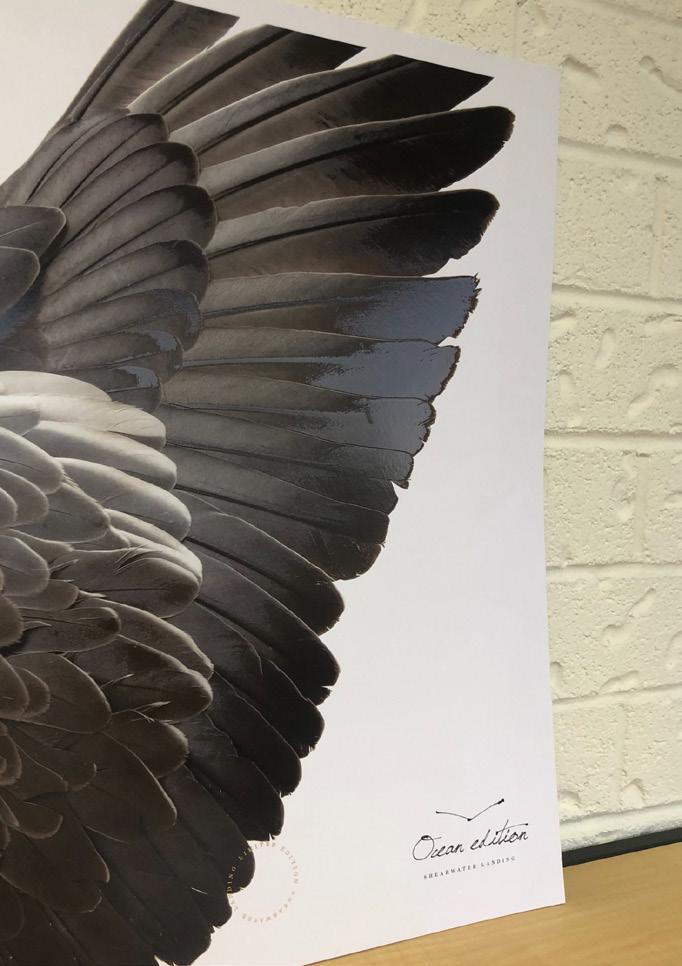

Velflex

Please pass on our thanks to the team for the quality and service for both prints this week. Arrived on time and in good shape which is a pleasant change from some of the jobs we have received from other places.

Kevin

I just wanted to say thank you for rushing those 2 banners through for me, I really appreciate how quickly you made that happen, pretty amazing service.

Kelly

Thank you for having this order completed so promptly, the print quality is faultless and the blind shipping is very much appreciated

Donna

The postcards were delivered to them this morning and the client is impressed bordering on disbelief. Not sure exactly how you and the team did it all so fast but thank you.

Tom

Great job on the books - client is stoked! Thanks again for suggesting the extra laminate -it really made a huge difference!

Appreciate it!

James

Loving the magnetic boxes the velvet cards come in, a great way to present the card to the client.

Sarah

A lot can happen in a couple of months in this industry. Consolidation is something that has featured prominently in the print industry over the last decade and this year it has continued. Leading the charge is Ovato’s slide into voluntary administration after some hard years hampered by a global pandemic, supply chain issues and rising energy prices. Six years ago, there were five major players in the large scale, high volume heatset web offset sector. Then there were two when IVE Group acquired Franklin Web and AIW Printing in 2016 and PMP and IPMG merged to form Ovato in 2017. Now there is one – IVE Group Ltd.

The sentiment that I am picking up around the traps is IVE’s acquisition of the majority of Ovato is a good thing – it has saved jobs and maintained supply for catalogue and magazine print customers so they will keep coming back which are positives. As I put the final touches on this issue of ProPrint, IVE has also successfully completed an institutional placement to raise $18 million from existing and new institutional investors so clearly the investors can also see the merits in IVE’s move on Ovato.

Consolidation is also taking place in other parts of the industry. Victoria’s Complete Colour recently acquired Erwins Printing, a wellknown and highly-regarded family-owned Victorian business built by the now-retiring Mick Edwards. The acquisition means Complete Colour will regain the B2 capacity it lost during the pandemic so it seems like a win-win.

The 2022 ProPrint Awards are also almost upon

us again with the event returning to the beautiful Shangri-la Hotel in Sydney on Thursday October 27. Judging for the Top 20 of the Printer 50 is all done, along with the Emerging 50 mentorship prize and the exclusive Industry Achievement Award. We look forward to seeing all corners of the industry –senior leaders, rising stars, suppliers and industry legends – come together again.

We hope you enjoy this issue. It includes a feature article on Adding Value to Print with embellishments and other finishing processes – something that is becoming increasingly popular among print consumers.

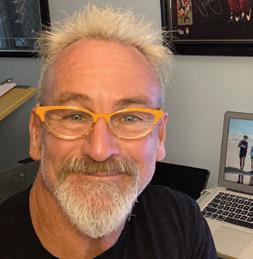

Ben Carroll’s twin businesses – Velflex and UltraColour – are the subject of our Star Business. It was a pleasure to catch up with Ben and learn more about the direction of his business as he continues to upend traditional screen printing methods.

And finally, there is a comprehensive photographic coverage of Visual Connections’ highly successful NSW Golf Day. Women in Print’s NSW Print & Prosecco Night is also in the Downtime this issue, along with the photo highlights from E-Bisglobal’s recent NAIDOC Week celebration which included a smoking ceremony to unveil a beautiful mural painted by local Aboriginal artist and E-Bisglobal trainee graphic designer Kyle Waters.

Enjoy the read. Go well and see you on October 27!

Design and Production Manager

Printed by Hero Print

Treatment by

Services

Park, NSW,

is published bi-monthly by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any

or liability for any loss or damage which may

from any inaccuracy or omission in the

publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication.

IVE Group has now completed its $16 million acquisition of substantially all of Ovato with the deal resulting in the 101-year-old publicly-listed giant being the only large scale heatset web offset print producer in Australia.

Ovato was formed through a megamerger between the historic Hannan family owned, IPMG, and PMP Ltd, a company which was once part of the Murdoch empire. After a number of difficult years, Ovato was placed in voluntary administration in July this year.

IVE Group soon emerged as a likely purchaser and offered to purchase Ovato’s heatset site located at Warwick Farm in NSW and Bibra Lakes in WA for $16 million with the purchase funded from the company’s existing facilities.

Over the next 18 months the Warwick Farm site, which includes seven heatset web presses, will integrate into IVE’s existing

IVE Group CEO Matt Aitken is the new president following the first merged board meeting of the Print & Visual Communication Association (PVCA) and The Real Media Collective (TRMC).

Spotpress managing director John Georgantzakos was declared the new deputy president, with Lamson Group CEO Rodney Frost honorary treasurer. The Label Factory’s Stuart Fysh retained his role as honorary secretary.

Aitken thanked the PVCA’s former deputy president and acting president Kuhn Corp managing director Walter Kuhn for his contribution over many years. Kuhn had taken on the acting president role following the passing of Peter Clark earlier this year.

Kuhn will remain on the board as a Board Officer along with Spot Productions managing director Simon Carmody, Eckersley Print Group managing director Tom

Commission approved the acquisition on August 30 and the deal has now been finalised. It ensures critical web offset printing capacity remains available to Australia's largest retailers and publishers, including magazines such as The Economist, Australian Women’s Weekly, Vogue and catalogue producers such as Woolworths and Aldi.

IVE Group says the Ovato assets acquired by IVE are in good condition, complementary to IVE’s existing production facilities and will be integrated into IVE's existing operations over an expected 18 month period.

In a statement to the ASX, IVE Group executive chairman Geoff Selig said the deal is expected to create a 21 per cent revenue uplift on IVE’s FY22 reported revenue of $760 million.

IVE Group executive chairman Geoff Seligoperations at Huntingwood and Silverwater in NSW and the majority of staff from the sites acquired will be retained.

