After an eight-year hiatus, the industry prepares for the world’s biggest trade show

Take the Nex t Step in Print Produc tion alligraphy cooperation: Miku People Technology Business www.sprinter.com.au APRIL 2024

expo

FESPA 2024 News and views, people and products from the Amsterdam

drupa 2024

HP

Open

Exclusive

International

House

coverage of HP’s two-day event for international trade

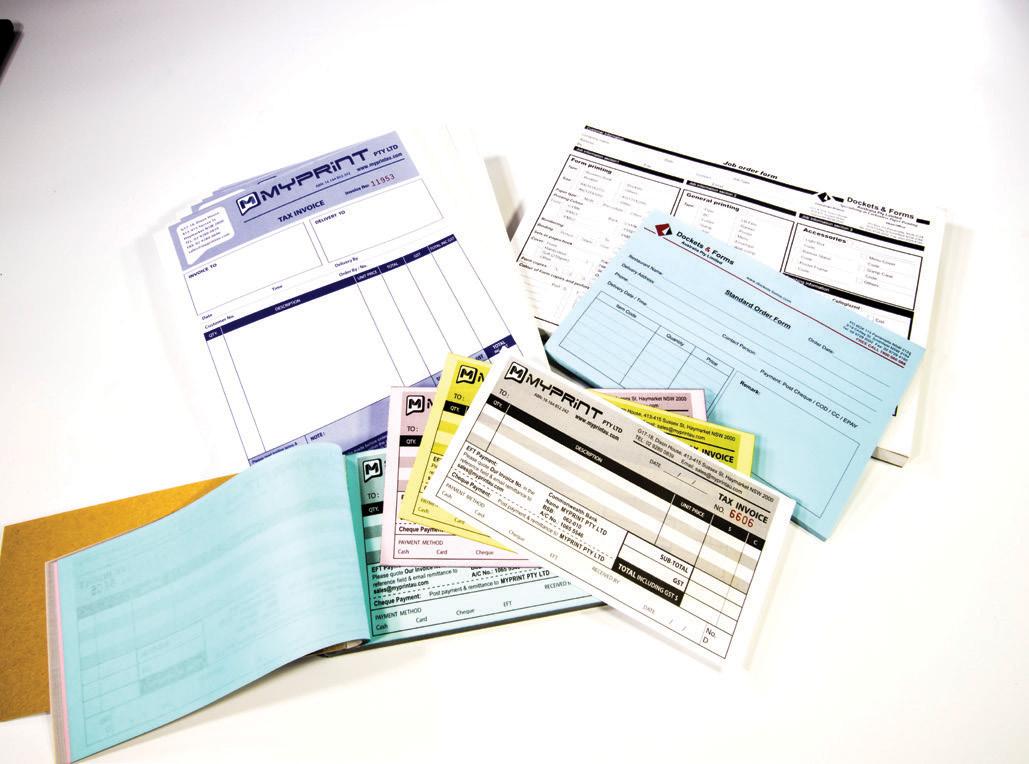

Great work, reliability and quality really help us look good to our customers, meaning you get more work.

Thank you for helping.

Ian - 12/12/23

Thanks for everything. The book is fantastic and is the cumulation of great graphic design and excellent printing!

Thanks to you for all your help which has been more than just doing the basic job.

Jeff - 4/12/23

Thanks also for all the hard work on the split delivery this week. They look great and I know you guys worked so hard to make that happen at your end.

Daniel - 22/11/23

Wow! Thank you for the amazing service! Got my order and the customer service and updates etc. Were all very much appreciated Love them.

Sophie - 21/11/23

Just wanted to send a huge thank you for all your quoting, recommendations, advice and assistance always – I know I throw you a few curve balls sometimes!

Thanks for the quick turnaround, high quality print and professional service.

Leeanne - 21/11/23

Calendars arrived safely yesterday. I wanted to just say thank you for such a seamless process.

The quality of the product is fantastic. I will definitely be recommending hero print!

Tim - 17/11/23

OF OUR NEW CLIENTS ARE REFERRALS YOU CAN SEE WHY...

AUSTRALIA’S BEST TRADE PRINTER

Anticipation builds for drupa 2024

This month, the ProPrint team has traversed continents, from FESPA in Amsterdam to HP’s Open House in Melbourne and Ricoh’s national roadshow. But while the weeks have been busy, our focus now moves to the forthcoming drupa 2024 in Düsseldorf.

After an eight-year hiatus, the return of drupa ignites excitement across the

industry, with preparations underway on a grand scale. Exhibits are being created to showcase printing innovation, new products and groundbreaking technologies. Attendees can anticipate an immersive experience within drupaʼs global hub.

The ProPrint team will be on the ground to provide comprehensive coverage, ensuring our readers remain informed

Contents APRIL

6 –9 Update

A round-up of all the big news from the world of print

10 Think Laterally – Mick Rowan

Mick Rowan discusses how stories foster relationships beyond the confines of a mere transaction

11 Comment – Charles Watson

The PVCA’s Charles Watson looks at understanding machinery supply issues

14 Epson 40th Anniversary

15 Photo Gallery:

Konica Minolta recognises staff after record year at Kick-Off event

16 – 19 Ricoh Roadshow

60 ProPrint Diary

Keep up to date with industry events

PROFILE

13 Zünd Australia moves on from Starleaton administration

FESPA 2024

20-25 A round up of announcements and familiar faces from Amsterdam

COVER STORY

Melissa Parker

of the latest developments and stories from the event. We are excited to bring you live updates and insights directly from Düsseldorf through the Sprinter and ProPrint platforms.

In this issue of ProPrint, we provide a taste of what to expect plus case studies, highlights from FESPA, and the freshest news and perspectives.

26-28 Screen’s new JET 560HDX roll-fed digital inkjet press and more premieres at drupa 2024

