8 minute read

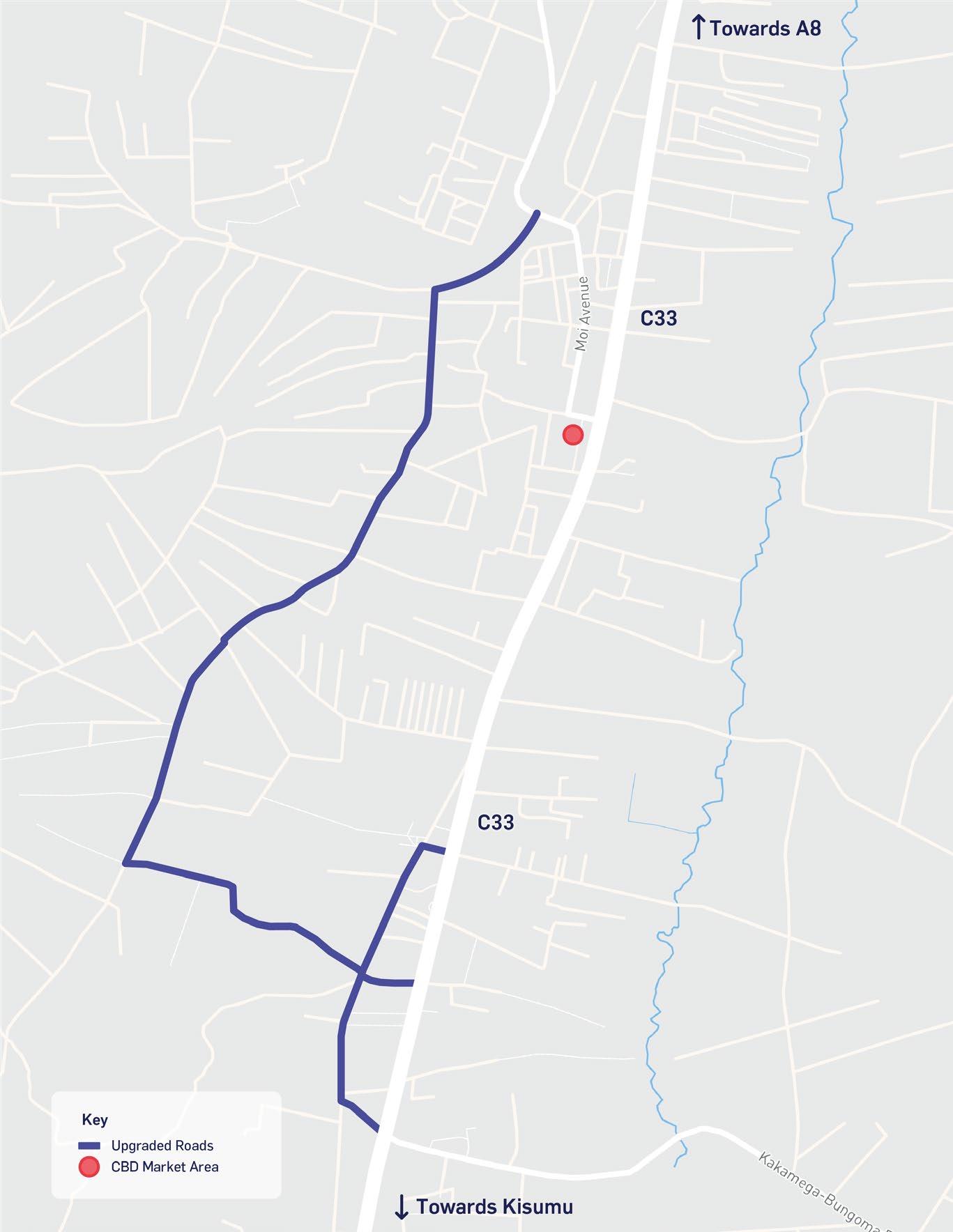

Figure 4-11 – Webuye Industrial Zone overview

Figure 4.11. below provides an overview of the Webuye Industrial Zone along with the proposed location of the Pilot Project to be developed on vacant land within the zone.

