke through different bottlenecks, successfully solving various issues and deficiencies related to existing building materials.

Legowall is more environmentally friendly than traditional building materials. It uses the innovative materials and special structural design to solve the moisture resistance, flame resistance, and earthquake resistance problems of brick walls. It has better water absorption and drainage than concrete and does not easily form wall cancer, while enhancing earthquake resistance, fire resistance, and sound proofing. The modular designs produce thinner thicknesses than traditional brick walls, improving the usability of the space. The different construction method introduces automated machinery into the production and construction processes of traditional industries, allowing construction to be completed faster, thereby reducing the work period and achieving energy conservation and carbon reduction.

With the main development strategy, the company is able to comply with circular design requirement and become an environmentally friendly, sustainable building material company. Through domestic and foreign distribution channels and a sales network consisting of agents, the company is able to strengthen the core developments of technical materials and design innovations, thereby establishing an industry ecosystem. At the same time, its corporate image was enhanced through the improved proprietary brand image, resulting in more orders and assisting the promotion of circular designs and environmentally friendly, sustainable building materials.

66 67