DRUPA 2024

30-48 Discover what to expect, from innovations to new products

STAR BUSINESS

50 Lamont Print & Signs leads in sustainable and recycling practices

OPEN HOUSE

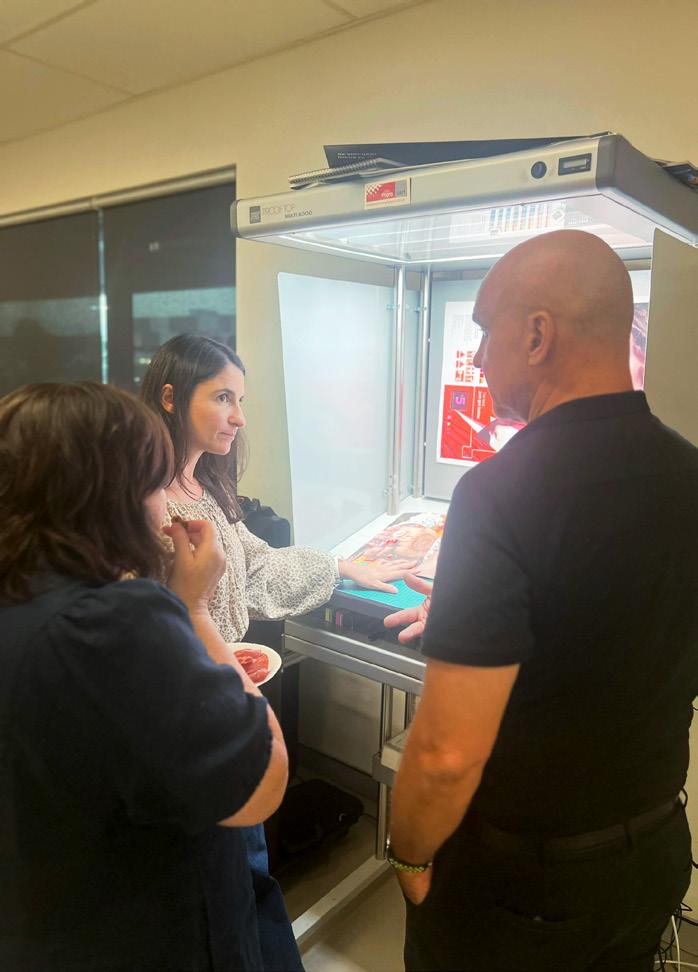

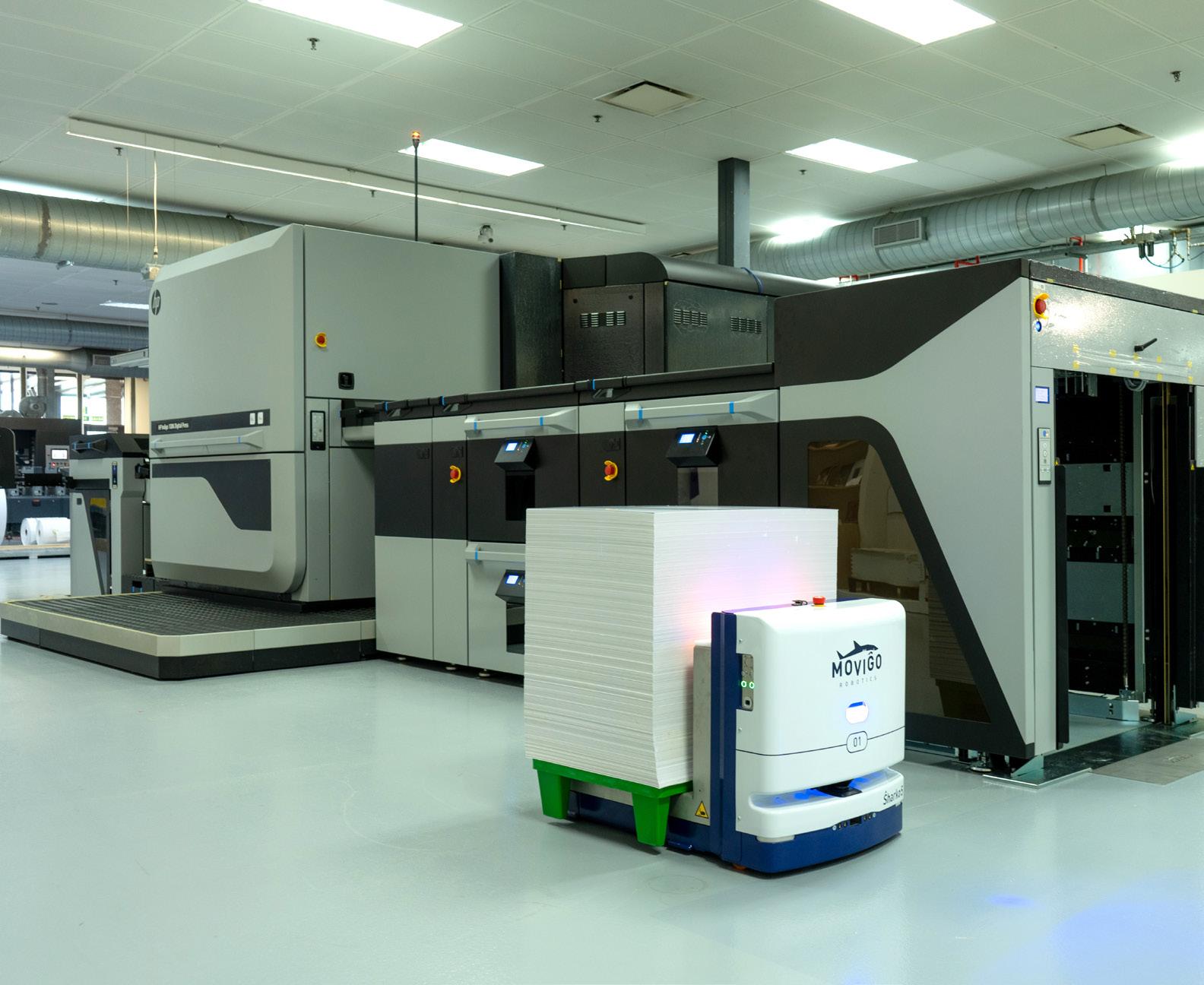

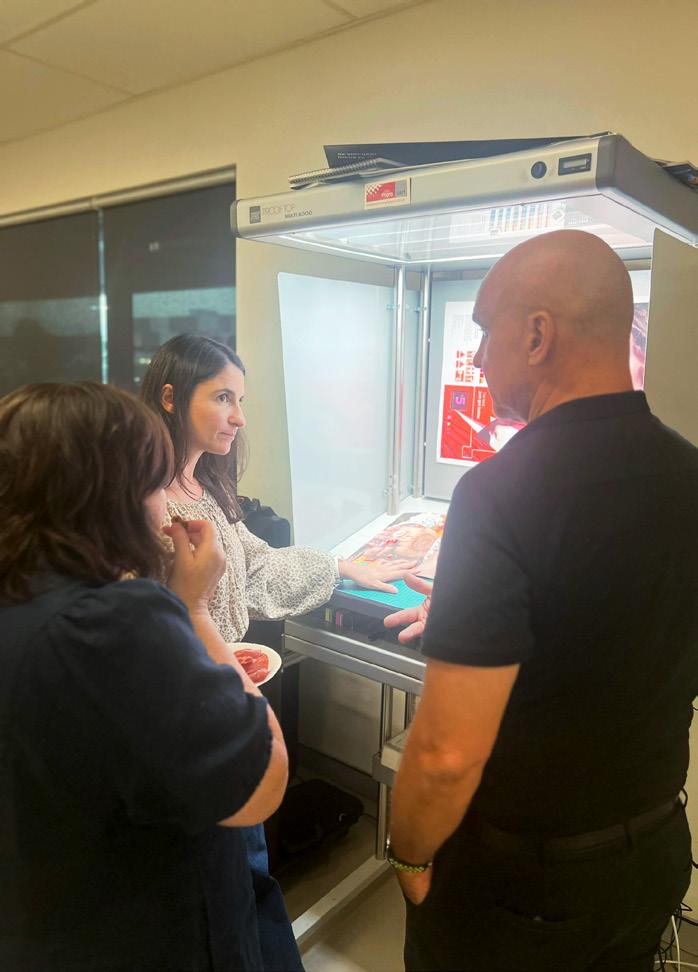

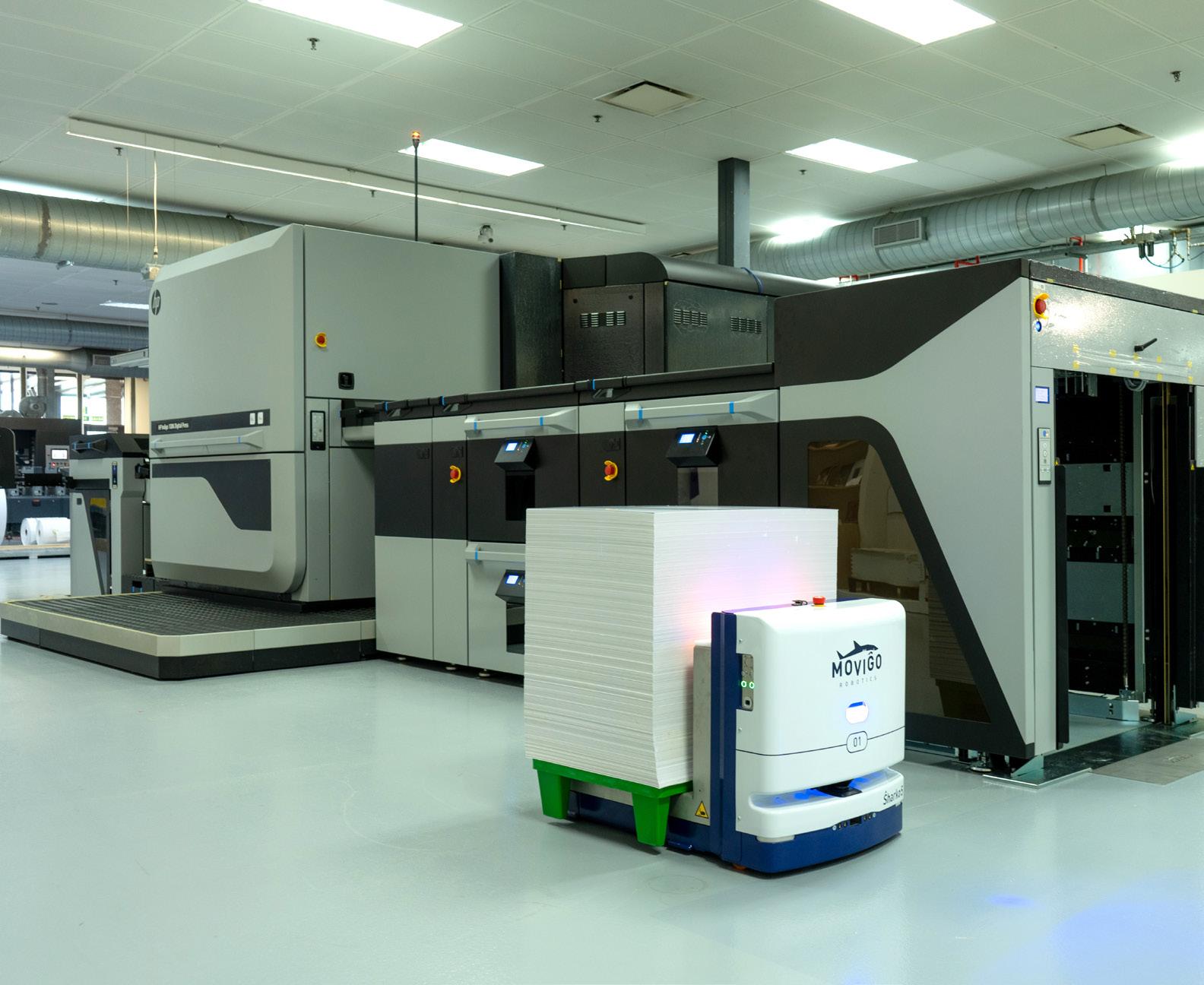

52 HP Industrial Print’s Commercial Printing B2 Open House Melbourne

HP invited print business owners from all over the Asia Pacific region to attend its two-day Commercial Printing B2 Open House event in Melbourne. ProPrint was there.

