WIDE FORMAT +Plus with 1987-2023 years in print New Zealand Printer Dscoop review Apprentice Finalists PrintNZ Board and AGM Design for success 05 08 J U LY SIGN + PR INT CR E A TE, MAK E & I NN O VA EXPO 2 2 0800 0800 52 0800 654 455 WW W N ZS D A.O R G.N Z WW W P R I N T N Z.C O.N Z

EXHIBITOR COLOUR STAND #

Aarque BLUE 26

Access Specialties PINK 32

Arlon YELLOW 1

BSL DARK GREY 13

Cambrian Plastics DARK GREY 21 PINK 36

A ne su Ma f orim b o

Carr Group DARK GREY 12

Cohesive BLUE 25

Computaleta GREEN 33

S ho P roje c t :

Ev en t C o ordina to r :

NZSDA

Clie n t :

N ZS D A 20 2 3 & St adi 9

D Graphics DARK GREY 20 Decrastrip GREEN 29 DisplayPro DARK GREY 19 Dynamic Graphics DARK GREY 20 Epilaser DARK GREY 13 Europoles GREEN 27 Fujifilm BLUE 35 HiTec Ink DARK GREY 22 Draw n b y :

Assembly LIGHT GREY 15,16 P ee k Displ a y St an d S z e :

Plastics LIGHT GREY 23,24 As indi c a te d Sc a e :

1 : 2 6 0 I ni

EXHIBITOR COLOUR STAND # A U T Foy e r drawin g s re s er v e d b y Corpora io n L t d an d s s su e d s no c opi e d o an y t hir d par y

MAG

Mulford

Currie Group DARK GREY 39,40 EXHIBITOR COLOUR STAND # Multicam LIGHT GREY 17,18 Pride In Print Awards LIGHT BLUE 39 PSP GREEN 30 Speaker Sessions LIGHT BLUE 34 T S Wilson Jr PINK 31 Total Supply BLUE 37,38 Training & Business Hub BLUE 40 Trotec Laser LIGHT GREY 9,10 WP3 DARK GREY 14

The New Zealand Sign & Display Association are proud to come together for the first time with Print NZ Association to bring Create, Make

wi t hou h e conse n Corpora io n L d I ni Revise in f o @ pe e k c o n z w w w pe e k c o n z r & St adi u m Dro p Ev en ts Cen tr e 05 08 JULY SIGN + PRINT CREATE, MAKE & INNOVATE EXPO 20 23 Make & Innovate Expo 2023. 0800 0800 52 0800 654 455 WWW.NZSDA.ORG.NZ WWW.PRINTNZ.CO.NZ Due Drop Event Centre | Auckland FREE entry and parking 05 08 JULY SIGN + PRINT CREATE, MAKE & INNOVATE EXPO 20 23

& Innovate

0800 0800 52 0800 654 455 WWW.NZSDA.ORG.NZ WWW.PRINTNZ.CO.NZ Due Drop Event Centre | Auckland FREE entry and parking

Expo 2023.

June 2023

Cover Story p2 Sign + Print Expo

2 Sign + Print Expo: Make sure you attend the only show dedicated to print and signage in New Zealand, the Sign + Print Expo. It runs from July 5-8 at the Due Drop Events Centre in Auckland. Check out the floor plan to see who is going to be there

Features p16-24

16 Fujifilm Business Innovation: We find out what makes the Epson SurePress label printers stand out from the crowd

18 Konica Minolta: Auckland Copy Shop has increased production with the AccurioPress C4070

20-22 Dscoop: The HP customers assembled in St Louis, USA, for this year’s Dscoop event included a 22-strong team from New Zealand and Australia

24 Think Laterally: Mick Rowan shares some ways you can use automation to power your business

PrintNZ p12-17

12-14 Helping Hand: Iain MacIntyre interviews our Top 6 Apprentice of the Year finalists

Wide Format Plus p25-41

26 Aarque: With a raft of consumables solutions, Aarque offers customers opportunities to grow their businesses

28-30 Durst: Prior to the Fespa show, visitors to Durst’s factory in Brixen, Italy witnessed first-hand how the company builds digital printing systems from the ground up

32 NZSDA Update: With the Sign + Print Expo looming, Melissa Coutts discusses the importance of live events in the industry and Laura McConchie shares the latest news from Signee NZ

33 NZSDA Signee Profile: West Coast’s Signlink demonstrates the importance of resilience for any business looking to thrive and grow

34 NZSDA President: Andy Lowe wonders if you are making the most of your design capabilities and has some advice on how you can use them to grow your business

36-37 Currie Group: The EFI Pro Series printers are proving ideal solutions for the New Zealand market. We hear from Currie Group’s Paul Whitehead and Craig Paul 40-41 Computaleta: Auckland-based Blink installed a Summa F1612 cutting table and did so well with it, followed that installation with an HP R1000 Latex printer

Why

16-17 Comment: Ruth Cobb reports back from the PrintNZ AGM, which has marked the past year’s achievements and outlined the challenges for the future

NEW

PO Box 32-395, Devonport, Auckland 0744

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Deb Corn, Melissa Coutts, Andy Lowe, Laura McConchie, Iain MacIntyre, Mick Rowan

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING:

Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION:

Sarah Vella - sarahvelladesigns@gmail.com

ISSN 1171 7912

Meet our Top 6 Apprentice

2023

Official Media Sponsor

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro

Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2023: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher.

as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

Copyright © 2023 — Charted Media Group Pty Ltd

4 newzealandprinter.co.nz June 2023

Advertiser’s Index Aarque Group Ltd 9, 27 APM 9 Computaleta Group 39 Contact Labels 9 Currie Group (NZ) Ltd 9, 35 Cyber 44 Durst Oceania 29 Eamar Plastics 42 Fujifilm Business Innovation 17 GLC 7 Konica Minolta 19 NZP Classified Cover, 2-3, 42 NZSDA 3 Pride In Print Awards Cover, 2-3, 43 PrintNZ 3, 13 Sign + Print Expo Cover, 2-3 Think Laterally 42 Wholesale Print 5

CONTENTS

DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person

that information. The user should make independent enquiries

using

ZEALAND

PRINTER

of the Year finalists,

page 12-14

choosing us as your trade partner is the right choice...

Offset Printing | Digital Printing | Wide Format | High Speed Inkjet Chat with us today 0800 289 774, or regsiter online www.wholesaleprint.co.nz YOUR TRUSTED TRADE PARTNER Offer your customers the whole kit and caboodle of print solutions. Wholesale Print is New Zealand’s largest locally owned and operated trade printer. Grow your print opportunities with trade rates, unbranded tools and samples, instant quotes and order online in minutes. Get in touch with the Wholesale Print Team today!

SEIKO EPSON CORPORATION and LOFTWARE have partnered to combine their respective colour label printers and enterprise labelling experience to “revolutionise” customers’ labelling workflows. The partnership will integrate the Epson ColorWorks series of label printers with Loftware’s NiceLabel Cloud platforms. Businesses can print from NiceLabel Cloud directly to Epson ColorWorks cloudconnected printers, which is expected to reduce their reliance on IT, reduce print errors, and reduce the cost and inventory of pre-printed labels.

EPAC FLEXIBLE PACKAGING has launched in-house design services to support brands of all sizes to optimise packaging design and branding. A network of designers has joined ePac to help bring new and existing customers’ brands to life, providing packaging design support, as well as branding and content services to support their growth journey. To celebrate the launch of the new offering, ePac is launching a design competition open to new and existing customers, as well as design and creative agencies. More information on ePac’s Instagram account.

HYBRID SOFTWARE has launched MyCloudFlow, an enterprise workflow delivered via a Software-as-a-Service (SaaS) product. MyCloudFlow presents customers with rapid access to CloudFlow enterprise workflow software. The company hosts it on one of the fastest cloud computing platforms to bring convenience and security to the label and packaging industry without requiring in-house IT support or heavy capital investment.

Koenig & Bauer and Durst accelerate VariJet 106 development

Koenig & Bauer and Durst have accelerated the development of the VariJet 106 for digital production in folding carton markets, with two beta sites confirmed and the first commercial customer starting production in a few weeks.

