When you need packaging designed, printed and converted. Or you have print for foiling or finishing…

May 2023

People in Print pics

Top 10 Apprentices

Training graduations

Charity Golf

with 1987-2023

When you need packaging designed, printed and converted. Or you have print for foiling or finishing…

May 2023

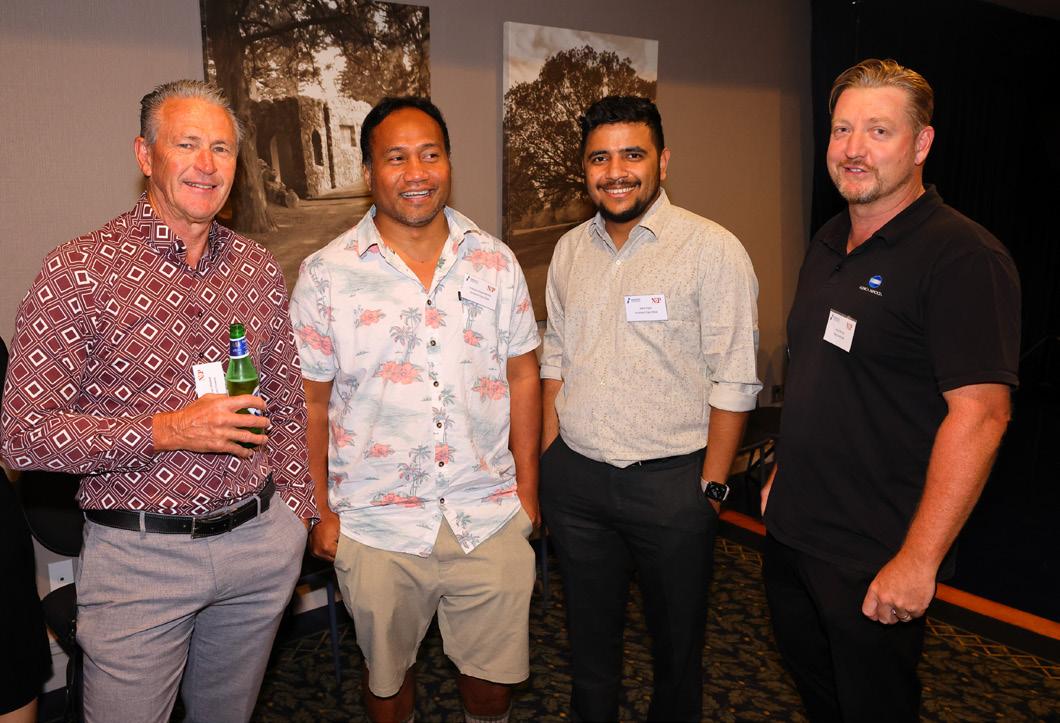

People in Print pics

Top 10 Apprentices

Training graduations

Charity Golf

with 1987-2023

12 Contact Labels: With 38 years of experience in the industry, Contact Labels provides a range of finishing and labels solutions for trade customers nationwide

Features p14-49

14 Durst: At Fespa, Durst will to showcase its production excellence and host attendees at its Brixen headquarters

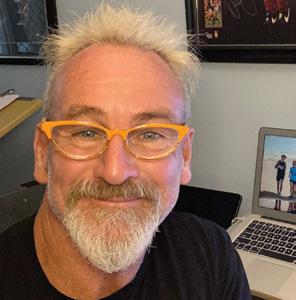

16 Think Laterally: Mick Rowan reflects on how digital technology has changed the industry

18 Konica Minolta: Printcraft has installed two new AccurioPress solutions

20-23 People in Print: Everyone had a great time at the recent People in Print Awards

24 drupa: Sabine Geldermann is optimistic about the industry’s future

32 People: Meqa Smith offers advice on recruiting staff in difficult times

33 Sales: People will pay for top performance, says Dave Fellman

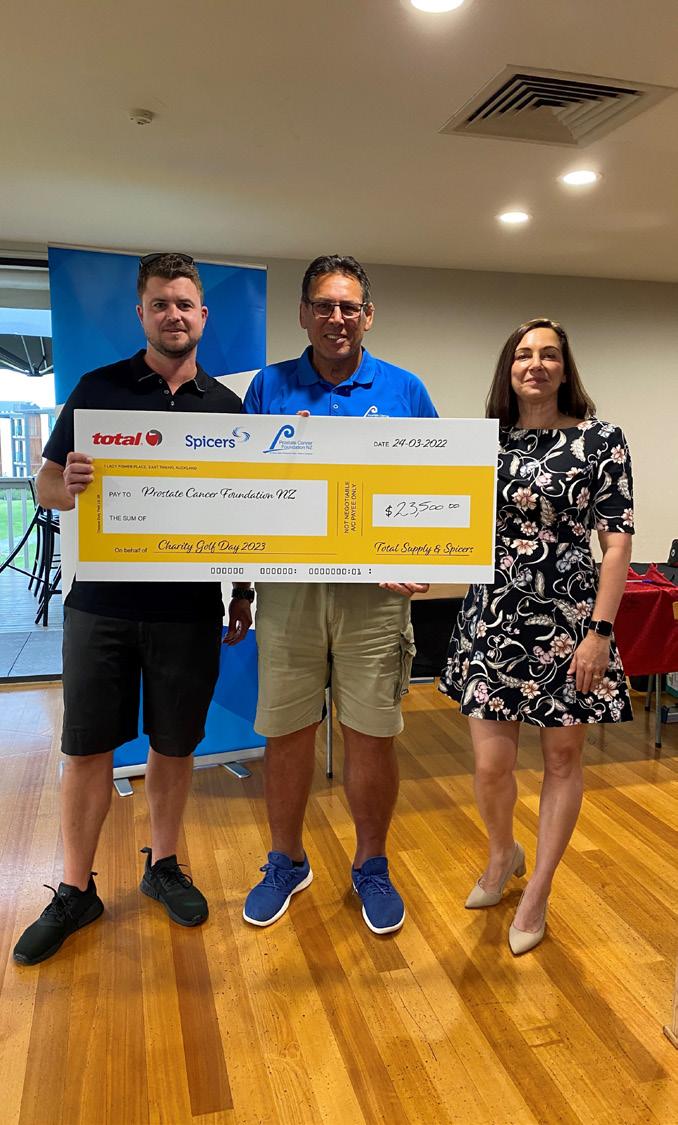

42-45 Charity Golf: The Total and Spicers Charity Golf Day raised funds for the New Zealand Prostate Cancer Foundation

46 Printerverse: Businesses must focus on customer needs, says Deb Corn

47 VDMA: Dr Markus Heering says we must use more sustainable resources

48-49 Sustainability: It’s time to address our plastic waste problem, says Mark Lapping

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

Piotr Wnuk, News Editor pwnuk@intermedia.com.au

CONTRIBUTORS:

Ruth Cobb, Melissa Coutts, Andy Lowe, Deborah Corn, Iain MacIntyre, Mick Rowan, Sabine Geldermann, Mark Lapping, Dr Markus Heering, Dave Fellman, Meqa Smith

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE:

Brian Moore - brian@newzealandprinter.co.nz

+61 410 578 876

CLASSIFIED ADVERTISING:

Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION:

Sarah Vella - sarahvelladesigns@gmail.com

8-10 Helping Hand: Iain MacIntyre has the 10 top print apprentices vying for this year’s Apprentice of the Year title