The acquisition does not include Ovato’s New Zealand business, its Brisbane packaging operation or its printing site in Cairns.

The Australian Competition and Consumer

“Once the integration is complete, the expected $15m increase in underlying net profit after tax (NPAT) would represent a 41% notional increase in underlying NPAT relative to IVE’s FY23 guidance of $36m,” Selig said.

IVE Group CEO Matt Aitken said, “IVE has a strong track record of successfully integrating businesses and optimising operating leverage to deliver synergies.

“This acquisition will further strengthen and deepen IVE Group’s already tier 1 customer base and create an opportunity to cross-sell IVE’s broader diversified offer into the acquired customer base.” PP

“Coming together as one board and one industry body now brings opportunity to be forward focused with a strategy to unite and strengthen the industry’s position,

output, and representation” Aitken said.

Georgantzakos previously served as honorary treasurer and over the last 18 months has led a cost reduction project to strengthen the PVCA’s financial position. In his new role, Georgantzakos will focus on membership growth and will work closely with the incoming team on member engagement programs.

Frost, the former treasurer at The Real Media Collective and now honorary treasurer at the PVCA, said: “We have been working through a rigorous governance and compliance process over the past 12 months to ensure the merger is successful for all our members, I am now excited to get on with the strategy and building new programs and value for members,” Frost said.

Monthly meetings will now take place as the board develops strategy and member deliverables. Key areas of focus include a new name and brand for the association, skills and training, industry representation, environmental and social governance plus member engagement and growth.

Ricoh Australia supported the meeting and sponsored lunch.

“We are committed to the industry above and beyond general sponsorship, we want a strong industry body, a united board and any role Ricoh can play in supporting the industry body achieve more for our industry we are happy to do so,” Ricoh Australia national sales manager Mark Moro said. PP

Newly merged industry association – made up of the Print & Visual Communication Association and The Real Media Collective – welcomed key announcements from the Jobs and Skills Summit but is concerned about VET funding and the removal of print apprenticeships from a skills priority list.

Thirty six initiatives were defined at the recent Jobs and Skills Summit. Included was a promise to spend an extra $1 billion on 180,000 new feefree TAFE places in 2023. Another key announcement was increasing the permanent Migration Program ceiling to 195,000 in 2022-23 to ease workforce shortages.

“We absolutely welcome the increase in migrants coming into the country as we have a massive skills shortage,” Northwood, the CEO of the TRMC & PVCA, said.

Then there is the issue of the low rate of apprentices considering the print industry. A situation hindered by the removal last May of five print apprenticeships from the Australian Apprentice Priority List by the soon-to-be disbanded National Skills Commission.

Jobs and Skills Minister Brendan O’Connor has introduced legislation to establish a new independent body, Jobs and Skills Australia, to work with governments, industry, employers, unions and training

providers to examine the VET system and ensure training is there for future job opportunities.

"We don’t have enough apprentices coming through and we have an aging workforce. We don’t think the National Skills Commission has done its job properly. They have struck off print apprenticeships without consultation and now together with the union and the LIA we have put in submissions criticising that process," Northwood said.

"We are working with Minister O’Connor in that regard and the very first thing we need to do is present ourselves with really strong arguments and metrics and have a compelling case.”

Charles Watson, the General Manager of IR, Policy and Governance at the TRMC/PVCA, is concerned about funding for TAFEs and private operators.

“It is all well and good having 180,000 fee-free places but you’ve got to get people to take those up. Some states and territories have greatly reduced their course offering. The VET sector has been taking a hit for years and it is great that the state and federal government are funding these feefree places but they have also got to look at the funding of TAFE and the private providers to have some

quality training and the courses available,” Watson said.

“Certain states don’t offer certain courses anymore or they have outsourced to private providers which is good but they are not funding those private providers to do certain courses across our apprenticeships and other industries. “It is a nice announcement but will it translate into uptake? That remains to be seen.” PP

watch

Scan

Last tickets are now available for the 2022 ProPrint Awards which recognise senior leaders, rising stars, suppliers and industry legends.

Melbourne’s Complete Colour has acquired Erwins Printing in a move that returns B2 printing capabilities to the company and further grows environmentally responsible onshore printing in Australia.

Complete Colour managing director and founder, Tim Michaelides, said he had been on the look-out for an acquisition with the opportunity to buy the long-running, trusted family-owned Erwins Printing coming at the perfect time.

“Erwins Printing is a great business and its owner, Mick Edwards, is a lovely fellow. Mick has been instrumental in solidifying Erwins’ position as one of the most respected Melbourne offset printing companies around. The business has great values; and like us enjoyed lifetime clients and staff,” Michaelides said.

“It is a great fit for the future of all

concerned. Now we want to continue the growth of Melbourne’s trusted print industry, with a strong environmentally responsible focus. Acquiring Erwins is a significant step in that direction.”

Now the acquisition is complete, Mick Edwards’ son, Sean Edwards, and daughter Stacey Minutello along with other key long-term staff have joined the Complete team at Cheltenham across the business in customer service, pre-press, and production.

Also included is a five-colour B2 Komori press which Complete Colour will integrate with its existing 10-colour Heidelberg press and digital equipment.

“We are taking two or three pieces of equipment and selling off the rest,” Michaelides said.

“We got rid of our previous B2 printer because the market had

dropped off leading up to Covid and then when it hit we just took the step to dispose of it and just run one press. That was a pretty good move for us.

“Over the last two years we have won a significant amount of packaging work that is probably more suited for a B2 press as well like beer cartons so now having this press will be helpful for us. We’ve also won some label work so it will be better to have those on the half sheet. It will give us more flexibility in the business,” Michaelides said.

Complete Colour director Geoff Lawyer added, “We’re really excited to continue the great work that Erwins Printing has undertaken for the last 50-plus years.

“Industry consolidation and integration is inevitable in this postCovid climate, and we’re delighted to have secured a future for a business that has operated under the same values and principles as Complete. Erwins is a great example of how solid operational ethics creates pillars of strength and longevity – for staff, suppliers, and clients alike. Erwins is a natural fit for Complete, and the future of environmentally responsible on-shore printing in Australia is looking very positive.”

Mick Edwards welcomed the buy.

“Complete operates on the same principles that we have based our business on over the past 32 years; quality, honesty and respect, which made them an excellent fit to continue servicing our clients’ needs into the future,” Edwards said.

Edwards and Ron Hall purchased Erwins Printing in 1990 from Erwin Luettin who started the company in 1970. PP

Leon Torzyn, the co-owner of South Australia’s Print Junction, made a flurry of equipment purchases during PacPrint with a new Horizon BQ-270V variable perfect binder among them.

The decision to invest in the new piece of Horizon equipment which automatically perfectly binds books of varying thicknesses has eliminated the need for Print Junction to send work offsite – a move which Torzyn says will save thousands of dollars every year.

Torzyn is a printing industry veteran who started Print Junction with his wife Sheila, a 60 per cent shareholder in the business, and daughter Leah 26 years ago. His son, Nathan Torzyn, also a qualified printer, is now the general manager and is taking on steadily increasing responsibilities of the business.

In 2012 Print Junction became fully certified as an Indigenous business with Supply Nation, due to Sheila’s Indigenous heritage.

Torzyn says adding the new Horizon perfect binder has helped set Print Junction up for the future. The investment completes a Horizon finishing corner in the print room. This includes a collator and creaser/folder –

Ai Group’s latest Australian Performance of Manufacturing Index (Australian PMI) has identified signs of manufacturing slowing down.

The report showed the Australian PMI dropping 3.2 points to 49.3 in August, indicating a slight contraction (readings below 50 points indicate contraction in activity, with lower results indicating a faster rate of contraction).

Ai Group said this is the first time the index has contracted since January 2022 following the Covid-19 Omicron outbreak.

Ai Group CEO Innes Willox said, “The Ai Group Australian PMI for August points to the end of the recent expansion of

all Horizon and all sourced through Currie Group, the exclusive distributor of the Japanese-made range of finishing equipment in Australia and New Zealand.

