Australia’s smart packaging powerhouse www.propack.pro December 2022 People Technology Business ALSO INSIDE... Functional packvertising A FOCUS ON: Smart packaging becomes active It is gaining pace and adopting new meaning as it promises to disrupt ‘functional’ packaging Pack Expo packs in the know how Visitors at the US show immersed themselves in the tech and trends A modern solution by inke packaging The Melbourne-based start-up is disrupting the packaging industry Part of the

Please pass on our thanks to the team for the quality and service for both prints this week. Arrived on time and in good shape which is a pleasant change from some of the jobs we have received from other places.

Kevin

I just wanted to say thank you for rushing those 2 banners through for me, I really appreciate how quickly you made that happen, pretty amazing service.

Kelly

Thank you for having this order completed so promptly, the print quality is faultless and the blind shipping is very much appreciated

Donna

The postcards were delivered to them this morning and the client is impressed bordering on disbelief. Not sure exactly how you and the team did it all so fast but thank you.

Tom

Great job on the books - client is stoked! Thanks again for suggesting the extra laminate -it really made a huge difference! Appreciate it!

James

Loving the magnetic boxes the velvet cards come in, a great way to present the card to the client.

Sarah

o Queen ^

‘CUSTOMER IS KING AT HERO PRINT’ ...AND

IT SHOWS

AUSTRALIA’S BEST TRADE PRINTER

Hafizah Osman

Smart packaging is the right step in any packaging company’s future direction. This is because it makes the manufacturing a more precise process and provides the entire supply chain with additional data for transparency and clarity.

The leaders in the adoption of smart technology have already seen its benefits and have realised how smart packaging can not only increase margins, but also enhance the customer experience and product packaging utility. Its benefits are not just limited to that. Smart packaging solutions also let businesses identify market trends and customer preferences.

There is little doubt that while smart packaging is currently in its infancy, its potential application and merits are immense when used across a variety of

industries such as foods, pharmaceuticals, and other types of verticals.

Research has identified that the global market for smart packaging is expected to reach US$26.7 billion by 2024. With modern companies seeking to invest in sustainable solutions and other technology integrated packaging solutions, it is expected to reach US$59 billion globally by the end of 2025.

This issue of ProPack.pro looks at how smart packaging has gained pace and is adopting new meanings as it promises to disrupt the ‘functional’ packaging that we are all familiar with, as well as reconciles our planet with profit, people, data and the Internet of Things. It also investigates how Peacock Bros. has become a smart packaging powerhouse in Australia. We hope you enjoy the read.

We would also like to issue a correction for the September 2022 issue of ProPack.pro. In the Auspack 2022 feature on page 27, the Foldline 9000 from Trimatt Systems can produce up to 20,000 sleeves per hour, instead of the 2,000 sleeves per hour mentioned in the story.

As this is the last issue of ProPack.pro for this year, we would like to take this opportunity to thank everyone that has supported our magazine and website. We look forward to working with you again next year. Merry Christmas and happy holidays!

Hafizah Osman | Editor hosman@intermedia.com.au Ph: +61 431 466 140

Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

www.propack.pro 4 ProPack.pro December 2022 EDITOR’S LETTER Stay informed… visit www.propack.pro and subscribe to receive the latest packaging industry news and views ProPack.pro is published by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication.

future is smart ProPack Industry Supporters Managing Director & Publisher: James Wells Editor: Hafizah Osman Design: Sarah Vella Sales Manager: Carmen Ciappara Production Manager: Jacqui Cooper Pre-Press Manager: Tony Willson Printed by: Hero Print, Alexandria, NSW 2015 Mailed by: D&D Mailing Services DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the

The

Copyright © 2022 — Charted Media Group Pty Ltd

IN THIS ISSUE...

P10-11 P28-29 P18-20

Going clean and green in the hospitality industry P6

As hotels strive for higher sustainability standards, amenities brands are rising to the occasion with eco-friendly solutions that impress

Consumer electronics industry works with external partners P8

The consumer electronics industry is collaborating more with agencies that advocate and lead in the delivery of sustainable practices

Building Australia’s smart packaging powerhouse P10-11

Peacock Bros.’ acquisition of AMR Hewitts PrintPackaging has united 280 years of printing history and created a powerhouse ready to start the smart packaging revolution

Peacock Bros. grows Little Bang Brewery’s sales volumes P12

Little Bang Brewery turned to Peacock Bros. to develop an efficient and flexible printing solution that could produce high impact visuals

Smart packaging becomes intelligent and active P14-16

Smart packaging is gaining pace and adopting new meanings as it promises to disrupt the ‘functional’ packaging that we are familiar with

How packaging can be emotional as well as functional P18-20

Whatever the package, it can work harder, offer more, engage the consumer and boost customer satisfaction when using Packvertising

Pack Expo International packs in the know-how P22-25

Visitors at the US show immersed themselves in technology and business innovations, heard about the latest trends and shared knowledge

The entry into the circular economy must succeed P28-29

Sustainable packaging points the way forward for the market

Using smart packaging where wine is verified by blockchain P30

Magic Add addresses a project that utilised a fully automated smart packaging production process

A new way to look at packaging: Greiner Packaging P31

Greiner Packaging provides some insight into its K3 Packaging solution

the best labelling recycling system for NZ P32

Finding

P26-27

Fulfilling packaging requirements with inke packaging

inke packaging aims to become a full-circle service provider by improving its products and expanding the offerings for its customers to utilise

THIS ISSUE SUPPORTED BY

A recent move promises to make sustainability even more effective

Pack diary P34

A guide to the upcoming events globally

www.propack.pro December 2022 ProPack.pro 5 CONTENTS

Clean and green for hospitality

By Ruth Hogan

An eco-revolution is underway in the hotel amenities space as brands take action to reduce their environment footprint. Groupe GM, a global leader in hotel amenities, is an example, having recently redesigned its popular Clarins hotel line to better reflect the company’s sustainability goals.

The relaunched Eau Dynamisante range features 100 per cent recycled plastic bottles in 30ml and 60ml sizes, as well as a larger 300ml Ecopump version, while a refillable packaging solution known as Ecofill will be rolled out in the coming months. Furthermore, the soaps are certified by the Roundtable of Sustainable Palm Oil (RSPO) and the range is packaged in the Forest Stewardship Council’s (FSC) white and red cardboard boxes.

Groupe GM CEO Laurent Marchand said the revamped range reflects the standards and beliefs held by both companies.

“Groupe GM is dedicated to innovation, quality, and sustainability and we share an important commitment to the environment. This collection of amenities is consistent with our Care About Earth program and it is ideally suited to our guests’ needs,” Marchand said.

Refillables on the rise

Large format, refillable solutions have become a preference for hoteliers

globally as they seek to reduce their impact on the environment.

“With some states internationally already mandating a move from singleuse amenities, the future of hotel amenities will be large format amenities in sustainable packaging,” Buzz Products APAC regional client service director Janet Gibson said.

No longer considered a low budget approach, refillable amenities have evolved to cater to the luxury guest.

“Brands are choosing better materials, quality pump dispensers with brackets and taking a more considered and responsible approach to manufacturing practices,” Hunter Amenities Australia APAC managing director Michael Matulick said.

Eco-conscious choices

Beyond refillables, there has been a raft of eco-conscious innovations to support the sustainability movement across materials, packaging, and formulations.

“We’re seeing a rise of more conscious product – whether that’s with considered eco-friendly packaging, certified organic local ingredients, or native botanicals –as well as clean, natural and non-toxic formulations that are free from parabens, silicones and not tested on animals,” Matulick said.

For example, Swisstrade has created factorysealed dispenser systems Press and Wash, Smart Care, and the recently launched SHAPE – short for Sustainable, Hygienic, Aesthetic, Pump, Evolution – which dispense the exact amount of product required.

Vanity Group recently introduced the world’s first 100 per cent sustainable amenity program incorporating aluminium tubes and woodchip bottle caps.

“This allows hotels to pursue a mini tube amenity program without contributing to the 450 million tonnes of plastic produced in the world annually,” its sales and key accounts vice-president Nick Mina said.

Post-consumer recycled material, repurposed OceanBound material, sugarcane, corn-derived plastics, and biodegradable additives are also being used in packaging to help hotels create a sustainable stay for guests.

