C eramic W orld

technology news markets R eview 陶 瓷 世 界 评 论 陶 瓷 世 界 评 论 Welcome to Uniceramics Expo 2023 欢迎来到2023佛山潭洲陶瓷展

THE FUTURE IS TODAY Thanks to our technologies your company will benefit from H2 and flexible Power and Heat solutions that are ready for both today and tomorrow’s challenges. +2Million hours with high H2 fuel up to100% H2 +16000 Gas Turbines sold For more information and to locate the office nearest you: visit solarturbines.com; Call +41 91 851 1511 (Europe) or +1 619 544 5352 (US) email infocorp@solarturbines.com | www.solarturbines.com CHANGING the rules of the game

www.projecta.it

Year 33, Chinese Edition

Supplement to No. 151

April/May 2023

Bimonthly review

7 E ditorial

The Chinese tile industry invests on quality and sustainability

中国瓷砖行业对质量和可持续发展进行投资 8 World NEWs

12 E co N omics

16

18

22 saNitaryWarE

India’s unstoppable growth 印度增长势不可挡

RAK Ceramics announces strong growth in FY 2022 RAK Ceramics宣布2022财年实现强劲增长

The Italian ceramic tile industry weathers the storm in 2022 意大利瓷砖行业在2022年经受住了考验

World sanitaryware exports and imports 世界卫生洁具进出口报告

28 Safer and more versatile and sustainable tunnel kilns 更安全、更通用、更可持续的隧道窑

Paola Giacomini

Ilaria Vesentini

Paola Giacomini

Luca Baraldi

Sacmi Sanitaryware Division

Sustainability as driver of change in the industry 可持续发展是行业变革的驱动力 Esmalglass-Itaca Group 36

Media for digital glazing with water-based glazes and engobes 水性墨水和化妆土数字化应用的介质 Lamberti

An integrated approach to large slab production 大板生产的整体方案 System Ceramics 42

Slabs and sub-sizes: high flexibility and a productivity of 21,500 sqm/day Gianluca Pederzini 大规格陶瓷板及其子尺寸:高度灵活,日产能高达21,500平方米 Andrea Bresciani

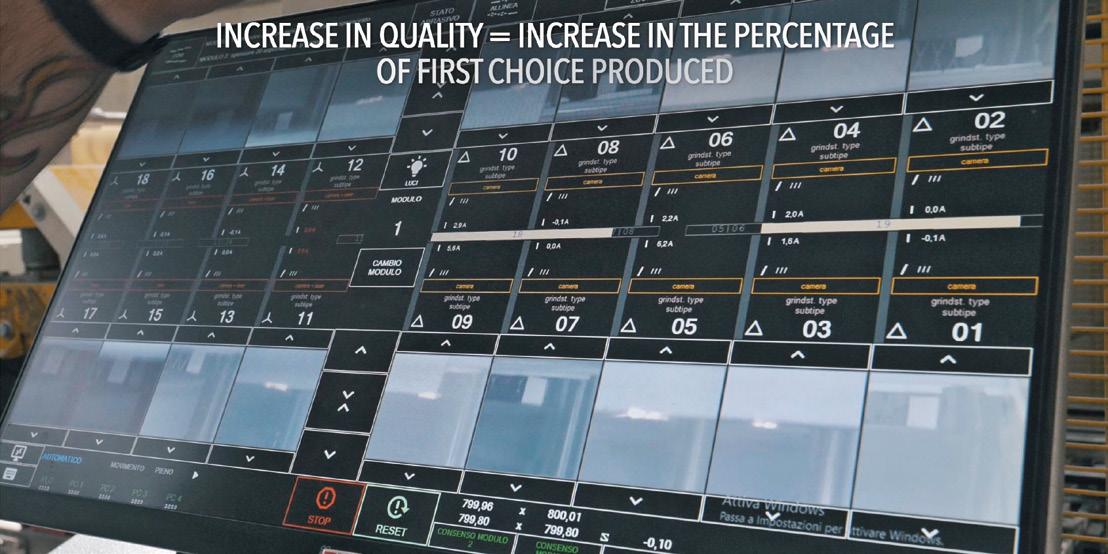

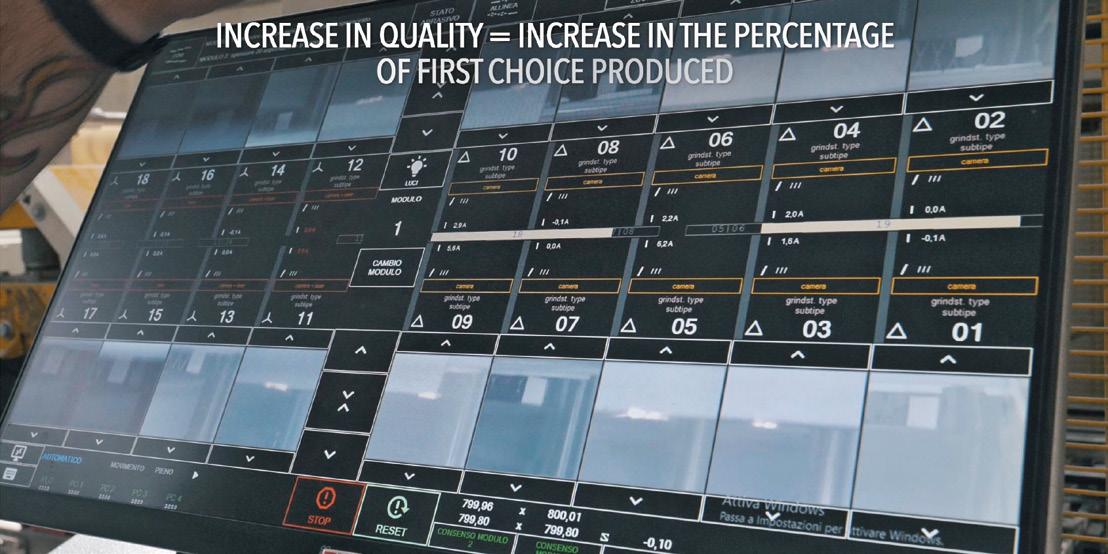

The dry squaring technology goes digital 干法磨边技术走向数字化 Bmr

Innovative and sustainable technologies to deliver unlimited aesthetic creativity 创新可持续技术带来无限的美学创意

Gruppo B&T

CWR CHINA 2023 3 contents

Cover picture by: Giancarlo Pradelli

34

38

46

50

52 Products 产品 TECHNOLOGY Bmr 49 Bongioanni Macchine 5 Certech 11-55 EFI Cretaprint 64 Esmalglass-Itaca Group 41 Hito 6 Lamberti 32 Mecs 27 Off. Smac 61 Poppi Clementino 45 Sacmi IV cop-33 Solar Turbines 1 Siti B&T 2 Syneco 4 System ceramics II cop Torrecid III cop Vidres 59 advertisers list

Publisher / Editore:

Administration and Editorial Office Amministrazione e Redazione

KAIROS MEDIA GROUP srl

Via Fossa Buracchione, 84 41126 Baggiovara (MO) - Italy

Tel. +39 059 512103 Fax +39 059 512157 info@tiledizioni.it

Iscritto al registro delle imprese di Modena C.F./P.IVA IT02778050365

Capitale Sociale: € 51.400,00

R.E.A. 329775. Iscrizione ROC n. 9673 Periodico bimestrale registrato presso il Tribunale di Modena al n. 21/17 in data 10/08/2017

• CEO: Gian Paolo Crasta g.crasta@tiledizioni.it

• Editor / Direttore responsabile: Paola Giacomini p.giacomini@tiledizioni.it

• Editorial Board / Comitato Editoriale: Luca Baraldi, Milena Bernardi, Cristian Cassani, Omar Gubertini, Francesco Incerti, Paola Rolleri,

• Advertising / Pubblicità: KAIROS MEDIA GROUP: Tel. +39 059 512103 Fax +39 059 512157

• Paola Giacomini mobile +39 335 1864257 p.giacomini@tiledizioni.it

• Silvia Lepore mobile +39 345 7218245 s.lepore@tiledizioni.it

• Elisa Verzelloni mobile +39 338 5361966 e.verzelloni@tiledizioni.it

• Translation / Traduzioni: John Freeman Ceramic Town Weekly (Chinese)

• Subscriptions / Abbonamenti:

www.tiledizioni.it/subscription

• Each copy / una copia € 4

• Annual subscription (5 issues)

Abbonamento annuale (5 numeri) Italy: € 50; International: €70; Special tariffs for group subscriptions are available on request. Tariffe speciali per abbonamenti collettivi sono disponibili su richiesta.

Spedizione in a.p. art. 1 comma 1 DL 353/2003 DCB MODENA

L’IVA sugli abbonamenti, nonché sulla vendita dei fascicoli separati, è assolta dall’Editore ai sensi dell’art. 74 primo comma lettera C del DPR 26.10.72 N. 633 e successive modificazioni e integrazioni.

• Graphic Layout / Progetto Grafico Sara Falsetti - s.falsetti@tiledizioni.it

• Printer / Stampa

Faenza Printing Industries SpA Via Vittime Civili di Guerra 35 48018 Faenza (RA)

• Photolits / Typesetting

Fotolito / Fotocomposizione Vaccari Zincografica S.r.l. Via Salgari, 61 - 41123 Modena

Entire contents copyright Kairos Media Group. All rights reserved. Opinions expressed by writers are not necessarly those held by the publisher who is not held responsible. Editorial material, manuscripts, photographs, transparencies and artwork will not be returned. Tutti i diritti di riproduzione e traduzione degli articoli pubblicati sono riservati È vietata la riproduzione anche parziale senza l’autorizzazione dell’Editore. Manoscritti, disegni, fotografie e altro materiale inviato in redazione, anche se non pubblicati, non verranno restituiti. La Direzione non assume responsabilità per le opinioni espresse dagli autori dei testi redazionali e pubblicitari.

date of going to press / chiuso in redazione il: 05/05/2023

KAIROS MEDIA GROUP S.r.l., in conformità al “Testo unico sulla privacy”, garantisce la riservatezza dei dati usati per gli abbonamenti e per gli scopi tipici della stampa specializzata e la possibilità di modificarli o cancellarli (art. 7 del D.L. 196/2003) a mezzo richiesta scritta.

promoted by

kairos media group also publishes:

ADVERTISING

HITO TECHNICAL INDUSTRIES, S.L. • Narcís Monturiol, 26 · 08187 Santa Eulàlia R. (Barcelona) · Spain · Phon. +34 938 449 982 · Fax +34 938 449 269 • Cantabria, s/n · Pol. Ind. El Colador · 12200 Onda (Castellón) · Spain · E-mail: hito@hito.es HITO GRINDING MEDIA, S.L. •Avenida de Aragón, 30 · Edificio Europa, planta 8 · 46021 Valencia · Spain Phon. +34 960 468 643 · Fax +34 960 468 601 · E-mail: ceramica@hito.es • ul. Tadeusza Kosciuszki 34 · 81-702 Sopot · Poland · Phon. +48 58 355 10 08 · E-mail: hitopolska@hitopolska.pl HITO TECHNICAL INDUSTRIES HIGH DENSITY ALUMINA BALLS AND LINING BRICKS ALUMINA NANOBEADS ZH HITO POLSKA Sp. z o.o. • Paseo de la Castellana, 141 · Edificio Cuzco IV, planta 5 · 28046 Madrid · Spain Phon. +34 915 726 529 · Fax +34 915 726 621 · E-mail: international@hito.es

Paola Giacomini, Editor - p.giacomini@tiledizioni.it

The Chinese tile industry invests on quality and sustainability

According to official data provided by the China Building and Sanitary Ceramics Association, the Chinese ceramic tile industry closed the year 2022 with a strong decrease of both production and sales, inverting the positive trend of the previous year. Participating at the 23th China Ceramic Tile Trend Conference, Mr. Miao Bin, President of the Association, confirmed that the demand of ceramic tile decreased in 2022 both on the domestic and exports markets, forcing the manufacturing companies to limit their production volumes to no more than 60% of the total capacity installed in the country.

In fact, although ceramic tile production capacity increased slightly last year (from 12.33 to 12.56 billion sqm), the real ceramic tile production registered a harsh double-digit decrease, falling from 8.2 billion sqm to no more than 7.3 billion sqm, underlining the huge overcapacity of the sector. Exports did not help, since they continued to decrease for the seventh consecutive year, from 601 to 579 million sq.m (-3.7% on 2021)

Mr. Gong Wei, Secretary General of the China Building and Sanitary Ceramics Association, added that around 115 ceramic companies (and 275 production lines) were closed in the period from 2020 to 2022.