The Horizon BQ-270V comes standard with a special book thickness caliper which means that as one book is cycling through the machine, a subsequent book of a different thickness can be measured with the data transferred for the changeover. This feature can result in a 30 per cent decrease in cycle time when compared to conventional models.

“For many years now, we have been offering the solution of perfect binding for specialist reports, high-end publications, annual reports, manuals and books of that

nature which we do quite a lot of,” Torzyn said.

“We have always said to our clients they will get a nice square back perfect-bound book and it will look good but then we would send it to a trade house. This meant getting it out of our factory, sending it to the trade house and falling into their hands and timeframes.

“We should have done this 10 years ago. I am retiring and we’ve got machinery here that is new and up to date and from this point on we are good for 10 years.

“It is very automated and very easy to operate. It fits our model and our production capabilities, and it can produce 350 to 400 books an hour.” PP

manufacturing activity. Production, employment, and sales were all down in August and most manufacturing sectors reported lower performance in the month.

“The chemicals subsector expanded as did the diverse textiles, clothing, footwear, paper and printing subsector. Prices and wages continued to push higher and with the Reserve Bank seeking to ease these pressures by raising interest rates, further

slowing in manufacturing looks increasingly likely over the coming months.”

The Australian PMI is a national composite index calculated from a weighted mix of the diffusion indices for production, new orders, deliveries, inventories and employment.

Australian PMI results are based on responses from a national sample of manufacturers that includes all states and all sub-sectors. PP

Why has the SCREEN Truepress Jet L350UV SAI won another EDP Award for the company? It’s the third time, as each generation of the L350UV label printers have received this accolade. The judges claimed it was primarily “for its ease-of-use thanks to its excellent software, as well as for its improved quality and speed.”

We agree, adding:

7 vibrant colours including a brilliant blue and orange

Speed of 60 mpm and 50 mpm when using white

Engineered for highest (>93%) uptime

Fully supported by local factory-trained technicians

User-friendly EQUIOS software integrates with MIS

DIC Australia has announced that over the next 18 months it will phase out ink and coatings production at its factory in Sydney’s Auburn with all domestic production to be carried out in Victoria.

The decision comes after the company conducted a full strategic review to ensure its sustainability into the future.

Staff and customers were notified of the impending closure of the 60 year-old production facility in Sydney in August.

The planned production consolidation includes a multi-million-dollar upgrade to the company’s site at Moorabbin in Victoria which DIC Australia Chief Operating Officer, Richard Kemp, is confident will create a significant number of new job and redeployment opportunities for the company’s valued employees.

Heidelberg is investing heavily in its core business with the launch of its new-generation Speedmaster SX 102, which has been enhanced in line with customer requirements.

This press is aimed primarily at commercial print shops that require a high level of productivity and top-quality perfecting printing. Typical areas of use range from brochures and commercial print products to inserts for pharmaceutical packaging, and therefore include applications involving very thin materials that need to be produced in a single pass.

The Speedmaster SX 102 features an ergonomic design with a new gallery and guards that come from the Speedmaster XL series.

The basic model comes in a new 92 format option (650mm x 940mm) which cuts printing plate costs by up to 20 per cent compared with the conventional 102 sheet format (720mm x 1,020mm), which is also available.

The new Speedmaster SX 102 is designed as a scalable press. Depending on the range of applications and the output/automation

“The printing industry has found itself in an unprecedented position over recent years and the commonality of challenges we all face together across the industry has resulted in many organisations reshaping their business models to ensure a sustainable future. DIC Australia is no exception,” Kemp said.

“Following a strategic review of our current business model, and alignment of our service and support platforms to the

current and future requirements of our market, DIC will now commence a program of work which includes a proposal to relocate and consolidate our manufacturing activities into Victoria.”

Kemp said the planned consolidation will see DIC commit to a multi-million-dollar upgrade of the DIC site in Victoria and investment in state-of-the-art automation of ink and coating manufacturing processes.

“We are confident that the upgrades to our Victorian facility will create a significant number of new job and redeployment opportunities for our valued employees,” he said.

“The planned consolidation may result in the change of local representative serving you. DIC is committed in continuing to deliver the high level of service your company deserves. Our assurance to responsiveness and client satisfaction has not changed.

“As the global leader in manufacturing and supply of printing inks, coatings, and associated products, DIC is fully committed to supporting the printing industry across Australia and New Zealand long term, building on our position as supplier of choice across the region. Should you have any questions or concerns, please do not hesitate to contact your local representative.”

requirements, the basic model can be ordered with many other assistance systems transferred from Speedmaster XL technology. These include Intellistart 3, Intelliline, Intellirun, Wash Assistant, Powder Assistant, and many more besides.

If required, the configuration can be extended all the way through to Push-toStop for autonomous printing. With the help of artificial intelligence, the digital assistance systems also achieve a further significant reduction in the number of manual interventions by operators.

Thanks to the Prinect Press Center XL 3 and the Prinect workflow, the Speedmaster SX 102 can also be fully integrated into a print shop’s

overall workflow, which ensures efficient data management, precise pre-settings, up-to-date production data, and informative reports. The Preset Plus feeder and delivery have also been taken over from XL technology, along with further proven solutions.

“With the new Speedmaster SX 102, we are once again emphasising our technology leadership,” Heidelberg head of product management, Stefan Hasenzahl said.

“Our customers benefit from a scalable press that can be fully integrated and, if necessary, adapted to their precise requirements using a whole host of established assistance systems from our Speedmaster XL solutions.” PP

printIQ, a software company which was launched as a start-up in New Zealand in 1999, has been acquired by Banyan Software, an investment firm which focuses on a buy and hold for life strategy for growing software companies.

printIQ CEO Anthony Lew will remain at the helm of printIQ along with the same teams for sales, marketing, customer service, support and product development.

“Over the last 20 years, and with the help of many amazing people, we have established our business as a market leader that drives innovation through the print industry,” Lew said.

“I am delighted to have found a partner that can help us to write the next chapter in our story. Banyan shares many of the values that we hold so high and has a proven reputation for growing businesses.”

Durst Group has officially opened the Durst Kraftwerk – a new 5,300 square metre facility which sits beside Durst’s stunning headquarters and factory at Brixen, Italy and serves as a home to spin-offs and start-ups of the Durst Group and Technicon Holdings.

“Born out of the need to give our US acquisition Vanguard Digital Systems a home in Europe, the idea for the Durst Kraftwerk was born,” Christoph Gamper, CEO and co-owner of the Durst Group, said at the launch.

“A powerhouse that brings together our spin-offs and start-ups and offers them a new home. In this way, we provide a creative environment where the companies can fully concentrate on their respective areas of expertise – without the ‘burden’ of integration into an established structure.

“I am grateful and proud of the individual co-founders and their teams and convinced that top performance and business success will go hand in hand in the Durst Kraftwerk.”

Lew said printIQ has always had a history of rising to the challenge of pushing the limits of what a print MIS can do.

“From our early days as a small New Zealand start-up, we have continued to work tirelessly to build the best solution possible. Our inspiration has always been our customers who have believed in the vision of that the platform could be,” he said.

“Consistently pushing it to the next level means that development is never complete. We are excited to have a partner who will help us deliver on that promise by

investing in R&D, growing into new markets, and delivering the best solutions for the print industry.

“It’s an exciting time as I already see many of the benefits of partnering with a long term investment focused software company. My goal is to continue building the product, extending our reach into new markets, and improving the way we listen, partner with, and support our existing customers.”

printIQ has experienced significant growth over the past 12 months with operations spanning New Zealand, the US, Europe, Australia and Canada and employing more than 50 staff.

Following the changes, Lew will remain at the helm as CEO along with the same teams for sales, marketing, customer service, support and product development.

Banyan Software CEO David Berkal welcomed printIQ to his company.

