Sustainability

stewardship means everyone who imports, designs, produces, sells, uses and disposes of products has a shared responsibility to reduce the environmental and human health and safety impacts of those products, as defined by the Department of Climate Change, Energy, the Environment and Water.

Product stewardship schemes support the environmentally sound management of products and materials over their life, including at the end of their useful life, which may be voluntary, mandatory or shared with industry.

Product stewardship is a strong focus for Electrolux and one of the pillars in its sustainability mission.

“In the past, efforts have been put into manufacturing and facilities because they are easier boxes to tick, but we need to focus on how we make products out of recycled materials, how those materials become recyclable, how we make products last longer and how we ensure we have spare parts and ultimately, how we keep our products out of landfill when they reach end of life,” Electrolux director of growth and operations, Derek Haley said.

“We have recycling programs in place at Electrolux and of the products that are sent back to us, we can repair and reuse about 60% but 40% ends up in a scrap metal arrangement. We know it’s recycled but we can’t be confident we know where the components are, how much ends up in landfill and how much is truly recycled.

“We are now working on refining measurement techniques to trace components and find out what components are recycled. Integral to this is building industry partnerships with competitors, retail partners, government and councils. We want to bring everyone together to work on improving sustainability.”

Electrolux recently began a global activation, Break the Pattern, focusing on the devastating effects of fast fashion and clothes waste. “With 90% of clothing being discarded by consumers way before they should be with significant negative environmental effects, it’s incumbent upon us to not only help in breaking this pattern of clothes wastage but ensure our products are contributing to making clothes last longer,” Electrolux ANZ managing director, Kurt Hegvold said.

“We want to get closer to our consumers not only by providing great products and service, but by also taking a leading position in educating them on how we can work together towards a more sustainable future. Our mission is to make clothes last twice as long with half the environmental impact by 2030.”

With 23 brands in its portfolio, every conversation Arisit has with suppliers involves sustainability. “Our goal is to eventually have no plastics or polystyrene in any packaging. As an example, in 2023, Sirius rangehoods won’t use any plastics in packaging. Whirlpool factories operate sustainability where no materials end up in landfill,” Arisit managing director, Simon Taylor said.

Mitsubishi Heavy Industries Air Conditioners Australia (MHIAA) senior sales advisor, Graham Hamilton acknowledged t here is no current mandate for product stewardship in the air conditioning industry, although there are discussions around co-regulatory and voluntary programs.

“When an air conditioner breaks down, it is replaced but it is up to the contractor who removes the old unit to decide what to do at end-of-life with regard to waste. Australia is good at recycling metals but given the rising cost of copper and other materials, I would expect a greater appetite to recycle but there

is no regulation and little responsibility, other than to reclaim and return refrigerant to participating wholesalers placed on contractors,” he said.

Miele offers removal and recycling of old appliances, whether it’s a Miele or competitor brand, working with a third-party company that separates the parts that can be recycled. “At Miele, we continue to enhance our circularity model and use more recyclable components. This is a process that is constantly improving and aligns with our philosophy, Immer Besser,” Miele marketing director, Michele Laghezza said.

“We want to prolong the lifetime of our products as much as we can. For most of our product categories, we keep spare parts for approximately 15 years after the product is first launched to help reduce our carbon footprint with end-oflife products.”

Globally, Panasonic is focusing on the development of products using recycled resources and integrating technologies to support this. For example, Panasonic reuses sorted-out plastics in some of its new products and has integrated technologies to develop a complex resin where cellulose fibres derived from plants are added to raw materials during the manufacturing process.

For Nespresso, a key area of investment is in waste recovery and ensuring second-life for its infinitely recyclable aluminium coffee capsules. “For more than a decade, we have refined and extended our dedicated recycling scheme, testing a complex mix of technical, logistical, financial and communications variables to improve the scheme’s outcomes,” Nespresso Oceania general manager, Jean-Marc Dragoli said.

Customers can recycle capsules via Nespresso’s dedicated recycling program and facility through participation in the company’s bulk recycling scheme, direct to boutiques, using dedicated recycling point businesses or returning used capsules via special Australia Post satchels.

According to Magimix managing director, Wivina Chaneliere, there is an expectation from both retailers and consumers within the small appliance category that at least 25% of the product range is new each year.

“This means we are constantly changing products and launching new products, but demand for new does not lend well into sustainability as it creates more landfill from obsolete product. Durability and performance is extremely important to Magimix which is why we offer a 30-year motor warranty and build products that last a long time,” she said.