Each decision a hotel makes about where the products come from also has an impact. Mina advises hoteliers to align with suppliers who have attained global accreditation from the likes of PETA and The Vegan Society.

Shared values

Many hotels are also seeking brands that align with their values, for example, Australian-made, eco-friendly, those who use native ingredients, and/or participate in community givebacks. These brands can act as an extension to a hotel’s corporate social responsibility.

“A growing number of operators in our region no longer view guest amenities as a cost, but as an extension of their marketing strategy, using toiletries brands for storytelling and to create memorable guest experiences that last,” Swisstrade director Peter Weingartner said.

Swisstrade recently launched SHAPE to help hoteliers reduce plastic and product waste

www.propack.pro 6 ProPack.pro December 2022 FOCUS HOSPITALITY

As hotels strive for higher sustainability standards, amenities brands are rising to the occasion with eco-friendly solutions that impress

Luxury guests now expect premium bulk amenities

REACH & SVHC COMPLIANT HEAVY METAL FREE VOC FREE BS5609 SECTION 3 COMPLIANT For more information, please visit durst-group.com/label Industrial scalability 330 / 420 / 510 m m print width Jumbo winders Flexo-like productivity Competitive ink pricing Low ink consumption Print quality 1200 x 1200 dpi @ 2 pl Up to 95 % P antone coverage BEST IN CLASS COMPETITIVE EDGE SCALABILITY TAU RSCi INNOVATES YOUR BUSINESS

Working with external partners

Packaging evolution for Belkin's 3-in-1 wireless MagSafe charger

Electrolux works with Sustainability Advantage, part of the NSW Government program, which has built a tool that allows organisations to measure how circular their products are by measuring the recycling process and showing how much ends up in landfill.

“Electrolux has also partnered with waste and recycling collection company, Waste Pro, that recycles EPS and are supporting our circularity journey through track and trace processes,” its A/NZ growth and operations director Derek Haley said.

MHIAA also works with the Australian Packaging Covenant Organisation (APCO) to help keep packaging materials out of landfill and is involved with the HVAC industry association, AREMA, as a resource centre for guidance around regulatory requirements, while CESA provides support from a whitegoods perspective.

Miele A/NZ partnered with Pangolin Associates in 2020 to support and assess its local carbon footprint, address key areas of improvement, and identify key priorities for the business. “For example, Miele has transitioned some of its delivery fleet to electric vehicles with the purchase of 26 hybrid trucks, which was part of our assessment of Scope 1 emissions, in conjunction with Pangolin, to reduce fuel consumption. We are constantly reviewing and optimising delivery routes,” its A/NZ marketing director Michele Laghezza said.

In Australia, Panasonic is an APCO member with a strong focus on working to reduce packaging and support sustainability, which involves developing a packaging manual to ensure it complies with sustainable goals.

Earlier this year, Nespresso gained B Corp certification, benchmarking its performance, bringing wider transformation and scaling its impact for climate, communities and circularity.

“In addition, we worked with international carbon experts, Quantis to conduct a comprehensive product Life Cycle Assessment (LCA) to study the environmental impacts of coffee growing, production, preparation, consumption and end of life and coming up with resilient strategies and robust metrics to implement intelligent environmental sustainability solutions,” Nespresso Oceania general manager Jean-Marc Dragoli said.

Magimix partners with BWES Compliance and Consulting, an electrical compliance committee that provides standards compliance services for selling products in A/NZ. “We partner with them because they always offer the best and latest advice on standards and compliance which is of utmost importance,” Magimix managing director Wivina Chaneliere said.

Olimpia Splendid works with APCO at a local level and PWC on an international level. “APCO is involved in collaboration to keep packaging materials out of landfill and retains the maximum value of the materials, energy and labour within the local economy. We are involved in reporting and goal setting through APCO to achieve this,” Olimpia Splendid Australia marketing and product development manager Peter Burnham said.

“Internationally PWC has created a sustainability report which contains both qualitative and quantitative information regarding Olimpia Splendid. They assist us through internal audits on employee diversity, waste management and other sustainability initiatives.”

While working with external agencies and experts remains paramount for Belkin, the company has invested in embedding sustainability into its own business.

“Our internal sustainability department, established 15 years ago, drives our global efforts with consistency and focus. It is

through this department that collaboration with relevant industry experts and consultants is driven including being an APCO member since 2010,” its sustainability leader Ernie Roberts said.

CESA continues to support CE industry

The Consumer Electronics Suppliers’ Association (CESA) is the national industry body representing the consumer electronics industry with members encompassing all major global suppliers to the Australian market, including retailers.

CESA advocates on behalf of members to federal and state governments and regulators on a range of environmental issues including product stewardship legislation, e-waste, energy efficiency, water efficiency, and product stewardship including the phase out of EPS packaging.

CESA was instrumental in the development and implementation of the industry-led product stewardship initiative for televisions and computers and a key stakeholder in the development and implementation of the Commonwealth’s National Television and Computer Recycling Scheme (NTCRS), according to CESA chief executive officer, Ian McAlister.

“CESA members endorse the broad objectives of the Australian Packaging Covenant Organisation (APCO) to reduce the environmental impacts of consumer packaging by optimising resource recovery through the supply chain and adopting approaches that make changes in the way we design, use and buy packaging and packaged products so that packaging uses less resources and is more easily recycled,” he said.

Earlier this year, Nespresso gained B Corp certification, marking the positive impact it has made in the coffee industry and beyond

www.propack.pro 8 ProPack.pro December 2022

FOCUS CONSUMER ELECTRONICS

Copyright 2022 HP Development Company, L.P. The information contained herein is subject to change without notice. One press, many possibilities Achieve high-volume production efficiency with a robust, 67” (1.7m) digital web-fed packaging platform for digital single-face lamination, corrugation, and folding carton applications. Find out more: www.hp.com/pagewide-T700i HP PageWide T700i Press

