PrintNZ on the big issues

PrintNZ on the big issues

Recently, at drupa 2024 in Germany, Aarque Group cemented its relationship with Zünd with an official distributor agreement to supply the New Zealand market exclusively.

Steve Wilton-Jones, national equipment sales for Aarque Group, and Lars Bendixen, segment manager Graphics at Zünd, confirmed the partnership. The agreement sees Aarque relinquish the Summa portfolio in favour of Zünd and this will come into full effect by the end of the year.

The long-term partnership began in January 2011 when Jason Bult reached out to Zünd with a carefully crafted email. Subsequently, the companies reached a mutual agreement to bring Zünd’s best in class product line to the New Zealand market.

Steve says, “After the deal was cemented, it really did not take long before savvy customers took up the opportunity to use

this outstanding technology with the first cutter going into the company that is now SCG, Soar Communications Group.

“Now, 13 years on with multiple installations completed, we look to the future where Zünd has a super wide portfolio catering to sign & graphics; packaging; leather goods; apparel; technical textiles; and composites markets.

“We have had the opportunity to supply cutters into some truly innovative New Zealand businesses in the Sign & Graphics market as well as working with commercial manufacturing leaders in

aviation, motor racing and industrial product development. We pride ourselves on having a depth of understanding that can translate into tangible benefits for our Zünd customers throughout the country.

“Zünd cutting systems are more than a way to help you reduce costs or speed up your production processes; they are an eco-system with increased flexibility and capability, enabling you to create customised products efficiently and economically. Digital cutting with innovative Zünd technology helps you to lay a foundation for your future growth”

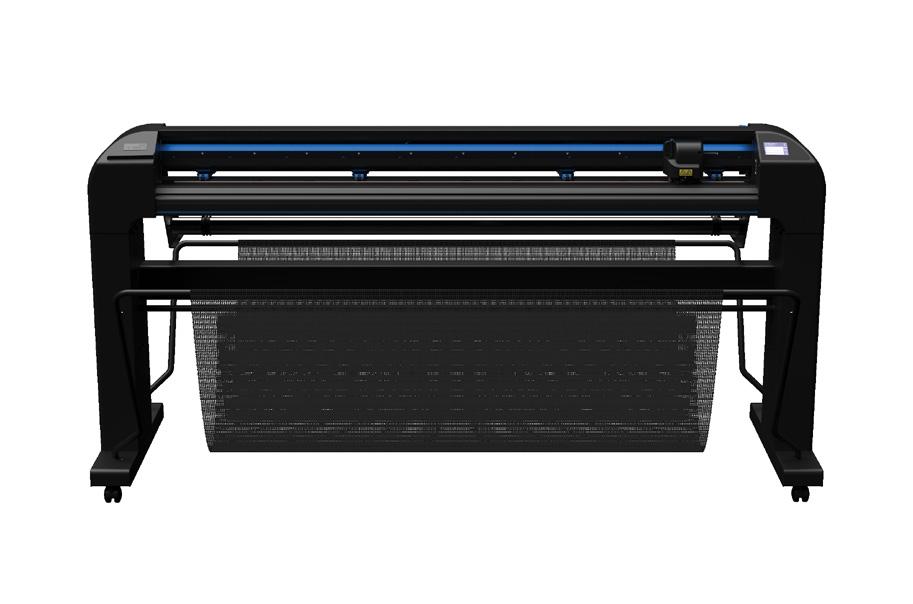

Zünd unveils an innovative loading system with integrated registration

With new Undercam, Zünd has introduced an innovative loading system involving a table extension and integrated registration system.

This solution enables simultaneous loading, job identification and registration

of various material types and formats, all carried out swiftly, precisely, and reliably, while the production process is ongoing.

The new board-loading extension with Undercam brings together two core functions: convenient loading of the cutter with a static loading table, plus optional fold-up loading extension. In addition, a precise capture system registers printed board and sheeted substrates from below. This combination ensures maximum efficiency and flexibility when cutting all kinds of materials.

This concurrent approach lets the cutter work at optimum capacity and reduces manual efforts to roughly 15 seconds per board, allowing the operator to focus on other tasks. The cutting process continues

automatically as soon as the next board is in place and confirmed. With one-shot capture, the process is much quicker than with conventional registration methods using the ICC camera integrated in the cutter’s tool carriage.

The board-loading extension with Undercam is equipped with its own lighting system and shields the area from ambient light that could interfere with the optical registration process. This ensures any printed images and material edges are captured precisely and reliably. Pressure plates press down on the board to make sure it lies flat on the capture surface. As a result, printed graphics can be registered with the utmost reliability on various kinds of materials, including corrugated cardboard.

Another feature of this new solution, a QR code-based production, enables the automatic retrieval of job files. As a result, various jobs of different material types and formats can be processed in mixed stacks, a boon for companies looking for maximum cutting flexibility.

The board-loading extension with Undercam is compatible with the Zünd G3 and D3 cutter lines and is available in four different widths. It seamlessly combines manual and automated processes: the operator accesses the job in ZCC, places the material into the registration position, and confirms this by pressing a hand or foot switch. The material is then fed automatically into the working area, and the cutting process begins or continues.

Steve adds, “This new solution from Zünd gives companies an efficient, reliable way to further optimise and automate their production processes while also enhancing their cutting precision.”

Zünd has simplified complex tasks with advanced and innovative software.

Zünd Cut Center works at the heart of the cutting system, acting as the production command centre, controlling the material-handling systems for loading and unloading. The software automates production workflow, from data import and optimisation to cutter control and production monitoring.

It is open to almost any import format because companies receive production data in different file formats every day and optimising them in file preparation is often time consuming. Zünd has developed Zünd Cut Center with the capability to interpret almost any vectorised file format, whether DXF, PDF, EDP or AI, hassles are removed.

Zünd Connect, the company’s web-based monitoring tool, highlights optimisation potential in productivity for each cutter. It records various key indicators and makes it possible to analyse and compare this data across jobs, production shifts, working methods and materials.

Zünd Design Center, an Adobe illustrator Plug-in, enables you to create one-piece and multi-part packaging or three-dimensional POP/POS displays quickly with parametric pre-made cut files.

Caldera PrimeCenter, the smart solution for Print+Cut prepress, delivers intelligent automation for a streamlined workflow. Automatic true shape nesting, pagination and utilisation of metadata for rules-based pre-flighting of files is crucial to be a productive business.

Zünd PreCut Center enables you to easily and efficiently create ready nested job files on unprinted materials. It significantly reduces the amount of work; optimally utilises the material; and eliminates potential sources of error.

Mind Software Suite is the pendant to Zünd Cut Center and drives the cutting system for leather and textile applications. With its smart and unique features, the software enables different ways of nesting cut files on leather hides easily and efficiently. It also comes with functions like Feature Recognition and Pattern Matching, offering innovative features for printed textiles, laces and patterns.

My Zünd delivers a single repository of information on consumables, accessories and software related to your Zünd, It is the first touchpoint for Zünd customers, including the web shop, Zünd Connect platform, software license management and more. Users can send supply requests to Aarque Group from the portal.

Zünd’s super wide portfolio caters to a wide range of commercial sectors including packaging

Soar Communications Group (SCG), the country’s largest independent communications group, develops creative, content and print solutions for a range of clients. SCG’s connection with Aarque Group has coincided with both companies’ growth and advances in technology.

Dave Atkins, co-managing director at SCG, says, “We have been with Aarque Group for over 20 years. The team at Aarque cut their teeth in the graphics industry with us. Jason Bult was the same age as I was as we came through and we have maintained a strong relationship, which began with Peter and Leo Bult. Aarque Group has had, and still has its fair share of colourful characters, and they have always maintained a strong service and support ethic.

“We took advantage of Aarque Group’s Zünd agency in 2011, when we installed

the first machine in the country. That machine lasted forever. In fact, one of our operators has been on it since the day we bought it.”