According to Mr. Ye Delin, President of New Pearl Group, the last 3 years were the most challenging for the ceramic industry in China, showing that the era of the fast development based on demography and urbanization has probably come to an end. But, convinced that “in the midst of every crisis, lies great opportunity”, Mr. Ye Delin suggests that the opportunity for the Chinese ceramic industry lies in the capability to transform it from “big” to “strong”, through innovation, quality and service. The gap between demand and supply has been growing day after day, generating a fierce competition, and the only successful strategy to beat it is to upgrade one’s brand reputation and product mix, and transforming the factories into green, sustainable, smart and efficient plants.

In this scenario, Uniceramics Expo, to be held from 30 May to 2 June in Foshan, will be the perfect chance to get a complete picture of the Chinese ceramic industry and seize new market opportunities. 5

根据中国建筑卫生陶 瓷协会提供的官方数 据,2022年中国瓷砖 行业产销均大幅下 降,扭转了前一年的 积极趋势。

在第23届中国瓷砖趋 势大会上,协会主席 缪斌先生证实,2022 年国内和出口市场对 瓷砖的需求均有所下 降,迫使制造企业将 产量控制在全国总装 机容量的60%以内。

事实上,尽管去年瓷 砖产能略有增加(从 123.3亿平方米增加 到125.6亿平方米), 但实际瓷砖产量却出 现了两位数的严重下 降,从82亿平方米下 降到不超过73亿平方 米,体现出该行业巨 大的产能过剩。

出口也不能扭转这种 情况,出口量连续第 七年下降,从6.01亿 平方米降至5.79亿平 方米(比2021年下降 3.7%)。

中国建筑卫生陶瓷协 会秘书长宫卫先生补

Follow us also on Social Networks. Daily updates! Search “Ceramic World Web” and “Tile Edizioni”

充说,在2020年至 2022年期间,约有115 家陶瓷企业,共275条 陶瓷生产线关闭。

新明珠集团总裁叶德 林先生表示,过去3年 是中国陶瓷行业最具 挑战性的3年,这表明 以人口和城市化为基 础的快速发展时代可 能已经结束。但是,叶 德林先生坚信“危机中 蕴藏着巨大的机遇”, 他认为中国陶瓷行业 的机遇在于通过创新、 质量和服务,实现从“ 大”向“强”的转变。 供需差距日益扩大,竞 争日趋激烈,唯一成功 的策略就是提升品牌 形象和产品组合,把工 厂改造成绿色、可持 续、智能、高效的工 厂。

在这种情况下,将于5 月30日至6月2日在佛 山举行的潭洲国际陶 瓷装备与材料展将是 全面了解中国陶瓷行 业并抓住新的市场机 遇的绝佳机会。 5

CWR CHINA 2023 7 editorial

www.CeramicWorldWeb.it

中国瓷砖行业对质量和可 持续发展进行投资

saCmi suPPlies

Continua+

teChnology for the new somany max Plant

Somany Ceramics, India’s second largest ceramic tile manufacturer with an installed capacity of more than 74 million sqm, is planning to start up its first line for the production of large highend slabs by the summer. Called Somany Max, this new industrial project is being carried out in partnership with Sacmi, which supplied Continua+ technology together with a cutting-edge dryer and kiln.

The line being installed at the Gujarat production facility, one of the ten owned by the Indian group, will consist of a highspeed PCR2000, a 58.8-metre ECP285 horizontal dryer designed to operate on zero fuel thanks to kiln heat recovery systems, and a 260.4-metre FCC295 kiln, a High Thermal Efficiency (HTE) model ready for the use of hydrogen in the fuel mix.

The Somany Max project is part of the Somany Ceramics Group’s efforts to position itself prominently in the high-added-value segment in both the domestic and international markets. The group’s management team led by Managing Director and CEO Abhishek Somany has been pursuing this goal through a major expansion in production capacity combined with this latest investment in new products, sizes and manufacturing technologies.

The new Somany Max factory will have a capacity of 4 million sqm/year and will produce 80x160 cm and 80x240 cm size slabs, as well as extra thick 80x320 cm worktops.

Somany’s choice of Sacmi pro-

cess technologies was based on the results delivered by the more than a dozen Continua+ lines installed in India in recent years. These plants have demonstrated a clear ability to combine high quality and performance with unmatched speed and fuel efficiency, a crucial competitiveness factor in this market.

SaCmi为印度陶企Somany 新 的max工厂提供Continua+ 技术

印度第二大瓷砖制造商 Somany Ceramics的装 机容量超过7400万平方 米,计划在夏季前启动第 一条生产大型高端陶瓷大 板生产线。这个名为 Somany Max的新工厂项 目是与Sacmi合作 的,Sacmi提供 Continua+技术以及尖端 的干燥器和窑炉。这条生 产线在古吉拉特邦安装, 这是Somany陶瓷集团拥 有的10条生产线之一,这 条全新的萨克米生产线, 由高速的PCR2000连续辊 压机,58.8米长的ECP285

卧式干燥器和一条260.4米 长的氢气式高热效(HTE)型 FCC295窑炉组成。

Somany Max项目是 Somany陶瓷集团努力在 国内和国际高附加值市场 中占据突出地位的具体表 现。由总经理兼首席执行 官Abhishek Somany领导 的集团管理团队一直在通 过大规模扩大生产能力以 及在新产品,尺寸和制造 技术方面的最新投资来实 现这一目标。

新的Somany Max工厂的 产能将达到400万平方 米/年,将生产80x160cm 和80x240cm尺寸的陶瓷 板材,以及80x320cm的 超厚台面。

Somany Max项目借鉴了 在印度的Sacmi Continua+解决方案的经 验(近年来已安装超过十 多条线)。这些工厂清晰 展示了将优质和高性能同 无与伦比的速度和燃料效 率相结合的能力,这是该 市场上至关重要的竞争力 因素。

Poppi Clementino, an Italian company specialized in energy saving solutions and heat recovery systems for the ceramic industry, is steadily growing its business on the Chinese ceramic market, where it has been establishing strong partnerships with the major manufacturing groups in the last years.

Poppi Clementino’s plants are now in fuction inside the tile factories of some of the biggest Chinese brands, five of which were awarded last year with the 10th China & Italy Ceramic Design Award, the competition co-organized by ACIMAC and Ceramic Town Weekly to strengthen the innovation cooperation between China and Italy of ceramic design, technology and manufacturing.

The five companies are: Foshan Gelaisi Ceramics Sales (Award of Gold), Foshan Golden Sun Ceramics Sales and Huiwanjia Ceramics (Award of Excellence), Guangdong Newpearl Ceram-

ics Group - Guanzhu Ceramics (Gold Award for Porcelain slabs), and Guangdong Mocolor Ceramics (Award of Advanced Technology).

PoPPi Clementino是中国主要 陶瓷企业的的合作伙伴

Poppi Clementino是一 家专门为陶瓷行业提供节 能解决方案和热回收系统 的意大利公司,其在中国 陶瓷市场的业务正在稳步 增长,过去几年,它一直 在与主要陶瓷生产集团建 立强有力的合作伙伴关 系。

Poppi Clementino的工 厂目前在一些中国最大的

陶瓷品牌的工厂内运作, 其中5家工厂去年获得了第 十届中国意大利陶瓷设计 大奖赛的奖项,这是一项 由意大利陶机协会 ACIMAC和陶城报联合主 办的比赛,旨在加强中意 在陶瓷设计、技术和制造 方面的创新合作。

五家陶瓷企业分别是:佛 山格莱斯陶瓷销售有限公 司(金奖)、佛山金朝阳 陶瓷销售有限公司和惠万 家瓷砖(优秀奖)、新明 珠集团股份有限公司—— 冠珠瓷砖(岩板金奖)、 广东蒙地卡罗陶瓷销售有 限公司(先进技术奖)。

CWR CHINA 2023 8

PoPPi Clementino is Partner of the major Chinese CeramiC tile ComPanies

Bongioanni maCChine: dies with Polyamide Coated Pressure heads for energy saving

A well designed die not only reduces clay consumption by optimising the size and weight of the clay bats but also eases the extrusion stresses that adversely affect the product drying process.

It is worth remembering that in order to form a tension-free bat, it is also necessary to use a suitable pressure head (clay accumulator) prior to the die.

The special self-lubricating polyamide coated HE pressure head from Bongioanni Stampi, a division of Bongioanni Macchine, guarantees a more uniform clay flow than the traditional steel pressure head, thereby resulting in significant energy savings.

The flowability of the raw material over steel surfaces is adversely affected by friction (heat generation = energy loss).

duravit india PurChases

seCond saCmi roBotglaze

Cell

Four years after adopting the first RobotGlaze unit which marked the conversion of the Ahmedabad plant to Sacmi’s robotized glazing technology, Duravit India has completed its investment with the installation of a second cell. The solution consists of a 4-position carousel served by a Sacmi-Gaiotto GA 2000 robot.

As with the previous supply, this machine has a simple and reliable configuration which further improves the level of automation at the German multinational’s Ahmedabad factory.

In addition to the perfect quality and repeatability of glaze application, RobotGlaze also facilitates circularity of the production

As the coefficient of friction of the polyamide coating covering the interior of the pressure head is significantly lower, much less heat will be generated (lower temperature = less energy loss).

Under the same extrusion conditions and using a suitable die, the use of the polyamide-coated pressure head guarantees a lower extrusion pressure.

This in turn results in lower energy consumption and a more uniform clay flow at any point in the die.

Bongioanni Macchine旗 下Bongioaanni Stampi 公司的特殊自润滑聚酰胺 涂层HE压头,与传统的钢 制压头相比,可确保粘土 流动更加均匀,从而显著 节约能源。

原料在钢表面上的流动性 受到摩擦的不利影响(热产

生=能量损失)。由于覆盖 压头内部的聚酰胺涂层的 摩擦系数明显降低,因此 产生的热量要少得多(温度 越低=能量损失越少)。

在相同的挤出条件下,使 用合适的模具,聚酰胺涂 层压头的使用保证了较低 的挤出压力。这反过来又 形成更低的能量消耗和在 模具中的任何一处更均匀 的粘土流动。

设计良好的模具不仅通过 优化粘土棒的尺寸和重量 来减少粘土消耗,而且还 减轻了对产品干燥过程产 生不利影响的挤出应力。 值得记住的是,为了形成 一个无张力的粘土棒,也

process thanks to spraying optimisation and the filter systems which allow for complete recovery of overspray.

This latest investment at the Indian production plant marks a new milestone in the global partnership between Duravit and Sacmi involving all the German group’s main factories in Europe, Asia and North Africa.

Duravit印度购买第二台 SaCmi roBotglaze设备

在采用第一台RobotGlaze 装置四年后,Duravit 印度 公司完成了投资,安装了 第二台设备。该解决方案 包括一个由Sacmi Gaiotto GA 2000机器人 提供服务的4位转盘。与之 前的供应一样,这台机器 具有简单可靠的配置,进

一步提高了德国跨国公司 印度艾哈迈达巴德工厂的 自动化水平。

除了完美的釉料质量和可 重复性外,RobotGlaze还

通过喷涂优化和过滤系统 促进了生产过程的循环, 从而可以完全回收过量釉 料。

这项对印度生产工厂的最 新投资标志着Duravit和 Sacmi之间全球合作关系 的一个新里程碑,该合作 关系涉及德国集团在欧 洲、亚洲和北非的所有主 要工厂。

world news

Bongioanni maCChine: 带有聚酰胺涂层压头的模 具,可节约能源”

有必要在模具之前使用一 个合适的压力头(粘土蓄能 器)。

CWR CHINA 2023 9

delta grouP adoPts industry 4.0 teChnologies from system CeramiCs

Delta Group, Brazil’s largest porcelain tile manufacturer and one of the leading ceramic tile producer in Latin America, has adopted Industry 4.0 technologies from System Ceramics (Coesia Group) as part of its programme to modernise its production processes. In keeping with its efforts to increase the level of digitalisation and automation of its lines, the Brazilian group has equipped its new plant in Rio Claro (São Paulo, Brazil), one of the most advanced anywhere in South America, with four Superfast mouldless presses that will guarantee a total production capacity of 66,000 sqm/day. The new presses will be used for the production of conventional tile sizes and will meet the required criteria of speed and flexibility, while also bringing significant advantages in terms of reduced energy consumption and raw material wastage given that a single Superfast

CerteCh grouP

Confirms its growth trend

Following a record 2021 performance (with consolidated turnover up 40% €52.6 million), Certech Group (Casalgrande, Reggio Emilia) closed the year 2022 with a further acceleration of its growth trend.

