Bring your passion and experience in the construction or transpor tation industr y to Ritchie Bros.! Solid customer bases and large growth potential for those with strong relationship building and prospecting skills. Join a leader in the global marketplace for insights, ser vices, and transaction solutions for commercial assets and get rewarded for your hard work. Positions open across North America.

to learn more!

McCOURT

Construction Company

COONEY

C.Construction Inc.

VALENTI

Construction, Inc.

PACELLA

Construction Corp.

OF DIRECTORS

MARCELLA ALBANESE

Brothers, Inc.

BARLETTA

Heavy Division

BISZKO, III

Contracting Corp.

BRANDFORD

Excavating

ANDREW DANIELS

Derenzo Company

GEORGE DeFELICE

Corporation

JERRY GAGLIARDUCCI

Construction, Inc.

JOE GIOIOSO

Gioioso & Sons, Inc.

DAN HORGAN

H. White Const. Co., Inc.

LISA FRENCH KELLEY

L. French Excavating Corp.

MADDEN

Paving Corp.

ROBBIE OUR

B. Our Co., Inc.

RICHARD PACELLA, JR.

M. Pacella, Inc.

BRIAN RAWSTON

Cashman, Inc.

FRED ROGERS

Inc./Minichiello Bros., Inc.

SVEDEN

N. Wood Company, Inc.

JORDAN TIRONE

Insurance Agency, Inc.

DAVID WALSH

Hot Mix Asphalt

MAHONEY

Director

Looking Ahead

Update:

Eventful MWRA

Meeting: Approves Additional $100 Million in I/I

and Temporarily Waives Joining Fee

MassDEP Proposes

Baker-Polito

Skills Capital Grants Awarded

to Know

Dinner

for Inventorying Large Fleets

Million in Coastal Community Resilience

Industry

Strikes

on Cape Cod:

Safety

Sewer System

Jeff Mahoney, Senior Editor:

Outlook

Board:

Editor:

McCourt,

Klayman,

Klayman,

Editor Suzanne Hatch,

Writer/Assistant Editor:

McCourt

Cooney,

Lenihan

Congress Street,

of

101, Quincy,

and

are

After a very dry summer, fall is off to a wet and cool start. The leaves are changing, the Red Sox season is mercifully over, football season has begun, and UCANE members are all working to complete jobs towards the end of what I hope has been a busy season.

While contractors are working hard finishing this critical work, UCANE continues to look forward and is working to assure that jobs will be put out to bid next year and for many years to come. Letting our elected officials and leaders know about what we do and the importance of clean drinking wa ter, wastewater, and our underground utility infrastructure is one of UCANE’s core missions. We continue to meet with lawmakers, state officials, and candidates all across the state on behalf of our industry to advocate for additional funding, and to make sure these vital proj ects are a top priority. This is particularly important as we deal with supply chain and inflation issues.

It is imperative that our elected officials know that the job is not done simply with the approval of addi tional funding through the Federal Infrastructure Bill, stimulus funds, and surplus tax revenue. We continue to work with all stakeholders to try to find ways to make it easier for cities, towns, and authorities to ap prove necessary projects.

UCANE’s September Dinner Meeting focused on this very topic, with UCANE members, engineers, and DPW Directors participating in a panel discus sion. You can read about the event beginning on page 48. We must ensure that these additional funds are actually spent, and that proper incentives are of fered so that municipalities and awarding authorities abandon the “kick the can” mentality, so that projects are funded and move forward without delay.

That is why at the federal level we work closely with the Clean Water Construction Coalition (CWCC), a group of 28 Associations from across the country representing over 11,000 firms. The states repre sented in the Coalition account for approximately 75 percent of the total annual funding for the Clean

Water and Drinking Water SRF programs nationally. We have worked together to push for increased fed eral levels in infrastructure funding and for legislation effecting our industry, culminating in the $1.2 trillion bipartisan Infrastructure Law. We are now focused on measures to alleviate some of the bureaucratic hurdles in programs that have been a deterrent in the past to maximizing their use and effectiveness.

Public awareness is also an important element of our advocacy. During the pandemic we began the #InvestinWaterMA campaign to continue to highlight the importance of our infrastructure through social media, billboards, articles, op-eds, and videos. The campaign is ongoing and we continue to add part ners to help us spread the word. We will once again be participating in the “Imagine a Day Without Water Campaign” on October 20 as a member of the Val ue of Water Coalition. This is a national awareness campaign highlighting the importance of clean water in our everyday life, This is the seventh consecutive year UCANE will be participating.

There is now a lot of focus and attention on the 2022 election, where there will be several new names on the ballot, including for Governor for Massachusetts. The barrage of the endless political commercials will be coming to an end in the next few weeks. But, in the end, regardless of who is elected, UCANE will focus on what’s important: making sure our industry is healthy, which in turn ensures the health and economic prosperity of all of our citizens. n

Mark Molloy, Esq., Cascade Strategies

Mark Molloy, Esq., Cascade Strategies

At its September 14 meeting, the MWRA Board of Directors voted to adopt the recommen dation of the MWRA Advisory Board to fund another phase of its longstanding wastewater Infil tration/Inflow Local Financial Assistance Program aimed at helping communities improve their local sewer systems.

Infiltration/Inflow is extraneous water that enters all wastewater collection systems through a variety of sources. During wet weather conditions, this ad ditional flow reduces capacity in the system, and can lead to sanitary sewer overflows. MWRA’s I/I Local Financial Assistance Program began in 1993 and is a critical component of the MWRA’s Regional I/I Reduction Plan. The amount available to each com munity is based upon each community’s share of the MWRA’s sewer charges.

With this vote, the MWRA Board of Directors has approved $861 million in grants and loans for MWRA sewer communities since the program’s inception in 1993. To date, $515 million has been distributed to fund over 600 local sewer projects. According to a press release issued by the MWRA Advisory Board, this additional $100 million marks the fourteenth phase of I/I Local Financial Assistance funding. Funds will be available as 75% grants and 25% interest-free loans paid back over 10 years. The program is extremely popular for MWRA’s member communities. Over 80% of eligible communities have used more than half of their available grant/loan funds, which sunset in 2030.

More than 600 projects have been completed across the MWRA sewer service area. To date, 80 miles of sewer lines have been replaced and 300 more miles have been lined, along with inspections and oth er repairs.

At the same meeting, the MWRA Board of Directors voted to adopt the recommendation of the MWRA Advisory Board to temporarily waive the entrance fee new communities pay to join the MWRA water system. Citing the challenges communities face – stressed river basins requiring water restric tions, rising concerns about PFAS, and constrained economic development – the vote of the MWRA Board of Directors removed one hurdle communities must clear to join the MWRA system.

While the majority of the Commonwealth remains under significant or critical drought status, the Quab bin Reservoir, which supplies the MWRA’s system, remains over 90% full placing it well within normal operating conditions for this time of year. Accord ing to the MWRA, even if the drought continued for several years, there would be adequate supply to fully meet the needs of MWRA’s existing water com munities and, if needed, to augment the supplies of adjacent stressed communities. Given the selling of an additional five million gallons per day would re duce MWRA water communities’ assessments by over $205 million over 25 years, the MWRA Advisory Board voted in June to recommend that the MWRA Board of Directors approve a five-year waiver of the entrance fee, subject to certain conditions.

The MWRA admissions process includes a robust environmental review, pipes must be built to connect the nearby communities to the MWRA’s system, and in some cases modifications to the MWRA’s infrastruc ture must be made to meet the requested demand.

To review the presentation on these issues from the September MWRA meeting, please visit: https://www. mwra.com/monthly/bod/presentations/2022/p2022-0914.pdf.

The Massachusetts Department of Environ mental Protection (MassDEP) announced that it will hold a public hearing on a newly proposed regulation, 310 CMR 7.41, Large Entity Reporting Requirement. The purpose of the pub lic hearing is to solicit comments on the regulation, which will require a one-time report from certain en tities on their medium- and heavy-duty vehicle use.