©

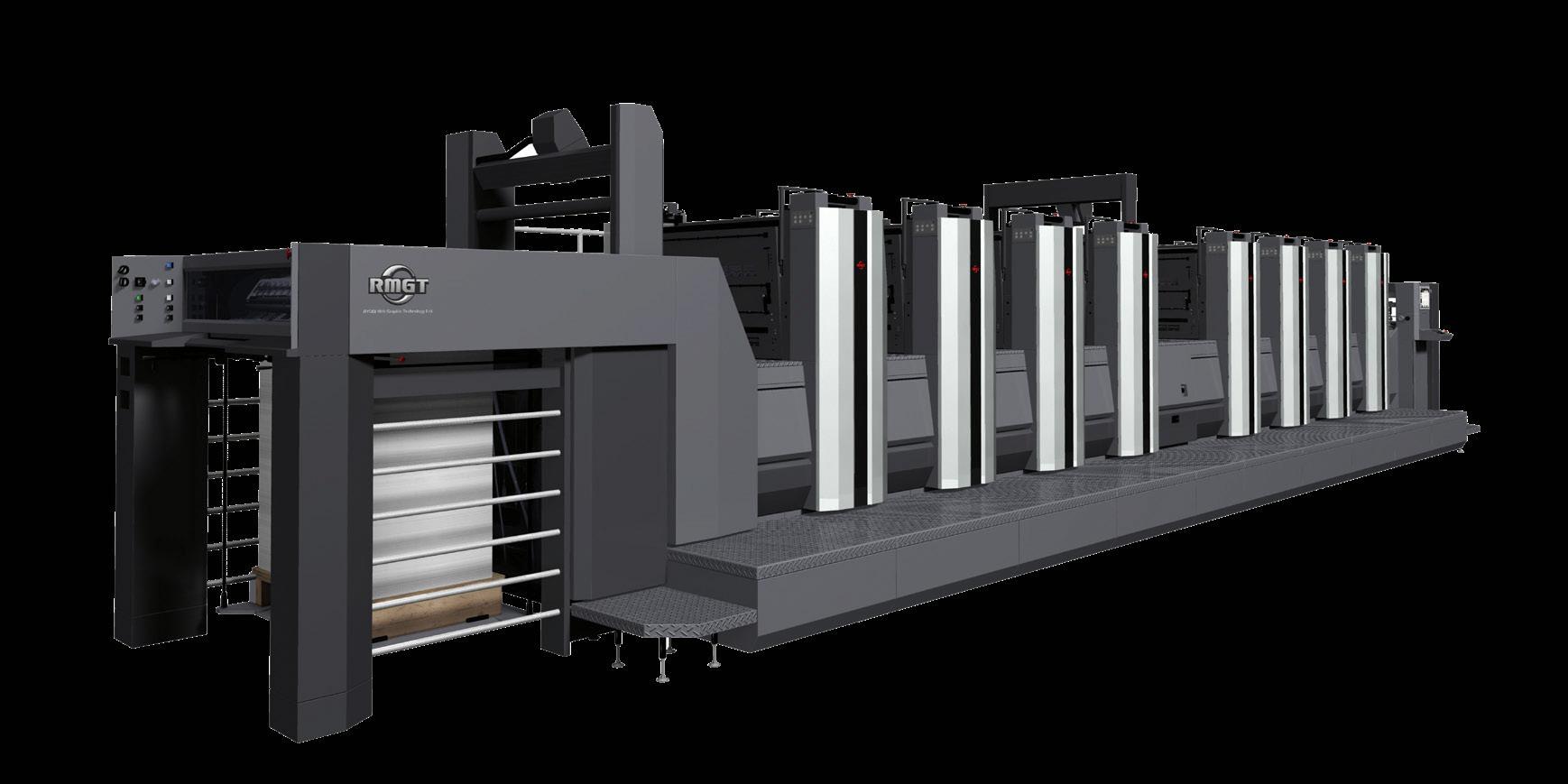

Australia’s smart packaging powerhouse

Peacock Bros.’ acquisition of AMR Hewitts PrintPackaging has united 280 years of printing history and created a powerhouse ready to start the smart packaging revolution

By Piotr Wnuk

In 1888, Ernest Peacock opened a small general printing business in Collins Street in Melbourne, Australia, with just one platen press. Seeing opportunities within the explosion of business in the new Federation, Peacock developed printing systems and binders – often in gold leaf –which quickly positioned him as a printer of quality.

Not content with limiting his offering to print system stationery, he gradually expanded the portfolio. Soon, he was trading filing cabinets, manila folders, book-keeping equipment, and even Millionaire, the first commercially successful mechanical calculator that could perform a direct multiplication.

Since then, innovation has been permanently engraved into the company’s operations and is the signature of Peacock Bros.

The company developed loose-leaf binders and filing systems for doctors, lawyers, real estate agents and payroll systems, as well as providing printing services for

a variety of clients, ranging from local schools to major companies such as Coles and Myers supermarkets.

In the 1970s, Peacock Bros. was the agent for the iconic Casio hand-held calculator, but it was, in fact, hand-marking machines that pointed the company in another direction. Cartons were still being labeled by hand, causing endless problems – it was the perfect time to address this need.

With the purchase of a Mark Andy press and producing a significant number of labels for chemicals and addresses, Peacock Bros. decided to sell off the general printing business in 1978 and concentrate solely on the manufacturing of labels and desktop printing systems.

The innovation continued. Peacock Bros. also became the first company in the region to invest in an HP Indigo 8000 just a few years later, in 2017, to utilise its capacity and high speeds as key to opening new markets. Today, Peacock Bros. is one of the most prominent label manufacturers in

the region, with branches and channel partners across Australia and New Zealand.

The company also made its name as a regional provider of barcode printers, data capture and software integration, and software products for warehouse, logistics, as well as stock distribution.

The books are filled with over 12,000 customers representing a wealth of industries – from manufacturing, distribution, warehousing, transport, and logistics to healthcare.

Coming together

The company has recently acquired AMR Hewitts PrintPackaging, a 146-year-old family-owned business specialising in printed carton packaging. It operates with over 35 staff members based in Victoria, Australia, primarily servicing packaging customers in pharma and food and beverage, including well-known brands like Aspen Pharmacare Australia, Ferndale Foods and BIC Australia.

www.propack.pro 10 ProPack.pro December 2022

FOCUS LABELS AND LABELING

AMR Hewitts is regarded as one of Australia’s pioneers and industry leaders in printed carton packaging

“We are delighted to announce the coming together of two of the great family-run printing businesses in Australia, with over 280 years of combined printing history, to create the most experienced local printing group in the country,” Peacock Bros. Group Managing Director Ryan McGrath said.

“The acquisition of AMR Hewitts will further strengthen Peacocks’ offerings in the printed packaging marketplace, complementing our current range of colour labels and flexible packaging products.”

The acquisition includes AMR Hewitts’ offices and production facilities in Tullamarine, expanding the Peacock Bros. coverage to include Melbourne’s west. Hewitts was established in Melbourne in 1876 by Thomas Hewitt, starting as a printing shop on La Trobe Street.

In 1985, Dandenong-based printers AMR took over Hewitts’ operations, leading to the creation of AMR Hewitts PrintPackaging at Tullamarine.

“AMR Hewitts is a proud family-run business with long-standing customers who have come to know and trust the quality of our work. We are so pleased to be joining the Peacocks Group given its shared values and operating culture and knowing that our staff and customers will be looked after and that the long history of the business and our brand will continue to grow into the future,” AMR Hewitts’ Matt Mimmo said.

AMR Hewitts is regarded as one of Australia’s pioneers and industry leaders in printed carton packaging – having led the adoption and specialisation of cold foil printing, pearlescent inks, holograms and tamper-evident packaging in the country; along with successfully securing several patents for its carton printing innovations. The company has the ability to print lithographic cartons with the highest DPI

dot to enhance the look of the printed product. Its presses can produce up to seven colours with two different coatings in one pass on the larger format machine and up to six colours with two coatings on the smaller format machine. AMR Hewitts has also recently invested in in-line cold foil printing to offer further enhancements for the look of folding cartons.

AMR Hewitts previously won the Heidelberg Australia Award for Excellence in Craft and has been inducted into the Victorian Manufacturing Hall of Fame for Sustained Manufacturing Excellence, acknowledging its pioneering achievements as an innovator in packaging research and development.

“Our businesses are culturally aligned: two great Australian-owned companies with a rich history in Australian manufacturing. Both businesses pride themselves on quality products, solutions, and services,” McGrath added.

“It is a sound investment opportunity from a shareholder perspective, and an opportunity to leverage and grow the business in time – adding more value to the overall business and to our customers. The carton market is also set for growth, especially with companies looking for more sustainable options and substitution of plastic materials.”

Smart packaging revolution

The smart packaging revolution is gaining momentum worldwide. Tracking and tracing high value goods through the supply chain has never been more important. Manufacturers, distributors and retailers all want confidence that what they are providing customers with is correct and of the highest quality. Furthermore, consumers expect end-toend traceability, authenticity and engaging experiences from their brands. Peacock Bros. is at the forefront with its in-house

manufacturing capabilities integrated with this new technology to offer its customers a single supplier that can digitise their products and take them to market.

“With consumers and brand owners across the Asia-Pacific region becoming increasingly concerned about authenticity, solutions that validate products and limit counterfeit goods in the supply chain will enhance buyer confidence and help protect brand reputation and integrity,” McGrath said.

“Securing products at item level provides us with the framework for implementing emerging technologies such as connected packaging solutions that provide advancements in consumer engagement (through augmented reality), product track and trace capabilities, and sustainability improvements within the supply chain.”

Peacock Bros. is a platinum partner of world leading technology companies like Zebra Technologies and Honeywell Solutions. Their devices are compatible with Peacocks’ smart packaging solutions. Peacock Bros. in-house software and engineering teams can handle the integration and rollout to digitise products ready for market – whether it’s a custom microprint, originally designed for pharmaceutical manufacturing, or printed digital identity with variable data to identify product packaging.

“Digitised product solutions such as anti-counterfeit, supply chain visibility, consumer brand engagement, and recycling initiatives are just some of the solutions we specialise in, and the ability to now offer these solutions to the printed carton marketplace is very exciting for our customers,” McGrath said.