“It was clear from the beginning how committed the team is to building quality solutions and providing excellent customer service, alongside an equal commitment to creating a culture that their employees are proud to be part of,” Berkal said.

“We’re very excited to welcome printIQ to Banyan as we continue to expand into the Australia and New Zealand market.” PP

Technicon Holdings is owned by the president of Durst Group AG Harald Oberrauch.

“Technicon Holdings unites internationally successful companies such as Durst Group AG and Alupress AG under its umbrella,” Oberrauch said.

“At the same time, we act as an incubator to promote new business ideas that arise in our companies’ environment. From a bird’s eye view, we can clear hurdles more quickly, accelerate development processes and connect teams.

“We aim to create a true innovation centre for specialised service providers at the Durst Kraftwerk.”

In addition to being a local base for Vanguard Europe, the European branch of the US company, Vanguard Digital Printing

Systems, which Durst Group acquired in 2020, the space will also house Durst’s academy training centre.

Another company using the space is adddam GmbH, which uses high-end 3D advanced manufacturing printing technologies to make components from metals and plastics. Other operations include additive 3D manufacturer, D3-AM GmbH, and DMC GmBH, Durst’s media company which specialises in B2B marketing communications and new storytelling.

Durst Oceania managing director Matt Ashman added: “This is the vision of Christoph Gamper and Harald Oberrauch, an incubator for new start-ups and business innovators in the heart of the Tyrol, next door to the little big company we all know so well – what inspiration.” PP

Ball & Doggett announced its acquisition of Conect Enterprises, a supplier of sign, display and digital products. As one of Australia’s largest distributors of printable materials and consumables, Ball & Doggett says the acquisition further solidifies its position as a supplier to the signage market.

Tony & Pam Coniglio established Conect Enterprises in 1985 and the couple will stay with the business for a short transition period. “This acquisition is good for our customers, suppliers, and staff. Ball & Doggett have the resources and infrastructure to take the business forward. It is about leveraging our combined strengths to provide greater value and options to support our customers,” Tony Coniglio said. Ball & Doggett CEO Luke Wilkinson said the move is an exciting next step for the company. “We welcome the Conect team into the Ball & Doggett family," he said.

Grafico has been awarded the City of Melbourne’s Small Business of the Year

2022 award in recognition of its innovation, creative marketing, sustainability initiatives and longstanding connection to the local government authority.

Damian Corney, the CEO of Grafico which specialises in design, print and signage, was presented the award by Lord Mayor of Melbourne Sally Capp at a special ceremony.

“Damian Corney and the team at Grafico are a leading example of a Melbourne-owned and operated business which has achieved huge success on a national level. We’re thrilled to recognise their achievements and look forward to seeing them further prosper,” Capp said.

Grafico was founded in 2004 by Corney as part of a university project. It produces custom wallpaper, mosaic tiles, vehicle wraps and vinyl wraps.

Landa has a established a new ink factory located in The Netherlands.

The facility

enables the Israel-based company to double production to support demand for Landa Nanoink. Landa CEO Gil Oron says establishing the site in Europe dramatically reduces lead times and environmental impact caused by shipping of raw materials.

“It provides Landa customers with local supply, which in times of very challenging worldwide logistics and parts supplies, offers considerable reassurance," Oron said.

"With customer production volumes increasing daily, this also ensures prompt and reliable delivery toocrucial in increasing efficiency.”

The inks produced in Europe will power Landa’s Nanographic printing presses. Landa says the presses provide a cost effective solution for short to medium run mainstream commercial print and packaging jobs.

Close the Loop has now recycled 50 million printer cartridges through the Cartridges 4 Planet Ark program.

Cartridges 4 Planet Ark is a recycling program that provides people with easy and environmentally accredited ways to recycle used printer cartridges.

The cartridges collected so far have been recycled into hundreds of new products including cartridges, inks, and Close the Loop’s TonerPlas product. Close the Loop CEO Joe Foster said, “We have reached a 50 million milestone of printer cartridges recycled through our popular Cartridges 4 Planet Ark program since its inception in 2003. “Keeping items such as these out of landfill and instead recycling them into hundreds of new products that people use every day is at the core of our operations.”

There are over 4,000 collection boxes located at corporate and government workplaces and schools across Australia.

Epson has recorded a 5.6 per cent revenue increase in the first quarter of 2022 to $3.2 billion but also reported a 6.6 per cent slide in profits due to supply constraints and increased logistics costs.

Within the printing solutions business, Epson said with supply constrained due to semiconductor shortages and the Shanghai lockdown, it increased revenue by dynamically adjusting prices based on supply and demand, but profit declined due to soaring material and logistics costs.

“Results were negatively affected by supply constraints, which caused unit sales to decrease, and by skyrocketing materials and logistics costs, but they were positively affected by dynamic product pricing based on supply and demand. Profit for the period was also positively affected by the weakened yen,” Epson said.

After a twoyear collaboration with Fujifilm Business Innovation Australia (FFBI), TIMG LitSupport has added a Revoria Press E1-Series amongst other technologies to harness cost savings and increase productivity.

Timg LitSupport is part of The Information Management Group litigation support division and is an authorised supplier of Victorian legislative publications. Following the install, the company noted a 26% reduction in total cost of operation and increases in staff productivity.

TIMG national bureau manager Carlo Di Toro said consistent on-time delivery of error-free documentation, with complete confidentiality and security is a client requirement. “Communication [with Fujifilm BI Australia] was so transparent that we knew we were working to the same outcome – getting the best equipment for the work, with value for money,” Di Toro said.

Jet Technologies, a supplier for the food packaging, industrial manufacturing and print and finishing industries, has released ‘Encore’, a new plastic film made from 30% recycled materials. Jet Technologies director Jack Malki says with organisations like the Australian Packaging Covenant setting 2025 targets of having 70% of plastic packaging being recycled or composted and 50% of average recycled content included in packaging, manufacturers are having to quickly take steps to increase sustainability.

“Encore is a strong first step in the right direction for using plastics within the circular economy and provide a sorely needed path forward for brand owners who are ready to work towards these recyclability and sustainability goals,” he said, adding Encore is suitable for businesses shifting from plastics, PLA (corn starch) or woodbased alternatives.

HP A/NZ vice president and managing director Mike Boyle (pictured) is relocating to Barcelona after being promoted to be the global head of large format at HP with the company’s current managing director for Africa, Brad Pulford, announced as his replacement.

Boyle has been with HP for seven years having started as vice president of APAC. Prior to this he spent five years at Canon and eight years with Océ, which Canon acquired in 2010. In his new role, Boyle will be responsible for the go-tomarket strategies for HP’s large format machines, including the Latex and DesignJet portfolios. “I’ve always had a background in large format and bring to my new role a deep experience of about 25 years. Large format is certainly something that I know well and love, and I’m excited about where I can help take this business,” he said. Pulford begins his new role from November 1.

David Crowther, aka the Colour Doctor, of Colour Graphic Services and Idealliance Australasia is offering two special offers to help printers of all sizes and types standardise colour and benefit from the savings that brings.

The first offer includes full training and set up of a print device to ISO 12647 or G7 or another standard of a printer’s choice and a copy of Mellow Colour PrintSpec for CMYK colour control, calibration, and verification.

An Idealliance G7 Master qualification is also included.

The second offer includes the same benefits but adds the Myiro-1 handheld spectrophotometer and Myiro Tools Advanced software for additional colour measurement, analysis and complete colour profiling.

“We are providing the tools, the instruction, the training, the support and Idealliance G7 Master qualification which would normally require some significant investment to complete,” Crowther said.

Fiery, EFI’s digital front end server and print workflow business, has introduced

new cloud capabilities and additional productivity enhancements in the new Version 6.8 of the EFI Fiery Command WorkStation management solution.

The new version boasts EFI IQ cloud integration which gives Command WorkStation users the ability to back up and restore their customised user interface settings, local presets and imposition templates.

