WHAT NEXT FOR 2023? 12 The recent TDUK Global Market Conference was cautious but upbeat about upcoming market prospects TIMBER IS THE ANSWER 20 Delivering a range of sustainable timber solutions to a busy design and build sector ROTHOBLAAS 18 Why choosing the right certified quality materials is so important for your project WINTER 2022 www.timbermedia.co.uk ISSN 2515–8686 (PRINT) 22 CONSTRUCTION

Our products and people continue to serve the housebuilding and construction industry with a wide range of wood panel products.

West Fraser trading as Norbord Europe Ltd.

uk.westfraser.com

New name. Same products.

Norbord is now West Fraser

02 News

The latest news and views from across the industry.

12 Timber’s Future Remains Bright

The long-term future for timber construction remains bright despite turbulent times ahead, as the speakers at the recent TDUK Global Market Conference found out.

14

Record Returns at UKCW

UK Construction Week Birmingham, made a welcome return to the NEC in October, with visitor numbers up 19% from last year.

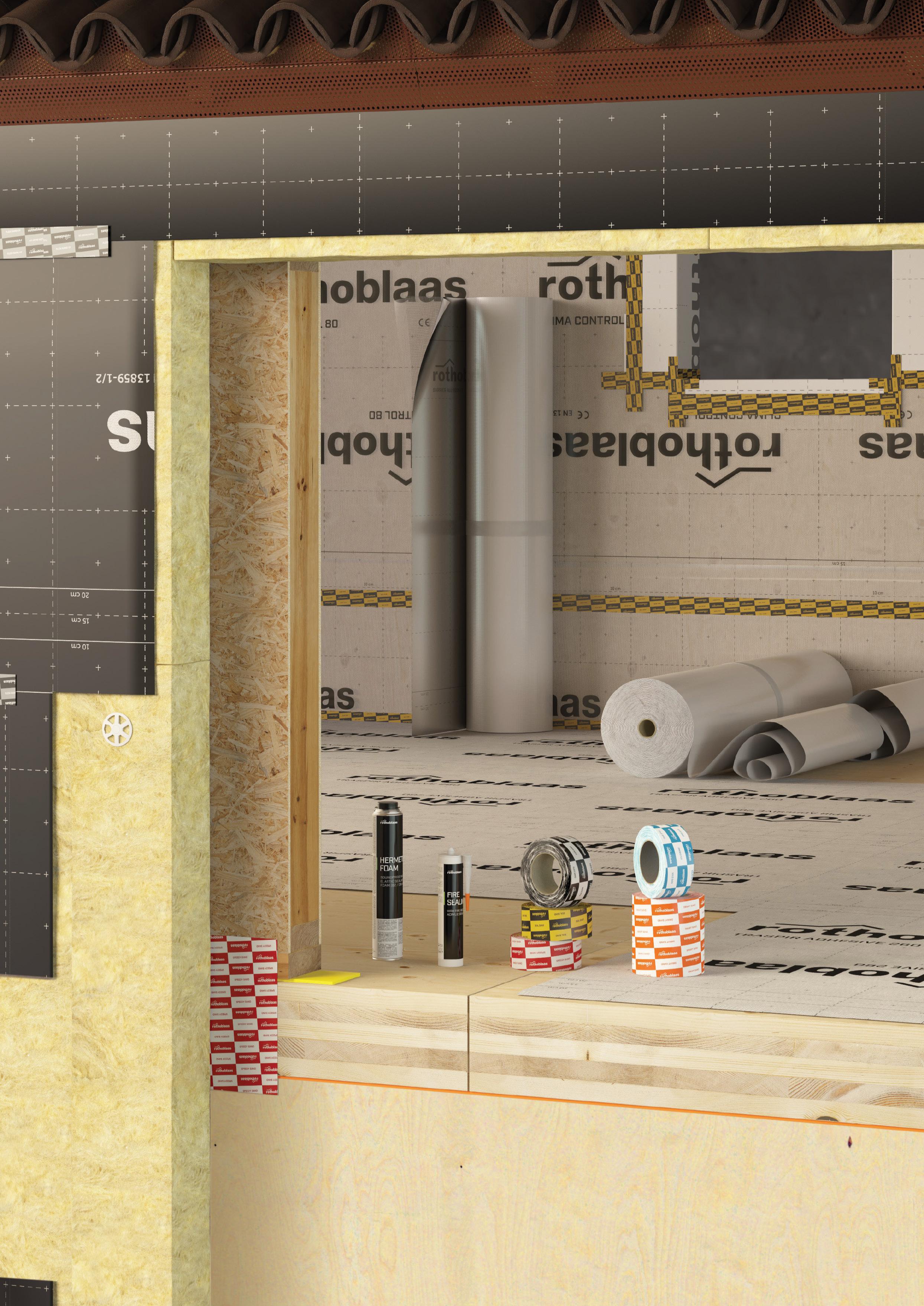

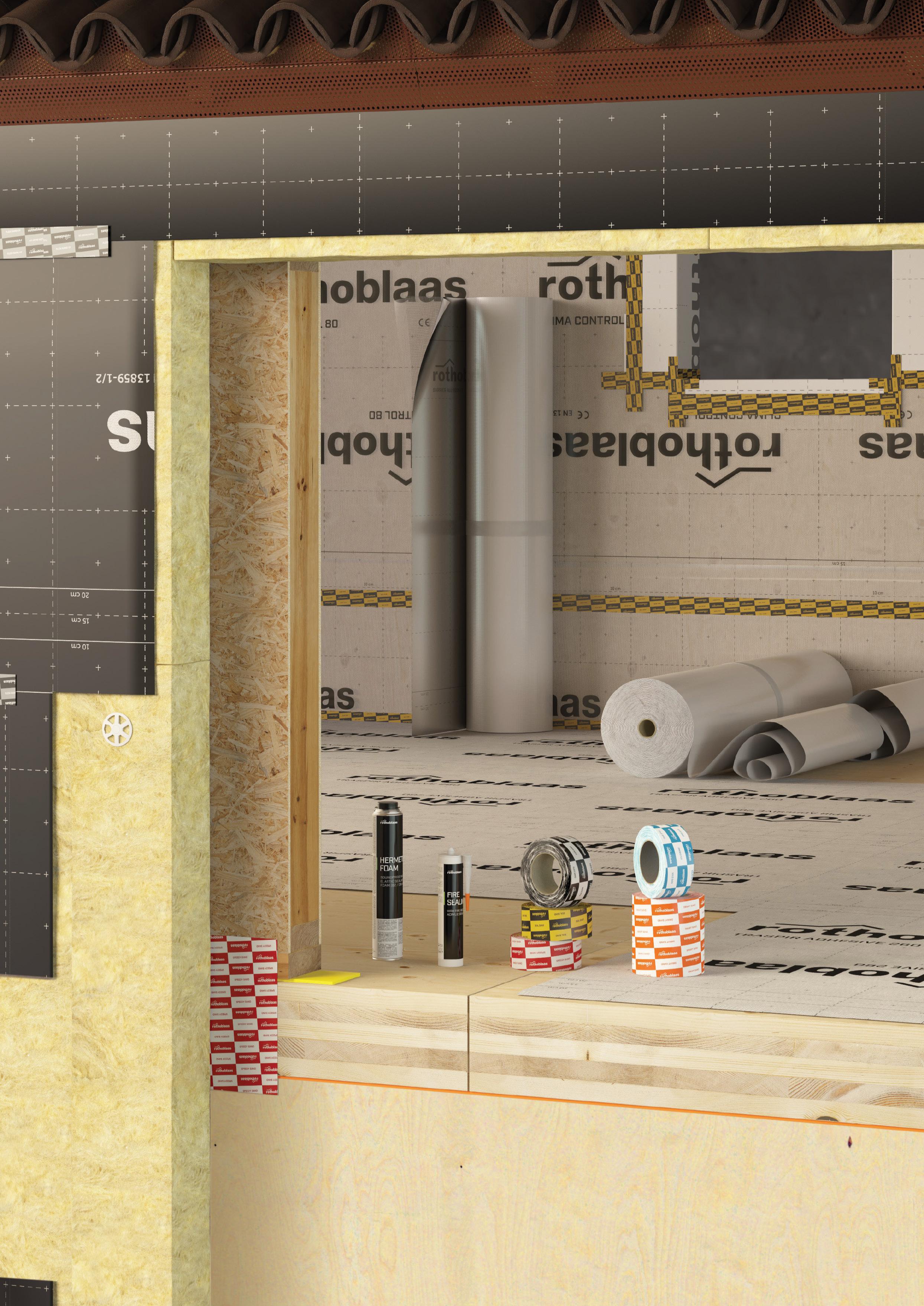

18 Cover Story: Rothoblaas

Rothoblaas offers a range of innovative solutions to support the growth of the Passivhaus sector and provides quality products for the most ambitious of timber construction projects.

20 Optimum Timber Performance

We spoke to John Maddock, co-founder and director of Sticx, to find out more about being a specialist provider of sustainable timber design and build options.

22 Free Form Flowing Timber

A superb Free Form roof that could redefine the future of timber construction has been proposed for Sweden’s National Museum of Science and Technology.

24 Be Aware: Close the Door

A third of the British public would not report a problem with a fire door, with a perceived lack of personal repercussions being one of the main reasons.

26 Weathering the Storm: Moisture Effects on CLT

Phil O’Leary, technical manager at BM TRADA, explores how moisture dynamics can affect the durability of cross laminated timber.