Figure 4-11 – Webuye Industrial Zone overview

Source: Atkins analysis

Pilot Project formulation

As part of the pilot project formulation and development, a range of feasibility studies need to be undertaken, such as geotechnical, hydrological, traffic, and environmental and social impact assessments (further described below). Moreover, guidelines on infrastructure requirements, cleaner production methods and eco-design principles have been outlined to ensure the pilot project and its site is developed as a green industrial park. These guidelines have been applied to ensure the pilot project will demonstrate how to approach development in a climate-resilient, inclusive and sustainable way in order to safeguard Bungoma’s characteristic natural environment and water resources.

Site investigation survey and technical studies: A walkover survey should be carried out to identify if there is any particular area of environmental sensitivity and ecological value within the site, if any hazardous waste has been dumped there in the past, and to remove it before main site preparation.

Although the site is relatively flat, a topography analysis, geotechnical and hydrogeological studies as well as flood risk assessment from the Nzoia River should be carried out to identify the characteristics and properties of the soils and ground conditions, and drainage patterns, to support the future infrastructure. Site clearance: Vegetation of no biodiversity and ecological value should be cleared from the site and could be composted or used for charcoal or briquettes rather than sent to the dumpsites. No waste is to be burned or buried on site or dumped in the rivers. Any other waste or materials identified could be used in construction of the industrial park, such as bricks and rubble that can be crushed and used as aggregate.

Feasibility study: This should be carried out to include a market demand analysis, a conceptual master plan, an economic impact assessment, a financial model, a Strategic Environmental Assessment (see below) and any other applicable regulation or guidelines including SEZA regulations if required.

Detailed master plan: This should include key ancillary facilities and land uses, buildings layout, plot sizes, utilities provision, parking and loading bays, infrastructure including buffer zones to protect environmental assets bordering the site, with a phased action plan to guide the development of the site. This may be accompanied by a Strategic Environmental Assessment (SEA) in line with the local regulations.

Environmental and Social Impact Assessment (ESIA): To be developed in accordance with NEMA regulations. This should include an assessment of the activities as well as provision of management, mitigation and minimisation of potential adverse environmental and social impacts, such as pollution control systems to mitigate industrial production and operation, or communication strategies to avoid negative impacts on the lives and economic activities of the local community. Consultation with stakeholders needs to be described and properly communicated. The ESIA process will also identify the requirement to obtain the respective environmental licensing and permits for the industrial park to operate. The displacement of communities and economic activities should be avoided whenever possible. When resettlement is unavoidable, a Resettlement Action Plan (RAP) should be prepared to mitigate adverse socio-economic impacts and the disruption of social safety nets. This plan should, at a minimum:

> Identify affected populations and potential negative impacts associated to the displacement through a census survey. Identify groups who may be particularly vulnerable to displacement and consider specific measures to support them (e.g. PWD, the elderly); > Determine and communicate the cut-off date to receive compensation/assistance and the implementation schedule in an accessible and timely manner. Clearly indicate the valuation methods utilised to determine compensation/assistance; > Consult affected populations about the relocation site/alternatives, the implementation schedule and compensation and assistance measures. Relocation alternatives should at least be comparable, and preferably improve, the livelihoods and standards of living affected populations had before the displacement; > Implement a grievance redress mechanism for disputes that might emerge during the resettlement process; and > Monitor and evaluate the resettlement process and the adequate implementation of compensation/assistance measures.

Sustainable Design and Cleaner Production Principles

A well-planned and organised green industrial park is defined by a set of principles that should guide the planning and design, construction, operation and maintenance of the park. These principles are grouped under a) sustainable design principles and b) resource efficiency and cleaner production.

Sustainable Design Principles to guide future on-site infrastructure, utilities and building facilities

Climate resilience and passive design principles

> Promote tailored strategies for the industrial park in order to take advantage of its unique characteristics and to address local climatic conditions, such as mitigating climate change effects like flooding; > Promote the design of passive buildings to reduce electrical cooling, heating, ventilation and lighting while guaranteeing comfortable conditions for all users; and > Integrate greening and landscape as a key element to help improving the air condition and pollution.

Low carbon or carbon neutral principles

> To use locally-sourced and sustainable construction materials; > To reduce carbon footprint. Shared utilities and logistics

> The clustering of business and industries within the park promotes the shared use of facilities such as warehouses and logistics, training and meeting facilities, and parking areas. This allows the park to benefit from economies of scale and achieve efficient infrastructure services and economic gains by reducing overhead costs; and > To foster the implementation of smart technologies to achieve a good and efficient management of the shared facilities, such as providing sustainable public transport for employees.