CASE STUDY

56 Agfa brings in-house print to PopArt

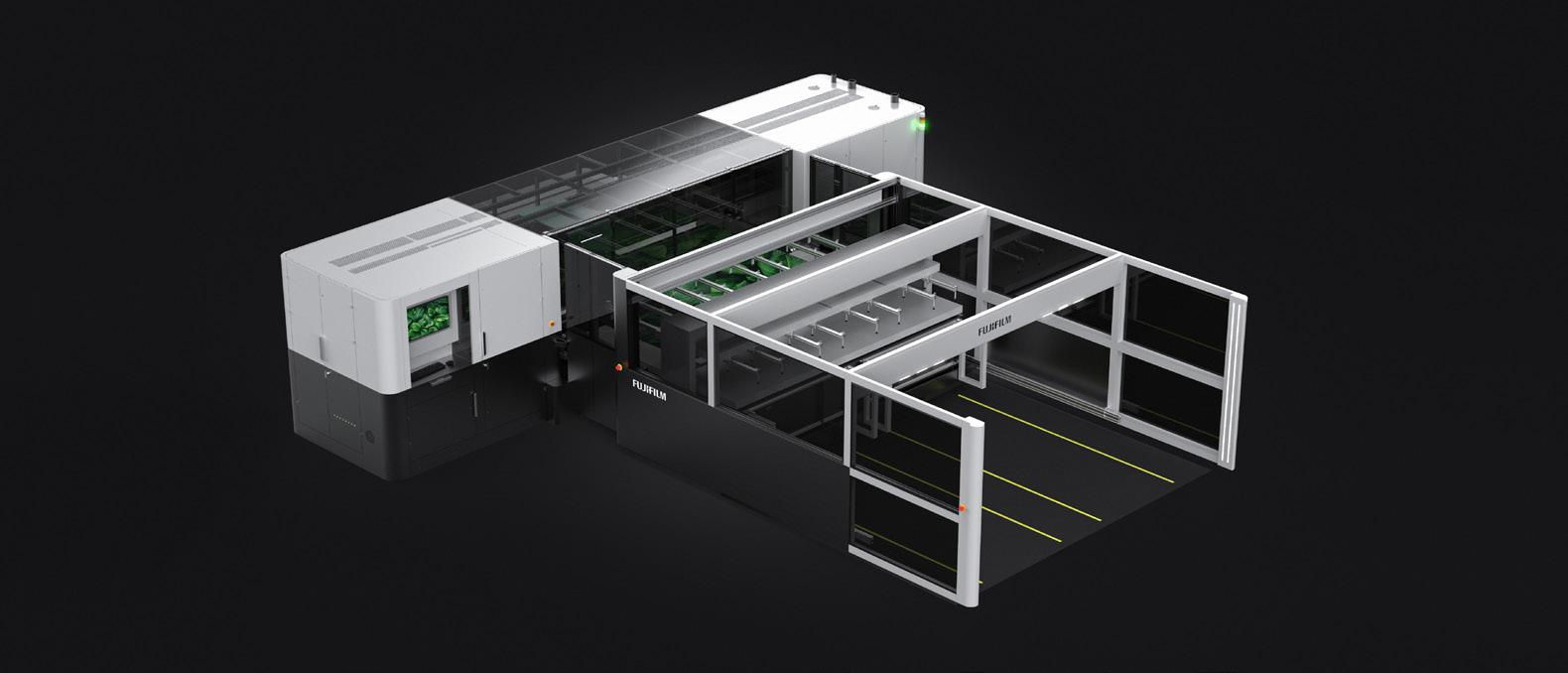

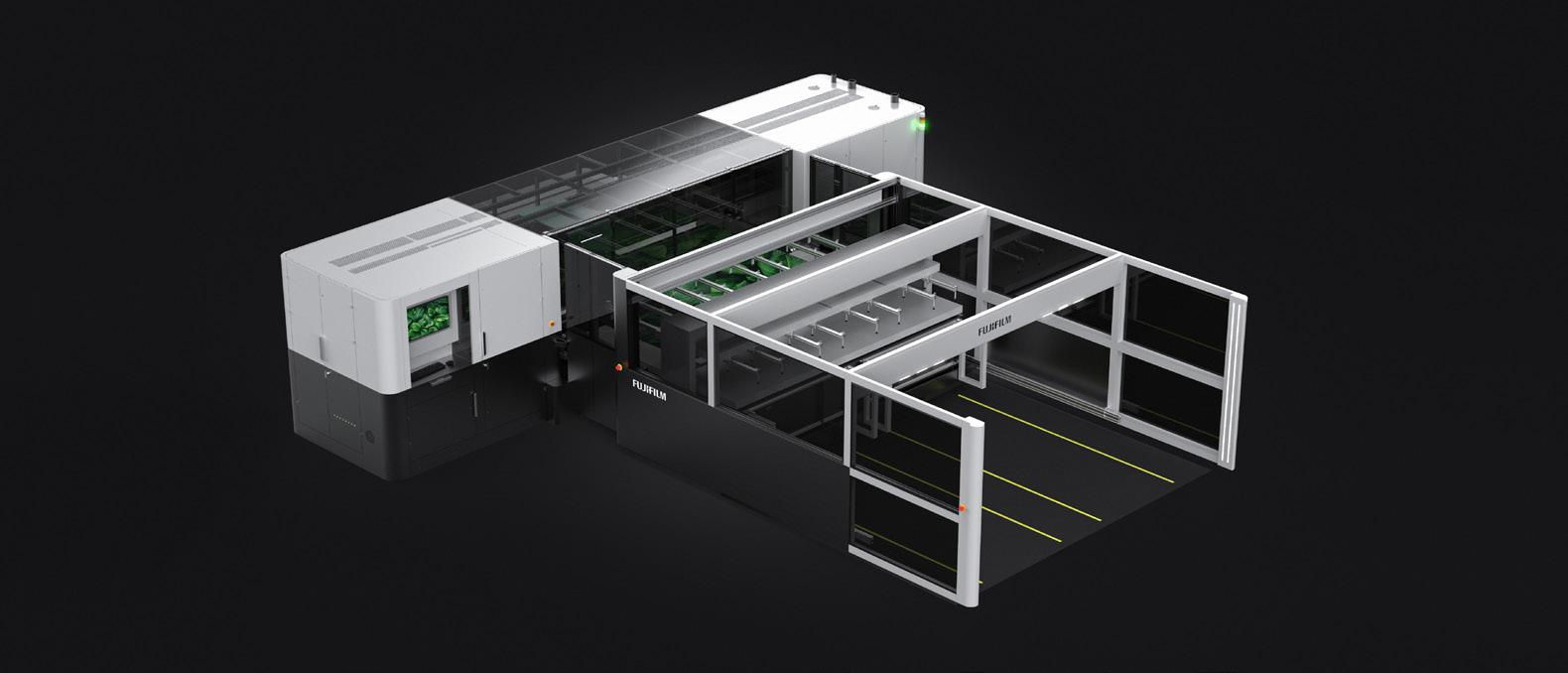

58 Centrum Group acquires FUJIFILM Acuity Prime 30

www.sprinter.com.au 4 ProPrint April 2024

NOTE Editor Melissa Parker, mparker@intermedia.com.au Design and Production Manager Sarah Vella, sarahvelladesigns@gmail.com Managing Director James Wells, james@intermedia.com.au Subscriptions (02) 9660 2113, subscriptions@intermedia.com.au Printed by Hero Print Alexandria, NSW, 2015 Mailed by D&D Mailing Services Wetherill Park, NSW, 2164

EDITOR’S

ProPrint is published bi-monthly by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication. DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2024 — Charted Media Group Pty Ltd ProPrint Magazine National Sales Manager Carmen Ciappara +61 2 410 582 450 carmen@proprint.com.au

ready to START UP?

The dna (drupa next age) forum is the place to learn about new technologies that will help evolve and transform your business, get strategic insights through daily presentations, panels and forums, and connect with industry innovators – from start-ups, through SMEs, to global players. The future of your business starts in hall 7.0. Be part of it! Discover the drupa trend forum May 28 – June 7, 2024 Düsseldorf Program and information: www.drupa.com/dna_en #drupa2024 www.drupa.com drupa.com/blog For further information and assistance with travel and accommodation planning Robert Laing Messe Reps. Pty. Ltd Tel. +61 427 353536 robert@messereps.com www.messereps.com

The drupa trend forum

Durst Oceania launches Vanguard

Durst Oceania has confirmed it will launch the entire range of Vanguard products in Australia and New Zealand.

In an exclusive interview, Durst Oceania managing director, Matt Ashman confirmed the full range of roll-to-roll, flatbed and hybrid products will launch following FESPA.

“I am pleased to confirm that Dan Mantel has come on board to develop the Vanguard business sector as business development manager, and we will be reaching out to work with potential partners as well as customers in the near future,” Ashman said.

“Durst acquired Vanguard back in 2019 and the Covid pandemic prevented us from launching it earlier into the local market. The benefit of waiting to launch has meant that the brand is now assimilated into the Durst business as well as the hardware and software ecosystem and this is fully backed by the Durst service network.

Dale Hawkins to lead new Zünd Australia subsidiary

Former Starleaton executive Dale Hawkins will lead a new Australian subsidiary of Zünd Systemtechnik AG based in Melbourne.

The decision to create a dedicated subsidiary follows the recent changes at Starleaton – the former distributor for Zünd – when Starleaton went into voluntary administration owing several companies deposits for Zünd equipment.

Starleaton Digitial Solutions (SDS) acquired the Zünd agency almost 10 years ago in late 2014.

Ben Eaton told ProPrint, he was working with equipment manufacturers, including Zünd, to organise repayment of deposits for outstanding contracts on equipment.

In a statement from Zünd obtained by ProPrint, the details of the new subsidiary have been revealed.

“Zünd Systemtechnik AG now also has its own branch in Australia. Zünd Australia will be based in Melbourne serving existing and new customers from all areas of application in which Zünd is active,” the statement said.

“Zünd Australia is a wholly-owned

“There are now over 1000 Vanguard installations globally and the brand continues to grow in the established market of North America as well as exponentially in the European market.

“Printers have been telling us that they are looking for an alternative to the other players in the market. There have been a number of manufacturers that have delivered some great innovation, but unfortunately, this was a number of years ago. Now Vanguard is here delivering what

Durst is famous for – innovation on a constant rolling basis. We will continue to be focused on what customers need and what customers want.

“Vanguard can deliver amazing quality at incredible speeds, while also providing a very commercially attractive proposition. Vanguard sits within the Durst range as a more accessible entry point for the aspiring print business and we look forward to welcoming new customers to the ever-growing Durst family.”

subsidiary of the Switzerland-based Zünd Systemtechnik AG. The new Zünd branch will be the local contact for existing customers and prospects.

“At the same time, Zünd Australia is also the new competent partner for all areas of application that want to digitise their cutting with cutting technology from Zünd. The partnership with Canon Production Printing will be continued and the aim is to further strengthen the cooperation.

Zünd Australia is under the leadership of managing director Dale Hawkins.

“Being associated with the Zünd products in Australia for 15 years I am excited to head up Zünd Australia. We are currently in the process of establishing a team of highly experienced technical personnel along with a new headquarters in Melbourne,” Hawkins said.

With Zünd Australia, the Swiss company said it will further strengthen its market position in Australia and open new areas of application in the medium term.

Oliver Zünd, CEO of Zünd Systemtechnik AG: “With Zünd Australia, we can support our existing and new customers directly and competently. The close cooperation with the new branch allows us to strengthen our market position in Australia. Zünd Australia enables us to continue to offer our Australian customers the best possible care in the long term. The team on site has a lot of experience with our cutting solutions. This will enable us to further improve advice and customer service.”

Printers interested in learning more about Zünd Australia or Zünd precision cutters, products, service, and support can email dale.hawkins@Zünd.com or call Dale Hawkins directly at +61 409 024 994. Zünd said it is looking forward to personally welcoming Australian customers at drupa in Dusseldorf. If you would like to make an appointment for a personal conversation in advance, you can contact Lars Bendixen directly, lars. bendixen@Zünd.com

UPDATE

www.sprinter.com.au 6 ProPrint April 2024

Dale Hawkins

Matt Ashman and Dan Mantel from Durst Oceania launch Vanguard at FESPA Amsterdam

Ben Eaton promises to repay staff 100 per cent as he regains control of Starleaton

A very emotional Ben Eaton said he will repay staff 100 per cent of their entitlements after creditors voted for him to regain control of Starleaton.

The voluntary administrator and creditors approved the Deed of Company Arrangement proposed by Eaton after the company went into voluntary administration in January 2024.

In an exclusive conversation conducted with ProPrint shortly after the second creditors meeting was held, Eaton said he will fulfill the commitments within the Deed of Company Arrangement that will see staff repaid their entitlements.

“What I would like to communicate is a clear message that under this proposal all staff will get what they are entitled to and this will also maximise the opportunity for a return to other creditors.

“Staff will receive 100 per cent of what they are entitled to,” he said emphatically.

Under the Deed of Company Arrangement which will now serve as the blueprint for the future of the business, Eaton will set aside $800,000 of funds to restructure the business for 24 months to help repay staff entitlements of $1,384,325.64.

Employee entitlements are estimated to be: Wages ($105,445.55) for 28 employees;

Superannuation ($133,396.73) for 35 employees; Annual Leave ($140,899.94) for 24 employees; Long Service Leave ($261,715.46) for 14 employees; Pay In Lieu Notice ($190,635.36) for 27 employees and Redundancy ($552,232.60) for 26 employees.

“It was critically important for this proposal to get this across the line as liquidation would have been a catastrophic event for everyone involved,” Eaton said.

ProPrint understands Starleaton now has seven employees, down from 35 prior to going into voluntary administration

“Hopefully this demonstrates our intentions to maximise returns for everybody involved after 45 years in business. I look forward to returning to business and getting everything back on track.”

“We are also working with equipment manufacturers regarding the payments made for outstanding contracts,” Eaton said.

ProPrint understands that there was not a 100 per cent consensus to support the Deed of Company arrangement, with some creditors voting against or abstaining from the vote.

Visual Connections welcomes international exhibitors to Visual Impact

Visual Connections CEO Peter Harper has said the upcoming Visual Impact exhibition in Brisbane will mirror global trade shows with increased Chinese attendance.

Harper told ProPrint the increased interest from Chinese companies to participate in Visual Impact represents a global trend and this will be reflected on the floor with a higher number of exhibitors at this year’s event on 17 and 18 July in Brisbane.

“Chinese companies have a greater appetite to exhibit in overseas shows and we are seeing this all around the world. It is well evidenced at drupa this year with almost 400 Chinese companies set to exhibit at the show in Düsseldorf this year. We would also expect the same trend [towards higher Chinese exhibitors] at the FESPA trade show in Amsterdam this year as well,” Harper said.

“Visual Impact Brisbane has attracted a larger number of exhibitor enquiries from Asian companies and we feel, like the drupa team does, that suppliers from China have every right to exhibit – as much

as any other international company. However, as we have always done, we do place some restrictions on exactly which offshore suppliers can exhibit in our shows. Primarily, they must not be selling print or signage directly into Australia and they must be looking for distributors into Australia. Is it hard to police – yes – but we monitor it closely,” he said.

Supported by Platinum Sponsor Roland DG, and Gold Sponsors Avery Dennison, Epson, Graphic Art Mart, HP, Spicers and Trotec, Visual Impact Brisbane has already attracted a long list of exhibitors representing many of the industry’s leading names, promising visitors a comprehensive display of everything from software and workflows to wide-format print, fabrication, illumination, engraving, laser cutting and more.