Recently, SCG replaced a Zünd S3 cutter (which was reinstated at another business) with a Zünd G3 2XL-3200. Dave says, “We are continually looking at ways we can improve our offering and updating our technology forms part of that strategy. The new Zünd G3 2XL-3200 is a high-spec machine that offers us a range of benefits such as the bed size that gives us the capability to run the cutter in a tandem mode which dramatically reduces time as we can load two 1220mm x 2440mm boards front and back, allowing us to unload and load while the initial board is being cut.

“It has increased speed. The setup is easy, and the tools are impressive.

I have not seen anything better. The scope of Zünd’s modularity and ability for us to scale the cutter with more automation and tooling gives us confidence for the future.”

SCG’s Zünd cutting systems offer the company multiple applications ranging from sign and display to routing and packaging work as well as everything in between. The company will stick with Aarque Group and Zünd. Dave says, “Over the years, we have looked at other machines but the Zünd cutting systems really fit our purpose more. The Zünd machines outperformed other machines.

“Relationships are important in this business, and they do change over the years but, when you have a company that delivers good service and support, then it makes the work easier. Aarque Group is a reliable partner; they have always helped us.”

2-5 Aarque Group: At drupa 2024, Aarque Group cemented its relationship with Zünd with an official distributor agreement to supply the New Zealand market exclusively. Zünd offers a super wide portfolio catering to the sign and graphics; packaging; leather goods; apparel; technical textiles; and composites markets.

16 Currie Group: A revamped Auckland demonstration centre features the HP Indigo 7K Digital Press and a raft of Horizon solutions.

18 Konica Minolta: Chris O’Hara looks at some key trends driving innovations in production printing.

20 Think Laterally: AI is here. Mick Rowan discusses how print businesses can benefit from its technological transitions.

10 Comment: PrintNZ is hard at work behind the scenes working on some big issues for the industry, reports Ruth Cobb.

12-15 Helping Hand: Iain MacIntyre finds out why the timeless process of screen printing remains at the forefront of the industry.

22-24 Durst Group: Sydney-based Coleman Group has installed its fifth Durst machine: a P5 350 HS.

26 Total Supply: As it brings 3M architectural films on board, Total Supply has created a new sales division, welcoming back James McIntosh.

28 NZSDA Update: The NZSDA connects sign makers, helping them build strong professional relationships.

29 NZSDA President: Shae Goom discusses changes to the Master Sign Makers accreditation.

30 NZSDA Highflyer: Mikayla Hopkins meets Jackson Brattle, this year’s Keith Langstone Highflyer Award winner.

32-33 Computaleta: Arlette Farland discusses the benefits of using a Summa S3 roll cutter.

36 Circular economy: Label and packaging businesses can prioritise sustainable packaging and policies, says Brandon Rogers.

38-40 Akanksha Meena reports on how brands are embracing new packaging design trends.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS:

Ruth Cobb, Arlette Farland, Shae Goom, Mikayla Hopkins, Sylvain Lieb, Iain MacIntyre, Akanksha Meena, Brandon Rogers, Mick Rowan

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

Wayzgoose 2022

Wayzgoose

September 17, 2022

September 17, 2022

Napier

Napier

Tokyo Pack 2024

www.inkianapress.co.nz

Foodtech Packtech

September 20-22, 2022

Auckland

Labelexpo Americas

March 12-15, 2024 | Melbourne Convention and Exhibition Centre

October 23-25, 2024 | Tokyo Big Sight, Japan

September 13-15, 2022

Chicago, USA

This will be the 30th anniversary of the show that organisers call the ultimate event for Japanese packaging technology and science. Tokyo Pack showcases everything related to packaging including distribution, sales, consumption, and recycling. www.tokyo-pack.jp

Labelexpo South China 2024

The Association of Handcraft Printers has a full day programme including visits to Havelock Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

People in Print Awards

December 4-6, 2024 | Shenzen, China

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise.

www.foodtech.packtech.co.nz

All in Print China

October 11-15, 2022

Shanghai

Auspack has transitioned into APPEX, the Australasian Processing and Packaging Expo. Organisers aim to truly represent all sectors of the industry: machinery, ancillary equipment, materials and packaging, food processing, and industry services. It will provide a comprehensive range of all processing and packaging equipment and services under one roof. www.appex.com.au

Foodtech Packtech

March, 2023 | Auckland

Foodtech Packtech

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

September 20-22, 2022

September 20-22, 2022

Auckland

Auckland

Wayzgoose 2022

www.newzealandprinter.co.nz

People In Print Awards

March, 2025 | Auckland

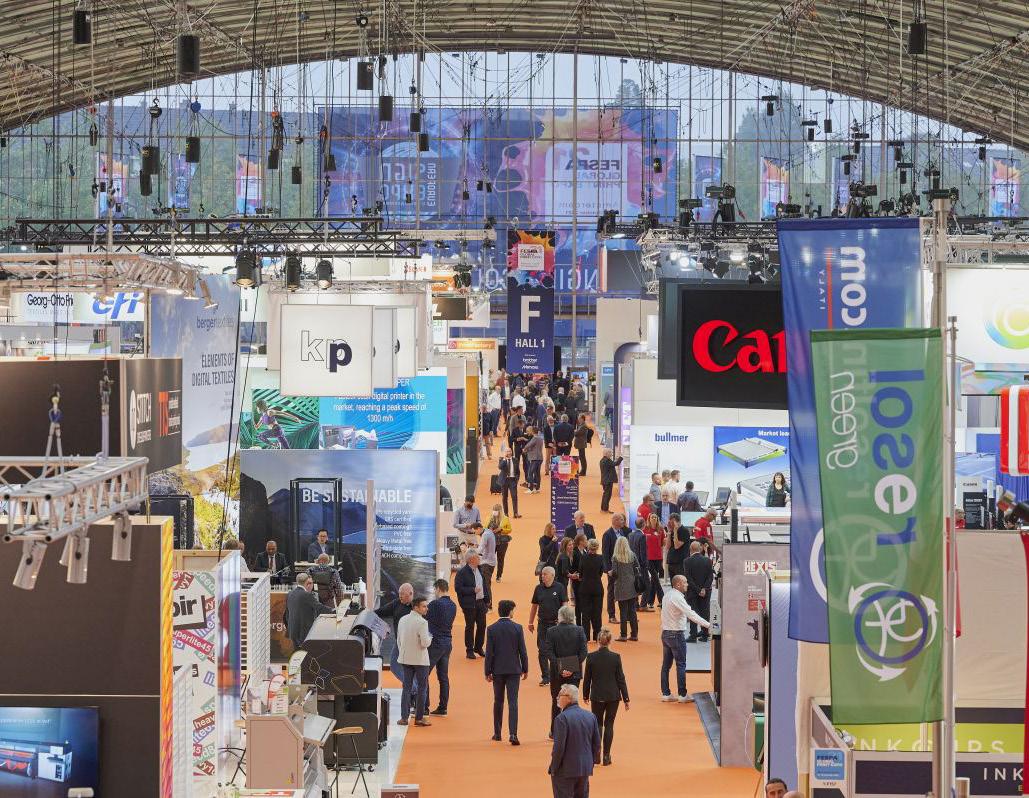

Fespa Global Print Expo

March 19-22, 2024 | Amsterdam

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

Nominations will soon open for the People in Print Awards and Rising Stars of Print Awards. Do you know someone who is consistently achieving excellence in their work in this industry? Of course you do, so when the time comes, put their name forward for these awards so they can receive recognition for their efforts.

South China remains a significant market for the label and package printing industry and Shenzhen is a vibrant hub for business and innovation. Organisers promise visitors an inspiring three days where they will see the latest technology and machinery shaping the future direction of the industry. www.labelexpo-southchina.com

September 17, 2022

Napier

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

www.allinprint.com

Organisers will soon call for nominations for next year’s People In Print Awards and Rising Stars of Print Awards. These awards recognise people in our industry who achieve outstanding results for their work, for their community, and for the environment; people who work alongside you. www.newzealandprinter.co.nz

Letterheads

All Print

All in Print China

October 21-23, 2022

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft.