“Pharmaceutical or beauty companies often have many different packaging needs depending on the type of product, so they can now work with one trusted single supplier. Evolving into the printed carton space allows us to provide a holistic solution to our customers and build our profile, broaden our skillset and overall offering, especially within the pharmaceutical, beauty and cosmetics space.”

Peacock Bros. might have just become one of the APAC region’s biggest and most modern printing powerhouses.

However, the business values and innovative ambitions have not changed since 1888 and are guarded by the founder’s first platen press, proudly displayed in the reception at the company’s Melbourne head office.

Visit www.peacocks.com.au for more information about the company and its smart packaging solutions.

www.propack.pro December 2022 ProPack.pro 11

FOCUS

LABELING

Peacock Bros can integrate various smart technologies into its packaging

LABELS AND

Peacock Bros. grows Little Bang Brewery’s sales volumes

Little Bang Brewery now has printing flexibility, meaning every label can be different, but within defined parameters.

The software can keep certain design elements as they are and allow others to be varied creating a dynamic set of labels in a single print run.

“The Mosaic software can keep certain graphic elements the same, while allowing others to be varied with infinite combinations. For Little Bang Brewery, this means that the company can develop a dynamic set of labels that can either vary wildly or look similar without being the same – attracting shopper interest,” McGrath said.

In an industry first, Little Bang Brewery also worked with Peacock Bros. to develop an algorithm that gave every single beer can a different name and printed these uniquely.

Peacock Bros. has successfully worked with Little Bang Brewery to help expand the beer-maker’s sales volumes from 5,000 litres to 400,000 litres annually.

Little Bang Brewery said it has achieved such strong business growth though the quality of its product and the high-impact visuals of its cans which Peacock Bros. created.

Operating with a limited sales and marketing budget in the early years as a business, Little Bang Brewery relied on bold, creative visuals on its cans to draw shopper interest online and instore.

“I wanted to turn every beer can into a little sales representative on the shelf,” Little Bang Brewery co-founder Ryan Davidson said.

“We knew that our business couldn’t afford a sales team all over the country pushing our product so that meant the product itself had to be out there doing the selling for us. On the competitive retail shelf, we need our beer cans to be reaching out to the buyers saying, ‘Pick up.’ And we knew that if we could grab a drinker’s attention for even two seconds, we were halfway to making a sale.”

In the past, Little Bang Brewery would develop the labels through Photoshop, having a labeller print them before staff manually applied these by hand. This process was not scalable though as the business grew, requiring Little Bang Brewery to seek an advanced, automated printing solution to meet their needs.

To assist Little Bang Brewery in developing an efficient and flexible printing solution that could produce high impact visuals to showcase the brand’s personality and provide a point of difference, the company turned to Peacock Bros.

“Peacock Bros. is proud to act as the label producer and printing partner for Little Bang Brewery,” Peacock Bros. group managing director Ryan McGrath said.

“Our HP Indigo digital colour label presses allow us to utilise features such as HP’s Mosaic variable data software functionalities. The digitally printed labels we produced deliver Little Bang Brewery high levels of creativity and colour variation in the artwork, with the flexibility to print different labels for every SKU.”

By working with Peacock Bros. and utilising the Mosaic printing functionality,

The initiative was developed for the Little Bang Hazy IPA beer can which has produced over 75,000 different names to date, meaning 75,000 different labels printed in runs of one.

“Peacock Bros. have been a true partner for Little Bang Brewery. They helped us develop a flexible digital printing solution that accelerated our creativity and amplified our brand personality that was scalable as our business grew. Standing out on a crowded retail shelf is difficult as a challenger brand and the Peacock Bros. solution helped us to do just that,” Davidson added.

www.propack.pro 12 ProPack.pro December 2022 IN DEPTH CASE

STUDY

Little Bang Brewery turned to Peacock Bros. to develop an efficient and flexible printing solution that could produce high impact visuals

(l-r) Little Bang Brewing co-founders Ryan Davidson and Fil Kemp

The high-impact visuals of Little Bang Brewing’s cans which Peacock Bros. created

Smart packaging becomes intelligent and active

Smart Packaging is gaining pace and adopting new meanings as it promises to disrupt the ‘functional’ packaging that we are all familiar with

By Andy McCourt

The AIPIA’s (Active and Intelligent Packaging Industry Association) World Congress, recently held in Amsterdam, stirred the smart and intelligent packaging movement into renewed action following the easing of pandemic conditions.

Smart Packaging – as reported here one year ago at the AIPIA Congress, also in the FPLMA Forum May 2022 issue and Auspack coverage – is gaining pace and adopting new meanings as it promises to disrupt the ‘functional’ packaging that we are all familiar with. It’s still about reconciling our planet with profit and people, but new facets are emerging, with data and the Internet of Things fully engaged.

Sustainability continues at the fore of smart packaging initiatives; it is now a given that packaging producers must strive for ‘zero packaging to landfill’ by the end of 2025, eliminate or reduce the use of

hazardous plastics and increase recycled content, to eventually reach a truly circular economy of packaging.

There are road bumps along the way, such as the suspension of soft REDCycle’s plastic recovery by the major supermarkets, due to a fire at its main re-processing plant, Close the Loop. The plant is not expected to be back online until mid-2023, during which time plastic stockpiles will bloat and much will go to landfill again. This in itself, is not smart!

The situation has become political, with Environment Minister Tanya Pilbersek stepping in and saying she expected Coles and Woolworths to come up with the answers and that government would work together with them. She noted that the government had set aside $60 million to increase soft plastic recycling and provided $1m to the Australian Food and Grocery Council to work with industry to

develop more sustainable solutions for their soft plastics.

Irrespective of finger-pointing and splashing funds, it is a fact that Australia only has one substantial soft plastic recycling plant and it is out of action until well into 2023.

Moving on to the November AIPIA World Congress in Amsterdam, defining what ‘Smart’ or ‘Intelligent and Active’ packaging is, is a science with frequently widening goalposts. This is largely due to the torrent of new technologies being applied to packaging.

However, one of AIPIA’s leading supporters, the US$5.5 billion revenue Sealed Air Corporation sums it up well. As the inventor of Bubble Wrap (originally a failed wallpaper!) and Cryovac, this company is in a good position to define packaging trends, saying:

www.propack.pro 14 ProPack.pro December 2022

AR smart

packaging can engage customers in competitions and other fun activities, as with this Cornetto campaign

FOCUS SMART PACKAGING

“Many brands are quickly learning that smart packaging, also referred to as digital packaging, is an excellent vehicle for connecting with consumers. More food products are ordered online now than ever before. The COVID-era made online ordering and hands-free delivery a necessity, but now they’re lifestyle preferences.

“This is more than a trend. It’s an evolution. Mobile technology is now interwoven into everyone’s lives. As more consumers turn to their phones and laptops, smart packaging has greater opportunities to link with consumers. These interactions provide the valuable data that companies need to gain market share.”

In summary, Sealed Air asserts that smart packaging provides:

• a way for companies to differentiate themselves from their competitors

• an opportunity for brands to deliver content to consumers in their preferred digital format

• more flexibility and personalisation

• added product tracking and security

At AIPIA, Sealed Air global leader for digital solutions Joe Lambert presented on “How digital-connected packaging drives efficiency down to the package level”.

Avery Dennison makes labels smarter

Another major supporter of the AIPIA is pressure-sensitive label manufacturer

Avery Dennison, with three speakers on the agenda.

Its director of global strategic innovations Iryna Garkushyna presented on: “How Digital Solutions Help Create a Circular Economy in Packaging”, demonstrating how digital triggers and a connected product cloud such as atma.io, can enable the circularity of primary and secondary packaging by assigning unique digital IDs, providing end-to-end transparency by tracking, storing, and managing all the events associated with each individual product’s journey. Every second, over 300 new items are connected to atma.io, who

currently has over 22 billion physical items managed by its database.

When large corporations designate a job function as: “Ecosystem engagement manager, food and beverage” you know it is serious about sustainability. This is Monica Gross’ title, another speaker at the AIPIA conference.

Her topic was all about digital product passports (DPP) – yes they are coming and may even be mandatory in Europe within three years. A DPP is designed to make it easier to repair or recycle products and track substances of concern along the supply chain.