The first beta site of the VariJet 106 B1 single-pass digital press started printing in May, and the second test customer will run the machine in a few weeks. Both sites are in Central Europe.

The announcements were made at Koenig & Bauer Durst VariJet 106’s Open House at the Sheetfed Division of

Koenig & Bauer in Germany on April 26-27.

Koenig & Bauer Durst managing director Robert Stabler said, “Built on marketproven technology, the VariJet 106 installations represent huge statements to the market – and we are really pleased with the substantial progress that has been made.

“Production is being ramped up, and new machines will become available in the second half of 2023 on the back of the relatively high demand we are witnessing.”

According to Stabler, these presses are tailored

to individual requirements enabling customers to optimise their production and reduce costs while offering new added-value business models.

The platform is based on Koenig & Bauer’s highperformance Rapida 106 platform and Durst printhead electronics, inkjet expertise and Durst workflow and RIP technology. It can produce up to 5,500 sheets per hour and uses de-inkable inks to increase packaging sustainability and comply with all the main food security standards.

XSYS launches Catena-E 48 exposure unit for narrow and medium web printers

XSYS has introduced ThermoFlexX Catena-E 48, a unit for LED exposure developed for the label, folding carton, and flexible packaging markets.

According to the company, the new equipment delivers high-quality flat-top dot plates at high productivity and low cost of ownership.

XSYS prepress global sales director Christophe Lievens said, “Catena-E LED exposure technology was first introduced to the market in 2020, and the larger Catena-E 80 model for wide web applications was quickly adopted by platemakers and

printing companies serving the global flexible packaging and corrugated board markets.

“Now with the Catena-E 48, narrow and medium web printers active in labels, folding cartons, and flexible packaging can enjoy the same excellent plate quality with faster LED exposure and consistent operation, which will boost their business.”

The company developed the Catena-E 48 for exposing plates in a maximum size of 900 x 1,200mm and up to 6.35mm (0.250”) in thickness. It matches the speed of the TFxX 48-S plate imager,

square metres per hour.

According to XSYS, the exposure takes less than 15 minutes. Customers can also opt for an automatic plate-loading door as an option. The new model is suitable for plates with fine surface microstructures, such as ThermoFlexX Woodpecker Nano.

6 newzealandprinter.co.nz June 2023 NEWS

IN BRIEF

Go to the news website newzealandprinter.co.nz Join the rest of the local print industry and sign up for your free newsletter NEWS for New Zealand all the latest print industry news from home and overseas, delivered to your inbox

Varijet 106 produces up to 5,500 sheets per hour

Catena-E 48 features remote calibration, troubleshooting and maintenance

CCG moves to new headquarters in Auckland

tired employees stretched to breaking point.”

CCG is also launching a new range of CCG Heat Presses to complement Stahl’s heat press range, aimed at entry to mid-level customers offering a great quality-toprice ratio and a one-year warranty.

Simpson added: “We have limited stock right now as a lot have sold through already, but we are expecting more stock in late June. We are looking to expand the range very soon and will keep you updated.”

IN BRIEF

After six months of planning and renovations, CCG has moved into its new, expanded headquarters in Albany, Auckland. It now offers a dedicated garment decorating showroom featuring DTF, heat transfer and screen printing equipment.

The new showroom at 13 Tarndale Grove, Albany, offers expanded production efficiency and office space as well as a dedicated Garment Decorating Showroom on the first floor featuring demo

screen printing equipment, Brother and Epson DTF and DTG printers, heat transfer solutions, and more.

Bryan Simpson, director of CCG, said: “We are now fully operational in our new offices. A massive thank you to all our staff and contractors, who have worked incredibly hard to get it all done in a short time frame. Apologies to our customers who had to experience a little more disruption than we planned and also experience a few very

Aldus Graphics expands its offering with Dingya Machinery equipment

Aldus Graphics has expanded its portfolio with Dingya Machinery Co. (DYM) machinery for the label printing industry.

DYM is a global engineering company that provides nonstop roll-changing solutions for the label, narrow and midweb industries.

The company has installed over 400 machines and works with 2,500 customers across the globe.

The benefits of DYM’s non-stop productivity can be applied to any job requiring one or more roll changes to increase productivity and quality control. Its tension coupling method handles various materials from 25-micron plastic film to 600gsm paper board and laminated tube materials.

All machines are designed to be user-friendly. When

purchased through Aldus Graphics, offer the support of the experience regional team.

In a statement, the company said: “We are excited to announce that Aldus Graphics has recently become a DYM distributor. DYM strongly focuses on technology and innovation for the label printing industry. Its technology maximises efficiency, improves yield and reduces waste through its non-stop zero speed and constant tension.”

The company plans to launch the DTF station range of products in June, including a full range of A3+ to 24” printers, shakers, ovens, automatic cutters and heat presses.

“We will make more of a song and dance about it in the next few months, but we can now offer next-generation solutions for DTF printing. DTF Station is based and fully supported out of the United States and backed by industry-leading warranties,” concluded Simpson.

ICS COLOR, one of the leading US-based remote digital proofing companies, has updated its Remote Director system and appointed COLOUR GRAPHIC SERVICES as its dealer and support agent in Australia and New Zealand. ICS Color has also updated the Remote Director addressing the need to dynamically incorporate substrates of all types into digital proofs to improve colour accuracy. New regional users can direct all enquiries to Color Graphic Services, which runs obligation-free demos.

FLINT GROUP has launched Prism, a series of plans to reduce its environmental impact under the new sustainability framework. The company’s Prism sustainability framework includes a range of targets such as circular economy product development, reducing operational impacts, and building a diverse workforce. Plans include Flint Group’s recent commitment to the Science Based Targets initiative (SBTi), with the company reducing carbon emissions in line with the 1.5°C scenario set out in the goals of the Paris Agreement.

7 newzealandprinter.co.nz June 2023 NEWS THERMAL LAMINATING • MATT & GLOSS • SPECIALTY FILMS • ADHESIVE LAMINATING • HOT FOIL STAMPING & EMBOSSING • ENCAPSULATION & WIDE FORMAT • METALLISED FILMS • SCRATCH OFF INKS SPOT & OVERALL UV FINISHES • SPECIALISED COATINGS • INDEX TABBING • NEW LAMINATES • SCRATCH RESISTANT MATT • VELVET FEEL • SLURPEX SOFT CLOTH & CHAMOIS PRODUCTS Unit 3, 343 Church St, PO BOX 12797, Penrose Auckland 1642, New Zealand, +64 9 636 8354 reception@glc.co.nz www.glc.co.nz ALBANY • PENROSE • PETONE

New showroom is located at 13 Tarndale Grove, Auckland

The DYM equipment handles a wide range of materials

Registration opens for Labelexpo Europe 2023

Tarsus Group, the organiser of the Labelexpo Global Series, has opened registration for Labelexpo Europe 2023.

This year’s edition of Labelexpo Europe returns to Brussels after a fouryear hiatus to offer masterclasses and special events focused on automation and flexible packaging on top of demonstrations of the latest printing and converting equipment.

According to the organiser, the new equipment on show will include the HP Indigo 200K press, the Xeikon CX500t Titon and the Screen Truepress PAC520P water-based packaging press.

Labelexpo Global Series portfolio director Jade Grace said, “We are delighted to be running Labelexpo Europe again and can promise visitors an extraordinary show across nine halls. We will see an explosion of cutting-

edge technology launched at the show, everything from prepress to materials and digital and conventional print and converting technology.”

Labelexpo Global Series strategic director Andy Thomas-Emans added, “We are already seeing key technology themes emerging at Labelexpo Europe 2023. Diversification across labels and

flexible packaging technologies, digital embellishment, workflow and machine automation, real-time data collection over the Cloud and sustainability across multiple fronts from LED-UV to more new materials and adhesives choices.”

Tickets to the show cost €95 ($165), with a €10 early registration discount until August 25.