Timber

Magazine Winter 2022 01 www.timbermedia.co.uk @Timber_Media

Construction

20 18 14 12 02 24 26 22 Managing Editor: Terry Hanlon terry.hanlon@timbermedia.co.uk 01925 872371 Artwork: Pete Awad artwork@timbermedia.co.uk Follow Timber Media: @Timber_Media Registered address: 9 Viaduct Street, Newton-le-Willows, Merseyside WA12 9PL Company registered in England and Wales. Company Number 10839173. TIMBER CONSTRUCTION ISSUE 22 CONTENTS The Perfect Partner for the Timber Industry combilift.com Timber Trader UK magazine 185 x 62 Liz nov2022.indd 1 15/11/2022 17:33:38

BSW Group continues drive to educate and inspire industry

The UK’s largest integrated timber and forestry business, BSW Group, is gearing up for a busy end to 2022, with its commitment to supporting STEM development continuing as students return to school.

Throughout the 2021-22 academic year, BSW Group members BSW Timber and Tillhill, along with associated partners, hosted secondary school students at sites across England, Scotland and Wales to enhance their understanding of the timber industry, with an emphasis on attracting young talent to the sector in the coming years.

Tony Lockey, BSW Group learning and development manager, stressed the importance of engaging with young people as they prepare to make decisions that could shape their future careers. He said: “What we offer at BSW is a fully rounded training package for our apprentices, not just study in the classroom but hands on experience with a range of jobs and opportunities. We build our teams through robust succession plans and choose the right individuals to take our business onwards.”

BSW Timber and Tilhill have worked closely with the Scottish Council for Development and Industry (SCID) and Young Engineers and Science Clubs (YESC) to deliver industry insights through the last 12 months. In April, 50 young people from primary and secondary schools descended on Aberdeen Science centre for a Regional Celebration of STEM in partnership with BP and Shell U.K. Limited, and a further 90 students attended Dundee Science Centre for a Celebration of Engineering.

Youngsters in Scotland were given an insight into how the timber industry can positively impact the environment, while also being given the opportunity to visit a Tilhill harvesting site at Bainloch and the BSW Timber sawmill in Dalbeattie. The students were studying land management and forestry as part of their new Rural Skills course and were hosted for the day by Tilhill and BSW Timber.

Harvesting manager Iain McMurtrie and Tilhill colleagues were able to give students an insight into the planning and preparation that goes into managing a working forest, and how harvesting can be carried out safely and effectively. There was time to get a close-up look at the modern machinery involved in this work and to talk to the team who were on site. Students were also shown how decisions are made about re-planting. At BSW Dalbeattie the group found out more about the high-tech sawmilling operation and how a tree is processed into sawn timber products.

Tony Lockey added: “A recent promotion saw several new Tilhill graduates sign up for STEM Ambassador status. This is a fantastic way to promote our business to a wide range of individuals and inspire future timber and forestry workers. This often promotes the roles that are available through site visits and demonstrations, bringing young people face to face with exciting new opportunities that many had never thought they would explore.”

Timber Construction Magazine Winter 2022 02 www.timbermedia.co.uk @Timber_Media

More

TIMBER CONSTRUCTION NEWS

at

www.thebswgroup.co.uk

COP27

Important progress on sustainable forest management and conservation has been made at the UN Climate Change Conference COP27 in Sharm el-Sheikh with the launch of the Forest and Climate Leaders’ Partnership (FCLP), which aims to unite action by governments, businesses and community leaders.

The Partnership aims to boost action to implement a commitment made by over 140 countries at COP26 in Glasgow last year to halt forest loss and land degradation by 2030 and to convert ambition into results on the ground.

A key report published this year by the UN’s Food and Agriculture Organization (FAO) – the State of the World’s Forests Report 2022highlights the need to step up action to unlock the potential of forests in tackling climate change and biodiversity loss.

Only by stepping up efforts to reduce deforestation and implementing other mitigation activities in the forest sector can the Paris Agreement goal of limiting global average temperature rise to 1.5 degrees above pre-industrial levels be reached.

Twenty-seven countries, representing over 60% of global GDP and 33% of the world’s forests, have already joined the new partnership and are committed to leading by example on one or more of the FCLP’s action areas. These include mobilizing public and donor finance to support implementation, supporting Indigenous Peoples’ and local communities’ initiatives, and incentivizing the conservation of highintegrity forests.

President of the European Commission, Ursula von der Leyen, on behalf of the European Union, said: “Only with healthy forests can we deliver on our shared climate commitments under the Paris Agreement. And only with intact, lively forests can we address biodiversity.”

Government representatives meeting at COP27 announced that of the $12 billion committed in Glasgow to protect and restore forests over 2021-2025, $2.67 billion have already been spent and that public and private donors have committed a further $4.5 billion since COP26. To ensure accountability, the FCLP will hold annual meetings and publish an annual Global Progress Report that includes independent assessments of global progress toward the 2030 goal, and progress made by the FCLP itself.

Timber Construction Magazine Winter 2022 03 www.timbermedia.co.uk @Timber_Media

More at

www.un.org/en/climatechange/cop27

makes more sustainable forestry pledges The Timber Decking & Cladding Association is an independent, not-for-profit technical and advisory trade body. Recognised as the authoritative source of expert opinion in the UK. DeckMark and CladMark schemes require a full business audit and assessment followed by annual surveillance audits. info@tdca.org.uk | 01977 558147 Get in touch and find a supplier today www.tdca.org.uk Are you an architect, contractor or work in housing specification? Sourcing for your next project? Find the best products or installer with DeckMark and CladMark Industry recognised, third-party accreditations From wood coating manufacturers, specialised fixings to timber products and design engineers Prowood Cheshire Mouldings Need the best Decking or Cladding? Look for the Mark TIMBER CONSTRUCTION NEWS

Donaldson Door Systems rebrands from Rowan Manufacturing

Scotland’s leading joinery manufacturer of door sets has a new identity. Following its acquisition by the Donaldson Group in 2020, Donaldson Door Systems (DDS) is the new brand of the business formerly known as Rowan Manufacturing Ltd (RML).

Established in 1979 as the manufacturing arm of the Rowan Group, DDS specialises in manufacturing, merchanting and supplying internal and external door sets, as well as staircases from its site in Plains, North Lanarkshire. Since its acquisition in February 2020, all colleagues and operations have moved over to the Donaldson Group, with Managing Director, Luke Roberts, and General Manager, Billy Cameron, continuing to drive the business.

Luke Roberts, managing director, Donaldson Door Systems said: “The rebrand to Donaldson Door Systems is an exciting new chapter for the company. Our people will move forward with the business as we hone in on our market-leading door sets with safety and security front of mind. We are proud to be a part of this trusted family business and we are certain

that our customers will continue to benefit from the high-quality products and services that the Donaldson Group is known for.”

Andrew Donaldson, CEO of the Donaldson Group, added: “The rebrand completely aligns Donaldson Door Systems with the Group, along with a new logo, branding and website. The response from everyone involved in the rebranding exercise has been overwhelmingly positive and we are excited to see Donaldson Door Systems develop and build on the strong foundations that were established in its 30 years of operation.”

DDS holds Secured By Design accreditation and is the only company in Scotland to be both Q Mark and Certifire certified. For 30 years, the business has been working with large housebuilders, local authorities and the domestic market, supplying them with high-quality and fireproof doors and stairs. More at www.donaldsondoorsystems.co.uk

Architects and building control officers praise new

A RIBA-approved CPD helping builders, architects and building control officers negotiate the complexities of the revised Part L of the building regulations is transforming the understanding of future homes standards for those in the industry.

Actis regional specification manager and co-author of the CPD, Amaret Chahal says the latest Actis’ CPD, Tomorrow’s Insulation Solutions for Future Homes Standards, has been praised by architects and building control officers getting to grips with changes to Part L

Created by insulation specialist Actis, has been opening the eyes of specifiers and architectural technicians across the country with its helpful breakdown of precisely how the changes will affect their day-to-day work. Takeup of the free one-hour module has seen Actis specification managers Amaret Chahal and Jason Docherty rushed off their feet travelling the country and sharing their expertise with other industry professionals.

CAD technician Nick Fisher from EK Architects in Pattiswick, Essex, whose team were among

the first to book the CPD, said: ‘The guys were super impressed with the presentation. It’s nice to have a CPD that has answers. We will certainly be using Actis products going forward, so thank you for enlightening us. You will be bombarded with requests for calculations!”

He praised the excellence of the content and presentation, which gives guidance on how to meet revised energy efficiency targets which see new build homes having to reduce carbon emissions by 31% over previous levels.

Architectural technician Ben Sayers from MMA in Tyne and Wear, who took part in one of the many privately booked sessions, echoed his sentiments. “It was an excellent presentation, well delivered,” he said.

Actis regional specification manager and co-author of the CPD, Amaret Chahal said: “The number of enquiries we have received shows that people are turning to us in a time of need and confusion, hoping we have all the answers. We are happy and proud to say we were poised and ready for all the new building requirement changes. The new CPD has been received so well

by everyone we’ve presented it to. These have included architectural practices and LABC offices around the country, many of whom, interestingly, had little to no preparation or awareness of the new regs.”

The CPD looks at different tactics to help achieve the greater goal of building net zero by 2050, such as the increased importance of having a ‘fabric first’ approach. It details ways to improve U-values, reduce thermal bridging, address the performance gap and improve air tightness. And to ensure these changes don’t create a problem in the other direction, it looks at how to ensure there are no issues with overheating.