Visual Connections events manager

Charly Blades said there are still some excellent stands available – but suppliers who want to take advantage of the opportunity will need to be quick, with several potential exhibitors already circling

many of the prime positions which remain.

“We’ve seen excellent attendances at recent shows, with industry businesses keen to see and experience the latest technologies and innovations and make major investment decisions after enduring such long breaks during the pandemic,” she said.

“Brisbane is shaping up as no exception to this. The floorplan is looking pretty full, which is great so far out from opening, and we have already received our first registrations after opening bookings so clearly there are business owners who are already looking forward to taking advantage of all the opportunities available to them in Brisbane.”

Blades confirmed that as always, there will be an educational element to the show, but this year the focus is on delivering maximum value for minimum investment of time, with a program the organisers are calling ‘Expert Connections’.

“Visual Impact only runs for three days, and we know that many visitors can only afford limited time away from their businesses to attend, so the sessions in our Connections Centre will be short, snappy and laser-focused on the topic at hand, whether that’s economic or business updates, market trends, expert opinions, or sessions on various technologies and innovations,” Blades explained.

“The idea is to make sure visitors can gather plenty of knowledge, insights and ideas, as well as connect with experts who can really deliver value to their business, without taking too much time away from the exhibition itself.”

UPDATE

Ben Eaton

www.sprinter.com.au April 2024 ProPrint 7

Peter Harper

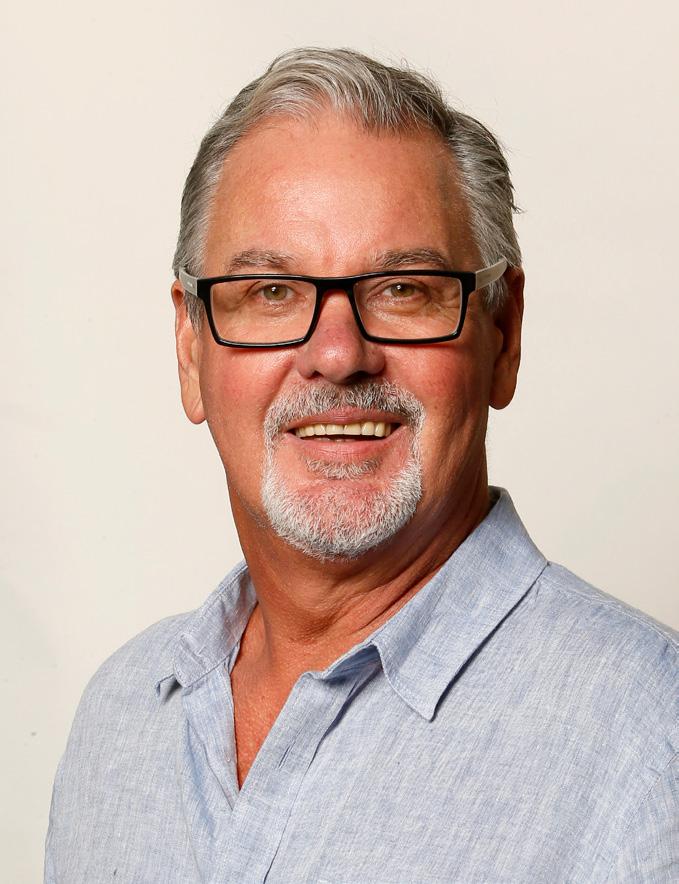

Vale Neil Mulveney - industry remembers a life in print

The print industry is mourning the passing of Champion Press’s Neil Mulveney, an industry stalwart who devoted his life to print.

Mulveney started in print at the young age of 11 years old, delivering copy for E. Angelo & Sons, commercial printers in Campsie. Fascinated by the ‘copy’ he delivered

returning a few days later in printed form he was hooked on the concept.

At the age of 19, from a garage in his parents’ backyard, Mulveney began trading as Dalnor Press (his brother Ronald’s name, backwards). This was the beginning of what was to become Champion Press.

Konica Minolta appoints former EFI executive Frank Mallozzi as president IPP

Frank Mallozzi has been appointed to lead Konica Minolta’s industrial print production channel, which includes the company’s highspeed inkjet, labelling, and embellishment businesses.

Mallozzi previously worked at EFI for 25 years, including eight years as chief revenue officer from 2015 to 2023, and as senior vice president of worldwide sales and marketing from 2005 to 2015.

“We are thrilled to welcome Frank to our executive team, and confident this important area of our business will continue to evolve under his leadership,” said Sam Errigo, president and CEO, Konica Minolta.

“Our industrial and production print business is a key strength for our US sales organisation. Frank’s extensive experience developing go-to-market

growth strategies and integrating solutions to accelerate profitability will keep us on a path of innovation and allow us to gain market share and strengthen our position in the marketplace.”

Mallozzi said it was an honour to join the Konica Minolta team.

“I’ve had the pleasure of working with Konica Minolta in different capacities throughout my career, and it is an honour to join the company and be leading this best-inclass team,” said Mallozzi.

Mulveney’s business quickly outgrew the garage and moved to a shop and dwelling on Stanmore Road, Petersham, in 1954. He acquired his first Heidelberg press, a 10 by 15-inch platen – a giant platen for its time – a small Heidelberg cylinder press, and his first KORD offset press.

The business was there for seven years before it moved to Marrickville, where he purchased another KOR offset press and a single-colour Heidelberg RON offset press.

In 1968, Dalnor Press bought out the Langlea Printery, which was in St Peters, and combined the two plants into the Langlea premises. As a result, Champion Press was founded in 1967.

In 1987, Mulveney sold Champion Press to Hannanprint.

“We could not have had a better outcome. The summation of the work of many paid off. The Hannan family were outstanding to deal with, and very accommodating to our staff,” Mulveney said at the time.

Mulveney witnessed vast changes in print over his life, especially with the growth of digital.

Until his final hours, Mulveney held a deep affection for the print trade.

“Like many of my contemporaries, I’ve had the best years in print,” Mulvaney

UPDATE

www.sprinter.com.au 8 ProPrint April 2024

Neil Mulveney

Frank Mallozzi

World first for CMYKhub and Currie Group

Australian trade print supplier CMYKhub has become the first in the world to confirm an order for the new EFI VUTEk Q3h XP and EFI VUTEk Q3h X hybrid printers, which were released to the market at FESPA Amsterdam in March.

The order, placed with EFI’s ANZ channel partner Currie Group, also includes an EFI VUTEk FabriVU dye-sublimation printer and will not only increase the capacity of CMYKhub’s rapidly growing wide-format trade printing service, but also add a completely new, softsignage service to the company’s growing offering.

The deal, which was signed by CMYKhub Director, Trent Nankervis, at EFI’s New Hampshire headquarters, puts CMYKhub at the forefront of wide-format print technology, allowing it to deliver to the most exacting standards, across a huge range of applications and, more importantly, to do so with reliable, 24-hour turnaround across Australia.

The first of the machines to be delivered will be the VUTEk Q3h XP, which is set to

arrive in Melbourne within the next six months, quickly followed by the VUTEk FabriVU 340i+ which is expected before Christmas. The VUTEk Q3h X will join its stablemates at CMYKhub’s Sydney premises next year.

Dayne Nankervis, CEO of CMYKhub, said the driver for such a significant expansion – which comes on top of a suite of other investments in labels, book finishing and more over the past 12 months – is quite simply to meet the needs of print service providers.

“As a trade printer, that’s always our guiding principle – we listen to what our resellers are telling us, what their customers are telling them. Then we make our own, strategic investments to ensure they can continue to grow and enhance their businesses, whatever sector of the market they are in, and wherever they are in Australia,” he said.

Paul Whitehead, business unit manager – sign & display for Currie Group, said that’s all part of the partnership.

“Demand on all print service providers to meet the ‘key three’ factors of price, quality and speed has never been stronger, and for trade printers like CMYKhub, those demands are amplified even more,” he said.

“It’s been a long process of consultation, investigation and evaluation to get to this

point, but it’s great to see the team now take this step, confident that it is the best technology to suit their own needs, and those of their resellers. With these cuttingedge solutions from EFI, CMYKhub has once again gone one step beyond, to stay at the very forefront of the trade print market well into the future.”

UPDATE

Trent Nankervis (CMYKhub) and Brett Addison (EFI)

THINK LATERALLY

Crafting business distinction

– the art and impact of storytelling

Mick Rowan discusses how stories foster relationships beyond the confines of a mere transaction.

In today’s hyper-competitive business landscape, saturated with an overwhelming array of products and services, the imperative to distinguish oneself from the relentless competition has never been more critical.

Amidst this crowded marketplace emerges the timeless and potent tool that is storytelling. Far surpassing its role in mere entertainment, storytelling has evolved into a strategic linchpin for establishing authentic connections, cultivating unwavering brand loyalty, and ultimately emerging as a beacon in the competitive market landscape.

Harnessing the power of storytelling is not just a choice; it is an essential tool for businesses striving to make a lasting mark. By going beyond the norm, entrepreneurs can utilise storytelling as an approach that captivates and connects with audiences on a deeper level. By transcending surface level interactions, storytelling becomes the catalyst for authentic emotional bonds, creating a space where brands can flourish and endure.

In business, stories are crucial. Never take their value for granted. It’s not just about recounting tales for amusement, but crafting narratives that etch themselves into the audience’s collective consciousness. These stories become the fabric that binds a brand with its consumers, fostering a relationship beyond the confines of a mere transaction. Through the artful use of storytelling, entrepreneurs can transform their businesses with a well-crafted and

compelling narrative that captivates, inspires, and endures.

THE HUMAN FACTOR

The allure of storytelling lies in its ability to humanise businesses, turning them from faceless entities into relatable protagonists in the stories of consumers’ lives. Storytelling invites the audience into a world where companies have values, missions, and journeys that echo their own. On this journey, brands and consumers embark together, creating a shared narrative that extends far beyond the boundaries of a simple exchange of goods or services.

However, a stark contrast exists: the soulless realm of online transactions. Consumers often encounter faceless entities in this impersonal space and the journey becomes a transactional exchange without values, missions, or shared narratives. In navigating this soulless terrain, businesses must recognise the challenge posed by online transactions’ cold, impersonal nature and leverage storytelling’s power to infuse warmth and humanity into the digital realm, creating meaningful connections that endure beyond the confines of a click.

As digital interactions dominate, the absence of a human touch creates a void where businesses struggle to connect with their audience’s deeper emotions and aspirations. The narrative is the tool that will transform the brand from being a mere provider of commodities into a storyteller, weaving a tapestry of experiences, values, and aspirations that resonate with the hearts and minds of the audience.

Storytelling goes beyond market noise, helping businesses carve a distinct identity. It functions like a symphony, resonating with the audience’s emotions and building a connection that outlasts trends. The real power of storytelling is not just about momentarily captivating; it lies in its enduring ability to establish a lasting niche in the memory and loyalty of consumers.

