21 minute read

Chevrolet XP-817

When Ford broke with the AMA agreement and went racing, Chevrolet lost no time preparing its counterattack. In the vanguard was Zora Arkus-Duntov with the radical CERV II

By KARL LUDVIGSEN

Advertisement

This amazing, four-wheel drive automobile was conceived in the autumn of 1963 as a contender for victory in the great international long-distance races. Styling staff marked the official beginning of project XP-817, as it was known, as 27 September 1963.

A year earlier Ford had unveiled its midengined Mustang at Watkins Glen. It was an early stage of Ford’s Total Performance initiative, openly promoted as the forerunner of a future Ford sports racer designed to compete on the world’s great racetracks.

Ford’s negotiations to buy Ferrari for this purpose hit the buffers in February 1963. And so, on 1 July that year, the company hired the exclusive services of British racecar manufacturer, Lola, to help build a car that could wave the Ford flag higher than Ferrari’s at Le Mans in its world famous 24-hour race.

For Chevrolet, this was a step too far. Chevy boss, Semon ‘Bunkie’ Knudsen immediately approved the plans of his Corvette head honcho, Zora Arkus-Duntov, to show the Bow Tie could fly the flag higher still.

CERV II, as this car became known, wasn’t the first Chevrolet Engineering Research Vehicle II. The same name was given to a rearwheel drive spaceframe roadster conceived in 1962 to compete in long-distance racing as a 4.0-litre prototype. It never progressed to the metal, though, the lightweight Sting Ray Grand Sport being built instead.

At arm’s length

Chevy’s plan for the XP-817 called for the building of one prototype, plus five racecars. These were to be ‘purchased’ by well-established teams to take to the races, where they would enter them at arm’s length from Chevrolet to evade GM’s management policy of non-racing, in a similar way to how such teams were also entering race-prepared Chevrolets into NASCAR races.

At that time, the World Sports-Car Championship posed no limit on engine size. This meant Duntov, his designer, Walt Zetye, and technicians Bob Kethmann and Ernie Lumus could think big with the engine. Their choice was one of the most exotic V8s in Dr. Duntov’s capacious cabinet of power.

The very special aluminum engine had a single overhead cam on each bank, driven by a train of gears in pure race engine style. The cams operated two valves per cylinder through rocker arms, feeding hemispherical combustion chambers.

Displacing 377ci, or 6.2-litres, this V8 was developed to produce more than 500bhp by Duntov’s engine team of Cal Wade, Fred Frincke and Denny Davis. While it was being tested in parallel, the engine actually used in the CERV II was a different all-aluminum, 377ci unit with pushrod valve gear like the ones used in the 1963 Grand Sport Corvettes. In fact, the engines, and other components in those GS cars, were being evaluated in the December races at Nassau to determine their suitability for the CERV II project.

Compact and purposeful, the CERV II was packed with innovations that could have made it a formidable competitor in long-distance races for which it was designed

The power unit installed in the CERV II prototype was fed fuel by Hilborn constantfl ow injection instead of the multiple Weber carburettors used in the Bahamas. This allowed methanol to be used so the output of the overhead cam V8 could be simulated during development of the new car’s chassis.

Advanced rubber

Putting this prodigious power on the pavement was the next requirement. Thanks to Duntov’s close relationship with Firestone, the CERV II was able to use the most advanced racing tyres then available. Duntov was the fi rst engineer outside Firestone to test the new, wider, low-profi le tyres it was developing late in 1963 for the 1964 Indy race. He found them highly adhesive and gratifyingly forgiving of driver error.

Duntov chose the 9.50 x 15 size for all four wheels, on 8.5in rims cast of magnesium by Kelsey-Hayes. Knock-off hubs were fi tted with the long-distance races in view.

All four wheels and tyres were identical because Duntov had decided to equip the CERV II with four-wheel drive. The Belgianborn, Berlin-educated Duntov had been thinking about various ways of driving all four wheels since he saw the 4WD Bugatti Type 53 win a standing-start sprint event in 1935. However, as the Bugatti was so strong on the straights but so poor in the corners, Duntov reasoned that there must be some way to combine good handling with the fi ne road grip given by four-wheel drive.