With the same EFI IQ account, managers can take advantage of cloud applications to extract value from their print shop data to minimise bottlenecks, optimise equipment utilisation, and track performance by shift.

“This new version of Command WorkStation is a significant milestone in our strategy to improve Fiery capability with EFI IQ cloud services,” EFI Fiery vice president of sales and marketing John Henze said.

HVG recently hosted its annual Salesmasters of the Year Awards at the Pullman Sydney Airport Hotel.

Two staff from the HVG Graphics Media team were recipients of category awards – Jason Rewse (pictured on right with HVG general manager Richard Lucas on left) received the HVG Graphics Media Salesmaster of the Year award for outstanding sales, while Glen MacKellin took home the overall HVG Sales Rookie of the Year award.

The HVG Awards aim to recognise and acknowledge the highest performing team members across all divisions who reflect HVG’s company mission, vision, and values.

“Congratulations to our two members from the HVG Graphics Media team. The HVG Graphics Media team is extremely proud of both Jason’s and Glen’s achievements,” Lucas said.

ATRUE GUIDE & GRIP REGISTER SYSTEMENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE IS CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH PRESS REGISTER EDGES.

ATRUE GUIDE & GRIP REGISTER SYSTEM ENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE IS CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH PRESS REGISTER EDGES.

ATRUE GUIDE & GRIP REGISTER SYSTEM ENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE IS CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH PRESS REGISTER EDGES.

ATRUE GUIDE & GRIP REGISTER SYSTEM ENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE IS CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH PRESS REGISTER EDGES.

Same

A TOP SUCTION AIR FEEDER IS POWEREDVIA A BUILT IN BLOWER PUMP IN THE MACHINE. AN OPERATOR CAN INDEPENDENTLY ADJUST VOLUMESOF BOTH BLOW & SUCTION TO ADJUST FOR THE WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKERHEADS CAN BE ADJUSTED TO SHEET SIZE.

A TOP SUCTION AIR FEEDER IS POWERED VIA A BUILT IN BLOWER PUMP IN THE MACHINE. AN OPERATOR CAN INDEPENDENTLY ADJUST VOLUMESOF BOTH BLOW & SUCTION TO ADJUST FOR THE WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKERHEADS CAN BE ADJUSTED TO SHEET SIZE.

A TOP SUCTION AIR FEEDER IS POWEREDVIA A BUILT IN BLOWER PUMP IN THE MACHINE. AN OPERATOR CAN INDEPENDENTLY ADJUST VOLUMESOF BOTH BLOW & SUCTION TO ADJUST FOR THE WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKERHEADS CAN BE ADJUSTED TO SHEET SIZE.

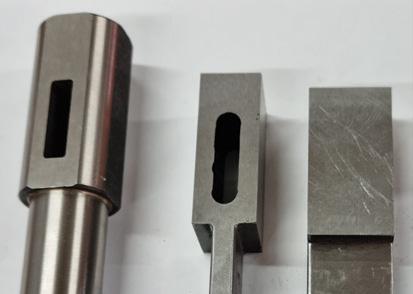

ARECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSISTENT DIE MOUNTING & ENSURES DIE TOOLS AREHUNG PARALLEL & CENTERED.

ARECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSISTENT DIE MOUNTING & ENSURES DIE TOOLS AREHUNG PARALLEL & CENTERED.

A TOP SUCTION AIR FEEDER IS POWERED VIA A BUILT IN BLOWER PUMP IN THE MACHINE. AN OPERATOR CAN INDEPENDENTLY ADJUST VOLUMESOF BOTH BLOW & SUCTION TO ADJUST FOR THE WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKERHEADS CAN BE ADJUSTED TO SHEET SIZE. ARECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSISTENT DIE MOUNTING & ENSURES DIE TOOLS AREHUNG PARALLEL & CENTERED.

ARECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSISTENT DIE MOUNTING & ENSURES DIE TOOLS AREHUNG PARALLEL & CENTERED.

APIN MOUNT SYSTEM ON DUAL MAGNETIC MACHINES ENSURE THE ALIGNMENT OF THE PAIRED SET OFDIE TOOLS. CYLINDERS ALSO HAVE BUILT-IN MICROADJUSTMENT CAPABILITIES TO ENSURE MATING.

APINMOUNT SYSTEM ON DUAL MAGNETIC MACHINES ENSURE THE ALIGNMENT OF THE PAIRED SET OFDIE TOOLS. CYLINDERS ALSO HAVE BUILT-IN MICROADJUSTMENT CAPABILITIES TO ENSURE MATING.

A PINMOUNT SYSTEM ON DUAL MAGNETIC MACHINES ENSURE THE ALIGNMENT OF THE PAIRED SET OFDIE TOOLS. CYLINDERS ALSO HAVE BUILT-IN MICROADJUSTMENT CAPABILITIES TO ENSURE MATING.

APIN MOUNT SYSTEM ON DUAL MAGNETIC MACHINES ENSURE THE ALIGNMENT OF THE PAIRED SET OFDIE TOOLS. CYLINDERS ALSO HAVE BUILT-IN MICROADJUSTMENT CAPABILITIES TO ENSURE MATING.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED EASILY VIA THE BLACK WHEEL. INFINITELY ADJUSTABLE UP TO 3,000 PSI OF CUTTING PRESSURE IS AVAILABLE. GAUGES ENABLE OPERATOR TO DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED EASILY VIA THE BLACK WHEEL. INFINITELY ADJUSTABLE UP TO 3,000 PSI OF CUTTING PRESSURE IS AVAILABLE. GAUGES ENABLE OPERATOR TO DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED EASILY VIA THE BLACK WHEEL. INFINITELY ADJUSTABLE UP TO 3,000 PSI OF CUTTING PRESSURE IS AVAILABLE. GAUGES ENABLE OPERATOR TO DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED EASILY VIA THE BLACK WHEEL. INFINITELY ADJUSTABLE UP TO 3,000 PSI OF CUTTING PRESSURE IS AVAILABLE. GAUGES ENABLE OPERATOR TO DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

Mick Rowan has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

They represent companies from forestry, pulp, paper, publishing, and printing to name a few, with a common goal of promoting the sustainability of the graphic communications supply chain. They also work to dispel environmental misconceptions about print. Two Sides have numerous resources that provide users with verifiable information on why print and paper are attractive, practical, and sustainable communications mediums.

And let’s not forget about our world-class local trade shows! PacPrint is the premier industry exhibition for the print and graphic communications sector. PrintEx for print, sign, wide-format, engraving, labels, and the packaging sector. And Visual Impact is the leading show for the region’s sign, display and graphics industries.

Access to resources, seminars, and industry events can keep you informed and updated on equipment, issues and best practices

It can be tough running a printing company. The competition is fierce, the margins are often small, and it seems like every other business is out to undercut you on price. So, where do you turn for support? Surprisingly, there’s more help out there than you might realise.

Our industry is fortunate to have some excellent associations designed solely to support and promote print. Many provide education, training, and advocacy on behalf of their members. And they’re often run by industry stalwarts with decades of experience.

Take, for example, Print NZ. They work on behalf of New Zealand printers to ensure they’re kept well informed, educated, and connected to other like-minded businesses. But they also offer advice on employment, health and safety and act as a much needed voice at the government level.

Then there’s the NZ Sign & Display Association (NZSDA), whose goal is to expand the knowledge within the signmaking industry. The NZSDA offers advocacy services, recruitment solutions, events, and networking opportunities. They also work

with local bodies on by-laws that might affect signage and maintain the apprenticeship training standards to develop future craftspeople for the industry.

Or how about The Real Media Collective, which represents the users, producers, and distributors of catalogues, direct mail, print, paper and more across the entire marketing channel. They provide a wealth of well-researched and verifiable resources, including their ‘Value of Paper and Print’ (VoPP), campaign. VoPP raises awareness of the power of paper, print and mail marketing and supports members with marketing collateral, media representation and targeted consumer research. The Real Media Collective does an excellent job of promoting the effectiveness and environmental credentials of print media in the Australian and New Zealand markets.