KNOW WHO YOU ARE

Embarking on the journey of storytelling begins by understanding your brand’s essence. Define your values and mission. Uncover the principles driving your business beyond profit. Know your audience intimately; tailor your narrative to resonate with their emotions and align with their values. Identify pivotal moments and characters in your business journey, weaving an authentic story. Transparency builds trust, so be genuine in your communication. Maintain a consistent brand voice across all channels, reinforcing your narrative for a lasting impact.

Storytelling is not a fleeting trend but rather a timeless strategy with the potential to elevate your brand to new heights. Instead of merely presenting products or services, offer a narrative that resonates, inspires, and etches an indelible mark on your audience’s consciousness. In a world overflowing with choices, the story you tell becomes the key, transforming your brand from a participant to a protagonist in the grand narrative of the market.

As we navigate the era of relentless competition and information overload, storytelling stands as a beacon of authenticity, transcending the transactional and resonating with the human experience. Mastering this art is not just about selling products but crafting stories that endure. In the dynamic landscape of modern commerce, remember that the most compelling narrative is the one that embeds itself into the hearts and minds of your audience, creating a legacy for your brand. So, entrepreneurs, let your story be the guiding force in your journey to success.

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

www.sprinter.com.au

10 ProPrint April 2024

Storytelling offers a narrative to inspire your audience

Understanding machinery supply contract issues

The PVCA’s Charles Watson looks at supply contract issues and explains how to safeguard your business interests when procuring goods and machinery.

As a business owner or manager, one of the critical decisions you’ll face is procuring machinery and goods from suppliers. Whether you’re establishing or expanding your operations or replacing and updating machinery, these transactions play a pivotal role in your business’s success. However, navigating supply contracts can be intricate, and overlooking crucial details may lead to costly repercussions.

To safeguard your interests, we review six essential steps to consider when entering into supply contracts:

1. Thoroughly Review Contract Terms

Before committing to any supply contract, it’s imperative to meticulously review the terms and conditions outlined within the contract. Pay close attention to key elements such as pricing, delivery schedules, warranties, and payment terms. Ensure that all specifications align with your business requirements and that there are no ambiguities or discrepancies that could lead to misunderstandings later on. If necessary, seek legal counsel and talk with your financial institution to clarify complex clauses and negotiate terms favourable to your business.

2. Clarify Deposit and Payment terms

In many supply contracts, suppliers may request a deposit or advance payment to initiate production or secure materials and equipment. While this is common practice, it’s essential to establish clear guidelines regarding the amount of the deposit, the timing of payments, and the conditions under which deposits are refundable, along with the security of the deposit. Further, and unlike property purchasing laws in certain states, deposits paid in relation to a supply contract may not be held in trust or escrow-type arrangements. Ensure related payment terms are understood and explicitly documented in the contract to avoid disputes or potential losses in the event of supplier default or non-performance.

3. Deposits and the Personal Property Security Register (PPSR)

Ordinarily a search of the PPSR may evidence security interests over property or goods that are being purchased. However, this will not likely be effective where a deposit is required by an agent or broker who will then source those goods or equipment. Effectively, they will not have the title over the goods or equipment, as this will remain with the manufacturer or current owner of the goods or equipment. To better protect your deposit, consider requiring the equipment manufacturer or owner to provide a confirmation (via the agent) that the deposit has been received and the purchase order is being honoured.

4. Verify Supplier Reliability and Quality Assurance

Before engaging with any supplier, conduct thorough due diligence to assess their reliability, reputation, and track record. Request references from past clients, enquire about their manufacturing or supply processes and assess their quality control measures. It’s crucial to partner with suppliers who prioritise quality assurance and can consistently deliver goods or machinery that meet your

specifications and standards. Additionally, consider including provisions in the contract for quality inspections and acceptance criteria to mitigate risks associated with substandard products.

5. Address Intellectual Property and Confidentiality Concerns

When purchasing machinery or goods from suppliers, intellectual property (IP) rights and confidentiality are paramount considerations. Ensure the contract clearly delineates ownership of any proprietary technology, designs, or innovations developed during the manufacturing process. Implement confidentiality provisions to safeguard sensitive information and trade secrets shared with the supplier.

6. Anticipate Contingencies and Mitigate Risks

Despite meticulous planning, unforeseen circumstances may arise that disrupt supply chains or impact production schedules. To mitigate these risks, include provisions in the contract for force majeure events, such as natural disasters, industrial strikes, or regulatory changes, which may excuse performance obligations or provide remedies in the event of delays or disruptions. Consider implementing contingency plans, such as alternative suppliers or production facilities, to minimise the impact of unforeseen events on your business operations.

By following these essential steps and exercising due diligence throughout the contracting process, business owners can mitigate risks, protect their interests, and establish mutually beneficial relationships with suppliers. Remember, investing time and resources upfront to negotiate favourable contract terms and mitigate potential risks can yield substantial longterm benefits for your business’s success and sustainability. I strongly advise business owners to seek professional guidance when negotiating supply contracts to ensure compliance with applicable laws and regulations and to effectively safeguard your interests effectively.

Charles Watson GM – IR, Policy and Governance Visual Media Association

This article is of a general nature and guidance only and does not constitute legal advice.

WATSON COMMENT www.sprinter.com.au 12 ProPrint April 2024

Zünd Australia moves on from Starleaton administration

Zünd Systemtechnik AG executive, Lars Bendixen has said it is time to move on from the Starleaton voluntary administration and shared his reasons for starting the new subsidiary.

In an interview conducted with Bendixen held at the FESPA Global Print Expo in Amsterdam, he confirmed that Zünd was no longer represented by Starleaton.

“Unfortunately, this is a situation where there are no winners,” Bendixen said.

“We are owed $833,947 and we have no interest in supplying any further hardware to Starleaton until the debt is cleared. We are still talking to Ben, but we have not been presented with any plans to reduce the debt, and it is unlikely that we will.

“We enjoyed happy times with Ben Eaton and Starleaton, but as a 40 year-old business with around 60 independent resellers we have never been in this situation before,” he said.

“We are talking to customers who have paid a deposit, and we would like to provide them with a machine,” Bendixen said.

“Unfortunately, we cannot honour the payments that have been made to Starleaton. We have built the machines, and they are in our warehouse.

“We want to take care of customers who have been left behind and our immediate focus is to clean up the mess and hopefully deliver some products to these customers.

“Everyone has a different situation, and we will strive to find a solution for each customer who feels they have been left out or left behind. The solution will be different for each case.

“We have invested in the Zünd Australia subsidiary to reassure the market, provide stability, and create long-term and reliable partnerships. The settlement we will offer to the customers left behind is entirely based on compassion and goodwill. It is also an investment in future relationships.

“When a customer in Australia does business with another party in Australia, that contract is typically governed by Australian law. The contracts between Zünd Systemtechnik AG and Starleaton are under Swiss law, as are the shipments of machines and money transfers.

Lars Bendixen

Lars Bendixen

“There has been some speculation about the legal claims and what the possibilities are under the scope of the law. This claim can only be made to Starleaton, and there is potentially nothing to get. We believe the money they are looking for isn’t there.

“Before Starleaton went into voluntary administration, as long as the ‘music was playing’ and everyone was in dialogue, we did our best to support Ben Eaton and the Starleaton business, and we would send yet another machine. Looking back, maybe we shouldn’t have shipped the last few machines to Australia.

“As a result, we have taken the decision to move on. It has been a hard lesson and we need to do what is best for the future and we decided to open the Zünd Australia subsidiary.

“We could see three options at the time. The first option was to write off the debt

and be represented only by our other distribution partner – Canon Production Printing in Australia. The second option was to go out and find another distribution partner to replace Starleaton. We decided to take the third option, which was to start our own subsidiary. We took this decision because we were able to access highly experienced and passionate employees like Dale Hawkins as well as other staff previously employed by the Starleaton business who were available to work with us – so on this basis, creating a new subsidiary was the best option for us.

“We have had a long relationship with Dale Hawkins since he was at Canon – and he represents the best leader for the future of the Zünd business in Australia.

“The Switzerland to Australia time difference is not ideal and we have also recently taken on Zünd Spain and opened Zünd Brazil – so this has not been the best time for another subsidiary – but this still seemed like the best option for us.

“There are hundreds of Zünd customers in the Australian market, and we now need to focus on getting Zünd operational.

“The future is a new beginning. Worldwide, the graphics and packaging market represents about half of our turnover. We sell machines for many other manufacturing applications, such as leather, shoes, handbags, fashion, textiles and apparel. We feel that we can represent these markets a lot better directly with our own subsidiary rather than by appointing another distribution partner like Starleaton.

“We hope we can focus on opening up these new market segments in Australia that have not been addressed in the past. We are certainly not neglecting the graphics and packaging markets – but there is certainly other opportunities available under a fully-owned subsidiary.

“We are currently looking for new premises in Melbourne. We have four staff members, including managing director Dale Hawkins and a team of specialists who deliver service and application support. We are likely to grow to six staff as we will require additional staff to address all our market opportunities.”

www.sprinter.com.au

PROFILE April 2024 ProPrint 13

Epson Australia celebrates 40th anniversary in Australia

Epson Australia is celebrating its 40th anniversary of operations, with the company set to use its 40th year to introduce new products in large format printing, projectors, office and industrial printing.

Epson Australia, a wholly-owned subsidiary of Seiko Epson Corporation, started in November of 1983 with a small team of 20 people in the suburb of Frenchs Forest on the northern beaches of Sydney.

Today, the company’s product portfolio consists of home and office printers, scanners, thermal receipt printers, projectors, large-format printers, industrial print solutions, and a wide range of software tools that enhance the productivity and usability of its products and provide more value to customers.

The company has also expanded its team to more than 150 people across Sydney, Melbourne, Brisbane, Adelaide, Perth and Auckland, with offices and showrooms in each location.

The company’s recent environmental initiatives include partnering with Earth Hour, sponsoring the Royal Botanic Gardens of Sydney and transitioning to 100 per cent renewable energy across its entire operation in Australia and New Zealand.

Epson Australia MD Craig Heckenberg said the local team was thrilled to commemorate this significant milestone in our company’s history.

“We are very proud of our achievements and success over the last 40 years. As such, I must thank all Epson staff both past and present, our channel partners and customers for contributing to this success. We now focus on the next 40 years and on creating continued growth through providing innovative products and services that make a positive impact to the lives of our customers, their businesses, and their communities,” said Heckenberg.

“Looking ahead, we have a lot more to accomplish and we pledge to continue to play our part to protect the environment by working with our customers and industry to help solve societal issues, strive for sustainability and improve quality of life.”

Seiko Epson global president, Yasunori Ogawa, congratulated Epson Australia for its 40th anniversary and thanked employees, partners and customers.

“Epson is committed to achieving sustainability and supporting the community and no group company embodies this commitment more than Epson Australia. I look forward to working with everyone to achieve even greater success both for Epson Australia and the wider community.”

www.sprinter.com.au EPSON 40TH ANNIVERSARY

14 ProPrint April 2024

Epson Australia MD Craig Heckenberg

Konica Minolta recognise staff after record year at Kick Off event

After a record year, Konica Minolta presented awards to staff at its recent Kick Off event in Sydney - the first time the internal company event has been held in five years.

An evening function held at Mosman Rowers recognised the top salespeople from within the organisation for the 12 months ending 31 March across the Konica Minolta Australia business.

