Setting an awardwinning pace

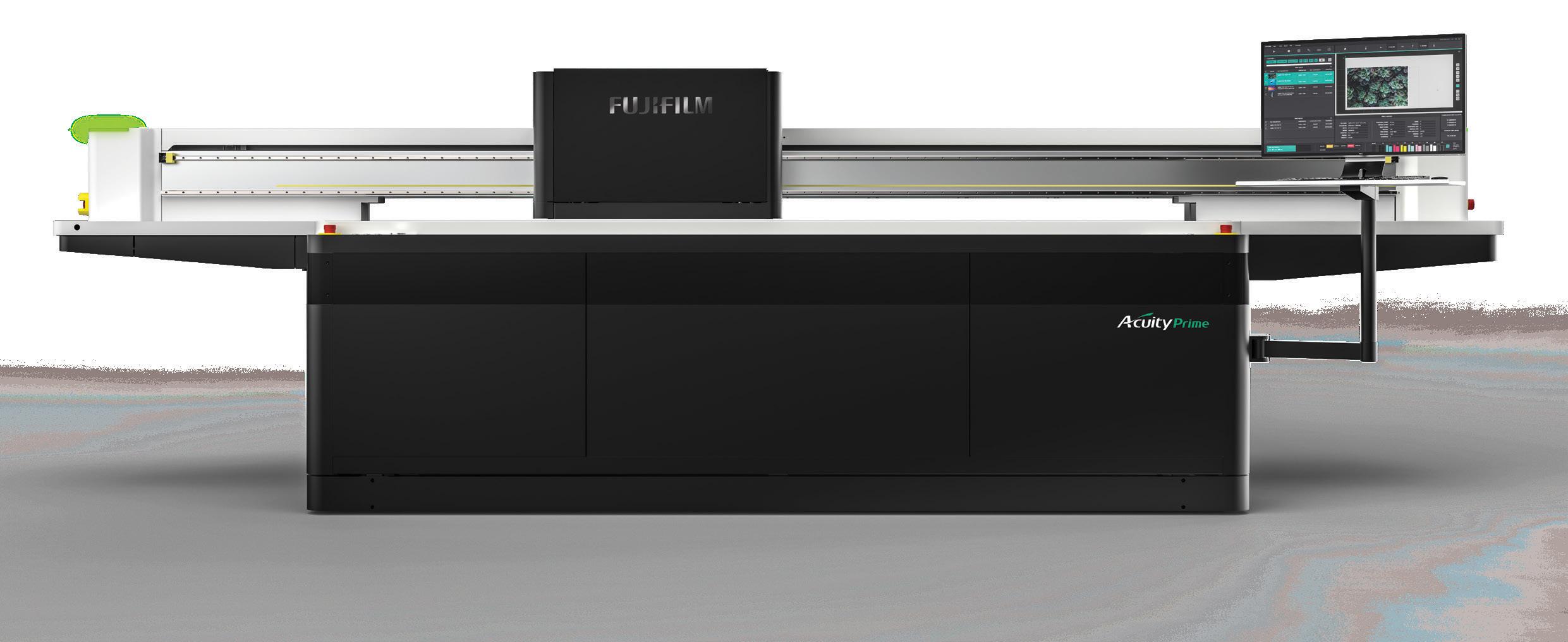

The new Acuity Prime FB30 and FB20 flatbeds offer high quality printing on a range of medias, supported by its five dedicated vacuum zones and optional jettable primer. This range is available at a cost effective price point and offers an excellent return on investment, and once you’ve had it installed, FUJIFILM’s nationwide service network will keep it printing!

With outstanding image quality and excellent adhesion to a broad range of rigid and flexible media, materials and objects, the Acuity Prime can produce an amazing variety of printed products for distance and close viewing. The vacuum table can handle almost any sheet material. It secures rigid and flexible media and holds it perfectly flat for high quality print across every sheet.

The option to print with white and clear inks, and to print directly to almost any material in perfect registration, enables the Acuity Prime to produce high value, creative work that could offer opportunities for new revenue. With the jettable primer option, the Acuity Prime can adhere to a wide variety of industrial media.

At Fujifilm we understand the value of production time and usability, so we designed the Acuity Prime with the operator in mind. With a new and user-friendly GUI, easy clean printhead maintenance and visible status lights for the ink tanks, operators are able to spend less time maintaining the machine and more time printing.

With variable drop-size printheads and highly pigmented inks, Acuity Prime printers lay down a thin ink film, which minimizes production costs, and in combination with a competitive system price, support an excellent ROI.

For more information contact the Wide-Format Team on 0800 242 646.

Finance avaiable though

Cover Story p16-18

In an ever-changing industry, Computaleta continues to lead, expanding its offering and winning awards along the way as it celebrates 40 years serving the industry

28 Aarque: The Arizona 135 GT continues a tradition of high quality wide format print production

30 printIQ: Home grown print software success story printIQ has joined forces with Banyan Software to expand its operation

34-35 Currie Group EFI: Powerpac has installed a new EFI Pro 30h printer, supplied through Currie Group

36 NZSDA Update: Melissa Coutts discusses timeboxing and how it can help your workflow

36 NZSDA Secretary: How can you attract new staff members and retain the ones you have?

37 NZSDA Signee: Napier’s HF Signs has over 60 years’ experience contributing to the look of the city

38 NZSDA President: Andy Lowe says signees need to invest in more diversified training and increase public awareness of their capabilities

14-15 Konica Minolta: Paeroa-based Goldfields Print & Packaging has installed the country’s first AccurioPress C7100

20 Fujifilm Business Innovation: A new Revoria Press PC1102 is making a huge difference at The Big Picture

22 GLC: The embellishment specialists at GLC have made some recent changes to the company

24 Think Laterally: If you feel alone in this industry, Mick Rowan has some advice about the support you can access

26 HP: Bringing virtual reality to your print shop, Currie Group and HP share the latest advances in technology to make your life easier

40 People in Print Awards: It’s time to send in your nominations for the People in Print Awards

PrintNZ p8-12

8 Comment: As the Pride In Print Awards approach a big milestone, Ruth Cobb shares some tips on how to successfully enter the competition

10-12 Helping Hand: 10-11 Helping Hand: The PrintNZ Board welcomes a new member and farewells another, Iain MacIntyre has the details

Advertiser’s Index

Aarque Group 7, 29

APM (New Zealand) 7

Cardy 25

CCGNZ Group 31

Computaleta 1, 19

Contact Labels 7

Currie Group (NZ) 7, 33

Cyber (Aust) 44

Eamar Plastics 42

FUJIFILM Business Innovation 21

FUJIFILM NZ 2

Graphic Lamination & Coating 5, 23

Konica Minolta Business

Solutions New Zealand Ltd 13

NZSDA 37

Pride In Print 43

Print NZ 9

Think Laterally 42

VPR Ltd 42

Wholesale Print 41

DSCOOP, the HP-based digital print and design community, has joined the Sustainable Green Printing Partnership (SGP). Marcia Kinter, co-founder of SGP, says, “By collaborating with Dscoop, the SGP Community can raise the level of sustainable practices in the printing industry. Our industry and our customers are setting ambitious sustainability targets for the printing industry to reach those targets, there must be transparency along the entire supply chain. This is where SGP and Dscoop can help with education and public certification criteria.”

UPM has received a platinum level rating from EcoVadis based on the company’s sustainability performance in four categories: environment, labour and human rights, ethics and sustainable procurement. Only one per cent of the 90,000 global companies assessed received the platinum score. Sami Lundgren, vice president of Responsibility at UPM, says, “The main improvement steps were taken in the labour and human rights category. We have introduced several new social responsibility targets for 2030.”

KOMORI has relocated its global parts centre to its Tsukuba Plant site to ensure a more stable parts supply. Goals and strategies aligned with the relocation include more effective use of space and securing of parts inventory by installing large movable racks; improved inventory management accuracy through the introduction of a real time visualisation system for inventory; shortened lead time for parts supply with minimum downtime; prompt delivery of parts by improving the convenience of both land and air transport; and shorter parts dispatch time.

Screen GP has introduced a new high opacity white mode for the Truepress Jet L350 UV SAI S inkjet label printing system, available as a retro-fit to existing Screen Truepress Jet L350 SAI installations, or as an inclusion in new installations.

Screen says white ink, most commonly applied as a base layer on coloured, metallic, or clear stocks, is used to overcome the colour, or translucency, of the substrate, providing a white background or base. On clear substrates and clear bottles, white can prevent light from passing through and washing out and affecting other colours.

However, if a bottle or package’s contents, for example, are darkly coloured,

the colour may show through a label, affecting the impact of its design. Screen says this has become a point of concern for printing companies seeking higher quality where fundamentally translucent media is concerned.

The company says its high opacity white mode, when used with clear film or similar labels, provides more opaque white, preventing the colour of bottles or package contents, from showing through. It adds that this helps to maintain rich colour saturation,

HP has appointed Brad Pulford to the position of Australia and New Zealand managing director.

He replaces Michael Boyle who will relocate to Barcelona to take up a new role as HP’s global head of wide format.

Pulford has served as HP managing director for Africa since 2020 and will commence his new role from

November 1, 2022. HP managing director

Greater Asia, TC Ng, confirmed the appointment in a statement. He said, “Brad Pulford has successfully led our Africa business since 2020. He will continue to serve as Africa managing director until November 1, and the search for a successor is underway. Brad is a highly accomplished global

ensuring high quality labels with eye catching visual appeal, even when applied to translucent base materials.