11 Comment: Ruth Cobb reports back from this year’s training graduations

Wide Format Plus p24-45

26 Aarque: Adgraphix has installed the first HP Latex 2700 printer in New Zealand

28 Canon Production Printing: The new Colorado M-series offers a range of features

30 Currie Group: Structurflex has brought its printing in-house with a new EFI VUTEk D3r printer

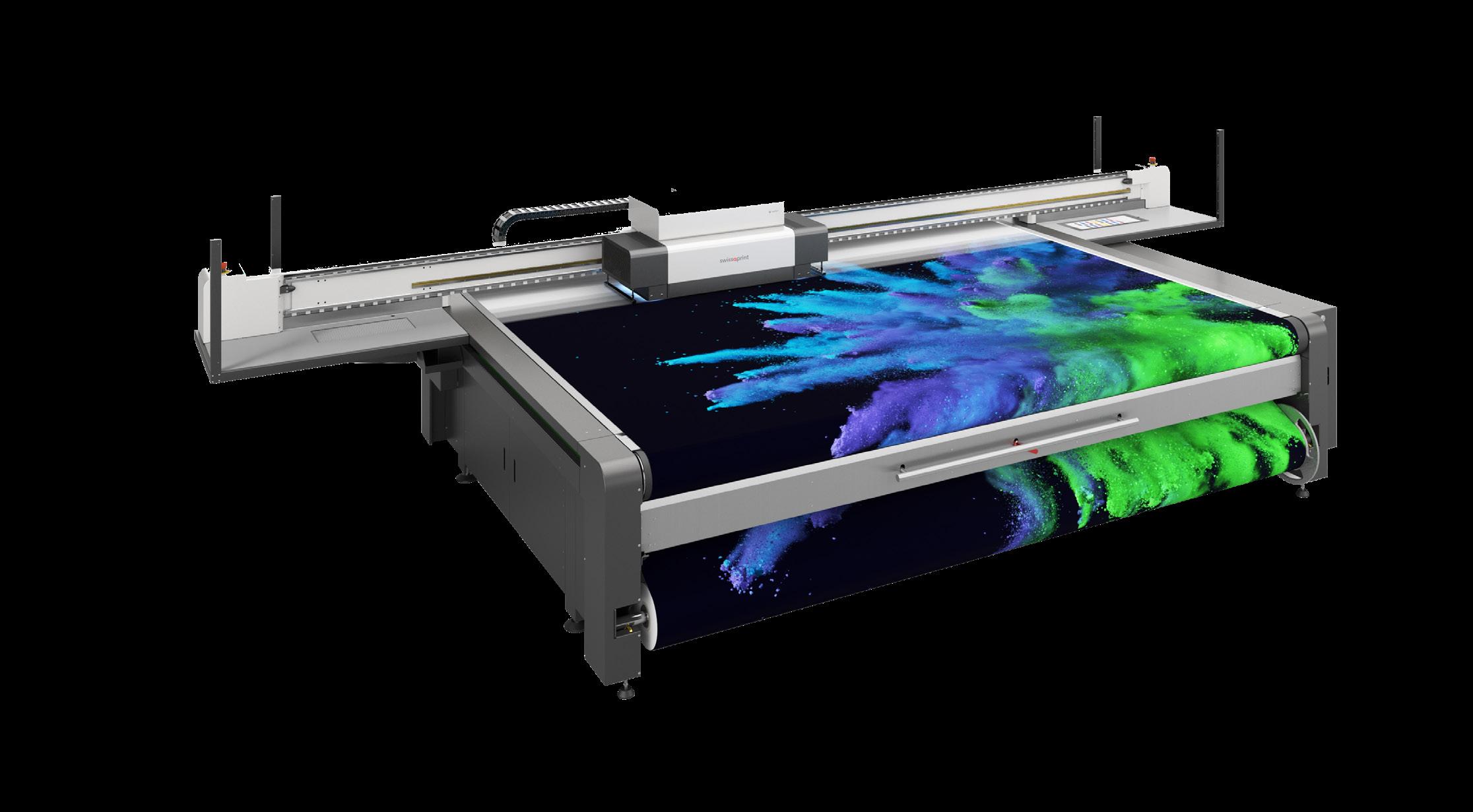

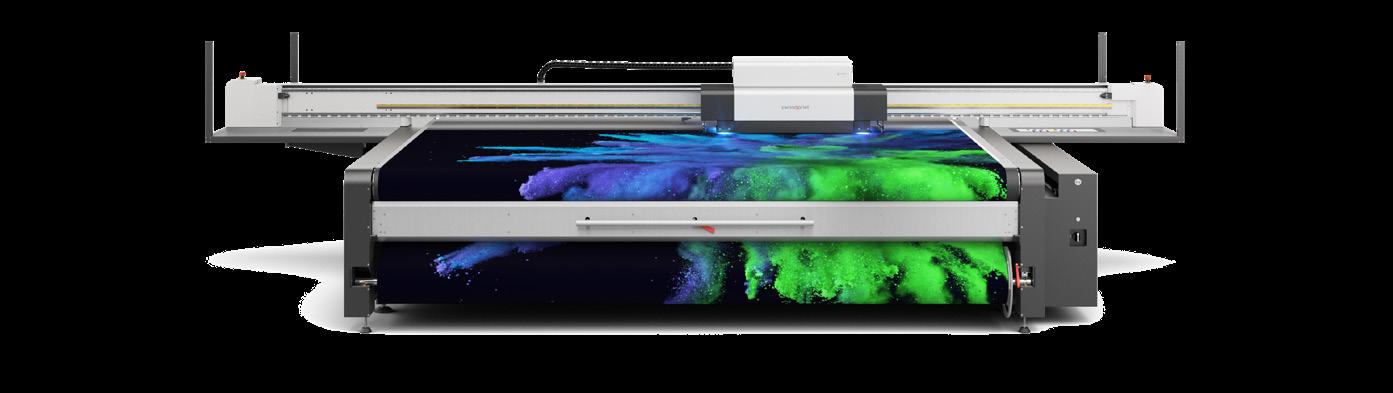

34-35 Total Supply: The new range of Mimaki and swissQprint printers have expanded Total Supply’s portfolio

38 NZSDA Update: Melissa Coutts explains what’s in it for you at this year’s NZSDA Conference

40 NZSDA President: The industry needs both old and new skills, says Andy Lowe

41 NZSDA Signee: Libby and Nathan Wood find that two’s company at Creative Sign Co in Wellington

People in Print Awards Night, photos on pages 20-23

ISSN 1171 7912

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer

Asia Pacific: ProPack.pro

Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2023: Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher.

2021

Official Media Sponsor

agents, company officers or employees. Any use of

is at

contained in

risk of the person using that information. The

should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

Copyright © 2023 — Charted Media Group Pty Ltd

AVERY DENNISON

CORPORATION has transitioned to a bespoke carbon footprint tool created in collaboration with the Carbon Trust to continue its drive towards transparency and continuous improvement in environmental impact measurement and reporting on its products. The Carbon Trust will present information and insights using verified primary data from Avery Dennison’s suppliers and operations to accurately measure the impact of current and future products.

ESKO has unveiled a new version of its software featuring a host of advanced new features that enable businesses to connect systems and workflows, automate processes, and accelerate innovation to help navigate the challenges they face in today’s market. From 3D to AI-powered bots, Esko says it has developed its software version 23.03 to enable customers to unlock value by improving working methods, eradicating waste, and optimising operational processes to overcome the challenges and bottlenecks associated with today’s megatrends.

MPS SYSTEMS has introduced VirtualCoach, part of the company’s connectivity and performance service offering, based on intelligent algorithms that give the operator awareness of the quality and efficiency of all the activities they perform on the press. It uses AI to constantly monitor and respond to processes in real-time, including register settings, machine speed, pressure settings, job preparation, job memory, web tension and service feedback.

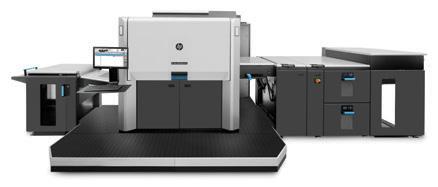

HP has unveiled the HP Indigo 200K Digital Press, developed to give digital flexible converters a competitive edge with better productivity, on-demand delivery, no minimum orders, distinctive designs, reduced energy consumption and minimal waste.

Currie Group, the authorised HP Indigo distributor for New Zealand and Australia, will supply the press locally.

The new press is based on field-proven digital technology for digital flexible packaging and a successful install base of over 300 HP Indigo 25K digital presses, series 4, worldwide.

The new series 5 HP Indigo 200K digital press prints up to 56 metres per minute. HP says it increases the productivity of high-margin, sustainable short runs of digital flexible packaging, enabling delivery within days.

Noam Zilbershtain, vice president and general manager of HP Indigo and Scitex, says, “The HP Indigo 200K is a mid web digital press specially designed for converters addressing the needs of brands in flexible packaging, but it also serves the growing requirements of the label and shrink sleeve industries for higher productivity and wider format.

New Zealand (FBNZ) has provided four heritage photocopying machines from the ‘50s to MOTAT, the Museum of Transport and Technology in Auckland. The donation includes one of the earliest commercial photocopiers, the Rank Xerox Model 1385.

Belinda Nevin, curatorial research manager at MOTAT, says, “We are so pleased to be receiving these devices from the Fujifilm team. To have several machines that showcase the

technological developments and advancements of photocopying in the mid20th Century is rare, and we look forward to adding these rare items to the collection at MOTAT.”

Built in 1953, the Model 1385 found a home at the Government Printing Office in Wellington. Although the 1385 machine made copying less time-consuming, it did involve a manual six-step process to create one copy, and it would take around five minutes to complete the process per sheet of paper.

The HP Indigo 200K digital press offers a 45 per cent boost in productivity

“Flexible Packaging is a growing market, and as HP Indigo customers are growing much faster than the market, I have no doubt that the HP Indigo 200K digital press will open the door for more flexo converters who want to join the success and reign in industry 4.0.”

According to the company, the HP Indigo 200K digital press offers a 30 per cent increase in speed and a 45 per cent boost in productivity compared to the HP Indigo 25K.

Kevin Ptak, head of marketing and communications at FBNZ, adds, “These machines were the first of their kind to enter New Zealand workplaces, starting a new era in office technology and completely changing how people worked.

“It was a pivotal moment in our technological history. Workplace technology has changed enormously since these machines launched, but we are still committed to bringing cutting-edge technologies to help people work smarter.”

German inks and chemicals specialist hubergroup Print Solutions has introduced the first coldset and heatset mineral, oil-free and lowmigration ink series for foodcompliant paper packaging, responding to the increased popularity of paper packaging in the food sector.

The company said that until now, low-migration offset inks were only used in sheetfed printing, and a new binder developed by hubergroup has paved the way for this innovation in web offset printing.

Thomas Stumpf, director of web offset at Hubergroup, said, “With the help of a special binder and the careful selection of raw materials as well as production methods,

we have succeeded in developing the first lowmigration and low-odour web offset inks.