The group’s Italian companies (Certech SpA, Eurorubber Industries, Mistral Italia, Rubbertech and Vibrotech) reported consolidated revenues of €87.6 million (+66.5% on 2021), excluding the activity of the three foreign subsidiaries (Certech USA in Lebanon, Tennessee; Certech Spain in Onda, Castellón de la Plana; and Certech Mexico in Monterrey, Nuevo León).

As from this year, Certech Group’s consolidated turnover

press can achieve the same level of productivity as two conventional presses (up to 24,000 sqm/day). With this latest investment, Delta Group aims to expand its product portfolio and strengthen its position both in Brazil and in the United States, the group’s main export market. The presence of the System Brasil branch in Rio Claro will ensure rapid and efficient customer support.

Delta集团采用SyStem

CeramiCS的工业4.0技术

Delta集团是巴西最大的 瓷砖制造商,也是拉丁 美

洲领先的瓷砖生产商之 一,该集团采用了System Ceramics (隶属于Coesia 集团)的工业4.0技术, 作为其生产流程现代化计 划的一部分。为了努力提 高其生产线的数字化和自 动化水平,Delta集团在 巴西圣保罗里奥克拉鲁地 区修建了新工厂,这是南 美洲最先进的工厂之一, 拥有四台超高速无模压 力机,将保证总产能达到 66,000平方米/天。新压机 将用于生产传统尺寸的瓷

砖,并将满足所需的速度 和灵活性标准,同时在降 低能耗和原材料浪费方面 也带来了显著优势,因为 一台Superfast压机可以实 现与两台传统压机相同的 生产力水平(高达24000 平方米/天)。

通过这项最新投资, Delta 集团旨在扩大其产品组 合,并加强其在巴西和该 集团主要出口市场美国的 地位。System巴西里奥克 拉鲁分公司将确保快速高 效的客户支持。

will also include Novatech’s results, the new company founded at the end of 2022 to supply plants and machines for raw material treatment and processing both to the ceramic industry and to other manufacturing sectors. The Certech Group is a leader in the various fields in which its companies operate: the production of rubber compounds; wear-resistant rubber coatings for the ceramic industry; vibrating screens and iron removers; chemical additives for the ceramic industry; and machinery and spare parts for the wet grinding and glazing departments.

CerteCh集团2022年的增长 趋势进一步加快

继2021创纪录的业 绩(合并营业额增长

40%,达5260万欧元) 后,Certech 集团(坐落 于意大利雷焦艾米利亚省 Casalgrand地区)于2022 年的增长趋势进一步加快。 该集团旗下的意大利公司 (Certech SpA、Eurorubber Industries、Mistral Italia、Rubbertech和 Vibrotech)报告的合并 收入为8760万欧元(2021 年增长66.5%),不包括 三家外国子公司(Certech USA位于美国田纳西 州黎巴嫩;Certech-Spain位于西班牙卡斯特利 翁Onda地区;Certech

Mexico位于墨西哥新莱昂 州蒙特雷地区)的收入。 从今年起,Certech集 团的合并营业额还将包括 Novatech的业绩,这家 新公司成立于2022年底, 为陶瓷行业和其他制造业 提供原材料处理和加工的 工厂整线和设备。

Certech集团是其公司经 营的各个领域的领导者: 橡胶化合物的生产;陶瓷 工业用耐磨橡胶涂料;振 动筛和除铁器;陶瓷工业 用化学添加剂;以及湿法 研磨和施釉部门的机械和 备件。

CWR CHINA 2023 10 world news

India’s unstoppable growth

印度增长势不可挡

India is attracting a great deal of attention from all the major Western economies, and not just because it holds the presidency of this year’s G20. First and foremost, it is seen as the great hope for everyone who still believes in the possibility of uninterrupted global GDP growth, the locomotive that aspires to take on the role that had been China’s from the beginning of the millennium through to the Covid pandemic. And now that China is showing signs of a post-Covid rebound, we may be about to witness a fascinating dual between the two Asian giants and between two very different growth models, one free market based, the other state controlled.

According to IMF forecasts, the Indian economy is on course to grow by 6.1% this year and by 6.8% in 2024 and will outperform all other countries in terms of dynamism after overtaking China last year (by comparison, the IMF forecasts for the Chinese economy are for 5.2% GDP growth in 2023 and 5.2% in 2024). This macroeconomic scenario provides the context for the figures for the Indian ceramic industry collected by the MECS research centre and published in the report entitled “India, ceramic tile market”

The aim of this first-ever edition of the report is to offer an insider’s view of the market and to attempt to accurately measure Asia’s second-largest ceramic tile producer country as well as the world’s second-largest consumer and exporter. India is also the country with the fastest social and economic

印度吸引了所有主要西方经济体的极大关注,而不 仅仅是因为它担任今年 G20 峰会的主办国。首要的 是,印度被视为每个仍然相信全球GDP有可能持续 增长的人的巨大希望,是渴望承担从千年伊始到新 冠肺炎疫情期间中国所扮演的角色的火车头。现在, 中国正显示出疫情后反弹的迹象,我们可能会看到 这两个亚洲巨头之间以及两种截然不同的增长模式 之间的极具吸引的双重性,一种是基于自由市场的, 另一种是国家控制的。

根据国际货币基金组织的预测,印度经济今年将增 长6.1%,2024年将增长6.8%,在去年增幅超过中国 后,印度经济活力将超过所有其他国家(相比之下, 国际货币基金会对中国经济的预测是2023年GDP 增长5.2%和2024年增长5.2%)。这一宏观经济形势 被MECS研究中心收集的印度陶瓷行业数据提供了 背景,并发表在题为“印度,瓷砖市场”的报告中。 首次发布该报告的目的是提供业内人士对市场的看 法,并试图准确衡量这个亚洲第二大瓷砖生产国以 及世界第二大消费国和出口国。印度也是社会和经 济增长最快的国家(几个月前,它超过中国成为世界

Source: India, ceramictile market, MECS, 2023

CWR CHINA 2023 12

6 15 52 212 380 22 0 50 100 150 200 250 300 350 400 Before 1980 1980-1990 1991-2000 2001-2010 2011-2020 After 2021 Incorporation date of Indian ceramic tile companies 614

Source: India, ceramictile market, MECS, 2023

Ilaria Vesentini, MECS-Acimac (Modena, Italy)

growth (a few months ago it surpassed China as the world’s most populous nation), two key factors behind the projections of large growth margins in public and private construction and infrastructure and consequently in the consumption of building materials, including ceramic tiles. The government led by Prime Minister Narendra Modi has also announced a series of plans and policies aimed at encouraging the kind of investment that could truly transform India into the world’s manufacturing powerhouse in most production sectors, including ceramics, within a decade. This in turn will enable India to rapidly scale the rankings of leading tile exporter countries (it is already the third largest tile exporter with exports totalling half a billion square metres and an exponential growth trend)

❱ The study

The analysis of the figures and companies in the Indian ceramic tile industry involved an eight-month-long study, for which purpose the MECS-Acimac research centre recruited a junior Indian economist and collaborated with tile producers in the Morbi district (in Gujarat, India’s westernmost state), the world’s second largest ceramic cluster and home to 95% of India’s ceramic tile producers. Questionnaires were sent to more than 800 Indian ceramic tile companies and over 500 responded, allowing the researchers to calculate the industry’s total production capacity with an unprecedented level of accuracy as 3.3 billion square metres.

上人口最多的国家),这是 公共和私人建筑和基础设 施 以及包括瓷砖在内的建筑材料消费 大幅增长 的预 测背后的两个关键因素。

印度总理纳伦德拉·莫迪(Narendra Modi)领导 的政府还宣布了一系列计划和政策,旨在鼓励投资, 使印度在十年内真正成为包括陶瓷在内的大多数生 产部门的世界制造业强国。这反过来将使印度能够 迅速提升其作为主要瓷砖出口国的排名(印度已经 是第三大瓷砖出口国,出口总量为5亿平方米,并呈 指数级增长趋势)。

❱ 研究内容

由于对印度瓷砖行业的数据和公司进行为期八个月 的研究分析,MECS-Acimac研究中心招募了一名 年轻印度经济学家,并与 莫尔比产区(在印度最西部 的古吉拉特邦)的瓷砖生产厂家合作。莫尔比产区 是世界第二大陶瓷集群,印度95%的瓷砖生产厂家都 在这里。调查问卷被发送给了800多家印度瓷砖公 司,500多家公司做出了回应,使研究人员能够以前 所未有的精度计算出该行业的总产能,达到33亿平 方米。

CWR CHINA 2023 13 economics

The other 300 companies that did not answer the questionnaire are mostly small businesses, so assuming that they each have a minimum production of 1 million square metres of tiles, the total production capacity for the Indian ceramic industry is already in excess of 3.7 billion square metres. Estimating the subcontracting rate conservatively as 10% and considering that Indian ceramic tile factories operated at 70% of their capacity in 2021 (due to macroeconomic difficulties such as Covid, energy prices, inflation and the slowdown in consumption, all of which are discussed in detail in the report) gives a figure of 2.5 billion square metres for tile production in 2021. This value is much higher than the figures that have been reported to date, but is far more plausible and confirms the country’s ranking as the world’s second largest producer.

The report would not have been possible without the patient and proactive cooperation of the Gujarat business leaders, who assisted the Italian research centre not only in collecting accurate data but also in analysing the business and process dynamics that occur within the cluster, which are very different from those found in Western or Chinese industries. In Morbi, companies are set up (and merged, demerged and shut down) at a very rapid pace, often by members of the same family. The business community exchanges orders on WhatsApp so that none are ever left unfulfilled, which makes the production system highly fluid and flexible but also very difficult to analyse

The report “India, ceramic tile market” begins with a general overview of the Indian economy, the construction industry and the factors driving demand for ceramic tiles, then goes on to examine the distinctive features of this manufacturing system, which has so far been totally impervious to the entry of western players. Apart from Rak Ceramics, there are no well-known foreign tile brands operating locally in India and there is very little foreign investment, but this too is a situation that is bound to change in the coming years.

The Indian tile industry entirely meets the country’s needs and a few years ago also began exporting its surplus output. Based on the responses of leading Indian players, export share is estimated to have already reached 25% of total production and will soon exceed 30% following dramatic growth in the last decade that has seen exports increase by a factor of 15, from just over 33 million sqm in 2012 to more than 483 million

其他300家没有回答问卷的公司大多是小企业,因 此假设它们各自的瓷砖最低产量为100万平方米,印 度陶瓷行业的总产能已经超过37亿平方米。保守估 计外包率为10%,并考虑到2021印度瓷砖厂的产量 为其产能的70%(由于宏观经济困难,如新冠肺炎、 能源价格、通货膨胀和消费放缓,所有这些都在报 告中详细讨论),得出 2021瓷砖生产的数字为25亿 平方米。这一数值远高于迄今为止报告的数字,但更 为可信,并证实了印度作为世界第二大生产国的地 位。

如果没有古吉拉特邦商业领袖的耐心和积极合作, 这份报告是不可能完成的。他们不仅协助意大利研 究中心收集准确的数据,还协助分析陶瓷产业集群 内发生的业务和流程动态,这与西方或中国行业的 情况大不相同。在莫尔比产区,公司的成立(以及合 并、分拆和关闭)速度非常快,通常是由同一家族的 成员组建的 。业界在WhatsApp上交易订单,这样 就不会有任何订单未完成,这使得 生产系统具有高 度的流动性和灵活性,但也很难进行分析。

《印度,瓷砖市场》报告首先对印度经济、建筑业和 推动瓷砖需求的因素进行了总体概述,然后考察了 这种制造体系的独特特征,迄今为止,这种制造体 系完全不受西方企业的影响。除了Rak Ceramics 一家企业,印度当地没有知名的外国瓷砖品牌,外 国投资也很少,但这种情况在未来几年也必然会改 变。

印度的瓷砖行业完全满足了该国的需求,几年前也 开始出口其剩余产量。根据印度主要参与者的反馈, 出口份额估计已经达到总产量的25%,并将很快超 过30% 。在过去十年中,出口增长了15倍,从2012年 的3300多万平方米增加到2021的4.83亿平方米。这 在很大程度上将取决于国内建筑市场的活力。

CWR CHINA 2023 14

economics

Source: India, ceramictile market, MECS, 2023

Source: India, ceramictile market, MECS, 2023

sqm in 2021. Much will depend on the dynamism of the domestic construction market.

The second part of the report contains data sheets for individual companies based on large quantities of homogeneous data and includes a more detailed focus on the leading groups such as Kajaria, Millennium Vitrified Tiles, Lorison Tiles, Somany Ceramics, Prism Johnson, Varmora and Simpolo, to name just a few. The MECS research centre’s databases also contain other information (albeit with insufficiently wide and homogeneous coverage to be included in the 800 company data sheets), especially regarding the technology suppliers and individual companies’ exports.