“We make small changes to design and functionality over time but never scrap a whole product and start again. For example, our food processors are relatively the same as they were 30 years ago, but we have introduced new colours and accessories. Our blender accessories are interchangeable so older blend cups and mix cups can be used on newer models.”

Many Olimpia Splendid products come with a replacement warranty, so if they cannot be repaired, customers can return them for a refund. “If we can repair them, we do so and sell them as seconds, giving them new life rather than scrapping them all together. When goods cannot be repaired, we strip them for parts and reuse components to refurbish other seconds stock,” Olimpia Splendid marketing manager, Peter Burnham said.

At Belkin , part of the product endof-life strategy involves determining the company’s overall footprint for a specific region or country.

“Once we have an accurate picture in-market, we tap into a wide range of e-waste partners and fund them to collect the same amount of electronics we placed on the market in that country or region. Another part of our end-oflife strategy is designing products for disassembly, so they are more easily broken down at end-of-life,” Belkin International senior sustainability manager, Ernie Roberts said. AR

Only 13% of Australian consumers are aware of the term ‘circular economy’, according to a new study by leading app comparison website, GetApp, highlighting the need for companies to educate consumers, specifically through their marketing efforts, with only one-third (34%) indicating they were aware of the concept itself.

The study also showed that the level of awareness of the circular economy concept in Australia is low compared to other countries, such as the Netherlands (30%). However, interestingly, awareness in the UK (14%) and Canada (13%) was similar to that of Australia.

Most respondents (78%) think recycling waste is one of the most effective ways to stimulate the circular economy, followed by 69% of respondents who believe that it’s down to companies reusing materials in the production process, as well as reducing waste caused by production methods (65%), producing products with longer lifetimes (63%), implementing a product buy-back or products recycling program (62%) and using renewable energy (61%).

Over one-third (35%) of respondents felt that one of the main reasons a company invested in the circular economy was due to economic opportunities and government incentives to encourage businesses to adopt and practice sustainable measures. However, when asked about a company’s primary motivation for adopting circular economy practices, over half (53%) said they thought it was because the companies want to mitigate environmental issues.

The research found that more than onethird (34%) of participants sometimes consider whether a company applies circular economy principles when buying a product. There also appears to be the need for sustainable Australian brands to communicate their efforts with consumers, with 42% of respondents stating that when purchasing a product, they would like to have the option of considering whether a company had applied circular economy principles in their processes.

Electrolux is on a mission to inspire you to break the pattern of clothing waste, giving you the tools to take better care of your clothes. After all, the most sustainable clothes are the ones you already have.

Swedish thinking. Better living.

Scan to learn more

The relationship between diversity on executive teams and the likelihood of financial outperformance has strengthened over time, according to a recent McKinsey report, titled Diversity Wins. The most diverse companies are now more likely to outperform less diverse peers on profitability.

Electrolux has always seen sustainability as allencompassing in terms of diversity and inclusion, charitable work through corporate social responsibility (CSR) programs and environmental impact.

“Electrolux has a global team dedicated to sustainability who focus on various projects including human rights audits. We established the Electrolux Food Foundation which is a global initiative not only focused on donations but educating consumers to enable change,” Derek Haley said.

“Food is a focus for our CSR programs as we have a strong relation through food preparation and preservation. We can help to influence and that’s why we continue to work closely with OzHarvest because they do tremendous good for people in need. The We Shine group, driving diversity and inclusion, acknowledges the benefits a culturally diverse team brings to our employees and the broader business.”

Arisit recently added two dedicated people to focus on diversity and inclusion. “However, we remain in the infancy stage as we detail our procedures and make appropriate decisions. Further, we are considering a carbon footprint consultant to measure carbon emissions and detail how we can offset and be a carbon neutral company,” Simon Taylor said.

Diversity and inclusion is at the heart of Miele Australia and New Zealand to ensure employees feel valued, accepted and seen as individuals. “We have a diversity and inclusion committee made up of more than 50 Miele employees to make change for the better with full support from the Miele ANZ leadership team. The committee consists of employees across various departments from the culinary team to human resources, with representation in all states around the country and in New Zealand,” Michele Laghezza said.

While Certified B Corps are legally required to consider the impact of decisions on stakeholders, Nespresso has long been committed to being a leader in diversity and inclusivity, regardless of certification.