“As safety and sustainability are our top priorities, we worked closely with our sheetfed offset experts who have been developing inks for food packaging for many years.”

hubergroup has conducted extensive practical tests with brand owners, printers, and the special paper manufacturer Drewsen.

The newly launched products enable the production of food-compliant paper packaging in large quantities using four-colour printing in web offset for the first time, opening a range of opportunities for food

The new inks will be initially available in Europe and Asia, with progressive product expansion globally

manufacturers to enhance their packaging designs.

The coldset series MGA Food News and the heatset series MGA Evolution are suitable for packaged baked goods, fast food, products from the deli counter and other packaging.

Printers can use the new ink series on all common coldset or heatset machines and rely on the hubergroup service team’s assistance during implementation.

Amcor has placed its first commercial order of certifiedcircular polymers leveraging ExxonMobil’s Exxtend technology for advanced recycling for packaging in the Australian and New Zealand market.

The order will make Amcor the first flexible packaging company to offer certified-circular plastics in this market, which supports partial displacement of fossil-based feedstock and meets the growing consumer demand for plastic circularity.

Using its Exxtend technology, ExxonMobil offers certified-circular polymers with the International Sustainability and Carbon Certification (ISCC) PLUS certification identical to polymers from conventional fossil feedstock. The certifiedcircular polymers can be used in existing applications requiring virgin resins.

Amcor’s sustainability

director for Asia Pacific, Richard Smith, sees this order as another step toward helping its customers achieve the circularity of their flexible packaging in Australia and New Zealand and meet Australia’s National 2025 Packaging Targets.

He said, “We are excited to provide our customers in Australia and New Zealand access to this important resource and to contribute to developing more sustainable solutions that help our customers and their brands continue to meet consumer needs.”

FUJIFILM GRAPHIC SYSTEMS has appointed Cary Rawson to the role of sales manager, based in Auckland. Rawson, a well-regarded industry specialist with over 29 years of experience in the graphic arts and print industry in New Zealand, worked for nearly 22 years at Heidelberg New Zealand, where he started in 2001 as a prepress service engineer. He climbed the ranks at the press giant in roles such as team leader for prepress and electrical, account service manager, service manager for Pacific Nations and most recently, national sales manager for New Zealand and Pacific Nations.

PULSE ROLL LABEL

PRODUCTS has launched PureTone DC, a new dual-cure UV LED ink range. The new food packaging-compliant ink range includes CMYK+OGV for extended gamut printing. The new ink has application for label converters supplying industry sectors that require compliance with food packaging regulations and guidelines and use just one set of inks with both UV and LED curing presses.

Fespa has confirmed that its Global Print Expo 2023 visitors will see the return of three popular features – World Wrap Masters, Fespa Awards and Sustainability Spotlight, on top of the new online Sustainability and Printeriors hubs.

Fespa Global Print Expo 2023 will host the World Wrap Masters Europe and Series Final (stand B2-D85), kicking off on Tuesday, May 23 and Wednesday, May 24, with the final regional qualifying event: Wrap Masters Europe. The

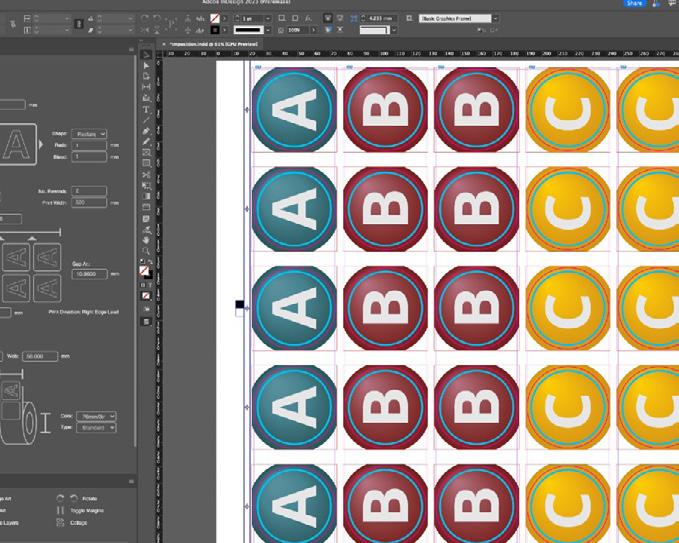

Mark Andy has announced ProWorx Label Suite, an Adobe Creative Cloud extension tailored to the company’s hybrid presses. The extension provides job defining and imposition for printing and post-processing, including diecutting, and, according to the company, allows for more efficient and sustainable label production.

The new software also offers an intuitive panel space to design, calculate,

successful entrants will then compete against winners of the regional heats in Belgium, Denmark, Finland, Japan, Mexico, The Netherlands, Norway, the UK, and Ireland.

This year also sees the return of the

Fespa Awards, which opened for entries in May 2022 for the first time since 2019. Fespa has received over 210 submissions from 34 countries.

Sustainability Spotlight (stand B2-B61) will allow visitors to see and touch various environmentally responsible graphics and textile material samples, including leather and leather alternatives, natural fibres, cellulosic and synthetics supplied by participating companies.

Fespa is also launching a new online Sustainability Hub, providing free and universal access to Fespa’s content, including guides and over 150 informative articles and best-practice case studies.

Printeriors will also be a virtual showcase hosted on Fespa’s website, providing a resource detailing dozens of interior décor applications created for the physical Printeriors showcase since its inception.

control of PDF layers for separation to die and flexo plates. Independent control of individual label lanes makes ProWorx Imposition suitable for multi-SKU gang printing, while Data Merge Assistant features support variable data printing.

Ben Richardson senior DFE specialist at Mark Andy, said, “ProWorx Label Suite is another software solution in our portfolio, following the recently launched sMArt Link, a real-time, on-press data collection and press monitoring system for narrow-web devices.

and record step and repeat data for semirotary and full rotary die-cutting. It saves and recalls imposition template files as well as exports XML data for use in a prepress automation system.

The primary function is the creation of an automatic imposition grid with direct

“It is Mark Andy’s response to customer feedback on their requirements and expectations and is designed to complement our top-class hybrid technology. In addition, it offers converters an advanced software solution that brings efficiency and sustainability to the entire manufacturing process.”

Labelexpo. An increasing number of customers are asking for and trying to explore technologies that can reduce their environmental impact.

“If we were to single out the one product that was the most popular, it would have to be our aluminium magnetic cylinders, made from aerospace-grade aluminium. They are up to 50 per cent lighter than conventional, steel-based, magnetic cylinders.”

Rotary tooling specialist Rotometal has expanded its product range with Eco CRO Sleeves GF, a new line of print cylinders manufactured using naturally derived or recycled materials.

The newly expanded portfolio includes Composite Rotometal Sleeves (CRO), which are modern, ultra-light printing cylinders made of composite

materials that can be combined with aluminium, as well as other plastics like PET, polyurethane, or polyester, using modern techniques to build all layers of the cylinder.

Agnieszka Przybysz-Andrasz, commercial director at Rotometal, said, “ECO CRO Sleeves GF, which include recycled PET plastic for its core layer and a green-technology resin, drove significant interest to our stand at

The company is completing the latest expansion of its manufacturing facilities in Poland, increasing production capacity, and enabling the business to continue widening its offering with additional wide-web cylinders and more innovations.

Przybysz-Andrasz adds, “We are also working on developing new markets. We already have an excellent base in Southeast Asia which will give us a great starting point as we move into Australia and New Zealand, our next focus region.”

Rotometal expands portfolio and prepares to enter local marketGlobal Print Expo 2023 will see the return of World Wrap Masters The software is tailored to Mark Andy’s hybrid presses ECO CRO Sleeves GF feature rPET and green-epoxy resin derived from plant origin

May 21 and 22

September 13-15, 2022

Brixen, Italy

Chicago, USA

Apart from the latest technology and solutions, Labelexpo Americas this year features a full two-day conference programme and two masterclasses organised by the Label Academy on digital embellishment and self-adhesive materials. www.labelexpo-americas.com

In addition to the vast booth at Fespa in Munich, Durst will open the doors to its premises in Brixen, Italy, where attendees will be able to explore the latest developments in digital printing, finishing and converting technology. Durst Oceania is organising a special Oceania Two-Day Event between 21 and 22 May.