Covering digital printing, screen printing, textile printing, garment decoration and signage, Fespa Global Print Expo will mix all the latest technology and solutions with events like the World Wrap Masters and Fespa Party Night alongside features such as its Sustainability Spotlight; Personalisation Experience, and Sportswear Pro.

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

October 11-15, 2022

Fespa Global Print Expo 2025

www.fespaglobalprintexpo.com

October 11-15, 2022

Sign Foundry, Welling

www.inkianapress.co.nz

Shanghai

Shanghai

May 6-9, 2025 | Berlin

Printopia

Foodtech Packtech

Foodtech Packtech

May 3-5, 2024 | Corbans Estate, Henderson

PacPrint 2025

Craig Paul 027 655 4267

Craig Paul 027 655 4267

September 20-22, 2022

Auckland

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

Covering screen, digital, wide format, and textile printing, the giant show brings hundreds of exhibitors to showcase their latest innovations and product launches across graphics, décor, packaging, industrial and textile applications. It features the World Wrap Masters Final 2025; the Sustainability Spotlight; and the Fespa Party Night. www.fespa.com/en

www.letterheads.co.nz

Now into its third year, the Printopia Festival of Original Print promises a fun, inspiring, print-filled weekend of artist talks, demos, workshops, live printing and of course our print fair. International artist Jenny Robinson will give the keynote presentation on May 4 and a masterclass the following day. www.printopia.nz

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

drupa

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

May 20-23, 2025 | Olympic Park, Sydney

May 28-June 7, 2024 | Dusseldorf, Germany

Interpack

May 4-10, 2023

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise.

www.foodtech.packtech.co.nz

Düsseldorf, Germany

Letterheads

Letterheads

• Consulting and Machine Recommendations Sourcing

October 21-23, 2022

October 21-23, 2022

All in Print China

• Export/Import Sales

The world’s leading trade fair for printing technologies has opened registrations to again welcome the industry’s main players, and quite a few minor ones. All will show their latest solutions. Visitors can stay on trend with the technology and seminars featuring topics from sustainability to digitisation. www.drupa.com

Sign Foundry, Welling

Sign Foundry, Welling

Billed as the most comprehensive and relevant business to business event serving the evolving needs of the print, sign and graphics industries in Australia, New Zealand and across the Asia-Pacific region, PacPrint will see around one hundred leading suppliers showcasing their latest products and services to thousands of industry professionals. www.pacprint.com.au

Foodtech Packtech

Visual Impact Brisbane Expo

July 17-19, 2023 | Brisbane

• Machinery Inspections & Valuations

October 11-15, 2022

Shanghai

September 2-4, 2025 | Auckland Showgrounds, Auckland

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

• Plant Relocation OFFICE: 09 8367577, ALEX MOB. 021 975 477 sales@apm.co.nz www.apm.co.nz

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

www.letterheads.co.nz

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

New Zealand’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion and the sharing of knowledge and expertise. It will attract more than 250 local and international exhibitors and around 4,000 visitors.

www.foodtechpacktech.co.nz

Visual Connections Australia will host visitors and exhibitors at the Brisbane Convention and Exhibition Centre. The Exhibition hopes to attract over 2,500 visitors interested in the signage, print, graphic and engraving industries and featuring digital printing, personalisation, signage, sublimation, design, routing, display solutions, and vinyl applications. www.visualimpact.org.au

Interpack

Interpack

newzealandprinter.co.nz

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”.

Printing United

May 4-10, 2023

May 4-10, 2023

www.allinprint.com

Düsseldorf, Germany

Las Vegas, USA | September 10-12, 2024

Düsseldorf, Germany

Letterheads

October 21-23, 2022

Sign Foundry, Welling

Showcasing the latest innovations and applications in specialised printing, the event attracts thousands of visitors from across the printing industry, serving as an exhibition and as a knowledge hub, where experts share their expertise and stimulate discussions about the future of the industry. www.printingunited.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

Craig Paul 027 655 4267 sales@curriegroup.co.nz

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke.

www.letterheads.co.nz

newzealandprinter.co.nz

newzealandprinter.co.nz

Interpack

May 4-10, 2023

Düsseldorf, Germany

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

KODAK reports solid second quarter financial results. Jim Continenza, executive chairman at Kodak, says, “Our results for the second quarter were in line with our long term strategic plan. We delivered a year over year increase in gross profit percentage for the seventh consecutive quarter despite an anticipated decline in revenue. We are getting leaner, introducing new products and partnering with the right customers. Building for the future, we continue to invest in our Advanced Materials and Chemicals group and are seeing results in terms of growing revenue in key product areas.”

COLOR-LOGIC has certified the PrintFactory Workflow RIP eco-system from a number of OEMs and dealers. Commenting on the certification, Mark Geeves, director of sales and marketing, says, “The PrintFactory Workflow RIP eco-system, combined with Color-Logic, produces embellishments which will open up new markets and applications for printers seeking opportunities in labels, signage, and point of purchase packaging for many markets, including healthcare, craft beer and wine, luxury brands, and events.”

HP has reported a rise of two per cent for its third-quarter net revenue. Enrique Lores, president and chief executive officer at HP, says, “We are pleased with our return to revenue growth and proud of the innovations delivered in the quarter, including the launch of our next generation AI PC lineup. We remain focused on our strategic plan and will prioritise opportunities that drive long term profitable growth while taking decisive action to navigate a dynamic environment.”

Epson has launched its newest on demand colour inkjet label printer: the ColorWorks C8010.

Purpose built for mid to high volume batch runs in on demand environments, Epson says the printer delivers exceptional print quality, reliable performance and high speed printing with advanced connectivity and cloud printing, allowing businesses to print almost any type of label.

Colour labelling offers numerous applications to improve efficiency, quality and customisation. Epson says

the new ColorWorks C8010 helps companies eliminate multi-step printing processes and stockpiling of pre-printed colour label rolls to print high quality labels in real time.

Designed to meet the high volume label production needs of businesses in several markets, the ColorWorks C8010 prints labels for the likes of prime and boutique, product ID and warehousing and logistics.

The printer features advanced PrecisionCore Heat Free technology, printing multiple labels with variable

Australian folding carton manufacturer Networkpak has installed a Screen L350UV SAI S digital printer, supplied through Jet Technologies.

Paul O’Sullivan, director of Networkpak, expects the new printer to play a crucial role in this expansion. He says, “As a company with deep roots in printed folded cartons, we have earned the trust of leading brands by consistently delivering top-tier products. The addition of the Screen L350UV SAI S to our lineup is a natural progression for us, enabling us

to offer an even wider array of solutions to our clients.

“We can now meet their label and packaging needs with the same level of quality and reliability they’ve come to expect from our carton work.”

The L350UV SAI S offers Networkpak the flexibility to produce a wide variety of labels, from simple designs to complex, high impact graphics, catering to the diverse needs of its clientele across various industries.

David Reece, sales director for Jet Technologies says, “We

data at speeds up to 30.48cm per second. Epson says its PrecisionCore permanent printhead allows for fewer interventions and low maintenance costs.

The company adds that durable, high performance UltraChrome DL pigment inks provide high quality, long lasting labels that resist smudging, smearing and fading. Customers can choose between Gloss and Matte Black ink to fit labelling needs. New high capacity ink packs target high volume batch runs.

Other features include advanced connectivity, such as cloud printing and optional Wi-Fi and Epson Cloud Solution PORT for remote management to better manage efficiency and optimise printer workflow, including viewing printer status and ink consumption.

are delighted to be working with Networkpak. Whilst they may be new in the label space, their team has significant experience in the market and their choice of the L350UV SAI S is a strong endorsement in the brand and our support.”