Of note, this proposed regulation – which mimics something that the California Air Resources Board (CARB) did in 2021 – seeks to create a baseline for the MassDEP to eventually set stan dards for medium and heavy duty truck (MHD) emissions in Massachusetts in the future. For now, as stated in the proposed regulation, the reporting requirement will apply to:

(a) Any entity with gross annual revenues greater than $50 million in the United States for the 2021 tax year, including revenues from all sub

sidiaries, subdivisions, or branches, that operated a facility in Massachusetts in the 2021 calendar year and had one or more vehicles over 8,500 lbs. GVWR under common ownership or control that were operated in Massachusetts in the 2021 cal endar year;

(b) Any fleet owner in the 2021 calendar year that had 40 or more vehicles with a GVWR greater than 8,500 lbs. under common ownership or con trol and operated a facility in Massachusetts;

(c) Any broker or entity that dispatched 40 or more vehicles with a GVWR greater than 8,500 lbs. into or throughout Massachusetts, and operated a facility in Massachusetts, in the 2021 calen dar year;

(d) Any Massachusetts government agency in cluding all state and local municipalities and public schools that had one or more vehicles over 8,500

As part of the Commonwealth’s celebration of Climate Week, which ran from September 19, 2022 to September 25, 2022, the Baker-Polito Administration announced the awarding of $12.6 mil lion in grants to support 27 local planning and shoreline management projects to aid Massachusetts’ coastal communities in preparing for severe coastal storms and the impacts of climate change, including storm surge, flooding, erosion, and sea level rise. The funding, provided through the Executive Office of Energy and Environmental Affairs’ (EEA) Office of Coastal Zone Management (CZM), has been awarded to Barnsta ble, Boston, Brewster, Chatham, Chilmark, Cohasset, Duxbury Beach Reservation, Inc., Gosnold, House of Seven Gables Settlement Association, Ipswich, Man chester-by-the-Sea, Marblehead, Marshfield, Mass Audubon, Mattapoisett, Nahant, New Bedford, Orleans, Plymouth, Provincetown, Salem, Scituate, Wareham, Wellfleet, and the Woods Hole Oceanographic Institu tion. Additional municipal partners of these projects in clude Braintree, Chilmark, Dennis, Duxbury, Eastham, Falmouth, Truro, and Winthrop.

CZM’s Coastal Resilience Grant Program pro vides funding and technical assistance for local ef forts to evaluate vulnerabilities to climate impacts, increase community awareness, and understanding of these issues, plan for changing conditions, rede sign vulnerable community facilities and infrastructure, and restore shoreline systems through nonstructural approaches. Grants may fund feasibility assessments, public outreach, design, permitting, construction, and monitoring of projects that en hance or create natural buffers to erosion and flood ing. Including the grants announced in this round, the Baker-Polito Administration has now invested $35.7 million in 182 coastal resilience improvement projects through the Coastal Resilience Grant Program since 2015. Funding through the program has supported comprehensive planning, infrastructure retrofits, and shoreline restoration projects to reduce wave energy, erosion, and flooding impacts.

Among the 27 projects receiving a total of $12.6

continued on page 15

million in Coastal Resilience Grants, the following projects may be of interest to UCANE members:

Barnstable: Sandy Neck Beach Facility Preliminary Design and Permitting ($128,127). The Town of Barnstable will design and initiate permitting for nature-based measures and a reconfiguration of the Sandy Neck Beach Facility to enhance storm damage protection to infrastructure, wetlands, and endangered species habitat areas.

Cohasset: Cohasset Cove and James Brook Watershed Flood Vulnerability Assessment and Resiliency Strategies ($161,925). The Town of Co hasset will assess the vulnerability of the Wastewater Treatment Plant and Influent Pump Station located in Jacob’s Meadow and other public assets to current and future flooding conditions within the Cohasset Cove and James Brook Watershed. The project will develop resiliency strategies to mitigate flooding risks to these critical local and regional resources.

Gosnold: Gosnold Fuel Resilience ProjectConstruction ($573,398). The Town of Gosnold will install a new above-ground fuel storage system that incorporates sea level rise considerations to replace re cently removed underground tanks. Providing a resilient source of fuel for vessels, vehicles, and home heating is critical to residents and visitors on the island.

Wareham: Resilient Main Street ($199,918). The Town of Wareham will develop a conceptual plan for implementable adaptation measures that can re duce flood risk to the Main Street commercial district. The project will increase public understanding of the vulnerability of the area and explore nature-based solutions.

The Massachusetts Office of Coastal Zone Management is the lead policy and planning agen cy on coastal and ocean issues within the EEA. Through planning, technical and grant assistance, and public information programs, CZM seeks to bal ance the impacts of human activity with the protec tion of coastal and marine resources. The agency’s work includes helping coastal communities address the challenges of storms, sea level rise, and other effects of climate change; working with state, re gional, and federal partners to balance current and new uses of ocean waters while protecting ocean habitats and promoting sustainable economic development; and partnering with communities and other organizations to protect and restore coastal water quality and habitats.

To review the variety of projects awarded under the CZM grant program, please visit: https://www. mass.gov/news/baker-polito-administration-invests126-million-in-coastal-community-resilience.

continued on page 17

Ferguson offers a complete line of products to cover all your water, sewer and storm water management needs, and our relationships with the waterworks industry’s top vendors give our customers peace of mind through unmatched customer service, on-time delivery, and industry leading fill rates.

Our Construction & Public Contracts practice is nationally ranked rst-tier in LitigationConstruction by U.S. News & World Report. We add value for our clients through the strong relationships we maintain with key industry participants, awarding authorities, and government agencies.

We specialize in solving complex issues and provide a full range of construction law and dispute resolution expertise including Compliance, Crisis Response & Management, Dispute Resolution, Government & Internal Investigations, Procurement, Risk Management, Surety, and Transactions.

James J. Barriere Boston/Albany

Christopher W. Morog Boston

At the end of September, the Baker-Polito Ad ministration announced that it had awarded $24 million in Skills Capital Grants to 14 dif ferent high schools. Each school received awards between $1 million and $2.5 million, which will en able the schools to modernize labs and significantly expand student enrollment in programs that provide career education.

The high schools receiving grants will make stra tegic investments over the next two years to grow their career education programs to provide more learning opportunities for both traditional high school students and adult learners, with several schools expanding their Career Technical Initiative (CTI) programs to of fer more learning opportunities in the late-afternoon and evening. Over the next five years, the aforemen tioned grant awards will directly impact approximately 10,000 students across 38 different programs.

The funding for this round of grants was included in An Act Relative to Immediate Covid-19 Recovery Needs, passed by the Legislature and signed by the Governor, which included $100 million in state resources to provide capital improvement grants to vocational high schools and public schools operat ing career and technical education programs. Since 2015, 491 Skills Capital Grants totaling more than $153 million have been awarded to different schools and educational institutions across the Common wealth, with many organizations receiving multiple grants over the years.

The Skills Capital Grant program was originally launched in 2015 with the goal of replacing outdated equipment and technology, mainly at vocational tech nical high schools and community colleges. Since then, the program has evolved into a crucial compo

nent of local workforce training efforts by expanding the number of young people and adults trained and experienced with the newest technologies used by local employers. The competitive grants are awarded to educational institutions that demonstrate partner ships with local businesses, as well as align curriculum and credentials with industry demands to maxi mize hiring opportunities in each region of the state.

The Skills Capital Grants are awarded by Gov ernor Baker’s Workforce Skills Cabinet, which was created in 2015 to bring together the Secretariats of Education, Labor and Workforce Development, and Housing and Economic Development to align educa tion, economic development, and workforce policies to strategize around how to meet employers’ demand for skilled workers in every region of the Commonwealth.

To review a list of award winners, please visit: https://www.mass.gov/news/baker-polito-adminis tration-awards-24-million-in-skills-capital-grants-tohigh-schools.

continued on page 19

Manufacturer & Installer of Bituminous Concrete Products: M.B.S. Construction Services/Paving

Holden Trap Rock Co.