Several sectors now welcome UV inkjet-based digital printing as a substitute for silk-screen printing. These include the liquor, cosmetics and toiletry industries. Screen says that digital printing offers numerous advantages, including shorter turnaround times, lower costs and reduced environmental impact, and demand is expected to grow consistently going forward.

executive, with a passion for technology advancement and business transformation.

“Anyone that has worked with Brad knows him as a very effective leader who embodies the HP values and we look forward to welcoming him and his family to the ANZ business in the coming months.”

Boyle is currently still in Australia working across both the ANZ vice president and managing director and global head of large format roles until he fully relocates to Barcelona as of January 2023.

Durst has announced upgrades to its Taur RSCi label printer.

Dan Mantel, technical sales manager for Durst Oceania, says, “The Tau RSCi label printer now has the option to fit another print bar to add another row of white print heads to the arrays. You will now be able to put down the same amount of ink but at a much higher speed. It will take the RSCi from 52 linear metres per minute to 80 linear metres per minute with the fastest white in the market without using any more ink.

“It also has the option to be equipped with two flexo

stations. One is before and one is after the digital print unit. This allows us to enter into some of the more technical markets like shrink sleeves and in-mold labels at 510mm wide and at a maximum speed of 100 linear metres per minute.”

Martin Leitner, labels product manager at Durst, says, “With these improvements, we can now produce in-mold labels for products like 25 litre paint buckets. IML labels for this application are 90cm or 100cm long and also wide. So we now have the perfect solution for the customer with a 51cm wide press, and we

Esko and GMG have created a connector between GMG’s profiling and colour prediction solution, GMG OpenColor, and Esko’s native prepress editing software, ArtPro+.

The collaboration aims to create a smoother and more efficient colour conversion process for packaging and label printers; trade shops; and pre-media houses.

The companies say the connector enhances the connectivity and data exchange between the two solutions, ensuring uninterrupted file processing and colour conversion and retaining critical metadata between systems, allowing both solutions to operate at their best.

Geert de Proost, director of product management at Esko, says, “Colour management is a complex

process and hugely important because there is no single quality standard that you can work with.

“The manual re-separation of images and artwork to match brands’ colour accuracy demands can be a laborious and error prone process. Automating the re-separation using the connector enables prepress professionals to accurately visualise colour in before and after states. Also, they can assess colour deviations on screen with precise Delta E readouts.

“ArtPro+ can modify colours, making it simple and quick to add file edits after conversion for multicolour process printing; and enhanced colour precision on press through standardising colour conversion using GMG’s enhanced spectral colour technology.”

don’t have a limitation in the repeat length. For large IML labels, there is now a digital solution on the market today, and it’s ours.

“We are also offering, for the first time in this model, the option of nine colour channels: CMYK, orange, violet and green with a dual white. We have learned recently from customers in the hair care and personal care markets printing labels for products such as shampoos or soap labels; they have requested more productivity on the white.”

EPSON has been included in the FTSE4Good Index Series for the 19th consecutive year. The FTSE4Good Index Series measures the performance of companies that demonstrate strong environmental, social and governance practices. Epson sees its inclusion as objective evidence that its efforts to address environmental and social issues are recognised, and that it is seen as a sustainable company. Epson says it is committed to cocreating sustainable and enriched communities.

SIEGWERK has received the EcoVadis Silver Medal rating placing it in the top 15 percent of companies in the manufacture of paints, varnishes and similar coatings as well as printing ink. Alina Marm, Siegwerk’s global head of sustainability and circular economy, says, “The Silver Medal is a testimony to the effort and focus we have put on building a leading role in the realm of sustainable business practices in the inks and coatings industry. We strive to increase sustainability in our operations and with our value chain

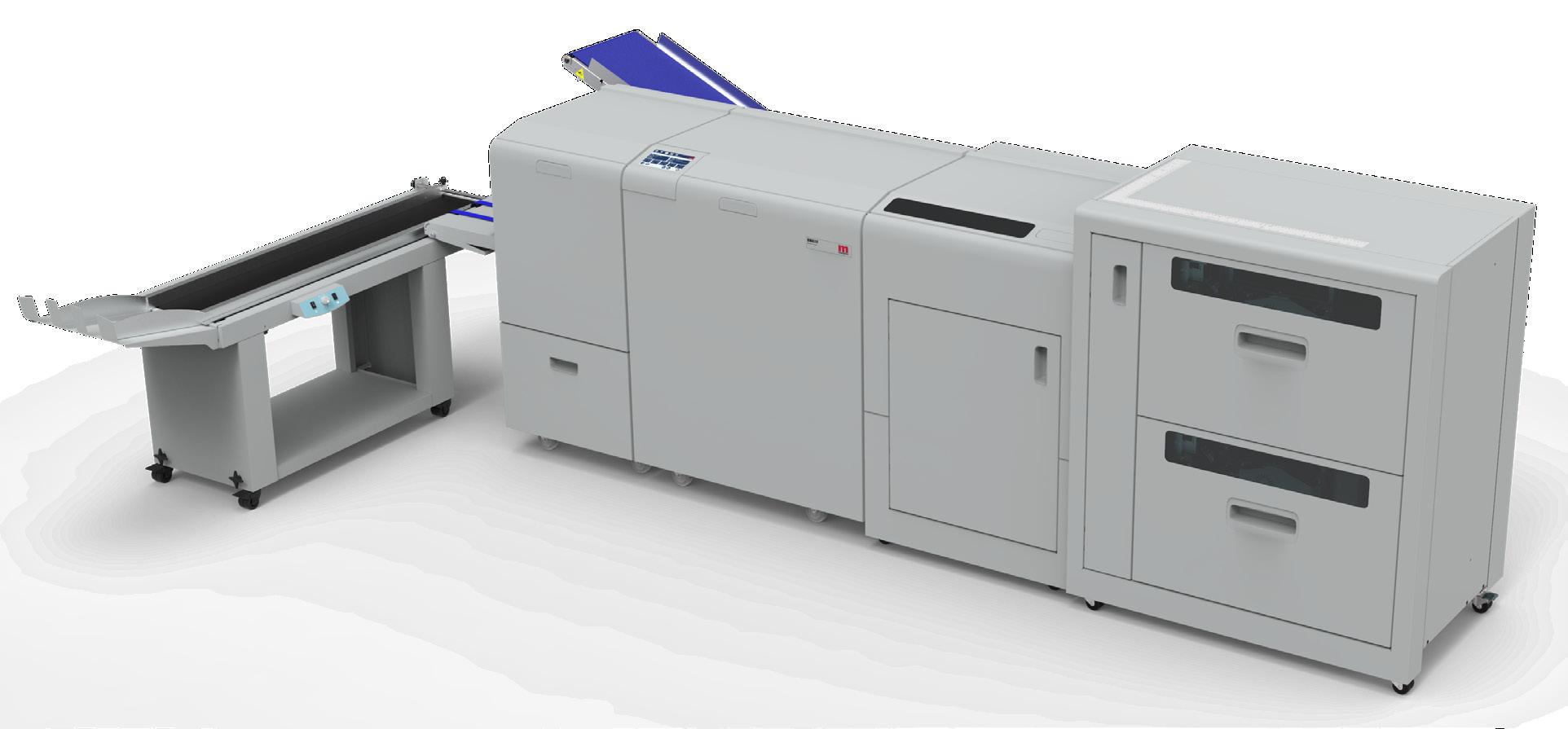

The new Plockmatic BM4000

bookletmaker

Plockmatic Group has announced the release of its BM4000 Series bookletmakers.

The new machines can staple and fold booklets of up to 140 pages (BM4035) or 200 pages (BM4050). Both models handle A6 size booklets up to A4 landscape and the 297mm X 297mm format. Plockmatic has designed these bookletmakers to work with low to mid-volume digital production printers.

The company says the new machines deliver booklets of exceptional quality, handling long printed sheets to produce a variety of work, including A4 landscape. Operators can produce corner or edge stapled documents along with regular spine stapling.

For booklets of up to 200 pages, operators can either hand feed in the most basic configuration or feed using the Plockmatic VFX high-capacity dual bin

Book publishing continues to grow across the country, according to the Publishers Association of New Zealand, Te Rau o Tākupu (PANZ), which has highlighted key findings from its recent survey results in its Book Industry Market Size Report.

Looking at the shape of Aotearoa New Zealand Publishing, the survey finds the local book market buoyant. Trade publishing has grown 6.7 per cent on the pre-pandemic level, and Te Reo Māori publishing rose with over 40 per cent growth in sales year on year from 2019.

The rest of the book market has remained constant with similar data emerging from last year. The market grew

feeder. The Crease and Side Trim module (CST), allows full bleed production with no need to side trim sheets on the guillotine prior to production. The system supports printed sheets of up to 660mm long (without the CST creasing and side slitting module) or 620mm (with CST). You can add bar code reading to the feeder to ensure set integrity or for variable data or variable sheet count booklets.

In a new design, Plockmatic has produced the combined square folding and face trimming unit in a single compact module. It says that square folding functionality enables bookletmaking on a wide range of media and booklet thickness.

For larger volume production, Plockmatic offers a high capacity belt option. You can configure it straight or in a 90-degree angle. It attaches after the

three per cent in 2020 and held steady across 2021 with a further 0.7 per cent growth and New Zealand educational content sold domestically grew by six per cent.

Physical books show no sign of disappearing anytime soon. Over 90 per cent of New Zealand’s book market value is in print formats. Both digital and print formats have seen nearly 10 per cent growth on 2019 values.