Letterheads meet in October in Christchurch

This year’s edition of Letterheads has been confirmed to take place between September 29 and October 1. It will be hosted by Anne McDonald of Signs of Art and located at Sign Foundry’s Christchurch branch.

Letterheads are a group of sign makers and decorative artists dedicated to passing down traditional sign-making skills.

The first New Zealand Letterheads Meet took place in 1998, and since then, all professionals have met for hand lettering events and to exchange lost “tricks of the trade” and accumulated skills.

This year’s event, hosted by Anne McDonald of Signs of Art, will feature a

series of workshops and demonstrations in the workshop format with industry experts such as Dean Evenson, Clinton Potter, Alan Clarke, Alex Burnett, Louisa Jessop

and Ross Probert.

Letterheads will learn several techniques, including gilding on glass, essential brush and beginners’ layout skills, Oamaru stone carving, gold foam carving, faux finishing, airbrushing, pinstriping and traditional chalkboards.

On Saturday, all attendees will be encouraged to concentrate on a project that utilises the skills learned on Friday and participate in a large community project mural.

Numbers are limited due to our small venue, so Letterheads are encouraging early registrations online at www.letterheads.co.nz.

Epson reveals SureColor F2260 DTG/DTF printer

Epson has launched SureColor F2260, the third generation of its top-selling desktop DTG model featuring a range of upgrades for faster and more efficient production while enhancing support for increasingly popular DTF (direct-to-film) production workflow.

The printer incorporates a 33 per cent larger PrecisionCore printhead for faster performance. It ships with upgraded Garment Creator 2 software for additional user functionality and more efficient output with finer imaging detail.

The SC-F2260 features an enlarged 4.3-inch touch panel display and a cleaner loading bay with repositioned controls. Macro head-height adjustment is simpler, and the printer features automatic fine head-height adjustment.

The new model will also employ upgraded ink, UltraChrome DG2,

designed to support a broader range of fabrics with better colour and less bleed. The new ink is compatible with DTF workflows.

True to Epson’s commitment to

sustainability, the SC-F2260 incorporates several features to reduce waste and operating costs. It uses 800ml ink pouches that are 33 per cent larger and include less plastic.

The new SC-F2260 incorporates a head that doesn’t require regular replacement.

Epson’s new Port service provides enhanced operator monitoring tools and enhanced service support by allowing technicians directly dial in, analyse the fault, and seek resolution.

Epson Australia Limited business marketing manager Gordon Kerr said, “With the SureColor F2260, Epson has further refined DTG while opening up the world of direct-to-film to customers with consistent, high-quality imaging and durable, cost-effective operation.”

The printer will ship in New Zealand from August 2023.

8 newzealandprinter.co.nz June 2023 NEWS

Labelexpo Europe 2023 takes place in September in Belgium

Anne McDonald will host this year’s edition

Epson SC-F2260 will be available in New Zealand starting from August 2023

NZ PRINTER DIRECTORY & CALENDAR

Pride in Print Awards 2023

Labelexpo Americas

June 23, 2023

September 13-15, 2022

Auckland

Chicago, USA

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

Since 1993, the Pride in Print Awards have been a pinnacle of recognition for the best in visual print communication products of any given year. They embody a culture of excellence aimed at meeting and exceeding the customer’s needs. This year’s Gala Night takes place at The Cordis Hotel in Auckland. www.prideinprintawards.co.nz

Wayzgoose 2022

NZ Sign and Print Expo

September 17, 2022

July 5-8, 2023

Napier

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Auckland

Sign Expo has evolved to recongise the sign of the times and renamed to the NZ Sign + Print Expo. NZSDA invited Print NZ to join and assist with the organisation and bring both print and sign suppliers together under one roof to view the very best in technologies, new innovations, services, and products at the Due Drop Event Centre in Auckland. www.nzsda.org.nz

Foodtech Packtech

September 20-22, 2022

Auckland

New Zealand Sign Display Awards

July 8, 2023

Auckland

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

All in Print China

October 11-15, 2022

Shanghai

This prestigious national event recognises and acknowledges outstanding design and craftmanship across a broad range of sign making methods and technologies. Sponsored by many of New Zealand’s leading sign and graphics suppliers, the annual awards evening is held in various locations throughout New Zealand, reinforcing the event’s national status. https://awards.nzsda.net.nz/

Labelexpo Europe

September 11-12, 2023

Brussels, Belgium

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

Letterheads

October 21-23, 2022

Sign Foundry, Welling

This will be the first Labelexpo show in Europe since 2019. Along with demonstrations of the latest printing and converting equipment will be masterclasses and special events focused on Automation and Flexible Packaging. New equipment to be seen at Labelexpo Europe includes the HP Indigo 200K press, the Xeikon CX500t Titon toner press and the Screen Truepress PAC520P waterbased packaging press. www.labelexpo-europe.com

Letterheads

September 29 – October 1, 2023

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

Christchurch

Interpack

May 4-10, 2023

Düsseldorf, Germany

This year’s event, hosted by Anne McDonald of Signs of Art, will feature a series of workshops and demonstrations in the workshop format with industry experts such as Dean Evenson, Clinton Potter, Alan Clarke, Alex Burnett, Louisa Jessop and Ross Probert.

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

Experts will be on hand to show both apprentices and those experienced in the industry “How to” with a variety of different old-school techniques on show. www.letterheads.co.nz

newzealandprinter.co.nz

Ad newzealandprinter.co.nz

NZ PRINTER DIRECTORY & CALENDAR (09) 274-7370 admin@contactlabels.co.nz www.contactlabels.co.nz 4A/157 Stoddard Road, Mount Roskill, Auckland 1041. Labels Foil Stamping Embossing Die Cutting Creasing Kiss Cutting Perforating Machinery Wanted Considering Cashing up Surplus Equipment? Graphic Machinery NZ Ltd Contact: John Lunt Ph: +64 21 817 455 E: sales@gmnz.co.nz W: www.gmnz.co.nz l Printing & Packaging Equipment l Import / Export Sales - New / Used l Plant Valuations & Inspections l Machinery Sourcing & Relocation l Policart Die Cutting Anvil Covers l Solema Graphic & Board Machines Craig Paul 027 655 4267 sales@curriegroup.co.nz Craig Paul 027 655 4267 sales@curriegroup.co.nz - PMS 308 - PMS BLACK Please respect legend colours integrity m - PMS 308 - PMS BLACK Please respect legend colours integrity m MACHINERY WANTED m m • Consulting and Machine Recommendations Sourcing • Export/Import Sales • Machinery Inspections & Valuations • Plant Relocation OFFICE: 09 8367577, ALEX MOB. 021 975 477 sales@apm.co.nz www.apm.co.nz Craig Paul 027 655 4267 sales@curriegroup.co.nz

Apprentice of the Year whittled down to the Top 6

The competition to find New Zealand’s finest up and coming print talent has now seen the field whittled down to a Top 6. These finalists will take the stage for the announcement of the BJ Ball Papers Print Apprentice of the Year at the Pride In Print Awards gala evening at Auckland’s Cordis Hotel on June 23.

The Top 6 Apprentices of the Year are:

• Paul Coe, MCC Christchurch (formerly Hally Labels) – Reelfed Labels

• Tammy Connolly, The Big Picture

– Digital (joint)

• Catriona Mellows, Display Associates

– Digital (joint)

• Waka Ropiha, Sealed Air Hamilton – Packaging

• Jamie Watson, Printcraft 81 Ltd – Sheetfed Offset

Ruth Cobb, chief executive at PrintNZ, says the fact that judges could not separate the two Digital Apprentices of the Year demonstrates the high calibre of candidates. She says, “In fact, it wasn’t just the Digital Apprentices that we were unable to separate, it was the Top 6 overall.

“They were all worthy of being recognised as being the best in their sector of the industry and we thought that they all stand a good chance of winning the overall Apprentice of the Year title, so we could not deny any of them the opportunity to contest that prize.”

Paul Coe

Paul Coe

Enjoying the process of learning new skills helped make Paul Coe’s apprenticeship more meaningful to him. He says, “I had the feeling of continually getting better at my work and I loved working with, learning from, and becoming closer to my co-workers.