Consequently, in 1937, he presented some of his thoughts in a technical paper on four-wheel-driven racecars.

By 1963, though, the fi rst great wave of enthusiasm for 4WD racecars was still half a dozen years in the future. Duntov elected to use it because his calculations showed it could provide a higher cornering speed, as well as much-improved acceleration with a very powerful engine, more than off setting the 125lb weight handicap.

Early in the 1960s, Chevrolet’s Research & Development department had been doing experimental work with torqueconverter transmissions in racecars that led directly to the Chevy-built unit used in the Chaparrals from 1964 onward. Duntov had planned an automatic transmission for his 1962 CERV II study all along, but it was a pure mechanical, power-shifted gearbox. Considering the torque converter approach less effi cient, though admittedly far simpler, Duntov saw he could use it for his new car, which would be generously powered for its 1900lb design weight.

Torque principal

Duntov took a further big step with his concept, deciding to drive the back wheels through one torque converter and the front wheels from the front of the engine through another one. It was a completely new principle on which Duntov lodged a US patent on 23 June 1966.

Not pretending to be a torque converter specialist, Duntov presented the parameters of his proposed driveline to the experts on GM’s engineering staff. As planned, the CERV II (or GS-3, as it was by then known, and later GS-10) had a static front / rear weight distribution of 46.5 / 53.5 per cent. With a c of g 14in high, the proportion of weight on the front wheels would drop to only 32 per cent when the car was accelerating at 1g, which was well within its capability.

‘What I want,’ Duntov told the transmission experts, ‘are torque converters that will deliver 35 per cent of the engine torque to the front wheels at low car speeds and up to 40 per cent at higher speeds.’

Excepting schemes that use separate engines to drive the front and rear wheel pairs, this was the first time anyone had tried to achieve a variation in the front / rear torque distribution of a four-wheel-drive car while it was in motion. Engineer, Raymond P Michnay, took on the job and handled it to perfection.

At the back of the engine, driving the rear wheels, Michnay specified an 11in Powerglide torque converter, modified so it didn’t approach a locked-up, or nearly 1:1, drive condition until 4500rpm. Then for the front wheels he provided a 10in converter from a Corvair Powerglide, placed ahead of the front-wheel centreline just as it was ahead of the Corvair’s rear wheels. It was rotated in the same sense by the universal-jointed shaft running forward from the front end of the crankshaft. The front converter approached lockup at 4100rpm.