More at www.insulation-actis.com/ cpd.html

Timber Construction Magazine Winter 2022 04 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

RIBA-approved Part L CPD

Wood Awards 2022 on display – in miniature

A free exhibition featuring the thirty-two shortlisted projects for this year’s Wood Awards will be on display at the Building Centre in London, from 31 October – 10 December 2022. Showcasing a stunning array of British architecture and design using wood, this special exhibit will feature building models from 14 of the shortlisted projects, allowing visitors to explore, in miniature, the evolution of intent that shaped the buildings.

The collection of models on display highlights the incredible depth of timber design talent in the UK, with the shortlisted buildings this year including stadiums, school halls, and private residences – which can be found from Devon up to Edinburgh. Visitors to the exhibit will be able to get a sneak peek into the daring wood designs found in the likes of ABBA Arena, the Sport’s Pavilion, Master’s Field, Homerton College Dining Hall and many more. Also on show will be information on all the furniture entries into the Wood Awards, which were front and centre during the Material Matters fair at London Design Festival.

David Hopkins, Timber Development UK chief executive, said: “It is really special to be able to bring these timber buildings in their miniature form to the general public for the first, and likely only time – you will be able see this wide an array of British design, architecture and ingenuity in one room. Wood is the first choice for sustainable construction and product design, so not only will this exhibit be an opportunity for visitors to explore design, but also how this sustainable, replenishable material can help shape our future.”

The Wood Awards is the UK’s premier competition for excellence in architecture and product design in wood. Established in 1971, the

Wood Awards recognises, encourages, and promoted outstanding wood design, craftsmanship and installation. Through the Wood Awards, we aim to continually encourage British designers and manufacturers to aim ever higher in the design world and showcase some of their incredible achievements to a national and international audience.

More at www.woodawards2022.online

Timber Construction Magazine Winter 2022 05 www.timbermedia.co.uk @Timber_Media

TIMBER CONSTRUCTION NEWS

Henry Brothers win award for University timber nursery

Leading construction company, Henry Brothers, has been named winner of the GB & Republic of Ireland Construction Project of the Year Over £2.5 million category at this year’s Construction Employers Federation (CEF) Excellence Awards.

Henry Brothers received the Construction Project of the Year Award for its completion of a £4.4 million woodland day nursery and forest school at Staffordshire University. Ian Taylor, Managing Director of Henry Brothers Midlands, said: “We are pleased to have received industry recognition for our very first carbon neutral project, representing a significant milestone in Henry Brothers’ strategy to reach net zero carbon emissions by 2050. Congratulations must go to our exceptional staff which have delivered an outstanding modern nursery and forest school on campus, with sustainability at its core. Henry Brothers is privileged to provide Staffordshire University with a truly futureproof facility which will provide significant benefit to staff, students, and their families.”

The Woodlands Day Nursery and Forest School, a single-storey building, is timber frame with timber cladding and features an external timber canopy covered walkway for social interaction. Set adjacent to a woodland, the building features four inspirational learning spaces enhanced with digital technology and a forest school provision. It is highly energy efficient, air-tight, and is targeting net-zero whole life carbon.

Other sustainable features of the building include REHAU earth tubes and air source heat pumps which use passive cooling/heating rather than mechanical ventilation; along with roof mounted solar photovoltaic panels to offset carbon emissions.

Sally McGill, Chief Financial Officer and Executive Lead for Sustainability at Staffordshire University said, “On behalf of the University I would like to extend my congratulations to Henry Brothers as winners of the award for Construction Project of the Year. Henry Brothers has created a

truly unique facility here at Staffordshire University which as our greenest building, forms a significant part of our green campus transformation and sustainability plans. As our first carbon neutral building on campus, this facility will support the next generation as well as communities, bringing the forest setting to our city through teaching, learning and embedding our ambitions for a more sustainable future.”

In addition to Henry Brothers, the project team consisted of Mace as project and cost managers, Feilden Clegg Bradley Studios as lead designer and architect, Max Fordham as building services engineers, Civic Engineers as structural engineers and transport consultants, and Re-form Landscape as landscape designers. The Henry Brothers’ design team included CPMG Architects, structural and civil engineer Hexa and Couch, Perry, Wilkes for M&E services.

Timber Construction Magazine Winter 2022 06 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

More at henrybrothers.co.uk

Tanasote® answers Creosote problems

The safety and environmental credentials of Creosote has been under review across Europe for quite some time. At the end of September 2022, the renewal of authorised applications for timber treated with Creosote was voted on by EU Member States, with the majority voting in favour of restricting authorisation even further.

From spring 2023, fence posts treated with Creosote will be banned from being placed on sale. The only authorised continued use for Creosotetreated timber is for railway sleepers and utility poles for electricity and telecommunications. The positive vote to ban the use of Creosote to treat fence posts across EU Member States was made on the grounds that suitable and sufficient alternatives are available. One alternative that is being referenced by a growing number in the timber industry is Tanasote®.

A modern hot oil-based copper wood preservative developed to protect timbers in the harshest of environments, Tanasote® is an ideal solution for agricultural and heavy-duty landscaping timber applications such as livestock fencing, bridges, hop poles and retaining walls.

With over a decade of research and development, Tanasote® wood preservative has been developed to deliver a service life of 40 years plus, depending on commodity, desired service life, timber species and application. This modern alternative to Creosote was launched in Europe in April 2021 following Biocidal Products Regulation (BPR) authorisation.

To date, Tanasote® has been authorised for use in UC3 and UC4, including poles and sleepers for at least 10 years – the maximum authorisation period under the BPR before re-authorisation. It has passed all necessary environmental, human and animal health risk assessments, as well as generating extensive data to prove that it is effective against wooddestroying fungi and/or insects.

To prove real-world performance in the most demanding of environments, Tanasote® has been subjected to additional testing in high humidity and accelerated agricultural trials, as well as laboratory fungal studies. Extensive testing of water-repellent properties has also been undertaken. Other benefits include deep preservative penetration and mobility in the Tanasote® treated timber, low odour, long-lasting waterrepellence to minimise splitting and an innovative organic co-biocide to protect against a wide spectrum of aggressive decay fungi.

Dr Stephen Uphill, technical lead for wood protection – Americas and Industrial at Arxada commented: “If wood is to be kept as a primary material of choice in important agriculture applications, the industry needs to be bold and adopt modern and innovative BPR-authorised alternatives. Future wood protection technologies should confidently deliver both high performance and a lower environmental impact than other materials, such as steel and concrete. Tanasote® is an exciting and proven alternative that will meet these criteria. An innovative preservative system from our experienced development team, it is designed to meet the future needs of highperformance timber applications, such as those used in agriculture.”

TDUK sign anti-greenwash charter

Timber Development UK (TDUK) has signed up to The Anti-Greenwash Charter as the next step in its sustainability journey. The Charter is sponsored by the Alliance for Sustainable Building Products (ASBP) and requires organisations to make a public declaration to uphold good standards of marketing practice, adopt a Green Claims Policy and, by doing so, adhere to the Government’s Green Claims Code and Code for Construction Product Information (CCPI).

Having signed up to the Charter, TDUK has written a Green Claims Policy to set out the standards it has committed to in its marketing and communications. The organisation also requires all its members to abide by these standards:

• Transparency: We commit to clear communication of what sustainability benefit our product or service offers and not to conceal or omit information.

• Accountability: We substantiate our sustainability claims with accurate, and regularly evaluated empirical evidence. We commit to sharing facts, figures and statements that can be checked.

• Fairness: We commit to using fair, clear and unambiguous language when providing comparisons with other products or organisations.

• Honesty: We ensure we make specific statements about our organisation’s sustainability efforts and that our actions match those promises.

The policy sets out practices that TDUK will follow to ensure all its communications comply with the Anti-Greenwash Charter and also includes key definitions of green terms commonly used to describe timber and woodbased products and services to help its members do the same.

Charlie Law, Sustainability Director of Timber Development UK, explains: “The importance of sustainability is becoming clearer to industries across the country, but we have all seen examples of misleading or false information within the built environment industry. We are determined to ensure our members cannot be accused of ‘greenwashing’ and to help to champion responsible marketing practices across the timber supply chain, which is why we’ve decided to sign The Anti-Greenwash Charter and develop our policy and associated guidance to help our members, and others in the industry make the correct claims.”

More at www.timberdevelopment.uk/anti-greenwash-charter

Timber Construction Magazine Winter 2022 08 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

More at www.trusttanasote.com

English woodlands could have the construction answers

A consortium of experts in timber construction and engineering is exploring ways to boost the use of English hardwood forest products across the built environment, in a move which could significantly improve the carbon footprint of the UK’s buildings and support diverse woodland ecosystems.

The project – led by the New Model Institute for Technology and Engineering’s (NMITE) Centre for Advanced Timber Technology (CATT) – is funded through the Forestry Commission’s Timber in Construction Innovation Fund, designed to increase the use of the natural carbon sequestering material in the built environment. Partners also include dRMM Architects, Ecosystems Technologies, Edinburgh Napier University and Built Environment – Smarter Transformation (BE-ST).

For the first time, researchers will examine the suitability of certain species of English homegrown trees for their use in construction, looking at sawn, engineered, and mass timber products including cross-laminated timber (CLT) and glue-laminated timber (glulam). The species will be chosen

according to future availability, and timber potential based on existing data, including more common species such as oak, beech and sweet chestnut, as well as birch, sycamore, ash, alder and willow, where existing research about their suitability is limited.