❱ A very young and fragmented sector

A more detailed analysis of the specific characteristics of the Indian ceramic tile industry reveals that it is a very young industry made up of small businesses. Eight out of ten companies were founded after 2000, more than half (55%) were founded in the last ten years, and only six companies have more than 40 consecutive years of activity behind them.

In terms of size, seven out of ten ceramic companies have an average annual turnover of less than €10 million and almost half (46.5%) less than €5 million.

❱ Forecasts

Up until 2021, production increased at a rate that would be unthinkable in the west, doubling since 2012 and maintaining a CAGR (compound annual growth rate) of 8.6%. In 2022, growth is estimated to have slowed slightly due to soaring energy costs, which forced several Gujarat producers to turn off their kilns for several months. However, the industry has more than 900 increasingly large and efficient production lines, corroborating the MECS research centre’s forecast that India will reach a production volume of more than 3.7 billion sqm by 2026, thereby maintaining a year-on-year growth rate of close to 8%. Domestic demand absorbs about 70% of this output, while exports are set to exceed 1 billion square metres (double the 2021 figure, see the report entitled “Ceramic tile market, Forecast analysis, trend 2022-2026”). 5

报告的第二部分 包含了基于大量同类数据 的 公司数据表 ,并更详细地关注了头部陶瓷 集团,如Kajaria、Millennium Vitalized Tiles、Lorison Tiles、Somany Ceramics、Prism Johnson、Varmora和Simpolo等。MECS研究中 心的数据库还包含其他信息(尽管800家公司的数 据表的覆盖范围不够广泛并单一),尤其是关于技 术供应商和个别公司出口的信息。

❱ 一个非常年轻且分散的行业

对印度瓷砖行业的具体特征进行更详细的分析 表明,这是一个由小企业组成的非常年轻的行 业。80%的公司成立于2000年之后,超过一半 (55%)的公司是在过去十年内成立的,只有六家 公司的活动连续40年以上。

就规模而言,70%的陶瓷公司的平均年营业额低 于1000万欧元,几乎一半(46.5%)低于500万欧 元。

❱ 预测

直到2021,印度瓷砖产量增长的速度是西方世界难 以想象的,自2012年以来翻了一番,复合年增长率 (CAGR)保持在8.6%。2022年,由于能源成本飙 升,增长预计略有放缓,这迫使古吉拉特邦的几家 生产厂家关停窑炉数月。然而,行业拥有900多条 规模越来越大,效率越来越高的生产线,这证实了 MECS研究中心的预测,即到2026年,印度的产量 将超过37亿平方米,从而保持接近8%的同比增长 率。国内需求约占该产量的70%,而出口预计将超 过10亿平方米(是2021数字的两倍,见题为“瓷砖 市场,预测分析,2022-2026年趋势”的报告)。 5

CWR CHINA 2023 15

Indian ceramic tile exports (million sqm) 33,2 55,3 102,4 134,0 185,7 227,6 274,0 358,7 436,7 483.1 0,0 100,0 200,0 300,0 400,0 500,0 600,0 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 x15

Source: India, ceramictile market, MECS, 2023

Source: India, ceramictile market, MECS, 2023

RAK Ceramics announces strong growth in FY 2022

RAK Ceramics (Ras Al Khaimah, UAE), one of the largest ceramics lifestyle solutions providers in the world, closed the fiscal year ended 31 December 2022 with record high full year performance.

Total revenue increased by 22.9% YOY to AED 3.52 billion (approx. €900 million), reaching the highest level since 2009. It was driven by robust core business growth in Tiles (AED 2.17 billion, approx. €554 million, up 11.0% on 2021), Sanitaryware (AED 551.0 million, approx. €140 million, up 4.1%), and Tableware (AED 353.2 million, up 38.9%), in addition to growth in Faucets on the back of Kludi consolidation since transaction closing on 1 June 2022 (+AED 276.5 million).

The revenue from other non-core units saw a growth of 25.4% to AED 139.2 million, driven mainly by the company’s ceramic raw material trading business. The Ras-Al-Khaimah Group also achieved very positive results in terms of profitability.

Total EBITDA increased by 15.1% to AED 577.2 million (approx. €147 million), and reported net profit increased by 19.8% to AED 340.1 million (approx. €87 million), an all-time record high performance in the history of the company.

“Notwithstanding the current macro-economic conditions marked by high inflation and persistent energy crisis, we have managed to achieve remarkable results,” Abdallah Massaad, Group CEO, RAK Ceramics commented. “We have managed to maintain our gross profit margin level at 36.1%, mainly due to our improved production efficiencies and optimized utilization in 2022. Growth was hindered by further costs associated with Saudi Custom Duty, higher input costs and energy challenges; nonetheless, we are working hard to overcome these challenges and are already seeing hints of correction in some instances.”

As far as the Tile and Sanitaryware divisions are con-

RAK Ceramics(阿联酋,哈伊马角)是世 界上最大的陶瓷生活方式解决方案提供 商之一,在截至2022年12月31日的财年 中,全年业绩创历史新高。总收入同比增 长22.9%,达到35.2亿迪拉姆(约9亿欧 元),达到2009年以来的最高水平。这主 要得益于瓷砖(21.7亿迪拉姆,约5.54亿 欧元,2021增长11.0%)、卫生洁具(5.51 亿迪拉姆斯,约1.4亿欧元,增长4.1%)和 餐具(3.532亿迪拉姆特,增长38.9%)的 强劲核心业务增长,此外,自2022年6月1日交易结 束以来,由于与Kludi合并,水龙头(+2.765亿迪拉 姆士)也有所增长。其他非核心部门的收入增长了 25.4%,达到1.392亿迪拉姆,主要受公司陶瓷原材 料贸易业务的推动。

哈伊马角陶瓷集团在盈利方面也取得了非常积极 的结果。息税折旧摊销前利润总额增长15.1% ,达 到5.772亿迪拉姆(约1.47亿欧元),净利润增长 19.8%,达到3.401亿迪拉姆,创下公司历史新高。

RAK陶瓷集团首席执行 官Abdallah Massaad 表示:“尽管目前的宏观 经济状况以高通胀和持 续的能源危机为标志,但 我们还是取得了显著的成 果。”。“我们成功地将 毛利率水平维持在36.1% ,这主要是由于我们在 2022年提高了生产效率 和优化了利用率。增长受 到沙特提高关税、更高的 投入成本和能源挑战的阻 碍;尽管如此,我们正在 努力克服这些挑战,在某 些情况下已经看到了恢复 的迹象。”

CWR CHINA 2023 16

Abdallah Massaad

RAK Ceramics宣布2022 财年实现强劲增长

cerned, in the UAE, revenue increased by 19.7% in 2022. The strong performance was bolstered by solid market fundamentals. Retail expansion, launch of e-commerce, increased participation in international fairs, among other initiatives, resulted in further brand visibility and strengthened positioning.

In Saudi Arabia, revenue grew by 9.0%, driven by growth in retail and projects despite the 12% custom duty charges. The focus remains on offering premium products, securing mega projects and expanding the retail footprint.

In Europe, revenue increased by 3.5% (or by 14.5% in local currency). Given the slowdown in economic activity and albeit the applied price increases in 2022, the macroeconomic pressure weighed in on bottom-line performance; Q4 2022 financials, however, saw signs of relief, enabled by correction in exchange rates and decrease in freight rates.

In India, RAK Ceramics reported a revenue growth of 2.9% (or 9.3% in local currency). Efforts were maintained in expanding distributors’ network and increasing retail presence via showroom openings. The performance remained solid, driven by growth in the top line and improved efficiencies, although hindered by rising input and energy costs.

In Bangladesh, revenue recorded a slight drop of 1.2%. The macroeconomic challenges and the currency devaluation impacted top line growth, as revenue is seen increasing by 8.8% YoY in local currency. Gas supply shortages experienced from 17 September to 7 December 2022 caused production disruptions, weighing in further on its bottom-line performance. In the Middle East (excluding UAE and KSA), revenue increased by 22.2% mainly due to the increase in brand exposure and growth in distribution network.

❱ Expansionary projects

Operationally, RAK Ceramics continued to progress in its expansionary projects both in the UAE and on multiple greenfield fronts in Bangladesh (for tiles and faucets) and in Saudi Arabia (for tiles).

In the UAE, the tiles enhancement project is in progress and production is set to begin in Q1 2023 for 5 million square metres of porcelain tiles. The sanitaryware capacity enhancement has also been completed and production has commenced, with full utilization of additional capacity (260,000 pieces) planned to be reached by Q3 2023. The tableware capacity expansion of an additional 10 million pieces is still underway, with commercial production estimated for Q3 2023. ✕

瓷砖和卫生洁具的市场结果在阿联酋,2022年的收入 增长了19.7% 。强劲的表现得益于稳固的市场基本面。 零售业的扩张、电子商务的推出、对国际博览会的更 多参与等举措,进一步提高了品牌知名度并加强了定 位。

在沙特阿拉伯,尽管征收了12%的关税,但由于零售和 工程项目的增长,收入增长了9.0% 。重点关注仍然是 提供优质产品、确保大型项目和扩大零售范围。 在欧洲,收入增长了3.5%(以当地货币计算增长了 14.5%)。鉴于经济活动放缓,尽管2022年出现了价格 上涨,但宏观经济压力影响了盈利表现;然而,由于汇 率调整和运费下降,2022年第四季度的财务状况出现 了缓解迹象。

在印度,RAK 陶瓷的 收入增长了2.9%(以当地货币计 算为9.3%)。通过设立展厅,继续努力扩大经销商网 络和增加零售业务。尽管受到投入和能源成本上升的 阻碍,但受利润增长和效率提高的推动,业绩保持稳 定。

在孟加拉国,收入略有下降1.2% 。宏观经济挑战和货 币贬值影响了利润增长,以当地货币计算,收入同比增 长8.8%。2022年9月17日至12月7日期间出现的天然气 供应短缺导致生产中断,进一步影响了盈利表现。

在中东地区(不包括阿联酋和沙特阿拉伯),收入增长 了22.2%,主要原因是品牌曝光度的增加和分销网络 的增长。

❱ 扩建项目

在运营方面,RAK陶瓷在阿联酋、孟加拉国(瓷砖和水 龙头)和沙特阿拉伯(瓷砖)的多个绿色开发区的扩张 性项目继续取得进展。

在阿联酋,瓷砖扩建项目正在进行中,预计将于2023 年第一季度开始生产500万平方米的瓷砖。卫生洁具产 能的提升也已完成,并已投产,计划在2023年第三季 度前充分利用额外产能(26万件)。新增1000万件餐 具的产能扩建仍在进行中,预计2023年第三季度将实 现商业化生产。 ✕

CWR CHINA 2023 17 economics

Despite the problems caused by spiralling costs, in 2022 the Italian ceramic tile industry succeeded in maintaining its production, sales and export volumes stable at the previous year’s levels.

According to the preliminary end-of-year results compiled by Prometeia and presented by Confindustria Ceramica in December, Italy produced about 448 million square metres of ceramic tiles in 2022, up 3% on the previous year, while total sales amounted to around 458 million sqm (up 0.7% on 2021 and 13% on 2019). Some 364 million sqm of this output was exported (+0.2%) and more than 93 million sqm was sold on the domestic market (+2.6%)

The Italian market accounted for 20% of the total share, while 48% was sold in EU markets and 32% in non-EU markets. Sales increased in the Gulf region and the Far East, remained stable in Western Europe, the Balkans and Latin America, and contracted in Eastern Europe and NAFTA.

The increase in selling prices introduced to compensate for the higher overall production costs pushed total sales revenues up 16.4% to around €7.2 billion compared to €6.2 billion in 2021 . The average overall selling price rose from 13.5 €/sqm to about 15.7 €/sqm and the export price from 14.3 €/sqm to 16.7 €/sqm.