“Although I found it challenging to deal with the added pressure of going from an assistant to a press operator,

10 newzealandprinter.co.nz June 2023

• Saxon White, Stuff Ltd Wellington – Reelfed Offset

I also discovered how stressful it can be knowing that the work I sent out the door had to be up to a high standard, and that I was responsible for it.

High calibre of apprentice talent sees six finalists for the peak apprentice award.

helping hand

IAIN MACINTYRE

Last year’s Apprentice of the Year finalists on stage at the Pride In Print Awards

Paul Coe

“When I started working in the printing industry, I was at a point in my life where I wanted to start focusing on a career. I began working at MCC Christchurch, which was then known as Hally Labels, and I remember thinking, ‘This could be a job I could do well’.

“The most rewarding aspect of my work currently is the feeling of accomplishment when solving a problem or completing work that I couldn’t do previously. It feels great knowing that all my training has paid off, and I can see the results first hand in my work.”

Tammy Connolly

Having had difficulties with spelling and writing dating back to school days, Tammy Connolly expresses great pride in the personal perseverance she demonstrated during her apprenticeship. She says, “I haven’t had the easiest road and giving up was an option that was looking more and more inviting due to some roadblocks that appeared in my way. However, I am not a person who quits easily, and I had to continually remind myself of this. No matter what cards were dealt my way, I persevered and got the job done.”

Handing in assignments was one of her favourite aspects of the apprenticeship experience. She says, “Once I had done all the hard work for each assignment, I got to choose how to present them using all the skills I had learned. I tried to use some out-of-the-box ideas to present my assignments, hoping to show my abilities not just in the written work but also in the presentation of the assignment.

“The knowledge I gained from my apprenticeship has assisted me to become

a more well-informed and valued member of our team. The apprenticeship made me ask heaps of questions and now, I always strive to know more.”

Catriona Mellows

Initially, she found the apprenticeship “quite daunting”, which she puts down to the challenge of facing the academic workload. However, she persevered, and things turned around. She says, “It was in my second year, when I went to a workshop in Auckland, that I started to feel inspired. Meeting other apprentices and visiting other print companies showed me how big the industry is and how it could take me anywhere.”

She devised strategies for dealing with the challenges. She explains, “I changed my focus from trying to plough through the assignments, to trying to get the most out of them. I started asking to learn new machinery at work so I could present my assignments in custom-made booklets and folders. I found a passion for absorbing information, going into as much detail as possible and taking onboard every bit of feedback from Malcolm Pearce from Competenz.

“The crazy thing is that I didn’t plan to get into the print industry at all. Like all so many good things in life, it just happened.

Describing “the most amazing kind of chaos” when first entering her new employer’s premises, Catriona Mellows says, “The first time I was shown around Display Associates, I was taken aback at how busy everyone was: the printers were running; people were shouting instructions; there were garments and vinyl everywhere.”

After his brother advised him about a job vacancy at Sealed Air, Waka Ropiha recalls welcoming a “new and exciting adventure in an industry previously unknown to me”.

He says, “Prior to joining the industry, I thought that this process would be complex. But since then, I have really

11 newzealandprinter.co.nz June 2023

Waka Ropiha

helping hand

Catriona Mellows

Tammy Connolly

Waka Ropiha

enjoyed learning and gaining knowledge. During my apprenticeship, I found how vast this industry has become. It is evolving and continues to thrive.

“The most challenging aspect for me wasn’t the apprenticeship itself, but finding a healthy balance and mix for family, work, study, and social lifestyle. During my apprenticeship, my partner and I grew our family from three people to six. Finding time for everything was the hardest, but we put our best foot forward and continued to give everything 100 per cent.

“I find responding to the challenges in creation and colour transformation satisfying, especially when we reach our end result. Right now, creation is the most rewarding part of the process.”

Looking ahead, he plans to continue to learn more about the industry and take on further leadership roles as he pursues “a pathway to evolving the printing industry and the environment”.

Jamie Watson

Solving problems in his work counts as both the most challenging and enjoyable aspect of James Watson’s apprenticeship experience.

He says, “The one thing that will knock your confidence in your solo printing abilities is when something on the press goes wrong and you don’t know how to fix it. But learning and developing the skills I need to diagnose and solve issues has been so fulfilling. It is a great feeling knowing exactly where to look and what to do when an issue occurs.

“And my supervisor’s mechanical and engineering background means we often dig deep into the inner workings of the machine’s components and electronics to fix problems. So, I am learning some elements of troubleshooting and improvising which many printers will miss out on.”

Now eyeing a move into digital printing, he says, “It will be exciting to learn a new method of print and we have an everexpanding list of digital clients, especially thanks to our two new presses.

“Beyond that, the computing end interests

me a lot. I’ve always enjoyed computers and technology and, while I don’t have an especially creative mind, I think the file management side of things is something I would really enjoy and excel at.”

Saxon White

Having previously completed an apprenticeship as an interior systems specialist in construction, Saxon White made the print career switch to both “be there more there for my wife and children” and to “jump into a new challenge”.

He says, “Not only did working for Stuff really get me dreaming, but the idea of learning how to operate a printing press and to actually work on the news and current affairs each day was a huge reason I was drawn to the role and to the industry.”

He adds that his apprenticeship has contributed to considerable self-learning. He explains, “I have learned I can work optimally in a team or completely on my own and that my leadership potential is as large and far reaching as I want it to be. Another realisation is that I now know that I can truly do anything I set my mind to. On top of all that, I am capable of working under stressful deadlines to still deliver a consistent, quality product.

“Doing this apprenticeship has challenged me to really think about print in the modern world and how I could contribute to its future, and really put that passion into my work. I wanted to understand all of the ins and outs and whizzes and whirls, and just exactly how the printing manufacturing process worked, from our clients to the newsstand.”

12 newzealandprinter.co.nz June 2023

helping hand

Jamie Watson

Saxon White

Keeping it local, let the world know Keeping print in New Zealand is more important than ever. Use this logo so both you and your customers can demonstrate the part you are playing. Apply to PrintNZ on info@printnz.co.nz or phone 0800 654 455 PNZORG 0000 WORKING FOR OUR INDUSTRY AND OUR MEMBERS EVERY DAY

AGM marks achievements and sets direction for PrintNZ

Busy year sees changes and challenges ahead

PrintNZ held its 115th Annual General Meeting on Tuesday May 23, followed by a meeting of the Management Advisory Group.

The organisation has two key groups that set the strategy and guidelines for the operation of PrintNZ: The Board of Management (BOM) and the Management Advisory Group (MAG).

Board of Management

The role of the BOM is to set the direction

for and oversee the operation of the organisation.

The AGM saw the completion of terms for four long-standing members of the Board: Tony Sayle (past president), Mark O’Grady, David Jack, and Lisa Hegh. Each of these people has made an outstanding contribution to the organisation during their time on the Board and this was noted at the AGM.

The remainder of the Board comprises:

President Fred Soar, SCG, Auckland Jill Cowling, Blue Star Group, Auckland David Parsons, CQ, Christchurch Ruth Cobb, PrintNZ chief executive

Plus, the Board has one co-opted member Tony Sayle, Jenkins Group, Tauranga.

This means the Board has two vacancies. The meeting noted that it should give

consideration to ensuring that the Board is diverse and widely representative across a number of areas. There was a strong desire to have input from the future leaders of the industry and provide them opportunities to learn more about the organisation and how it is governed.

As a result, the nominations that were received for the remaining two positions will be reviewed by the Board through a broad lens, alongside looking to accommodate up and coming board members through a programme of governance associates.

This is an exciting step towards ensuring that PrintNZ has a strong succession plan, something that is just as important to our business as it is to yours.