Nevena Nikolic, territory manager, Nielsen BookData New Zealand, says, “The New Zealand publishing industry once again proved to be resilient in the face of the many pandemic-related challenges, on top of which were added, inflationary pressures, paper shortages, and further supply chain issues.

“Also, many of these issues affected publishers globally so were not unique to New Zealand. However, they were exacerbated by our geographic location and further distance from the main

standard output tray. This allows for unattended runs and it stacks up to 1,000 A4 booklets of four pages.

The heavy duty staple mechanism, designed for durability, is maintenance free and uses a patented solution that eliminates periodic service intervals. With its adjustable staple and fold position, the BM4000 Series has a patented set positioning mechanism. This allows the operator to adjust the staple position in the direction of travel via the intuitive user interface.

The Plockmatic VFX, a two tray, high capacity vacuum feeder, can feed a range of paper types and weights, with sheets up to 660mm. Equipped with automated vacuum feeder, it handles a range of pre-printed media. An automatic tray switching feature enables unattended runs and the loading of empty trays during a run.

supply warehouses based in Australia.”

Post-pandemic, PANZ has focused on rebuilding export markets, which provide vital income for New Zealand authors and publishers. The export market saw a one per cent growth in exported titles. Australia continues to be the dominant export market for the book trade. It showed 10 per cent value growth. In education exports, China just edged out the United States as the key export market holding 33 per cent of all export revenue for the first time.

PANZ president Graeme Cosslett, says, “PANZ has a vision for a thriving, sustainable and inclusive publishing industry for local and global readers. Whilst the global pandemic continues to present challenges, the New Zealand publishing industry has held steady when compared with 2020.

“This report shows our industry remains resilient, sustainable, and in good heart.”

industry that embrace the core values of sustainability, innovation and wellness.

In 2023 there will be further category updates to reflect changes in the publications and packaging sectors as we align them to current practices and technology. The recommendations for change come from both within the industry and from the judging experts and are then endorsed by the committee to ensure they reflect the spirit of the Awards programme.

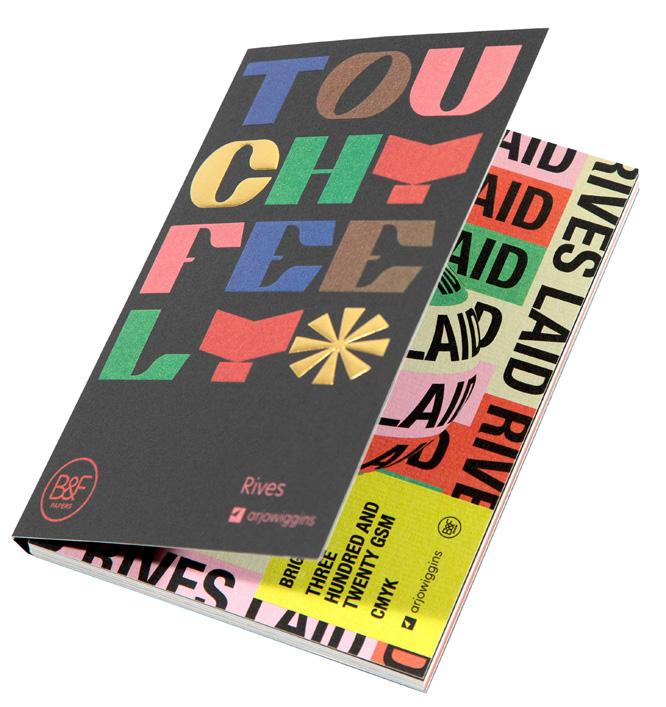

Logick Print won the Supreme Award at this year’s Pride In Print Awards with Touchy Feely, a promotional pocket book of embellished stocks commissioned by B&F Papers

The Awards are run by a committee made up of industry representatives from the Designers Institute of New Zealand, the Print Finishers Association, PrintNZ, Pride In Print New Zealand, Plastics New Zealand, We Print, the Quick Printers & Copy Centres Association, the Sponsors’ Representative, the Patron of the Awards, and the Self-Adhesive Label Manufacturers Association.

1. A simple job won’t win: Not true. If it is perfectly printed, it will receive the recognition it deserves. Degree of difficulty is taken into consideration, but perfect is perfect.

2. You can’t compare a digital job to an offset job: True – and we don’t. Each job is judged on its own merits and takes into account the processes that were used to print it.

3. Judges are judging their own work: Not true – judges step back from any work that has come from their company and this is strictly enforced.

4. My job didn’t win for no good reason: Not true – a job can only be rejected once three independent judges have confirmed there are faults with the work, and they are recorded on a sheet that is then returned to the entrant once the Awards have all been announced.

RUTH COBB

Established in 1993, the Awards have a goal to promote excellence in print in New Zealand, recognising and celebrating technical skill and innovation created by an industry that continues to expand its horizons and raise the bar.

But they are more than the pinnacle of recognition of the finest in printing and packaging. They embody a culture of excellence aimed at providing solutions for the buyers of print year after year and reinforce the key role that print plays in so many aspects of business and life.

The Awards programme has gone through quite a metamorphosis over its 30 years and continues to evolve today. Each year, they are tweaked and updated as we make sure the Awards remain relevant and reflective of the enormous advances our industry has made across all sectors. In 2021, we expanded the Awards programme to introduce three new awards to recognise the businesses in the

The committee is responsible for the overall approval of the annual programme including categories, budgets, expenditure, campaign content and the Awards event. These people all volunteer their time and we are extremely grateful for the well-considered input they provide.

The Awards are judged by a broad panel of industry experts that are nominated by both the committee and their industry peers. The judges are put into teams based on their expertise, and are allocated work that is relevant to their field. Each team also has judges that cover the overarching aspects of the work including design, prepress and print finishing.

We try to ensure that judges are rotated on a regular basis so there is always fresh blood on the teams. New judges often comment that being part of the judging panel is an eye opening experience for them, as it shows the depth of technical expertise that is in the room, and the absolute scrutiny that each job goes through before decisions are made.

Here, I have listed some of the common misconceptions we hear about judging:

5. The judges didn’t understand the entry: Could be true if you didn’t supply sufficient information on your entry form. If the entry has a story to go with it, tell the judges. They pay a great deal of attention to the information that is provided with the entry; the more you can tell them, the more they will understand it.

But most obviously, you are not going to win if you don’t enter, so start getting your entries ready. Entries will open shortly and work printed between January 1 and December 31, 2022 will be eligible. If you haven’t entered before, or have been disillusioned in the past, give it a go. These awards are not just recognition for your business, but for the hard work your staff put into the work they produce, and for your customers choosing to print.

I was part of the management team for the very first one and am thrilled to be part of the management team for the 30th, although maybe I shouldn’t be admitting that!

It’s going to be a special celebration on June 23, 2023 in Auckland. See you there as you collect your commemorative gold medal.

She says, “Every member of the board brings their own experience and a unique view of the industry which contributes to the strategic direction of the organisation.

“We are lucky to have such committed members that are willing to participate and it is a pleasure to work with them.

She adds that David’s marketing experience will be a “huge asset” to the organisation. She says, “Particularly as we look to promote the efficacy and sustainability of print and paper to a broader audience. His ability to think outside the square and his passion for sustainability will be valuable, and we look forward to the contribution we know he will make.”

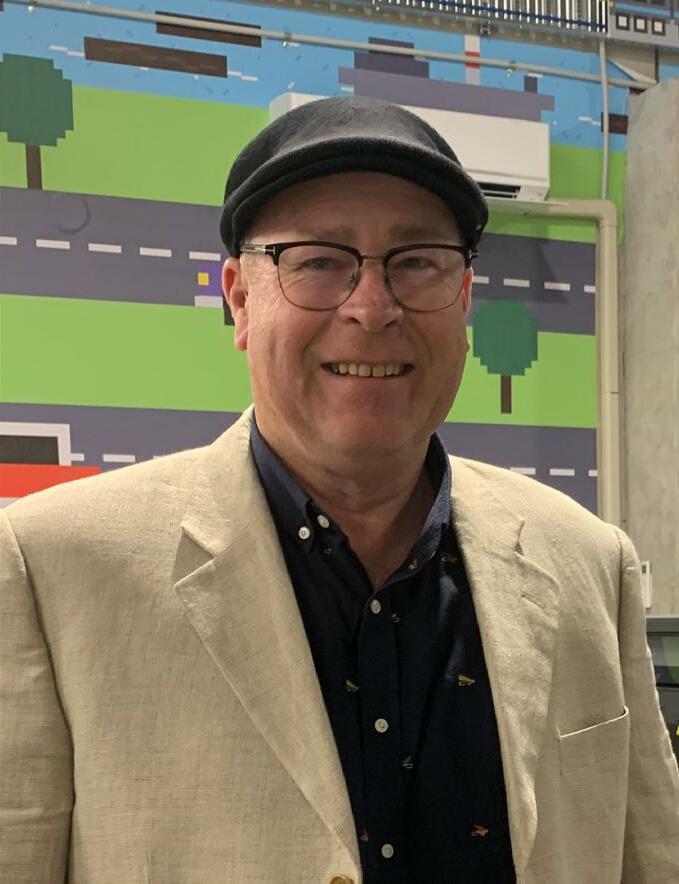

PrintNZ has welcomed CQ Group co-owner David Parsons onto its board and expressed appreciation to Images Unlimited managing director Jonathan Lewis for his six years of service.

Ruth Cobb, chief executive PrintNZ, says the board has a rotational policy which recognises the importance of ensuring that its make-up is not static, allowing for new blood and fresh ideas.