One of my favourite industry promoters is Two Sides, created in 2008 by graphic communications supply chain members. Two Sides is a not-for-profit organisation that provides a forum for the industry to work together and share experiences that will improve standards and practices and maximise customer confidence in our industry.

There are also events a little further afield, such as the incredible Hunkeler Innovationdays, drupa, Labelexpo and the various HP and Fespa events. These events expose attendees to a future they might barely have imagined while creating even more opportunities to chat with colleagues, customers, and competitors.

Undoubtedly, most business owners feel isolated at times, regardless of their industry. But having access to resources, seminars, and industry events can keep you informed and updated on equipment, issues and best practices and provide a window into a far bigger world.

The prospect of increasing your knowledge and learning more about what it takes to succeed in this industry or meeting with other professionals who can share their insights on equipment, trends and potential business opportunities is one we should all strive towards.

If you’re looking for support, whether that be advice, education, training, or perhaps a n industry get together, there are plenty of organisations out there to help. I’ve only mentioned a few above, but please do yourself a favour and find a group (or two!), or an event to attend, that can help you and your business grow. You’ll be so glad you did. PP

The Real Media Collective’s IR expert Charles Watson decodes the difficult process of terminating an ill or injured employee when they are no longer able to carry out their duties.

It is unfortunate, but realistically there will be occasions where an employer has no other option but to terminate an ill or injured employee. Having to let an employee go because of their ongoing inability to undertake the inherent duties of their role is never easy. This issue is one of the most difficult to deal with for employers. In these situations, employers have numerous legislative obligations depending upon whether the illness or injury was workrelated or otherwise. By understanding your obligations and the best way to manage these situations will lessen the likelihoods of litigious risks and your stress.

Section 352 of the Fair Work Act prohibits an employer from dismissing an employee because the employee is ‘temporarily’ absent from work because of an illness or injury. Specifically, the Fair Work Regulations 2009 provides that an employer must not dismiss an employee who is absent for a period of up to three months, after having exhausted all personal leave. This three-month period can also be assessed from a series of absences over a 12-month period, resulting from one or more injuries or illnesses.

If the illness or injury is work-related each state and territory has workers compensation related legislation and requirements that will apply. Each state or territory scheme requires an employer to focus on returning the employee back to work and to make ‘reasonable’ adjustments where possible. This may include providing suitable alternative employment to the

injured employee where possible for period of time. However, employers need to be mindful if an employee continues to perform alternative or modified duties for an extended period, and with no clear plan to return to their pre-injury duties, it could be seen the employee has had their duties permanently amended.

Additionally, each state or territory scheme generally prohibits an employer from dismissing an employee on the grounds that they are not fit for employment due to having suffered a work-related injury. This protection is generally afforded for a period of six months after the employee first becomes unfit to work due to the injury. Having a good understanding of the specific requirements under the relevant workers compensation scheme will be advantageous.

Further, and depending upon the circumstances, the termination of an ill or injured employee can potentially constitute a breach of disability discrimination legislation if the illness or injury constitutes a disability. This is regardless of whether that person has been absent for a period of three or six months, or longer. To defend such a claim an employer will need to be able to establish that the employee is unable to carry out the ‘inherent requirements’ of the job.

Often the reason for terminating an employee who is ill or injured will come down to their inability to perform the inherent requirements of the role for which

they are employed. This will vary depending upon the specific job, but likely relate to an inability to work safely, the likelihood of further or repetitive injury should they continue to perform their role, or the inability to perform the core functions of their role as a result of their injury or illness. It is a good idea to provide the employees treating doctors with an explanatory list of the employee’s duties, including the regularity of each one, so that the treating doctor can base any assessment on that list rather than take a generalised approach. How often does a medical certificate state in general terms that an employee can’t lift over 10 kilograms, but doesn’t clarify they could lift that weight several times in the day as required by their role!

The right approach to managing these issues and deciding to terminate will depend upon the individual circumstances of the employee and the business. Any decision to terminate an ill or injured employee should be based on a fair, defensible, transparent and evidentially detailed process.

Such a decision should only be made after a complete assessment based on all available medical information and opinion is available, ensuring compliance with all legislative requirements, having clear discussions and communication with the employee, a consideration of any company policies, and a consideration of all related risks. Ultimately, you need to fairly balance the employees’ health circumstances, their role and its specific duties, and the needs of your company.

If the terminated employee makes a claim relating to their termination, the process that was applied in making the decision will be crucial in defending such a claim. Essentially, you as an employer need to be able to put your hand on your heart and state that there was no other options that could have reasonably been implemented to avoid the termination. As always, seek specific advice should these issues arise in your workplace.

Charles Watson GM – IR, Policy and Governance PVCA/TRMC PP

Charles Watson GM – IR, Policy and Governance PVCA/TRMC PP

Ricoh Australia has won the confidence of two key Australian printers with IVE Group and Cheque - Mates signing up with the leading provider of smart workplace technology and production print equipment after rigorous testing.

Winning Preferred Print Partner status with Australia’s largest printer, the ASX-listed IVE Group, was no mean feat. It followed a fourweek on-site testing period which involved putting the Ricoh Pro C9210 Graphic Arts Edition digital colour press in a direct face-

off with flagship digital presses from two other vendors.

IVE Group chief operating officer Brent McCulloch said choosing Ricoh as a Preferred Print Partner was a major decision for the company, particularly as it involved bringing in a new vendor for the first time in many years.

With some of IVE Group’s printing infrastructure reaching end of life, McCulloch said the time had come to assess other

options in the market. IVE went on to request a proposal from seven vendors and three were shortlisted. Proof of concept testing was due to take place in the facilities of each of the shortlisted vendors, but Covid-19 travel restrictions meant this process was unable to proceed.

Instead, the three shortlisted vendors installed their proposed equipment at an IVE production facility for four weeks. Each system was run with the same jobs with the output and performance statistics presented to IVE senior management for consideration.

“The third phase involved vendor capability presentations and final commercial submissions at the end of December. At that point, we selected Ricoh as our new preferred technology partner,” McCulloch said.

“Choosing Ricoh was a major decision for us at IVE Group as was bringing in a new print vendor, the first in many years. We made the change because Ricoh was able to clearly show it was the vendor most capable of meeting the production requirements of Australia’s largest commercial printer.”

After finalising the agreement in December last year, IVE Group installed six Ricoh Pro C9210 Graphic Arts Edition presses in April, along with two Ricoh Pro C7210X digital fivecolour units which include additional colours white, clear, neon yellow, neon pink, gold, silver and invisible red.

Top-of-the-line EFI Fiery colour controllers were also installed for each press.

“As part of the testing process, we found that the Ricoh printers gave us great quality and print registration,” McCulloch said.

“They were also able to deliver high levels of uptime and were preferred by our operating teams because of their ease of use.

“Ricoh has enabled us to increase our print efficiency which has lowered our cost base. From initial installation to production, everything has gone very smoothly.

"Once each machine had been delivered to site, it was up and running within a week.

“The support we have received from Ricoh has been second to none. We look forward to working with them.”

Ricoh Australia managing director Yasu Takahashi said after such a rigorous selection process, Ricoh is delighted to have been chosen as IVE’s Preferred Print Partner.

“IVE Group is Australia’s largest diversified marketing and printing company and we are delighted that Ricoh has been selected as a preferred print provider after such a rigorous selection and testing process,” he said.

“The unique aspect of having three competitive print engines operating alongside the machines to be replaced provided IVE Group with real insight into the production capabilities of the Pro C9210 and the support offered by Ricoh Australia. It is a testament to the teamwork of our sales, support, service, logistics and operations that we were able to meet a very tight installation schedule.

“We look forward to strengthening our relationship with IVE Group. Through improving our collaboration, we can share expertise and experiences with each other, finding better ways to serve IVE Group and its customers, and incorporate feedback back into product development and the services we offer.”