September 17, 2022

Napier

Reserve your place by contacting Durst Oceania managing director Matt Ashman at matt.ashman@durst-group.com

Fespa

May 23-26, 2023

Munich, Germany

The Association of Handcraft Printers has a full day programme including visits to Imprimo in Havelock North and Neighbour’s Press in Hastings; a swap meet; as well as a barbecue dinner at the Napier RSA. This is a must attend event for all interested in letterpress and the craft. www.inkianapress.co.nz

Foodtech Packtech

September 20-22, 2022

Europe’s leading printing and signage exhibition will reunite the industry to discover new perspectives with face-to-face business, accessing the latest innovations and trends within the printing sectors. www.fespaglobalprintexpo.com

Auckland

June 23, 2023

Auckland

The country’s largest food manufacturing, packaging and processing technology trade show brings industry professionals and decision makers together providing a forum for education, discussion, as well as sharing knowledge and expertise. www.foodtech.packtech.co.nz

October 11-15, 2022

Shanghai

Since 1993, the Pride in Print Awards have been a pinnacle of recognition for the best in visual print communication products of any given year. They embody a culture of excellence aimed at meeting and exceeding the customer’s needs. This year’s Gala Night takes place at The Cordis Hotel in Auckland. www.prideinprintawards.co.nz

July 5-8, 2023

Auckland

More than 1300 exhibitors will demonstrate their solutions across the 120,000 square metres of show space at the Shanghai New International Expo Centre. Organisers expect more than 160,000 visitors from all over the globe as they open the “Oriental Window of the World Printing Industry”. www.allinprint.com

Letterheads

October 21-23, 2022

Sign Foundry, Welling

Sign Expo has evolved to recongise the sign of the times and renamed to the NZ Sign + Print Expo. NZSDA invited Print NZ Association to join and assist with the organisation and bring both print and sign suppliers together under one roof to view the very best in technologies, new innovations, services, and products at the Due Drop Event Centre www.nzsda.org.nz

September 11-12, 2023

Brussels, Belgium

The call has gone out for all signees to grab their brushes and head to Lower Hutt for the annual Letterheads event. This year’s theme is ‘Red and Blue’. Your hosts this year are Lydia Reeve and Duncan Rourke. www.letterheads.co.nz

Interpack

May 4-10, 2023

Düsseldorf, Germany

The global packaging industry will meet in Düsseldorf with a focus on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. www.interpack.com

This will be the first Labelexpo show in Europe since 2019. Along with demonstrations of the latest printing and converting equipment will be masterclasses and special events focused on Automation and Flexible Packaging. New equipment to be seen at Labelexpo Europe includes the world premiere of the HP Indigo 200K press, the Xeikon CX500t Titon toner press and the Screen Truepress PAC520P water-based packaging press. www.labelexpo-europe.com

Having no experience of the industry before commencing with Dzine Signs, Caleb now serves as the firm’s tradesman signwriter, and runs the CNC machine and engineering area, as well as completing applications and onsite installs as required. Dustin adds, “Through quality apprentices like Caleb, we are proud to be doing our bit to keep the trade alive and strong.

fitted in perfectly with our team and company culture. It is to her credit that she has done so well in her apprenticeship. Since joining us in 2018, Tammy has developed into an invaluable team member. The Big Picture team is very privileged to have her on board.”

Brendan Eyles

PrintNZ has announced the 10 top print apprentices to go through for selection to become the BJ Ball Papers Print Apprentice of the Year.

Ruth Cobb, chief executive officer at PrintNZ, says, “Once again, the calibre of graduates made it difficult to narrow down to just 10. In reading through the comments from their trainers, you will see that every one of them without exception has a thirst to learn and has embraced the opportunities that the apprenticeship and the industry have provided them with.

“Going through the selection process never fails to remind me that the future of the industry is in good hands.”

• Caleb Bowater – Dzine Signs and Display

• Paul Coe – Hally Labels

• Tammy Connolly – The Big Picture

• Brendan Eyles – Williams Signs

• Isaac Kightley – Blue Star Collard

• Catriona Mellows – Display Associates

• Waka Ropiha – Sealed Air (NZ) Hamilton

• Tana Stewart – Hamilton Stripes and Signs

• Jamie Watson – Printcraft

• Saxon White – Stuff, Lower Hutt

Caleb Bowater

Since joining Dzine Signs and Display as a general sign shop worker in 2018, Caleb Bowater has impressed everyone at the company. General manager Dustin Brattle says, “Caleb’s can-do attitude and willingness to learn new areas in the trade constantly is what shines immediately, but then his calm nature under pressure is what is most special. We love having him as part of the Dzine Signs crew.”

“We are employing more apprentices and focusing on making sure they all get the space they need to qualify as good and proactive tradespeople in the sign and print industries.”

Paul Coe

In October 2017, Paul Coe started as a print assistant at Hally Labels. The firm’s labels operations manager Nick Keats says, “Paul has excelled from the beginning.

“He is friendly and personable; he listens to advice; and he will do anything that we ask him to do. Additionally, he is not fazed by working on the more complicated machinery.

“It comes as no surprise to us to see how well Paul has done in his apprenticeship. He is well organised and good at meeting deadlines.

“We feel proud to see Paul continuing a tradition of printers who have journeyed through their apprenticeship at Hally Labels. They have all been very competent. Paul also follows in the footsteps of previous company apprentices who have been named in the Top 10.”

Tammy Connolly

Paige Bell, general manager at The Big Picture, praises Tammy Connolly’s commitment to her work.

Paige says, “In a stressful industry, with tight turnarounds often demanded day in, day out, Tammy always maintains a personable, friendly energy, which buoys the whole team; all the while efficiently working through a big workload.

“She goes out of her way to help others and she can adapt to any task required. She’s fantastic with clients and has

A sign installer and applicator, Brendan Eyles has made his mark since joining Williams Signs, two-thirds of the way through his apprenticeship, at the start of last year.

Peter Ryder, director at Williams Signs, says, “Brendan shows a willingness to learn and accept challenges to improve his work. His attendance has been excellent, and he has a positive attitude.

“Brendan is a focused young man and has worked hard during the apprenticeship, ensuring his theory work was submitted on time and was thorough.

“It’s great to see young people like Brendan taking up the challenge to improve their skills, gain experience and bring fresh ideas to the industry.”

Issac Kightley

Blue Star Collard operations manager Allen Masterson says that, with a family

High calibre of apprentices shows the industry’s future is in good hands.IAIN MACINTYRE Caleb Bowater

helping hand

background in the print business and having established his own reputation since joining the Blue Star Group in 2018, Isaac Kightley’s capabilities deservedly earned the apprenticeship opportunity.

Allen says, “The nightshift supervisor at the time recognised quickly that Isaac had good skills and aptitude and was able to adapt to any requirements of the jobs that he was performing.

“Isaac has been a keen family man from a fairly early age which no doubt has made him learn to manage the pressures, expectation, and stress of being a parent and sole income earner for the family.

“He always handles his responsibilities in a calm and measured manner. It is this quality in his work life that sets him apart. As we all know, print is a bit of a pressure cooker, where everything is needed now and at top quality. Anyone who fails to deal with that aspect of the trade won’t last long.”

Display Associates manager Blair Symes says Catriona Mellows has shown that she has “something different”, since entering the industry in 2017.

Blair says, “I have had several apprentices over the years that start with a hiss and a roar but tend to wane towards the end of the apprenticeship. I say to anyone we place into an apprenticeship: they need to understand what they are getting into.

“Yes, you can pass or satisfactorily complete the modules, maybe during work time, or you can take it to the next level. That is what Cat has done and I have seen her on the weekends and always after work, deep into her assignments.

“We can also tell how she has personally benefited from the apprenticeship. For example, on several occasions when we have worked on streamlining a process, she has referenced previous assignments she has completed, taking the opportunity to implement what she has learned.”

Waka RopihaDamion Robinson, manager for Printing and Laminates at Sealed Air NZ Hamilton, says, “Since he joined us, Waka has demonstrated excellent attention to detail, and a willingness to go the extra mile to excel in everything he does.

“This includes his outside interests like integrated martial arts. He achieved his blue belt promotion alongside his son, while training for and winning the Waikato championship tournament in

the 80kg-90kg class. At the same time, he completed his apprenticeship to a high level.

“Within his first few assignments and seeing the standard of work he was submitting for sign off, we knew he would be in the running for Apprentice of the Year.

“Waka is a great asset to the Sealed Air team. With his commitment, enthusiasm and focus on everything he does, you just know Waka will go far in life.”

Tana StewartHamilton Stripes and Signs director Nick Ross fondly recalls Mr Stewart walking into the firm’s workshop as a 17-year-old in 2017 “fresh faced and eager” looking for an entry-level position.

Nick says, “We took him on and started training him in all aspects of the job, then offered him an apprenticeship about a year later. Tana has a passion for signwriting, and he takes pride in his workmanship. He is also thoughtful and dedicated in his day-to-day tasks. He is a very respected and valued member of our team of six.

“Tana is always on the lookout for new ideas and skills, looking for new and better ways of doing things, and is not afraid to suggest or teach the junior staff what he has learned. He was motivated and dedicated throughout his apprenticeship.

“From day one, he embraced the challenges that came along with doing the apprenticeship modules and kept up the momentum throughout. This has also shown in his day-to-day work ethics.”

Jamie Watson

Having joined Printcraft in February 2018 as a factory hand with no prior print industry experience, Jamie Watson is now entrusted with operating five-colour A2 and

single-colour A3 sheetfed offset presses. Peter Watson, managing director at Printcraft, says, “For a young man, Jamie impressed us with his reliability and attention to detail.

“We were more than happy to offer Jamie the apprenticeship when it became available. He maintains a high standard of work and has proven to be a particularly good trouble shooter, thinking outside the box for solutions.

“We are pleased Jamie has made the Top 10 after all the hard work he has put into his apprenticeship over the last four years. It is well deserved.

“Jamie has also demonstrated a willingness to upskill into new areas of our print environment. He is a prime example of what our industry needs in its workforce to grow and adapt in the modern print world.”