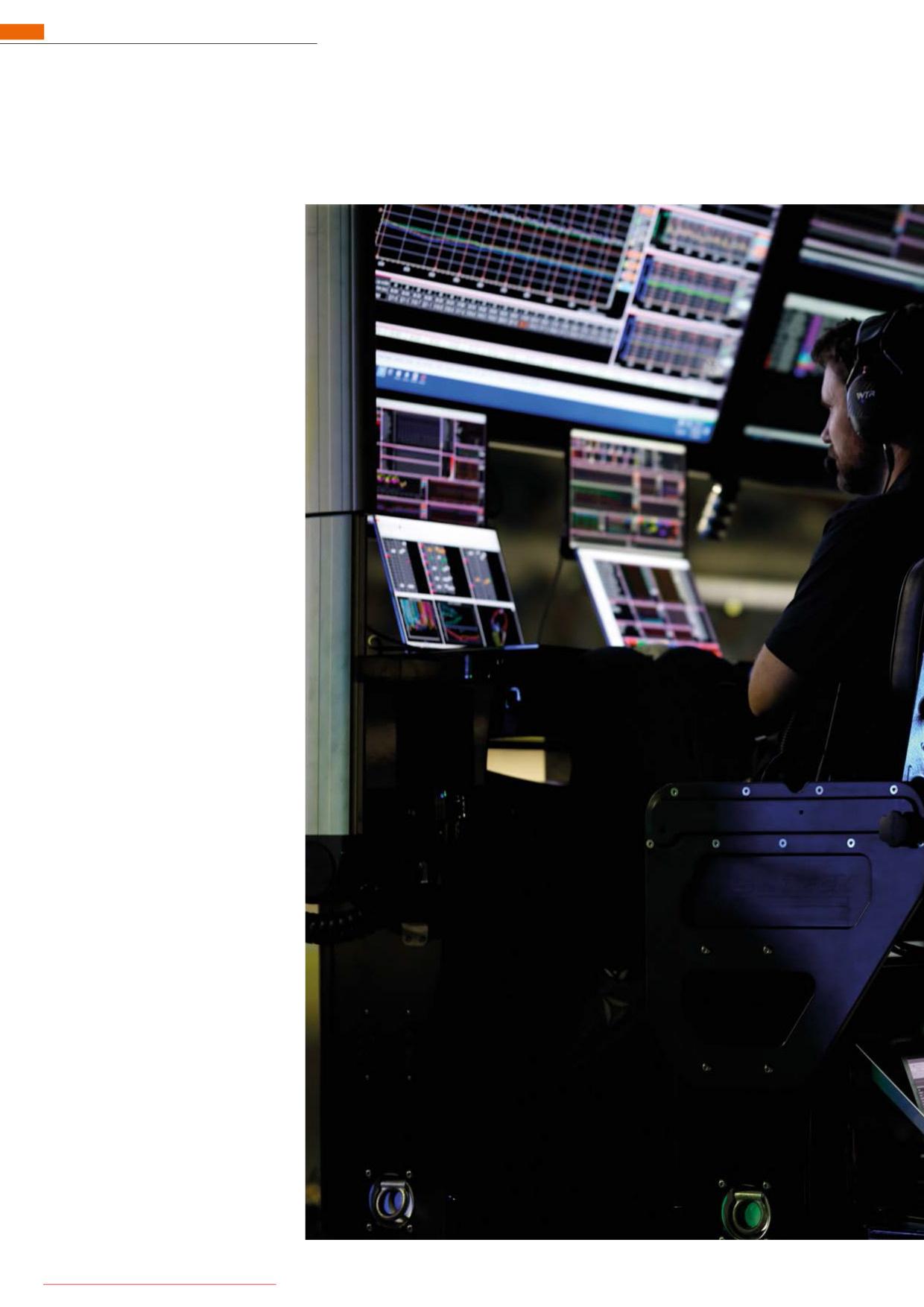

In GM Styling Staff’s basement studio in late 1963, looking at the body designed by Larry Shinoda and Tony Lapine for the closed coupé version of Duntov’s four-wheel drive Chevrolet Engineering Research Vehicle II

Best of both worlds

Performance calculations showed that with a low final drive ratio, the CERV II would accelerate from zero to 60mph in 2.8 seconds, and reach a top speed of 115mph. With a higher ratio, maximum speed would go up to Conceived for endurance racing, the CERV II would have been fitted with a closed coupé body and endowed with a 46.5 / 53.5 front / 183mph, though the time to reach 60 would rear weight distribution. At GM Styling Staff, the car was originally known as Project XP-817, but later as GS-3, and later still as GS-10 be much longer, about four seconds.

Deciding to have the best of both worlds, Duntov equipped both axles of CERV II with compact two-speed gearboxes like those used in the Chaparrals through 1965.

Controlled by a single cockpit lever, the gearboxes gave a direct drive and a 1.5:1 reduction. With a 3.55:1 axle ratio, this gave speeds of 107mph in low and 160 in high, at 6500rpm, taking into account three per cent slippage in the converters above 6000rpm.

The gearbox at the front had to be specially made with concentric shafts that allowed the torque converter to be overhung at the front of the chassis.

Though a limited slip differential was made for the rear-wheel drive, it was never used. Open differentials were kept at both front and rear. Open driveshafts to the wheels had Hooke-type universal joints outboard at the rear, CV joints at the outer front ends. With its generous cockpit air scoops, the CERV II would have been a striking endurance racer, but it was never run in this format

Zora Arkus-Duntov

Tony Lapine (left) and Zora Arkus-Duntov were the architects of the engineering of CERV II. They used cutting-edge (for 1963) techniques in both its suspension and driveline technologies

A section view of CERV II showed the sliding inboard universal joint and lower wishbone angle that helped lift its roll axis height

Inboard ends of all four driveshafts had conventional pot-type universal joints that allowed plunging movement of the shafts as the suspension flexed.