As a key partner in the project, Jet Technologies facilitated the installation and ensured Networkpak is fully equipped to leverage the capabilities of the new press. Paul adds, “Since installation, we have been impressed with the L350UV SAI S. It has done absolutely everything that we expected and has not skipped a beat. Jet Technologies has been outstanding with its service and support, ensuring that we have made a seamless transition into labels.”

In Auckland, the Newmarket Business Association (NBA) has doubled down on print media to attract domestic tourists.

Mark Knoff-Thomas, chief executive at NBA, says, “We focus on showing domestic tourists that Newmarket is a must visit spot. By putting out top notch editorial content and stunning visuals, we showcase the best that luxury and design in New Zealand has to offer.

Since its inception nine years ago, the magazine has become one of the country’s most widely distributed lifestyle magazines. Readership has grown from 5,000 readers in 2015 to over 180,000 today.

Webstar prints the magazine, which NBA publishes in house. The magazine has expanded its reach with distribution to major centres around the country, including Wellington, Christchurch, Queenstown and Dunedin. It has added a nationwide subscription service to further broadens its reach.

NBA says the expansion follows a surge in interest from consumers and businesses alike. It says many businesses have successfully leveraged the magazine to market their products and services locally, reporting increased footfall and enquiries as a result.

Mark adds, “Promoting the precinct has just been an amazing plus. Our nationwide expansion is a testament to the fact that Kiwis still crave high quality, entertaining media that appeals to their interests, despite the widespread desire for short form digital content. Placing increased emphasis on design

Organiser Visual Connections has rebadged the traditional Sydney show, PrintEx, to PacPrint and scheduled it for May 20-23, 2025, at the Sydney Showground. It adds that PacPrint 25 aims to provide industry businesses with intelligence, ideas, information and inspiration to survive, and prosper, into the future.

Since its inception in 1970, PacPrint has welcomed business owners and key decision makers in the visual communications sector. The shows allow industry professionals to keep up with trends, experience the latest innovations, and gather the information and inspiration they need to build business success. With a strong track record as an internationally recognised

and creative input enables the visually stunning and engaging magazine that aims for people’s experience to be more akin to a leisurely Sunday perusal over coffee, rather than a quick skim in a waiting room.

He adds, “The magazine has attracted attention from both local and international brands and businesses, and its strong offerings have cemented Newmarket as the premier precinct for retail, hospitality and art, with a strong undercurrent of heritage and supporting local.”

“Print is alive, and we feel proud to play a small part in that ongoing media battle.”

platform for suppliers of technologies and services, PacPrint helps generate business opportunities.

Visual Connections says planning is progressing well for next year’s show. Several exhibitors have confirmed their attendance, but the show has some available space, although it is filling fast.

PacPrint 25 will co-locate with the Label & Packaging Expo and with the Visual Impact Expo, which will showcase the signage, engraving, display and wide format markets.

Visual Connections says that the three co-located shows provide a comprehensive showcase for all sectors of the print, sign, graphics and wider visual communications sector, with more than 16,000 square metres of state of the art equipment and technology on display, industry leading education and networking programmes and an audience of thousands of industry professionals.

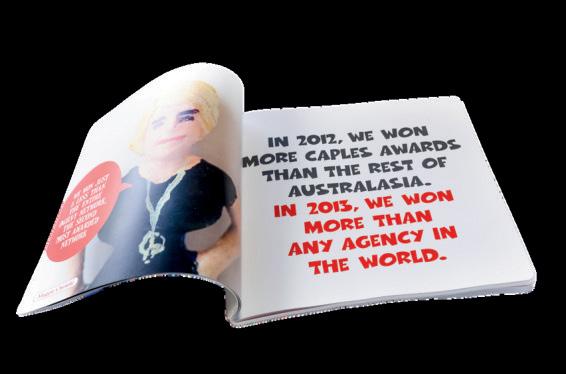

your print projects with our finishing services

P (09) 444 5523

M 021 190 1305

E info@bookbindingpress.co.nz www.bookbindingpress.co.nz

An update on PrintNZ’s progress with four important issues.

There is plenty going on behind the scenes that require us to make some noise. Here are four matters at the top of the list.

The creation, and now disestablishment, of the behemoth TePukenga organisation that encompassed all Polytechs, and work based learning organisations affects the entire industry.

In August, the government finally released a consultation paper with its proposal for the new-look vocational education system, giving a short six week period to digest it and provide feedback. This required an enormous amount of time and consultation with other organisations to prepare a submission to voice the requirements of our industry and where it did and did not fit into the proposal as laid out.

Work-based learning is vital to our industry. The print, packaging and print finishing trades training takes place fully in the workplace and it is many years since there has been any interaction with the Polytech system. The training programmes are designed by industry, for industry and we need to ensure there is no weakening of that standard. We need

to be sure that the Minister understands what this means, and that includes not only our submission, but those of you who supported us by putting in submissions of your own.

Among substantial concern around the price and availability of energy, I worked with the Manufacturers’ Alliance to make representations to Minister Brown about the negative impact this has had on the manufacturing sector, including some of the large businesses that are part of the supply chain of our industry that have had to pause or close down. Escalating energy prices have become a significant threat to the global competitiveness of New Zealand manufacturers, and this is affecting exports and those competing with imports in the domestic market.

The Minister recognised the significant volatility of the current situation and while some of the issue has righted itself following a bout of rain, he acknowledged that there needs to be a clear pathway to ensuring a long term, cross-party goal of affordable pricing alongside surety of supply. The government is working to take away barriers and are undertaking a review of the market to deliver globally competitive energy prices while emphasising it is committed to the Net Zero target by 2050.

Many of the new Accredited Employer Workplace Visas that were granted through Covid have ended. The current framework does not allow their renewal.

The government is focused on building talent and skills and ensuring that the ratio of skilled vs unskilled migrants is reduced to an acceptable level and those that don’t meet the criteria are required to leave New Zealand for 12 months. This directly impacts some of our members and we are working with them and Immigration to try and ensure that the staff they have employed and spent considerable resource training, are able to remain.

The Skilled Migrant Category is not fit for purpose, and we are lobbying to ensure that trades are recognised and provide a pathway to residence for those migrants that come in under this system. In an industry where technology is continuously evolving, we often rely on bringing in skilled workers to train kiwis in how to use the new machinery. Being able to provide these people with a reassurance that they can build a life here with their family is important.

Immigration is a moving feast, and we continue to monitor the changes and support members that require it.

Continued extraordinary price increases and a contraction in delivery services from NZ Post over the last few years have directly impacted volumes of print distributed. NZ Post is subject to a Deed of Understanding between it and the government which details certain minimum service obligations NZ Post must meet.

We have lobbied across all political parties and the Deed is now under active review. We seek transparency and a sustainable and signalled strategy regarding increasing costs; a return to NZ Post meeting its social obligations; and a refocus on it being accountable to the principles of the Deed.

The letterbox remains the only channel that provides a communication pathway to every household in New Zealand, and it is an important network for our industry, but only if it works for all parties.

These four matters require ongoing work and, as an industry association, we are here to do that on your behalf. With many more issues in the background, we will keep our fingers on the pulse.

Screen printing, a process which reportedly dates to the Chinese Song dynasty of 960-1279, continues to produce bespoke, high quality work that other forms of print cannot replicate.

Understood to have spread to Western Europe by the late 18th Century, today

this sometimes overlooked sector of the industry provides value to discerning print buyers.

Artrite Screen Printing managing director Glenn Taylor, whose firm’s high quality work claimed the prestigious 2023 Pride In Print Supreme Award, considers the process to have particular strengths in versatility, colour vibrancy and affordability.

He says, “We have the ability to print small or large formats on many surfaces and substrates, all shapes and sizes, to a very high quality. Having the ability to laydown solid layers, we can achieve many looks, metallics, fluoros, high glosses, and glitters, to name a few.

“We can print high quality photo process reproductions as well as solid spot Pantone colours, with UV lightfast inks. This makes our process durable and able to withstand outdoor environments without fading. No other process can match this.