Saxon White

Manuel Leota, press supervisor at Stuff, Lower Hutt, says Saxon White made a big decision to leave a building industry apprenticeship to begin his career in printing. Manuel says, “Saxon was enticed by the exciting career opportunity to join the printing industry as a reelfed apprentice.

“Throughout his time, and up until now, he has shown a desire to learn more about the press and the printing industry. This is evident with his aspiration to do a Diploma in Print Management through PrintNZ. He has become an integral member of our print team. He posseses a can-do attitude and the willingness and courage to take on tasks to help with the running and operations of the press.

“Saxon is a highly valued and well-liked member of staff, not only in the press department, but also throughout the print site overall. It is no surprise to those of us here that he has been named a PrintNZ Top 10 Apprentice of the Year.”

Winners named across the two graduations:

• Heidelberg Offset Apprentice of the Year – Jamie Watson, Printcraft 81, Masterton

• BJ Ball Packaging Apprentice of the Year – Waka Ropiha, Sealed Air, Hamilton

• GAPF Digital Apprentice of the Year (joint winner) – Catriona Mellows, Display Associates, Wanganui

• GAPF Digital Apprentice of the Year (joint winner) – Tamzin Connolly, The Big Picture, Wellington

After completing our industry training graduations in Auckland and Christchurch, I want to shine a much deserved light on the people and companies that are our training champions of 2022.

The graduations recognise the amazing group of graduates who have made a commitment to improve their knowledge base and complete a training programme in the previous year, hence the 2022. They worked hard and persevered to complete their learning programmes. and this represents a significant milestone in their journey.

The bespoke nature of our industry requires print to be versatile and agile. The talent of the people employed is what gets the work to where it needs to be and does what the customer needs it to do.

The word resilience became part of our vocabulary in 2022 and it has carried over to 2023. All the people that completed their apprenticeships and diplomas last year have done the entirety of their study under the shadow of Covid-19 and all its spin-offs. For workbased learning; that is an outstanding achievement. While working around shutdowns, restricted operations, staff shortages and limited access to assistance, they still achieved their goals.

Of course, it takes more than just great printers to make a successful printing company. This year we had 12 people complete Level 5 Diplomas, the highest number ever in a single year, and this assures us that the future of the industry is in good hands. The Diploma in Print Management covers a broad range of topics that take a more in-depth look at what it takes to run a printing company

and the result is a group of well-rounded individuals who can continue to progress their career.

The number and calibre of the Diploma graduates made it extremely difficult to select the winner of the Diploma in Print Management Student of the Year. The two finalists are Rachel Orr from Labelmakers in Hamilton and Sarah Knight from The Big Picture in Wellington.

Selecting finalists for the Trainer of the Year and the Training Company of the Year is no easy task as they have all made worthy commitments to nurture the talent in their businesses and give them a chance to succeed. Those companies and trainers have made an extraordinary effort and we recognised them both for what they do for their own businesses and what they are doing for the industry. We need people like them that are prepared to train others to ensure that the industry has a solid future.

We devote the final part of the night to the sector winners of the Apprentice of the Year Awards, alongside the winners of the Jenkins Award and GAPF Scholarship. These people have excelled in their apprenticeships and as seemed to be the theme this year, the competition was too tough to split. Judges selected six apprentices to contend for the overall BJ Ball Print Industry Apprentice of the Year title.

Our industry relies on highly skilled people to produce the outstanding work that our customers require. You can’t do this without people that are willing to learn; people that are willing to teach; and companies that are willing to support the process: all vital parts of the learning journey.

• PrintNZ Reelfed Offset Apprentice of the Year, Saxon White, Stuff Ltd, Wellington

• Trust4Skills Reelfed Label Apprentice of the Year – Paul Coe, Hally Labels, Christchurch

Jenkins Award:

Paul Coe, Hally Labels, Christchurch

GAPF Scholarships:

• Catriona Mellows, Display Associates, Wanganui

• Tamzin Connolly, The Big Picture, Wellington

Trainer of the Year Finalists

• Rob Ritchie, Opal Packaging, Christchurch

• Wade Collins, Sealed Air Hamilton

• Jason Marshall, MCC Auckland

• Travis Jordan, SCG

• Cheyne Lesa, Blue Star Wellington

Training Company of the Year

Finalists

• Hally Labels, Christchurch

• Opal Packaging NZ

• Sealed Air Hamilton

• MCC Auckland

• Rapid Labels

• SCG

• Blue Star Wellington

The awards culminate in the winners of the Training Company of the Year, Trainer of the Year and the overall BJ Ball Print Apprentice of the Year being named on stage at the Pride In Print Awards on June 23 in Auckland, appropriately recognised for their achievements in front of the whole industry.

On behalf of the industry, a huge congratulations to all our graduates and finalists.

Training graduations show our industry is in good hands.Amanda Wheeler, director of Competenz/TePukenga between the joint winners of the Diploma in Print Management Student of the Year; Rachel Orr (l) from Labelmakers and Sarah Knight from The Big Picture

enjoy being busy. Throughout Covid, we did not have a break.

“Each job is different and one thing we are aware of is that we can’t afford to make mistakes. Once something is on the paper, we can’t take it off. So, it is about performance and understanding the needs of the New Zealand print market.

“We handle all kinds of print volumes and sizes, from A1 sheets and down. Fast turnaround has become the norm in the industry, but it is important to retain high quality for all the printed products we add value to — from business cards and packaging to tickets and vouchers.”

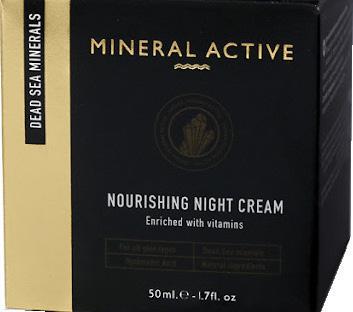

Recently, Contact Labels installed a new press for embossing/debossing and diecutting. She says, “We are excited with the new machine and look forward to putting it through its paces. Embossing gives a printed product a distinctive appearance.”

Contact Labels now offers a range of embellishments including:

• Foil stamping, including hot foil stamping. They offer a wide range of foil colours, which add a luxury look and feel to products.

From its Auckland base, the three person team at Contact Labels provides a range of label and print finishing solutions to trade and retail clients nationwide.

Under the guidance of manager Denyse McQuoid, the company has established a reputation for quality and service. She says, “To achieve a quality print finishing job, you need precision and attention to detail, as well as a passion for the work. We aim for excellence in every job we complete.

“Near enough is not good enough; it must be perfect. If we have to move something half a millimetre, then that is what we will do to make it work.”

A qualified offset printer with decades of experience in the industry, Denyse has helmed Contact Labels for 14 years. She says, “I love the challenge of making a customer happy by meeting, or exceeding, their expectations. From the beginning, it is a matter of getting them on board and taking them through the process.”

She has a knack for working closely alongside customers and believes this is vital for achieving excellent results

and making a difference to their printed product. She explains, “It is worth spending the time with clients to learn and extract all the information they can share, so we can understand their products. This enables us to guide them through what we can provide. It is great when we can make it a happy experience for them.”

She points out that once people in the industry understand how Contact Labels can add value to a printed product, they can offer their own clients a superior service. She says, “Working closely with clients, designers and sales reps has an advantage for everyone as this enables all the people involved to grow as they learn the processes of hot foiling, embossing, debossing, kiss-cutting, die-cutting and many other services.”

As a top trade provider, Contact Labels has built strong relationships within the print community. In addition, word of mouth has proved an invaluable marketing tool for the company. Denyse says, “For most jobs, people come to us. We welcome the challenges that each job brings, and we

• Embossing and debossing.

• Die-cut printing, kiss-cut labels, creasing and perforating techniques.

She says, “Foil stamping adds a new dimension to any printed product. We offer hot foiling in a range of colours and sizes on a multitude of print surfaces. Our skilled die-cut work can fit any shape and size on many types of printed products.”

In addition to its print finishing capabilities, Contact Labels offers a high quality label service. The company’s label production includes hot foil stamping labels, digital labels, and security labels. These can be adhesive, laminated, standard or custom-made. Denyse says, “Our team creates custom labels that allow our clients to convey the right messages to their customers. Once we have had the discussion with them, we can help with their design. Sometimes those conversations take place over the phone.”

She concludes, “We feel passionate about our work, whether it is a simple embellishment or a sophisticated label job. It can start with a phone call or an email, so please get in touch for a free quote on any of our print finishing or labels solutions.”

Trade and retail customers benefit from decades of industry experience.Experience and passion: Denyse McQuoid, general manager at Contact Labels

Automat, P5 TEX iSUB large format dye sublimation printer, TAU Series and Durst Alpha Wallpaper Edition.

Besides the exciting print tour, Durst invites attendees to experience Brixen’s rich culture and history by taking a stroll through the historic old town, admiring the unique architecture of this dual German/Italian city, and indulging in local delicacies.

Durst Oceania will organise a special Oceania Two-Day Event in Brixen on May 21 and May 22.

Durst Group, a manufacturer of advanced digital printing and production technologies, will present its 360 Production Excellence at Fespa Global Print Expo 2023 in Munich, Germany.