Kat Scott, sustainability and regenerative design manager at dRMM, said: “By manufacturing viable and scalable homegrown timber alternatives to carbon-intensive materials, we are aiming to reduce the UK’s reliance on imported products. Widening the range of species that provide a domestic wood supply could also provide a boost for localised manufacturing facilities and supply chains.”

Focusing on the use of timber in modern methods of construction, partners will collate data on the potential strength grading of each species while also assessing the use of homegrown co-products such as wood fibre insulation. The three-year project could help to reduce the UK’s reliance on imported construction materials, as well as providing lowcarbon alternatives to concrete and steel.

Sam Hart, head of modern methods of construction at BE-ST, said: “As the UK faces a

climate emergency, demand is growing rapidly for more sustainable construction approaches such as timber-based offsite design. By building a robust evidence base, we can inform future approaches to forestry and woodland management across England that includes the species best suited for use in the structure of buildings. At the same time, the trees will sequester significant amounts of carbon, helping to reduce the environmental impact of the built environment in the years to come.”

Professor Robert Hairstans, director of the Centre for Advance Timber Technologies at NMITE, added: “This research represents a strategic convergence of England’s forestry, manufacturing, and construction industries to drive the increased adoption of homegrown, renewable timber in construction. By so doing we can inform future forest strategies to ensure resilience against pests, diseases and climate change and be less reliant on imported resources and the current monoculture of commercial species.”

More at www.be-st.build

•

•

•

•

•

Timber Construction Magazine Winter 2022 09 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

CHARGED AND IN CONTROL.

Remote monitoring

Fully

and supported by Koppers

backed, developed

Can help with treatment efficiencies

Detailed reporting for industry compliance

On-site system training and support available • Customisable alarms and reporting Introducing the new cutting-edge in control systems. With its user-friendly interface, ease of installation, live information and accurate plant mirroring, ProTreat delivers a new level of efficiency in timber treatment. www.kopperspc.eu | kpc.uk.sales@koppers.eu | +44 (0)1628 486644 ™ Protim Solignum Limited trading as Koppers Performance Chemicals. Koppers is a registered Trademark of Koppers Delaware, Inc. Whilst every attempt has been made to ensure the accuracy and reliability of the information contained in this document, Protim Solignum Limited gives no undertaking to that eect and no responsibility can be accepted for reliance on this information. Information will be updated when the need arises. Please ensure you have an up to date copy. All products are produced by independently owned and operated wood processing facilities. All other trademarks are trademarks of their respective owners. Koppers Performance Chemicals, Protim Solignum Limited, Fieldhouse Lane, Marlow, Buckinghamshire, SL7 1LS. Visit: www. kopperspc.eu, Email: kpc@koppers.eu, Call: +44 (0)1628 486644, Fax: +44 (0)1628 476757. Registered in England 3037845. © Copyright 2020.

Arbor celebrates 70 years with bigger greener lorry fleet

Arbor Forest Products has put sustainability at the heart of its new fleet of lorries, highlighting both the company’s drive for greener thinking as well as its ambition to help customers meet everincreasing environmental targets.

Successfully in business for over 70 years, Arbor supplies over 500,000m3 of quality timber to the building, DIY and construction trades every year from its 90-acre site in New Holland (North Lincolnshire). It is the largest dedicated timber terminal and processing facility in the UK. With 100s of orders to process every day, and large-scale logistic challenges a mainstay of the industry, Arbor has continued to look for greener solutions that optimise fleet utilisation, reduce carbon emissions, improve efficiency levels, and replace existing manual processes.

One of the results has been the creation of ‘Warehouse on Wheels’, a one-stop shop concept that delivers products at the right place and time, and in the precise volumes required. By providing mixed product deliveries nationwide (removing the need to use separate suppliers), Arbor is using fewer vehicles on the roads, making fewer deliveries and reducing its carbon footprint. In addition, transport planning is automated through routing and scheduling software, further maximising efficiencies and vehicle fill rates. With fresh panel designs, Arbor’s new-look lorry fleet is also ready to take the Warehouse on Wheels concept to the next level and help the company’s customers enhance their own green credentials.

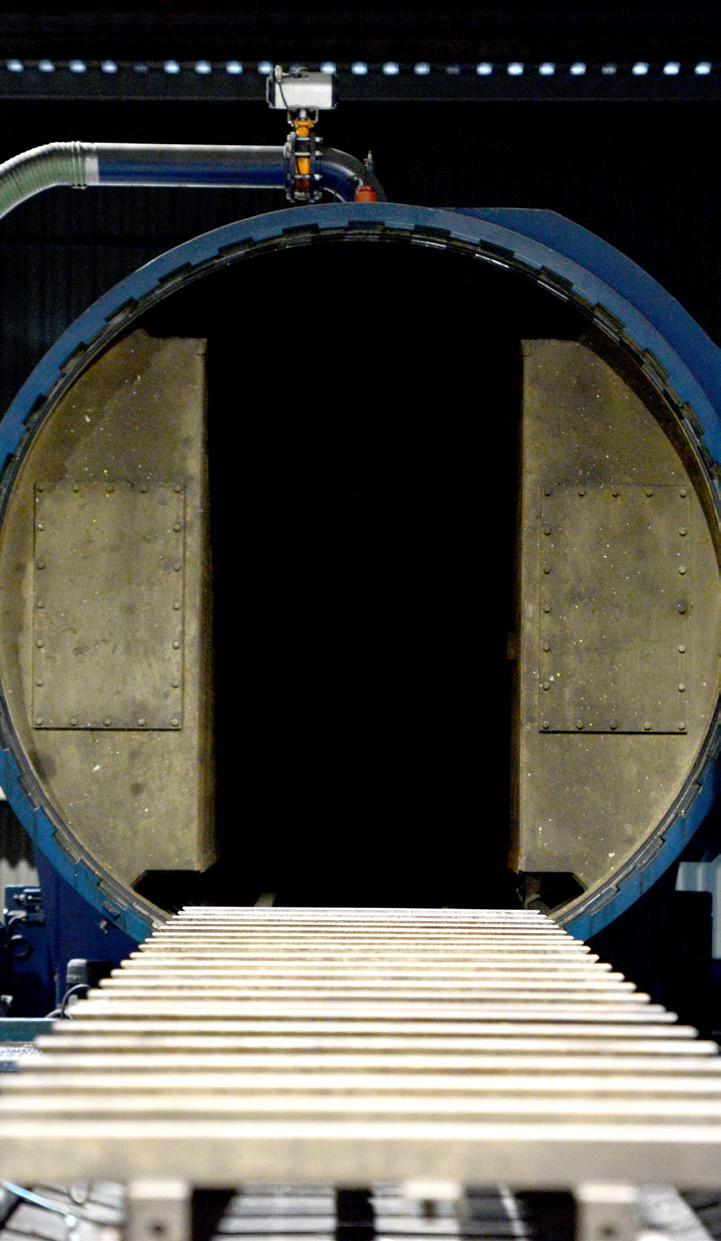

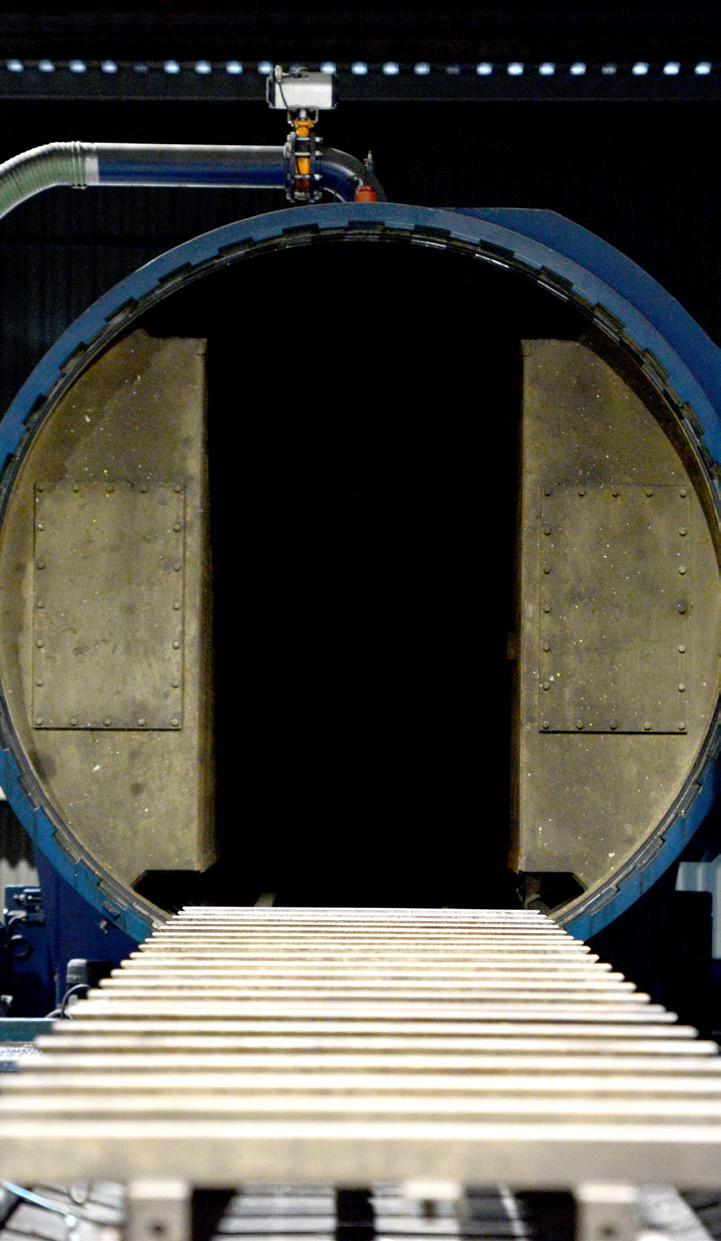

Accsys increases Accoya® wood capacity by a third

Accsys, the manufacturer of highly sustainable Accoya wood, has successfully expanded production capacity at its facilities in Arnhem, the Netherlands. The first commercial batch of Accoya wood has been produced from its new, fourth acetylation chamber.