“We offer clients a strong, longer lasting product for their investment. And in screen printing, the setup costs are the same for small or long runs. This means the longer the runs, the unit price reduces dramatically, offering better pricing on large volumes.”

Dylan Southan, director at Southan Print, endorses Glenn’s sentiments, emphasising how screen printing commands a strong demand for jobs that other printing

processes can’t achieve. He says, “An example of this is how we print a number of outdoor signs that could require a vibrant orange. CMYK digital couldn’t get the same result or cosmetic finish.

“We can adjust this manually by printing our ink through a coarser mesh to get a heavier laydown and add a stronger pigment into the ink to give it more punch.

“Screen printing still has a strong place in the printing industry as it is becoming more of a niche form or style of printing.”

Top Kiwi quality

At Colour Evolution, general manager Mike Mossman says that the process is not only here to stay but is also thriving globally for the most part. He says, “Screen printing as a process from a

consumer perspective has a distinctive feel, longevity, opacity and often solves problems with mechanical stretch, adhesion, UV stability and washability, and delivers cost savings in long runs that digital can’t.

“Companies are investing in new machinery development and automation, and it is the decoration of choice on hundreds of thousands of different substrates.”

Having spent considerable time overseas attending tradeshows and conducting print business transactions, Mike says New Zealand screen printers produce world class quality. He explains, “On the knowledge, machinery and consumables side, we draw from Europe, the United States and Asia and, being far away from the suppliers, we have developed our own training and standards, driven by

a market that is possibly the fussiest in the world.

“So, our line in the sand in terms of quality is higher. We decorate a far more diverse range of products and are far more flexible than big countries that can afford to be more niche. Doing so many more items to such a high standard of print quality has meant our skillset and equipment has to be top notch.”

Dylan adds, “I do feel as Kiwis, we take quite a lot of pride in the quality of what we are producing, as we are much smaller in comparison to volumes in other countries. It is great to see what is still getting produced in our country within the screen printing sector.”

However, he laments that the process is sometimes overlooked in favour of other forms of print which may have the allure of significant recent technological advancement. He says, “For example, there could be a job that the end customer is looking to produce that would naturally go to digital CMYK, but it could actually be cheaper, and a better result screen printed.

“This could be a signage job, decals or corflute, in which the artwork is two colours and a quantity of 1000. This would be more cost-effective to be screen printed for the volume and the print would be much more durable with better density and longevity for the spot colours themselves.

“The advanced range of substrates coming through the market is also exciting to see. It gives us an opportunity to think outside the square to get better results to deliver to customers that are more sustainable.”

Noting the range of variables that screen printers master in their process, Mike concurs that the sector remains in good stead. He says, “There are not really other options for decoration in many instances. So, it is here to stay and will continue to grow, even if it’s in a business that offers multiple forms of decoration.

“Constant marketing of the digital process lends some print buyers to potentially forget that screen printing is here and still a very viable option.

“Our quality and colours are ‘in’ and superb, and we are very competitive on price. A lot of people think that all we can produce is t-shirts. This is far from the reality. We can still screen print high quality photo images using the CMYK method.”

Constant evolution

Glenn Taylor emphasises that New Zealand screen printing firms are constantly evolving and still learning.

He says, “As a company, we are always finding and working on new techniques and methods, from prepress through to print, to offer visual effects and looks that others can’t achieve. Development for us is also reintroducing to the market what our capabilities are, re-educating people on the benefits of screen printing.”

Acknowledging that the screen printing process is one of the oldest printing styles around, Dylan says, “There is still good technology going into screen printing machines, such as self-registering print heads and automatic inline machines.

“As screen printing is still a manual style of printing, the craft remains the same. At Southan Print, we are using more eco-friendly inks such as water-based. Customer feedback is they are loving the sustainability.”

Similarly, Colour Evolution continues to invest heavily in the latest screen printing accessories and consumables such as jigs, clamping systems, special effects inks and stock substrates. Additionally, the company actively pursues new, cutting edge machinery, alongside an ongoing realignment of its business model.

Mike Mossman says, “Colour Evolution has always been at the leading edge of technology and some of our machines have high specifications. Some are among the first couple of dozen manufactured globally.

“However, in terms of the essence of the print form, my team members still really enjoy screen printing as a process. Screen printing comes down to the skill level of the operator. It is more of a craft

and hands on style of printing. So, when you get to the result of a job, it is quite rewarding to see what you have brought together, especially if it is a multi-colour printed job.

“Having been in the screen printing sector for a long time, I also feel training is definitely important in our trade. It is awesome to see young trainees still coming through to learn the art.”

A full screen printing apprenticeship remains available in New Zealand. Ruth Cobb, chief executive of PrintNZ, says,

“The screen printing apprenticeship reinforces the skill that is involved in this special sector of our industry.

“The high quality and distinctive work that screen printing produces remains much in demand in this country and globally. This fact is no better evidenced than by virtue of five outstanding screen printing jobs having claimed the coveted Supreme Award over the Pride In Print Awards’ 31-year history, including as recently as last year.

“Screen printing is a special, niche sector of our industry and it should not be underestimated.”

Since its inception in 1993, the Pride In Print Awards has recognised the quality of the work of the country’s top screen printers with numerous prizes, from highly commended and gold medal winners to the category and, of course, the screen process awards. The Pride In Print Supreme Award has gone to screen printers on five separate occasions and we recall their amazing work here.

1.

the

2. Aaria Design won the 2013 Supreme Award with New Zealand Postcard, Milford Sound

3. Original Screen won the 2008 Supreme Award with Wella

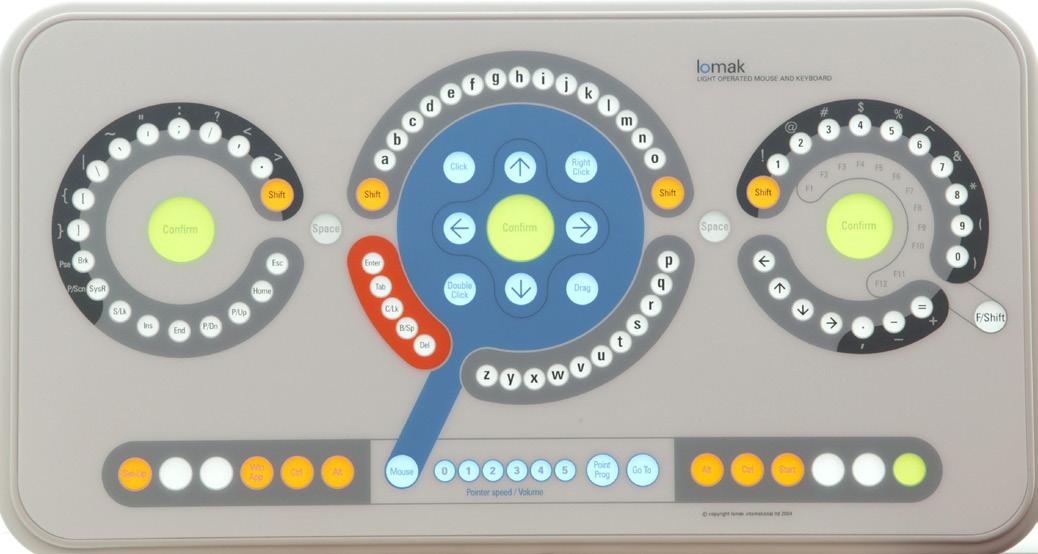

4. Permark Industries won the 2005 Supreme Award with Light Operated Mouse & Keyboard

5. Original Screen won the 2004 Supreme Award with 100 Pure New Zealand. Proudly displaying the work and the award: are former Original Screen directors: the late Greg Nash (l) and Warren Fenning

A

finishing solutions are among the technology running

Centre.

