2 minute read

Figure 4-6 – Poultry Operating costs 2026

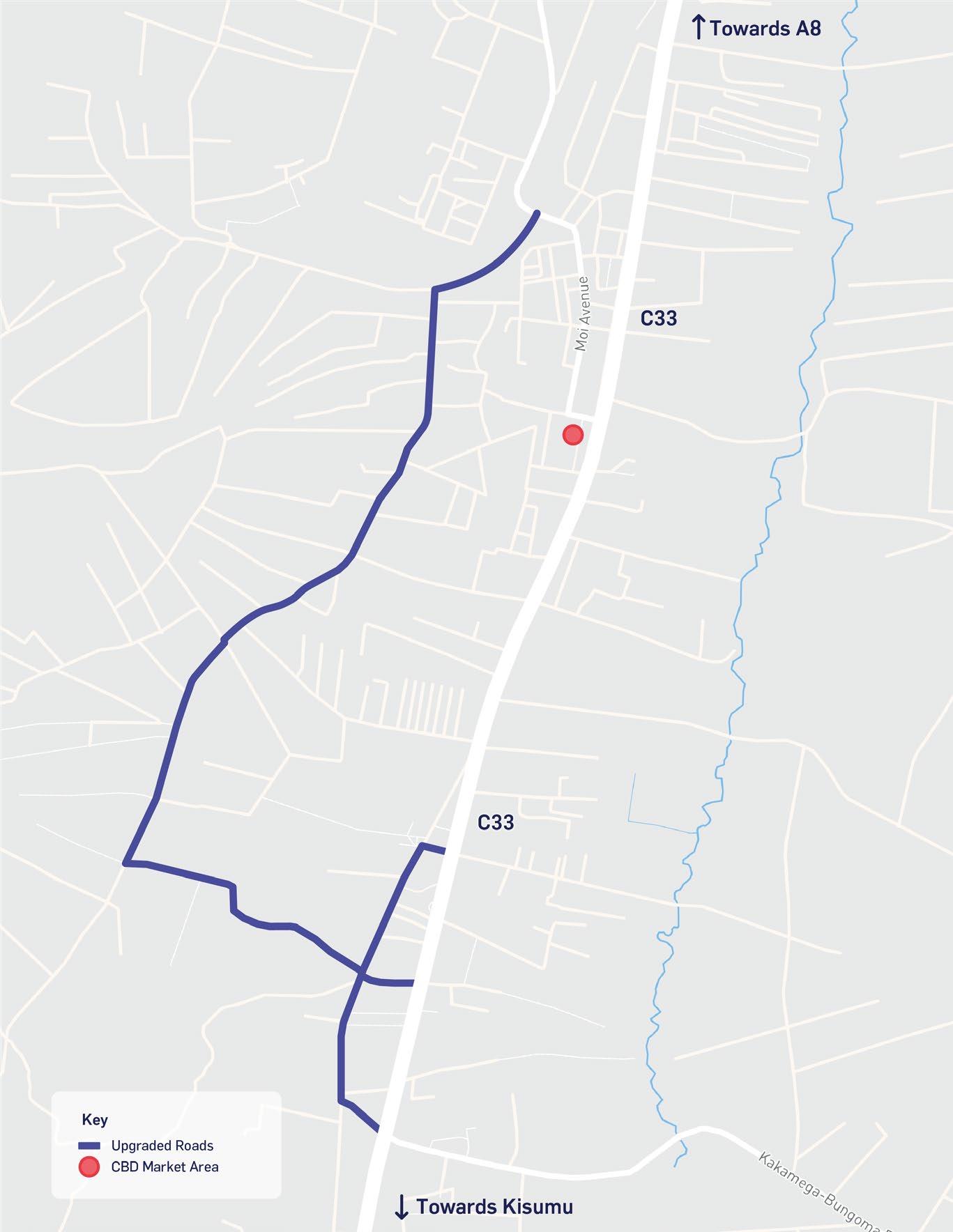

Location-specific Analysis

The total space required for the VC, with a new hatchery, model farm and supporting logistics services, is estimated at some 2,900 m2.

Where there is already an operational slaughterhouse in Chwele to undertake the processing element of the VC, the main physical component driving this VC is the provision of a new hatchery to support the supply chain with a reliable supply of chicks. Discussion with key parties involved in this supply chain identified two potential locations for the hatchery. The first potential location is Mabanga, not far out from Bungoma Town just off the A8, Mabanga is well-connected to the relevant supply chains and urban centres. Also located in Mabanga is the agricultural technical training college. Shiffa Chicks is exploring the available land in the technical training college as a location for the hatchery and has already expressed its interest. If successful, its aspirations for the land includes the co-location of a hatchery, a feed mill, aggregation services, and other supplier support (such as a lab, and input provision). The other potential location explored for a hatchery was Chwele, again the primary motivation was co-location of the different activities along the poultry supply chain. Chwele is the home of the Bungoma slaughterhouse which is currently being operated by Shiffa Chicks. There is also good land availability in Chwele, and it is well-located again to Bungoma Town and the County’s key roads. There is no significant infrastructure required for the early development of this VC, instead, the key to unlocking this VC’s potential lies in the ability to build capacity and empower its supply chains. Sections 4.2.1 and 4.3.1 capture the required softer interventions needed to support the development of this VC. 4.2.2.3 Indicative Costs and Revenues Investment

The total investment required (Capex) is estimated at around KES 120 million, of which 20% covers incubators and pens, 30% is for vehicles, 30% for buildings (including offices and stores) and site preparation, and the rest is for working capital.

Operating costs

Total operating costs are expected to be around KES 40 million per year, with around half of this being manpower costs. The costs of direct inputs into the hatchery and model farms (mainly feed) are estimated at KES 7 million, with transport costs for the logistics operations estimated at KES 6 million per year.

Figure 4-6 - Poultry Operating costs 2026

Source: SUED, 2022 Human resources

The total headcount for the VC is estimated at 60 FTE, including 12 FTE operating the hatchery, 6 FTE for the model farm, 16 FTE for logistics operations and 12 FTE providing technical support to farmers.

Manpower costs are based on:

> Headcount of 60 FTE in total; > Monthly salaries of KES 12,500 to KES 30,000 depending on skills; and > Additional employment costs estimated at 25% of salary.

Revenues

There will be three main revenue streams for this VC. Firstly, the hatchery, which could bring in revenues of up to KES 50 million per year. This is followed by the logistics operations, with estimated revenues of KES 5 million for broiler collections, and potential for additional revenues from feed and veterinary supplies. The model farm operation would have revenues estimated at around KES 2 million per year at full production.

Potential revenues from advisory and financial services (technical support, loan financing, insurance, etc.) have not been included at this stage.