The biggest challenge faced by the Italian ceramic tile industry in 2022 in terms of costs was without question the soaring

尽管成本不断攀升造成了问题,但在2022年,意大利 瓷砖行业成功地将其生产、销售和出口量稳定在前一 年的水平。

根据Prometeia汇编并由意大利陶瓷工业联盟 Confindustria Ceramica于12月公布的初步结果, 意大利2022年生产了约4.48亿平方米的瓷砖,与上一 年相比增长3%,总销售额约为4.58亿平方米(比2021 年增长0.7%,比2019年增长13%)。其中出口约占3.64 亿平方米(比去年增加0.2%),在国内市场销售超过 9300万平方米(比去年增加2.6%)。

意大利市场占总份额的20%,欧盟市场占48%,非欧盟 市场占32%。海湾地区和远东地区的销量有所增长, 西欧、巴尔干半岛和拉丁美洲的销量保持稳定,东欧 和北美自由贸易协定的销量有所下降。

销售价格的上涨弥补了整体生产成本的上涨,使 总销 售收入从2021的62亿欧元增至72亿欧元左右,增长了 16.4%。整体平均售价从13.5欧元/平方米上升至15.7 欧元/平方平方米左右,出口价格从14.3欧元/平方米上 升至16.7欧元/平米。

就成本而言,2022年意大利瓷砖行业面临的最大挑

CWR CHINA 2023 18

Lea Ceramiche

La Fabbrica

Paola Giacomini - p.giacomini@tiledizioni.it

意大利瓷砖行业在2022年经受住了考验

The Italian ceramic tile industry weathers the storm in 2022

energy prices, which according to Confindustria Ceramica’s calculations placed an extra cost burden on the sector’s companies of more than €1 billion for the thermal energy component alone. These higher costs were offset not only by price adjustments but also by government incentives in the form of energy and gas tax credits.

Confindustria Ceramica chairman Giovanni Savorani gave us a more detailed analysis of the sector’s mood and state of health.

CWR: Mr Savorani, was 2022 on the whole a better or worse year than you had expected?

GIOVANNI SAVORANI: Based on the figures, it is clear that the results were better than we might have anticipated a year ago, when the outbreak of the war in Ukraine had raised fears of a far more critical scenario. Many things played out more positively than expected. Despite all the difficulties and soaring costs, we were able to rapidly replace Ukrainian raw materials without sacrificing quality. Moreover, market demand remained strong at least for the first half of the year, despite a more than 16% increase in our selling prices.

CWR: Even allowing for the increase in revenue generated by the higher selling prices, in 2022 you maintained the record 2021 results driven by the post-Covid recovery.

战无疑是能源价格的飙升,根据意大利陶瓷工业联盟 Confindustria Ceramica的计算,仅热能部分就给

意大利陶瓷企业带来了超过10亿欧元的额外成本负 担。这些更高的成本不仅被产品销售价格的调整所抵 消,还被政府实施的能源和天然气税收抵免激励措施 所抵消。

意大利陶瓷工业联盟Confindustria Ceramica主席 Giovanni Savorani对该行业的氛围和健康状况进行 了更详细的分析。

CWR:Savorani先生,2022年总的来说是比你预期 的好还是差?

Savorani:根据2022年的生产和销售数据,很明显 结果比我们一年前预期的要好,当时俄乌战争的爆发 引发了人们对更危急情况的担忧。许多事情的结果比 预期的要积极。尽管困难重重并成本飙升,但我们能 够在不牺牲质量的情况下迅速找到替换乌克兰的原材 料。此外,尽管我们的售价上涨了16%以上,但至少在 今年上半年,市场需求仍然强劲。

Talking to...

CWR CHINA 2023 19

Giovanni Savorani

TAB. 1 - THE ITALIAN CERAMIC TILE INDUSTRY 2016 2017 2018 2019 2020 2021 Var. 2021/2020 2022 Forecasts Production (mill. m2)) 415.9 422.5 415.5 400.7 344.3 435.3 +26.1% 448.0 (+3%) Total sales (mill. m2) 414.6 421.9 410.1 406.9 391 455.3 +16.4% 458.3 (+0.7%) - Domestic sales (mill. m2) 82.9 83.7 82.4 83.5 73.3 91.2 +24.4% 93.5 (+2.6%) - Exports (mill. m2) 331.7 338.2 327.7 323.4 317.7 364.1 +14.6% 364.8 (+0.2%) Total Turnover (mill. €) 5,417.1 5,546.5 5,380.9 5,341.3 5,132 6,166 +20.1% 7,177 (+16.4%) - Domestic sales (mill. €) 828.8 842.4 834.0 832.0 720.0 967 +34.3% 1,085 (+12.2%) - Exports (mill. €) 4,588.3 4,704.1 4,546.9 4,509.3 4,410 5,199 +17.9% 6,092 (+17.2%) economics

G. SAVORANI: That’s right. Volume figures for production, sales and exports were all above the 2019 pre-Covid levels.

CWR: The resilience of exports also demonstrates that Italian products continue to be appreciated in the high-end markets. Does this mean that your policy of offering high quality products and services pays off?

G. SAVORANI: Definitely. Over the years, we have always highlighted just how much it costs in terms of investments to maintain a leadership position. It requires continuous innovation of products and their applications, a constant increase in the value of products, and a level of service that fulfils customers’ expectations, which over the past year has above all meant guaranteeing supplies. In a scenario in which all global producers have had to pass their higher production costs on to the market, having a high value-added product to start with has made this less problematical, at least in some markets. Overall, Italy has managed to keep the increase in its average export selling price to just 2.4 €/sqm (from 14.3 to 16.7 €/sqm), a smaller rise than many of its competitors. This has enabled us to maintain our shares and even strengthen our position in some European markets as well as in the Far East and the Gulf region. In other areas, this has simply not been possible.

CWR: Are you referring to the US market?

G. SAVORANI: Specifically, yes. Last year, our exports by volumes to the USA fell by about 2.8% compared to the overall 2% decrease in tile imports into the country according to the latest data from the US Department of Commerce. Although we performed better than other European competitors, the US market is seeing a surge in local production (partly controlled by Italian groups) and an increase in imports from neighbouring Mexico and even more significantly from India, which is gradually taking over the position formerly occupied by China.

CWR: Are the risks the same?

G. SAVORANI: That remains to be seen.

CWR: Regarding this, would you say that the EU has been sufficiently proactive in applying anti-dumping duties on Indian products?

G. SAVORANI: The European Commission gave final approval for these duties at the beginning of February for a period of five years. But I think that their real impact on the market will be virtually non-existent as we are talking about duties of between 6.7% and 8.7% on products that cost just over €3 per square metre. What does surprise me is the difference in treatment towards imports from Turkey which are also subject to duties, in some cases as high as 20.9%.

CWR: Let’s return to your results. Last year’s strong performance was the combination of an excellent first half of the year and a second half that was clearly impacted by the slowdown in global demand. Are there fears that this negative phase will become even more acute or long term?

G. SAVORANI: Not really, or at least the indications don’t appear to be so alarming. For sure, global demand

CWR:即使考虑到较高的销售价格带来的收入增长,在 2022年意大利仍保持了在疫情后复苏推动下的2021年 创下的业绩记录。

G.Savorani:没错。生产、销售和出口的数量数字均高 于2019年疫情前水平。

CWR:出口的弹性也表明意大利产品在高端市场上继 续受到赞赏。这是否意味着你们提供高质量产品和服务 的策略得到了回报?

G.Savorani:当然。多年来我们一直强调需要多少投资 来保持领导地位。它需要产品及其应用的不断创新,产 品价值的不断提高,以及满足客户期望的服务水平。要 做到以上这些,这意味着我们在过去的一年里首先要保 证供应。在所有全球生产商都不得不将更高的生产成 本转嫁给市场的情况下,至少在一些市场上,拥有高附 加值的产品一开始就减少这一问题。总的来说,意大利 成功地将其平均出口售价的涨幅保持在2.4欧元/平方 米(从14.3欧元/平方米升到16.7欧元/平方平方米),这 一涨幅要低于许多竞争对手。这使我们能够保持我们的 份额,甚至提高我们在一些欧洲市场以及远东和海湾 地区的地位。在其他领域,这根本不可能。

CWR:你指的是美国市场吗?

G.Savorani:具体来说,是的。根据美国商务部的最新 数据,去年,我们对美国的出口量下降了约2.8%,而对 美国的瓷砖进口量总体下降了2%。尽管我们的表现比 其他欧洲竞争对手好,但美国本土市场的瓷砖产量激增 (部分工厂隶属于意大利集团),从邻国墨西哥的进口 增加,从印度的进口增加更为显著,印度正在逐步取代 以前由中国占据的地位。

CWR:风险相同吗?

G.Savorani:这还有待观察,如果2022年印度对美国 的进口量增长30%,我不会感到惊讶,那么这将会是奥 兰多举行的Coverings展览上最大的话题之一。

CWR:关于这一点,你会说欧盟在对印度产品征收反倾 销税已经做得足够积极了?

G.Savorani:欧盟委员会于2月 初最终批准了这些关税,为期五 年。但我认为它们对市场的真正 影响几乎不存在,因为我们谈论 的是对每平方米价格略高于3欧 元的产品征收6.7%至8.7%的关 税。令我惊讶的是,从土耳其进 口的产品本来在待遇上是存在差 异的,但也要缴纳关税,在某些 情况下高达20.9%。

CWR:让我们回到你的结果上 来。去年的强劲表现是上半年表 现出色,下半年明显受到全球需 求放缓的影响。是否有人担心这

CWR CHINA 2023 20

ABK

has contracted in general compared to a year ago, mainly due to rising inflation and the consequent slowdown in consumption that has impacted almost all economies. But as I mentioned earlier, this contraction has merely brought supply and demand back to the 2019 pre-Covid levels. According to several of our industry’s business leaders, the slowdown may continue until June followed by a return to a state of normality. In the meantime, companies that had emptied their warehouses are now replenishing them, while good levels of orders have been maintained in the first two months of 2023.

CWR: Are large size tiles and slabs continuing to play a key role?

G. SAVORANI: Absolutely. They are amongst the most prestigious of all high-end Italian products, and at a time of soaring production costs companies have wherever possible increased their output of products with greater added value and higher margins compared to more traditional product ranges that would have been less competitive.

CWR: So after overcoming the Covid crisis, would you say the Italian ceramic tile industry has also weathered the storm caused by spiralling costs?

G. SAVORANI: Yes, at least based on the industry’s overall figures. However, we must bear in mind that our industry is made up of companies of very different sizes – small, medium, large and very large – and they have not all had the same resources available to respond to such a severe threat to profitability. We will need to see the balance sheets to discover just how much companies’ margins have been squeezed. One factor that has really made a difference is whether or not companies had access to gas supply contracts with locked-in prices. In this connection, we mustn’t forget the importance of the Italian government’s support for energy-intensive companies in the form of energy and gas tax credits, particularly in terms of protecting jobs. In the Spanish district of Castellón, which did not have access to similar incentives, more than a thousand workers have already lost their jobs and thousands more have been temporarily laid off. Bear in mind that the cost of gas has risen much more in Europe than in the rest of the world, widening the competitive gap with respect to non-European companies.

CWR: On the subject of gas, for months now the Italian ceramic industry has been urging the government to increase the use of national resources.

G. SAVORANI: In Italy the energy crisis requires above all structural measures, such as allocating a higher share of domestic natural gas to gas-intensive sectors. It is to be hoped, however, that the prices will be proportionate to extraction costs and not (as appears to be the policy) set on the basis of TTF prices.

This would have the additional benefit of immediately reducing CO2 emissions associated with gas imports and would allow companies in non-electrifiable sectors to maximise their investments in production process decarbonisation. ✕

种消极阶段会变得更加严重或长期消极? G.Savorani:并不完全如此,或者至少这些迹象看起 来没有那么令人担忧。可以肯定的是,与一年前相比, 全球需求总体上有所收缩,主要是由于通货膨胀加剧和 随之而来的消费放缓,几乎所有经济体都受到了影响。 但正如我早些时候提到的那样,这种收缩只不过将供 应和需求带回了2019年疫情前水平。根据我们行业的 几位企业家的看法,经济放缓可能会持续到6月,然后 恢复正常状态。与此同时,已经清空库存的公司现在正 在补充库存,而2023年前两个月的订单保持在良好水 平。

CWR:大尺寸瓷砖和陶瓷板是否继续发挥关键作用? G.Savorani:当然。它们是意大利所有高端产品中最 负盛名的产品之一,在生产成本飙升的时候,公司尽可 能增加产品产量,这些产品具有更高的附加值和更高的 利润率,而不是那些竞争力较弱的传统产品系列。 CWR:那么,在克服了新冠疫情危机之后,你是否认为 意大利瓷砖行业也经受住了成本飙升带来的一系列问 题?