The Production and Industrial Print business team was acknowledged, including its general manager Andrew Cocker, who secured the highest-ever revenue in the history of operations when his division set a new record in hardware sales for the 2023/24 financial year.

Sales achievements were recognised with awards, and members of the KM sales team were awarded for exceeding targets, including David Paterson (Victoria), Adam Todd (National), Colin Johnstone (Victoria), Blaise Masson (Queensland), Mary Kiely-Scales (Queensland), and Jim Abouraad from New South Wales, who was recognised as the Production and Industrial Print salesperson of the year.

www.sprinter.com.au

PHOTO GALLERY April 2024 ProPrint 15

Honours Club winners 2024

WA team wins State Of the Year

Melissa Dempsey (Konica Minolta), Carmen Ciappara and James Wells (Printer Media Group) and Andrew Cocker (Konica Minolta)

Yohei Konaka, Paul Colarelli, Dean Hosking

Kevin Ryan, Yohei Konaka, Gabrielle Stevens, Kyle Young, James Rolland

Ricoh takes to the road while preparing for its super-sized presence at drupa 2024

Ricoh recently hosted a national roadshow featuring a series of exclusive events in four different states to showcase innovative technology and printing advancements as well as revealing its big plans for drupa 2024 in May.

Products on show at the event included the newly launched Pro C7500 and Pro C9500 models. These products replace the market-leading Pro C7200X and Ricoh Pro C9200/C9210.

ProPrint spoke to chief sales and marketing officer, Tina Economou and national sales manager, Mark Moro about drupa 2024, Ricoh’s ambitions in the

Australian market and its new platforms.

Moro said the progression into the new models has been a result of the industry’s requests for “better image quality, media capabilities, productivity and better operator efficiencies”.

Moro presented a sneak peek into the Henkakuverse, Ricoh’s extraordinary

drupa 2024 two-storey stand complete with café, theatre and product showroom. He encouraged everyone who is visiting drupa to visit the large Ricoh stand.

Guests at the roadshow event also experienced the yet-to-be-launched Pro Z75, which will also be showcased at drupa. The team at Ebina, Ricoh’s technology centre in Japan, created an

www.sprinter.com.au MELBOURNE RICOH ROADSHOW

16 ProPrint April 2024

Celebrating the first leg of the Ricoh Roadshow at Ricoh’s showroom in Port Melbourne

exclusive and personalised video taking guests through the Pro Z75. As a memento of the night, guests received a personalised, labelled bottle of wine.

Moro says Ricoh’s approach to the Australian market is selected and focused, while Economou says the business has done a lot of work engaging customers and assessing needs before bringing products to market.

Economou says drupa 2024 presents an

RICOH ROADSHOW

excellent opportunity for the sales team to engage with Ricoh’s customers and for the teams to look at what else is happening in the global market that doesn’t make it to Australia.

“Getting that opportunity for the teams to go out, see what’s happening, learn from others, and bring those insights back to the customers who perhaps aren’t able to get to drupa, to me is a critical part,” says Economou.

MELBOURNE

“Drupa is the innovation hub. Customers get to see automation and finishing, work with all our partners, and see how everything connects.”

“But it’s also about the voice of the customer, getting that feedback is the critical piece because it goes back into influencing innovation,” Economou concludes.

The Roadshow headed to Melbourne, Sydney, Brisbane and Adelaide.

www.sprinter.com.au

April 2024 ProPrint 17

David Kegan, Mark Moro and Victor Gonzalez

Heath Nankervis, Southern Impact with John Yiannis and Geoff Lawyer, Complete Colour

Ricoh’s Mark Moro presents to guests at the Melbourne showroom

Minuteman’s Michael Milan with Go to Print’s Linda Angelone and Victor Gonzalez

Minuteman’s Michael Milan with Ricoh’s John Yiannis

The Ricoh team. John Yiannis, Allan Webb, Michael Crawford, Tina Economou, Michael Leins, Mark Baker and Mark Moro

Ricoh’s technical manager, Mark Baker, shows guests the Ricoh Pro 7500

Australia’s first purchasers of the Ricoh Pro 7500 are Victor Gonzalez and Linda Angelone from Go to Print pictured here with Ricoh’s Tina Economou and John Yiannis

www.sprinter.com.au 18 ProPrint April 2024

SYDNEY RICOH ROADSHOW

Ash Harrigan (Snap Franchising), Mark Moro, national sales manager (Ricoh Australia)

Mark O’Connell (Sydney DPS) with doors open on the Pro C9500

Ricoh’s Sydney, Eastern Creek Showroom

Matthew Taylor, key account director (Ricoh Australia), Damien Woods (Link Group)

Grazing board organised by Christina Lewanski, Marketing Co-ordinator (Ricoh Australia)

Personalised bottles of R.S.R 2015 Cabernet Sauvignon for each guest as a token of Ricoh’s hospitality

Henryk Kraszewski, product and marketing manager, Ricoh Graphic Communications

www.sprinter.com.au April 2024 ProPrint 19

SYDNEY RICOH ROADSHOW

Sydney attendees enjoying the presentation

Sydney attendees at Ricoh’s showroom in Eastern Creek

Sydney attendees enjoying the presentation

Christine and Cassandra Farrugia (Creative Plastic Cards), Carmen Ciappara (Printer Media Group), Christina Lewanski (Ricoh Australia)

Stephen Reid, production solutions consultant (Ricoh Australia), Mark O’Connell (Sydney DPS), Henryk Kraszewski, product and marketing manager, Ricoh Graphic Communications

Richard Granger, Production Solutions Consultant (Ricoh Australia) showing prints from the Pro C9500 to Christine and Cassandra Farrugia (Creative Card Plastics)

Richard Granger, production solutions consultant (Ricoh Australia) demonstrating the Pro C9500 to Anthony Col (Snap Wynyard)

Oppboga showcases new innovation at FESPA 2024

Oppboga’s sales director, Frederik Johansson, shows ProPrint readers the benefits of the company’s innovative paper products, which are distributed in Australia by Spicers.

OPPBOGA SHOWCASES FLOWER POT WITH WATER-RESISTANT PAPERBOARD AT FESPA

Swedish paper company Oppboga, distributed in Australia by Spicers, has showcased a water-resistant paperboard flowerpot filled with water.

Speaking with ProPrint at the recent FESPA exhibition in Amsterdam, Oppboga sales director Frederik Johansson showcased the moisture-resistant paperboard called Oppboga Resilient.

“Here at FESPA, we are showing Oppboga Resilient as a flowerpot filled with water inside. This is a paper product that is made from 100 per cent fibre and can sustain a lot of water exposure. This will last for three or four days before it starts to leak from the flowerpot,” he said.

“We also sell this material for election signs, which can easily last outside for three or four weeks without any problems. We have invested a lot of resources, and with the upcoming European elections, hopefully, many political parties will use our product.”

Watch Oppboga sales director Frederik Johansson explain the paperboard flowerpot at FESPA.

OPPBOGA CONFIRMS FURTHER INVESTMENT IN ACE SCREENBOARD

Swedish paperboard manufacturer,

Oppboga, distributed in Australia by Spicers as Ace Screenboard, has confirmed it will invest in new machinery to maintain growth.

Speaking with ProPrint at the recent FESPA exhibition in Amsterdam, Oppboga sales director Frederik Johansson, said new machinery has been purchased to assist with the global growth of the fibre-based consumable substrate.

“We are the suppliers of the Ace Screenboard sold by Spicers in Australia that has been produced since the 1970s. Sustainability has been a hot topic and we are investing in a new machine to meet with the increasing demand.

The Ace Screenboard range, comprising Ace Kraft, Ace High White, and Ace Outdoor, stands out as the ultimate fibre-based solution for both indoor and outdoor signage.

“Our Ace Screenboard range offers unmatched versatility and durability, making it the perfect choice for any signage application,” says Wayne Hood, Spicers Visual Communications portfolio manager.

These products are integral to Spicers’ fibre-based solutions within the Visual Communications range, ensuring reliability and quality for businesses.

“Customers consistently turn to this range due to its exceptional sustainability features-it’s FSC certified, recyclable,

and boasts versatility in various applications,” adds Hood.

From retail displays to outdoor signage, Ace Screenboard delivers outstanding performance while aligning with environmentally conscious practices. It’s the preferred option for businesses seeking effective, sustainable signage solutions that don’t compromise quality or durability.

Johansson said he has a strong relationship with the Spicers team selling the Ace Screenboard product in Australia.

“Wayne Hood and the team from Spicers are stocking three of our products that are made from 100 per cent paper. Ace Screenboard looks like a plastic sheet that we sell as a product to build signs and displays. Not only does it look the same as plastic, but it is made from paper, and it is easy to recycle. After a customer has used it – for example, as a sign hanging from the ceiling, the retailer can take the sign down and add it to the normal paper waste with other recycled products, such as corrugated packaging and other paper, which can go into the recycling stream.”

Watch Oppboga sales director Frederik Johansson explain the Ace Screenboard at FESPA.

www.sprinter.com.au

20 ProPrint April 2024

Johansson with the Oppboga Resilient flowerpot

Ace Screenboard

FESPA 2024

Ace Outdoor Ace Kraft

Did you know that D&D Mailing Services is one of the largest mailing companies operating in Australia?

D&D Mailing Services:

High speed laser printing and print supply services

Cost-effective parcel and postal distribution analysis

Expertise in Australia Post regulations and services

‘Pick and Pack’ warehousing services

Overseas mail inbound and outbound

Specialised hand-finishing services

D&D Mailing Melbourne 16 Elonera Road Noble Park VIC 3174 03 9790 5844 ddmail@ddmail.com.au

D&D Mailing Sydney 1064 Canley Vale Road Wetherill Park NSW 2164 02 9725 2114 ddmail@ddmail.com.au www.ddmail.com.au

www.ddmail.com.au

D&D Mailing Services

FESPA 2024 Global Announcements

FESPA 2024 proves an effective international stage to showcase industry innovation. Here is a round-up of the top stories from FESPA 2024 in Amsterdam.

EPSON SETS FOCUS ON MICRO-PRODUCTION DIGITAL PRINTING

Epson has set its focus on personalisation through micro-production at FESPA Amsterdam, with the company showcasing its first small-footprint UV flatbed printer (SC-V1060) and new entry-level DTG hybrid printer (SC-F1060) for the first time at FESPA in 2024.

“FESPA has been all about demonstrating how Epson’s micro-production digital printing technology can support businesses producing beautiful, bespoke products that enhance our lives,” said Chris Davies from Epson Europe’s commercial and industrial printing division.

“The variety of printing techniques on display demonstrates the many advanced flexible applications of Epson’s digital printer range, including the latest dye sublimation, direct-to-garment (DTG) and ultra-violet (UV) signage printers.”

At FESPA, Epson showcased its new SureColor-V1060 A4 flatbed UV printer and entry-level SureColor-F1060 DTG printer. Epson’s SureColor-V1060 A4 UV flatbed printer has been designed to serve the needs of businesses in the promotional goods industry.

Accompanying the SureColor-F1060 on the stand was Epson’s recently launched DTG

hybrid SureColor F2200, which has been designed for start-up companies or medium-volume businesses requiring high levels of flexibility, accuracy and rapid turnaround.