“It’s the data, stupid”

With apologies for paraphrasing Bill Clinton’s famous “It’s the economy, stupid” chiding of a journalist, what AIPIA has made clear is that packaging must become a data-collecting and management medium. Tim Sykes from Packaging Europe, made this clear when chairing an opening panel discussion about Connected Packaging and Redefining the Data Flow.

Sykes said all along the value chain, data can provide critical insights about a product, its journey and how consumers react to it. Smart packaging opens a new dimension to the collection and delivery of data which can then be used to enable new product development, provenance, authentication, supply chain security and consumer engagement.

Data flows two ways – outwards to your suppliers, retailers and customers and internally to improve production, distribution and marketing. Being able to interpret this stream of data is vital. All stakeholders in the supply chain need to change their way of thinking about how to handle data, to ensure it is shared across all parts of the business.

Harnessing the power of this data is key. Thanks to smart packaging, it has never been easier to collect data about

Consumer Packaged Goods (CPGs) and the people who buy them. This data flows both ways, outwards to suppliers, retailers and customers but also internally, to improve production, distribution and marketing.

Using this data effectively is a vital business function. However, this means many companies need to change the way they share data across their businesses.

Sustainability is the overriding ‘smartness’

Without sustainability as the guiding principle, all other benefits –differentiation, content delivery to consumers, personalisation, tracking and security – will suffer.

Consumers expect sustainability in both product and packaging. They actively seek out products that appeal to their sense of social and environmental responsibility; that help them ‘do their bit’ for the planet while knowing that that core issues are mega, global and beyond their individual control. Such conscientiousness extends to the way that products they consume are sourced, manufactured and transported.

Today’s ‘smart’ consumer abhors slave labour; they hate the idea of children being exploited as cheap labour; they shun products that they know to be unsustainably mined or harvested or contribute to deforestation.

They loathe the use of pesticides and other harmful chemicals. Waste and landfill are no-nos. They see packaging as something that has safely conveyed a product into their homes, ensuring genuineness, safety of use and even convenient storage – but they want that packaging taken back and re-used either as packaging or other products.

All of this can be communicated to consumers via smart packaging. Naturally, the first step is with the ‘label on the tin’ –bold statements that support sustainability. Next, good graphics portraying the wholesomeness of both product and package. Then newer tech

www.propack.pro December 2022 ProPack.pro 15 FOCUS

PACKAGING

SMART

Joe Lambert, Sealed Air’s global leader for digital solutions

Avery Dennison food and beverage ecosystem engagement manager

Monica Gross

Etiko’s founder Nick Savaidis embraces sustainability, fair trade, climate action, FSC – all with clothing and footwear

FOCUS SMART PACKAGING

such as augmented reality links using QR and GS1 codes scanned on smartphones.

One of the best-articulated commitments to sustainability is that of the Melbournebased Etiko clothing and footwear brand, founded by Nick Savaidis in 2005. It’s not mere mission statements with Etiko (motto: ‘Wear no Evil’), it’s the circular economy as it should be.

Raw materials including organic textiles are ethically sourced, Etiko’s Fairtrade membership ensures workers are paid a fair wage, FSC certifies all packaging is sustainably sourced. In fact, when receiving cardboard (no plastic) packs of Etiko underwear, the packaging screams “I was recycled – recycle me again!”

Etiko’s humanitarian ethos is summed up thus: “By creating fair, transparent, environmentally friendly supply chains, Etiko has directly supported the human rights and labour conditions of countless cotton growers, rubber tappers, apparel workers, shoe manufacturers and sports ball producers living in India, Sri Lanka and Pakistan. This has positive flow-on effects for these workers’ families and their communities.”

were transported from Britain to Australia in the 1800s, sometimes for political or petty misdemeanours. Many went on to become high-achieving pastoralists and even judges.

19 Crimes’ Ming Alterman, US brand director of 19 Crimes, decided that creating an app that enabled linking to an AR website and telling the stories was the go. This worked so well that 19 Crimes sales rocketed in the US, so much so that the app can now feature rapper Snoop Dog – a brand ambassador who embodies the spirit of 19 Crimes – the spirit of 19 Crimes –rule breaking, culture creating and overcoming adversity.

“The interactive web-based augmented reality allows consumers to interact with Snoop without downloading an app. Instead of a face talking off the bottle, Snoop now jumps right off the bottle and

answers any questions his fans would like to ask,” Alterman said.

19 Crimes was the first wine brand to launch an AR component to their collection. Although Living Wine Labels was launched in 2017, it continues to innovate and the partnership now extends to Squealing Pig, Matua, Lindemans and Wolf Blass wines – also Treasury brands.

All it took was an app and website – and a lot of imagination. “Don’t just drink wine –experience it” is the great tagline. You can see samples on www.livingwinelabels.com.

Tell the stories, save the data

AR and XR (eXtended reality) is in its infancy when looking at the potential in packaging of all kinds – not just labels. One idea; how about potato chips with an AR link that takes the consumer all the way back to the farm from where the potatoes were grown?

The harvesting, slicing and cooking processes, all using bio-organic products and finally, the responsibly sourced packaging with vegetable inks that can be recycled into playground insulation?

AR studios are springing up everywhere and the app can either be an adaptable ‘off the shelf’ such as Blippar or ZapWorks, or a custom-built app by an AR studio.

The link between AR, XR and brand packaging is too good to overlook and suppliers of labels and cartons should look towards offering it as an additional service to converting – it’s a natural companion to track & trace, authentication and other forms of turning packaging into an active and intelligent medium.

It’s the brave new world of smart packaging.

The next step will surely be adding augmented reality (AR) to Etiko’s packaging, to tell the story of just how committed the company is to its beliefs.

Living wine labels with AR

Smart packaging comes in many forms, but data and sustainability are common themes. A third theme presents the possibility to really engage consumers in conversations, with entertainment as the driver.

Wine house Treasury Wine Estates decided to ‘make labels come alive’ for its 19 Crimes series that celebrates convicts who

www.propack.pro 16 ProPack.pro December 2022

Etiko’s packaging is sustainably smart

Treasury Wines uses an artificial reality app to connect customers to the stories behind its 19 Crimes labels

Rapper Snoop Dog is helping to sell Australian wine in the US – with AR labels

Expand your service offering with high quality short-run digital labels of exceptional quality and improve your bottom line. SurePress is easy to operate, offering consistent colour reproduction and precise colour matching. • Extra wide colour gamut including Orange, Green & Opaque white inks • Improved turn-around times • Proven Epson technology • Non-contact Epson micro-piezo printhead array delivers high quality results even on textured and uncoated materials THE NEW SUREPRESS DIGITAL LABEL PRESS Versatile Printing. Consistent Quality. Learn more, visit www.epson.com.au/surepress • Extra wide colour gamut including Orange, Green & Opaque white inks NEW MODEL SurePress L-4733AW *Product shown includes Epson SureSpectro AS-4000 option

How packaging can be emotional as well as functional

By Andy McCourt

Conventional marketing wisdom says that, to sell more FMCGs, you need to advertise across the five main media – TV, print, radio, outdoor and online/social media. However, the emergence of the ‘pack’ itself as an advertising medium, driven by digital variance and personalisation, presents some compelling arguments for exploring new possibilities.

Purchasing decisions made by ‘looking on the shelf or POS display’ represent the largest percentage of consumer buying decisions. Add ‘looking online’ for the home delivery folks and it is a well-established fact that packaging appearance and perceived brand promise are as vital as ever for market share.

The statistics vary depending on whose research is used, but the parameters start at around 60 per cent and go as high as 82 per cent. That’s between six and eight out of every 10 shoppers make their final buying decisions in-store.

Sure, brand loyalty and special pricing, points and competitions can make a

difference before entering the aisles but few consumers these days make a shopping list with brand names in them.

Brand X baked beans are more likely to be just ‘baked beans’ on the list and if a ‘brand Y’ shrink-wrapped pack of four cans at a dollar per tin sits alongside the $2 product – there’s an 80 per cent chance that will make the sale.

This isn’t guesswork, verified research from bodies such as Inmar Intelligence Inc. and the Multisense Institute of Sensory Marketing have been researching and helping brands, retailers and healthcare systems since 1980, to make it possible for their consumers to do more, save more, connect more, and thrive in an everchanging world.