Currie Group has refreshed its Auckland Demonstration Centre with a revamp that includes the HP Indigo 7K Digital Press, plus a range of print and finishing solutions for the New Zealand market.

Craig Paul, country manager for Currie Group New Zealand, says the catalyst for updating the Auckland Demonstration Centre came from a visit to Currie Group’s Melbourne facility. He says, “I must admit that I was experiencing some showroom envy on a visit to Melbourne

last year. When I discussed the possibility of revamping our space here with my colleagues at Currie Group, I received strong support and encouragement. They also shared innovative ideas about making the most of the space we have here.

“Another factor was that we moved here, into our Orbit Place premises on Auckland’s North Shore back in 2013, so a refresh was due. We began with a repolish for the floor and we had the walls printed after that. The next step was moving new equipment in.”

A brand-new HP Indigo 7K Digital Press was first on Craig’s list for the Demonstration Centre. He says, “The HP Indigo 7K Digital Press is so versatile. It is an ideal fit for Kiwi print shops as it offers the ‘gold standard’ HP Indigo print quality, production values, and extras at an entry level investment. We are really looking forward to running live demonstrations on this press for customers.”

Travis Jordan, national account manager at Currie Group New Zealand, agrees. He says, “The HP Indigo 7K Digital Press enables you to expand your capabilities and open new business opportunities with a massive range of high value applications. It offers the widest range of specialty inks and media and handles numerous substrates from black and coloured media to metallised substrates and synthetics.

“I am continually impressed with the capabilities of the HP Indigo Digital Presses, so like Craig, I can’t wait to bring customers here to show them what they can achieve with this technology.

The Auckland Demonstration Centre also houses a range of Horizon finishing solutions including the BQ-270V Perfect Binder, the RD-N4055 Rotary Die Cutter, the CRA-36 Auto Creaser and the SPF-200L landscape bookletmaker.

Currie Group also supplies HP 3D printers and 3D finishing equipment. The Demonstration Centre is currently running the 3D finishing equipment and has a number of samples on display.

Craig says, “We invite everyone to come in and see the solutions running in real time. To arrange a demonstration, please call us at Currie Group New Zealand on 09 477 2140.

Scan the QR code to learn more about the solutions at Currie Group’s Auckland Demonstration Centre

Advances

in technology, as well as

a

strong focus on sustainability and efficiency, are driving innovative solutions in digital production printing.

As production printing continues to undergo significant transformation, we see several factors driving innovations in the field such as technological advancements, market demands, and the push for sustainable practices.

Chris O’Hara, national production print manager for Konica Minolta New Zealand, says, “The latest innovations in digital printing are having a major impact on the likes of publishing, packaging, and commercial printing.

“Six key trends to watch out for in digital production printing include:

Digital printing advancements

Digital printing technology continues to evolve, offering many benefits over traditional offset printing. Key advancements include:

High speed inkjet printing — Modern high-speed inkjet printers deliver faster print speeds and superior image quality, ideal for large-scale production.

Enhanced colour management — Advanced colour management systems ensure consistent and accurate colour reproduction, meeting the stringent demands of brand owners.

Variable data printing — Digital printing enables personalised and customised prints with variable data, catering to marketing campaigns and personalised products.

Sustainable printing solutions

Sustainability is a critical concern in production printing. Innovations in this area aim to reduce environmental impact and promote eco-friendly practices.

Recyclable/biodegradable materials — Use of sustainable substrates, such as recyclable and biodegradable papers and plastics, is increasing.

Eco-friendly inks — Water-based and vegetable-based inks are replacing traditional petroleum-based inks, reducing harmful emissions.

Chris O’Hara, national production print manager for Konica Minolta New Zealand

Energy efficient equipment — New printing presses are designed to be more energy efficient, lowering the carbon footprint of production facilities.

Integration of automation and AI

Automation and artificial intelligence (AI) are streamlining production printing processes, enhancing efficiency, and reducing labour costs.

Automated workflow systems — Integrated workflow solutions automate tasks such as file preparation, colour correction, and print scheduling, minimising manual intervention.

AI-driven quality control — AI systems monitor print quality in real-time, detecting, and correcting defects to ensure consistent output.

Predictive maintenance — AI algorithms predict equipment failures before they occur, enabling proactive maintenance and reducing downtime.

Innovations in finishing techniques enhance the final appearance and functionality of printed materials:

Digital embellishments — Techniques such as digital foiling, embossing, and varnishing add tactile and visual appeal to printed products without the need for traditional dies and plates.

Smart packaging — Incorporating technologies like QR codes, NFC tags,

and augmented reality into printed packaging provides interactive and engaging experiences for consumers.

Hybrid printing — Combining digital and traditional printing methods allows for creative effects and high quality finishes.

On demand and short run printing

The need for flexibility and cost-efficiency continues to drive the demand for on demand and short run printing.

Print on demand services — These services allow businesses to print materials as needed, reducing inventory costs and waste.

Short run production — Advances in digital printing make it economically viable to produce small quantities of high-quality prints, catering to niche markets and limited-edition products.

Just in time production — Printing only what you need, when you need it, aligns with lean manufacturing principles, and reduces excess inventory.

The integration of production printing with digital platforms is creating new opportunities for cross-media marketing and enhanced customer experiences:

Web-to-print solutions — Online platforms allow customers to design and customise printed materials, streamlining the ordering process.

Cross-media campaigns — Integration with digital marketing channels enables coordinated campaigns across print, email, social media, and more.

Augmented Reality — Printed materials with these capabilities provide interactive and immersive experiences, bridging the gap between print and digital media.

Chris adds, “As these major trends continue to develop, production printing will remain a vital and dynamic industry, driving growth and innovation across a wide range of sectors.”

MINOLTA

More profitable business through a press that works smarter, not harder, with the AccurioPress C7100 series. You serve more customers and complete more jobs with innovative technologies that power your success.

Find out more at k konicaminolta.co.nz/C7100

Giving Shape to Ideas

How print businesses can support staff through technological transitions.

Like other sectors, the printing industry is experiencing a wave of technological transformation. Automation and digitalisation are becoming integral to operations, offering improved efficiency, productivity, and cost savings.

However, these advances can also stir up staff concerns, especially about job security and changing work roles. It is vital to manage this transition in a way that supports employees and cultivates a positive workplace atmosphere.

Balancing automation with human skills

Automation often raises fears of job displacement as machines take over tasks traditionally performed by humans. However, it’s essential to view automation not as a threat but as a tool that enhances human capabilities. Technology can handle repetitive and routine tasks in the printing industry, freeing up employees for more strategic, creative, and higher value activities. For example, automated printing processes can streamline workflows, allowing staff to focus on client relations, quality control, or innovative design solutions.

The print sector must embrace a balanced approach, leveraging automation to improve business efficiency while preserving the crucial human elements of creativity, problem solving, and customer service. This means that businesses should not treat automation as a complete replacement for workers but rather a complementary tool that allows employees to focus on areas where they add the most value.

Job Displacement: A Manageable Concern

One of the most pressing challenges is managing the potential for job losses due to automation. With machines increasingly taking on once labour intensive tasks, it’s understandable that some roles may become redundant. However, businesses can take proactive

Machines can automate many tasks, but the human touch remains indispensable

measures to mitigate these risks by focusing on employee development and future-proofing their workforce.

Training programmes that emphasise reskilling and upskilling are crucial in ensuring employees remain relevant in this new technological landscape. By investing in training, employees can learn to operate new machinery, manage automated systems, or move into new roles that require advanced technical expertise. Offering structured pathways for career development can help staff feel secure about their future and reduce anxiety about technology’s impact.

Communication plays a vital role in managing technological transitions. Employees must feel informed, included, and reassured about the business’s future direction. By fostering an environment of open dialogue, businesses can address employees’ concerns about automation and its implications for their roles.