2077 N. Main Street (Route 122 A)

Holden, MA 01520

Tel: 508-829-5353

Fax: 508-829-9346

Berlin Stone Co. 332 Sawyer Hill Rd. (off Rt. 62 & 495) Berlin, MA 01503

Tel: 978-838-9999

Fax: 978-838-9916

• RMV Expanding Accessibility and Availability of Same Day Services. The Massachusetts Registry of Motor Vehicles (RMV) announced that it is expanding the accessibility and availability of same day walk-in services for required in-person registration-related transactions including registering a vehicle and transferring an exist ing registration to a new vehicle. Appointments for these transactions will no longer be necessary and became unavailable for scheduling as of Monday, September 26. According to the RMV, customers are encouraged to continue to conduct RMV registration transactions by working through their insurance agents and auto deal ers who are able to complete bulk transactions in-person through Business 2 Business (B2B) services at select service center locations and electronically use the Elec tronic Vehicle Registration (EVR) Program. (The Chicop ee RMV is strictly a B2B location and walk-ins cannot be conducted.) Transactions include new registrations and titles, registration transfers, cancellations and renewals, and license plate swap transactions. Customers can also visit AAA sites, if they are AAA members. Any registra tion appointments that have been previously scheduled online to date will remain in place and be honored.

• Information About Massachusetts 2022 Ballot Ques tions. In an effort to educate voters about statewide bal

lot questions that will be decided during the November general election, Massachusetts Secretary of State Bill Galvin has published a resource that explains each ballot question. In addition to explaining the ballot question, the Secretary’s information resource provides a central argu ment for and against each question from leading propo nents and opponents. To review information about each ballot question, please visit: https://www.sec.state.ma.us/ ele/ele22/information-for-voters-22/quest_1.htm.Each question may be viewed in turn by selecting “next” at the bottom of the screen.

• City of Worcester Awarded MVP Grant. The Common wealth awarded the City of Worcester a little over $1.2 mil lion in grant funding in September to develop and implement a drainage and green infrastructure plan for the city. The plan will help remediate flooding and heat islands in Worcester neighborhoods. These competitive grants — awarded by the Massachusetts’ Municipal Vulnerability Preparedness (MVP) program and administered by the EEA — support cities and towns in identifying climate hazards, developing strategies to improve resilience, and implementing priority actions to adapt to climate change. Worcester’s Drainage and Green Infrastructure Master Plan is one of 73 projects to have received action grant funding in the latest round of applications. n

As discussed at last month’s UCANE’s Board of Director’s meeting, federal contractors and subcontractors need to create an account on the U.S. Department of Labor’s Office of Federal Contract Compliance Programs (“OFCCP”) new online platform. The platform, referred to as the Notification of Construction Contract Award Portal (“NCAP”), launched on August 26, 2022 and was created to modernize how OFCCP receives required notifications.

Who is required to submit construction contract award notifications?

First, construction contractors are required to submit written notice to OFFCP within 10 working days of awarding any construction subcontract in excess of $10,000 at any tier of construction work performed under a federal or federally assisted con struction contract. 41 CFR 40-4.2(d)(3). Second, federal contracting officers, applicants for federally assisted construction projects, and covered non-construction contractors are required to submit written notice to OFCCP within 10 working days of awarding construction contracts in excess of $10,000. 41 CFR 40-4.2(c). Guidance makes clear that awarding contracts and not award recipients are required to notify OFFCP. Additionally, if a company subcontracts a portion of an award in excess of $10,000 it then is required to notify OFCCP of that award.

Contracting officers, applicants, contractors and subcontractors need to set up a NCAP account to provide necessary notifications to OFFCP going for ward. This can be done at login.gov. NCAP can be accessed at ncap.dol.gov. NCAP collects the infor mation required on the OMB Form CC-314, so be sure to have that available when logging on to create an account.

Additionally, parties that submit notification to OFF CP through NCAP must ensure that all solicitations for offers and bids and federal assisted construction con tracts or subcontracts include the Standard Federal Equal Employment Opportunity Construction Contract Specifications set forth in 41 CFR 60.43. They also must include the notice set out in 41 CFR 60.42(d).

OFCCP collects this information as a source to determine contractors over which it may have jurisdiction. The notices provide an information source for neutrally scheduling construction contractors and subcontractors for compliance evaluations and is designed to allow the OFCCP to evaluate a com pany’s compliance with Affirmative Action Plan and Equal Employment Opportunity requirements. OF CCP receives name and contact information for all contractors and subcontractors that receive notice of requirement for affirmative action to ensure equal employment opportunity, which sets forth goals for minority and female participation in construction trades and covered areas.

If you have any questions about this require ment the OFFCP has published a Q&A that answers questions about how to login and setup an account, as well as submitting notification of awards. https:// www.dol.gov/agencies/ofccp/faqs/Notification-ofConstruction-Contract-Award-Portal. n

Construction & Public Contracts Group, Hinckley Allen, LLP

WASHINGTON – To strengthen enforcement and improve compliance with workplace safety stan dards and reduce worker injuries and illnesses, the U.S. Department of Labor is expanding the criteria for placement in the Occupational Safety and Health Administration's Severe Violator Enforcement Program.

The new criteria include violations of all hazards and OSHA standards and will continue to focus on repeat offenders in all industries. Previously, an em ployer could be in the program for failing to meet a limited number of standards. The changes will broad en the program's scope with the possibility that ad ditional industries will fall within its parameters.

Since 2010, the Severe Violator Enforcement Pro gram has focused on enforcement and inspection resources on employers who either willfully or repeatedly violate federal health and safety laws or demonstrate a refusal to correct previous violations. In addition to be ing included on a public list of the nation's severe viola tors, employers are subject to follow-up inspections.

"The Severe Violator Enforcement Program em powers OSHA to sharpen its focus on employers who – even after receiving citations for exposing workers to hazardous conditions and serious dangers – fail to mitigate these hazards," said Assistant Secretary for Occupational Safety and Health Doug Parker. "Today's expanded criteria reflect the Biden-Harris

administration's commitment to ensuring OSHA has the tools it needs to ensure employers protect their workers or hold them accountable when they fail to provide safe and healthy workplaces."

Specifically, the updated criteria include the fol lowing:

Program placement for employers with citations for at least two willful or repeated violations or who receive failure-to-abate notices based on the pres ence of high -gravity serious violations.

Follow-up or referral inspections made one year –but not longer than two years – after the final order.

Potential removal from the Severe Violator En forcement Program three years after the date of re ceiving verification that the employer has abated all program-related hazards. In the past, removal could occur three years after the final order date.

Employers' ability to reduce time spent in the program to two years, if they consent to an enhanced settlement agreement that includes use of a safety and health management system with seven basic elements in OSHA's Recommended Practices for Safety and Health Programs.

The updated program instruction replaces the 2010 instruction, and remains in effect until canceled or superseded. n

Nicks Rock Road

MA 02360

House: 508-732-9148

Asphalt Plant: 508-732-9140

At a recent meeting the MWRA Board of Di rectors voted to adopt the recommendation of the MWRA Advisory Board to temporarily waive the entrance fee new communities pay to join the MWRA water system. Citing the challenges communities face – stressed river basins requiring water restrictions, rising concerns about PFAS (the so-called “forever chemicals”), and constrained eco nomic development – the vote of the MWRA Board of Directors removed one hurdle communities must clear to join the MWRA system.

Romero, MWRA Advisory Board

That’s why the Advisory Board began exploring the option of temporarily waiving the entrance fee.”

Contacts: Matthew Romero, MWRA Advisory

Selling an additional five million gallons per day would reduce MWRA water communities’ assess ments by over $205 million over twenty-five years.

Ria Convery, MWRA

Emails: matthew.romero@mwraadvisoryboard.com ria.convery@mwra.com

Following months of discussion and debate, the Advisory Board voted in June to recommend that the MWRA Board of Directors approve a five-year waiver of the entrance fee, subject to certain conditions.