We are reviewing all areas of our business based on the B Corp certification, from the way we approach diversity and inclusion to how we govern employment and supply chains,” Jean-Marc Dragoli said.

“We have a comprehensive global sustainability strategy and a local sustainability team dedicated to ensuring that Nespresso Australia continues to set the standard for excellence in CSR embedded throughout the business.”

The Magimix Australia team is small, so as managing director, Wivina Chaneliere is responsible for diversity and inclusion. “We could do better in being more balanced from a gender perspective as most of the team are women, but we don’t hire based on gender, age, or background. We choose people who are best suited to the role and acknowledge that our target market is predominantly females,” she said.

Olimpia Splendid meets with staff on a quarterly basis to train and deliver updates on issues such as sustainability, OHS, products and procedures. “In addition, our parent company has implemented an annual sustainability report for each subsidiary. The marketing department manages sustainability from a communications aspect, but all departments are responsible for contributing to reporting and maintenance of sustainability,” Peter Burnham said.

Diversity, Equity, Inclusion and Belonging (DEIB) is a core commitment at Belkin. “Important employee resource groups include the Women’s Network Group and the Black Excellence in Tech group, which reflect our ongoing commitment to equity and equality. We also have a small group dedicated to CSR. Key pillars such as education, community, research and development and innovation are core to Belkin’s DNA and this team ensures it remains at the centre of every decision made,” Ernie Roberts said. AR

Electrolux works with Sustainability Advantage, part of the NSW Government program, which has built a tool that allows organisations to measure how circular their products are by measuring the recycling process and showing how much ends up in landfill.

“Electrolux has also partnered with waste and recycling collection company, Waste Pro, that recycles EPS and are supporting our circularity journey through track and trace processes,” Derek Haley said.

MHIAA continues to work with the Australian Packaging Covenant Organisation (APCO) to help keep packaging materials out of landfill and are involved with Australia’s leading HVAC industry association, AREMA, as a resource centre that provides leadership and guidance around regulatory requirements, while CESA provides support from a whitegoods perspective.

Miele ANZ partnered with Pangolin Associates in 2020 to support and assess its local carbon footprint, address key areas of improvement, and identify main priorities. “For example, Miele has transitioned some of its delivery fleet to electric vehicles with the purchase of 26 hybrid trucks, which was part of our assessment of Scope 1 emissions, in conjunction with Pangolin, to reduce fuel consumption. We are constantly reviewing and optimising delivery routes by ensuring the journey is as short and efficient as possible,” Michele Laghezza said.

In Australia, Panasonic is an APCO member with a strong focus on working to reduce packaging and support sustainability, which involves developing a packaging manual to ensure packaging complies with sustainable goals, and regular packaging reviews.

Earlier this year, Nespress o gained B Corp certification, benchmarking its performance, bringing wider transformation and scaling its impact for climate, communities, and circularity.

“In addition, we worked with international carbon experts, Quantis to conduct a comprehensive product Life Cycle Assessment (LCA) to study the environmental impacts of coffee growing, production, preparation, consumption and end of life and coming up with resilient strategies and robust metrics to implement intelligent environmental sustainability solutions,” Jean-Marc Dragoli said.

Earlier this year, Nespresso gained B Corp certification, marking the positive impact it has made in the coffee industry and beyond.

The Consumer Electronics Suppliers’ Association (CESA) is the national industry body representing the consumer electronics industry with members encompassing all major global suppliers to the Australian market, including retailers.

CESA advocates on behalf of members to federal and state governments and regulators on a range of environmental issues including product stewardship legislation, e-waste, energy efficiency, water efficiency, and product stewardship including the phase out of EPS packaging.

CESA was instrumental in the development and implementation of the industry-led product stewardship initiative for televisions and computers and a key stakeholder in the development and implementation of the Commonwealth’s National Television and Computer Recycling Scheme (NTCRS), according to CESA chief executive officer, Ian McAlister.

“CESA members endorse the broad objectives of the Australian Packaging Covenant Organisation (APCO) to reduce the environmental impacts of consumer packaging by optimising resource recovery through the supply chain and adopting approaches that make changes in the way we design, use and buy packaging and packaged products so that packaging uses less resources and is more easily recycled,” he said.