Encouraging staff to ask questions, share their thoughts, and provide feedback during the transition process ensures that they feel involved in decisionmaking, which can boost morale and foster trust within the organisation.

value of human creativity and innovation

While machines excel in speed and precision, human workers bring specific skills to the table: creativity, empathy, problem-solving, and adaptability. Automation can’t replicate the nuanced decision making or innovative thinking that humans provide. In the printing industry, this is especially relevant when designing custom solutions, managing client relationships, and responding to project demands.

Encouraging a workplace culture that celebrates innovation and out of the box thinking can motivate employees to see

automation as a tool that complements their abilities, rather than something to fear.

Technological change can be a stressful time for employees, who may feel anxious about the future of their jobs. Businesses can provide counselling services or access to mental health professionals to help staff navigate the emotional and psychological challenges of change. Whether through in-house support programmes or external services, giving employees a place to voice their concerns and work through their anxieties can improve overall workplace wellbeing.

Offering career coaching and guidance can also help employees explore new opportunities within the organisation, aligning their career paths with the evolving technological landscape. In this way, companies can retain valuable talent while preparing their workforce for future demands.

Employees who feel valued and recognised are more likely to embrace change rather than resist it. Companies should foster a workplace culture that rewards hard work, encourages teamwork, and promotes work-life balance. Encouraging a sense of community and collaboration will ensure that employees feel supported not just by management but also by their peers.

As the printing industry continues to evolve, success hinges on recognising that while machines can automate many tasks, the human touch remains indispensable.

The skills, creativity, and problemsolving abilities that humans bring to the workplace are essential for driving innovation and long-term success. By balancing technology with a focus on people, printing businesses can confidently navigate this technological revolution, ensuring a prosperous future for employees and the company.

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

Coleman Group recently added on a Durst P5 350 HS large format printer and Durst P5 TEX iSub dye sublimation printer to sit alongside its Durst Rho 325, Rho 512R and Rho P10 250 machines.

Glenn Coleman can’t remember exactly when he bought his first Durst as it was so long ago, but since then he has bought another five machines that are all operating on the floor of his event and exhibition signage business in Sydney.

“We bought our first Rho 800 in either 2007 or 2008 when Durst was managed in Australia by PES. Nine years later we upgraded to the Rho 325 and Rho 512R and that was six years ago. We also have a Rho P10 250 – and they all continue to operate today,” he said.

Last year, Coleman added more firepower to his business with the introduction of a P5 350 HS and a P5 TEX iSub dye sublimation machine. After a significant reorganisation on the floor of his factory, Coleman now has two Durst textile

machines and three Durst UV machines all operating within metres of each other.

“We have found the new Durst P5 TEX iSub has been great – it can print direct on to certain fabrics and creating jobs directly is a huge advantage. We also print to paper on this machine as well. I would recommend it for people that maybe don’t want to invest in a separate finishing machine for dye sublimation.

“The P5 350 HS was a machine we loved as soon as we saw it at the Durst factory in Brixen in February 2023 after attending the Euroshop exhibition at Düsseldorf. It has been going very well since it was installed late last year.

“We put similar work through the older Durst machines as the new machines,” Coleman said.

“Our customers are very deadline driven – we just can’t not deliver – it is not an option and that is why we have Durst, why we chose Durst originally and why we have stuck with Durst.”

While some companies have only recently started seeing a move towards more sustainable materials including fully recyclable exhibition materials –Coleman claims this trend is not new.

Durst Oceania managing director, Matt Ashman, is not only the supplier of machines and consumables to Coleman Group, but has also experienced what it is like to be a customer as well.

“It is great to continue the relationship we have with Glenn, Rod and Coleman Group. We chose Glenn and Rod ourselves to launch Durst Oceania at PrintEx in 2019.

“Coleman Group built our stand and created all of the graphics and they did an amazing job – the entire stand was erected and installed by the team. And sometimes the concept doesn’t always meet the expectation from a design perspective – not from a printing perspective. And when it needed to be changed – it was reprinted within hours.

A

“They use their five Durst machines like Ferraris – and they have a superb garage featuring high performance equipment ready to go to meet a deadline.

“These machines are all top-quality examples of European engineering and Italian manufacturing that have been specifically chosen and calibrated to do a job. Even if they are not operational

all day every day like other businesses, they are sitting there just waiting to be ready to win the race for not only Coleman Group, but for the customer.”

When asked if this will be his final Durst purchase, Coleman reluctantly disagreed.

“We expect to have another Durst when we upgrade again in a few years from now.”

deep-dive into the machines owned by Coleman Group

The P5 350 HS large format printer

The P5 350 HS is a hybrid solution for roll and board printing of up to 3.5m and a productivity of up to 708 square metres per hour. Fast media change, easy maintenance handling and full safety are only a few of the reasons that Coleman Group render the printing process way more efficient.

The P5 350 HS is a fully integrated machine that makes the increasing complexity in large format printing more manageable. The printer is equipped with the Durst Print Workflow software and the monitoring tool, Durst Analytics. Coleman Group finds that the P5 350 HS provides optimum performance, from pixel to output.

The P5 TEX iSUB is a dye-sublimation printer with an integrated inline fixation (iSUB) for a one step direct to fabrics printing process. The Durst P5 TEX iSub’s contactless fixing technology ensures excellent colour consistency, as well as sharpness of detail in images and text. Blurring or bleeding of colour is also eliminated.

A wide range of applications on polyester material can be implemented with the new dye sublimation printer, such as light box and decorative fabrics including difficult media as blackback and flags.

However, the printer is not limited to direct printing. Transfer papers can also be printed and further processed in the usual way – a plus for the needs of Coleman Group.

The Rho 512R is a super-wide 12 picolitre roll-to-roll UV inkjet printer with Variodrop technology. With a print quality of up to 1200dpi and at speeds of up to 385 square metres per hour, the Rho 512R has allowed Coleman Group to print a variety of large format advertising materials by handling three 1.6m rolls simultaneously.

The Rho 512R is equipped with Variodrop technology and uses multiple impulses for modulating the droplet size.

Thus, the exact amount of ink is placed, which prevents drop satellites that are more common in conventional grey-scale printing. Unattended printing and very low production costs have also enabled the Rho 512R to be one of the most economical printers for the business.

With the 3.2m Rho 325, Coleman Group can utilise a dual-purpose printing system that combines direct-to textile printing with dye sublimation transfer printing technology. Depending on the application and fabric, this printing system can alternate between paper transfer and direct printing on polyester-based materials quickly.

This is possible because of Durst’s WTS printhead technology, which achieves an exceptionally highquality print using water-based, environmentally friendly dispersion inks for various printing materials, and a print speed of almost up 390 square metres per hour.

The Rho 325 is also equipped with an integrated hot air dryer, automated nozzle cleaning system, and additional features for 24/7 production reliability.

The Durst Rho P10 250 large-format UV inkjet flatbed digital printer

The Rho P10 250 large-format UV inkjet flatbed digital printer

The Rho P10 250 inkjet printer enables Coleman Group to deliver quality work within industrial print production.

The printer combines speed and quality without compromising either. Furthermore, just like previous flatbed and roll-to-roll printers, its ability to print on the widest range of rigid and roll media provides Coleman Group with the ability of unrivalled and convincing versatility.

Equipped with the Durst Quadro Array 10 print head technology, this system achieves a print quality of 1000dpi without loss of speed. This also applies to the use of light colours. The compact and robust print machine for industrial production is also designed for non-stop printing with minimum downtime.

New deal sees Total Supply expand its already impressive portfolio.

Total Supply has announced its appointment as the newest distributor of 3M Architectural Films in New Zealand.

Gareth McGrail, general manager at Total Supply, says, “Total Supply has been leading the charge in innovative graphic solutions across New Zealand and we are excited to continue this through the addition of the 3M Architectural Films collection.

“This collaboration enhances our current 3M product lineup, now featuring DINOC, Fasara, and an array of Window Security Films and Tints. These premium 3M finishes provide on-trend options for diverse architectural and design projects.”