G.Savorani:是的,至少从行业的总体数据来看是这 样。然而,我们必须记住,我们的行业是由规模非常不 同的公司——小型、中型、大型和超大型公司——组 成的,它们并没有相同的资源来应对盈利能力这种严 重的威胁。我们需要查看企业的资产负债表,才能发 现他们的利润率受到多大程度的挤压。真正产生影响 的一个因素是,公司是否能够获得价格锁定的天然气 供应合同。在这方面,我们不能忘记意大利政府以能 源和天然气税收抵免的形式支持能源密集型公司的重 要性,特别是在保护就业方面。在西班牙卡斯特利翁 产区,由于没有获得类似的激励措施,已有1000多名 工人失业,另有数千人被暂时解雇。请记住,欧洲的天 然气成本上涨幅度远高于世界其他地区,这扩大了与 非欧洲企业的竞争差距。

CWR:在天然气问题上,几个月来,意大利陶瓷行业一 直在敦促政府增加国家资源的 利用。

G.Savorani:在意大利,能源

危机首先需要采取结构性措 施,例如将国内更高份额的天然 气分配给天然气密集型行业。 然而,希望价格与开采成本成比 例,而不是(正如政策所示)基 于TTF价格制定。

这将带来立即减少与天然气进 口相关的二氧化碳排放的额外 好处,并使非电气化行业的公司 能够最大限度地提高对生产过 程脱碳的投资。

✕

economics CWR CHINA 2022 21

Flaviker

World sanitaryware exports and imports

Luca Baraldi, MECS / Acimac Research Dept. (l.baraldi@mecs.org)

World ceramic sanitaryware import/export flows grew by 81% from 2.16 million to 3.9 million tonnes over the period 20102021, corresponding to a compound annual growth rate of 5.6%. The positive trend that lasted for almost the entire decade (with the sole exception of 2020 due to the pandemic) was further strengthened by the strong recovery in exports observed in all geographical areas of production and in the largest exporting countries in 2021 (+16.5% on 2020)

Asia further consolidated its position as the world’s largest sanitaryware exporter, increasing its share of world exports to 64.6% thanks to 19% growth to 2.5 million tonnes. This development was the combined result of rebounds experienced by all the major Asian exporters, namely China, India, Thailand, Vietnam and Iran.

Exports from the European Union , the world’s second largest exporter, also grew by 13% to 552,000 tonnes. Poland, Germany and Portugal, the three largest sanitaryware exporters in the EUaccounting for almost half of total EU exports, increased their exports by between 10.5% and 26%.

Exports from North America (NAFTA) remained in positive territory (379,000 tonnes, up 2.9% on 2020), despite the de-

2010年至2021年期间,世界陶瓷卫生洁具进出口流 量从216万吨增长到 390万吨,增长了81%,复合年

增长率为5.6%。这一积极趋势几乎持续了整个十年 (2020年因疫情影响除外),所有卫生洁具产地和最 大出口国的出口在2021年强劲复苏(比2020年增长 16.5%),进一步加强了这一趋势。

亚洲 进一步巩固了其作为世界最大卫生洁具出口国 的地位,增长了19%至250万吨,占世界出口的份额 增加到64.6%。这一发展是所有亚洲主要出口国,即 中国、印度、泰国、越南和伊朗均出现反弹的综合结 果。

世界第二大出口国 欧盟 的出口量也增长了13%,达到 55.2万吨。波兰、德国和葡萄牙是欧盟最大的三个卫 生洁具出口国,占欧盟总出口量的近一半,出口量增 长了10.5%至26%。

尽管墨西哥的出口量下降了1.3%,但 北美 (NAFTA) 的出口量仍保持正增长(37.9万吨,比2020年增长

22

CWR CHINA 2023 TAB.

2010 2014 2015 2016 2017 2018 2019 2020 2021 % 21/20 CAGR 21/10 % on 2021 world exports Asia 1,100,506 1,679,102 1,697,734 1,603,571 1,756,791 1,988,977 2,220,614 2,127,623 2,531,633 19.0% 7.9% 64.6% European Union 522,118 530,149 569,475 583,409 570,549 585,034 541,584 488,917 552,268 13.0% 0.5% 14.1% Other Europe 132,132 178,482 185,960 187,805 203,077 220,127 237,166 235,176 278,859 18.6% 7.0% 7.1% NAFTA 268,401 329,677 340,565 368,326 366,973 375,412 365,789 368,372 379,235 2.9% 3.2% 9.7% South America 100,043 82,515 72,548 80,315 79,513 89,375 86,782 78,814 99,851 26.7% -0.02% 2.5% Africa 35,861 88,524 84,042 71,958 65,933 66,113 75,238 64,296 75,386 17.2% 7.0% 1.9% Oceania 1,960 847 902 1,084 411 583 580 315 364 15.6% -14.2% 0.0% TOTAL WORLD 2,161,021 2,889,296 2,951,226 2,896,468 3,043,247 3,325,621 3,527,753 3,363,513 3,917,596 16.5% 5.6% 100.0% % var y-o-y 11.8 2.1 -1.9 5.1 9.3 6.1 -4.7 16.5 Source: Mecs / Acimac Research dept. on BSRIA and ITC data

1 - EXPORTS OF SANITARYWARE BY AREA (TONS)

世界卫生洁具进出口报告

crease in Mexico (-1.3%).

Exports from non-EU European countries registered a significant growth (+18.6% to 279,000 tonnes), thanks to the increase in exports from Turkey (203,000 tonnes, up 22.3%). Next came South America (100,000 tonnes, +26.7%) and Africa (75,000 tonnes, +17.2%).

A glance at the 11-year period as a whole provides a clear picture of how exports have evolved in each area and in particular reveals the growth of Asia, whose exports have more than doubled from 1.1 to 2.5 million tonnes (CAGR 2021/2010 +7.9%). Asia’s percentage share of global exports has risen from 51% in 2010 to the current figure of 64.6%, winning shares from almost all the other regions.

By contrast, EU exports have remained stable at around 522,000 tonnes compared to the volumes exported in 2010, equivalent to a contraction in the region’s share of world trade from 24.2% to 14.1%. The NAFTA region’s share fell from 12.4% to 9.7% despite an overall 41% growth in exports over the 11-year period. South America, which in 2010 accounted for 4.6% of world exports, saw its share drop to 2.5%, while volumes remained stable over the 11-year period. The only ex-

2.9%)。非欧盟欧洲国家 的出口量大幅增长(增长 18.6%至27.9万吨),这主要得益于土耳其出口量的增 加(20.3万吨,增长22.3%)。其次是 南美(10万吨,增 长26.7%)和 非洲(7.5万吨,增长17.2%)。

纵观过去11年,可以清楚地看到每个地区的出口发展 情况,特别是亚洲的增长,其出口量从110万吨增加 到250万吨,增长了一倍多(2021/2010年复合年增 长率增长7.9%)。亚洲在全球出口中所占的比例已从 2010年的51%上升到目前的64.6%,几乎超过了其他 所有地区。

相比之下,与2010年的出口量相比,欧盟的出口量稳 定在52.2万吨左右,相当于该地区在世界贸易中的份 额从24.2%收缩到14.1%。北美自由贸易协定地区的 份额从12.4%降至9.7%,尽管在11年期间,该地区的出 口总体增长了41%。2010年占世界出口4.6%的南美的 份额下降到2.5%,而这11年期间的出口量保持稳定。 唯一的例外是非欧盟的欧洲国家和非洲。在过去的

sanitaryware CWR CHINA 2023 23 TAB.

2010 2014 2015 2016 2017 2018 2019 2020 2021 % 21/20 CAGR 21/10 % on 2021 world exports China 901,962 1,280,270 1,335,212 1,238,558 1,378,951 1,532,833 1,747,579 1,698,152 1,968,003 15.9% 8.1% 50.2% Mexico 226,569 276,984 295,439 322,169 326,289 342,666 335,958 333,230 328,904 -1.3% 3.8% 8.4% India 15,076 119,626 119,752 135,776 137,717 182,691 199,371 171,698 264,253 53.9% 33.2% 6.7% Turkey 94,354 125,256 120,613 127,065 140,759 154,285 164,809 166,370 203,467 22.3% 8.0% 5.2% Thailand 57,189 75,794 79,242 81,016 86,512 96,067 92,094 87,129 111,703 28.2% 6.9% 2.9% Poland 67,572 69,913 77,048 80,323 76,620 78,617 77,470 82,537 91,206 10.5% 3.0% 2.3% Germany 63,742 58,343 65,734 79,124 75,478 81,952 80,382 75,861 88,863 17.1% 3.4% 2.3% Portugal 75,049 78,360 87,434 93,891 94,164 101,654 81,574 65,438 82,200 25.6% 0.9% 2.1% Vietnam 19,590 57,424 47,892 35,034 40,457 41,292 52,982 51,986 67,565 30.0% 13.2% 1.7% Iran 25,895 38,894 31,420 33,962 35,206 46,573 46,469 48,893 52,869 8.1% 7.4% 1.3% TOTAL 1,546,998 2,180,864 2,259,786 2,226,918 2,392,153 2,658,630 2,878,688 2,781,294 3,259,033 17.2% 7.7% % on total world exports 71.6% 75.5% 76.6% 76.9% 78.6% 79.9% 81.6% 82.7% 83.2%

Mecs

2 - THE TOP EXPORTING COUNTRIES (TONS)

Source:

/ Acimac Research dept. on BSRIA and ITC data

ceptions were non-EU European countries and Africa. NonEU Europe saw its share of world exports rise from 6.1% to 7.1% over the 11-year period thanks to a 111% increase in export volumes, while Africa’s exports grew by 110% over the period, raising its share of global trade from 1.7% to 1.9%.

The 2021 ranking of the top 10 exporter countries remained unchanged from 2020 in terms of positions, but saw Russia exit and Iran enter in tenth place.

China continued to top the rankings in 2021 with 1.98 million tonnes (up 16% on 2020 and up from 902,000 tonnes in 2010, equivalent to a CAGR of +8.1%). China alone accounted for 78% of Asian exports and 50% of world exports.

Mexico, the second largest exporter country with an 8.4% share of global exports, suffered a 1.3% fall in its exports in 2021 to 329,000 tonnes. Buoyed by 54% growth on 2020 from

11年里,非欧盟欧洲地区的出口增长了111%,占世界 出口的份额从6.1%上升到7.1%,而非洲的出口增长了 110%,占全球贸易的份额从1.7%上升到1.9%。

2021年 前十大出口国 的排名与2020年相比没有变 化,但俄罗斯退出排名,伊朗进入第10位。

中国 在2021年以198万吨继续位居榜首(比2020年增 长16%,高于2010年的90.2万吨,相当于8.1%的复合 年增长率)。仅中国一国就占亚洲出口的78%和世界出 口的50%。

墨西哥 是第二大出口国,占全球出口量的8.4%,其 2021年的出口量下降了1.3%,至32.9万吨。由于2020 年从17.2万吨增长到26.4万吨的54%,印度 仍然位

24 CWR CHINA 2023 TAB. 3: IMPORTS OF SANITARYWARE BY AREA (TONS) 2010 2014 2015 2016 2017 2018 2019 2020 2021 % 21/20 CAGR 21/10 % on 2021 world imports Asia 478,338 847,357 818,090 793,850 833,259 926,612 1,023,083 942,443 1,076,833 14.3% 8.5% 27.5% European Union 692,328 729,926 791,241 812,874 837,139 880,867 913,292 838,875 969,639 15.6% 3.4% 24.8% Other Europe 96,507 124,274 89,772 70,806 77,761 90,187 87,862 96,767 111,027 14.7% 1.4% 2.8% NAFTA 620,716 749,982 809,546 819,097 866,815 948,435 967,327 986,193 1,132,053 14.8% 6.2% 28.9% South America 119,957 136,408 146,436 130,758 140,950 145,579 158,296 143,521 217,371 51.5% 6.1% 5.5% Africa 111,952 247,685 235,655 199,740 221,986 259,390 310,834 288,084 332,847 15.5% 11.5% 8.5% Oceania 41,223 53,664 60,486 69,343 65,337 74,551 67,059 67,629 77,971 15.3% 6.6% 2.0% TOTAL WORLD 2,161,021 2,889,296 2,951,226 2,896,468 3,043,247 3,325,621 3,527,753 3,363,513 3,917,596 16.5% 6.1% 100.0% % var y-o-y 11.8 2.1 -1.9 5.1 9.3 6.1 -4.7 16.5

TAB. 4 - THE TOP IMPORTING COUNTRIES (TON) 2010 2014 2015 2016 2017 2018 2019 2020 2021 % 21/20 CAGR 21/10 % on 2021 world imports USA 500,415 624,259 683,754 690,500 738,424 811,329 817,814 837,589 931,311 11.2% 6.4% 23.8% Republic of Korea 84,543 115,816 132,361 147,756 142,706 142,732 142,658 127,185 156,902 23.4% 6.4% 4.0% Germany 107,509 128,532 142,391 147,060 140,282 148,431 150,425 144,299 155,318 7.6% 3.7% 4.0% France 115,108 104,078 101,819 107,421 116,870 125,738 135,313 125,226 150,811 20.4% 2.7% 3.8% Canada 104,680 109,559 104,119 108,442 106,137 103,682 107,464 107,013 138,487 29.4% 2.8% 3.5% United Kingdom 103,815 138,337 147,323 145,992 151,904 138,454 143,344 118,906 131,784 10.8% 2.4% 3.4% Spain 83,634 82,755 88,245 93,758 89,036 108,096 104,981 86,835 118,467 36.4% 3.5% 3.0% Vietnam 3,866 4,719 7,693 12,476 20,855 32,342 55,237 68,354 75,538 10.5% 34.6% 1.9% Italy 60,906 53,181 55,328 61,716 63,316 66,391 63,955 61,044 75,137 23.1% 2.1% 1.9% Philippines 25,667 27,838 39,508 41,191 39,507 49,829 55,205 49,561 71,708 44.7% 10.8% 1.8% TOTAL 1,190,143 1,389,075 1,502,541 1,556,312 1,609,037 1,727,024 1,776,396 1,726,011 2,005,463 % on total world imports 55.1% 48.1% 50.9% 53.7% 52.9% 51.9% 50.4% 51.3% 51.2% Source: Mecs / Acimac Research dept. on BSRIA and ITC data

Source: Mecs / Acimac Research dept. on BSRIA and ITC data

172,000 to 264,000 tonnes, India remained in third place followed by Turkey with 203,000 tonnes (up 22% on 2020), then Thailand, Poland, Germany, Portugal and Vietnam. Overall, the 10 largest sanitaryware exporter countries accounted for 83% of global exports.