Management Advisory Group

The MAG comprises representatives from

14 newzealandprinter.co.nz June 2023

PRINTNZ COMMENT

Training Company the Year, from left: PrintNZ membership co-ordinator Linden Hoverd alongside PSI Brand apprentice Niue Vaimoli and general manager Jim Crawshaw

RUTH COBB

David Jack

Mark O’Grady

Lisa Hegh

PRINTNZ COMMENT

each of the regions and technical sector groups who act as a voice for the members in their specific sector or region. This group meets annually to provide input into the PrintNZ Strategy; feedback from the regions/sectors; training; and help set the focus for the coming year.

This year the group received an update on the review of qualifications that have taken place over the last 18 months with Hanga Aro Rau. This has seen four qualifications reviewed; one new qualification created; 109 unit standards reviewed; and two new micro-credentials established. This massive task that has been undertaken by volunteers from the relevant industry sectors.

The second topic covered was the PrintNZ Strategy with the key priorities for the next two to three being:

• the promotion of print by investing in marketing of the sector

• access to resources for members

• strengthening PrintNZ’s voice

• a continued focus on the changes being made in the training sector

• looking at opportunities to work more closely with other like-minded organisations.

Accounts

The Annual Report and Accounts were presented to the AGM. PrintNZ made a pretax profit of $85,960 for the 12 months to 31 December 2022 (compared to $52,078 in 2021). This is an excellent result in a period of continued disruption from Covid-19 and increasing inflationary pressures. The organisation has equity of $1.4m (up from $1.32m in 2021) and an investment portfolio valued at $1.6 m which generated dividend income of $60,522.

Activities

The annual report details of the activities of PrintNZ and the following outcomes were highlighted at the meeting:

• Membership at December 2022 was 494 compared to 489 at December 2021.

• Learning numbers in 2022 were 416 compared to 484 in 2021.

• A well-attended training graduation was held in Auckland in May once Covid restrictions on events had been lifted.

The Apprentice of the Year Sector winners were:

Sheetfed: Kosema Fuiono, Blue Star Collard, Auckland

Packaging: Frey Head, Oji Fibre Solutions, Auckland

Digital: Nana Southall, Blue Star Constellation, Auckland

Screen: Liam Blom, ACI Screen & Print, Auckland

Reelfed: John Reddy, Philstic, Auckland

Apprentice of the Year was awarded to Kosema Fuiono from Blue Star Collard in Auckland.

PSI Brands in Napier was named Training Company of the Year and Mandy Nilsson from Blue Star Constellation in Auckland was named Workplace Trainer of the Year.

PrintNZ successfully managed the 29th Pride In Print Awards, held in Christchurch at the new TePae convention centre. Logic Print was named the Supreme Award winner, its fourth title, making it the most awarded Supreme Award winner.

In 2022, PrintNZ managed the sale of Rapid Antigen Tests to members, generating extraordinary income of $196,758. Our thanks go to Blue Star Group for the bulk supply of the tests.

PrintNZ worked closely with Competenz as the Review of Vocational continued to move through its transition and Competenz was merged into the Work Based Learning subsidiary of the large TePukenga organisation. This work was important to ensure that the function that is responsible for delivering training in our organisation was not compromised in the changes.

Hanga Aro Rau makes up the other half of

the new training structure. PrintNZ has good representation in this organisation with Mark O’Grady on the Board and Ruth Cobb on the Industry Stakeholder Group, allowing a two way flow of information.

Substantial time was spent lobbying government across a broad range of topics that affect the industry. This was done both individually as PrintNZ and as part of wider groups of organisations to increase the power of our voice.

PrintNZ has continued to participate in the Value of Paper and Print, Two Sides and Love Paper campaigns, promoting print to a broader audience and providing collateral to members to use in their businesses.

Thanks to you

Our organisation exists for our members and PrintNZ remains focused on delivering services that provide value and relevance, looking for opportunities to deliver further benefits and support, and continuing to look for prospects for growth for the organisation, both within the industry and across complementary groups.

But we are nothing without our members, our staff, and our Board, and a huge thank you goes to all the businesses and individuals that recognise the value of having an industry organisation, in good times and in bad, and support PrintNZ accordingly through membership, sponsorship and participation.

15 newzealandprinter.co.nz June 2023

Tony Sayle

David Parsons

Fred Soar

Jill Cowling

Debunking inkjet myths

New Zealand Printer had the opportunity to discuss industrial inkjet technology with Epson Australia’s business development manager for industrial label and textile print, Terry Crawford, to debunk some of the myths and shed light on the actual prowess of this groundbreaking technology.

Epson SurePress inkjet presses represent the forefront of industrial printing technology, offering a range of advanced digital label presses designed to meet diverse needs in the printing industry. Overall, each model in the SurePress series offers unique advantages while maintaining the core values of Epson: reliability, efficiency, and quality.

The SurePress L-6534VW, for instance, is built for high-speed, high-quality printing, with UV ink that allows for robust resistance.

The SurePress L-6534VW model, equipped with UV ink, offers precise quality control and enables printing on heat-sensitive materials due to its UV LED curing function.

The SurePress L-4533AW is designed for flexibility, using water-based pigmented inks to print on various substrates with an impeccable finish, making it perfect for labels and flexible packaging.

Addressing cost issue

A widespread belief is that industrial inkjet technology is costlier to maintain and operate. However, factors like highspeed production, minimal waste, lower maintenance requirements, and higher durability of printheads make it a costeffective solution in the long run.

According to Crawford, “Two types of toners exist in the market: dry and liquid. Both

technologies estimate costs by calculating the click rate. Epson’s business model doesn’t operate on a click rate. Instead, our customers purchase ink as they require it. To ensure accurate cost accounting, we advise customers to take three labels of varying coverage and run them through built-in SurePress cost calculator.”

Crawford further explained that Epson’s SurePress machines can handle variable web widths from 80mm to 330mm, which leads to additional cost and material savings. “Printers can select a substrate width which is most economical for the job”. This approach distinguishes us in the cost market.”

Though initial expenses might seem high, the total cost of ownership often turns out to be less over time.

“Purchasing a digital press entails a hardware price, an ink price, and a service price,” Crawford stated. “We traditionally offer a 12-month warranty with our SurePress machines. After that, customers can opt to buy a service agreement. During the printer’s lifespan, all parts are covered. Our presses also offer a lifespan of 10 years. We can guarantee the availability of spare parts for that entire period.”

Epson also provides an ink negotiation component as part of the equipment purchase. “Based on the client’s projected print volume, we can negotiate the most favourable ink price point,” Crawford said. When making a purchase decision, service and support are significant considerations for any printer.

“In a toner business model, there are fixed costs for hardware, consumables, and service contracts,” Crawford said. “Customers must be mindful of the

fine print as toner manufacturers may impose extra charges if print volumes are unmet. Epson operates differently – our customers buy inks when they need them.”

New levels of productivity

Another important factor when considering the overall cost of operations is machine uptime. Even small gains on each printing job can contribute to enormous operational improvement in the long term. Machine uptime is here critical indicator of productivity.

“Our presses are all remotely connected to a central server. This serves multiple purposes, including remote diagnostics, allowing our technicians to monitor the presses and troubleshoot any problems immediately.

“This data provides feedback on print volumes and ink usage. Our customers also have access to this information, which they can use for management purposes, such as tracking printing trends, ink usage, and waste,” said Crawford.

Additionally, Crawford emphasized the reliability of SurePress machines, saying, “Our average uptime is 98 per cent, a very high percentage that attests to the reliability of our presses.”

Industrial inkjet technology has evolved exponentially, breaking away from the limitations of its predecessors. Misconceptions still linger, but a closer look reveals a dynamic, precise, costeffective, and environmentally friendly technology already shaping the future of large-scale printing.

For live demonstrations of the SurePress L-4533AW, please contact your account manager from Fujifilm NZ Ltd or Fujifilm Business Innovation NZ Ltd.

16 newzealandprinter.co.nz June 2023 EPSON SUREPRESS INKJET

TECHNOLOGY

Industrial inkjet technology has long been a cornerstone of large-scale printing, yet several misconceptions cloud its reputation, obscuring its true potential.