Magimix partners with BWES Compliance and Consulting, an electrical compliance committee that provides standards compliance services for selling products in Australia and New Zealand. “We partner with them because they always offer the best and latest advice on standards and compliance which is of utmost importance, as you can’t afford to take any shortcuts,” Wivina Chaneliere said.

Olimpia Splendid works with APCO at a local level and PWC on an international level. “APCO is involved in collaboration to keep packaging materials out of landfill and retains the maximum value of the materials, energy and labour within the local economy. We are involved in reporting and goal setting through APCO to achieve this,” Peter Burnham said.

“Internationally PWC has created a sustainability report which contains both qualitative and quantitative information regarding Olimpia Splendid. They assist us through internal audits on employee diversity, waste management and other sustainability initiatives.”

While working with external agencies and experts remains paramount for Belkin, the company has invested in embedding sustainability into its own business. “Our internal sustainability department, established 15 years ago, drives our global efforts with consistency and focus. It is through this department that collaboration with relevant industry experts and consultants is driven including being an APCO member since 2010,” Ernie Roberts said. ARPackaging evolution for Belkin's 3-in-1 wireless MagSafe charger.

It’s time to rethink fast fashion and outdated care habits.

Reducing clothing waste is a simple sustainable action we can take now. Help us break the pattern and make clothes last longer.

Scan to learn more

thinking. Better living.

Electrolux benchmarks its operations through real estate services company, JLL from a CO 2 and building efficiency perspective. “Every site in Australia and New Zealand has been benchmarked globally and locally, both internally and externally, and we are driving towards greater than four-star energy ratings for all facilities, and five stars where possible,” Derek Haley said.

Since partnering with Pangolin Associates, Miele has been measuring its emissions across Scope 1, 2 and 3. “We have made strong progress over the last year across Scope 1 and 2 and Scope 3 emissions are now a key area of focus for us – in particular how we can educate our consumers to better use our products as a major contribution to our carbon footprint,” Michele Laghezza said.

Since 2016, Panasonic has evaluated new suppliers using self-assessments made on the environment, health and safety, human rights and ethics, and included a CSR clause in first business contracts.

Panasonic has also enforced that all existing suppliers outside of Europe and the US conduct routine self-assessments every two years, conducted field surveys and urged corrective actions to ensure fair and sustainable transactions.

In 2021, Nespresso published results against its seven-year sustainability strategy, The Positive Cup. “The report revealed more than 93% of Nespresso permanent coffee is sourced sustainably through our AAA Sustainable Quality Program and that Nespresso had increased its global recycling rate by 17%,” Jean-Marc Dragoli said. “As a certified B Corp, we are also required to track our progress, and will be reassessed every three years to retain our status.”

Being an APCO member, Olimpia Splendid is required to fill out an annual report and create an action plan. “Areas for consideration include governance and strategy, design and procurement, recycled content, disposal labelling, on-site waste

and problematic materials. The benefit of working with APCO is that we have access to companies from all participating industries and where relevant we can implement successful strategies,” Peter Burnham said.

Belkin’s progress is measured based on several widely accepted and easily benchmarked reporting standards including SASB, GRI, CDP PRI and TCFD. All utility information and calculated emissions factor is based on the utility provider directly or from data provided by the government, such as the US EPA, or the UK GHG conversion factors for company reporting. “After our own extensive internal auditing, we leverage third party audits to confirm our data where applicable and benchmark. Similarly, we are transparent in our performance and targets and make our data public. We publish a dedicated sustainability Annual Report and contribute to our parent company’s ESG reporting, as required by the Hong Kong Stock Exchange,” Ernie Roberts said. AR