Accsys has invested over €30 million in expanding the Arnhem site, including improving the wood handling for the whole site. The new acetylation chamber, which weighs in at 65 tonnes and over 14 metres long, increases the production capacity at Arnhem by a third, up from 60,000m3 to 80,000m3 (25.4 to 34.0 million board feet) a year.

In addition to the new acetylation chamber, Accsys has also invested in developing the Arnhem plant’s facilities. The improvements include: new capabilities to support safe and rapid handling and logistics of the increased volumes of wood; and a new quality monitoring and assurance technology with cameras, infrared scattering and x-rays to examine every board to ensure customer satisfaction with the products. A new 20,000m2 (200,000sq. ft.) warehouse opened in October at Hoevers, which will provide 35,000m3 of raw material storage close to the Arnhem site.

Rob Harris, CEO Accsys commented: “The world urgently needs solutions for sustainable construction. Durable, sustainable, and with incredibly high performance, Accoya is in high demand – and we’re working as hard as we can to produce much more of it. We have earned a loyal customer base and our priority is to deliver more of what

Arbor’s logistics manager, David Garbutt says: “We’re incredibly proud of our Warehouse on Wheels concept, as it allows us to fulfil orders in a single delivery. This is not only great news for our customers, but better for the planet. It’s a win-win situation. Our ability to generate precise transport plans means we can maximise our resources while maintaining our delivery promise. We’re also using data to achieve more accurate, environmentally beneficial route optimisations, so we’re expecting to see Warehouse on Wheels improve further in the future.”

Arbor’s Operations Director, Phil Yell, adds: “Sustainability is an evergrowing concern for businesses, so it’s essential that organisations such as ours proactively drive forward greener practices. The bottom line is that we genuinely care, so this governs how we act and the way we help our customers meet stringent environmental legislation. By increasing our in-house transport capabilities, we now have visibility over a wide range of KPIs helping us to reduce mileage and improve fleet utilisation, while always delivering on our service commitment to customers.” More at www.arborforestproducts.co.uk

they need. Our expansion at Arnhem is a significant step in the right direction of getting more Accoya out to the market. It’s part of our ambitious growth plan to expand production and fulfil our purpose of changing wood to change the world.”

Alongside the expansion at its existing site in Arnhem, Accsys is developing a facility in North America. In April this year Accsys began groundwork for a new factory in Kingsport, USA, which is anticipated to begin producing in 2024. The project is a joint venture with Eastman Chemical Company and is due for completion and first production batch in Q1 2024.

Accoya wood has been on the market since 2007 and is now sold by stocking distributors in more than 35 countries. The drive to net zero and rise in conscious construction have accelerated demand for timber construction materials. Unlike other woods, Accoya is long lasting and is manufactured so as not to visibly swell, shrink or distort. It is a natural carbon sink and is certified at the C2C Gold level for its circular economy benefits

Timber Construction Magazine Winter 2022 10 www.timbermedia.co.uk @Timber_Media TIMBER CONSTRUCTION NEWS

More

at www.accsysplc.com

Timber Construction Magazine Winter 2022 11 www.timbermedia.co.uk @Timber_Media NEED MORE INFORMATION? CONTACT YOUR EXPERT: Elisabeth PIVETEAU | +44 (0) 7821 807 788 | elisabeth.piveteau@piveteau.com RICH RESERVES OF DOUGLAS FIR: France is the number one producer of Douglas Fir in Europe. Second in the world! Great mechanical properties so the ideal construction material as glulam, finger-jointed or CLT Naturally durable heartwood to Use Class 3.2 so can be used outdoors without treatment. Sap can be pressure treated grey or brown up to Use Class 3.2. Versatile: perfect for use as cladding or decking. DOUGLAS FIR THE TIMBER SPECIES OF THE FUTURE. LAMWOOD total engineered timber production: 100,000 m3/year. PERMANENT STOCK OF 3,000M3 of GL24h Douglas Fir, Spruce and treated Pine in 13m lengths. STATE OF THE ART MACHINING AND CUT TO LENGTH SERVICE available for all your projects. PIVETEAUBOIS Technical centre Cinema «Les Fauvettes»Architect : Françoise RAYNAUD

Timber’s Future Remains Bright

More than 130 industry leaders came together in London on 2 November to discuss the state of the timber sector at Timber Development’s UK’s (TDUK) Global Market Conference. While numerous speakers warned of stormy weather ahead amidst gloomy economic projections for 2023, they also said that brighter days would follow, with the industry poised for major growth considering timber’s status as a key low-carbon solution.

Attendees were welcomed by TDUK chief executive David Hopkins, who began proceedings by reiterating the recent merger between the Timber Trade Federation and TRADA to become Timber Development UK (TDUK). He said: “TDUK has been formed to better reflect the reality of the market. Most of our members sell more than just one set of timber products to their customers, so we want to bring everyone together and get a better sense of what is happening right across the timber market.

“TDUK will lead best practice with the industry’s most comprehensive technical resource library. We’ll also give you the tool and guidance to lead the timber sector towards a low-carbon future, which now has to be central to the way we all do business.”

This was followed by a presentation on the current state of the timber supply trade from TDUK head of technical and trade, Nick Boulton. Nick outlined the way volumes of timber imports into the UK have fluctuated over recent years, both during and immediately after the Covid pandemic.

He said: “By the end of 2021, shortages of other materials encouraged people to delay work and so demand for timber fell, resulting in ports being full of unneeded timber stock. That’s part of the reason why, in the first six months of 2022, volumes of imports decreased while the backlog at the ports cleared. But in recent months, loss of consumer confidence has become the main cause of reduced demand for timber, and other building materials, in the domestic RMI market. We did see growth in the market during Q1 of 2022, which continued until June before starting to fall in line with decreasing consumer confidence, exaggerating the usual summer slowdown in the softwood market.”

The challenging task of predicting what lies ahead for timber and the wider construction industry fell to Professor Noble Francis,

Economics Director at the Construction Products Association (CPA). Noble began by acknowledging how difficult it currently is to forecast accurately for 2023 considering the recent political and financial chaos. “No-one knows what’s definitely going to happen, and there’s real uncertainty around the 2023/24 forecasts,” he said.

He explained that UK GDP got back to pre-Covid levels at the start of 2022, but that economists were expecting it to fall during both Q3 and Q4 this year, putting the UK into recession. Noble believes there will be further contraction at the start of 2023, but that the recovery will begin during the second half of next year, and that interest rates will peak somewhere around 4% in 2023.

While the UK entering recession with a forecast 1% fall of GDP next year is not a positive step, Noble reassured the gathered delegates that these falls are not as catastrophic as the economy saw during the crash of 2008, when GDP fell by 5%. He also pointed out that construction was at a very high level during 2020 and 2021 due to all the domestic RMI work carried out during Covid, and so the decline in construction is from these high points, and that he expects construction to begin its recovery in 2024.

Concluding the conference, David added: “The last couple of years have thrown some considerable challenges at our industry, with the pandemic, invasion of Ukraine and political instability placing the market on a rollercoaster, where highs are to be matched by lows. This coming winter looks no easier with energy security likely to be a key concern for businesses and households across Europe, as spiking interest rates, inflation, and labour availability create a challenging business environment.

“However, against this gloomy outlook, there is room for optimism on a policy level, with our speakers outlining the increasing recognition of timber as a climate change solution for the built environment. Through TDUK we are creating an opportunity to significantly advance timber’s position in the market, as we build strong connections between suppliers and specifiers.”

Timber Construction Magazine Winter 2022 12 www.timbermedia.co.uk @Timber_Media

More

at www.timberdevelopment.uk

FEATURE TDUK

The long-term future for timber construction remains bright despite turbulent times ahead. This was the conclusion of speakers at the recent TDUK Global Market Conference.

Record Returns at UKCW

The UK’s largest event for the built environment, UK Construction Week (UKCW) Birmingham, made a welcome return to the NEC in October, with visitor numbers up 19% from last year.

The show drew over 23,900 visitors from as far afield as Turkey, Brazil, Australia and Canada, and included a host of high-profile names including West Midlands Mayor Andy Street, Channel 4 presenter George Clarke, and BBC journalist and presenter Simon Jack.

Co-located within UKCW Birmingham was Timber Expo, which attracted over 2,000 visitors (8% of the total attendees) across the three days, including architects, local authorities, merchants, developers, housebuilders and contractors.

Designed for people who use, specify, design and build with timber, and offering the opportunity to join hundreds of other brands showcasing their latest innovation, products and services, Timber Expo was backed by and held in collaboration with Timber Development UK, BM TRADA, Timber Construction and Timber Trader UK.

Nathan Garnett, UKCW event director, commented after the show: “It is crucial that timber, as a sustainable building material, is placed front and centre of the UK’s largest construction event. There is so much happening in the construction industry right now that has put UK Construction Week into a unique position, whereby it can inform and educate the sector as it moves forward. There is a real sense of momentum now as we plan the next one, especially on meeting our next zero targets and creating long lasting culture change. A record number of companies have signed up for 2023 so we look forward to really growing the UKs largest trade show for construction.”