Epson Australia business development manager for industrial label and textile print Terry Crawford

Chris Cordes (l), national production print specialist and Grant Blockley, national wide format specialist with the Epson SurePress L-4533 AW at Fujifilm Business Innovation in Auckland

SurePress L-4533AW Digital Press

Versatile printing Consistent quality

Revolutionising digital label printing.

The SurePress L-4533AW is the ideal solution for label converters looking to expand their operations. Deliver consistent, high-quality products while ensuring reliability, flexibility and performance, with minimal downtime.

To find out more visit fujifilm.com/fbnz

DIGITAL

Auckland Copy Shop upgrades to AccurioPress C4070

Innovations improve production and quality for growing print shop

so, all our staff members can operate the AccurioPress C4070, which currently runs eight hours a day and five days a week.

The AccurioPress C4070 has increased production at Auckland Copy Shop. Parth continues, “The AccurioPress C4070 is a real time-saver. We used to complete our finishing work manually, but we now have the trimmer unit and bookletmaker. We are putting so much more work through, all as finished product.

“Prior to getting the AccurioPress C4070, we could only do a 40-page booklet, but now we can produce a 120-page booklet. Also, we could only do A4 or A5 books, but the bookletmaker enables us to produce anything from A6 up to landscape.”

From its central city base, Auckland Copy Shop offers a range of print services based on its digital output. Director and owner Kirabuke (Keyz) Mareko says, “Most of our work is small format digital, producing everything from flyers and business cards to brochures and booklets.

“He moved to New Zealand from Kiribati in the 1990s to attend high school at Lindisfarne College in Hawkes Bay. He says, “After high school, I completed a degree at AUT and then a post-graduate degree at the University of Auckland, qualifying as a computer engineer. I briefly returned to Kiribati for a holiday, and I was fortunate to help my family’s company, training the staff in IT.

“My father has a print shop, and I was always interested in connecting IT with printing. From my university days, I had a friend who went on to work for the Konica Minolta New Zealand reseller at that time. He helped me out with technology for the Kiribati business and that is when I got to know the Konica Minolta Engineers.

“I returned to New Zealand and started Auckland Copy Shop in 2011. We have used Konica Minolta solutions from the beginning. Our first machines were a

bizhub Pro 1050 for black and white and a bizhub Pro C650 colour machine.”

However, Keyz wanted to further his aspirations in engineering. He explains, “While I love the printing, I am a trained engineer and I have always had a desire to make use of my degree working in IT.

“About six years ago, I had the good luck to employ a high school student, Parth Patel, as a part-timer. He had arrived in Aotearoa in 2016 to study at the University of Auckland, where he also gained a degree in computer engineering. Parth is now a permanent New Zealand resident and has taken over as general manager at Auckland Copy Shop, allowing me to work as a computer engineer.”

Production ramps up

In January, Auckland Copy Shop installed an AccurioPress C4070 printer, updating its technology and continuing its successful partnership with Konica Minolta.

Parth Patel says, “We only needed a few hours training on it, and we were up and running. We were already familiar with Konica Minolta technology but the AccurioPress C4070 has so many more functions than the older models. Even

He is also impressed with the accuracy and colour management the AccurioPress C4070 delivers. He adds, “The print quality we get from the machine is excellent and all automated from the IQ unit, which is great. We used to have to do colour calibration twice a day and now that is all done automatically. Also, the double-sided printing is incredibly accurate.”

Auckland Copy Shop will increase its output even further. Parth says, “We are in the process of increasing the workload for the C4070 because we are taking over another copy shop. Right now, we have the basic engine in the AccurioPress C4070, but we may upgrade it in the future.

Both Parth and Keyz enjoy the association with Konica Minolta. Keyz says, “We are definitely sticking with Konica Minolta. We know the team well, and they are easy for us to work with. It is important to have confidence in the service and support we need. We love doing this.

“I am also thrilled that Parth has grown so well into his role at Auckland Copy Shop. He does everything from customer service to accounting and production as well as helping me with sales decisions. I just provide cover when he needs time off.

Now married, with an 18-month-old daughter, Parth adds, “I love it here in New Zealand. The people are friendly, and Auckland Copy Shop is a great place to work.”

18 newzealandprinter.co.nz June 2023

Parth Patel (l) and Keyz Mareko, with the Konica Minolta AccurioPress C4070

WITH THE ACCURIOPRESS C4080/C4070

Introducing the AccurioPress C4080/C4070 - incredibly versatile digital print systems that can help your business succeed. With exceptional output quality, enhanced media capability, compact footprint and expanded finishing options you can build a configuration to suit your requirements and say yes to more opportunities to grow your business.

To rethink versatility, simply visit: konicaminolta.co.nz/AccurioPressC4080series

Dscoop inspires hundreds of businesses in the printing and packaging industry

Dscoop, one of the world’s largest and most collaborative digital print and design communities, provides its members with the latest news and education from HP innovators and industry experts. It recently hosted the Dscoop Edge World Expo in St. Louis, USA.

Dscoop members from 38 countries attended, including a 22-person team from A/NZ, which joined HP and Currie Group for some extracurricular activities.

Dscoop Edge St. Louis Conference chair and an Arizona State University Print and Imaging Lab member Kyle Pendeley said, “The global Dscoop community has an impressive history of looking

forward instead of backward. Even as our companies face big challenges, we do whatever it takes to continually learn, connect, and advance. That’s the awesome spirit of Dscoop”.

This year’s event programme did not disappoint those eager to learn about what the latest HP technologies offer in their production environment. It also featured two high-energy keynote speakers who set a positive mood across the event’s three days and inspired attendees to exchange experiences, raise questions and collaborate to find answers to today’s market challenges.

Local printers join international community

For over 15 years, groups of printers from A/NZ have been travelling to the US to be part of this one-of-a-kind experience.

This year was no different. The 22 regional representatives joined Mark

Daws and AJ from Currie Group and Craig Walmsley and Duncan Bray from HP Indigo. Daws said, “There was a range of companies from all facets of the industry – from commercial printing to labels and packaging. Joining us from New Zealand, we had Matt Mills from Fuzed and Ruth Cobb from PrintNZ.

“From Australia, we hosted members of Photo Create, Rawson Print & Packaging, Next Printing, CMYKhub who sit across both commercial printing and, more recently, in labels and packaging, Dflow, Courtney Brands, Peacock Bros, and Colemans Printing.

“Also in attendance was Kelvin Gage, who not only sits on the Dscoop board but was also the emcee for the event. He certainly did us proud.”

Print NZ chief executive Ruth Cobb said, “Having an ANZ contingent simply added a whole other layer to the event, and being part of that team made us feel welcome

members from 38 countries attended this year’s event in St. Louis

20 newzealandprinter.co.nz June 2023 DSCOOP EDGE 2023

The Dscoop community in attendance at this year’s Edge World Expo included a 22-person team from A/NZ, which joined HP and Currie Group for some extracurricular activities

Dscoop

Dscoop Edge St. Louis Conference chair Kyle Pendeley welcomed the community in the America’s Center

The A/NZ regional team at one of the road trip stops, Fortis Solutions Group in Flowery Branch

rather than isolated. Both Currie Group and HP were outstanding hosts, and being able to swap notes with others on some of the sessions you couldn’t attend was remarkable.”

The A/NZ team gathered a few days before the event to go on a road trip, which took them from Atlanta to St. Louis, stopping off at some of the world’s leading print manufacturers based in the US. This included packaging printer Fortis Solutions Group in Flowery Branch; Benson Integrated Marketing Solutions in Alpharetta; Tucker-based full-service commercial printer Bennetts Graphics; and flexible packaging specialist PouchIt in Atlanta.

Those who stopped by the famous HP Graphics Experience Centre, established as the only site in the Americas, saw HP’s entire graphics portfolio in one place. Often described as the ‘Disneyworld of Print’, this leading-edge 6038 square metre facility enables visitors to experience automated, end-toend graphics arts solutions that can professionally print everything from postage stamps to building wraps.