“Jonathan Lewis has made a valued contribution, particularly his insights into the sign sector of the industry. This is an area of expansion for many of our members and having Jonathan’s knowledge has been invaluable.

“A huge vote of thanks goes to him for his time on the board, especially through one of the most difficult times our industry has experienced.”

CQ Group, the multi-faceted Christchurch printing firm that Parsons founded over 20 years ago, has a slogan of ‘printing for good’.

Parsons says, “I feel passionate about print and its future, particularly in relation to sustainability and

environmental impact and perception around print.

“This is something that needs to be forefront of our minds as this, I believe, will be a challenge going forward with the new generation. Moving away from plastic to paper products is part of the opportunity for print.”

With marketing one of his strengths, Parsons says he has been known to view situations, concepts and ideas from a different perspective. He says, “I would like to support the other board members in bringing about change where needed and looking for new opportunities that may help in any areas of PrintNZ.

“I would like to thank PrintNZ for giving me this opportunity and hopefully I will add some value for now and the future of print.”

Parsons commenced his career with Xerox in 1982, initially as a salesperson of analogue copiers in Christchurch, before moving to Auckland “to sell copiers to accountants and solicitors”. Subsequently joining Panasonic, as a salesperson of computers and copiers, he then relocated back to Christchurch “to be closer to family for our daughters”.

He continues, “An opening was available in Konica Minolta (Ubix at the time) in sales before moving to open up the first Ubix Copy Centre in Christchurch.”

In 2001, Parsons and wife Nicolette, launched their own all-digital print centre, Copy Quality. He says, “It was all very new technology and a new type of print business model, being all digital. Later we added wide format, and a scanning and archiving service.

“Nicolette left her sales job to join me in the first week to run the accounts and staff, and we still work together 21 years later.

“Christchurch is an interesting and challenging place to do business, especially since 2009 when we had our first earthquake. We have been through a lot and this continues with the current times. Christchurch is quite distinctive in that the businesses have managed to work together a little more than some cities, maybe because of what we have been through.

“Having our CBD totally vanish overnight gave us a new perspective on business. It also gives us, as it does for Christchurch printers generally, an advantage over the rest of the country as our CBD and surroundings continue to rebuild and flourish.”

The couple have also been involved in establishing the Heartlands Ashburton and Timaru print centres. Clarity Press, a small offset business, became a sister company in a separate location before the two businesses were combined in the firm’s current location.

Looking forward to now turning greater focus to his own signage solutions business, Jonathan Lewis says it has “been an honour” to serve on the PrintNZ board over the past six years.

He says, “It is something that I have enjoyed immensely, but I do feel it is probably time for fresh blood and for someone else to take over my role there.

Reflecting on the period, Mr Lewis says one of the biggest challenges – and successes – for PrintNZ has been relevantly filtering and relaying global pandemic-related developments to members.

“The Covid-19 responses that we as an organisation, and chief executive Ruth Cobb particularly, were able to put out and the speed of that information, were really quite incredible.

“PrintNZ was able to get communications out to all of its members and nonmembers within hours of most of the Government announcements that were made over the Covid-19 period.

“We had the daily 1pm announcements and a weekly one that was usually slightly more important, so lots of information was being sent across the country, and PrintNZ’s ability to disseminate that information and put it into a useful email was fantastic.

“It is testament to Ruth really for doing that and it meant we had a source of accurate and timely information.”

Another highlight during his time on the board was how the organisation has navigated the “continual changes” mandated in the training sphere. He says, “We have worked very hard. We’ve changed into Competenz and from there into the new industry training organisations that are currently being put into place throughout New Zealand.

“Being able to support the message of print through that time and making sure that we did not lose our voice was a big thing for PrintNZ. Again, it was mainly down to Ruth and chair Tony Sayle.”

He has also particularly enjoyed being involved in the board meetings and interactions with other PrintNZ directors. He continues, “As a signwriter on the board, there were lots of different experiences from day-to-day business that my fellow board members had that I did not have. The highlight was probably learning more about their particular businesses, who they are, the challenges they face and I guess sharing my knowledge of what we were doing as well.”

Looking ahead, he sees technology providing a positive for the print sector.

“It is always going to be moving, it’s always going to be interesting and there are always going to be new challenges. While some of the more traditional print avenues are in decline, new markets are opening up all of the time and that’s an exciting industry for us all to be a part of.”

He sees recruitment as the major current challenge. He concludes, “The quality of the people we can find to drive the industry forward is going to be a significant driver of success. Recruitment is probably going to be the biggest challenge over the shorter period.”

the various bits and pieces on the C7100. We are still learning so much on it, which is very exciting as it expands the possibilities for print.

“In this short time, we are already seeing the benefits from having the C7100. The print quality is absolutely amazing. We have placed our old jobs side by side with the new work and the difference is impressive.”

The new AccurioPress C7100, incorporates many of the key features of the successful AccurioPress C14000 Series and AccurioPress C4080 Series.

From intelligent automation and enhanced finishing to quality, advanced capabilities, and exceptional durability, the new machine gives printers the power to grow their businesses through a press that works smarter.

Printing at 100 colour pages per minute, the AccurioPress C7100 enables printing of long sheets up to 1300mm and autoduplex sheet sizes up to 900mm, while having the flexibility to handle embossed and textured media.

Goldfields Print & Packaging has operated in Paeroa for over half a century.

Jacqui Buckton, managing director at Goldfields, says, “We print nearly everything except for cups, caps and t-shirts. We offer a range of stationery, commercial print and signage. We have done packaging work, since the early 1990s and that is now probably the biggest part of Goldfields

In May, Goldfields installed the country’s first Konica Minolta AccurioPress 7100. She says, “I had been working on getting a replacement for our old digital press since late last year. The C7100 has a number of features that make it an asset for us, for example, it handles stocks up to 400gsm and the paper suction prevents jamming, but it was the full package that Konica Minolta offers that made the difference.

“The team at Konica Minolta New Zealand is great. They are clued up

and we are really comfortable working with them. Our account manager Wade Marriner is really good, and the whole team helps our business.”

The AccurioPress C7100 works as a full service, end to end solution. She says, “We wanted the capability to offer small, medium and large runs. The C7100 means we can offer our customers smaller runs on the packaging side. We use it as part of a full end to end solution for our packaging work.”

For this end to end process, Konica Minolta has placed automation into its range of finishing options. This enables Goldfields to move the print job from prepress to invoicing in the fastest time possible without compromising on quality.

Jacqui says, “The finishing unit is fantastic, as is the IQ unit. They have helped us improve our digital workflow. After the installation in May, we used June to get organised and to learn about

With a focus on optimising performance, offering new and advanced print products, and growing the entire business, the AccurioPress C7100 series is designed to complete more jobs with innovative technologies.

Other features include an optimised paper transport solution; a double swing registration system for improved paper compatibility and feeding accuracy; a more durable lubricated drum; and double corona wires with automatic cleaning.

From vinyl to digital

Graham Hill started Goldfields Print in 1970. Initially, three people worked in a rented corner of a warehouse, manufacturing circular labels for the centre of vinyl records for Pye electronics and the growing local music industry. Before long, Goldfields had the contract to produce full-colour gloss album sleeves for RCA records.

Jacqui joined the company in 2006. She says, “I had spent most of my life in film

and television. I moved to the Hauraki area and got a job as commercial manager for Goldfield’s Officeline business. I saw that as semi-retirement job but it has not worked out that way.”

In 2012, she bought the company. She says, “I am a printer now. Previously, I had commercial industry knowledge but not printing knowledge. I worked closely with the original owner of Goldfields when I first joined and I continue to learn more about printing every day. I enjoy the work and the people. My best week is when we have smooth production, a happy team and happy customers.”

As a commercial printer that offers creative customised packaging, Goldfields can produce smaller size runs economically for boutique businesses as well as larger carton runs for its corporate customers. The AccurioPress sits comfortably in this environment, which also contains some quite old machinery. She says, “We have a number of old machines that we still use, such as our

pad machine from the 1930s. It is so old that someone has placed a T-Rex on it.”

“We are a manufacturing plant and we can do everything from start to finish, and that includes trade work for other printers. We still create docket books and NCR books.”

The company’s history with printing record labels and covers caught up with it during the recent revival in vinyl record sales. She says, “For a period, we had requests for labels and covers again but that has since subsided. It is still cool going into specialist shops that sells records from that time and seeing ‘printed by Goldfields print’ on them.”

Teamwork forms an integral part of the work at Goldfields. She says, “We have five full-time staff and another three part-timers. Having a great team means we have been able to get through these times with Covid-19; we worked through it. We were lucky to have customers who needed essential work

“It will take a while to recover from everything that Covid-19 brought, but we feel fortunate that we long standing relationships with our customers. They never went away during the worst of the pandemic, so when everything started returning, we were able to pick up again.

“Right now, the hardest challenges we face are the ones that are basically out of our control, like the freight. Trying to obtain stock and also running short of stock. With the problems in the whole supply chain, we can’t ensure that material is always available, so we have had to go back to the customers and discuss the work.

“Of course, the cost of everything has risen, nearly 25 per cent in some cases. We don’t want to have to pass it on. In some cases, we have had to change our suppliers. We have had to work out who can give us great customer service for what we need at the price we can afford.

“We focus on the customer. Great customer service is what makes us thrive. Word of mouth is really helpful as well. When we get a new customer, we do whatever we can to meet their expectations. We have some customers who have found the grass is not greener on the other side.”