Chloe Donovan, chief executive of Natural Building Systems, said: “We’ve had an amazing time - met everyone from potential suppliers, industrial partners, contractors and investors; I can’t recommend it highly enough.”

Gary Scott, managing director at Hanson Plywood, commented: “We were at the show because it’s the hub of the UK construction industry. We get a lot out of it; we don’t do many shows, but UKCW Birmingham does work.”

Exhibitors at Timber Expo include Rokamat, Engineered Timber Solutions Ltd, Woodolex Ltd, the Ghana Forestry Commission and Hanson Plywood Ltd who specialise in the import, storage and distribution of wood-based panel products throughout the UK.

Timber Expo featured a programme of industry leaders, including architects, developers, housebuilders and merchants to name a few. They debated and discussed the sector tackling post pandemic supply issues, post Brexit challenges, the impact of the Ukraine conflict on timber supply chain and the drive to net zero as we strive to meet COP26 targets.

The exhibitor profile includes structural timber frame, sawmills, merchants, glulam, SIPs, CLT, fixings and fastenings, timber cladding, doors and windows, mouldings, skirtings and flooring products.

Andy Howe, founder and managing director of CareersForce, was named UKCW Role Model 2022; CareersForce helps UK key workers such as those from the armed forces, police and NHS to forge a new career in a range of new sectors including construction. The winning exhibitors of this year’s Stand Awards included: Rolec (best 50m+ space stand), Harwoods (best space under 50m), Restec (best shell scheme), Tough CAD (best use of marketing), Zero Hub (most interactive) and Celsa (for innovation).

UKCW London will take place from 2-4 May 2023 at ExCeL UKCW Birmingham will run from 3-5 October 2023 at the NEC. More at www.ukconstructionweek.com

Timber Construction Magazine Winter 2022 14 www.timbermedia.co.uk @Timber_Media

FEATURE TIMBER EXPO 2022

Timber Construction Magazine Winter 2022 15 www.timbermedia.co.uk @Timber_Media WE MAKE MORE THAN CABINETS ONE OF THE LARGEST AND MOST MODERN FACTORIES IN ASIA ELEGANCE AND FUNCTIONALITY Over 400,000 sq ft of combined factory space and over 800 employees in Vietnam and China. Export capacity of over 400 containers per month. ISO 9001 and FSC Certified. KITCHEN CABINETS SUGI (JAPANESE CEDAR) LUMBER WALL PANELS DECKINGS SOLID COUNTERTOPS TWO FACTORIES IN ASIA FINGER JOINTED AND EDGE GLUED FOR A CLASSIC BUTCHER BLOCK LOOK www.OwenInternational.co.uk

Tradition, Innovation & Years of Experience

Insulating clinker facade insulation

When using insulating clinker bricks, building owners have an opportunity to solve two problems at once. This includes upgrading the home with an attractive appearance with a new clinker facade and at the same time getting significantly improved thermal insulation. The insulating clinker is a type of thermal insulation composite system (ETICS). This composite system is then used to insulate building facades. This means that insulating clinker bricks are an alternative to conventional external insulation with a stone look. With the help of the use of insulating clinker bricks, the property owner receives both the thermal insulation and the clinker brickwork of the facade in one.

Safety and energy cost reduction

Haacke insulating clinker is an innovative product for effective, reliable, safe and sustainable thermal insulation. It is a product that can be used in the construction of buildings. It helps reduce energy costs by at least 40%. Haacke insulating clinker is an innovative product for effective, reliable, safe and sustainable thermal

insulation. This product was developed for the construction industry over a hundred years ago. It has been used in the construction of many different buildings such as hospitals, schools, bridges, etc.

Optimum heat protection

A modern, elegant facade with a sophisticated and visually appealing appearance: the clinker bricks are a great insulator and also very beautiful to look at. Our insulated clinker bricks offer excellent thermal insulation and clearly exceed the prescribed values. You will certainly be glad that investing in a Haacke insulating brick set has had a significant impact on the energy efficiency of your house - it is significantly more economical than standard insulating bricks. You will feel very comfortable in your summer and winter living spaces now and for years to come.

Distributed by Haacke Insulated Brick Panels Ltd Tel: 0203 921 0676

More at www.facebook.com/HaackeUK

TDUK Wins Sustainability Award

The TDUK stand stood at the centre of the Timber Expo pavilion, where visitors could ask questions and get advice on how to incorporate more timber in their construction projects. They were also able to access a wide range of free information and materials, including the first issue of TDUK’s Designing Timber magazine for architects and specifiers, and a three-volume series of textbooks on the Design of Timber Structures created by Swedish Wood in partnership with TDUK.

As the main supporter of Timber Expo, TDUK also organised a series of presentations as part of the Sustainability Hub. TDUK chief executive David Hopkins was on stage to chair discussions on a wide variety of topics including the commercial reality of low-carbon construction, how to achieve affordable zero-carbon newbuild homes and an introduction to Timber TED: an exciting new model for upskilling professions in timber engineering, design and construction.

In recognition of its focus on sustainability, TDUK was presented with the UKCW Sustainability Award at the end of the three-day exhibition.

David said: “We were thrilled with the response to Timber Expo. The panel discussions at the Sustainability Hub were incredibly well attended and are a testament to the growing interest in timber as a low-carbon building material right across the supply chain.

“Attending Timber Expo and UK Construction Week gave us a fantastic opportunity to raise awareness of the new TDUK brand now that the Timber Trade Federation and TRADA have merged into one organisation. The TDUK stand was incredibly busy throughout the whole event, and we were very pleased by the positive response to our new brand and our renewed commitment to support the timber industry as the largest, most comprehensive supply chain body for timber in the UK. We were especially delighted to be chosen as winner of the UKCW Sustainability Initiative Award in recognition of our efforts to promote timber across the entire construction supply chain.” More at www.timberdevelopment.uk

Timber Construction Magazine Winter 2022 16 www.timbermedia.co.uk @Timber_Media

FEATURE TIMBER EXPO 2022

Haacke Isolierklinker – a company with tradition and know-how with optimal detailed solutions and the color design of a facade that can give any house style and character.

During Timber Expo, the Timber Development UK (TDUK) team were on hand to showcase the many benefits of timber in construction.

TDUK chief executive David Hopkins (middle) and head of education and engagement Tabitha Binding receive the UKCW Sustainability Award.

Timber Construction Magazine Winter 2022 17 www.timbermedia.co.uk @Timber_Media

Sustainable building: why you should choose certified quality materials

Rothoblaas

Passivhaus sector and provides quality products for the most ambitious of timber construction projects.

The comfort offered by timber construction depends on how well it is sealed and waterproofed. Quality construction limits heat loss from the interior during winter and prevents interstitial condensation and the choice of the right membranes and adhesive tapes for roofs is important to guarantee the correct functionality of the building and favours the best thermo-regulation.

Anyone who has ever been part of a building project knows that qualified products are fundamental to its success. The essence of construction is to last long and be efficient: no wonder that nowadays the quality of a building is measured by its durability and effectiveness, and this inevitably starts from the quality of the materials used.

Passivhaus approach

Passivhaus, as a scientific certification protocol for low-energy buildings, was founded at the end of the last century in Germany with the aim of identifying a building model that could guarantee excellent energy performance and high comfort throughout its life.

To build according to the passive building criteria does not necessarily mean building according to one certain certification protocol. The design phase plays a major role in the definition of a building, in fact, the most important certifications concern design development processes and not later certifications. A designer who aims at achieving very high energy performance standards must inevitably respect certain rules and criteria that have now become the milestones of every certification protocol and have been developed over the years by theorists and researchers in the sector.

In recent years, the world of timber homes has seen numerous innovations in the field of energy efficiency with passive construction now a well-tested construction concept and can be applied by anyone, anywhere.

The certification of a product, especially when carried out on a voluntary basis, is a formal act through which a company states, with reasonable reliability, that a product conforms to a declared standard and is therefore suitable to achieve excellent quality standards. Passivhaus components certification is exactly this – a seal of quality that helps designers in choosing the materials to use for their projects.

Rothoblaas-certified products and their strengths

SPEEDY BAND: The tape ensures excellent adhesion and resistance. Applicable both indoors and outdoors, it guarantees fast and safe sealing on the most common substrates. It is free of separating film, for extremely quick installation and real savings on costs for the disposal of construction site waste. It has excellent mechanical tensile strength thanks to the reinforcement mesh.

FLEXI BAND: This polyacrylate tape ensures excellent adhesion strength and resistance on all surfaces. The special adhesive compound guarantees functionality even in non-optimal conditions, for example on very porous, dusty, or humid surfaces. The wider versions are perfect for sealing chimneys, windows, membranes to plaster or concrete and many other applications. FLEXI BAND is the perfect tape for anyone looking for a universal product of extraordinary quality.

SEAL BAND: is the acrylic tape that adheres effectively to all types of wood, for any sealing inside the building envelope. It is available in versions with liner divided into two or three parts, it simplifies the laying on edges, corners and any other critical node, while the impregnated paper support guarantees great workability and quick installation. SEAL BAND is the tape that simplifies any complex sealing.