It was a similar story at Cheque - Mates, a trade-only printer which is part of The Lamson Group of Companies and headed up by CEO Rodney Frost.

Cheque - Mates created a shortlist of three vendors and conducted similar testing in vendor showrooms with the Ricoh Pro C9210 triumphing in the end.

“The technology selection process is very important for our business as we are ultimately investing on behalf of our channel partners,” Frost said.

“Our technology needs to deliver as we have a lot of companies in the trade relying on us. We spent a significant amount of time carefully assessing equipment from a variety of vendors before creating a shortlist of three which included Konica Minolta, Fujifilm, and Ricoh.”

Frost said his team were very impressed with the quality of the engineering of the machine together with the consistency of the output.

“During the testing process the Ricoh printer did not experience a single paper jam which is remarkable,” Frost said.

“Our industry is spoilt by the options that we have in machinery at present, however the Ricoh Pro C9210 stood out for our needs.”

Frost added the Ricoh Pro C9210 is generating productivity improvements at Cheque - Mates, as a result of significantly improved uptime.

“The rated speed in a brochure isn’t always necessarily what you see come to fruition as actual production output. Jobs can be completed more quickly which means we can achieve improved output volumes and faster results for our partners,” Frost said.

“With the experience we have enjoyed with Ricoh, we have a strategic partner for the long-term.”

Ricoh Australia graphic communications national sales manager, Mark Moro, is delighted a growing list of Australian printers are signing up with Ricoh.

“The feedback we received is that the Pro C9210 offers an unmatched combination of outstanding print quality, productivity, ease of use, flexibility and reliability that enables these printers to support print business momentum. We look forward to a long and fruitful partnership with Cheque - Mates.”

• A high-capacity workhorse which can produce one million colour copies per month at speeds up to 135 pages per minute in high definition with auto-calibration and auto-registration.

• Paper capacity can be increased to 17,600 sheets.

• Broad stock versatility including coated and non-coated, linenlook, super gloss, metallics and synthetics which give way to highdemand and high-value tactile finishes.

• It can print on cardstock up to 600 microns (0.6mm) thick – opening print business owners up to shortrun packaging and labels opportunities.

• Able to print sheets from 330mm to 1260mm for gatefold brochure covers.

• Choice of two EFI Fiery controllers.

• In-line and off-line finishing options available.

Ricoh has a steep heritage in inkjet production, despite being more well known in Australia for its toner production devices. It is using this capability to further build its strength in the continuous feed space to allow more offset and digital printers to produce applications including high-end photo books and luxury catalogues.

At drupa 2016, Ricoh launched the Ricoh Pro

VC70000 with this model introducing new revolutionary drying technology which did not exist in its predecessor, the Pro VC60000.

Continuing this trend of constant improvement, in August Ricoh unveiled the Pro VC70000e which is field upgradeable and interchangeable with existing Pro VC70000 installations. It features multiple print quality and productivity enhancements including useful Artificial Intelligence and Machine Learning benefits.

For offset printers, this model eases concerns of making the inkjet transition due to its undercoating technology, which enables printing on a broader range of substrates.

Ricoh Australia product marketing manager Henryk Kraszewski explained the undercoat feature, and why it is something the market is calling for.

"The enhancement here is a new undercoat feature. Our inks on the Pro VC70000 have no need for an undercoat but the new features enables printing on a broader range of substrates with enhanced print quality, easing the path for offset printers to make the inkjet transition," Kraszewski said.

“Next year will be our 50th anniversary in inkjet R&D, a long heritage of inkjet development. The Pro VC70000 family includes our printhead technology, our own ink technology, and our controller technology. We feel this is a key point of difference as we make the whole solution and what that means for the customer at the end of the day is that we are responsible for every part of that engine.

“It's all our technology, so, what ends up on the printed page is what we control.”

For more information, please visit www.ricoh.com.au. PP

After spending more than 30 years working in the printing industry, Mark Moro is just as excited about its potential today as he was in the 1990s.

and now production print sectors.”

Moro prides himself on his ability to carefully manage both internal and external customer relationships, remaining totally focussed on the required outcome to deliver a high degree of excellence.

In his current nationally focused role, Moro is overseeing the extension of Ricoh’s footprint among large-scale business and commercial print houses. This is being backed by an extension of the company’s product range in Australia and extensive training of sales professionals.

“Ricoh has always been very strong within midsized businesses,” says Moro. “Our focus is on growing our presence within Australia’s largest printing firms.”

During the past couple of years, when the global pandemic made business travel all but impossible, Moro focused on using digital collaboration tools to maintain contact with key clients and make introductions to new prospects.

marketing campaigns to back-office workflows. The technologies used to deliver printed pages will continue to evolve but the vital role played by printed collateral will remain.

When considering the key forces currently shaping the future of print, Moro says there are some significant trends at work.

One is the strategy being adopted by companies such as Ricoh to expand their product and service offerings into non-print areas. Ricoh now has a portfolio of digital services that support workplace collaboration and communication.

“This trend certainly does not mean that we are turning our backs on print – far from it,” he says. “It is a way for Ricoh to deliver even more value for our customers and allow them to take advantage of some exciting new technologies and services that are shaping the world of work.”

As Ricoh’s Australian national sales manager for Ricoh Graphic Communications, Mark Moro is charged with growing the company’s business, maintaining existing customer relationships, and identifying opportunities for growth.

During his career in print, Moro has undertaken a variety of roles but has particularly enjoyed those where he has had the opportunity to manage and motivate teams to achieve corporate goals. At the same time, no matter what role he has been tasked with over the years, Moro has consistently been passionate about helping customers achieve their strategic objectives.

“I have developed specific expertise in the coaching, training, and development of sales professionals,” he says. “These have been gradually honed over years of experience within the corporate, SME,

“While this is very effective from a time management perspective, nothing can beat meeting up with people in a face-to-face environment,” he says. “With restrictions having eased, I am really enjoying getting out and meeting customers once again faceto-face.”

During his time in the printing industry, Moro has watched the constant evolution of both technologies and products with interest. He points to the introduction of digital techniques and the significant growth in colour printing to be highlights.

“For many years there have been people who have predicted the death of print and the rise of the so-called ‘paperless office’,” says Moro. “Yet, you only need to have a casual glance around any print business to see that is not the case. The 2022 Industry Insights Report by The Real Media Collective reinforced the importance of print and digital media working collaboratively.”

Moro says print continues to play a central role, supporting everything from sales and

Moro says another important but less positive trend being noted across the sector is the gradual ageing of the workforce. The average age of the technicians charged with keeping large, sophisticated printers fully functional is rising and there appears to be a lack of younger people to fill the gaps.

“This is something that needs urgent attention,” says Moro. “If we don’t attract fresh talent into the sector, there will be a detrimental impact on customer service and satisfaction.”

In terms of answers for the challenge, Moro says TAFE colleges should be encouraged to increase the training offered and the number of places made available each year. This would allow more young people to be exposed to the print industry and the various career options that it provides.

Moro says it’s also important to have greater gender diversity to help strengthen organisations and the sector as a whole.

"Ricoh is an active supporter of the initiatives of The Real Media Collective and chief executive officer Kellie Northwood in promoting a more diverse workforce across our broad industry," Moro said. PP

simplify digital transformation, so you can focus on moving forward

Ben Carroll owns Velflex and UltraColour Transfers – two B2B operations which are revolutionising the way heat transfers are manufactured and applied in Australia.

By Sheree YoungYou need a lot of energy and insight to launch a digital screen-printing business and upend the way this type of manufacturing has been done for decades.

Luckily for Ben Carroll he has both in spades.

Fifteen years ago, Carroll was in his early 20s and together with his printing industry stalwart great uncle Noel Wighton took a major professional gamble by launching Velflex, a B2B supplier of digital heat transfer technology. The move came after the pair saw how technological advancements were increasingly lending themselves to producing highly detailed digitally produced garment transfers.