Fespa, scheduled to take place between May 23 and May 26, is returning this year, promising to be one of the biggest shows to date, with over 490 international exhibitors already confirmed.

Durst, a platinum event sponsor, is gearing up to showcase its new and integrated systems and solutions for automated, sustainable, cost-effective large-format print production in Hall A2, Stand A10.

Christian Harder, vice president of sales at Durst Group, said, “The focus today is on automation, sustainability, and profitability, and Durst Group’s offerings align with this focus.”

The company will exhibit an impressive installation of next-level automation for unattended print production. As a product launch, Durst Group will introduce the fastest roll-to-roll printer to date.

Durst will also showcase its water-based and UV-LED portfolio of ink systems that follow all relevant regulations and thirdparty sustainability requirements.

The company’s software division will

showcase its advanced software solutions tailored to digital printing, allowing streamlining of the process “From Pixel to Output”: from initial file creation to pre-press, production and final analysis. This enables greater levels of automation and efficiency, improved print production processes and streamlined business.

Durst Group will bring the taste of South Tyrolean hospitality to Munich with the Durst Lounge, a place to discuss, relax, and enjoy some of the region’s speciality foods and drinks.

Attendees will see the P5 500 in the production environment at Escher Digitaldruck, about one hour away from the exhibition. The P5 500 is the reference in the field of five-metre roll devices and the successor of the Rho 512.

While in Munich, visit Durst at its home!

Durst Group also offers a shuttle service to its headquarters in Brixen, Italy, to view the entire P5 large-format portfolio and other segment solutions such as labels and flexible packaging, textile, wallpaper, and ceramic tiles at the Durst Customer Experience Center.

Attendees will take a factory tour and speak to its technical experts while seeing all Durst’s top-of-the-line equipment, including the: P5 500i D4, P5 350 HS hybrid solution, P5 350 HS D4 with

Matt Ashman, managing director of Durst Oceania, said, “Durst sits in the high quality and high production end of the market, but there are two sides to that story. First, we know people want to produce reasonable volumes quickly and at a high quality, but we are seeing that turnaround time is more important than capacity.

“There is also a misconception that Durst caters only for high-volume large companies. Nothing could be further from the truth. Across several print sectors, Durst solutions are ideal for businesses of all sizes. When you look at the production footprint and labour footprint of a Durst machine, you can see how having one Durst printer can free up people who can be better purposed in other parts of the business.

“Durst builds the most technologically advanced printing machines in the world. It delivers a commercial business proposition with a return on investment that can’t be ignored. With a single operator, you can deliver a world-class result. Durst provides automation and efficiencies with greater reliability. From the Durst entry-level label printer to the wide format P5 platform, which is designed for versatility, our solutions continue to surpass our customers’ requirements.”

To coordinate visits or for further information, please visit www-durst-group.com or write to Durst Group. You can also reserve your place today by contacting Durst Oceania managing director Matt Ashman at matt.ashman@durst-group.com.

P5 350/HS

The hybrid printer that elevates the efficiency in your production cycle.

For more information, please visit durst-group.com/p5350

Along with growth will come increased cross-channel marketing opportunities, such as tech-enabled interactive labelling and packaging with links to social media, QR codes and even interactive games. Digitally created interactive labels will also enable users to integrate with the brand at a deeper level, with the ability to access brand-specific micro-sites to promote individual products, events, or campaigns.

Ispent years attending trade shows the world over and loved every minute. Along the way, I gained an intimate knowledge of how quickly technology evolves; it is almost mind-blowing.

I would block out hours to chat with vendors about integrations and possible automated workflow solutions, imagining how far we could go linking upstream and downstream operations via e-commerce.

Jump forward to 2023, and it is no longer a competitive advantage but an absolute requirement. If you haven’t connected your digital front-end with CRM, MIS, digital press, inline finishing and so on, you are missing out. It doesn’t seem that long since I had imagined a time when an order could be automated from commencement directly into the warehouse. As it turns out, this is only the beginning of our digitally connected future.

From a manufacturing perspective, the digital production line can produce finished output inline. So, a savvy operator can automate from commencement to completion. This offers the ability to integrate custom embellishment techniques into the workflow, such as embossing, laser die-cutting, and even foiling. Adding these types of finishes can increase quality perception, the quality that customers recognise via an item’s look, touch, and feel, by up to 46 per cent. Take packaging, for example; foil enhancements increase attraction rates by more than 250 per cent.

Then there’s the evolution of the digital presses themselves, where the world’s most productive B2 digital solution, the HP Indigo 100K Digital Press, prints over 100,000 impressions per shift. Combine that speed with abundant upstream and downstream capability, and you have one hell of a workflow.

Not to mention the AccurioPress C14000. It’s the flagship model in Konica Minolta’s range of SRA3 format digital toner production presses, introducing new levels of automation and self-calibration, plus plenty of configuration options and inline finishing modules.

Then there’s the Scodix Ultra 2000 digital enhancement press that fuses flexibility, quality, and productivity. Scodix provides a vast array of enhancements on a single platform, replacing the need for separate systems on a production floor. Included as standard is: Scodix Sense, foil, metallic, glitter, and spot, plus a range of optional extras.

These days, print companies are no longer content to simply churn out standardised products; they’re innovating with cuttingedge digital tech and becoming increasingly focused on delivering personalised experiences. So, we’ve gone from one size fits all to tailor-made solutions. Which makes perfect sense if you check the data.

According to research from leading industry analysts, Smithers, the analogue print industry was worth $734.5bn in 2017. By 2027, this market is expected to be worth $721.4bn. Digital print, on the other hand, was worth $122.9bn in 2017 and is expected to reach $189.8bn by 2027. We should also see a 3.1 per cent compound annual growth rate (CAGR) for packaging over the next five years but an 11 per cent CAGR for digitally printed packaging, representing a massive gain in market size.

When you buy something online, it’s a wonder the physical universe hasn’t broken down yet. Between orders, printing, embellishing, and packaging to tracking, delivery, follow-up notifications and special offers, we owe our modernday convenience to an intricate dance between digital and reality.

Get ready to enter a whole new shopping dimension. Consumers of the present and near future are all about speed, convenience, and having access to every channel available. Without further ado –welcome to frictionless retailing.

In a world of advanced technology, the ability to implement digital printing, integrated workflow, automation, and enhanced finishing options gives business owners an undeniable edge. The digital printing revolution is here, levelling the playing field for all brand owners.

The benefits are clear. Streamlined production, cost savings, and improved customer satisfaction are only a few of the rewards that businesses can reap if they incorporate modern technology with tried-and-true production methods. With increased access to advanced tools, there’s never been a better time to take control of your printing process and get ahead of the competition.

The future has arrived, calling for innovators to power their businesses forward. Get ready – it’s time to start planning how you’ll bring cutting-edge technology into the fold.

Mick Rowan has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

The new AccurioLabel 230 offers enhanced productivity, job flexibility, operability and excellent image quality at an affordable system cost, making it the perfect solution to ensure you always deliver high quality labels on time, every-time. Printing at an impressive 23.4 metres per minute and with a compact footprint, this label press is perfect for label converters looking to convert to digital technology as well as those entering the label market.

To rethink label printing, simply visit: konicaminolta.co.nz/AccurioLabel-230

Last September, Masterton-based Printcraft updated its Konica Minolta AccurioPress C6100 with an AccurioPress C7100. The company also installed an AccurioPress C4070.

Peter Watson, owner and managing director at Printcraft, says, “We were happy with the C6100, but we still went to market, exploring all the options available. My wish-list was long and tough. I decided early on that to improve productivity, we were best to purchase a second machine, rather than opt for one

machine with more capability. But the second machine would have to be capable of producing the same quality as the main digital press.

“Right from the outset, Adam Hawkes and the team at Konica Minolta worked hard to make sure their proposals aligned with my wish-list. They succeeded. No one else came close to offering as many options as possible at a manageable price.

“Both machines have bulk bins, IQ colour management units, and stitching units.

The C7100 also has the new stacker unit which will fill the stacker, eject to a trolley, and continue running to the stacker, for ‘hands free’ operation. Both run Konica Minolta Controllers which are extremely versatile for experienced operators. As we had already run this RIP on the C6100, it was an easy transition.

“A big one on my wish-list was a colour management system which we could manage offline, measure a result to a small tolerance, and get written reports to ensure we always get as close to our

colour standard as possible. Konica Minolta came through with the Konica Minolta FD-9 spectrophotometer and the AccurioPro Colour Manager Suite.

“Mark Northin, from Konica Minolta, worked long and hard with an expert on my team to tailor this system and create custom profiles, specifically to our needs. It is fantastic. Every day, we are sure we are meeting our standard for our clients. Occasionally, we get a fail, which alerts us to wear and tear on parts before it becomes a visible issue.

“I am constantly amazed how the two printers match print exactly. I can split long run jobs between the two or run any historical job on either machine without compromise on colour or quality. A job we ran three months ago matches exactly to the job we will run today. No more wasted time adjusting files to try to match something we printed last week.

“Productivity has doubled. We are already well into the millions of clicks. The result is higher productivity, less stress on staff, and less late nights trying to meet deadlines.