An analysis of 2021 imports to the various continents not only confirms Asia, North America and the European Union as the three regions accounting for the majority of sanitaryware imports but also reveals that they are almost level in terms of imported volumes: North America at 1.13 million tonnes (28.9% of global imports, +14.8% on 2020); Asia at 1.08 million tonnes (27.5% of global imports, +14.3% on 2020); and the EU at 970,000 tonnes (24.8% of global imports, +15.6% on 2020). Imports to Africa (+15.5%), South America (+51.5%) and non-EU European countries (+14.7%) also saw very positive growth.

EXPORTS BY AREA (SHARES IN % - 2010 VS. 2021) area

(quote % - 2010 vs. 2021 )

居第三,其次是 土耳其 (20.3万吨,比2020年增长 22%),然后是泰国、波兰、德国、葡萄牙和越南。总 体而言,10个最大的卫生洁具出口国占全球出口的 83%。

对 2021年各大洲的进口进行的分析不仅证实了亚洲、 北美和欧盟是卫生洁具 进口的三个主要地区,而且还 表明,就进口量而言,这三个地区几乎持平:北美 为 113万吨(占全球进口的28.9%,2020年为14.8%); 亚洲为108万吨(占全球进口的27.5%,比2020年增 长14.3%);欧盟 为97万吨(占全球进口的24.8%,比 2020年增长15.6%)。

非洲(增长15.5%)、南美洲(增长51.5%)和 非欧盟欧洲 国家(增长14.7%)的进口也出现了非常积极的增长。

IMPORTS

AREA (SHARES IN % - 2010 VS. 2021 ) area geografica (quote % - 2010 vs. 2021 ) la torta del 2010 è uguale a cwr 144

IMPORTS BY AREA (SHARES IN % - 2010 VS. 2021 ) area

integrated areas (same continent of production) - % share 2021 esportazioni rispetto al continente di produzione - 2021

sanitaryware

CWR CHINA 2023 25

FIG. 2 - SANITARYWARE IMPORTS BY AREA (SHARES IN % - 2010 VS. 2021)

sanitaryware Exports by area sanitaryware imports by area Export inside and outside integrated areas Asia 50,9% European Union 24,2% Other Europe 6,1% NAFTA 12,4% South America 4,6% Africa 1,7% Oceania 0,1% 2010 European Union 14,8% Other Europe 7,1% NAFTA 11,1% South America 2,4% Africa 1,9% 2020 Asia 22,1% European Union 32,0% Other Europe 4,5% NAFTA 28,7% South America 5,6% Africa 5,2% Oceania 1,9% 2010 Other Europe 2,9% NAFTA 29,8% South America 4,3% Africa 8,7% Oceania 2,0% 2020 61,2% 15,8% 3,4% 26,4% 70,3% 2,2% 60% 70% 80% 90% 100%

BY

area geografica (quote % - 2010 vs. 2021 ) la torta del 2010 è uguale a cwr 144

Asia 50,9% Africa 1,7% Oceania 0,1% 2010 Asia 64,6% European Union 14,1% Other Europe 7,1% NAFTA 9,7% South America 2,5% Africa 1,9% 2021 Asia 22,1% European Union 32,0% Europe 4,5% Oceania 1,9% 2010 Asia 27,5% European Union 24,7% Other Europe 2,8% NAFTA 28,9% South America 5,5% Africa 8,5% Oceania 2,0% 2021 16,0% 3,5% 22,1% 6,0% sanitaryware Exports by area sanitaryware imports by area Export inside and outside integrated areas Asia 50,9% European Union 24,2% Other Europe 6,1% NAFTA 12,4% South America 4,6% Africa 1,7% Oceania 0,1% 2010 European Union 14,8% Other Europe 7,1% NAFTA 11,1% South America 2,4% Africa 1,9% 2020 Asia 22,1% 32,0% Other Europe 4,5% NAFTA 28,7% South America 5,6% Africa 5,2% Oceania 1,9% 2010 Other Europe 2,9% NAFTA 29,8% South America 4,3% Africa 8,7% Oceania 2,0% 2020 3,4% 2,2% 100% European Union

FIG. 1 - SANITARYWARE EXPORTS BY AREA (SHARES IN % - 2010 VS. 2021)

EXPORTS

AREA (SHARES IN % - 2010 VS. 2021)

BY

outside

geografica

la torta del 2010 è uguale a cwr 144

geografica (quote

-

vs.

la torta del 2010 è uguale a cwr 144 outside integrated areas (same continent of production) - % share 2021 esportazioni rispetto al continente di produzione - 2021 Asia 50,9% Africa 1,7% Oceania 0,1% 2010 Asia 64,6% European Union 14,1% Other Europe 7,1% NAFTA 9,7% South America 2,5% Africa 1,9% 2021 Asia 22,1% European Union 32,0% Europe 4,5% America Oceania 1,9% 2010 Asia 27,5% European Union 24,7% Other Europe 2,8% NAFTA 28,9% South America 5,5% Africa 8,5% Oceania 2,0% 2021

%

2010

2021 )

The 2021 rankings of the 10 largest sanitaryware importing countries saw some new entries and changes in positioning with respect to the previous year. Overall, the ten largest sanitaryware importers accounted for 51% of global sanitaryware imports (2 million tonnes).

In 2021, the United States was once again the world’s biggest sanitaryware importer with 931,000 tonnes (11.2% up on 2020). It retained a strong lead over all other importer countries with 23.8% of world imports, as well as almost all (83%) of imports to the NAFTA region. This marks the continuation of a longstanding record considering that in 2010 the USA imported more than 500,000 tonnes, 23% of world imports.

Korea climbed to second place, importing 157,000 tonnes (+23.4% on 2020), narrowly ahead of Germany (155,000 tonnes, +7.6%), followed by the France (150,000 tonnes, +20.4%), Canada (138,000 tonnes, +29.4%), United Kingdom and Spain. Vietnam, Italy and the Philippines entered the rankings in place of Saudi Arabia, Nigeria and India.

Germany and Vietnam rank among both the top 10 exporters and the top 10 importers of sanitaryware both with higher import than export volumes.

与前一年相比,2021年十 大卫生洁具进口国 的排名 出现了一些新的国家,各 国的排名也发生了一些变 化。总体而言,十大卫生 洁具进口商占全球卫生 洁具进口量(200万吨)的 51%。

2021年,美国 再次成为世

(quote % - 2010 vs. 2021 ) la torta del 2010 è uguale a cwr 144

One final point of interest is the analysis of the main export destinations with respect to the geographical areas of production. Four out of seven areas sell the vast majority of their exports within their own geographical regions or continents: 96.5% of North American exports remain in the NAFTA region; 94% of Oceania’s exports remain in Oceania; 84% of the European Union’s exports are sold in EU markets; and 77.9% of South American exports are shipped to other Latin American countries.

At the other extreme, 88% of exports from non-EU Europe are sold in other regions, particularly the EU (Turkey’s largest export market). Likewise, 75% of African exports are sold outside Africa and Asia ships 61% of its exports outside the Asian continent thanks to the ability of China to reach almost all areas of the world.

界上最大的卫生洁具进 口国,进口量为931000 吨(比2020年增长11.2% )。美国以23.8%的世界 进口量,以及几乎全部 (83%)的北美自由贸易协 定(NAFTA)地区进口量, 远远领先于其他所有进口 国。2010年美国进口了超 过50万吨卫生洁具,占世 界进口量的23%,这是美 国卫生洁具进口量稳居榜 首的标志。

韩国 攀升至第二位,进口 15.7万吨(比2020年增 长23.4%),略高于德国 (15.5万吨,增长7.6%), 其次是 法国(15万吨,增 幅20.4%)、加拿大(13.8 万吨,涨幅29.4%)、英国 和西班牙。越南、意大利

Export inside and outside integrated areas (same continent of production) - % share 2021 Destinazione

esportazioni rispetto al continente di produzione - 2021

和菲律宾取代沙特阿拉 伯、尼日利亚和印度进入 榜单。

德国和越南都是卫生洁具 的前十大出口国和前十大 进口国,进口量均高于出 口量。

最后一个值得关注的点是 对 各大主要产区出口目的 地 的分析。7个地区中有4 个地区的绝大部分出口都 在其所在的地理区域或大 陆内销售:北美96.5%的 出口仍在北美自由贸易协 定地区;大洋洲94%的出 口仍在大洋洲;欧盟84% 的出口产品销往欧盟市 场;77.9%的南美出口产品 运往其他拉丁美洲国家。 另外,88%的非欧盟欧洲 出口产品在其他地区销 售,特别是欧盟(土耳其 最大的出口市场)。同样, 非洲75%的出口产品销往 非洲以外,亚洲61%的出 口产品销往亚洲大陆以 外,这得益于中国产品几 乎可以出口到世界所有地 区。 5

26

CHINA 2023

sanitaryware CWR

5

FIG. 1 - SANITARYWARE EXPORTS BY AREA (SHARES IN % - 2010 VS. 2021) Export di sanitari per area geografica (quote % - 2010 vs. 2021 ) la torta del 2010 è uguale a cwr 144

FIG. 2 - SANITARYWARE IMPORTS BY AREA (SHARES IN % - 2010 VS. 2021 ) Import di sanitari per area geografica

Asia 50,9% European Union 24,2% Other Europe 6,1% NAFTA 12,4% South America 4,6% Africa 1,7% Oceania 0,1% 2010 European Union 14,1% Other Europe 7,1% NAFTA 9,7% South America 2,5% Africa 1,9% 2021 Asia 22,1% European Union 32,0% Other Europe 4,5% NAFTA 28,7% South America 5,6% Africa 5,2% Oceania 1,9% 2010 Other Europe 2,8% NAFTA 28,9% South America 5,5% Africa 8,5% Oceania 2,0% 2021 38,8% 84,0% 12,2% 96,5% 77,9% 25,2% 94,0% 61,2% 16,0% 87,8% 3,5% 22,1% 74,8% 6,0% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Asia European Union Other Europe NAFTA South America Africa Oceania Export inside integrated areas Export outside integrated areas

delle

FIG. 3 - EXPORTS INSIDE AND OUTSIDE INTEGRATED AREAS (SAME CONTINENT OF PRODUCTION) - % SHARES 2021

18.5 billion € 21.34 billion sqm 3.7 billion sqm 5.2 4.1 5.67 9.4 45.2 17.6 12.4 44.85 9.4 57.43 12.55 12.85 20.12 96.41 1.7 8.3 7.22 6.8 world tile export world tile consumption in 2026 Indian manufacturing potential T. +39 059 7231870 info@mecs.org www.mecs.org MECS SRL Via Fossa Buracchione 84 41126 - Baggiovara (MO) ITALY DIGITAL & HARD COPY . Balance sheets . China & India reports . Prod & Cons in 90 countries . Forecast up to 2026 Custom analysis on request From the past to the future All about the world ceramic market

Safer and more versatile and sustainable tunnel kilns

The continuous ceramic sanitaryware kilns developed by Sacmi-Riedhammer combine the advantages of higher output and lower consumption while allowing for a customised approach to innovation in keeping with market and product trends and social and environmental conditions.