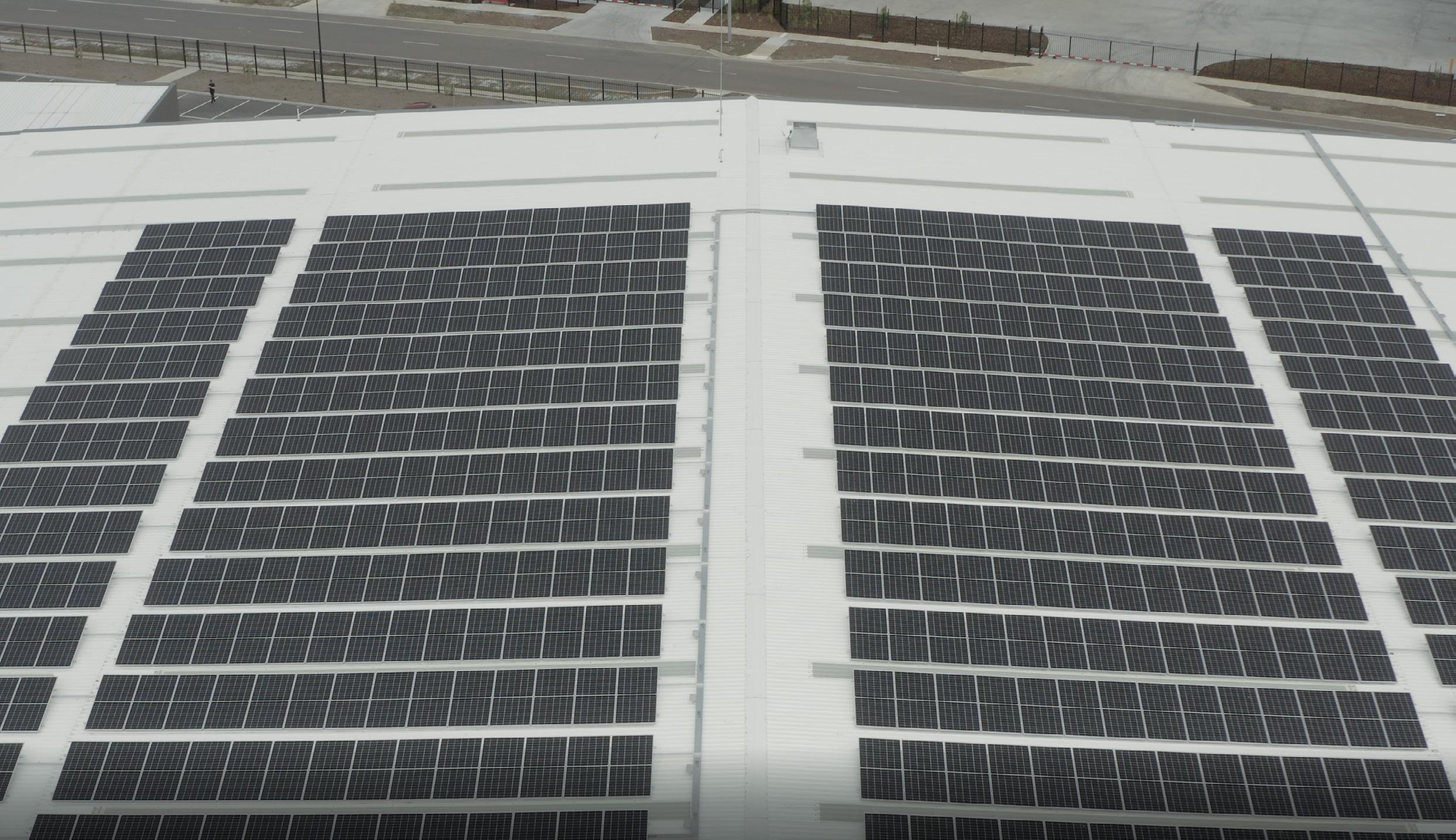

Solar panels on the 6-star Electrolux Ravenhall facility in Melbourne.

Through its AAA Sustainable Quality program, Nespresso works with farmers to help them grow high quality coffee and increase the productivity of their farms.

When Electrolux opened its Ravenhall distribution centre in Victoria, the company partnered with the local Melton City Council to help identify areas to add benefit within the local community, one of those being a co-sponsor of their Business Awards in the sustainability category. “We want to help other businesses in the community increase their sustainability capabilities for a more substantial and long-term effect,” Derek Haley said.

At Arisit , plastic in packaging is progressively being reduced. “We also bring faulty products into our warehouse to strip them and send material for metal recycling. The introduction of our ERP system has dramatically reduced the need to print documents allowing for cloud storage,” Simon Taylor said.

One of Miele’s recent achievements is the production of the Stories of Sustainability film series which educates consumers on how to be more sustainable in everyday life. “We received a Green Seal certification from the Environmental Media Association (EMA), a body which honours and recognises progress in sustainable production – a first in the industry,” Michele Laghezza said.

“We have recently launched our latest assortment of laundry appliances. With Australia’s largest range of 10-star efficiency tumble dryers, our commitment towards creating sustainable innovations is evident and something we want our consumers to be able to experience within their homes.”

In 2022, Panasonic opened a hydrogen fuel cell-based power plant where 100% of the power used for site operations is generated from renewable resources.