That change includes massive increases in footfall in-store post-pandemic. Inmar says that 75 per cent of consumers altered their brand preferences in 2021, and 80 per cent are actively looking for the best deals, no matter what brand, when they visit stores. That figure could go even higher given skyrocketing food and FMCG prices due

the energy crises and conflicts such as that in Ukraine.

So, whatever the package, it can work harder, offer more, engage the consumer and boost customer satisfaction if it uses a little something extra – such as Packvertising.

Buzzword or opportunity?

The practise of advertising on packaged goods is not new, but embracing the ‘Packvertising’ philosophy is, as evidenced recently by SAPPI – originally South African Pulp & Paper Industries and now a global solutions company active in 150 countries.

Sappi hosted an interview episode of what it calls the ‘Blue Couch’ series, which investigated what is meant by ‘Packvertising’ and how brand manufacturers can best present their products at the point of sale, taking onboard all the sensory and emotional factors that influence us all.

Olaf Hartmann, managing director of the Multisense Institute for Sensory Marketing explained in an academically researched

www.propack.pro 18 ProPack.pro December 2022 IN DEPTH PACKVERTISING

Whatever the package, it can work harder, offer more, engage the consumer and boost customer satisfaction if it uses a little something extra – such as Packvertising

(l-r) Sappi’s Lars Scheidweiler and the Multisense Institute for Sensory Marketing’s Olaf Hartmann at the Blue Couch Packvertising interview

way that, apart from protecting goods, performing a function and fulfilling legal requirements; packaging is a communications medium and Packvertising should appeal to all of the senses, since we are all automatically and constantly influenced by small, sensory stimuli.

This goes all the way back to primeval instincts, such as sensing danger from wild beasts, sensing safety or sensing threats.

The average human makes up to 35,000 decisions a day based on automatic ‘fast brain’ stimuli. This prevents overloading the ’slow brain’ (known as System 1 –automatic, fast and System 2 – slower, cognitive, biased – (ref: ‘Thinking Fast, Thinking Slow’ book by 2002 Nobel Prize winner Daniel Kahneman).

Not psycho-babble: it’s who we are

This may all sound like psycho-babble but Kahneman’s System1/2 research is used by all major FMCG brands to increase sales. It can even affect whether a person will donate to a charity.

Hartmann cites a study where people were approached in the street to donate to a worthy charity. They handed the targets one of two clipboards explaining the benefits that their donation would achieve and the bona-fides of the charity. One clipboard had a smooth surface on the back and one had a rough, almost sandpaper like surface.

The results were, that three per cent of those holding the smooth surface clipboard donated, while 26 per cent of those holding the rough surface donated. Hartmann explained that this was because the roughness signalled “danger, I must do something” to the automatic System 1 brain – something he compared to rocks and caves and “the breath of a SabreToothed Tiger”. It’s like the primeval instinct of fight or flight.

Having said that, Hartmann noted that it is all contextual: “We don’t buy brands, we buy categories. We need to understand the context in which the brand is perceived by the customer,” he said.

Drill buyer wants a hole, not a drill

signals can affect buying decisions and substrate choice for labels, cartons and boxes is as important as the printed graphics and embellishments that may be used in the converting process.

He said, “The way people make purchase decisions in the face of overwhelming choice is very complex. Subconsciously, the brain is constantly at work making judgements about sensory signals such as touch, smell and sound. To attract customer attention, manufacturers should not only pay attention to functionality when selecting packaging material, but also never lose sight of the tactile experience”.

Of importance to converters, Scheidweiler emphasised that creative Packvertising designs must be achievable in production – and sustainable.

“Consumers must have a good feeling about buying the product and knowing that the materials used and their ultimate recyclability, adds enormously to that emotional feeling of satisfaction.”

The entire interview can be seen on this link: https://www.sappi-psp.com/the-bluecouch-series

Seven paths that take you on the road to Packvertising

Effective Packvertising should harness the System 1 heuristic, automatic, sensory decisions that then send signals to the brain’s System 2 to form what is known as cognitive bias. We all have it whether we like it or not – we are irrational in this respect, we form habits and ‘like’ or ‘dislike’ irrationally.

Put very simply, for example, the System 1 brain may deduce “I am thirsty, I need to drink”. It sends this information to the System 2 brain, which might decide “I’ll pull into this 7-11 store” and then use cognitive bias to decide what kind of drink it will buy.

To underscore this, Coca-Cola knew about it as long ago as 1915 when it briefed a bottle designer to: “Create a bottle so distinct that it could be recognised by touch in the dark, or when lying broken on the ground.”

Coke may not have called it Packvertising 107 years ago – but that is what its soft drink bottle achieved.

He used the well-known marketing proverb that a person buying a 5mm drill doesn’t really want the drill – he or she wants a 5mm hole. Beyond that, they really want a sturdy shelf for a wall and even further, they may want to create a new look for a room within their house, along with the appreciation of their family for being creative, caring and a DIY whizz. Does this sound like Bunnings – the ultimate category-killing success story – to you?

Lars Scheidweiler, head of packaging Solutions at Sappi, explained that sensory

Sydney-based packaging design consultancy Grounded Packaging, started up as recently as 2019 by New Zealand-born Ben Grant and Josh Kempton, is on a mission to create circular packaging economies and eliminate plastic waste in our oceans. Grounded also knows all about Packvertising and has published seven tips towards achieving it:

1. Bring your brand to life

In Australia our biggest supermarket holds more than 20,000 products and in other parts of the world, it is close to double that. Ironically, we’d probably struggle to name 50 of those brands.

www.propack.pro IN DEPTH PACKVERTISING December 2022 ProPack.pro 19

“All about reaching the emotions” – Olaf Hartmann, MD of the Multisense Institute of Sensory Packaging

Bad hair day or good pasta day? The packages speak for themselves

IN DEPTH PACKVERTISING

2. Treasure the brand’s unique packaging assets

These assets play a critical role in helping brands get noticed. With our brains always looking for shortcuts, these assets are effective because they trigger recognition, meaning and memory, in categories loaded with competition.

3. Let the product speak for itself Ben Grant gives the example of Russian designer Nikita Konkin, who took packaging design to another level, by allowing the product features to come to life, creating surprise, joy and more importantly aiding how one navigates the range. The picture ‘speaks for itself’.

4. Make a real statement on shelf or online – anywhere

Grant uses the example of Monday Haircare. Using a monochrome pink package, they are making a statement that is reflected in their sales. The brand is flying off shelves, selling 10 bottles of its shampoo and conditioner every minute.

6. Respect and embrace sustainability Grounded cites the team at Zero Co, who are turning ocean plastics into home-cleaning and personal-care products. And in the process of eliminating single-use plastics from laundries, kitchens and bathrooms.

with production choices, context and the increasing amount of research data that explores the inner motivations of consumer decision making.

However, modern production methods, material choices and the short-run nature

5. Make packaging a part of the brand experience for consumers

Anything is possible when it comes to making packaging part of the brand experience. From the unboxing to employing the packaging as part of gameplay, to integrating technology into the experience, such as augmented reality linked by QR codes.

Sustainability is not just essential, it is a powerful Packvertising strategy.

7. Balance freshness with consistency What this means is keeping what makes the packaging unique while injecting new life. Absolut Vodka is referenced as a brand that continues to deliver on this time and time again. They employ limited edition packaging designs that look like works of art.

(Acknowledgement: www.groundedpackaging.co )

In summary

Effective Packvertising can be a complex undertaking, combining design creativity

of digital converting can make testing, adjusting and re-testing relatively inexpensive compared to older mass production methods. The results are speaking for themselves – a wellresearched, tested and implemented Packvertising campaign will boost sales and market share for all brands, big and small.

The product still needs to live up to the promise – all good marketing starts with a great product but, the saying “If you build a better mousetrap, the world won’t beat a path to your door” still holds true. You need to extol the benefits, reach the emotions, persuade and convince.