Sacmi-RH tunnel kilns make a vital contribution to energy efficiency and productivity and have evolved in recent years to achieve greater versatility, a drastic reduction in consumption and an ability to adapt to the general trend towards factory automation

❱ On/off & low/high production

Historically designed to operate 24/7 at full load, tunnel kilns for firing ceramic sanitaryware are now evolving in a quite different direction. For example, they can be switched off at weekends and above all allow for dynamic and flexible load management according to production trends and market requirements.

While the idea is simple, implementation requires specific design solutions to reduce diseconomies when the kiln is shut down and to allow it to be used dynamically according to real production requirements. One interesting approach to flexi-

Sacmi-Riedhammer开发的连续陶瓷卫生陶瓷窑炉 结合了高产量和低消耗的优势,同时允许根据市场和产 品趋势以及社会和环境条件进行定制化创新。

Sacmi-RH隧道窑对能源效率和生产力做出了重要贡 献,近年来不断发展,实现了更高的 多功能性 ,大幅降 低了消耗,并能够适应工厂自动化的总体趋势。

❱ 开/关和低/高产量

历史上,用于烧制陶瓷卫生用品的隧道窑设计为全天 候满负荷运行,现在正朝着完全不同的方向发展。例 如,它们可以在周末关闭,最重要的是允许根据生产趋 势和市场需求进行 动态和灵活的生产管理。

虽然这个想法很简单,但实施起来需要具体的设计解 决方案,以减少窑炉关闭时的导致成本增加的因素,并 允许它根据实际生产需求动态使用。灵活生产的一个 有趣方法是设计能够 仅使用其部分装机容量运行的连 续式窑炉。

例如,通过采用模块化设计和对不同区域的独立管

28

Sacmi Sanitaryware Division (Imola, Italy))

CWR CHINA 2023

更安全、更通用、更可持续的隧道窑

ble production involves designing continuous kilns capable of operating using only part of their installed capacity

For example, by adopting modular design and independent management of the different areas, just an 80-metre section of a 100-metre long kiln can be used to handle a given production flow at a given time. This means that 20% of the kiln can be left turned off without affecting the overall efficiency of the process.

❱ The environmental factor

With thousands of machines installed in the factories of leading industry players worldwide, Sacmi-Riedhammer’s sales and customer service network makes a real difference in terms of the ability to meet customers’ needs with specific design solutions.

Examples include the solutions adopted to eliminate kiln purge time after an unexpected stoppage (for example due to a power failure, which in some countries may even occur several times a day). The new design together with the configuration of the gas train and the safety systems adopted makes it possible to avoid the purge process while fully complying with applicable safety standards

The kiln is designed to ensure both operator safety and environmental protection.

To avoid workplace accidents and the risk of industrial disasters caused by natural events (earthquakes, floods etc.), the Sacmi-Riedhammer range includes a series of specific optional devices such as gas leak detectors (the biggest risk in the event of an earthquake), ceramic fibre kiln linings and fire-fighting systems.

In the areas of the world most susceptible to these risks, where specific regulations are often in force, numerous Sacmi-RH kilns have already been supplied with this type of equipment.

❱ Safety and performance

On modern Sacmi-RH kilns, safety and performance go handin-hand. This means using materials certified according to international standards such as EN, JIS, OSHA and FM. Furthermore, the materials used to build the kilns are free from exposed volatile fibres, they do not produce harmful dust, and

理,100米长的窑炉中只有80米的部分可以在给定的时 间用于处理给定的生产流程。这意味着可以关闭20% 的窑炉,而不会影响整个过程的效率。

❱ 环境因素

凭借全球领先行业的企业工厂安装的数千台机 器,Sacmi Riedhammer的销售和客户服务网络在通 过特定设计解决方案满足客户需求方面发挥了真正的 作用。

例如,在 意外停机(例如由于电力故障,在一些国家甚至 可能一天发生几次)后采取的解决方案,以 消除前后气 体的置换时间 。新的设计加上燃气阀组的配置和采用 的安全系统,可以避免停窑,同时完全符合适用的安全 标准。

窑炉的设计确保了操作人员的安全和环保。为了避免工 作场所事故和自然事件(地震,洪水等)造成的工业灾害 的风险,Sacmi-Riedhammer系列包括一系列特定 的可选设备,如气体泄漏探测器(地震发生时最大的风 险),陶瓷纤维窑炉内衬和消防系统。在世界上最容易受 到这些风险影响的地区,这些地区往往有具体的条例, 许多Sacmi-RH窑炉已经配备了这种类型的设备。

29 sanitaryware CWR CHINA 2023

System for recovering heat from the kiln

they are made with a minimal quantity of VOCs (volatile organic compounds).

Moreover, thanks to the technical and design consultancy of Sacmi’s Filtering, Energy & Environment Division, the kiln can be supplied together with complete systems for heat recovery and exhaust gas filtering. The main advantage of these solutions is the possibility of radically improving the factory’s energy and environmental performance. Overall, the combined installation of kiln heat recovery systems can lead to energy savings of up to 25% compared to a factory where the dryers and spray-dryers are powered exclusively by natural gas. As regards emissions, Sacmi’s filtering systems are capable of controlling a wide range of substances, from inorganic compounds such as acidic gases (which are treated with bag filters) to the latest solutions for the treatment of volatile organic compounds (VOCs) carried out by a self-recovering after-burner system with more than 95% efficiency

The different types of plant can be installed in a combined setup to achieve the best results during production.

❱ Smart solutions & automation

As mentioned, one of the advantages of the Sacmi-Riedhammer approach is that it delivers tailor-made innovations capable of responding to the real needs of customers and the market.

One of these is the development of a multilayer kiln design, a configuration that enables the machine’s efficiency to be increased while reducing its specific consumption

In certain production conditions, the multilayer configuration can provide a solution to the need for flexibility during firing, allowing the kiln to be used at full capacity even with complex and diversified production mixes

❱ 安全性和性能

当前Sacmi-RH 的窑炉安全性和性能是相辅相成的。 这意味着需要使用根据EN、JIS、OSHA和FM等国际 标准认证的材料。此外,用于建造窑炉的材料不含暴 露的挥发性纤维,不会产生有害粉尘,并且使用最低 量的挥发性有机化合物。

此外,得益于 Sacmi的过滤、能源和环境部门 的技术 和设计辅助,该窑炉可以与完整的热回收和废气过滤 系统一起供应。这些解决方案的主要优点是可以从根 本上改善工厂的能源和环境性能。

总的来说,与干燥窑和喷雾干燥塔完全由天然气供电 的工厂相比,窑炉热回收系统 的组合安装可以节省高 达25%的能源。

在排放方面,Sacmi的过滤系统能够控制各种各样 的物质,从 无机化合物 如酸性气体(用袋式过滤器处 理)到最新的 挥发性有机化合物 (VOCs)处理解决方 案,该解决方案由自动后燃烧器系统执行,效率超过 95% 。

不同类型的设备可以安装在一个组合装置中,以在生 产过程中获得最佳效果。

❱ 智能解决方案和自动化

如前所述,Sacmi Riedhammer技术的优势之一是 它提供量身定制的创新,能够满足客户和市场的真实 需求。其中之一是开发了多层窑炉设计,这种配置可

以提高设备的效率,同时降低其特定的消耗。

30 CWR CHINA 2023

Multilayer kiln design

This can be done for example by combining the different loading deck heights (as when simultaneously firing WCs and washbasins) or using mixed loading decks that share different levels. Furthermore, the availability of automatic loading/unloading systems can overcome the potential disadvantage of a vertical configuration (i.e. the need to control several loading levels). In general, Sacmi-Riedhammer’s tunnel kilns are perfectly suited to the modern fully automatic factory concept , an approach that until recently was almost exclusively restricted to roller kilns. Once again, this has been achieved thanks to the availability of automatic loading/unloading systems, LGV product transport systems and in general the increased use of robotics and smart handling systems for stages ranging from casting to palletisation.

Another Sacmi solution for smart factory management is the HERE factory supervisor, which features advanced MES (manufacturing execution system) functions and KPI (key performance indicator) monitoring for the machine, plant or multiple interconnected production units. This involves an incremental and customised approach in which Sacmi acts as a digital partner by analysing the state of the factory and the concrete and measurable advantages that can be achieved by installing the software.

❱ From energy management to the fuels of the future

Sacmi-Riedhammer kilns can be equipped with heat recovery systems designed by the Energy Division and are therefore intrinsically designed to recover as much heat as possible and re-use it inside the kiln or to power other machines or parts of the factory. Called EMS (energy management system), it is a state-of-the-art solution for minimising the kiln’s environmental impact.

在某些生产条件下,多层结构可以解决烧制过程中对 灵活性的需求,即使在生产复杂和多样化的产品时, 也可以满负荷使用窑炉。例如,可以通过组合不同的 承载垫板的高度(如同时烧制马桶和洗手盆时)或使 用不同高度的垫板来实现。此外,自动装载/卸载系统 的灵活性可以克服垂直结构的潜在缺点(即需要控制 多个垫板高度)。

总的来说,Sachi Riedhammer的隧道窑非常适合 现代全自动工厂概念,这种工艺在不久之前还几乎仅 用于辊道窑。再次,这要归功于自动装卸系统、LGV 激光导向车产品运输系统,以及从铸造到码垛等阶段 机器人和智能搬运系统的增加使用。

Sacmi智能工厂管理的另一个解决方案是 HERE 工厂 管理数字平台,它具有先进的MES(制造执行系统) 功能和KPI(关键性能指标)监控功能,可用于机器、 工厂或多个互连生产单元。这涉及到一种增量和定制 的方法,在这种方法中,Sacmi作为数字合作伙伴, 通过分析工厂的状态,以及通过安装软件实现的具体 和可衡量的优势。

❱ 从能源管理到燃料的发展

Sacmi-Riedhammer窑炉可以配备由能源部门设 计的热回收系统,因此 本质上设计为尽可能多地回收 热量并在窑内重新使用,或为工厂的其他机器或部件 提供动力 。它被称为

EMS(能源管理系统)

,是一种最 先进的解决方案,可以最大限度地减少窑炉对环境的 影响。

sanitaryware

31 CWR CHINA 2023

Kiln saturation with complex and varied production mixes

sanitaryware

The top-of-the-range model (EMS 400) offers a package of features including partial recovery of waste air which is redirected to the combustion system at a temperature of 400°C, enormously increasing efficiency.

However, this alone is not sufficient. Given the increasing social and regulatory attention to reducing CO2 emissions in most areas of the world, it has become necessary to redesign the kiln based on potential alternative fuels, electricity from renewable sources and hydrogen

Already today, the standard Riedhammer kiln would be capable of operating using up to 20% hydrogen mixed with natural gas (for example, one scenario that is gaining traction in Europe is the development of networks with hybrid natural gas and hydrogen distribution). With suitable modifications this percentage could be increased to 100%

Another R&D project currently in progress concerns the development of a new hybrid kiln capable of integrating electricity from a renewable source which could be used to heat items by convection inside the tunnel kiln in synergy with the other primary sources (natural gas, hydrogen or mixtures).

Crucially, Sacmi-Riedhammer is capable of adapting these technical developments according to the real availability of the new energy sources, while always putting the sanitaryware manufacturer’s needs first.

顶级型号(EMS 400)提供了一系列功能,包括部分回 收废气,这些废气在400°C的温度下被重新输送到 燃烧系统,极大地提高了效率。

然而,仅靠这一点是不够的。鉴于社会和监管部门越 来越重视减少世界大多数地区的二氧化碳排放,有 必要根据潜在的 替代燃料、可再生能源的电力和氢 气 重新设计窑炉。

如今,标准的Riedhammer窑炉将能够 使用高达 20%的氢气 与天然气混合运行(例如,在欧洲越来 越受欢迎的一种情况是开发具有混合天然气和氢气 分配的网络)。通过 适当的修改,这个百分比可以提 高到100% 。

目前正在进行的另一个研发项目涉及一种 新型混合 窑炉 的开发,这种混合窑炉能够整合来自可再生能 源的电力,可以与其他主要能源(天然气、氢气或混 合燃料)协同作用,通过隧道窑内的对流来烧制产 品。

至关重要的是,Sacmi-Riedhammer能够 根据新 能源的实际可用性调整这些技术发展,同时始终将 卫浴制造商的需求放在首位。 5

Media for digital glazing

what we control:

Rheology of the engobe/glaze

Surface tension

Binding properties

Interaction between the glaze drops and support

5

ADVERTISING

Sustainability as driver of change in the industry