“Ensuring the availability of clean, safe drinking water is critical to public health, safety, and protecting our environmental resources,” said Energy and Environmental Affairs Secretary Beth Card, who chairs the MWRA’s Board of Directors. “The MWRA’s water supply system is a tremendous resource and by waiv ing the entrance fee for new communities, interested municipalities will be able to better assess their own communities’ needs and the hurdles that may impact them, such as ongoing drought conditions, PFAS, and aging infrastructure.”

“We’ve always been interested in responsibly growing the system,” said Fred Laskey, MWRA Executive Director. “Thanks to water conservation and system improvements, MWRA is now 100 million gal lons per day below its safe yield,” he added. “That’s 100 MGD that communities in need could use if they joined the system, and this vote by the Board of Di rectors will make it easier for them to do so.”

BOSTON, MA, September 22 – At its meeting last week, the MWRA Board of Directors voted adopt the recommendation of the MWRA Advisory Board to temporarily waive the entrance fee new communities pay to join the MWRA water system. Citing the challenges communities

September 22 – At its meeting last week, the MWRA Board of Directors voted to recommendation of the MWRA Advisory Board to temporarily waive the entrance pay to join the MWRA water system. Citing the challenges communities basins requiring water restrictions, rising concerns about PFAS (the so chemicals”), and constrained economic development – the vote of the MWRA removed one hurdle communities must clear to join the MWRA system. of clean, safe drinking water is critical to public health, safety, and environmental resources,” said Energy and Environmental Affairs Secretary Beth MWRA’s Board of Directors. “The MWRA’s water supply system is a and by waiving the entrance fee for new communities, interested able to better assess their own communities’ needs and the hurdles that as ongoing drought conditions, PFAS, and aging infrastructure.”

face – stressed river basins requiring water restrictions, rising concerns about PFAS (the called “forever chemicals”), and constrained economic development – the vote of the MWRA Board of Directors removed one hurdle communities must clear to join the MWRA system.

While the majority of the Commonwealth remains under significant or critical drought status, the Quab bin Reservoir, which supplies the MWRA’s system, remains over 90% full placing it well within normal operating conditions for this time of year. According to the MWRA, even if the drought continued for several years, there would be adequate supply to fully meet the needs of MWRA’s existing water communities and, if needed, to augment the supplies of adjacent stressed communities.

Though the MWRA removed one barrier for en try, many others remain. The admissions process includes a robust environmental review, pipes must be built to connect the nearby communities to the MWRA’s system, and in some cases modifications to the MWRA’s infrastructure must be made to meet the requested demand.

“Ensuring the availability of clean, safe drinking water is critical to public health, safety, and protecting our environmental resources,” said Energy and Environmental Affairs Secretary Card, who chairs the MWRA’s Board of Directors. “The MWRA’s water supply system is a tremendous resource and by waiving the entrance fee for new communities, interested municipalities will be able to better assess their own communities’ needs and the hurdles may impact them, such as ongoing drought conditions, PFAS, and aging infrastructure.”

“The MWRA has excess water to sell, and many communities near our system need water,” explained Lou Taverna, Chairman of the MWRA Advisory Board. “The benefit for existing communities is a reduction in their assessments each time a new member joins.

“We have a unique opportunity given unprecedent ed levels of federal and state funding that could poten tially be used to help pay for these infrastructure costs,” explained Joe Favaloro, MWRA Advisory Board Execu tive Director. “If all of the stars align, this could be a “winwin” situation. Communities with water challenges can meet their needs and safeguard their residents’ health with the best drinking water in the country, and MWRA communities receive some much-needed rate relief.”

the Commonwealth remains under significant or critical drought status, which supplies the MWRA’s system, remains over 90% full placing it operating conditions for this time of year. According to the MWRA, even if for several years, there would be adequate supply to fully meet the existing water communities and, if needed, to augment the supplies of

While the majority of the Commonwealth remains under significant or critical drought status, the Quabbin Reservoir, which supplies the MWRA’s system, remains over 90% full placing well within normal operating conditions for this time of year. According to the MWRA, even the drought continued for several years, there would be adequate supply to fully meet the needs of MWRA’s existing water communities and, if needed, to augment the supplies of adjacent stressed communities.

If you would like more information about this topic, please contact the MWRA Advisory Board at mat thew.romero@mwraadvisoryboard.com

Concrete Systems, Inc.: Manholes & Catch Basins, Box Culverts, Utility Structures, Special Box Structures, Containment Vaults, Fire Cisterns, CSI Arc-Span™ Bridges, Rigid Bridge ™ Systems, Bridge Deck Slabs, Permanent & Temporary Median Barrier, Uwall™ Retaining Wall Systems, Stablewall™ Retaining Wall, Headwalls & Wingwalls. Clampcrete Construction Systems: TL-4 Anchored Barrier for Roadway Structures. Tunnel Systems: Precision Segmental Tunnel Lining Rings. Cleco Manufacturing: Precision Fabricated Forms & Forming Systems, Complete Plant Design, Batch Plant Computer Automation, Countercurrent Mixers & Concrete Delivery Systems.

Patrick W. Saltmarsh Corporate Safety Director J. Derenzo Companies Tim Hunt, CHST Dir. of Envt’l, Health and Safety W. L. French Excavating Corp.

Patrick W. Saltmarsh Corporate Safety Director J. Derenzo Companies Tim Hunt, CHST Dir. of Envt’l, Health and Safety W. L. French Excavating Corp.

aims to raise fire safety awareness and help ensure your home and family are protected. In 1922, the National Fire Protection Association (NFPA) named Fire Prevention Week the second week of October, commemorating the Great Chicago Fire in 1871.

• Three of every five home fire deaths resulted from fires with no working smoke alarms.

• Less than 50% of homeowners have an escape plan.

• Carbon monoxide (CO) is the #1 cause of acci dental poisoning in the U.S.

• 60% of consumers do not test their smoke and CO alarms monthly.

• Only 47% of people report having CO alarms in their home.

• Unattended cooking is the #1 cause of home fires. Fires are fast, hot, dark, and deadly. In less than 30 seconds, a small flame can turn into a significant fire. It only takes minutes for thick black smoke to fill a house to engulf it in flames. The heat from a fire is more threatening than the flames. Room temperatures in a fire can be 100 degrees on the floor

and rise to roughly 600 degrees at eye level. Inhaling this super-hot air will scorch your lungs and melt your clothes. Fire starts bright, but it quickly produces black smoke and complete darkness. A fire's smoke and toxic gases kill more people than flames. Fire produces poisonous gases that make you disorient ed and drowsy. Everyone needs to get out as fast as possible when a fire starts.

A well-developed and practiced fire escape plan might be the difference between life and death for those caught in a fire. Remember that every second counts in the event of a fire. Escape plans help you get out of your home quickly. Practice your home fire escape plan twice each year. Some tips to consider when preparing this plan include:

• Find two ways to get out of each room if the pri mary way is blocked by fire or smoke.

continued on page 29

• Make sure that windows are not stuck, screens can be taken out quickly, and that security bars can be correctly opened.

• Practice feeling your way out of the house in the dark or with your eyes closed.

• Teach children not to hide from firefighters.

• If you use a walker or wheelchair, check all exits to be sure you can get through the doorways.

• Pick a meeting place outside in front of the home and away from the path any emergency vehicles may be taking.

The best way to avoid a fire in the home is to take action to prevent it. The next best thing to do is to be prepared for a fire in the house. A working smoke alarm significantly increases your chances of surviv ing a deadly home fire. Replace the batteries twice a year unless you are using 10-year lithium batter ies. Ensure that smoke alarms are installed on every level of your home, including the basement. A rule of thumb is to replace the entire smoke alarm unit every ten years or according to the manufacturer's instruc tions. Remember that the best course of action in a fire is to get out. When the smoke alarms go off, and you react to them, the fire may already be too big to fight with an extinguisher. n

Dana Kepner Company purchased

Pipe at the end of 2021.

have even greater access to an

inventory, additional resources,

benefits of a wider market area.

are looking forward to earning your trust and confidence.

you for your continued business.