Unlike many 4WD cars, no attempt was made to mount the brakes inboard. Instead, Girling wheel cylinders were adapted to wider caliper bridges to accommodate ventilated brake discs at the wheel hubs.

Disarmingly simple

The suspension design for CERV II was disarming in its simplicity.

‘The front roll centre height is about 3.5in,’ said Duntov, speaking at the time of its parallel wishbone layout. ‘That’s a standard number with me. At the rear, it’s about three inches above the ground.’

Trailing radius rods locating the rear hub carriers and reversed wishbones were angled to give a mild anti-squat effect.

On a four-wheel-drive car there’s a tendency for the front to lift under the direct influence of drive forces. To counteract this, Walt Zetye built an anti-lift effect into the front suspension design by inclining the axis of the lower wishbone pivots upward toward the rear at an angle of eight degrees.

Unusual on a car intended for racing were rubber bushings for the inboard wishbone pivots. Duntov felt they should be used for their simplicity and shock absorption capability where the design didn’t demand a hard-surfaced bushing.

CERV II’s rear hub carriers were machined steel and those at the front made of cast nodular iron with forged steel steering arms. Outer balljoint locations at the front were angled to give a steering axis that intersected with the ground three inches inboard of the centre of the tyre patch.

Concentric coil springs and adjustable Armstrong dampers were fitted at all four wheels. Their placement at the front provided

A single overhead camshaft on each cylinder bank operated the inclined overhead valves of the 377ci, all-aluminium V8 designed and built to power CERV II. Sadly, this too never had a chance to strut its stuff on the racetrack Gear trains from the crankshaft drove the overhead cams of the 6.2-litre V8 intended to power the CERV-II in endurance racing. A patented feature, the paired gears on each side allowed their running clearances to be fine tuned

The front of CERV II is at the right in Duntov’s patent on its use of two torque converters to drive the front and rear wheel pairs. The gearboxes (items 10 and 20) were manually-engaged, two-speed units employed so drivers could increase top speed capability

an abject lesson in the packaging of a lot of machinery into a very confined space.

Ahead of the front suspension was rack and pinion steering gear, built by GM’s Saginaw division to Duntov’s requirements. It required only 1.8 full turns of the steering wheel from lock to lock.

Steel tub

Fabricated steel arches carrying the front suspension components were welded to the monocoque tub, adopted instead of the tubular spaceframe used for the 1962 design study. Like that of Ford’s GT40, the CERV II’s tub was fabricated from sheet steel, 0.025in thick instead of the 0.024 and 0.028in thicknesses used by Ford. The tub began at the footwell, extended back around the fuel cells at the sides, where it was stiffened by glued-on aluminum braces, and ended at the transverse firewall behind the seats.

From the firewall to the rear, the big V8 was the major frame member, a design technique that later became commonplace but was then rare and adventurous. The engine was attached to the firewall at the front and to a 2.5in transverse tube at the back, above the rear torque converter, this being further braced by two 1.0in tubes at each side of the engine.

Initial tests in torsion showed the complete frame structure was well below par with a stiffness of 2000lb.ft per degree. With the curve of frame deflection in torsion showing a sharp break through the engine area, measurements of the engine’s cylinder bores showed they were being distorted significantly by the application of torsion to the frame. The addition of a four-legged tubular brace above the engine raised stiffness to the more satisfactory level of 5000lb.ft per degree, though even this was less than half the 12,500lb.ft figure quoted by engineers at Ford for its GT40.

The rear wheels of the CERV II were driven through a Powerglide torque converter and two-speed gearbox like the one used in the Chaparral sports racecars. Here, a carburetted MkIV Chevrolet big block engine is fitted

An aluminum crossflow radiator sat in the nose of CERV II. Warm air ducted up and away from it didn’t overheat the front torque converter and also helped reduce front-end lift

Built expressly for racing, CERV II had its very upright driving position on the right. The central tunnel was needed for the driveshaft that went forward from the engine to drive the front differential through a torque converter and another two-speed gearbox

A view of CERV II’s right front corner discloses its double wishbone suspension, ventilated disc brakes and driveshaft coming from the front differential

At the time CERV II was created, driving positions were sinking lower and lower to reduce the frontal areas of the power poor, 1.5-litre Formula 1 cars. Duntov decided not to cater to this trend because his car was designed to do its job at relatively low speeds, through better acceleration and cornering, and would have a plethora of peak power with which to generate any required maximum speed.