Goldfields has a rich heritage and a bright future in print. Konica Minolta will play a significant role in that. Jacqui adds, “While it is early days with the AccurioPress C7100, we are enjoying what it can deliver. We have a great relationship with Konica Minolta. They quickly take care of any issues that we have, which is impressive because we are in Paeroa. We don’t have much downtime when we have a problem because they are very efficient.”

Celebrating 40 years, industry stalwarts Computaleta continues to lead in an industry of change.

In the last three years, Computaleta has expanded its offering to the sign and print industries, setting a fast pace that shows no sign of slowing.

After making the decision to return to supplying hardware, Computaleta partnered with graphics giant HP for its Latex printing technology. With their environmental credentials, the latest HP Latex wide format printers fit well with Computaleta’s intention of helping industry professionals to provide more sustainable options to their customers.

Computaleta exceeded all expectations with HP and earlier this year, it won the HP Digital Manufacturing Partner of the Year Award. Mike Jamieson, sales director for HP New Zealand Enterprise, said,

“Computaleta just goes that extra mile for its customers and for us. Their willingness to work together in a collaborative and transparent way means they are a highly engaged partner that delivers a lot of value.

“What’s great about the Computaleta team is they are willing to listen and try new things and that has been hugely successful for them and us in the past year. They always have the stock and supplies on hand that are needed by their customers and they seek advice and offer us solutions which means we can collectively deliver the best outcomes for our customers.”

Not resting on its laurels, Computaleta has also partnered with Summa to supply its flatbed and roll cutters. Aaron Kemp, hardware manager at Computaleta, says his experienced team are passionate about ensuring all customers get the support they deserve when buying cutting equipment, be that a small roll plotter or when making a significant investment into a digital flatbed cutter.

“We bring Computaleta responsiveness when it comes to selling and supporting hardware equipment and are very excited to now offer that same support with Summa.”

Another recent addition is Osram, the German multi-national lighting giant. Computaleta now provides Osram LED modules and drivers for illuminated signage to the New Zealand market. Of

particular interest is Osram’s patented square lens technology, which achieves ideal uniformity by reducing black spots, decreasing the number of modules usually required and lowering overall system costs.

Signwriter and LED lighting specialist, Aaron Morrison heads up Computaleta’s Lighting Division. Osram has won numerous high profile awards for its sustainability and for the quality of its technology.

Darren Miruzzi, head of sales for Osram Australia and New Zealand, says, “We are excited to team up with Computaleta because of what it represents in the New Zealand market: an excellent reputation, an enviable market network and, most importantly, a comprehensive understanding of the signage industry.”

The recent addition of a large warehouse in Albany, on Auckland’s North Shore, is adding capacity for Computaleta to better forward order and stock more products; a smart move in light of the global supply chain issues. As part of the company’s growth strategy, it will eventually be home to a new flatbed showroom for its hardware portfolio.

The new building also complements Computaleta’s large warehouse and branch in Onehunga, as well as its four other locations throughout the country.

As the only nationwide family-owned graphics supply company in New Zealand, Computaleta continues to bring best in class solutions to its customers.

The company’s customer focused philosophy comes from its founder, industry innovator Noel Morrison, who brought the first computer and vinyl cutter into the country in 1981. Noel established the company in 1982 and he grew the business as the industry evolved alongside it.

As one of the Kiwi pioneers who ushered in a new era of signage and printing, Noel welcomed his daughters into the company. First Arlette and Adele in 2009, and more recently Janene.

These three women, shareholders and directors, have taken up Noel’s challenge

“to help our customers bring their ideas to life through signage and print”.

While they are not the only women running a company in New Zealand, they do occupy a distinctive position in the signage and print industries, which have a preponderance of male owners and managers. Arlette says, “Interestingly, one of Computaleta’s longest-serving managers is Irma Turnbull, who runs Computaleta Hamilton, and Wendy Beyer who is our Wellington Branch manager. Collectively they have been with us for 52 years, so we have always had strong women involved in the company.”

When Arlette and her two sisters took over the company’s management the industry was going through a decade of profound change. Significant mergers and acquisitions amongst competitors and customers alike, saw boundaries merge between signage and print.

Securing new hardware brands has allowed Computaleta to diversify their offering and stay relevant as they move into the next phase; industry sustainability.

“When you have such an enormous depth of history behind you, staying relevant is the greatest challenge. Knowing what the next drivers of your business will be and being at the cutting edge of that is critical. When you have generations behind you, protecting our industry and our business for that next generation has become our central driver. I feel with the new brands we have on board, and the significant growth they are contributing, secures that future.”

“However, our greatest strength is the quality of our team members. Their value to the industry is immense and we take great pride in featuring five of them in this story.”

One of Computaleta founder Noel Morrison’s three daughters, who now collectively run Computaleta. Janene is the most recent family addition to the company, having joined in 2017.

Arlette says she spent a good year twisting Janene’s arm to return to Computaleta.

Arlette says, “Many people don’t realise that Janene is a heavy hitter. We needed someone in our business with her skills and experience to help us lock in our processes and deliver for our customers as our business grew.

“Janene was working for a sizeable Australian firm at the time and was in charge of over 600 employees and half a billion dollars in revenue. She took some convincing, but I got her back to New Zealand to oversee our company-wide operations. Without her, we would not be as strong as we are in delivering on our promises.”

He says, “I have been fortunate to work with and learn from several companies over recent years and have found my niche at Computaleta, a forward-thinking and iconic company in the printing industry.”

When Computaleta announced it had secured distribution for HP Hardware in December 2020, Aaron Kemp jumped at the opportunity to get back to doing what he loved with a brand he enjoyed.

With 15 years of experience in capital equipment sales, he also wanted a chance to work in a family-owned business similar to the many years he spent as a key account manager at Jenrite.

As Computaleta and HP embarked on their supply partnership, Arlette started to put together her dream team. With experience in software and hardware, Alex Tse was at the top of her list.

“With his software knowledge, Alex is the company’s colour management specialist as well as an expert engineer in production machines. He has a background with HP as its former Solutions Centre manager in Hong Kong for many years and has a deep understanding when it comes to HP Latex.”

He says, “I love working for this friendly family orientated business. We have a flexible attitude to problem solving and it is useful for me to speak to customers directly; they don’t have to worry about talking to someone else at a call centre. Having been in the industry for 20 years, I think it is great that I am always learning something new, and I love the interaction with our customers and everyone here at Computaleta.”

Arlette says that Deena’s reputation speaks for itself with over 15 years of experience within the sign and print industry. Her work has covered customer service, operations, technical and, for the past 10 years, as Computaleta’s key account manager in Auckland. Her knowledge of print and signage products runs deep.

Deena says, “I love what I do, and the industry is always exciting. Computaleta has been a distributor to the industry for 40 years, and my team has a wealth of knowledge and experience ready to share.”

One of Computaleta’s longest-serving employees, Irma joined the company 26 years ago as branch manager in Hamilton. Since then, she has single-handedly developed the Waikato and Bay of Plenty regions for the company.

Before joining Computaleta, she worked in the science field as a lab technician. This has helped her as the technical knowledge behind how products behave during and after printing and installing, is a valuable skill.

Irma says, “I love my customers, and I enjoy helping them find solutions to their problems. I am their problem solver.”

Hamish says, “Currently, we are consolidating and streamlining. I have recently made the call to wind down our secondary location in Tauranga and bring the production operations down to our original branch in Wellington.

“The last couple of years have accelerated the viability of remote working, online ordering and the use of courier services for everything. As a result, our customers are becoming less and less location-dependent, to the point where having a second production location is no longer necessary.

“Operating as a single, streamlined operation encourages us to have more efficient, high end capabilities, like the Revoria, in one location, rather than adding more mid-range devices.”

Turnaround times continue to shrink. He says, “Customer expectations for turnaround times get tighter and tighter every year. We meet these requirements by bringing more work in house and investing in the best equipment to keep up with demand.

In April, The Big Picture installed a Revoria Press PC1102, supplied through Fujifilm Business Innovation, into its Wellington plant.

Hamish Woulfe, managing director at The Big Picture, highlights several features that enable the company to deliver high quality on demand print for its customers.

He says, “The special colours (white, silver, gold, pink, clear) and larger sheet sizes help us to expand our offering. The Revoria is a more advanced and robust machine in pretty much every way. It allows us to produce larger volumes and a wider range of products and services, all in the same shift.

“It has six bulk feed trays which help us run unattended for longer and/or keep our core stocks loaded and ready to go.

“Aside from the special colours, we are achieving great quality on our everyday CMYK work, with a good level of automated calibrations and minimal downtime.

“We are still just scratching the surface in terms of discovering new processes and products we can offer but one cool thing we can do is event accreditation. We can produce items like ID cards and Tyvek wristbands using special colours, like metallics for added security and counterfeit protection. I enjoy the creative

side of the business. As much as I should be working on the business instead, I still get a kick out of producing something special like combining metallics, white and clear.

“The Revoria replaces our Versant. Of course, it is more complex than the Versant, but it offers greater control and maintenance at the operator level, resulting in less downtime.

“The installation went well. Most of the Revoria operation was pretty familiar for our operators, after years of working with the lower level presses, but Fujifilm Business Innovation was there to talk us through anything new. They made the transition and upgrade as pain-free as they could, shuffling our different devices around during the decommissioning and installation phase to minimise downtime.”

Hamish started in the industry in 2009 while studying at Victoria University, He says, “It was a part-time job that turned into a side hustle, that turned into a print company.”

That print company has grown its range of capabilities to now produce digital printing and signage, anything from the business cards and brochures through to billboards and event displays.