In the early 70s, as a youngster growing up in Braintree, MA, Jon D’Allessandro spent his days, after school and on the weekends, working at his grandfather’s farm in Abington, MA. He learned to take care of the animals, drive trucks, and operate the farm equipment. His uncle Donald Caliacco, and cousin Steven Comoletti had a construction business (P. Caliacco Corp.) and when Jon was of junior high school age he spent every summer either working on the farm or on one of the construction sites.

“I loved working with my family,” recalls Jon. “We were doing site work, sewer and water mains, parks, and road jobs in the Boston area. After high school I wanted to work full time with them. School wasn’t for me, I was happier getting my hands dirty. I was taught how to work with purpose, how to care about what I was doing and do it right the first time. I was happy to labor, drive a 10-wheeler, and operate backhoes and excavators. I was having a great time. I loved the work, I was learning the construction business, and I was getting paid for something I loved to do! I definitely credit my cousin Steve for helping me get the ‘bug’ for underground construction.”

Jon D’Allessandro worked at P. Caliacco Corp. for about seven years from laborer to operator to eventually supervising his own crew. He also learned the economics of the business and how to bid some of this work. In 1987, he decided to venture out on his own and he established D’Allessandro Corporation. His office was a 2-room apartment in Quincy and his key pieces of equipment were a 580 Case loader/backhoe, and a pickup truck. With one employee, Jon set out to do underground construction work.

According to Jon, the first year in business was a challenge. “I was doing some small site jobs for residen tial developments and doing some water and sewer con nections. I was running night and day trying to bid the work, get the work, do the work, and collect the money. I was working so many hours I didn’t even have time to fig ure out if I was actually making any money,” laughed Jon. “As I look back, I guess the late 80s was the right time to start my business. Private work was plentiful and build ers were putting up houses and apartments everywhere. Contractors that could do sitework and underground utili ties were in demand.”

The young company worked mostly as a subcontractor early on, but Jon remembers still having some great jobs during that period in both private and public markets. It didn’t take long for the economy to change and by 1990 the work opportunities were shrinking. D’Allessandro decided to focus on the public market and on being able to bid as a general contractor. “I was able to secure some limited bonding capacity and suddenly I was a GC,” re calls Jon. “I remember how nervous I was attending those first few sealed bid openings.”

“I remember one of my first public bids that I was low bidder on was a $40,000 job for the City of Newton,” remi nisces Jon. “It was a shallow pipe job installing the first PVC sewer pipe in the City. The inspector made us rotate all the pipes so you could read the manufacturer’s name from the top.” The jobs got a little larger and D’Allessandro Corp. soon had five employees and an excavator and loader-enough to make a pipe crew. The first project that established D’Allessandro as a competitor in the public utility construction business was a sewer project for the City of Cambridge. The $200,000 contract required sepa rating the combined sewer and drains by rerouting the drain pipe around the combined manholes. It would be the first of many successful projects that D’Allessandro Corp. would complete for the City of Cambridge over the years.

Throughout the 1990s, the young company experi enced steady growth and was increasing its volume and its bonding capacity almost every year. Jon preferred the urban projects and by 1993 D’Allessandro Corp. was a recognized name within the industry and at bid openings in Cambridge, Boston, and other surrounding cities. According to Jon, “We were aggressive and full of energy during the 90s and we bid on as many jobs as we could that came out in the Boston area. I added some great management people and we were running two, then three, then four pipe crews, and everything was clicking.”

Public owners were taking notice of the complicated projects that D’Allessandro Corp. was bidding, winning, and successfully completing. “Our great crews were tack ling tide gates, jacking operations, heavy shoring, and sewer bypassing,” says Jon. “We even took on 24/7 Emer gency Repair Contracts for both Cambridge and the Bos ton Water and Sewer Commission (BWSC). We did those emergency repair projects for many years.” By 2000 – 13 years after incorporating his one-person fledgling business

– Jon had grown D’Allessandro Corp. into a well-respect ed public works construction company with revenues ap proaching $15 million/year and employing 50 people.

Growth continued beyond 2000 and the company be gan diversifying their operations. The urban utility work remained the core business, but they began doing road way reconstruction work, park and landscape work, and some marine work with cofferdams. The company was performing projects for BWSC and MWRA (Massachu setts Water Resource Authority) that involved rehabilita tion of old brick sewers, cleaning of pipelines, structural lining, and extensive bypassing. Pipe bursting was a new technology and D’Allessandro Corp purchased the spe cialized equipment for that work and was also one of the first utility contractors in New England to purchase their own vacuum excavator.

There have been many jobs since 2000 that were instrumental to the successful growth of D’Allessandro Corp. Perhaps two of the most significant were:

• Boston – Morrisey Boulevard Drainage Conduit – 2007-2009. This CSO project was performed for BWSC and designed by Fay, Spoffard and Thorndike Engineers. The ambitious project included 3,500ft of 12’ x 12’ box culvert installed within the northbound

lane on one of the most heavily travelled roads in the City and terminated with an ocean outfall structure into Savin Hill Cove. The large size of the new culvert required multiple relocations of various utilities and portions of the route required the culvert to be sup ported on driven pipe piles and concrete caps. Due to the depth of the excavation and the proximity to exist ing live utilities, the project required permanent steel sheet piling to be driven and left in place along the entire length. The $29M project was one of the larg est projects put out to bid by BWSC at the time and remains a milestone project for D’Allessandro Corp.

• Western Ave., Infrastructure Improvements –2012-2014. This $17M project called for rebuilding Western Ave., a one-way heavily travelled four lane roadway between Memorial Drive and Massachu setts Avenue. Starting with complete water, sewer, and drain replacements. The project also included an outfall into the Charles River. Total roadway re construction followed on this 3,000ft project including three signalized intersections, a bicycle lane, and ex tensive sidewalk and landscape construction. Traffic control – vehicular, pedestrian, and bicycle- was a daily challenge at every step in the project. continued on page 35

Steel Cofferdam at Quincy Bay

continued from page 33

By 2015 D’Allessandro Corp. was doing $30M in an nual revenues and employing 110 employees that Jon proudly described as “the best in the business.”

It didn’t take long for Jon D’Allessandro to see the benefits that being a member of a contractor’s association could provide for himself and for his young busi ness. Jon joined UCANE in 1991. Through the 90s he immersed himself in the organization by attending events and participating on several committees. In 1995 he was elected to the Board of Directors where he rose through the ranks to become President of the Association in both 2000 and 2001. In 2001, Jon also received the associa tion’s highest honor when he was voted UCANE’s “Contractor of the Year” by his peers.

“I was eager to learn and enjoyed meeting with my fellow competitors. I’ve made great friendships through UCANE over the years,” according to Jon. “But I also feel that all contractors should try to support their industry. I continue to be active and a big believer in UCANE. My oldest daughter Julia is continuing in my footsteps and has been on the UCANE Safety Committee for the past three years.”

According to Jon the company still seeks out chal lenging work and prefers to work in and around down town Boston whenever possible. The company runs nine crews these days continuing to concentrate on water and sewer projects but with their eyes always open for other types of horizontal and heavy civil work.

In 2020, Jon purchased all the pipe jacking, bor ing, and ramming equipment from his retiring friend, and former UCANE member, Maurice Plourde of M&P Pipe Jacking Co. “Maurice is a great guy, the best in his trade,” says Jon. “I’m also fortunate to have him available to work with us anytime.”

Jon is also fortunate that his children have shown in terest in joining the first-generation business. Two of his three daughters, Julia and Laura, have graduated with college degrees, while daughter Olivia is currently en rolled at NYU, and son John just graduated high school.

Laura and Olivia both live in New York, but still work part-time doing the company’s social media, newsletters, and maintaining the corporate website. But during the summer months and school vacation they can be found working on the jobsite setting brick and pouring concrete.