Also showing at FESPA is Epson’s recently launched 17-inch photo and fine-art production printer. The new SureColor-P5300 combines the technology of the Epson SC-P700/P900 with the production capability of the Epson SC-P5000 and is designed to serve the needs of professional photographers, fine-art users, design agencies and photo retail stores.

AGFA UNVEILS NEW INKJET PORTFOLIO

The three new inkjet printers that made their global debut in Amsterdam included the Anapurna Ciervo H3200, the Jeti Condor RTR5200 HS, and the Jeti Bronco H3300 S. Rebranded models also showcased included the Onset Grizzly X3 HS and (previously the Onset X3 HS) and the Jeti Tauro H3300 UHS.

The machines are branded with names of “formidable animals that reflect their unique strength” as part of Agfa’s new branding campaign,‘Powerful by Nature’.

“Agfa really has a beast for every need,” said Bruno Vermeulen, director of

marketing for Agfa DPC (Digital Print and Chemicals).

“It doesn’t really matter what type of printer you’re looking for – we have hybrid, flatbed, and roll-to-roll printers in our portfolio – and it doesn’t really matter what speeds you are looking for. If you look for a wide-format inkjet printer then Agfa is just the place to be, and that’s the message we wanted to convey,” he said, adding Agfa will continue to build on the portfolio.”

The Jeti Condor RTR5200 S is a 5.2m-wide roll-to-roll printer that can print up to 672sqm/hr and handles a wide variety of flexible substrates at up to three rolls simultaneously. It is field-upgradable with light colours and features white and varnish for increased design and application options.

The Jeti Bronco H3300 S is a 3.3 m highend UV LED inkjet printer that prints a variety of sign and display jobs in six colours plus white, with optional primer. In the first stage, the Bronco will be available with two rows of print heads. However, its horsepower is fieldupgradable to a four-row version.

According to Agfa, the Anapurna Ciervo H3200 boasts a much higher productivity than its predecessor, with an almost 70 per cent increase in printing speed in Production Mode. The CMYK/Lc/Lm plus white machine’s highest speed is 209m2/h while the printer’s continuous board feeding capacity enables efficient printing on rigid materials, at up to four boards simultaneously.

Also showcased at FESPA were the newly rebranded Onset Grizzly X3 HS and Jeti Tauro H3300 UHS.

The Onset Grizzly X3 HS is a high-speed flatbed inkjet press, with a speed of up to 1450 m²/h, fast set-up, and multiple automation options – including loading/ unloading robots.

SWISSQPRINT LAUNCHES 36-MONTH WARRANTY

swissQprint announced the launch of a three-year manufacturer’s warranty across all of its products at FESPA.

Pozitive managing director Phil Trumble, was in Amsterdam for the announcement and spoke to ProPrint

www.sprinter.com.au

Agfa unveiled its expanded and rebranded inkjet printer portfolio, including three new machines.

22 ProPrint April 2024

Chris Davies

FESPA 2024

Bruno Vermeulen

“We have always had this as an optional extra that you can purchase, but the renowned reliance of a swissQprint machine, 36-month manufacturer warranty is now a standard feature of the swissQprint machines from today onwards.

“We call this supported reliability, and it is swissQprint’s proof that the machines and the build quality are reliable, and swissQprint stands behind the product and backs it from the factory,” he said.

swissQprint also reinforced its green credentials at the event.

“Every swissQprint machine — no matter how small, or how big it is or how fast it can print uses the same amount of power as a kettle. It is amazing that swissQprint has put so much effort into making its machines as sustainable and as green as possible. At the end of a swissQprint machine’s life — 95 per cent of its parts are recyclable and I think that is quite amazing for the type of product that we are talking about and in an industry where sustainability is at the forefront of a lot of people’s minds, it gives all of our customers reassurance that if they invest in a swissQprint machine today, not only do they use low energy on a day to day basis, but at the end of that life the machine can be recycled and remanufactured into other things.”

FESPA CONFIRMS NEXT GLOBAL PRINT EXPO IN BERLIN FOR 2025

FESPA CEO Neil Felton has confirmed that the Global Print Expo will be held in Berlin from 6 to 9 May 2025.

Felton told ProPrint in an exclusive interview there were some reasons for the decision.

“Eastern Europe is a fast-growing market and Berlin also has a fantastic structure

for halls and we also hosted the exhibition in Munich last year,” he said.

Felton said he has enjoyed returning to Amsterdam for the first time since 2021, in what they describe as the ‘four-year cycle’ that coincides with the drupa exhibition every four years.

“This has been one of the strongest exhibitions within our four-year cycle. The last time FESPA was in Amsterdam was in 2021, and before that, it was in 2016 when we had four halls back then, and we have six halls this year – so this year is about 33 per cent bigger than 2016.

“In 2021, we were very lucky as we were five weeks into Amsterdam opening up and then five weeks after the FESPA exhibition was held – it was locked down again. We managed to hold a show in that 10-week period and it was one of the most emotional and incredible shows I have ever been to. Amsterdam has a warm place in my heart – I love the city and I love the venue.

“We have 512 exhibitors overall, and we have grown in textiles and across our Sportswear Pro, and we also now have the Personalisation Experience, which we didn’t have in 2016, so this has introduced a number of new companies since then.”

FESPA on Film

The ProPrint Editorial Team toted cameras and microphones at FESPA this year, capturing the vibe on the ground on film in a series of interviews with local industry champions.

Click on the following QR codes for an eye into what it was like to be in the halls at the FESPA tradeshow in Amsterdam.

OPPBOGA CONFIRMS FURTHER INVESTMENT IN ACE SCREENBOARD

Swedish paperboard manufacturer, Oppboga, distributed in Australia by Spicers as Ace Screenboard, has confirmed it will invest in new machinery to maintain growth.

Speaking with ProPrint at the recent FESPA exhibition in Amsterdam, Oppboga sales director Frederik Johansson, said new machinery has been purchased to assist with the global growth of the fibre-based consumable substrate.

B-FLEX SHOWCASES NEW DTF FILM AT FESPA AMSTERDAM

New B-Flex Direct-to-Film (DTF) film products, distributed locally by B-Flex Pacific, and sold by dealer Pozitive sign & graphic supplies, were unveiled at the FESPA Global Print Expo in Amsterdam.

JOHN BUITENKAMP CONFIRMS RETURN TO AUSTRALIA WITH KLIEVERIK

Speaking with ProPrint at FESPA in Amsterdam, former Starleaton executive John Buitenkamp confirmed he will be visiting Australia later in 2024 to promote the Klieverik range of calender machines alongside new distributor Ball & Doggett following the announcement in March.

www.sprinter.com.au

April 2024 ProPrint 23

Phil Trimble (Pozitive) and Marco Pigato (B-Flex)

John Buitenkamp demonstrates Klieverik calender machines at FESPA Amsterdam

FESPA 2024

Neil Felton

Familiar Faces at FESPA 2024

The annual FESPA Global Print Expo 2024 took place in Amsterdam, bringing together executives from screen, digital, wide format printing and textile printing industries at the four-day event. ProPrint spotted a few familiar faces that made the journey to the tradeshow.

www.sprinter.com.au FESPA 2024

24 ProPrint April 2024

Serge Clauss, Matt Ashman, Fabian Sottsas, Michael Deflorian, Frank Kirsch on the Vanguard stand at FESPA Amsterdam

Neil Felton, Duncan MacOwan and Michael Ryan (FESPA)

Matt Ashman (Durst Oceania), Neil Felton (FESPA) and Keith Ferrel (Cactus Imaging)

Stephen Lamont (Lamont Print & Signs), Wayne Hood (Spicers) and Daniel Lamont (Lamont Print & Signs)

Adriano Gut (swissQprint) and Yianni Moritidis (GENR8 Printing)

Mark Canavan (Graphic Art Mart) and Neil Gomez (Arlon Graphics)

www.sprinter.com.au FESPA 2024 April 2024 ProPrint 25

Andy Fryer and Adam Parnell (Easy Signs), Rafa Menedez (PlastGrommet) with Nigel Spicer and Keith Ferrel (Cactus Imaging)

Kohei Kobayashi, Takao Terashima, Yasuhiro Haba and Rodd Harrison from Mimaki

Colm Garvey (FUJIFILM), Keith Ferrel (Cactus Imaging), Shaun Holdom (FUJIFILM) and Nigel Spicer (Cactus Imaging)

Richard Lucas (HVG Graphics Media) and Benjamin Burkard (3A Composites)

Kerri Underwood (VMG Print Group), Pat Cybulski (Mimaki Aust), Michelle Merriman (AJ Parkes & Co)

Andy Fryer and Adam Parnell (Easy Signs) with Matt Ashman (Durst Oceania)

Dan Mantel (Durst) and James Smith (Eurotech)

Nigel Davies (FESPA) and Matt Ashman (Durst Oceania)

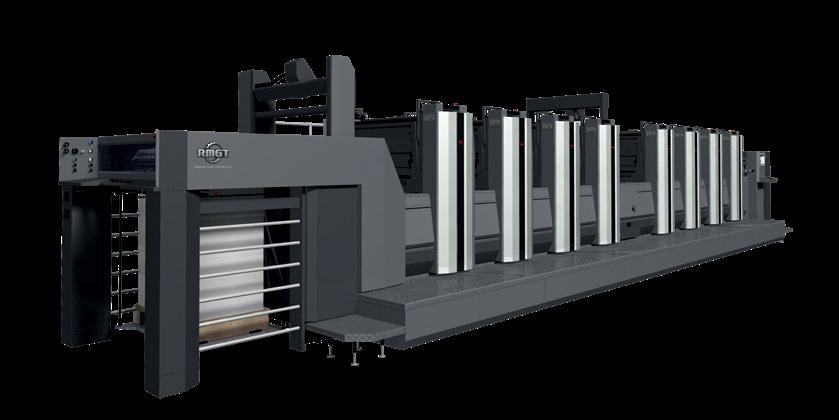

Screen’s new JET 560HDX roll-fed digital inkjet press and more premieres at drupa 2024

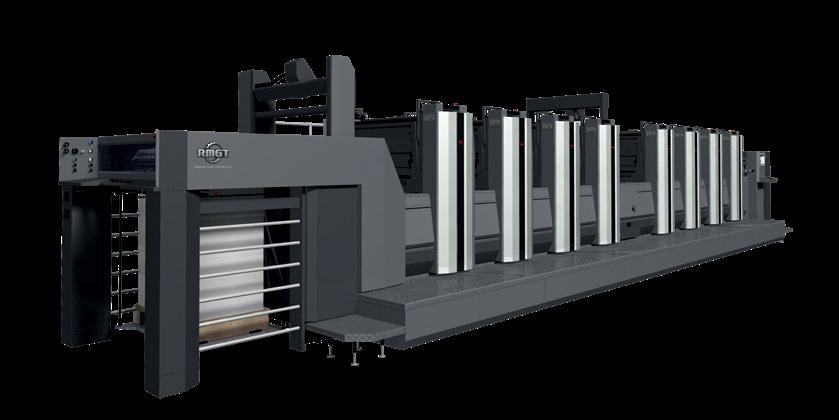

It was drupa 2008 when the world first saw Screenʼs commercial introduction of its first entry into inkjet digital printing – the Truepress Jet520. Previewed at Ipex two years prior and OEMʼd to IBM as a transactional output printer, this launched Screen onto the path of transition from a purely CtP and prepress manufacturer, to a major force in POD digital print, with hundreds of installations worldwide, many model variants and now, a colour quality that rivals offset.