Panasonic recently joined the Low Carbon Patent Pledge (LCPP), granting free licenses to the Panasonic green tech patents to encourage innovation and help create a more sustainable future. Panasonic seeks to support the LCPP’s efforts by making certain patents for low-carbon technologies available royalty-fee.

Nespresso’s recent B Corp accreditation is a testament to the work the company has done from

the AAA Sustainable Quality program which works with farmers to help them grow high quality coffee and increase the productivity of their farms, to its global recycling program. “I am proud that we continue to innovate locally and overseas, with regenerative agriculture, eco-design and recycling initiatives such as our recent kerbside collection trial, Curby,” Jean-Marc Dragoli said.

For Belkin , an important milestone was reaching over 50% reduction in GHG emissions from Scope 1 and 2 in the past 10 years. “The establishment of regional sustainability committees at Belkin HQ, in the EMEA and ANZ has seen best-practice initiatives become globally adopted, including the work done on packaging in the Australian market in conjunction with APCO,” Ernie Roberts said.

One of the biggest achievements at Magimix is a 30-year motor warranty on all Magimix products. “Every day we hear from customers who bought our machines 30 or 40 years ago who tell us the machine is still working; they just need a new set of bowls,” Wivina Chaneliere said.

Olimpia Splendid reuses virtually every part of its panel heaters. Being mostly made of metal, over 90% of the units can be recycled when it is not possible to refurbish. “Our factories minimise the number of parts required for the job to reduce the amount of waste and increase efficiencies,” Peter Burnham said. AR

Panasonic's new environmental concept reflects the company's commitment to net zero CO2 emissions at all operating companies by 2030.

Magimix offers a 30-year motor guarantee on all products and makes spare parts available for 30 years.

Metal recycling efforts at Olimpia Splendid.

Metal recycling efforts at Olimpia Splendid.

Mitsubishi Heavy

Mitsubishi Heavy

» Auckland facility is being rebuilt and projected to become a five-star facility with solar panels and water recycling, as well as a new lighting and air conditioning system.

» A virtual energy network is being implemented to put solar panels on all sites and share the energy virtually.

» Forklift fleets are transitioning to electric.

» Building a six-star facility in Brisbane.

» A zero-waste program in South Australia will be rolled out nationally.

» New route planning software will reduce travel journeys by approximately 20%.

» Reduce plastics in warehouses and packaging.

» Transition company cars and forklifts to electric.

» In 2021, Miele achieved carbon neutrality relating to Scope 1 and Scope 2 emissions and now aiming to reduce the offsetting component as much as possible.

» Explore energy audits across facilities and get energy from green sources such as solar.

» Further educate consumers around reducing wastage and being more sustainable.

» Supporting circular innovation through the Australian StartCup challenge – a new competition which supports and rewards innovative, circular business ideas.

» Evolving the Nespresso recycling program to boost participation.

» Regenerating nature via a long-term partnership with Greening Australia to build resilience in local landscapes in the face of climate change.

» Transitioning to polystyrene free packaging.

» Communicating sustainability through the Magimix logo and packaging.

» Continuing to roll out new software on Magimix machines, offering customers the latest updates free of charge.

» Green Impact initiative highlights the shift in focus to actively address how much the company can contribute to the challenges of global society towards carbon neutrality.

» Advanced manufacturing technology and clean energy solutions reduce CO2 emissions from factories and committed to achieve carbon neutrality in manufacturing.

» Accelerate the transition to clean energy and reduction of CO2 emissions by expanding solutions which create and use clean energy efficiently, reduce energy consumption and improve the efficiency of business processes.

» Work with suppliers to cut down on wastage in packaging by converting polystyrene to cardboard or other biodegradable material where possible.

» Implement Wi-Fi in new products where possible to allow consumers to run products more efficiently and control products from anywhere.

» Expanding one box solution offering, Unico, compared to split systems to cut down on packaging, plastics and metal.

» Furthering efforts in packaging and material efficiency where possible, in parallel with APCO obligations.

» A deeper dive into Scope 3 emissions.

» Improving efficiency in data collection, calculation and reporting of ESG efforts.

21 billion tonnes of clothes end up in landfill every year*. So, by 2023, we want to make clothes last twice as long with half the environmental impact.

Reducing clothing waste is a simple sustainable action we can take now.

Swedish thinking. Better living.

Scan to learn more