Jon’s oldest daughter Julia has been with the compa ny for 10 years, “but really since birth!” laughs Jon. Start ing in the field she has been exposed to every aspect of the business. According to Julia, “My father wanted all his children to see the work actually being done in the field and to understand how the company made money. We didn’t get any special treatment and there were no days off. He always stresses the importance of personal accountability to all of his employees, and his kids are no exception.” Julia is currently Business Manager and added the role of Safety Manager during COVID-19.

continued on page 37

“There’s no doubt that Julia jumped in with both feet with me,” says Jon. “Having dragged her and Laura to all of my jobs when they were very young are some of my best memories and looks like it paid off. But with Laura living in New York, it makes it a little more difficult, and with Olivia, we’ll just have to see what she decides to do after college. I’m keeping my fingers crossed that both of them will want to join the business!”

Son, and youngest child, John D’Allessandro recent ly graduated from High School (2022) and there was no question what he wanted to do. “My son was more like me,” laughs Jon. “He found every excuse to be in the ga rage or come with me to the jobsite since he was 10 years old. He loves to get his hands dirty and can operate most of the company’s equipment. He started working with us full-time this summer as a laborer. He’s got lots to learn but he’s working with a crew of professionals who will teach him and I’m proud to have him aboard.”

As we end this interview with Jon D’Allessandro at his new (2020) headquarters in West Bridgewater, MA, there is lots of activity in the office as project managers talk with their field crews and co-ordinate equipment moves. The company is just wrapping up several nice jobs with Boston Public Works and BWSC, and estimators are busy

working on upcoming bids. “We are keeping our eyes on the rollout of the Infrastructure Bill,” says Jon. “2022 was a little under-whelming as far as the bill’s impact, but I think in 2023 we’ll see some more work around here. Maybe we’ll add a couple of crews or maybe we won’t. I’m kind of liking where we are right now.”

As Jon D’Allessandro celebrates his 35th year in a very challenging business, he admits to being just as mo tivated as ever. He attributes the company’s success to his great team and because of them, looks forward to be ing able to relax a little. He has certainly earned it and has a lot to be proud of.

D’Allessandro Corp. in reaching the 35-year milestone. We are proud to count this successful company as a UCANE member and wish them many more milestones ahead! nFirefighter’s Memorial Park, Brockton, MA

Waste bans help to increase recycling and sup port the recycling economy, which provides thou sands of jobs and millions of dollars in economic ac tivity in Massachusetts. By reducing the disposal of banned materials, we also capture valuable resourc es, reduce greenhouse gas emissions, save energy, and reduce our need for landfills and incinerators.

collected through separate collections or drop-off events. In other cases, materials such as vehicle bat teries, tires, and cathode ray tubes may be collected by retailers.

Matthew Martin CommissionerJanuary 26, 2016

What materials are banned from disposal?

• Glass, metal, and plastic containers (bottles, cans, jars, jugs and tubs)

• Paper, paperboard, and cardboard

• Leaves, grass and brush (less than 1 inch in di ameter)

For residents who receive private collection ser vices (not through your city or town), ask your service provider for recycling options. You can also check for other recycling options here: http://www.mass.gov/

For more information on the waste bans see:

The Massachusetts Department of Environmental Protection (MassDEP) is pleased to present the Final 2016 Intended Use Plan (IUP), which details the projects, borrowers and amounts that will financed through the Clean Water State Revolving Fund (CWSRF) loan program. The CWSRF joint federal-state financing loan program that provides subsidized interest rate loans to improve protect water quality in the Commonwealth.

• Large appliances such as refrigerators, freezers, stoves, washers, and dryers

• Tires

• Cathode ray tubes (older televisions and com puter monitors)

• Vehicle batteries

As noted in Table 1, Massachusetts is offering approximately $414 million to finance clean water projects across the Commonwealth. Approximately $380 million will fund 35 new construction projects and an additional $15 million will be allocated towards funding 9 previously approved multi-year projects. $2 million has been allocated to the emergency set-aside account, and $3 million will be directed to the Community Septic Management Program to remediate failed septic systems in participating communities. An additional $13.8 million will fund 15 planning projects.

• Construction materials including asphalt pave ment, brick, concrete, metal,

• wood, and clean gypsum wallboard

• Mattresses (effective Nov. 1, 2022)

• Textiles (effective Nov. 1, 2022)

• Food material (only from businesses or institu tions that dispose of one ton or more per week. (Will drop to ½ ton per week effective Nov. 1, 2022.)

The Water Resources Reform and Development Act of 2014 (WRRDA) amended the Clean Water Act resulting in important changes to the CWSRF Program that will affect most borrowers. The primary changes to the program are the requirements for borrowers to develop and maintain a Fiscal Sustainability Plan, which is similar to an asset management plan and a certification that the cost effectiveness of the project has been evaluated and that the project maximizes water efficiency and energy conservation. The body of the IUP discusses these new WRRDA requirements in greater detail.

Most waste ban materials are collected through regular municipal collection or drop-off programs. In some cases, particularly with larger items such as cathode ray tubes or appliances, materials are

The United States Environmental Protection Agency (EPA) has not yet determined the exact 2016 SRF grant allocations to the states. Based on the overall , MassDEP expects receive an estimated $44 million federal grant to subsidize the CWSRF program. Under the Fiscal Year 2016 Omnibus Appropriations Bill, Congress is requiring that at least 10% of the federal grant be used to fund “green infrastructure”. The 2016 Final IUP lists 16 new “green infrastructure” construction projects. The exact monetary value of the green portion of these projects will be determined when project applications

submitted

are expected to be well in excess of 10%

federal grant.

METHUEN — In response to the four water mains that have ruptured since June, 80% of the $46 million that Methuen received from the American Rescue Plan Act will be used to fund a series of improvements to the aging water and sewer network.

Seven projects are currently slated to take place over the next four years. The largest task, funded at $9.7 million, is the combined sewer project in the Arlington neighborhood. This calls for the separation of the sewer system that Methuen cur rently shares with Lawrence as well as the replace ment of a 100-year-old water main.

“This is one of the main reasons the City Council approved the use of almost 80% of our ARPA funding on upgrades to water and sewer service,” said Mayor Neil Perry.

Although much of the city’s water and sewer in frastructure is more than a century old, Perry said increased water usage caused by drought was the probable reason for the water main breaks.

“More water breaks occur in extreme weather conditions,” he said.

City Council President DJ Beauregard said the water and sewer infrastructure has only become a priority in the past few years.

“The goal is to eventually be in a position where we no longer need to turn to Band-Aid solutions to address these issues,” he said. “While we’re certainly not there yet, this administration is making tangible progress.”

Councilor-at-Large Jessica Finocchiaro said the water main breaks are “indicative of larger issues.”

“The Greater Lawrence Sanitary District needs additional funding to further increase capacity to minimize combined sewer overflows (CSOs) during heavy rainfall, so less waste flows into the Merrimack River,” she said.

Finocchiaro also described the city’s extensive water and sewer network.

“Methuen has hundreds of miles of water and sewer lines, more than 6,000 catch basins, more than

2,000 drainage manholes, more than 600 raw sew age outfalls, water towers, pumping stations, pressure boosters and treatment plant facilities to main tain,” she said, adding that more than 2,000 acres of land is located within the 100-year flood plain.

“We need to be better positioned to help our selves financially, though our needs can’t be fully met without significant state and federal investment.”

Finocchiaro said additional upgrades in the fiscal year 2023 Capital Improvement Plan include installing an emergency generator for Riverside Drive, updating the Forest Street water tank, having hydraulic three di mensional modeling of water infrastructure and monitoring systems for the city’s 23 pumping stations.

Although the improvements will not be visible to the public, East District Councilor Steven Saba said the projects will be beneficial in the long-term.

“I continue to urge the mayor to put these projects before the council as soon as possible before the deadlines to spend this money are exhausted,” he said.

Written by Christopher Robinson. Reprinted from the Eagle Tribune. n

Privately held and family owned businesses often face unique issues and challenges. Hinckley Allen attorneys have been advising such businesses for decades and have accumulated deep expertise.

We understand that the issues faced by a privately held or family owned business often reverberate through the broader family dynamic, and that a clearly defined strategy for running and transitioning the business is essential for both corporate and familial harmony.