Using a more upright seating position allowed Duntov to keep his car short, with just a 90in wheelbase and 157in overall length. Front and rear tracks were set at 53.5in and overall width at 66in.

Around CERV II’s upward-ducted front radiator – a Duntov feature dating from the Corvette SS – and built-in rollover bar, Larry Shinoda and Tony Lapine in Styling’s underground studio came up with a bold body shape. For the German-born Lapine, this was one of his last major projects before he returned to Europe, to Opel, later becoming director of styling for Porsche.

Their roadster shape executed in glass fibre had a low, peaked nose and indentations at the rear, with ports for the twin tuned exhaust pipes part of the original plan. Quarter-scale models were tested in a California wind tunnel to refine the shape before the full-size contours were confirmed.

Moveable aero

Initial tests showed the body worked well. Only a slight curve in the front windscreen was needed to deflect air completely clear of the driver. However, after high-speed trials showed instability, a spoiler – called a ‘cow’s tongue’ by Duntov – was fitted at the rear, protruding from the transverse slot in the engine cover in such a way that it could be deployed when needed. This made CERV II

entirely stable at the 214mph it reached on the Milford five-mile track with a high final drive ratio and the 377ci pushrod engine.

The designers also modelled a coupé version of the CERV II. This had its water radiators mounted in its rear quarters, requiring substantial scoops along the sides of the cockpit. This alternative design allowed the nose to be lower and sharper.

CERV II first rolled on its four driven wheels in March 1964. In early tests at Jim Hall’s private and well-instrumented Rattlesnake Raceway at Midland, Texas, in comparison with the rear-wheel drive GS-2 (forerunner of the Chaparral 2C) built by the Chevy R&D department, it didn’t show to its best advantage for several reasons. The special two-speed gearbox for the drive to the front wheels hadn’t been completed, so it could muster only a single ratio. Its brake discs were also at the time an experimental – and, as it turned out, unsatisfactory – forged aluminium protected by sprayed-on facings.

Driving sensation

During the tests at Midland, the CERV II was tried by Jim Hall and Roger Penske. Both found its traction and handling very impressive. Penske, in particular, liked its driving position and said he was unable to detect any sensation that the engine was powering the front wheels as well as the back ones. At the limit in a turn, the CERV II did require an unorthodox technique because releasing the throttle tended to cause a fast flat spin. Up to that point, however, its tyres and drive system made this the only road racer of its era that could make full use of a very large engine and horsepower well in excess of the 500 level.

In the on / off cycle of attitudes toward racing that prevailed during the Bunkie Knudsen regime at Chevrolet, the stop light facing CERV II turned from green to red late in the summer of 1964. Chevy decided it didn’t want to pose an open challenge to Ford at Le Mans (though later it did offer opposition, indirectly, with the 2D Chaparral in 1966 and the 2F in 1967) and another promising Duntov idea came to a ‘screeching halt.’

Several years later, for tyre tests conducted by Corvette development driver / engineer Bob Clift, CERV II was fitted with an allaluminum ZL-1 engine of 427ci displacement. It carried a single four-barrel carburettor and individual exhaust stacks, both fitted for maximum operating ease rather than ultimate performance. External piping from the rocker covers drained oil to its wide wet sump with a swinging oil pick-up. Wider rims allowed 10.50-15 tyres to be fitted.

Fed by a specially developed, constant flow fuel injection, the chain-drive version of the 377ci V8 developed 545bhp at 6000rpm and 512ft.lb of torque at 4800rpm

Disadvantage in design

With this powerplant, CERV II went back to Rattlesnake Raceway to take part in tests when Chevy’s R&D Department was assessing new design approaches for the Can-Am series, then in full flow. Weighing several hundred pounds more than R&D’s version of a Chaparral, though, it was significantly outperformed. Duntov, who hadn’t been able to attend the tests, never got over the feeling that his brainchild had deliberately been disadvantaged in some manner.