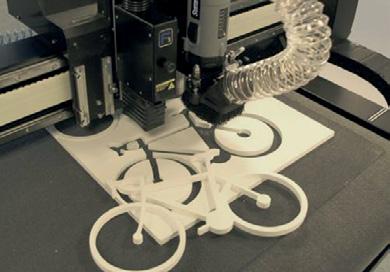

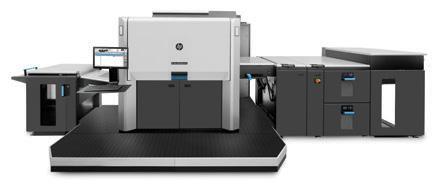

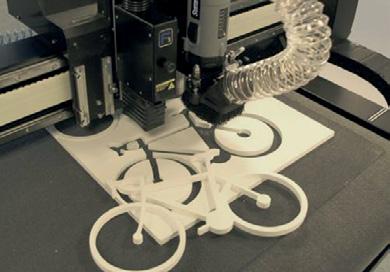

Daws mentioned that it was an excellent opportunity to see everything HP Industrial offers, from signage to wide format and high-speed inkjet, as well as the capabilities of the HP Indigo and the Jet Fusion 3D printers.

Daws said, “What’s unique is not just the equipment that HP provides, it is the complete end-to-end solution, the workflow partners and finishing solutions provider that complements the entire production line.”

Collaborating and trending

After the three-day long road trip full of new inspiration, the A/NZ team joined over 1,100 HP users from across 38 countries for a feature-packed Dscoop Edge at the St. Louis World Expo.

Over four days, Dscoop members came together with infectious energy and remarkable idea sharing. The ‘Gateway to Growth’ theme was fuelled by printers and partners eager to learn, connect and advance.

In his welcome speech, Dscoop executive director Peter van Teeseling said, “It doesn’t mean anything if there’s no heart and soul – and that’s all of you. You are all part of a truly amazing global community”.

Dflow chief executive Doug Robey remarked, “We travelled as a team of four to the event, and for three of us, it was our first Dscoop. We had heard

a lot of great things about it over the years. I was amazed by the openness, collaboration and ideas sharing. It was an embracing type of environment, which was interesting”.

Dscoop delivered inspirational content from celebrity guests as well. On the first evening, drummer Mark Schulman, who usually shares the stage with P!nk, touted gratitude and a positive attitude in business.

Meanwhile, Los Angeles Lakers legend Earvin ‘Magic’ Johnson delivered an inspiring presentation on business acumen and giving back to the community. As a former NBA legend and chairman and CEO of Magic Johnson Enterprises, he made history in 2012 when he became a co-owner of MLB’s Los Angeles Dodgers. He also co-owns the Los Angeles Sparks of the WNBA, Major League Soccer’s Los Angeles Football Club, and eSports franchise Team Liquid.

Fuzed director Matt Mills confirmed this keynote speech’s inspiration: “This guy knows a thing or two about leadership, teamwork, and reaching the pinnacle of success, no matter which way you slice the pizza of life.”

HP Industrial Print senior vicepresident and general manager Haim Levit said, “Dscoop is about harnessing the power of community to network, communicate, and innovate. This event is the opportunity for the entire Dscoop global community to meet HP leadership and engineers, to listen to each other and discuss current and future challenges, and to enable developing a joint roadmap to continued market leadership.”

This included discussions around sustainability. Cobb said: “None of your customers is ever going to ask your business to be less sustainable than it currently is, so you need to get on with your sustainability journey. This is something that PrintNZ is keen to focus on helping members with.”

The Dscoop Expo reaffirmed Cobb’s unwavering commitment to ‘Glocalisation’ over ‘Globalisation’. She said “Glocalisation means working on a global scale but utilising local connections to get jobs printed in other locations to save shipping and reduce not only the time to get the job to the customer but reducing the carbon footprint of the work.”

Dscoop Edge delivered over 60 education sessions over seven tracks, hosted by HP experts and top-level sales and marketing coaches. Cobb added, “The sessions were great. They covered various topics across different streams. The main difficulty came from choosing what sessions to attend when they ran concurrently, and there were no repeats, so you had to choose very carefully. The two streams I was interested in following were sustainability and marketing of the printing industry, and small nuggets came out of each of those sessions.”

Matt Mills gravitated towards marketing and sales workshops, which rejuvenated his professional soul. He said, “They delved into the magic of social media and why it’s more important than ever in today’s digital jungle. They unleashed a flurry of sales strategies and shared secrets on how to keep your company as relevant as a viral cat video in this everevolving digital world.

“After the sessions, when you gather with other attendees from Australia and New Zealand, it’s like entering a brainstorming bonanza. You start gaining a better snapshot of what they took away from the same workshops you attended and those you didn’t manage to sneak into.”

21 newzealandprinter.co.nz June 2023

DSCOOP EDGE 2023

One of the keynote speakers Mark Schulman touted gratitude and a positive attitude in business

Los Angeles Lakers legend Earvin ‘Magic’ Johnson delivered an inspiring presentation on business acumen

DSCOOP EDGE 2023

Indigo, we’ve announced the launch of the 200K press. It’s not just about the product; it’s about the complete solutions that we’re bringing to the market to help users grow their businesses.

“We are investing in labels and flexible packaging and starting to penetrate the corrugated and folding carton markets. This approach will enable us to bring the most comprehensive versatility and productivity to market.”

Daws said the global trends and challenges discussed are no different from those the local printers face daily, adding, “Supply chain challenges, rising costs, automation and sustainability – these are all the hot topics of today. It is the sort of narrative that we hear at most industry events.

“However, A/NZ businesses in the industry should be immensely proud of what they can achieve and have achieved, given that, in many cases, we have much higher labour rates, inflation and supply chain challenges than those in the US.”

Face-to-face with the latest digital printing technology

HP is developing products and services to address current challenges and meet customer demand for the latest trends, including the labour crisis, sustainability, automation, and consumer buying behaviours.

Therefore, Dscoop has been a platform to host 75 partner companies in its Solutions Showcase. As part of the showcase, HP featured its 200K Digital Press, engineered for flexible packaging.

Haim Levit commented, “We really want to unlock the label market. We are accelerating analogue to digital conversion in the label market. And for

Following a record year of B2 sheetfed press volumes, HP Indigo also celebrated the installation of its 1,000th HP Indigo B2 press and announced the new HP Indigo 100K HD, with “smooth and razorsharp image quality”.

The HP PageWide demonstrated innovations to the HP PageWide Advantage 2200 with high HDNA quality at full speed, up to 50 per cent faster prints, and a new version of PrintBeat within PrintOS.

Another debut was HP Large Format, with the company showcasing the HP Latex R2000 Plus Printer, a hybrid solution that is equally strong in rigid and flexible substrates.

Matt Mills said: “As most of us already know, technology is like that one friend who never stops evolving. Seriously, it’s like trying to catch a slippery fish with a pair of chopsticks. So, while strolling around and ‘nerding’ out over the latest gadgets in the Solutions Showcase and the HP COE, it was mind-boggling to witness how HP and other industry wizards are constantly tweaking their thinking and offerings.”

Ruth Cobb came back from the trip impressed with the wide web digital flexo and the flexibility that it can offer. Still, as she notes, there were also many incremental innovations on display from the industry partners.

Levit concluded the event with a statement and commitment to the HP community, “We have the widest portfolio in the printing industry, bringing a solution to every market segment. We are investing US$180m ($296m) annually to serve the printing market better. HP is committed to investing in and growing the business. We aim to ensure our customers succeed, be profitable, and have the best experience. ‘Better Together’ is not just a slogan; it is our way of life.”

Matt Mills added, “To all proud owners of HP Indigo presses, or whether it’s the mighty Page Wide or the impressive Wide Format, mark my words: you absolutely cannot afford to miss these incredible events. Trust me, after enduring the tumultuous roller coaster ride that was the past three years of Covid, this kind of tour was like a refreshing oasis in the desert of routine. It had everything I needed and more - it was invigorating, inspiring, informative, and, let’s not forget, a whole lot of fun.

“If you’re sitting there with burning questions about Dscoop or just eager to know more about next year’s conference in Indianapolis, don’t hesitate to reach out to me directly. Consider me your tour guide through the world of Dscoop and all the exhilarating experiences it offers.