Our attorneys can assist with a variety of legal issues: including succession and tax planning issues, employment-related issues, retaining quality outside directors and advisors, and managing exit transactions.

more about our offering at www.hinckleyallen.com

Jennifer V. Doran

Cranes are a vital piece of equipment on many jobsites. However, just like any equipment, cranes can pose dangers to those around them. It’s important to have proper training for operators, supervisors, mechanics and anyone else involved in crane operations. Workplaces may or may not have crane safety training requirements, but there are federal requirements.

There are a variety of training programs available from organizations such as OSHA (Oc cupational Safety & Health Administration) and Crane Safety Associates of America. Many in surance companies also offer training programs. These trainings can be targeted toward specific roles or more general. Here are just a few types of crane safety training:

• Rigging safety

• Supervisory

• Inspections

• Crane operator

• Jobsite

While there’s no requirement for ongoing training, industry resources recommend that em ployers provide ongoing training resources and hold retraining opportunities at least every two years. Insurance carriers may require additional or more frequent training.

According to OSHA, in addition to safety training, crane operators must be certified and retested every five years. There may be addi

tional state or local requirements.

OSHA-approved testing organizations:

• National Commission For The Certifica tion Of Crane Operators (NCCCO)

• Crane Institute Certification (CIC)

• Operating Engineers Certification Program (OECP)

• National Center For Construction Education And Research (NCCER)

Consistent training and recertification are important for many reasons, including updated procedures, new equipment and safety refresher courses. While training can seem like a hassle, it keeps employees safe, decreases the likelihood of an accident at the jobsite, and increases productivity. There are a variety of programs

Advantage Drug Testing is a new UCANE member specializing in drug-free workplace programs and FMCSA compliance. Company President, Ted Dawson brings 17 years of experience advising employers on the FMCSA regulations and compliance programs.

Advantage provides complete drug and alcohol programs with on-site and 24-hour emergency response services. Driver qualification file management systems and on-site FMCSA physical exams are available to ensure compliance with FMCSA regulations. Advantage supports over 300 employers with managing FMCSA drug-free workplace programs, including many UCANE members. UCANE member companies have provided the insightful comments below.

The Dow Company: “Since 2006, they have provided the drug and alcohol testing services we need to ensure compliance and save time for our team.”

– Mike DowAlbanese Brothers: “We prefer to work with local businesses we can trust, and I can’t say enough about Advantage Drug Testing. Since 2009, they have consistently provided us with the support we need. They are always ready and willing to answer questions and come to our job sites when requested. Advantage Drug Testing is an integral part of our team.” – Marcella Albanese

Truck

Stone Products

Stone Crushing, to Grading, to

anything from Truck and Equipment

to Rhode Island, Massachusetts,

other surrounding

to Stone Products to Stone Crushing to Grading to Milling to installing the final asphalt surface. Our Products and Services are provided to Rhode Island, Massachusetts, Connecticut, and other surrounding areas.

Scituate Concrete: “They answer my questions in a timely manner, come on-site for our random testing and help keep us informed of and in compliance with, regulatory changes like the Clearinghouse. I have had only positive experiences when working with ADT.” – Leanne Karagosian

Albanese D&S: “Since 2006, Advantage has consistently provided excellent compliance support for our business, answered our questions and sent technicians to our office and job sites. The office staff is great, providing friendly and knowledgeable customer service.”

Shea Concrete: “Since 2010, Advantage has been providing us with excellent service. With both on-site testing

FMCSA compliance support, I have found the company to be a valuable resource.”

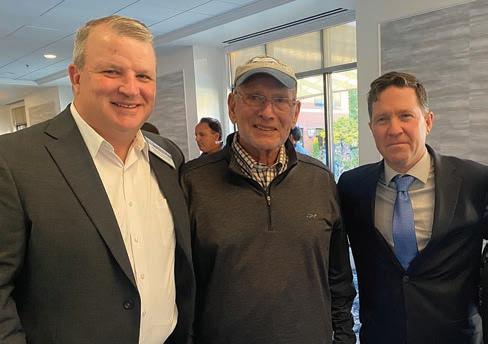

UCANE held its September Dinner Meeting at the Four Points Sheraton Hotel in Norwood, MA on September 14, 2022. The Social Hour in advance of the dinner gave the more than 150 members and guests an opportunity to catch up on business or small-talk while enjoying some hors d’oeuvres and a cold beverage. Once again our hosts at Four Points provided our group with a sumptuous meal served by their first-class and very at tentive waitstaff.

Following dinner, UCANE Executive Director Jeff Mahoney welcomed attendees and provided them with some current Association updates and pertinent industry news. But it was obvious that the buzz in the room was about the Panel Discussion that was soon to begin.

At several recent Board of Directors meetings, UCANE contractors and associate members have had lengthy discussions about three industry concerns. These same three concerns not only affect UCANE members, but also our partners in this industry - namely the engi neering community and the owners of public works proj ects.

1. What seems to be holding up the roll-out of the projects funded by the bi-partisan and massive Federal Infrastructure Bill?

2. How can the industry address current supply chain issues and rampant inflation in a fair and equitable manner that will allow the bidding pro cess to go forward for these much-needed infra structure projects?

3. Does the industry have enough workers to han dle the increased workload that is anticipated in the Infrastructure Bill, and how do we attract the next generation of industry employees?

Last month Jeff Mahoney reached out to our con tacts at the Boston Society of Civil Engineers (BSCE- Ex ecutive Director Abby Goodman) and our friends at the Norfolk-Bristol-Middlesex Highway Association (NBMPresident John Sanchez) to discuss the potential for an Industry Panel Discussion. Both Associations applauded

the idea and each recruited two of their members to participate in the event.

An impressive panel, to be sure. All members of the panel are recognized leaders in their field, wheth er it be as a contractor, a consulting engineer, or as a director of public works. Each panelist is active within their own professional associations and each is very familiar with the process involved in getting infra structure projects funded, designed, and built.

All the panelist (as well as the peers they rep resent) have a vested interest in making sure that any impediments to getting in frastructure projects “out to bid” be recognized and resolved. After all, this “once in a generation” Infrastructure Bill is intended to:

1. Invest in and improve New Eng land’s long-neglected infrastruc ture,

2. Protect the environment for future generations, and

3. Improve the quality of life for all citizens.

Moderator Jeff Mahoney had previously pro vided our panel experts with some of the questions so that they could be prepared. The comments and insight provided by each of the panelists completely held the interest of the audience. There were ideas put forward on how to “work-around” some of the supply chain issues and still move jobs forward. Price volatility on certain products was discussed including options on how bidding documents might be written to allow both contractors and owners to be protected while moving jobs forward. Manpower challenges are

being seen across the construction, engineering, and public works sectors, and ideas were exchanged on how to address that important issue.

The panel discussion was a great opportunity to exchange information and ideas and was very infor mative to the audience. Some bumps or impediments in the rollout of the infrastructure funding can be solved through mutual collaborative efforts like our panel dis cussion. Other issues are potentially larger bumps and will take more effort on behalf of all parties and some assistance from the federal government.

The important take-away from the September Dinner Meeting was that the increase in funding provided through the Infrastructure Bill has a sunset and is not guaranteed to be around forever. Only through continued communication, open dialogue, the sharing of ideas, and by working together can contrac tors, engineers, and public works owners realize the unique opportunity provided through the Infrastructure Bill. n

Trucking groups slammed the tolling plan as soon as it was proposed in 2015. Neverthe less, a modified version was signed into law in 2016, requiring 18-wheelers to pay up to $20 to cross the state traveling on Interstate 95. A single truck would be capped at paying $40 a day.

The tolls were intended to finance a 10-year plan to repair deteriorating bridges in the Ocean State; Rhode Island has the highest percentage of struc turally deficient bridges in the country. The tolls, to be collected electronically via 14 gantries, were ex pected to bring in around $45 million a year.