Although the prototype’s ability to make full use of a big engine, thanks to its four-wheel drive, was well in advance of its time when it was conceived, it had been impossible to foresee that the Goodyear / Firestone tyre wars would soon produce rear tyres so wide that all-wheel drive wouldn’t give an advantage for road racing. The CERV II’s design didn’t allow it to run the latest wide rims at the rear, so it was denied this chance to exploit its attributes.

Nevertheless, the CERV II’s torqueconverter propulsion was shrewdly thought out and striking in its logic and effectiveness. Considering its primary mission was longdistance racing, in which weather conditions often influence the outcome, such a system might have been useful. Not least because it would have allowed the use of narrower tyres that were less likely to suffer from aquaplaning on a wet track.

In the form you see here, with its blue and white livery, CERV II was first revealed to the world by this author in the November 1970 issue of Motor Trend. Though it never took part in a race, CERV II was spurred into being by the pressure of competition. As such, it made a valuable contribution to the evolution of the Corvette, and Duntov would take full advantage of what he’d learned with CERV II in his future Corvette designs.

Another version of the 6.2-litre V8 had a wider vee angle for its inclined overhead valves and chain drive to its single overhead cams

Here to help the Motorsport Sector Claim Research and Development Credits

BHC Technology is the only company with experienced & qualified motorsport personnel to offer Research and Development tax incentive. If you are a motorsport company or a team that has a dedicated motorsport specialties - we will help maximise your entitlement to a claim. The R and D incentive is available to all limited companies, it is not a grant or loan and does not have to be paid back. BHC Technology have a 100% success rate in this sector meaning the applicants receive either cash refunds or reduced Corporation Tax liabilities – your choice!

We also run a successful historic sports car team!! Contact Phil or Stuart:

Stuart@bhc-tech.co.uk Phil@bhc-tech.co.uk

OUR ROADMAP FOR YOU

BHC Technology has worked hard to build its reputation in the market and with HMRC. As a result, we have achieved a 100% success rate to date. BHC Technology endeavours to claim for the maximum entitlement available to you, the company. BHC Technology know exactly which activities qualify and which don’t. We are here to help and guide you step by step through the claim process.

1 INTRODUCTION

1st person phone call / online meeting to identify potential R&D projects. If R&D is available, agree to move on to the next step in the process. (Our Ref: BD)

8 COMPLETION The final step... HMRC takes approx. 4-6 weeks to process your claim and any refund is directly sent to YOUR bank account. (Our Ref: AC) 2 ENGAGEMENT

Our Letter of Engagement is emailed for signature. The Letter of Engagement instructs BHC’s writer to carry out (until otherwise notified & if applicable each year) the R&D claim for the business. Clients requested to email (if available) individual projects/jobs for each R&D claim year, so our R&D Writers can start the narrative. (Our Ref: BD)

7 SUBMISSION Once provided with the financial R&D summary, your company Accountant is required to (re)submit revised tax computations and CT600 to the HMRC. BHC Technology submits your technical report to HMRC. (Our Ref: AC) 3 R&D TECHNICAL

A 2nd meeting is conducted with the R&D writer to detail the specifics of each individual project / job relating to each year of the R&D claim. (Our Ref BD/RDW) BHC Technology conducts the relevant research to confirm and validate the R&D claim is eligible. (Our Ref: RDW)

6 FINAL CHECKS Your final report is compiled and submitted for quality checks by our quality department. (Our Ref: AC) 4 FINANCIALS

BHC will email for the following financial information: • Year End Accounts • Tax Computation • Payroll and any other cost information to support the spend Please confirm details of the Accountants (either in-house or 3rd party)

5 CALCULATION Our in-house Accountant calculates the claim value of the associated costs such as payroll percentages against projects / jobs and provides you with the tax saving. (Our Ref: RDW/AC)

BHC Technology Limited • 8 King Cross Street • Halifax • HX1 2SH 07834 548 965

LISTA STORAGE SOLUTIONS FOR MOTORSPORT

BENEFITS

+Proven expertise

Many years of experience equipping all areas of Motorsport

+Modular design

Universal modular system +Completely universal

From a single mobile cabinet to full facility fit out

+Top industrial quality 10 Year guarantee + Customisation

Define your exact requirements

CALL US NOW OR SEND AN E-MAIL 01908 222333 info.uk@lista.com