Product range

The expanded product range now includes 3M DI-NOC Architectural Finishes. These versatile finishes mimic natural materials such as wood, metal, and marble, ideal for cost-effective interior and exterior refurbishments.

Gareth says, “DI-NOC’s library has hundreds of patterns providing designers with limitless creative possibilities.

“3M has designed its Fasara Glass Finishes to enhance the aesthetics and functionality of glass surfaces, providing decorative solutions ranging from frosted to textured patterns, which are suitable for creating privacy in commercial and residential spaces.

“3M Window Tinting Films offer superior sun control, heat reduction, and UV protection, contributing to improved energy efficiency and comfort in buildings.

“3M Safety & Security Window Films reinforce glass, reducing the risk of injury and property damage by holding shards in place upon breakage. 3M Surface Protection Films, an extension of the existing automotive PPF range, protect surfaces from scratches and wear in hightraffic areas.”

Gareth says that a significant advantage of this new distributorship is the expanded supply network through a strategic alignment with parent company, Spicers Australia.

By leveraging Spicers Australia’s extensive distribution channels already established in Australia, Total Supply can offer shorter lead times and a broader range of stock to the New Zealand market.

This enhanced supply chain ensures product can be delivered efficiently, enabling customers to meet project deadlines with increased flexibility in product selection.

James McIntosh has rejoined the team at Total Supply to head the new sales division supplying Architectural Films.

Gareth says, “We’re thrilled to have James rejoin the team, with his extensive experience and proven track record, James is poised to lead our new division to success. James brings an innovative approach and his deep industry insights will be invaluable as we expand and enhance our service offering.

“3M’s architectural films offer significant advantages, including ease of application, durability, and various finishes that meet both aesthetic and practical requirements.

“These products provide architects and designers new possibilities for creating visually stunning and functional spaces while offering practical benefits such as energy efficiency and safety enhancements.

“We share a commitment to excellence with 3M. Total Supply has proudly distributed 3M films in New Zealand for over a decade and the extension into architectural films underscores its dedication to providing innovative solutions to the industry.

“For more information about Total Supply’s expanded 3M Architectural Films range, please contact our sales team.”

Epson fabric solutions let you say ‘yes’ to more work.

Enjoy more vibrant and accurate colour with better image quality and faster production speeds. Benefit from flexible media support, advanced management tools, and reduced operational costs with up to 5 years comprehensive service cover, including printheads. Whether it is dye sublimation, DTG or DTFilm, Epson offers superior solutions for your business.

Learn more at www.epson.co.nz/fabric

NZSDA connects sign makers, helping them build strong professional relationships.

VMIKAYLA HOPKINS Lead Projects, Events, and Marketing Specialist NZSDA

isits to sign shops across the country have kept the NZSDA busy over the past few months, and there is more to come.

Last month, we headed down to Dunedin to visit our members in the region. That

provided an opportunity for us to discuss the value of active membership and the many new benefits available to members this year.

This month, we visited Auckland, holding two regional meetings, and using the rest of the time to meet many of our associate members. It was fun and full on with over 22 Certificates of Recognition to present to long-term members.

Next month, we travel to the Manawatu and Whanganui to meet with members in that part of the country. Keep an eye out for upcoming communications around this as we will releasing the details soon.

We are already deep into the planning stage for our 2025 conference and sign awards. This year we will be combining the two events under the same theme as part of our 60th anniversary celebration. Pre-registration for this is open now so please contact me to indicate your interest and to book your spot early.

Recently, we ran the third episode of our HR webinar series. This instalment provided tips on standing out from the crowd and identifying your point of difference. You can watch this excellent session in the members section of our website. Why not play during your morning coffee break or at lunchtime.

Initiatives in the pipeline include updates for Terms of Trade, the Wage and Salary Guide, and a brand-new focus and pathway for achieving Master Sign Maker accreditation. Keep an eye out on our social media to see when these are released.

A big thank you to Mark Stephens from Horton’s Signs and Mark Larsen from Larsen’s Art ‘n’ Sign, who represented the industry at the North Canterbury Youth Futures Expo 2024. Over 1300 attendees at the show provided a constant stream of interested people at their stand. We are always looking for people who are keen to present the industry at careers expos around the country.

Please consider the importance of being active in your membership. Attending meetings and connecting with fellow members helps you build strong professional relationships, which can lead to referrals and collaborations.

It also gives you the opportunity for sharing and gaining insights as well as staying informed. It also helps you to continuously learn and contribute to the growth of both your business and the wider community.

“E hara taku toa i te toa takitahi, engari he toa takitini”

My strength is not that of an individual, but that of the collective.

Becoming a Master Sign Maker can provide numerous benefits to your company.

Over the winter, we have worked on revising the Master Sign Maker accreditation. We have looked at what it means to be a Master Sign Maker, and how achieving the accreditation benefits your company.

Our objectives include working to make the Master Sign Maker accreditation as accessible as possible for well-run sign companies, especially those who are active in the community and at our events throughout the year. This has involved coming up with an upfront recipe or formula to create a clear guide for companies to follow, so they can promote themselves as a market leader to the general public.

At the end of this month, we hope to release this new pathway. I think it is a really exciting move that I hope will get some positive engagement.

Also, later this month, we plan to release the updated Terms of Trade to help businesses through this tougher business environment. In addition, we will soon release our Wage and Salary Guide, which is now in its final stages.

We have locked in the dates for our 60th annual conference. Alongside our flagship awards event, the conference will take place in Nelson from June 12-14, 2025.

Currently, we have three concepts for the event’s theme, which we really do want to resonate with everyone, being our 60th year of the New Zealand Sign & Display Association. We want to see as many people attending as possible, especially those that have not made it to an event for a number of years.

Who can remember a year that has passed us by so fast? Before we know it, we will be into Christmas and many companies have already sped up. I do hope that all our members can find time to give to themselves, away from the hustle of work.

While many people will feel glad to have the days slowly getting longer and warmer, I look back at our winter disappointed as I was only able to fit in half a day of snowboarding on the slopes. With this warming pattern, I have opted to put my gear away for another nine months or so, which is a sad reflection on one of my favourite winter hobbies. However, it does mean I can now focus on my new sport, having just purchased a small new yacht to do some racing in from October. A good way to make the most of our seasons here in New Zealand.

As one that has already cleaned off the barbecue, I hope you all get to enjoy these new smells of spring and get ready for this run into the end of the year. I celebrate a milestone birthday in a couple of weeks, so hopefully this will be a day when the sun is shining.

NZSDA has explored what it means to be a Master Sign Maker?

Hard-working apprentice has become Dzine Signs’ first pick for hard to do tasks.

Jackson Brattle, from Wellington’s Dzine Signs, won this year’s Keith Langstone Highflyer Award for his outstanding dedication to his employer and his customers.

The third generation sign maker works with his father, and boss, Dustin Brattle, who nominated Jackson for the award, highlighting his son’s determination, hard work, and exceptional team skills. Jackson puts his hand to any skill in the shop, from design, print, wrap, electrical, LED, manufacturing, welding, installations, and CNC operating.

As first pick for tricky work, after-hours tasks, specialist projects, and training clients with LED software, Jackson has shown a scope of skills far beyond that expected of a final year apprentice, always upholding the company’s proud customer service standards. A worthy award winner, his eagerness to learn and understand all processes sets him apart.

Recently, Mikayla Hopkins caught up with Jackson.

Mikayla Hopkins: How does it feel to be recognised and what does this award represent for you?

Jackson is

Jackson Brattle: I was stoked to get the award and be recognised for the skills I have gained from my work at Dzine. I pride myself on having a can do attitude towards learning new skills in the industry.

MH: Unfortunately, you couldn’t make it to the awards ceremony. How did you find out you had won the award and what was your reaction?

JB: My dad was present at the ceremony and received the award on my behalf. He messaged me and told me I had won; he was pretty excited. My grandpa Steve Brattle also messaged me soon after dad.

MH: What are your goals for the future?