In 2018, the American Trucking Associations, along with Cumberland Farms Inc., M&M Transport Services Inc., and New England Motor Freight, sued Rhode Island, arguing that the RhodeWorks plan violates the Constitution’s Commerce Clause by dis criminating against out-of-state economic interests in order to favor in-state interests, and by designing the tolls in a way that does not fairly approximate motor ists’ use of the roads.

Over the next couple of years, the case bounced from courtroom to courtroom as a battle was waged over whether it belonged in state or federal court.

This week, U.S. District Court Judge William E. Smith ruled the system unconstitutional and ordered the state to stop charging tractor trailers within 48 hours, according to the Providence Journal.

“Because RhodeWorks fails to fairly apportion its tolls among bridge users based on a fair approxima tion of their use of the bridges, was enacted with a discriminatory purpose, and is discriminatory in ef fect, the statute’s tolling regime is unconstitutional under the dormant Commerce Clause of the United States Constitution,” Smith wrote in the ruling.

ATA and the state trucking association hailed the decision.

“It has been a long road to get to this point,” said Rhode Island Trucking Association President Chris Maxwell, in a news releaes, “but this is a tremendous day for our industry — not just here in Rhode Island, but across the country. Had we not prevailed, these tolls would have spread across the country, and this ruling sends a strong signal to other states that truck ing is not to be targeted as a piggy bank.”

ATA's Interstate One passes under a toll gantry in Exeter on the first day of Rhode Island's truck-only tolls in 2018. Photo: Rhode Island Trucking Association

This map from the Rhodeworks website shows the location of 12 current truck-toll gantries.

Image: RhodeWorks

ATA General Counsel Rich Pianka called it “a strong ruling that provides our industry a significant win on a critical issue. This ruling vindicates ATA’s contention that the Constitution prohibits states from tolling schemes targeted at the trucking industry, at the expense of interstate commerce.”

This story originally appeared on Heavy Duty Trucking’s website, www.truckinginfo.com, and is used with permission. n

A U.S. District Court has ruled Rhode Island’s controversial truck-only tolling plan, RhodeWorks, unconstitutional.

Construction work is a risk. Each year, the industry is rated as one of the most dangerous in America — and for good reason. Your projects are never the same for more than a few days, materials move, people change shifts and deadlines tighten.

These are a few reasons construction fatalities hit a 12-year high back in 2019, according to the Bureau of Labor Statistics. Yet more than half of all fatal injuries were related to just four hazards: falls, electrocutions, being struck by and getting caught in — or between — objects. You may recognize these as the Occupational Safety and Health Administration’s (OSHA) Focus Four Hazards. These hazards are more than a coined term — they’re a tool. As a senior safety consultant, I’ve watched firsthand how these pillars can improve your safety efforts. These strategies and hy pothetical scenarios, should provide at least one new idea or reminder to fine-tune your safety efforts. The hy pothetical descriptions used below are not based upon any specific individual, entity or set of facts.

Fall hazards can appear in many forms, and in 2019, they were the leading cause of non-transportation-related fatalities. Any walking or working surface that could cause your workers to lose their balance can qualify as a fall hazard.

The hypothetical scenario: While standing on a loader tire, a technician loses his balance. He falls and strikes his head on the ground 5 feet below, sus

taining an injury requiring emergency surgery. Possible prevention strategies:

• Evaluate machinery and other elevated areas technicians may need to access and develop specific procedures to reduce the risk of slips, trips and falls from these areas.

• Use a three-point mounting and dismounting technique for heavy equipment.

• Add guardrails with the proper height require ments when working above ground.

• Require workers to wear fall protection equip ment when working higher than 6 feet above the ground.

• Train technicians and other employees who may work at elevated positions on proper safety pro cedures.

• Monitor employees and enforce procedures in volving heights and property controls.

• Provide periodic refresher training on required procedures, machinery and personal protective equipment (PPE).

• Seek input from OSHA or the original equipment manufacturer (OEM) regarding best practices to

could

safely access hard-to-reach areas of machinery.

• Maintain a clutter-free jobsite.

Struck-by hazards are the second most common cause of worker fatalities. You can identify these risks as any flying, falling, swinging or rolling object that could cause forcible contact with a person on your jobsite.

The hypothetical scenario: A subcontractor is working on the third floor and bumps a piece of pipe. The pipe rolls off a ledge and ends up striking a work er on the ground level. The affected worker suffers severe blunt force trauma to their head.

Possible prevention strategies:

• Incorporate toe boards, net ting, or guardrails if people are working at different heights.

• Implement pre-task-planning to reduce the likelihood of overlapping work that could cause injuries across or below from where the task is taking place.

• Place warning signs through out the jobsite to communicate where work is taking place at different heights.

• Provide and require hard hats, glasses, high-visibility vests and PPE specific to each task.

• Remind employees to stay outside the swing radius of heavy equipment and receive acknowledgment from the op erator before they approach.

• Only allow trained flaggers to direct traffic.

• Secure tools and materials when working overhead.

Like the risks listed prior, elec trocution hazards present them selves in a variety of situations. Any situation that could expose some one to a lethal amount of electrical energy is an electrocution hazard.

You may recognize these risks in the form of work that takes place around powerlines or temporary power sources. If you work in a location where wet conditions may impact your project, your team

an even higher risk

The hypothetical scenario: An employee is using

saw to complete a task, which relies on a generator for power. After a brief rainfall, the employee resumes using the saw where a puddle has formed around the electrical cord without a ground fault circuit interrupter in place and an electrical current from the saw’s connection electrocutes the employee.

Possible prevention strategies:

Request employees to complete a job hazard analysis before completing work involving electri cal equipment.

a cadence for evaluating the age and wear of electrical equipment.

Color

extension cords to confirm the date

Protect Your Jobsite continued from page 59

• Contact utility companies to de-energize and ground power lines before working near power lines.

• Use ground fault circuit interrupters when using electrical equipment.

• Ensure ground pins are included on all electrical plugs.

• Establish a methods of procedure (MOP) require ment where employees list out the steps they’ll take before working with, or near, energized elec trical equipment.

• Require clothing that covers most surface areas of the body in case of sparks.

While caught-in or -between hazards are the last risk mentioned on this list, they require the same dedication as the three discussed above. These hazards are anything that could squeeze, catch, crush, pinch, or compress a person between two or more objects.

The hypothetical scenario: An employee begins work in a 10-foot-deep trench without proper shoring installed. The trench collapses, burying the employ ee. Trained personnel dig the employee out and the

employee sur vives with severe injuries.

Possible prevention strategies:

• Install shoring, sloping, shielding and benching systems based on soil classifications before starting trench work.

• Assign a competent person to be present for trench examinations and — if necessary — sys tem implementation.

• Place ladders within 25 feet of workers for trenches deeper than 4 feet.

• Equip noise and light features that activate when heavy equipment moves forward or backward.

• Provide PPE such as hard hats, safety shoes and high-visibility vests.

Timelines, planning and quality all contribute to an effective project. But every year, the most successful projects finish with the least number of injuries.

Remember, others are here to support your efforts. Consult your local experts, insurer and OSHA guidelines for more help managing the complex risks your team faces. Good luck in the year ahead.

Written by Larry Barone. Reprinted from con structionbusinessowner.com n

Welcome to National Grid’s Tips of the Trade. National Grid is committed to your safety, and these tips are intended to help you work safely near our natural gas pipelines. Please review these tips with your coworkers at your tailgate or toolbox meetings before work begins.

Welcome to National Grid’s Tips of the Trade. National Grid is committed to your safety, and these tips are intended to help you work safely near our natural gas pipelines. Please review these tips with your coworkers at your tailgate or toolbox meetings before work begins.

Cast iron natural gas pipelines are the grandfathers of the natural gas distribution system. They've worked hard and done their job well for generations, but now cast iron natural gas pipelines are being replaced by steel and plastic across the country. At National Grid, we are replacing miles of cast iron natural gas mains every year, but there are still many miles left in the system. We need your help protecting these old workhorses until they can be retired.

Welcome to National Grid’s Tips of the Trade. National these tips are intended to help you work safely near our these tips with your coworkers at your tailgate or toolbox