CLIMA CONTROL 80: is a variable diffusion membrane. It has variable resistance to vapor diffusion, which results in maximum protection within

Timber Construction Magazine Winter 2022 18 www.timbermedia.co.uk @Timber_Media

COVER STORY ROTHOBLAAS

offers a range of innovative solutions to support the growth of the

The Rothoblaas range of tapes, sealants and membranes

the walls and excellent safety in insulation. It is ideal for increasing the energy performance of packages and solutions in the renovation of existing structures and is easy to install thanks to its transparency. It regulates the passage of water vapor according to climate and humidity.

TRASPIR 110: is a highly breathable membrane. The three layers of the synthetic membrane can be applied directly on the outmost side of the walls, right after the heat insulation on the walls.

The added value of Passivhaus-certified components, as in the case of a membrane for a building’s airtightness, is hands down its total independence from climatic zones. The quality of a component suitable to the highest standard of passive buildings is guaranteed regardless of the place where the building we are planning will be built. Therefore, the standard is internationally recognised as a mark of quality. We are very proud to have obtained BBA certification for one of our breathable membranes, TRASPIR 95. We are working on getting this certification for more products. In the era of major climate change, design must also have a say in energy saving, comfort, and sustainability.

Rothoblaas and EPD: knowing our products’ environmental impact

Environmental sustainability is an increasingly central issue in the construction sector, and it has been considered in our company for a long time. Although timber construction is in many respects more sustainable than other building systems, an assessment of the impacts linked to the entire life cycle of the products is still necessary in order to make an objective comparison between different building systems. A suitable tool for this is the Environmental Product Declaration (EPD).

Why is an EPD useful?

Designers: who want to make a good design of the building also from the environmental point of view. Because only through an EPD it is possible to know the environmental profile of a product and make reliable comparisons between two products from the environmental point of view.

Customers: who want to know the impact of the product on the environment or stimulate awareness of the choices made by the manufacturer during its production.

Manufacturers: as they acquire an awareness of the production phases that have the greatest impact on the environment of their products.

The Market: because to build ‘green’ buildings we need data on which to make choices. Without the study of the lifecycle of the product and without an EPD these would not be available.

It’s important because only after an assessment based on reliable and recognised tools such as EPD we can talk about the sustainability of a product without risking unfounded statements. In fact, it is impossible to determine in advance if, from an environmental point of view, one product is better than another as every assumption is personal and can lead to incorrect interpretations. Following the process that leads to the EPD avoids all this, returning verified, exploitable, and comparable data to the client.

Where I can find them?

Valid EPDs can be browsed in the archives of the various Program Operators available on the market, among which there are often mutual

An EPD contains transparent, comparable, and independently verified information about the life cycle environmental impact of the product to which it relates. The EPD is the final document that shows the data of the product’s lifecycle assessment (LCA) and allows the assessment of the environmental performance of the product by studying all the steps it goes through during its life cycle from an environmental point of view.

What does having an EPD mean?

For the product, it means having studied its production process from an environmental perspective having analysed every aspect of it, from the raw material input to its disposal. For a manufacturer, it means being aware of the type of information needed to make a lifecycle analysis, how to find the information, and how each production and management aspect of the product influences its environmental impact. Following this, improvement actions can be identified to make production and product management even more efficient.

recognitions that allow an EPD published in one country to acquire visibility in another. It is understood that the EPD, being a document independently verified and drawn up according to an ISO standard, is already valid and usable worldwide.

This is a voluntary initiative, not obligatory by law, which we have decided to implement to know the environmental impact of our products and to allow the designer to have an accurate idea of the ecological footprint of the building he is designing.

You can find our EPDs on our website in the Technical Insights section. Interested in gaining proficiency with airtightness? Practical training can be arranged with your local representative. Get in touch at UnitedKingdom@rothoblaas.com

More at www.rothoblaas.com

Timber Construction Magazine Winter 2022 19 www.timbermedia.co.uk @Timber_Media

COVER STORY ROTHOBLAAS

BAND

CONTROL 80

©

SPEEDY

CLIMA

SEAL BAND - timber frame private structure renovated

Letts Buildings Services

FLEXI BAND

Optimum Timber Performance

Sticx was founded by two directors that were very experienced in construction, rather than manufacturing. Chris Dermody had 20 years of experience running a company erecting timber frames for other manufacturers and John Maddock had 20 years of main contracting experience. This has served them well over the last 11 years.

“A framer’s performance at site level may only account for 20% of what they do, but it is almost entirely what they are judged on by clients,” says John. “Sticx has grown organically with a long list of repeat clients who know that we understand that the proven benefits of timber frame construction. Our ability to prefabricate open or closed panels is matched by our considered approach to delivery. We can erect prefabricated panels, stick build frames where access is limited, fabricate floor cassettes on or offsite and other options that are selected to suit site requirements.

“We moved from Bootle to larger premises on the Wirral in 2016 and have continued to grow,

despite the recent challenges of Covid and timber price instability. We took the decision a few years ago that the advantages of metal-web joists were so significant that they would be our standard offering, so we set up Joistz Ltd to fabricate them for all our projects and to create a second line of sales to builders and other framers.”

Supply chain pressures

The timber material supply chain has been under real pressure for some time and the Ukrainian conflict has added to this – and does seem to be stabilising – but still has created a number of business pressure points. “Timber pricing went through a crazy period as Covid finished,” says John. “We buy directly from the importers and prices, that had been relatively stable for many years, suddenly went up around 250%. Given that the construction industry over the last 30 years has all but forgotten about inflation and clients expect extended fixed price periods, it has been a challenge.

“Fortunately, prices have dropped back down but the concern we have about this is that

it reflects a reduction in demand, which is a result of a cooling market. The good thing as far as we’re concerned is that cementitious products and masonry all require high energy expenditure in production and this is now giving us an advantage that it’s difficult to see us losing.”

Not all about housing

With continual discussion over the quality and quantity of housing required across the UK, timber frame is in a perfect position to capitalise on the requirement for quicker and more sustainable homes. But is housing still the main sector driving timber frame specification – or have others started to catch up such as education and retail?

“Unusually, we have come the other way,” says John. “Most of our work was in education and student accommodation, until we made the decision to take our experience to clients who were interested in saving money through design improvement. We have clients now who are more willing to invest in design, to standardise details and to save money through

Timber Construction Magazine Winter 2022 20 www.timbermedia.co.uk @Timber_Media

FEATURE THE BIG INTERVIEW

Sticx deal in a wide range of timber systems and since 2011 have grown to become a specialist provider of sustainable design and build options. We spoke to co-founder and director John Maddock.

the elimination of waste. Whilst everyone is concerned about material price hikes, the real issue that is coming down the road is the skill shortages in traditional trades. Partnering with a specialist framing contractor, secures clients ability to deliver projects that they may struggle to deliver otherwise. Long-term relationships de-risk so much of the work, clients are really cottoning on to this.”

There has been a big uptake and interest in engineered timber – CLT and glulam – in recent years above the classic timber frame/panel systems? But questions surround whether CLT/ glulam is suitable for smaller development – is it cost-effective? “To find the optimum solution for a project, it’s important to have all the tricks at your disposal. Early involvement of a timber frame specialist allows architects and engineers access to the best solution for any particular project. It’s unlikely that CLT will be the best value solution for social housing any time soon, but it will start to sneak into projects where there are architectural imperatives, and as this happens it will be selected more by architects and engineers who know where to go to get the design support they need.”

The timber sector has been historically slow in the uptake of digital technology – is that true and how are you using the latest architectural and building design software?

“I think we’d argue that the timber frame sector has not been slow with digital technology,” adds John “Design is a large part of what we do. Practical and accurate design leads to waste reduction and successful projects and I would say somewhere around a third of our overhead covers our design costs. I think generally the industry needs to reverse the trend we’ve seen

since the wholesale introduction of design and build contracting and invest in project designers.

“The main obstacle to the adoption of BIM and better use of the technology is the commercial approach of risk aversion. Clients not wanting to procure traditionally because they think they’d rather divest themselves of the design and measurement risk. It has lead us down a path where the people best placed to design out waste don’t believe it’s in their interest to do so because they aren’t paid a sufficient fee. Waste in the industry is hidden but there is so much abortive work and wasted, repeated effort. We can do so much more with the technology we have, but the procurement method must align itself with a progressive approach.”

Green and lean

The construction industry is under huge pressure to provide zero carbon design and adopt a more circular approach – how is Sticx ensuring high levels of sustainability, certification and streamlined offsite production processes? “We’re firm believers that panelised systems are the way forward. We think that there is a huge amount of wasted effort going into volumetric solutions where the concept is basically flawed. Timber is the only sustainable construction material. All of our material is PEFC-certified. Timber frame promotes better insulation detailing and the extra attention to design reduces wasted material and just as importantly wasted effort.

“We have partnered with the Sovini Group on Merseyside, who have a pipeline of 1000 new units to build. We are helping them to standardise their designs, to make the small adjustments that reduce wasted effort from following trades, to take the lessons learnt from site and feed them back into the designs for the next project. The partnership allows us to work as a team with our partners and the success of the relationship is a continuously improving outcomes for all of our partners. The entirety of this arrangement is the definition of sustainable building.”

How do you see the timber sector developing over the next 18 months and what plans has Sticx for 2023? “The rise of timber frame is inexorable. The climate emergency demands the use of sustainable materials – the skills shortage in traditional trades drives the need for more offsite fabrication and generally we think we’re riding that trend. We’re obviously mindful of the macro economic climate going into 2023: rising costs, lack of available money and a general slowdown in activity. We believe that timber frame will continue to grow its market share. The price of timber has dropped back to normal levels whilst cementitious products and steel, with the cost of energy in their production, will still be inflated over the next year. We see more clients adopting timber frame because of this and we expect to continue to grow.”