“We can now enjoy three weeks between tech visits. We have not had this level of stability with any other digital press system. The team at Konica Minolta are also open to trying ‘press only’ stocks on these machines, even some that are a definite ‘No’ from other suppliers. Subsequently, we have enjoyed enormous success in opening new markets which suit the versatility of digital, while still being able to use challenging stocks.

From his start in the industry at Government Print as a photolithographer almost 40 years ago, to his position running Printcraft today, Peter has witnessed some profound changes in the sector. He says, “I have been in the industry all that time, and it is a fast-changing beast, particularly in prepress. I absolutely love the challenge of new technology and the way we must constantly adapt to fresh ways of producing printed material.”

Printcraft is a print institution in the Wairarapa, currently employing 16 staff. He says, “Printcraft has supplied print from Masterton since before World War II. I began here nearly 25 years ago, and I was lucky enough to have the opportunity to purchase the company three and a half years ago.

“I have an absolutely fantastic team. We enjoy a wide variety of work from an eclectic mix of clients. Every day we are looking at new ways to produce work or have the chance to produce something

completely new. My team are always up for the challenge, and it makes for an exciting workplace.”

He is realistic about the industry’s future. He says, “The print industry is having a tough time of it, but haven’t we been saying that for the last 30 years?

“There is no denying we are still in the grip of supply issues. It is improving slowly, but lines of paper are coming and going at a horrifying rate. Trusted paper brands suddenly dry up and we are faced with testing, and budget reworks to try to leave the client as unaffected as possible.

“Rising prices from every direction have caught many of us out. Margins have been squeezed at such a rate that we have found ourselves on the back foot for the last 18 months. We underwent a review across the board in January, and it proved how far behind we were. Many customers have trimmed the fat, including their print requirements, but we keep giving them the best service possible, so as the economy strengthens, we are set to help them grow again.

“This year, I have seen a marked improvement in business confidence across my client base. Inflation and the New Zealand Dollar are arguably stabilising. Businesses are just getting back on with it. My export clients are experiencing good growth. I am feeling positive for the coming year. I think we should try to ignore the negative media and economic forecasts. Just get on with what you do well.

“I firmly believe print has a solid future. Packaging, labels, and signage are still experiencing solid growth. We have diversified and expanded into these growth areas with solid success. “Online ordering is here to stay, but whether the purchase is instore or online, as a customer you want to feel wowed with the packaging when you open the product.

“Printed books are also a winner for us. People are realising that a great healer for mental health is a good read. You can feel the tide turning against online advertising too. It bombards the audience so much that it is mostly ineffective.

“Our bright future requires partners we can rely on such as Konica Minolta, and I have become increasingly fussy on which partners we choose. It is vital that the service and supply of print production equipment is sourced directly from the manufacturing company, so having Konica Minolta New Zealand as a direct operation is a real plus. The level of service we are receiving is top notch.

“The sales and technical teams are always available, often working very long hours to sort solutions and keep us pumping. Their work ethic is second to none.

“It is also the only company whose managing director has taken the time to talk with us. Spending time chatting with Eric Holtsmark has shown how he takes a genuine interest in the businesses looking at purchasing Konica Minolta products.”

Over 100 print industry professionals joined New Zealand Printer Magazine and PrintNZ in Auckland to celebrate at the 2023 People in Print Awards and Rising Star Awards.

GOLD SPONSORS

SILVER SPONSORS PLATINUM

BRONZE SPONSOR

global population, rising demand and saturated markets caused by the ongoing e-commerce boom. Furthermore, more environmentally-friendly technologies are expected to generate new growth potential for the industry by using sustainable paper, inks and coatings, which are in turn are expected to drive the demand for innovative machinery and applications. We should therefore not lose sight of the new and very exciting vertical market of functional and industrial print.

Solutions revolving around sustainability and digitalisation as well as new applications will be centre stage this year and over the coming years. drupa 2024 will show how these will impact processes, products, business models and the future of our constantly evolving industry. We will be prioritising topics such as the circular economy, resource efficiency, recycling, automation, print and finishing 4.0, artificial intelligence, platform economy and connectivity.

2022 was a challenging year – still characterised by the effects of the pandemic, the war in Ukraine, disrupted supply chains, the energy crisis and inflation. Nevertheless, there is an opportunity in every crisis and against this backdrop, there were also many positive developments. After many difficult COVID years, 2022 sent out the signal of departure of the pandemic, of the re-starts of trade fairs and events and a new normality, which gave a fresh boost to many industries.

However, the war in Ukraine and its consequences had and still has the greatest impact. Geopolitical impacts therefore also prove by far the greatest challenges for most print service providers and upstream suppliers. The print industry is affected, especially by paper supply bottlenecks and high energy costs. But the industry is resilient, and we can feel that sense of new departures fuelled by innovative technologies and opportunities in new target markets. The industry looks to the future with optimism.

I expect that in 2023, we will continue to struggle with the effects of the crisis and skilled labour shortages will also remain a major challenge. But confidence and trust will increasingly return allowing the industry to unfold its full potential. The print industry is highly relevant in terms of its diversity and areas of application. With the help of smart,

strategic investment, market players will succeed here.

Transformation brings new opportunities. And this is what makes the print industry special. We see the courage to venture into innovative and new business models and the big growth potential offered by digital technologies.

In 2022, many companies acquired new core competencies and optimised their internal processes in terms of IT structure, the further digitalisation of workflows and processes, efficiency and automation. All of this goes hand in hand with understanding and fulfilling the needs of brand owners.

On the quest for growth opportunities, you must always be up to date, analyse trends and markets and be aware of innovations. It is advisable to put one’s own actions to the acid test constantly. Ask yourself: Am I well placed? Am I leveraging technological progress? Am I investing in the right things? And am I investing enough? The process associated with structural change is not always easy to introduce and often hampered by obstacles and resistance.

The areas of growth potential within the print industry are wide and varied. Looking at the results of the 8th drupa Global Trends Report, we see a positive outlook especially for the packaging market due to a growing

drupa views itself as a relevant platform for knowledge transfer and as an innovation driver for the industry. This USP also holds true for the non-drupa years. At present, our focus is entirely on drupa 2024.

“We create the future” – the drupa 2024 claim – highlights how the industry will rise to tomorrow’s challenges to tap into opportunities, potential and new business models. To stay successful in the future, companies will identify their development potential, adapt future technologies and mega trends for their needs to take corporate decisions with strategic confidence. This goes hand in hand with the goal of developing a clear vision of the future, a vision for relevant changes and necessary adjustments for today’s and tomorrow’s business.

We are planning the details with our exhibitors and designing our Special Forums, which are touchpoint packaging, dna – drupa next age, drupa cube, touchpoint textile and touchpoint sustainability.

Prior to drupa 2024, drupa Global Events will tour the world and attend the Print & Digital Convention from 16 to 17 May in Düsseldorf, Pack Print International and CorruTec Asia from 20 to 23 September in Bangkok, Pack Print Plas Philippines from 5 to 7 October in Manila and All in Print China from 11 to 14 October in Shanghai.

Jeff says, “You can achieve so much with the latest HP digital technology. The HP Latex 2700 printer’s quality is up there with all of HP’s other platforms. We have high expectations in terms of the quality of products we deliver to our customers, and we spend a great deal of time and effort getting things right. We complete all our printing profiles and colour calibration in-house. The HP Latex 2700 printer falls in line with all our other HP gear, which means we have colour consistency across different machines.

“It is printing billboards right now and we are building our own profiles with it. So far, what we have seen of the machine is excellent and speed wise, it surpasses our older platform. The HP Latex 2700 printer offers so many benefits with operator functionality, which come from HP innovations in the new technology.”

Christchurch-based Adgraphix produces the full range of wide format printing, from signage, trade show and retail displays to vehicle graphics, soft signage, and old-fashioned signwriting as well as high-end print production.

Jeff Gibson, a screenprinter and Scott Shore, a signwriter, founded the company 25 years ago. They have built a solid reputation with quality printing and customer service. Jeff says, “We have diverse a range of clients, many local and several nationwide. Most of our clients give us print ready work so production is our core business. Many clients are designers themselves.”

Recently, Adgraphix installed the country’s first HP Latex 2700 printer, supplied through Aarque. Jeff says, “We have several HP wide format machines including an HP 800 and HP R2000. This is an upgrade. HP builds reliable machines and we really got a good run out of the HP printer that the HP Latex 2700 printer replaces.

“The installation went smoothly. HP flew an engineer over from Barcelona, Spain

and one from Sydney. The HP Latex 2700 printer arrived on the Tuesday, and we were up and running on the Thursday. Our operators are quite well versed on the new kit. To start with, we will use it to mainly produce billboard and PVC-free banner products, as well as high volume self adhesive jobs.”

HP says its 3.2m wide HP Latex 2700 printer takes production efficiency to the next level, offering vivid colours at up to 89 square metres per hour via symmetrical double printheads, which come equipped with automatic printhead cleaning technology. It enables you to take on high-margin jobs with 30 per cent wider gamut at high speed, preserving media gloss and feel across a range of signage and décor applications including thin films, vinyl and paper.

The new printer takes HP Eco-Carton cardboard–based ink cartridges that reduce plastic by using one hundred per cent recycled and recyclable cardboard containers, as well as recycled plastics from HP’s closed-loop recycling process, including post-consumer beverage bottles and U-validated ocean-bound plastics.