Now, 15 years later Velflex supplies a range of heat transfer technology and consumables to a wide range of national clients.

The popular Hotronix Heat Press range is among the offering. Starting at around $1,400, these presses allow print shop owners to easily add a heat transfer capability as customers increasingly ask for printed apparel. The top model in the range, the Hotronix Dual Air Fusion, features two platens which mean one

operator can double their output – one side of the plate is dedicated for pretreatment with the other providing the heat for transfer application. Also on offer is the Mimaki range of printers and cutters.

Five years after taking the big step and launching Velflex, Carroll identified another opportunity and launched UltraColour Transfers – a trade only operation which produces around 20,000 vibrant and variable digital heat transfers for thousands of Australian printers every day. Order quantities are as low as 10 units but go up to tens of thousands for the larger customers.

Since launching UltraColour Transfers, Carroll made another big decision and moved the business from NSW to Brendale, a suburb in the Moreton Bay region north of Brisbane. He also invested over $1 million in printing equipment to keep up with booming demand.

UltraColour Transfers is built upon a technology known as “UltraColour” which Carroll invented.

This dedication to technological innovation has also now seen UltraColour

Transfers become the Official Licensee for all apparel related to the A-League, including member kits and team apparel. UltraColour is also the go-to transfer choice for some AFL teams and Cricket Australia.

UltraColour transfer technology involves pairing two innovative print production technologies – a recently acquired HP Indigo 7600 Digital Press and three new Polish-made INO screen printing lines which utilise the latest in laser and optical registration technology for optimal results.

This production method is designed to produce tens of thousands of different transfers a day – each bearing high levels of graphic detail whilst also being stretchable, durable and washable.

Each of the INO lines has a specific job when it comes to treating the transfer sheets once they have been digitally printed by the HP Indigo.

One INO line is used purely for laying down a layer of white screen print ink on the back of the transfer. It is this layer of white ink which creates the trademark vibrancy of the final product. The second line spreads an adhesive powder over the back of the sheet and the third line is dedicated to sports number production.

“Innovation has always been my major driver,” Carroll said.

“The INO takes the printed digital sheets from the HP Indigo and runs a white ink over the back of them, so the final product is bright against any colour of clothing. It then drops a power glue over the back, goes through a drying process and is ready for guillotining and despatch.

“Using a system like this, where they have innovated the technology in this way, allows us to use screen print for short run custom work in a much more efficient and effective way. Screen printing traditionally was good for long runs where the set-up time takes a long time.

“This sort of technology minimises that set up time down to a smaller possible moment and allows maximum uptime

which matches against the market’s demand for short, customised runs.

“The magic for us is creating a transfer that is both digital print CMYK but also has the benefits of the traditional screen print process which gives you the opacity of the white vinyl and the strength on the shirt that you couldn’t get through a digital print.

“We are merging the best of both worlds – the best of digital print with the HP Indigo and the INO. This is very exciting. It is a massive investment into Australian manufacturing.”

Direct-to-Film technology is a new frontier for the apparel industry and one that Carroll is preparing for through thorough machinery testing.

“We are currently exploring the new direct-to-film technology and trialling the best consumable and hardware outcomes to help our customers avoid the pitfalls of a fledgling technology,” he said.

In further developments, UltraColour will later this year install a new management information system through eProductivity Software.

This installation will further streamline UltraColour’s operations and bring enhanced efficiencies as print customers will be able to more easily seek quotes and place orders for jobs.

Producing sports numbers is integral to the story of Velflex.

Carroll’s Uncle Noel owned Sports Numbers on the Gold Coast and prior to that established Albury’s Flexiprint. A growing demand for high quality sports numbers – which could withstand the rigours of contact sport and multiple washes – provided the key plank for launching Velflex.

The goal was to ensure the industry was supplied with reliable equipment and consumables which would safeguard the industry and importantly keep manufacturing onshore.

In addition to supplying equipment and consumables through Velflex and producing UltraColour Transfers for the trade, Carroll is also passionate about ensuring all of his customers – from either business – have best practice knowledge for applying transfers.

As he says in one of his many YouTube videos – some of which have attracted 250,000 views, “There is nothing worse than a customer coming back with a garment that has the transfers half falling off.”

To ensure his customers achieve optimum results and high-quality products, Carroll regularly runs masterclasses at the company’s headquarters in Brendale.

“Both my businesses are B2B supplying and supporting printers, we support not compete,” he said.

“As well as constantly testing and looking for solutions to support our customers last year we launched our ‘Heat Press Workshops’ an intensive 2-day course where I educate attendees on everything I know about heat press printing, troubleshooting and improving production turnaround.”

It has been a big 12 months for Carroll and his team.

“In the last 12 months after some major investments in infrastructure I was proud to see my company’s revenue grow by more than double and our staff grow from 10 to 45 employees,” he said.

“I was also excited to see us gain recognition in the industry through a number of articles, a Power 50 recognition for myself and a HP Award for Excellence for the UltraColour product. We were also excited to see the return of trade shows, we attended the APPA Roadshow and had our biggest stand ever at the recent PacPrint show in Melbourne.” PP

A stunning four-metre mural painted by E-Bisglobal trainee graphic designer, Kyle Waters, was recently unveiled at a special smoking ceremony at the company’s head office on the NSW Central Coast.

E-Bisglobal, a leading procurement and print management firm in Australia based on the NSW Central Coast at Tuggerah, recently marked NAIDOC Week by unveiling a stunning four-metre “Whales Country” mural which was painted by the company’s trainee graphic designer, Kyle Waters.

The ceremony was attended by David Harris, the Member for Wyong and Shadow Minister for Aboriginal Affairs; Tim Selwyn from Girri Girra Aboriginal Experiences; Adam Crouch the Member for Terrigal; Andrew Malloch and Chris Thew from Bara Barang Corporation and Deb Barwick, the CEO of the NSW Indigenous Chamber of Commerce. Also in attendance were E-Bisglobal staff, clients, suppliers and business partners.

E-Bisglobal CEO Sean Havard opened the ceremony and provided a brief background to guests on E-Bisglobal’s Aboriginal heritage. He also outlined the company’s procurement services to government and public business sectors and partnership with Bara Barang Corporation.

Tim Selwyn from Girri Girra Aboriginal Experiences performed the Acknowledgement to Country and Smoking Ceremony.

Thikkabilla Vibrations, an Aboriginal dance group, in traditional paint and dress sat at the fire as the guests passed through the cleansing smoke before staging several performances with clapping sticks.

The group's dance performance also told stories of traditional practices on the stark black background of the hidden mural.

Deb Barwick went on to unveil the stunning mural. The mural was painted by Waters, who joined E-Bisglobal as a trainee graphic designer through the company’s partnership with Bara Barang Corporation.

The NAIDOC theme for 2022 was Get Up! Stand Up! Show Up!

Lunch followed the unveiling featuring bush tucker as well as kangaroo, buffalo, emu and barramundi.

P

A bright white coated paper with outstanding colour reproduction, runnability and minimum drying time, I’m the paper that’s reliable whilst saving you money.

Ideal for photographic reproduction, the vast text and cover weights feature a double coating, assuring excellent ink lift, smoothness, opacity and bulk. Sovereign Silk also available in gloss is available with the option to o set your purchase as carbon neutral. Print on me digitally or traditional o set, I’m the easy fitting, go to choice.

I’m like your favourite jeans. Reliable, a ordable and makes you look good every time!

For

The

Visual and tactile enhancements can draw a shelf product into a shopping basket. Digital enhancement of print is now a much sought-after element of package printing. So how can you get into the act?

By Peter Kohn

By Peter Kohn

Prince’s lyrics sum it up. The look is the hook. Dressing up a printed product with tactile and eye-catching finishing is big business. The printed medium lends itself to an array of enhancements – whether this be eyepopping spot colour, foiling, holograms, embossing, debossing, die-cutting, celloglazing or laminating.