“Our customers have broader product and service requirements: The market, for us at least, has changed over the last few years. These days, our clients want to reproduce something cool they have found online. So we face a constant challenge to source particular stocks or create specific effects that are outside the box. We like a challenge though; it keeps us on our toes!

“Like many others, we are seeing constant cost increases across the board with the accompanying financial pressure, but perhaps the bigger challenge is it just means we can’t relax and settle into this new normal that we have talked about for the past couple of years. Our suppliers and customers are all in the same boat with us, so we just need to communicate and ride it out together.

“Print will continue to change. While some parts of the industry will suffer, there are thousands of printed products that will never be replaced by screens. Print technology will continue to develop and remain relevant for many years to come.”

The Revoria forms part of that relevant technology. He adds, “We have been with Fujifilm Business Innovation since 2009 and we don’t plan on changing. They know our business inside out and have a clear understanding of our needs.”

Discover the power of orange in breathtaking detail.

From Specialty Dry Ink in the revolutionary Revoria PC1120 Press. Make neons and pastels pop with electrifying Pink Dry Ink that reproduces the colour gamut in crisp, vivid dimensions. Disocover a wondrous realm of possibilities.

To find out more, head over to fujifilm.com/fbnz

eventually returned to GLC. After managing GLC Wellington, he has returned to Auckland and is heavily involved in a new packaging venture, Total Pak, a GLC sister company.

Gary says, “The time that Dan and TJ worked in the factory while they were at school, has given them an appreciation of the business from the ground up.”

As a leading embellishment house, GLC occupies a distinctive position in the industry, enabling it to identify trends as they unfold.

John Jenkins says, “We have seen growth in foiling, especially in the packaging sector. Specialty laminations like antiscratch and velvet touch have become common as well as anti-bacterial and biodegradable films.

Graphic Lamination & Coatings (GLC) has a rich tradition of supplying high quality embellishments using a wealth of knowledge and expertise alongside dedicated machinery.

With operations in Auckland’s Penrose and North Shore as well as Wellington, the company provides a nationwide service for the industry. Across the Group, GLC employs around 26 staff.

Since its inception in the 1980s, the company has had to adapt to numerous changes in technology and the business environment. Directors John Jenkins and Gary Mathers have overseen GLC’s diversification of its finishing services from providing not only laminating, spot UV and foiling to adding coatings, wiro and tabbing.

John says, “As the industry continues to evolve, we adapt with it. We have also seen the consolidation taking place. GLC purchased Lamatex in Auckland and Clear Film in Wellington as part of that reality. For us, it is about ensuring that GLC customers receive the same high levels of service they are accustomed to. Within the factory, we also update the machinery, but we always keep the upgrades within the space of what GLC does. It is important for us to have a planned growth path.

“Another change that we have worked on

is the succession plan for GLC. Of course, Gary and I are very much still part of the industry, but we appreciate that we are getting older. We feel fortunate that we have younger people to take over. Gary is guiding the younger members of the team through the business and we are confident they have the capabilities to take GLC to the next level.”

When John and Gary talk about “younger members of the team”, they are referring to experienced and knowledgeable professionals, in particular Stu Dally, TJ Mathers and Dan Jenkins.

Stu Dally, who now manages GLC Penrose, has worked for the company for 22 years. After cutting his teeth in screenprinting, he completed a Diploma in Print Management. Subsequently, he transferred to the Wellington branch, which he ran for five years before returning to Auckland.

TJ Mathers, Gary’s son, now manages GLC Albany. He started in the business as a schoolkid, sweeping the factory floor. After finishing his foiling apprenticeship, he completed a Diploma in Print Management.

Dan Jenkins, John’s son, also worked on the factory floor in his school days, continuing into his university years. Dan completed a Bachelor of Arts in Psychology and Criminology and

The GLC team works with designers and prepress to achieve better results. Stu says, “The earlier we get involved, the better the results. We can give designers the advice they need to make their foiling designs work. Designers know what they want but they don’t necessarily understand the process required to get there. Part of our work is educating clients and their customers about what they can achieve.

“Sometime things have to be redesigned because when it isn’t designed properly, it increases manufacturing times; it increases costs; and we see greater waste. So often, with some of our big contracts, we see a difference in the original design and the eventual product.”

Knowledge and expertise matter in selecting the right process for each job. He says, “Some machines run certain products better in different ways. That is where we can make changes and move work around when needed; we know the different types of work required for each job.”

Gary adds, “A good example of how we work with the designer is the Webbs auction catalogue, where the customer did not want a debossed effect as this leaves an impression on the inside front cover. They preferred a raised effect. This led us to foiling first, anti-scratch laminate over the top of the foil, then applying a high build UV that gives the raised effect over the foiled and other areas which really makes the cover stand out.”

It can be tough running a printing company. The competition is fierce, the margins are often small, and it seems like every other business is out to undercut you on price. So, where do you turn for support? Surprisingly, there’s more help out there than you might realise.

Our industry is fortunate to have some excellent associations designed solely to support and promote print. Many provide education, training, and advocacy on behalf of their members. And they’re often run by industry stalwarts with decades of experience.

Take, for example, Print NZ. They work on behalf of New Zealand printers to ensure they’re kept well informed, educated, and connected to other likeminded businesses. But they also offer advice on employment, health and safety and act as a much needed voice at the government level.

Then there’s the NZ Sign & Display Association (NZSDA), whose goal is to expand the knowledge within the signmaking industry. The NZSDA offers advocacy services, recruitment solutions, events, and networking opportunities. They also work with local bodies on

by-laws that might affect signage and maintain the apprenticeship training standards to develop future craftspeople for the industry.

Or how about The Real Media Collective, which represents the users, producers, and distributors of catalogues, direct mail, print, paper and more across the entire marketing channel. They provide a wealth of well-researched and verifiable resources, including their ‘Value of Paper and Print’ (VoPP), campaign. VoPP raises awareness of the power of paper, print and mail marketing and supports members with marketing collateral, media representation and targeted consumer research. The Real Media Collective does an excellent job of promoting the effectiveness and environmental credentials of print media in the Australian and New Zealand markets.

One of my favourite industry promoters is Two Sides, created in 2008 by graphic communications supply chain members. Two Sides is a not-for-profit organisation that provides a forum for the industry to work together and share experiences that will improve standards and practices and maximise customer confidence in our industry.

They represent companies from forestry, pulp, paper, publishing, and printing to name a few, with a common goal of promoting the sustainability of the graphic communications supply chain. They also work to dispel environmental misconceptions about print. Two Sides have numerous resources that provide users with verifiable information on why print and paper are attractive, practical, and sustainable communications mediums.

And let’s not forget about our world-class local trade shows! PacPrint is the premier industry exhibition for the print and graphic communications sector. PrintEx for print, sign, wide-format, engraving, labels, and the packaging sector. And Visual Impact is the leading show for the region’s sign, display and graphics industries.

There are also events a little further afield, such as the incredible Hunkeler Innovationdays, drupa, Labelexpo and the various HP and Fespa events. These events expose attendees to a future they might barely have imagined while creating even more opportunities to chat with colleagues, customers, and competitors.

Undoubtedly, most business owners feel isolated at times, regardless of their industry. But having access to resources, seminars, and industry events can keep you informed and updated on equipment, issues and best practices and provide a window into a far bigger world.

The prospect of increasing your knowledge and learning more about what it takes to succeed in this industry or meeting with other professionals who can share their insights on equipment, trends and potential business opportunities is one we should all strive towards.

If you’re looking for support, whether that be advice, education, training, or perhaps an industry get together, there are plenty of organisations out there to help. I’ve only mentioned a few above, but please do yourself a favour and find a group (or two!), or an event to attend, that can help you and your business grow. You’ll be so glad you did.

Demand for short-run packaging has never been higher and continues to grow. With excellent print quality, and ability to print on flexible materials this easy to use equipment will be an asset in any print business. The FP-230 press is an economic, low waste setup press which when compared to traditional production methods such as Flexo and Roto, it significantly reduces plastic waste by using only 2.5m (8.2') of film for job setup In-house production of flexible packaging has never before been easier.

The new Afinia FP-230 Flex Pack Press has revolutionised label & packaging roll production. Impressively compact and easy to operate, the FP-230 lets you create high-quality, full-color flexible packaging with ease.

Ideal for small to medium runs and high levels of varying data or design, the FP-230 is a ground-breaking solution that opens the door to endless opportunities.

All on-site, all on-demand.

Following a hugely positive response to its debut at PacPrint, Currie Group has officially launched HP xRServices, a mixed reality platform which it says will transform not only service delivery on the company’s range of HP Indigo digital presses, but its entire product range.

Marcus Robinson, Currie Group’s director of operations, says the company has been working for 12 months to implement this unique support platform that connects print service providers directly with Currie Group and HP product specialists at the touch of a virtual button.

He says, “If you attended PacPrint in Melbourne, you may well have been able to experience HP xRServices or have seen other visitors on the Currie Group stand deeply engaged in activity using what appeared to be a set of virtual reality goggles. These were in fact the Microsoft Hololens 2 headset which give users the feeling of being actually physically present with a virtual HP technical expert, who can guide them through basic service tasks, production troubleshooting or training on HP and other equipment, in real time.”

Like other augmented reality platforms, the headset combines real-world visuals with superimposed information, allowing

the virtual coach to see exactly what the user sees, and collaborate to diagnose, identify and workshop issues.

Robinson explains, “We’ve been fielding requests for reliable remote support for years but, until now, we hadn’t found a system we considered reliable enough to bring to market.