Circular economy and zero-waste

> Rethink the waste management system to turn waste into resources. To minimize the generation of waste by reorganizing industries in a way that one could use the waste from another as an input into a process or as a source of energy; and > Accommodate remanufacture, restore, or repair shops to rescue waste and support a circular economy.

Water management

> To promote sustainable urban water cycles by implementing rainwater collection, storm water retention and harvesting techniques and wastewater recycling; and > To promote the efficient use of water resources and ensure good water quality while protecting environmental assets. Sustainable transport

> To design an urban layout which optimises the network infrastructure, reducing vehicle movements while promoting walking and cycling and the use of electric vehicles within the industrial park; > To encourage sharing facilities resulting in a reduction of private car usage; > The urban design needs to focus on improving the public space network with a streetscape which promotes healthy and active lifestyles where residents and workers are encouraged to walk rather than travel by car; and > To promote the use of smart technologies to digitalise transport infrastructure allowing the exchange of information in between vehicles, drivers, passengers and transfer hubs. An example of these are streetlights capable of monitoring parking spaces as well as traffic patterns.

Local and inclusive community employment to enhance the social performance by:

> Creating local jobs; > Providing better working and labour conditions; > Fostering gender, age and (dis)ability sensitivity in the green industrial park's operations; > Providing better security by embedding security features in the park's design; > Providing social infrastructure to the workers and community; and > Improving occupational health and safety.

Cleaner production guidelines and principles to be followed by industries and businesses on the site during the industrial process, products and services:

Renewable energy and energy efficiency

> To use renewable energy sources such as solar energy, wind power, biomass or hydroelectric power; and > To identify opportunities for common energy and heat exchange networks. For example, at some point in the future this area could be a potential location for an incinerator that would reduce the distances that waste is transferred from the industrial park as well as providing heat and electricity, if it is a combined heat and power incinerator.

Resource efficiency and circular economy

> To encourage the use of smart technologies and automation to achieve an efficient use of natural resources and industry outcomes; > To foster industries which reduce industrial environmental footprint by minimising waste and emissions; > To encourage industries to reuse and recycle water to reduce water consumption; > Waste generated in the production to be recovered when possible through sorting, cleaning, conditioning, that can be used as raw material for other industries and businesses; and > To re-use the by-product from one industry as an input for another. Clean air and low pollution

> To support industries which minimise emissions; > To encourage industries to generate as little as possible of hazardous materials; and > Waste to be appropriately disposed of and treated.

Development of Pilot Project site

The pilot project development is located on two adjoining sites within the Webuye Industrial Zone. The smaller of the two sites is 7.5 Ha. in size and has been chosen as the preferred ‘Phase 1’ site due to its location adjacent to the A104. The second site of 9.4 Ha. is allocated for future expansion to the north. The pilot project site will have the option to accommodate non-critical VCs and will allow for future expansion of these VCs and any other supporting service industries and suppliers.

Phase 1 of the pilot project site includes a total of 11 serviced industrial units. They are split between eight sites of 2,000 sqm each and three sites of 4,500 sqm each. A further 17,260 sqm of land is available for future expansion. The site also includes two wooded areas of approximately 25,000 sqm which it is proposed to retain as open space with potential passive recreational facilities for industrial park workers. It also includes the following utilities:

> Water Treatment Plant - one plot of 2,000 sqm has been provided to service Phase 1, however, it can also accommodate the future expansion of the industrial park. This will aim to provide recycled water for the industrial processes within the overall park; > Access roads are to be bitumen with sustainable urban drainage systems (SuDS) to minimise storm and flood conditions and capture/ retain water for reuse within the park; > A potential railway extension or siding from the MGR (to the north) has been identified to service the Webuye Industrial

Zone. This can be incorporated into the pilot project scheme; > Waste collection along with possible segregation and recycling facilities can be integrated into the park land use and operations; > Solar energy and energy management systems should be integrated into all buildings and operations within the park to reduce demand loads on local power supplies; and > Green links have been located within the plots to encourage walking and provision of NMT facilities.