To paraphrase the old adage: “It pays to Packvertise!”

www.propack.pro 20 ProPack.pro December 2022

Standing out – Monday Haircare made sure their products get noticed

Beer six-pack rings are notorious for harming sealife. Saltwater Brewery make theirs from biomass – you can even eat them

Absolut Vodka keeps consistency of its product but ‘packvertises’ with fresh, localised graphics in multiple versions

Graffica Pty Ltd PACKAGING AND DISPLAY EQUIPMENT KOLBUS AUTOBOX The original and leading complete custom box machine manufactured in Germany and the UK, since 1979 with 60 plus units installed in ANZ. THE BOXER As demonstrated at PacPrint and sold to APC Innovate, AKL, NZ Box making systems incorporating inline digital printing MULTI-NOVA Large format, straight line crash-lock box gluer CENTURY LARGE FORMAT DIECUTTERS Leading large format diecutter in Australia Sizes Available: 1050/1300/1450/1650/1850/2100 & 2300 Flute/Solid Fibre/Corflute/Polyprop etc Full & Semi auto; various feeding options With or without stripping AMEIDA CUTTING TABLES Fast, efficient with various tooling 2500mm x 1600mm unit with cut/crease and v-cut options DATIEN CUTTING MACHINE High speed, heavy duty, sizes from 115cm to 300cm Phone +61 477 200 854 I Email grafficapl@bigpond.com I Visit Us www.graffica.com.au

Pack Expo International packs in the know-how

Over four days in October, visitors at the US show immersed themselves in technology and business innovations, heard about the latest trends and shared knowledge

The world’s packaging and processing industries recently converged on Chicago’s richly storied McCormick Place – a venue familiar to many Australian providers in packaging and related industries – for Pack Expo International. Over four days in October, visitors immersed themselves in technology and business innovations, saw machinery in action, heard about the latest trends from experts, and shared knowledge with colleagues.

From October 23 to 26, attendees revelled in the post-pandemic freedom to communicate face-to-face at a ‘what-you see-is-what-you get’ expo. It was one of the only events this year to showcase entire production-line solutions, offer more than 100 free educational sessions, and provide the know-how to compete in a changing marketplace. In fact, there were more than 2,000 exhibitors, representing some 40 vertical markets.

For the first time, Pack Expo International offered new features and focal points. Pack

Over four days, visitors of Pack Expo International immersed themselves in innovation

To The Future was an interactive exhibit celebrating the role of packaging and processing throughout history and the impact it is poised to have on our future.

The curated exhibit included historical equipment, materials and photographs spanning 250 years, journeying through the evolution of packaging and processing, and highlighting how the industry developed alongside civilisation.

Looking ahead, the Pack To The Future exhibit provided sessions on industry innovations and features, presentations by industry experts on advances in pharmaceutical packaging, wireless factory automation, sustainable alternatives, smart packaging, artificial intelligence, and more.

The Processing Zone housed a broad variety of food and beverage processing equipment. Pack Match was a one-on-one consultation process offering attendees personalised guidance to locate targeted solutions in 30-minute pre-show virtual

consultations which aligned visitors with their optimal suppliers at the show, based on their markets.

Pack Challenge, sponsored by PepsiCo, was a first-of-its-kind packaging competition that brought six high-school teams together for a fun competition in machine building. There were new pavilions at this year’s event, including the Healthcare Packaging Pavilion, a showwithin-a-show offering the latest advances in packaging and the life sciences. With the boom in ecommerce, the Logistics Pavilion offered targeted solutions related to the supply chain, including warehousing, fulfillment, distribution logistics services, and transportation providers.

Regular Pack Expo International favourites returned for the 2022 show, including the PACKage Printing Pavilion, featuring digital printing and converting, labelling, coding, and marking technologies, while the Containers and Materials Pavilion was a prime destination for companies looking for new materials solutions to address

www.propack.pro 22 ProPack.pro December 2022

PACK EXPO INTERNATIONAL

sustainability, refresh a brand, launch new products and broaden appeal. The Reusable Packaging Pavilion explored reusable transport packaging products and services and innovative re-use solutions from over 30 exhibitors.

The Packaging & Processing Women’s Leadership Network held a breakfast event to discuss advances in women’s careers in packaging and processing. A record-breaking attendance at the breakfast brought together nearly 1,000 professionals to hear Dawn Hudson, former chief marketing officer at the US National Football League and former president and CEO of Pepsi Cola North America, talk about her experiences in the workforce.

Meanwhile, young professionals in the packaging industry held their own event, and the show hosted the Technology Excellence Awards, which recognised the most innovative technologies not yet shown at a previous Pack Expo (See breakout box)

The Pack Expo Green Program embodied the commitment of the expo, and all its partners, vendors, and exhibitors, to working together to create a more sustainable world. Pack Expo’s Sustainability Solutions Finder was a tool that proved popular among visitors.

As the show opened its doors, Jim Pittas, president and CEO of the show’s organisers, the US-based Packaging Machinery Manufacturers Institute (PMMI) (aka the Association for Packaging and Processing Technologies), stated, “As the industry’s largest gathering place, Pack

Expo International is back and better than ever. No other event this year will showcase entire production-line solutions and offer everything needed to compete in today’s changing marketplace.” And over the next four event-packed days, the show was as good as its promise.

Pack Expo International convened over 44,000 attendees, surpassing the 2018 event. With 2,200 exhibitors showcasing cutting-edge packaging and processing innovations over 1.2 million net square feet of expo-centre real estate, the show managed to bring the entire industry together this year.

The expo welcomed an industry ready to do business after years of consistent growth. In 2019, the market for packaging machinery was $US10.8 billion; this year the industry broke the $15 billion mark, a growth of 40 per cent, according to PMMI.

“The success of Pack Expo is a testament to our industry’s continued growth as well as PMMI’s commitment to bringing the industry together to share cutting-edge innovations,” Pittas said.

“No other event this year showcased so many end-to-end solutions, offering attendees everything they need to compete in a changing marketplace.” And industry growth translated into buyers coming in significant numbers, ready to see the latest packaging materials, as well as technology in action.”

During the show, PMMI released its report, The Future of Automation in Packaging and Processing, focusing on worldwide labour shortages, which have driven consumer

packaged goods (CPG) companies to adopt automated solutions.

The report highlights how CPGs are looking to enhance and optimise their production, storage, and distribution processes using automated solutions, including automated guided vehicles, industrial robots, collaborative robots (cobots), and mobile robots, with some of these technologies supported by artificial intelligence (AI) and advanced vision tools.

According to the report, ecommerce is fuelling the automation trend, moving companies towards more responsive modes of distribution such as Direct-toCustomer, disrupting traditionally highly manual warehousing formats, and in some cases eliminating the need for warehousing.

Additionally, supply-chain problems are impacting the availability and cost of raw materials and parts for packaging machinery. Over 90 per cent of CPGs say these problems are either extremely impactful or somewhat impactful and while most companies expect them to be resolved over the short term (within three years), at least 25 per cent of companies anticipate them persisting over a longer time span.

With this boom in ecommerce, coupled with the challenges arising from widespread supply-chain issues, the Logistics Pavilion at Pack Expo drew much interest, with attendees finding targeted solutions related to the supply chain, including warehousing, fulfillment, distribution logistics services and transportation providers.

The show opened against a background of encouraging figures in shipments of packaging and converting machinery in the US. According to this year’s PMMI report, the value of domestic shipments for packaging machinery rose 11.2 per cent to $US10.5 billion in 2021 and is forecast to grow at a CAGR of 5.4 per cent to $12.9 billion in 2027.

Similarly, the value of domestic shipments for converting machinery also increased by 9.5 per cent to $1.1 billion in 2021, despite order backlogs in both categories increasing by double digits in 2021, compared to the end of 2020.

The demand for packaging machinery is largely driven by the increase in consumer goods demand, the rise in adoption of automated packaging machines, and development of energyefficient machines, states the PMMI report.

Advancements in electronics, computing technologies, and rising awareness of the inherent benefits of automation have encouraged numerous industries to embrace

www.propack.pro December 2022 ProPack.pro 23

PACK EXPO INTERNATIONAL

Pack Challenge brought six high-school teams together for a competition in machine building

The busy showfloor of Pack Expo International

Dawn Hudson, former chief marketing officer at the US National Football League and former CEO of Pepsi Cola North America

integrated packaging machinery solutions. As such, robotic packaging automation is poised to emerge as the future of packaging in the coming years in both primary and secondary packaging applications.