“Now, with HP xRServices, we can confidently offer that virtual support drawing on the collaborative brilliance of HP and Microsoft in a print industry first.”

The technology, he says, is a ‘gamechanger’, with the virtual support person able to display on-screen information, photos or drawings, circle or highlight various things in the user’s field of vision, identify parts, share documentation or provide other commentary, and also provide real-time feedback on the operator’s actions and adjustments.

He adds, “The benefits are obvious: no time wasted on long service calls; instant answers to production questions; swift resolution of any problems; all leading to minimal downtime on systems and equipment.

“The system has also proven valuable for installation and training purposes, an

application that was successfully piloted during lockdown when technicians from Israel and Singapore collaborated with our technicians and CMYKhub staff on the installation of Australia’s first HP Indigo 100K Digital Press in Victoria.”

The innovative system has been specifically designed to support new or already-installed HP technologies with a high level of HP resourcing in the back end, but Robinson says it has now been made available for products across Currie Group’s entire range.

Robinson continues, “This broad application, together with the affordability of the subscription-based system, is generating plenty of interest, with users able to add it to an existing service agreement, or as a stand-alone service. We’re also still offering it at our special PacPrint promotional price, making it a ‘no brainer’ for many of those who have seen it in action.”

HP xRServices is just one example of how Currie Group is bringing even more resources to bear on supporting print service providers as they seek to successfully deliver on higher production targets in even shorter turnaround times.

Robinson says, “We have listened to our customers and responded with a differentiated service model which takes into account the delivery metrics businesses are subject to, and provides genuine value.

“Within weeks, we will also move to a ‘24/6’ support model which will see customers able to access technical advice and support 24 hours a day, six days a week, with our expanded technical support team.

“We’ll also be continuing to lift our service KPIs to further streamline call processing with instant call logging and response, extended remote support and reduced response times for on-site service, so printers can enjoy maximum uptime and maximum profitability.”

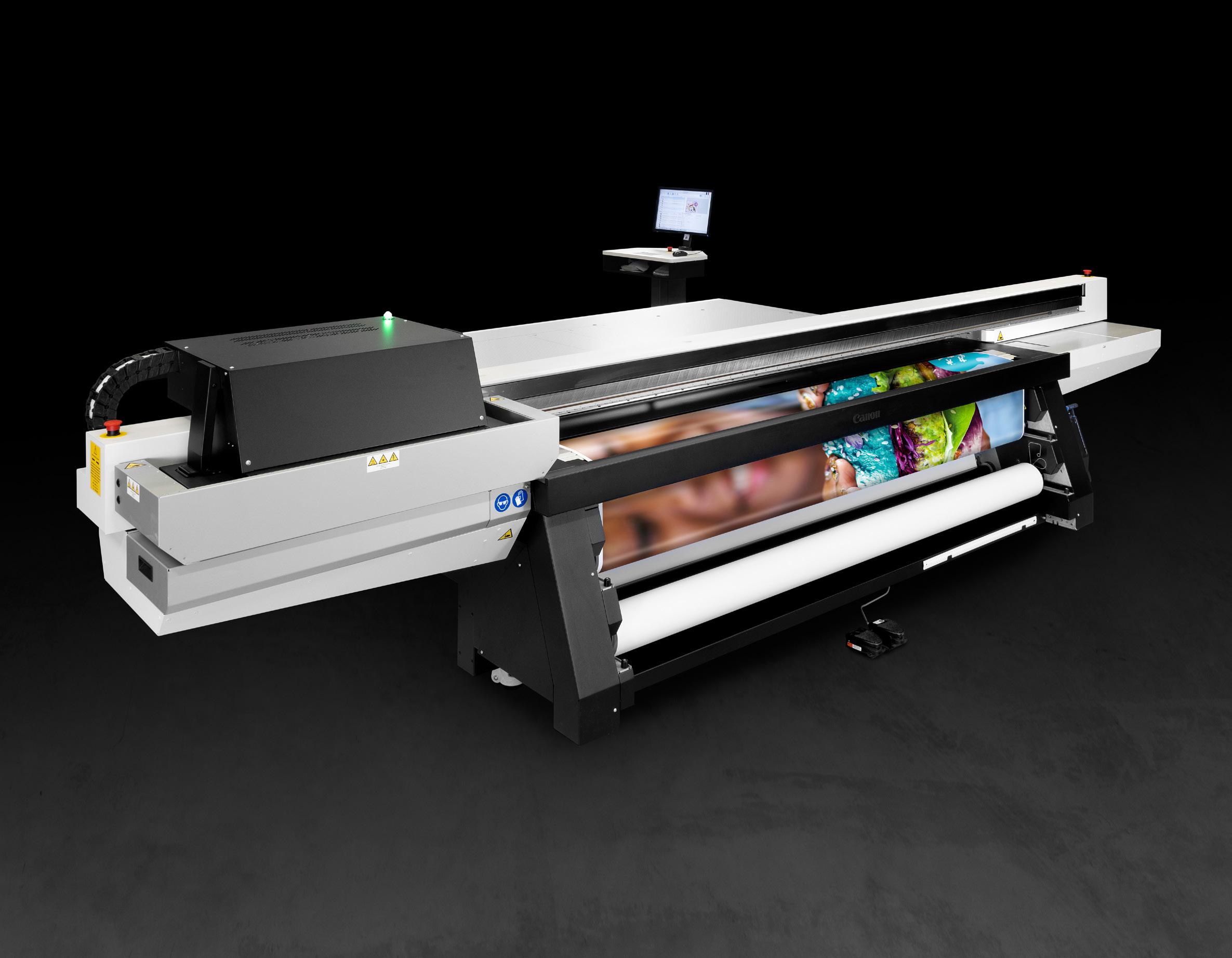

Since 2007, Arizona wide format printers have proved popular with more than 7,500 installations globally.

The Arizona 135 GT wide format printer, the latest member of the fifth generation of the Arizona series, offers signage, print and packaging companies a chance to update their operation and grow new business.

Steve Wilton-Jones, national equipment sales consultant for New Zealand Canon Arizona supplier Aarque, says, “The Arizona 135 GT is a smart business investment. It enables you to create impressive applications across an extensive range of rigid and flexible media. It offers outstanding productivity; high print quality and application versatility; as well as clever innovations in ease of operation and curing technology.”

The Arizona 135 GT comes standard with white ink in a convenient one litre cartridge and CMYK each as 800mls. The Arizona prints on almost any rigid or flexible media, UV LED curing means a fast turnaround time for a range of applications that include standard and textured surfaces, glass composites, aluminium and other products such as metals, canvas, wood, MDF, cardstock, ceramic tiles and plastics.

Steve says, “Arizona series printers can print on rigid materials up to 50.8mm thick, which means edge to edge printing with ease, for media or objects of any size up to 1.25m x by 2.5m. The Arizona classic high pressure vacuum system provides extremely reliable media holddown during printing.

“A roll media option enables you to create flexible media applications up to 220cm wide, including thin and heat sensitive media. You can make the most of output capacity by running roll to roll jobs unattended overnight. Also, the Arizona static suppression option enables you to print on hard plastic materials such as acrylic, polycarbonate and styrene.”

Canon says that compared to systems using fixed dot imaging technology, the Arizona’s VariaDot technology produces droplets in different sizes to give finer details, beautifully smooth quartertones with greatly reduced graininess, smoother gradients from the highlight areas to the mid-tones, and uniform solid colours.

The company adds that Arizona prepress software enables you to design and produce high value applications such as elevated print. It includes recipes to create applications and it allows you to exchange recipes directly with your customer. Designers can preview the end product

with a 3D view minimising the chance of any design flaws.

Arizona functionality includes nesting; batching of complex jobs; step and repeat; mirroring; and re-assignment of print modes. Steve says, “The Arizona approach to first time right printing leads to less waste and fewer costly mistakes which, in turn, leads to better overall margins and faster turnaround times. You can avoid errors with accurate print registration, and save time by making last-minute adjustments at the printer.”

Service features include an automated maintenance system for hands free printhead maintenance to selectively restore nozzle function in seconds. The Arizona on remote service enables you to grant access for authorised remote assistance by certified service technicians.

Following its Kyosei philosophy, which promotes living and working together for the common good, Canon supports customers in their efforts to reduce their own environmental impact.

Canon says the Arizona printing process consumes as much as 50 per cent less ink than regular flatbed printers. It adds that, as a VariaDot printer, with variable drop sizes from 6 to 30 picolitres, the Arizona 135 GT consumes less ink and creates less waste than comparable fivechannel printers using fixed droplet inkjet technology.

The UV-LED cured inks used in the Arizona 135 GT are Greenguard Gold certified for use anywhere, including retail environments, schools, hospitals and hospitality venues. Canon says Arizona printers consume less energy thanks to their instant-on functionality; standard voltage power supply; energyefficient curing process; and powerefficient vacuum pumps. Designed for minimal health impact in the production environment, Arizona printers do not require extra air circulation or ventilation systems.

Steve concludes, “We look forward to discussing the profitable commercial opportunities this wide format printer offers. With all of its capabilities, and a low total cost of ownership, the Arizona 135 GT makes a sensible choice for anyone wanting to increase revenue and control the print process.”

more than 50 staff. Lew says, “I am delighted to have found a partner that can help us to write the next chapter in our story. Banyan shares many of the values that we hold so high and has a proven reputation for growing businesses.”

He adds that Banyan Software provides “the best permanent home for successful enterprise software companies, their employees, and customers. With a permanent capital base set up to preserve the legacy of founders, Banyan focuses on a buy and hold for life strategy for growing software companies”.