More at www.sticx.co.uk

Timber Construction Magazine Winter 2022 21 www.timbermedia.co.uk @Timber_Media

FEATURE THE BIG INTERVIEW

“I don’t see how you can in one breath claim a climate emergency and then continue specifying concrete and steel. Timber has to be the way forward.”

Free Form Flowing Timber

With its wave-like roof made of spruce laminated veneer lumber, it pushes the boundaries of what was previously considered possible. The Free Form roof was designed by the Swedish architecture firm Elding Oscarson in collaboration with the Norwegian construction engineer Florian Kosche. Based on their designs, the timber construction specialists at Blumer Lehmann created the detail plans for the unique free form building together with their planning partners.

The pioneering Wisdome Stockholm is already being characterised as one of Sweden’s most important building projects. It features a spectacular timber construction with a surface area of 1,325sq m and a unique vaulted main roof. Inside this experience arena is a hemispherical dome theatre with a diameter of almost 22m and a height of around 12m. The theatre includes a 3D cinema with 100 seats. With 360-degree 3D projections and cutting-edge visualisation technology, it allows visitors to experience the world of science and engineering in a new and fully immersive way.

Pioneering timber design

The heavily curved Free Form timber roof connects the inside and outside areas of the National Museum of Science and Technology and creates a spectacular interior for the dome structure of Wisdome Stockholm. The roof geometry spans a footprint of 25m x 48m, without columns. On three sides of the building, a projecting roof supplements the roof support structure and brings the curvature of the roof surface level with the eaves line. The Free Form structure is based on a grid system of LVL beams.

The dome below the vaulted roof is made from cross laminated timber (CLT). A requirement of the architecture competition was that timber be used in the construction, in particular CLT and laminated veneer lumber (LVL). One of the main partners of the Wisdome Stockholm project is Stora Enso – the Finnish-Swedish company also supplied all the timber construction material for the project. The flagship building marks a milestone in sustainable, climate-friendly construction. It pushes existing technical boundaries and is intended to showcase what is possible with wood as a climate-friendly construction material.

Roof support structure with 20

km

of LVL panel strips

With its experience in timber construction and its technical expertise in project planning and the implementation of sophisticated Free Form

geometries, the Swiss timber construction

was the perfect partner to execute this ambitious project.

For the main roof, the timber construction engineers at SJB Kempter Fitze opted for a lattice-shell structure with criss-crossing LVL beams. With interlocking dowel joints and the help of cutting-edge planning tools, these were connected to form a double-curved grid. The differently vaulted roof construction is supported around the edge by 24 solid columns that are made from block-laminated LVL with dimensions of 60 x 80 and 60 x 60cm. The columns are connected rigidly to the approximately 1.20m-high concrete base. To limit the horizontal deformation of the roof support structure, tensioning rods are integrated into the wooden columns, to which a considerable pretensioning force is applied after assembly. A solid edge beam is arranged on the column heads to enclose the Free Form construction all the way round.

1:1

model for the roof construction

Two mock-ups provided the information needed for the construction design. The lattice-shell roof support structure consists of three transverse layers of LVL beams and two longitudinal layers of beams. Unlike constructions made of laminated timber, which are bent and milled in the factory beforehand and delivered to the construction site as complete components, for construction of the main roof only the lowest panel strip layer was laminated in the required curvature and delivered as a finished component. This layer served as a scaffold and structural aid for the complex assembly process. The remaining four beam layers were only bent and dowelled during assembly on site. All the connections are designed with dowels and peg connections, which are milled from the same LVL material. Wisdome Stockholm is scheduled to open in 2023. More at www.blumer-lehmann.ch

Timber Construction Magazine Winter 2022 22 www.timbermedia.co.uk @Timber_Media

company Blumer Lehmann

A superb Free Form roof that could redefine the future of timber construction has been proposed for Sweden’s National Museum of Science and Technology.

FEATURE WISDOME STOCKHOLM

Timber Construction Magazine Winter 2022 23 www.timbermedia.co.uk @Timber_Media

Be Aware: Close the Door

(32%)

Organisers of Fire Door Safety Week say the findings show that there is a “clear lack of accountability” over reporting fire door issues, and that lives are being put at risk as a result. Despite three quarters (75%) correctly believing that propping a fire door open stops it performing its role in the event of a fire, 44% wouldn’t take

action over a propped open fire door as they wouldn’t know who to report it to, and almost half (49%) do not feel it’s their place or role to report it.

Helen Hewitt, CEO of the British Woodworking Federation which founded Fire Door Safety Week, said: “There were 243 fire-related fatalities in England in the past 12 months, so individual action really is crucial

in preventing tragedies. Fire doors propped open put lives at risk in the unfortunate event of a fire. Without being properly closed, a fire door cannot hold back the spread of fire and smoke to fulfil its life-saving role.”

The research showed that propped open fire doors are a common occurrence, with 10% of respondents having seen a propped open fire door in their place of residence on some occasions and

A specialist manufacturer of fire rated, acoustic and PAS 24 security doors and doorsets, is adding a second factory to boost its manufacturing capacity, ahead of its 100th anniversary next year.

Birmingham-based E&SW Knowles employs 114 people and is expanding its manufacturing operation into a second building, adding 13,750sq ft to its existing 44,500sq ft capability. It is designed to support strategic growth and will further improve manufacturing efficiencies and customers’ experience.

The investment has been announced following the company’s recent acquisition by Sentry Doors Limited. The two companies’ product ranges are complementary and have minimal overlap in the industry sectors they serve. The partnership will provide both businesses with opportunities for further innovation and growth.

Managing director Steve Horner said: “This strategic acquisition along with our 100th anniversary will mean that 2023 will be a very big year for us. We wanted to do something that marked this achievement but also put a marker in the sand about where we are going and our intention to become the UK’s leader in timber fire safety and security doorsets. We are committed to the West Midlands area, and will create 10 more jobs next year alone. The new facility will mean more new machinery, processes, and infrastructure to support our growth ambitions. We are very proud of our 100-year heritage and

industry experience but are also looking ahead to ensure we remain competitive, customer-focused, and innovative.”

Born from a family-owned business, E&SW Knowles’ products are widely specified in the education, healthcare, leisure, commercial and social housing sectors, complying with the latest standards, building regulations and sustainability demands. Sentry Doors is a specialist manufacturer of bespoke, fully certified timber fire and security entrance doors for the social housing, public sector residential markets and the supplier of choice for local authority, housing associations and their contractors.

Timber Construction Magazine Winter 2022 24 www.timbermedia.co.uk @Timber_Media

A third

of the British public would not report a problem with a fire door, with a perceived lack of personal repercussions being one of the main reasons for not reporting, new research to mark Fire Door Safety Week found.

FEATURE FIRE DOOR SAFETY

More at www.knowlesdoors.co.uk

Fire Door Manufacturer Adds Second Factory

Build better to improve living comfort

ENERGY EFFICIENCY IN CONSTRUCTION

Rothoblaas believes in developing passive architecture and invests in innovative solutions in order to sustain the growth of the sector and to offer quality products for the most ambitious projects.

Discover more: www.rothoblaas.com/energy-efficiency

20% in the workplace. It also identified that the two most common objects used to prop open a fire door are a wedge and a fire extinguisher.

Concerningly, 31% incorrectly believed that a fire door that was propped open with a wedge or a fire extinguisher was safe and 18% didn’t believe a propped open fire door poses a risk to those in the building so wouldn’t take action. Not only was a propped open fire door incorrectly deemed as safe, but 15% believed that keeping a fire door closed stops it performing, highlighting a lack of understanding around the role fire doors play in the event of a fire.

Gavin Tomlinson, National Fire Chiefs Council (NFCC) Chair for Protection and Business Safety said: “We urge everyone to help keep buildings and their occupants safe and Close the Door on Fire. A fire door can only protect from fire and smoke if it is closed. We ask that if

people see a fire door propped open, they close it. It’s a simple ask that could save a life.

“Everyone has a role in ensuring their buildings remain safe from fire, and if you have any concerns, then please ensure these are reported to the building owner or person responsible for the fire safety of that building. If it continues to be a problem or you are concerned about fire doors in a building, you can contact your fire service for advice and support.”

The research also found a lack of understanding over what constitutes a safe fire door. Alarmingly, 44% believed that either: a fire door is a normal door covered in fireresistant paint (13%), a fire door is a normal door but with ‘fire door’ signage (13%), or that any timber door was a fire door (7%).

Helen Hewitt added: “There is clearly still a dangerous lack of understanding and need

for education on the role of fire doors. The encouraging news is that when people are better informed about fire doors, they’re more likely to report issues. Half (49%) of respondents said having a better understanding over what fire doors do and how they work would encourage them to take action.”

More at www.firedoorsafetyweek.co.uk

Fire door keep shut

Timber Construction Magazine Winter 2022 25 www.timbermedia.co.uk @Timber_Media FEATURE FIRE DOOR SAFETY

EPD LCA EN 13501-1 B-s1,d0

Weathering the Storm: Moisture Effects on CLT

Cross laminated timber (CLT) has become a popular choice for designers over the last 15 years. Spanning residential buildings to educational and commercial spaces, the market growth of CLT can be attributed to its usability in complex timber structures. Modern lightweight timber frame buildings have been used for nearly 100 years. Plus, a large proportion of the UK housing stock has timber pitched roofs, many of which are centuries old.