“So, gear up, my fellow HP enthusiasts. It’s time to unleash your printing prowess and embark on an adventure that will leave you with cherished memories and a renewed passion for your craft. Let’s make the most out of this extraordinary community and create print magic together.”

22 newzealandprinter.co.nz June 2023

Dscoop Edge delivered over 60 education sessions over seven tracks

HP debuted its 200K digital press at the Solutions Showcase

Scan the QR code to see highlights

Scan the QR code to see the interview

Matt Mills and Ruth Cobb at Dscoop Edge 2023

from Dscoop Edge St. Louis

with Currie Group’s Mark Daws

Five signs you’re a print junkie – 2023 edition

You measure twice, cut once. Now apply that to customer communications. Are the right people getting the right message at the right time? If not, get out the ruler and segment your customer lists, again. Many print customers have changed companies since 2020, and have new roles and new responsibilities, some with access to new budgets, so it’s time to revisit your lists.

4. You examine everything printed to decipher the types of presses, processes and inks used. Bonus Print Junkie points if you randomly share this information with strangers in the grocery store.

Curiosity is contagious and can be fun. So, consider sending your customers a sample kit of your capabilities across printed materials and have a contest where the winner has identified the most on each piece, correctly.

2. You use your fingers as a paper stock weight gauge. Bonus print junkie points if you can also detect the specific finish on coated paper.

Supply chain issues have certainly made more customers more flexible when it comes to ‘their paper’ and getting comparable options to honour brand standards. Invest some time to share paper possibilities with your customers this year. Invite paper merchants and mill reps to your print shop and have a paper sample party with customers and prospects.

Produce blogs and video content with the paper people and use it to inspire projects and creativity. Repurpose for your social media and you have a marketing campaign guaranteed to generate ROI on many levels.

Do you see print everywhere? Do you count down the days until the new printing press or finishing equipment arrives at your print shop? Do you know what Pantone colour the sky is? Do you make vacation plans around printing industry events or incorporate them? Do you look at digital marketing and come up with 10 ways print marketing could support the campaign? Do you think about print in the shower?

If you answered ‘yes’ to any of the above, you might be a Print Junkie!

Unlike other addictions that may require interventions and medical care, standing up and declaring yourself as a Print Junkie can be liberating and rewarding with your print customers. Here are five signs (in descending order) that you may be one, and how to turn your passion into profits:

5. You have no less than three rulers at your disposal. Bonus Print Junkie points if any of them measure picas, are made by Schaedler, or are from your first job.

Make the prize something fun for customers and rewarding for you. Perhaps you can invite them for a VIP tour of your print shop and give them personal printed items from photos or files they send over before their visit. Avoid the “gift card” and anything else that could be an issue for some corporate and agency buyers. Ask them if you aren’t sure what crosses the line – they know! Then, adjust as needed.

3. You are a print sniffer… and when you do it, you close your eyes and savour the sniff! Bonus print junkie points if you do this in public, and extra bonus points if anyone asks what you are doing, and you don’t even realise you are doing it.

Print love can be contagious. Send customers cool things you see and share how they could be applied to help achieve print marketing and communication goals. You can also send aspirational examples. I had a ‘draw of print dreams’ in every agency I worked at just waiting for the right client or creative brief to come along and manifest them into reality.

You want to be the first print shop I call when discussions start. Buyers may still need to triple bid the project, but if all is equal, they will usually reward the ‘printspirational’ source – I know I did.

1. You are still here. It has been rough for many print junkies looking to score big over these past three years.

They kept it moving, did whatever they could to keep the presses churning and made it work to make it here. Congrats to all of you, but the work is not done.

To keep print coolness and topical information flowing with print customers you must do your part and attend industry webinars, demos, events, and user groups. Participate in industry studies, join many organisations and contribute to the greater good.

To understand how print is being used, misused, or not used by other industries, I implore you to attend events outside of print – but related. Meeting and event planners have events, digital marketers have events, and associations of all kinds have events. Those are the lowest-hanging fruit examples.

Deborah Corn is the Intergalactic Ambassador to The Printerverse at Print Media Centr, a Print Buyerologist, international speaker and blogger, host of Podcasts From The Printerverse, cultivator of Print Production Professionals, Head Girl in Charge at Girls Who Print, host of #PrintChat, the founder of International Print Day and the founder of #ProjectPeacock.

23 newzealandprinter.co.nz June 2023 TALES FROM THE PRINTERVERSE

Having a print obsession is a habit you don’t want to break. A shout-out to all the Print Junkies!

DEBORAH CORN

Being a Print Junkie can be liberating and rewarding with your print customers

Use automation to power your business

Simplify your business processes with slick applications

Zapier removed the need for developers by turning the tech babble into simple building blocks, allowing the less-thantechnical amongst us to create integrated workflows from ready-made elements.

This ‘No-Code’ technology is a gamechanger for companies that can’t afford or don’t need large IT departments. Staff with industry knowledge but no coding experience can empower their businesses without programming skills.

Zapier serves as a bridge between different web applications, allowing users to connect and automate tasks across multiple platforms. It supports integration with popular tools like Facebook, Google Suite, Mailchimp, Slack, and Trello, to name but a few. This enables businesses to streamline workflows, automate data transfers, and eliminate manual data entry.

Maximising efficiency is vital to maintaining a competitive edge in business, yet investing in expensive, complicated software can seem overwhelming. However, optimising sales and marketing automation doesn’t have to come with a hefty price tag. HubSpot and Zapier offer affordable and potent platforms to revolutionise workflows, freeing valuable time for crucial business tasks.

By leveraging these tools, you can spend less time on menial tasks and more time focusing on core functions in your business. And with a relatively small spend, your company can be equipped with a versatile platform brimming with efficiency-enhancing potential!

Let’s start with HubSpot, one of the market’s best bang-for-buck apps, in my humble opinion. Once you understand what HubSpot can do, you begin to realise that it is capable of pretty much everything you need to support your core marketing and sales workflows. And while there are alternatives such as ActiveCampaign, Pipedrive, and Salesforce, to mention a few, here is why HubSpot is my go-to every day of the week.

HubSpot has email marketing, social media management, lead generation, analytics, and customer relationship management (CRM) all in one platform,

so you can easily streamline your workflows and boost efficiency.

The interface is intuitive and userfriendly, so you can build and manage campaigns with just a few mouse clicks. Plus, with their CRM system, you’ll have all your customer data in one place, making tracking leads and nurturing relationships easy.

The automation features simplify your workload by handling repetitive tasks like email sequences, lead nurturing, and social media scheduling. And you can customise messaging based on customer behaviour and segmentation, increasing engagement and conversion rates.

You can also track the success of your marketing campaigns, monitor website traffic, and understand customer behaviour with robust analytics tools. Then use the data-driven insights to make informed decisions and optimise your marketing efforts for even greater success.

Zapier is my other bang-for-buck app. I have been a massive fan since I first ran across Zapier almost a decade ago when they had a mere 66 integrations. Jump forward to 2023, and there are over 5000 connected apps. Zapier is my go-to tool for helping users to connect apps and automate workflows. If you like the idea but want alternatives, consider IFTTT, Make (formerly Integromat), or Parabola.

Before Zapier, no one considered turning complicated APIs into simple visual blocks. APIs, or application programming interfaces, allow different software systems to communicate and work together smoothly, resulting in hassle-free integration for developers.

With Zapier, users can create workflows called ‘Zaps’, which trigger actions in response to specified events or conditions, allowing seamless data synchronisation and task automation. This saves time, reduces errors, and increases productivity. You can streamline workflows and automate routine tasks without sacrificing brainpower. Thanks to Zapier’s user friendly interface and intuitive setup, you simply point and click to set up seamless integrations.

From sending weekly reminders to syncing data across your apps, Zapier is a lifesaver for those repetitive tasks that clog up your day. Effortlessly transfer information from your project management tool onto your personal todo list and stop wasting time on mindless, low-priority tasks.