In finalising the development of its new Truepress JET 560HDX roll-fed digital inkjet press, Screen’s line-up for the commercial printing, book, direct mail, and publishing printing markets has taken a major upward shift into its first wider web roll feed machine at 560mm wide. All previous models have been 520mm webs.

Itʼs also faster and higher resolution and uses the remarkable proprietary SC2 inks and drying system for printing offset quality on standard offset stocks. This lowers the cost of papers from specially coated substrates engineered to receive aqueous inkjet inks and enables fast drying.

Screen says that the commercial printing market requires flexible print solutions with high-value economics because of more complex work, faster turnaround times, shorter print runs, multiple versions, late — stage revisions, and variable information—all demanded by todayʼs end customers. These requirements have created new business opportunities for high-productivity digital inkjet presses offering offset-like economics.

LOCAL FRIENDLY FACES ON SCREEN STAND, HALL 8A

Screen GP

Australiaʼs managing director

Peter Scott, who will be on Screenʼs stand at drupa 2024, says: “The introduction of the Truepress JET 560HDX is the culmination of years of experience and listening to customers in the high-volume digital printing space. At drupa 2024, the company has chosen a theme of ‘Creating a Future in Print – Tech x Irodori’ where visitors to our booth will gain valuable insights into the transformative impact of industry cooperation on the future of printing.”

Scott continues, “In Japan, Irodori literally means ‛to add colour’ but also implies

ʻchange for the betterʼ. The 560HDX sums this up beautifully. The specifications and print samples I have seen are stunning. It’s no coincidence that our US branch has already logged two orders from existing Truepress 520 users, for the first installations of the 560HDX, with one exclaiming, ʻIt canʼt get here soon enough!ʼ It’s going to really help printers please more customers, more quickly. One of our US staffers says, ʻIt ʼs not just another new press to sell; it’s a whole new horizon for print.ʼ I can only agree with him and look forward to meeting with Australian and New Zealand customers on our stand at drupa to show how good it is, with live demonstrations.”

CHANGING REQUIREMENTS OF PUBLISHING AND DIRECT MAIL

The publishing market requires aggressive economics and high-quality as well as flexible format sizes to enable a growing number of companies to benefit from the capabilities of roll-fed, high-speed and digital inkjet press systems and workflows. Facing ever-shortening production runs and even ‘books of one copy’ requirements, book production systems need to be optimised for superlow to mid-volume production.

With direct mail, the market’s needs are for high productivity, flexibility to run lightweight uncoated papers as well as thicker, attention-getting, high-gloss selfmailers at low fixed and variable costs. These aspects are essential to help offset the rising cost of postage and other forms of distribution. Driving direct mail production costs as low as possible will encourage marketers to continue to use this valuable, tactile, and effective medium over saturated, confusing, and untrusted electronic communication.

In response to these changing market realities, Screen initially introduced its Truepress JET 520HD, 520HD+ and 520 HD-AD printers with Truepress SC and SC+ inksets. With this combination, Screen became the first manufacturer to provide a practical solution to printing directly onto offset-coated papers with a digital inkjet system and without the need for an inkjet media pre-treatment.

THE 560HDX OFFERS A 360-DEGREE VIEW OF PRINT’S FUTURE

Drupa visitors will be able to witness Screen’s latest development in this area, with the Truepress JET 560HDX, a unique system expected to drive further innovation in printing generally. The Truepress JET 560HDX can operate in a variety of print modes, enabling it to handle paper widths of up to 560mm at speeds of up to 150 metres per minute, with a maximum resolution of 1200 x 1200 dpi. It is also compatible with Screen’s SC2 Truepress ink.

This newly developed, high-optical density inkset allows printing directly onto offsetcoated papers without any pre-treatment. The SC2 inkset’s special properties produce high vibrancy colours that ‘pop’ and have deeply saturated hues, as well as dense and neutral blacks for clearer printing of the very finest text and line work.

www.sprinter.com.au COVER STORY

26 ProPrint April 2024

Peter Scott

In addition, a new high-efficiency, intelligent drying system enables substrates with high ink loadings to be dried efficiently, thereby supporting superior quality and wide- gamut printing on a wide range of papers. The Truepress JET 560HDX is also equipped with a new, fast-start operating system that inherits and further improves on the Truepress series’ market-proven technologies. This system ensures flawless integration of all internal hardware and software as well as with both pre- and post- finishing equipment.

Screen anticipates that the Truepress JET 560HDX will become a benchmark contributor to the next generation of smart factories, where it is expected to introduce new economic efficiency, high-availability productivity, and print quality to satisfy the most demanding customer needs.

It will be a centrepiece of Screen’s exhibit at drupa 2024, from 28 May to 7 June in Düsseldorf, Germany and will also be displayed at Screen’s Inkjet Innovation Centres in the USA and in Europe, along with Screen’s other digital inkjet solutions for the labels and flexible packaging sectors.

‘completing the loop’ of CtP-offset; high- volume digital and short-run digital sheetfed production.

MONO NOT FORGOTTEN

It’s easy to get carried away with brilliant colours but the market for monochrome books and paperbacks in short runs is still strong. At drupa 2024, Screen aims to redefine monochrome printing standards to unprecedented heights with its Truepress JET 520HD Mono running the new SU Black ink with increased levels of optical density for uncoated or inkjet coated paper. Engineered as the nextgeneration monochrome inkjet press, this

MORE INKJET INNOVATIONS FROM SCREEN ON DISPLAY AT DRUPA 2024

drupa will also see inkjet innovations from Screen in the sheetfed SRA3 sector, a new high opacity mono ink for bookwork and also Labels and Flexible Packaging.

drupa 2024 will be an opportunity for Australian and New Zealand printers to get a first look at a fully featured model of its Truepress JET S320 sheetfed printer, a cooperation with Kyocera Document Solutions, announced and previewed at Printing United USA in October 2023.

The S320 also uses Screen’s Truepress ink SC/SC+ technology for ink compatibility with standard coated papers and unrivalled colour vibrancy. Billed as ‘the offset printer’s digital press’ the S320 will be offered without the traditional cutsheet ‘click charge’ model and is seen as

innovation is optimised to print directly onto offset-coated papers.

The well-established Truepress 520HD Mono inkjet press goes beyond the sharp replication of text characters and

barcodes, introducing a new level of richness in gradations for any image and reliable variable data printing capabilities. This high-speed inkjet digital press is equipped with greyscale printheads that masterfully control droplet deposition, reliable web transfer, and tension control, ensuring precision even with thin papers as light as 40gsm.

Applications such as pharmaceutical leaflets, direct mailing overprints, on-demand book printing and instruction leaflets also benefit from denser, sharper blacks.

LABEL PRESS SUCCESS JOINED BY FLEXIBLE PACKAGING

Screen’s well-established Truepress Label 350UV SAI inkjet range of UV presses, sold throughout Australia and New Zealand by Jet Technologies, will also be featured at drupa. A newly developed digital primer unit for label printing will be demonstrated, broadening the range of label materials that can be printed.

The L350UV and SAI range has proved extraordinarily successful in Australia and New Zealand and, indeed, globally, delivering a high-uptime and fast digital label press to packagers and converters. Using inkjet UV, the L350 series is faster than most other digital methods and can be supplied as either a stand-alone digital solution or integrated inline with flexo and converting modules from Nilpeter to create a total integrated solution that can include semi-rotary die-cutting, hot and cold foil, high-build varnish, doming,

www.sprinter.com.au COVER STORY

April 2024 ProPrint 27

Screen Truepress JET 560HDX new digital webpress

Screen Truepress JET S320 cut sheet printer

Screen TP L350UVSAI labelpress

lamination, matrix stripping, video inspection and more.

The hybrid model is based on Nilpeter’s famous FA-line converting and includes the Screen digital module, which can print up to seven colours, including white.

One advantage of Screen’s L350UV SAI ‘S’ model is that, when equipped with white ink, its speed is still a healthy 50 metres per minute – a very small change from its normal 60 mpm. Coupled with proven high uptime and durability, this makes the L350UV SAI the most productive narrow web digital press overall. In fact, even older, slower models are in high demand when traded in for the new SAI series.

BACK TO SUSTAINABLE PAPER FOR SOME PACKAGING

With increasing concern over microplastics and fossil-resource-based materials, Screen was one of the first to introduce a digital-flexible packaging press capable of producing high-value paper packaging.

intricacies of achieving digital printing on filmic flexible packaging using waterbased food-compliant inks.

The Truepress PAC 830F water-based inkjet digital press has been specifically designed to produce short printing runs in a cost-effective manner while providing total flexibility to operations. This new single-pass industrial inkjet digital printing press is a fit-for-purpose printing solution that allows packaging converters and brands to capitalise on emerging

The Truepress PAC 520P inkjet press uses water-based food-compliant inks for paper packaging, which will also be demonstrated at drupa to help converters and brand owners achieve their sustainability goals. The company intends to present a range of label and packaging samples utilising eco-friendly base materials, introducing sustainable solutions and productivity-enhancing options for digital inkjet printing of small and medium-lot jobs. Screen personnel will elaborate on how these solutions present substantial new business opportunities during drupa presentations.

AQUEOUS DIGITAL FLEXIBLE PACKAGING HAS ARRIVED

The long-awaited Screen Truepress PAC 830F inkjet system for flexible packaging films will also be shown at drupa. This will provide an opportunity to explore the various features of this press, including its innovative design, and delve into the

trends in flexible packaging, boosting profitability in short-runs.

Running at 75m/min, its CMYK and Heavy White water-based inks fully comply with the standard food safety regulations. At drupa, packaging printers will have the

first opportunity to witness the printing module of PAC830F for the first time and see their sustainable future take shape!

DID SOMEONE SAY CTP?

After thirty years of developments, computer-to-plate may seem mature, but Screen – recently surpassing 25,000 devices shipped – has never stopped innovating. It will present the new PlateRite HD 8900NII, an eight-page CtP system and the latest addition to its PlateRite series.

As a solution provider from print data creation, Workflow (EQUIOS) to printing, Screen will present its unique digital and offset hybrid solution to support various applications and run-lengths integrating digital web-fed inkjet presses, sheet-fed presses, CtP, software, colour management and over eighty years of deep experience –all at drupa 2024 in Hall 8A.

Local MD Peter Scott says, “Screen extends a warm welcome to all Australian and New Zealand visitors to drupa to learn more about its vision for the future of printing on multiple levels. I have attended many drupas and other international trade shows, and I don’t think I have ever been so excited about the new technologies to be released and new key learnings to be gained. After all, it’s eight years since the last drupa in 2016, and the innovation will be twice as impressive!”

Screen can be visited in Hall 8A, stand A03 at drupa 2024.

www.sprinter.com.au

28 ProPrint April 2024 COVER STORY

Screen Truepress P520P flexible packaging press

Screen Truepress PAC 830F aqueous flexible packaging

Screen PTRHD8900NII-Z CTP device