The topic of cybersecurity has emerged as a leading consideration due to new points of vulnerability, as new technologies such as fully integrated enterprise resource planning (ERP) systems, remote access, and cloud computing and connected machine sensor networks continue to emerge and evolve.

The industry is also experiencing a large push for ecommerce solutions, accelerated by the COVID-19 pandemic. The shift in online purchasing habits will continue to drive demand for packaging machinery –as ecommerce differs from traditional retail outlets due to increased touchpoints to reach the customer, increased

packaging, and supply-chain challenges. Sustainability presents an opportunity for businesses facing increasing economic pressures to gain value and competitive advantage as they respond to environmental concerns and the pressures of resource scarcity, population growth, and higher and more varied consumer expectations. Various eco-friendly material innovations also are emerging, requiring specialised machinery to run such materials.

The PMMI report found tremendous opportunity in these segments for more growth and innovation as equipment manufacturers leverage growing trends like ecommerce, sustainability, and the rise in automation, and build machinery to address these trends.

Pharmaceuticals are a specific growth sector. The US pharmaceutical industry

registered $US800 million in sales in 2020 and is forecast to grow at a 7.6 per cent compound annual growth rate through 2026, according to Pharmaceutical Manufacturing Trends Shaping the Future, a PMMI white paper published in March this year.

The industry must keep pace with changing product formats and production preferences. The shift towards higher value injectables and customised runs is driving the expanded use of contractors, while also pushing manufacturers towards more automated production lines.

Meanwhile, the pace of digitisation is accelerating to meet the requirements of the US Drug Supply Chain Security Act, address cybersecurity concerns, achieve operational visibility, and support blockchain product tracking, according to the PMMI.

The PMMI also noted that manufacturers must adjust to steady growth in direct-toconsumer ecommerce channels and consumer preferences for sustainable practices. To meet sustainability objectives, 67 per cent of pharmaceutical manufacturers are light weighting packaging, 53 per cent are increasing postconsumer recycled content, 47 per cent are seeking more energy-efficient equipment, and 40 per cent are changing packaging formats.

Supply-chain challenges have created shortages and delivery delays in packaging materials, raw materials, equipment, and parts. These delays and shortages have postponed both product launches and operational improvements.

As a result, pharmaceutical manufacturers are seeking closer collaboration and cooperation with OEMs and suppliers of packaging and raw materials. To achieve this goal, pharmaceutical manufacturers want OEMs and suppliers to offer aftermarket service/support, integrate new machines, enhance equipment accuracy and reliability, simplify changeover, maximise machine flexibility, deliver parts quickly, and provide support for concept models to visualise equipment, as well as for installation qualification and operational qualification.

Parallel to all this is the growth of automation. CPG companies have embraced robotics. Expanded intelligence, mobility, and sensing capabilities are opening new applications for robots and cobots in processing, primary packaging, secondary packaging, and transport packaging. As a result, usage is growing along the entire line from initial inputs to end-of-line, according to Robots & Cobots, An Automated Future, a white paper produced by PMMI.

www.propack.pro 24 ProPack.pro December 2022

PACK EXPO INTERNATIONAL

The Packaging & Processing Women’s Leadership Network discussed advances in women’s careers

More than 2,000 exhibitors, representing some 40 vertical markets were at the show

The Pack Challenge event this year was sponsored by PepsiCo

Visitors check out some of the technologies on display

Most CPG companies (84 per cent) operate robotics somewhere on the line, and this number will rise to 93 per cent in the next five years, as shown in a forecast presented in Robots & Cobots, An Automated Future, an infographic produced by PMMI.

Deployment of cobots will also see strong growth, with usage more than doubling from 27 per cent in 2022 to 57 per cent in 2027. Improvements in functionality such as vision, self-learning, and AI will spur adoption.

For CPG companies, installation of robotics can achieve multiple goals, says the report. They can reduce labour and repetitive tasks, increase speed and productivity, achieve repeatable quality and consistent product handling, improve operator safety, and minimise waste and human error.

Today’s robots are more intelligent, significantly faster, capable of lifting heavier loads, and easier to operate. Cobots now have sensors for feedback, use hand movement-based guides for self-learning, and are more mobile. Robots and cobots also are easier to program and require a smaller capital investment.

Nevertheless, one of the main challenges to adoption is ROI justification. Other hurdles include internal shortfalls (time, skills, budget); total cost of ownership; OEM support for integration, training, and service; technology and functionality; and identifying appropriate applications.

Of course, the warp-speed embrace of automation technologies also increases the potential for and impact of cybercrime, notes PMMI.

The use of new and evolving technologies such as fully integrated enterprise resource planning (ERP) systems, cloud computing and connected machine sensor networks, remote access, and Industrial Internet of Things (IIoT) connectivity has increased exponentially over the last two years, but while these technologies make manufacturing more efficient, they also create new exploitable points of vulnerability, according to PMMI’s white paper, Cybersecurity: Assess Your Risk.

With that in mind, Pack Expo International showcased the latest solutions to keep businesses safe. Cybersecurity was a key topic of focus at The Forum, a presentation and ideas program held during this year’s show. The Forum comprised 45-minute interactive sessions, beginning with short presentations by top experts, then moving on to roundtable discussions.

“As our industry increases its reliance on digital technology, it is critical for manufacturers to improve cybersecurity preparedness and stay abreast of the latest

tools and technologies to protect their operations,” Pittas said.

“With top industry experts and leading suppliers all under one roof, Pack Expo International is the best place to gain the knowledge and understanding needed to reduce the risk of a cyberattack on operations.”

According to PMMI’s white paper, in the first quarter of 2020, attacks targeting the manufacturing sector accounted for 11 per cent of all cyberattacks that occurred across all industries. By the second quarter of 2020, cyberattacks targeting manufacturers accounted for 33 per cent of all incidents across all industries.

This increase in attacks is especially alarming, considering there are real, growing costs to manufacturers that experience a cyberattack. In 2020, the average cost of a cyberattack stood at around $US3.86 million, and that is before factoring in ancillary impacts such as lost opportunity and damaged customer loyalty.

A major component of this year’s show was the Emerging Brands Summit, a first for Pack Expo International. Produced by PMMI Media Group, the one-day event featured educational content and tabletop exhibits aimed at assisting start-up manufacturing companies grow their operations. The new program is for founders and leaders of start-up manufacturing companies looking to scale their brand to larger production through inhouse facilities, build-out, or outsourced relationships with contract manufacturers and packagers.

Exhibitors included suppliers of packaging machinery, packaging materials, processing equipment, and contract manufacturing and packaging services. The event was especially designed for companies evaluating inhouse and outsourced manufacturing and packaging solutions, founders of high-growth emerging brands looking to scale operations, and leaders of product development, operations, or finance.

Kim Overstreet, director of PMMI’s Emerging Brands Community, reflected, “With so much change in the industry over the last few years and the increase in ecommerce and consumer demand in every industry vertical, we felt that it was important to launch a program that can serve as a roadmap to help companies take their operations to the next level. Now more than ever, brands need support and adequate resources to keep up with the rapidly growing demands they are facing.”

The show provided a lot of fun too – and a Pack Gives Back event allowed students and the next generation of professionals

to tour the show floor, before rocking out to legendary band STYX. The band draws from over four decades of barn-burning chart hits, joyous singalongs, and harddriving deep cuts such as, Renegade, Come Sail Away, Lady, Blue Collar Man, Too Much Time On My Hands, Mr Roboto, Fooling Yourself, The Grand Illusion and more. It was all part of the package.

For Australians committed to travelling to see some of the best packaging technology the world has to offer, there are two events in the Pack Expo portfolio coming up next year – Expo Pack Guadalajara in Mexico (June 13 to 15, 2023) followed by Pack Expo Las Vegas (September 11 to 13, 2023).

Technology Excellence Awards

An interesting indicator of what’s hot in packaging is the innovative line-up of products on offer from manufacturers who won PMMI’s Technology Excellence Awards, announced ahead of this year’s Pack Expo International.

A tethered closure providing a solution to enhance its recyclability, while still offering consumers a convenient and comfortable drinking experience, earned Berry Global the award in the food and beverage section.