The HP Latex 2700 printer is not the company’s only New Zealand first. In 2018, Adgraphix installed the country’s first HP R2000 Latex wide format printer. Jeff says, “There was a time, we would have felt quite apprehensive about having the first printer. However, this no longer fazes us because we know we have the service and support we need.

“We have enjoyed a strong relationship with HP going back 20 years. For us, having the faith that if something goes wrong, they will back us up is important. We have a really good relationship with Aarque, having known Leo and Jason Bult from our early days. They gave us a lot of help then and we see them as good friends.

“When Scott and I started the company, digital was coming along and we took a punt. We are pleased we did, although looking back, the past 25 years seems a bit of a blur. It feels like we started out only yesterday.

“Aarque has quite a strong team and the local Aarque salespeople are definitely reactive to our needs. In this industry, everyone wants everything yesterday, so it is good have a strong supplier behind us knowing they will support us with everything from hardware to inks and from rolls to flat sheets.”

The new large format Colorado M-series is equipped with UVgel Ink support, including optional white ink, amongst other stellar features

Canon Production Printing (CPP) has expanded its roll-to-roll printers portfolio with Colorado M-series, a modular 1.6m machine with two speed configurations and Canon UVgel white ink support.

The new large format printer has been developed to boost productivity and substantially expand the range of applications, supporting business growth with diverse graphics and décor applications.

Retaining Colorado’s industrial build quality, the new M-series design is based on a single platform that can be configured to customers’ needs and grow alongside their business with easy in-field upgrades.

The scalable series includes M3 and M5, two base models offering a choice of an output cruising speed of 29sqm/h and 40sqm/h and maximum print speed of 111sqm/h and 159sqm/h, respectively. Both printers can be easily upgraded to W versions for white ink (M3W and M5W).

Introducing a white UVgel ink maximises performance for a full spectrum of premium graphics and décor applications, such as window graphics, labels and wallpaper.

The Colorado M-series also features new media detection sensor technology for easy media handling, offering customers expansion of their typical product with heavy structured, transparent, coloured, reflective and magnetic materials.

The unique gel formulation of Canon UVgel ink translates to a fast build-up of dense and opaque white images in fewer passes than with conventional printing technologies, with printed output maintaining its original whiteness over time.

According to CPP, it also eliminates many production issues commonly associated with white ink, such as nozzle cleaning and maintenance, offering smooth, error free printing and minimising ink usage and waste while maximising productivity.

FLXfinish+ option to add matte, gloss or mixed matte and gloss on the same print without additional varnish. High-volume customers can automate the print-tofinish process with a UVgel Print Factory or UVgel Wallpaper Factory configuration, which integrates the Colorado M-series printer with cutting, rewinding, taping or sheet stacking to manage volumes of at least 50,000sqm per year with minimal operator time.

Craig Nethercott, managing director of Canon Production Printing Oceania, says, “Ever since they burst onto the market, Colorado printers with UVgel ink have set the highest bar for speed, quality and allround productivity.

“On top of these business-critical performance criteria, customers today want to make smart, environmentally responsible investments in large format graphics printing solutions that can evolve with them and help them tap into lucrative creative applications, products and markets.

“With the addition of an easy-care white ink option, the new modular Colorado M-series is the growth engine that businesses need to level up their capabilities and turn ideas into reality.”

CPP says UVgel ink delivers pin-sharp image quality and consistent colour, while its instant drying properties enable immediate cutting and finishing, and its

ultra-durability removes the need for lamination.

According to the company, compared to other ink technologies, such as latex or eco-solvent inks, UVgel technology consumes up to 40 per cent less ink to build up the same image quality and colour intensity.

The low-heat, energy-efficient LED curing system and instant-on operation reduce energy use compared to other technologies. With UVgel technology, customers can print on environmentally responsible materials, even uncoated, PVC-free, paper-based media. This means the Colorado M-series printer fits perfectly in a sustainability-conscious organisation.

Like previous Colorado models, the M-series is designed to handle the workload of multiple legacy roll-to-roll printers, with industrial-grade round the clock reliability and unattended printing with minimal operator intervention.

It is supported by PRISMAguide software and designed with a low total cost of ownership and rapid return on investment in mind, thanks to the low operating costs, the ability to produce high-value applications, and the modular upgrade options.

The Colorado M-series is available via accredited partners and CPP’s regional direct sales organisations.

Are you ready for the next level in productivity, creativity and profitability? With the Colorado M-series, now including white ink, say ‘yes’ to more jobs, create stunning applications and promise short turnaround times. It’s field upgradeable to grow with your business, and designed for a low cost of ownership.

urgent jobs. For us, completing all the production in-house is the only answer as we grow. Our production bottleneck was always the signwriting, but the EFI has removed that.

“The EFI is printing on 900gsm truck curtain fabric and right now, we are printing three to four sets of truck curtains per day. We know it can handle more work, so we have capacity to grow. We use the EFI software, and it is pretty user friendly. The EFI VUTEk D3r is a reliable machine so we don’t have much downtime.

The country’s largest industrial fabric product manufacturer has a long history that goes back to its beginnings in 1937 as Sails & Covers, designing and producing sails and marine products.

During the 1970s, a company restructure saw the creation of Structurflex as a subsidiary of the sail-making business. The new company focused on the design and manufacture of industrial products, such as truck covers, marker buoys, railway wagon covers and flexible containers.

Structurflex has grown dramatically and developed new technology to become one of the world’s leading suppliers of innovative tensile membrane structures with a commitment to creating innovative, cost-effective products.

Simon Higgs, managing director at Structurflex, says, “We have manufactured truck curtains since the early nineties and for over 25 years, we outsourced the printing and signwriting. Initially, a much larger portion of the curtains were signwritten, rather than printed, but as technology has improved, we have brought the graphics in-house.

“We still do some signwriting, but it is labour intensive, time consuming and there is a lot of waste with it. Also, it requires skilled staff, which are very hard to find these days.”

Last year, Structurflex installed an EFI VUTEk D3r, supplied and serviced through Currie Group. He says, “EFI has a proven track record in Australia and the two big curtain manufacturers there have this machine. We have a relationship with one of them, and I saw their machine in operation two years ago.

“Previous to installing this machine, we had not been in the printing business, so we were not looking to reinvent the wheel. We know printers in the past have failed on the truck curtain side of things because the requirements are different than other wide format printing. With a billboard, it does not open and close 50 times a day.”

The new printer has made a significant difference to production. He says, “When we used to outsource the printing, they could only print on white substrates. And, prior to getting the EFI, all coloured fabrics had to be signwritten. The EFI has given us the white ink, which enables us to print on the likes of yellow, green, blue, and black fabrics.

“The adhesion is amazing, better than we expected. The print quality could not be better. It is significantly better than the solvent printers used when we outsourced the work.

“We have cut down on transport and lead times. We now have the ability to do

“As an option, we went for the super-duty winder, which helps when handling heavy rolls. This motorised winder uses a tensioning bar, reducing the chance of having a fault. We have the option to add other features, such as a slitter, in the future. We currently hang banners and truck curtains on the wall to clearcoat them, but the EFI has a clear option to print, which we are looking at using.”

Currie Group is impressed with how well Structurflex has integrated the EFI VUTEk D3r into its operation. Paul Whitehead, business unit manager, Sign & Display at Currie Group, says, “When installing this system, we knew the technology was proven. However, we went in knowing there would be a steep learning curve, given that in-house digital production was new for Structurflex. It has been amazing to see just how fast the team has got up to speed with the technology and more so, how much of the work has already now been converted to digital.”

Simon adds, “We have found Currie Group to be very helpful. We have a good relationship with Craig Paul, Currie Group New Zealand country manager, and Paul Whitehead in Australia is really knowledgeable. Currie Group’s New Zealand office is only a short drive from here, but we have not needed the technical support as much as we thought we would.

“We like providing our customers with high quality products and providing exceptional customer service and one of the cool things is that we see our products all the time.”

© 2021 ELECTRONICS FOR IMAGING, INC. ALL RIGHTS RESERVED. | WWW.EFI.COM

© 2021 ELECTRONICS FOR IMAGING, INC. ALL RIGHTS RESERVED. | WWW.EFI.COM

Here are the five pillars of the insp-hiring methodology to help you think through your approach:

1. Perspective: Are you approaching all things talent as though it’s a partnership? From hiring through to all aspects of the employee experience. Do you understand the human operating system and what people are really looking for from work?

The post-pandemic talent landscape feels very unfamiliar to most business leaders right now. There’s a giant skills shortage, people won’t come into the office unless they must, and advertising on jobs boards isn’t delivering the number of applications you used to get.

It’s difficult to keep people as they’re often headhunted by competitors for more money and balancing productivity and morale is a constant struggle.

When and why did everything change? And more importantly, what can we do about it?

Things have been changing for many years now, but the pandemic shutdown accelerated things dramatically because it allowed people the space and time to think about how they were feeling instead of running relentlessly on the treadmill of work and life.

New roles are being created daily and others are disappearing, so we have many people looking for work who just don’t have the skills to do what’s needed –and few if any, who do.