David Berkal, chief executive at Banyan Software, says, “It was clear from the beginning how committed the printIQ team is to building quality solutions and providing excellent customer service, alongside an equal commitment to creating a culture that their employees are proud to be part of.”

Lew continues, “printIQ has always had a history of rising to the challenge of pushing the limits of what a print MIS can do. From our early days as a small New Zealand start-up, we have continued to work tirelessly to build the best solution possible. Our inspiration has always been our customers who have believed in the vision of what the platform could be. Consistently pushing it to the next level means that development is never complete.

Canadian company Banyan Software will acquire printIQ in a move to boost research, development and growth for the local print software success story.

Anthony Lew, chief executive at printIQ, says that after 22 years building the business, it became obvious printIQ needed “a partner to invest in growth and take us to the next level”.

He says, “With the help of many amazing people, we have established our business as a market leader that drives innovation through the print industry.”

Significantly, printIQ will continue as a standalone business but with the long-term backing of the Canada-based software investment company. Also importantly, Lew will remain in his role with the same team.

He sees this as similar to other Kiwi businesses that have made it to “a certain point but then need help and investment to take the next step”.

The company has achieved significant growth over the past year with operations spanning New Zealand, the US, Europe, Australia and Canada and employing

“We are excited to have a partner who will help us deliver on that promise by investing in the business, growing into new markets, and delivering the best solutions for the print industry.”

With the same teams for sales, marketing, customer service, support and product development, he has a clear focus for printIQ, He adds, “My goal is to continue building the product, extending our reach into new markets, and improving the way we listen, partner with, and support our existing customers.”

Berkal concludes, “We are very excited to welcome printIQ to Banyan as we continue to expand into the Australia and New Zealand markets.”

Taya Groups has launched three new products in its Kavalan PVC-free range: Spiderweb 300 L!ner, Sunlight Weldable Basic, and Sunlight Zero.

Stark Digital distributes Kavalan products in New Zealand.

I-Chien Lin, chairman of Taya Groups, says, “We are proud to be adding three original products to the Kavalan range. These really open up the PVC-free revolution to a host of new businesses of varying size and scope, whatever stage they may be at on their green journey.

“We have ramped up research and development. Also, we have worked closely with our customers to ensure we are delivering the solutions that the industry needs. As we move closer to PVC-free being standard as opposed to specialised, we will continue to develop our portfolio.

“As Kavalan expands geographically through its fast-growing distribution network, the extended range of PVC-free products will make it possible for many more businesses to embrace sustainable wide format banner materials.”

An American auction house has set a new world record for the most expensive antique advertising sign sold at auction, a 122cm double sided porcelain Musgo Gasoline sign. The selling price of US$1.5m ($2.6m) broke the previous record of US$400,000.

Collectors have described the Musgo sign as the holy grail of antique advertising signs. Discovered in an attic

Avery Dennison has reported its second quarter financial results for 2022, with net sales increasing by 11.7 per cent to US$2.3bn ($3.38bn).

Mitch Butier, chief executive at Avery Dennison, says, “We once again delivered

The company says Spiderweb 300 L!ner is the first PVC-free mesh liner available on the market and complements its Spiderweb PVC-free mesh banner material. It says Spiderweb 300 L!ner will allow for a more versatile application of the material across businesses. It also says the new product is an environmentally friendly alternative to

in Michigan, it had never been seen by the public. The Musgo Gasoline company, originally located in Muskegon, Michigan, was believed to be open for less than six months during the mid-1920s. Following its closure, most of their signs were used as septic tank lids causing one side to decay from septic fumes. This record breaking sign was described a “new old stock” as it was never used as a septic tank lid, making it the best-known example of a Musgo Gasoline sign.

Jordan Richmond, founder and chief executive of Richmond Auctions, says he has a passion for automobilia, gas, soda, oil, and other collectibles. He says, “The Musgo Gasoline sign was discovered without touch ups, restoration, or

strong financial results amidst a dynamic environment, with earnings above expectations. Label and graphic materials and retail branding and information solutions delivered impressive earnings growth and momentum in intelligent labels is further accelerating.

“Our strong performance comes at a challenging time as supply chains remain tight, inflationary pressures are significant and Covid-19 continues. Despite these challenges and a significant currency translation headwind, we have raised our guidance for the year.

PVC mesh. The new liner is lighter.

Sunlight Weldable Basic is a more entry-level option instead of Kavalan’s flagship PVC-free product Sunlight Weldable. Taya Groups says Sunlight Zero, Kavalan’s first fully biodegradable product, is a landmark innovation in wide-format materials, considering the amount that ends its life in landfill.

Discovered in an attic, this sign fetched a record price at auction

enhancements, something unheard of for a collectible of this nature. The US$1.5m dollar price tag speaks to the great condition and uniqueness of this item.”

“The strategic foundations we have laid enable us to generate superior value creation through a balance of GDP-plus growth and top quartile returns over the long-term.

“I want to thank our entire team for their tireless efforts to keep one another safe while continuing to deliver for our customers during this challenging period.”

The company adds that inflation continues to be a significant factor in its materials businesses, anticipating more than 20 per cent inflation in 2022 compared to the prior year.

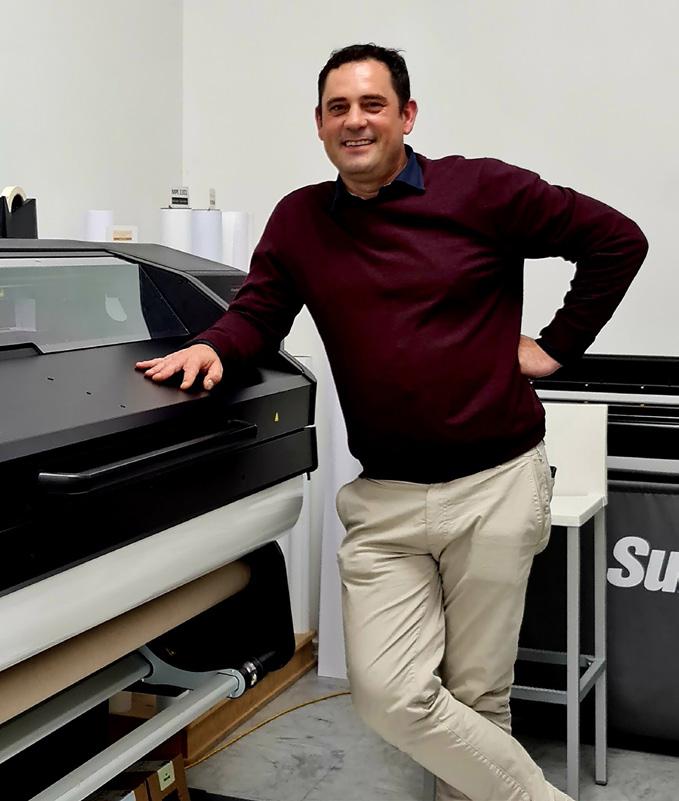

Earlier this year, Wellington-based Powerpac installed the country’s first EFI Pro 30h wide format printer, supplied through Currie Group.

The new machine offers a top print speed of up to 230 square metres per hour (or 48 boards per hour). Continuous board printing is a standard feature that allows Powerpac to make the most of the printer’s full production speeds. It provides a fast and easy changeover from rigid to flexible printing as well as dualroll printing.

Hugo Niemand, division manager at Powerpac, says productivity played a major part in the company’s decision to buy the EFI Pro 30h. He says, “Speed matters in our work. We need a printer

that is super-fast and reliable. Currie Group and EFI delivered this with the Pro 30h.”

The EFI Pro 30h replaces two flatbed machines. He says, “The EFI Pro 30h has increased our production capacity by four times, operating with the same amount of staff. We can print on any substrate up to 50mm thick so we are doing some great work with it.”

Print quality makes the EFI Pro 30h a vital addition to Powerpac’s production workflow. It provides two channels of white and features UltraDrop Technology seven picolitres printheads, with greyscale printing up to 1200 dpi. Its magnetic linear drive helps deliver superior drop placement, resulting in a

greater colour gamut. Hugo adds, “The quality is great, truly world class. It is our first EFI printer and we are impressed with its performance.

“The EFI RIP software is really easy to use and smart. We have setup workflows and automated several previously manual tasks, which saves time and effort.

“Our floor space is really limited, so investing in new equipment and smart floorplans means we can utilise the same amount of space with more capacity.”

Steve Suckling founded Powerpac 1982. Still family-owned, David Suckling heads the company with sons Patrick, Jay and Ben.

Hugo says, “We started off catering for the construction industry, covering all health and safety signage requirements. This evolved into Powerpac becoming the preferred supplier for all branding needs to the largest construction companies in New Zealand.

“Projects we have been involved in include Transmission Gully; the Auckland Downtown Wharf renovations; the Central Interceptor; the Waikato Expressway; and Wind Farm Projects in Palmerston North and Makara.”

Growing up in the industry, he recalls, “In 1984, my grandfather started a sign shop called Progressive Signs back in South Africa, which became one of the largest shops in the East of Johannesburg. We were the preferred supplier for companies such as DHL and Sandvik Mining and Liebherr Cranes.

“From the age of 12, I worked holidays and weekends developing skills such as graphic design, signwriting (operating printer, cutters, engravers and screen printing) and business management.”

In 2012, Hugo’s parents immigrated to New Zealand and he followed them, with his wife and two children in 2019. He says, “My first New Zealand role was as a signwriter at a local sign shop. When I joined Powerpac, signage was a small department and maybe accounted for around three to four per cent of our turnover.”