3 minute read

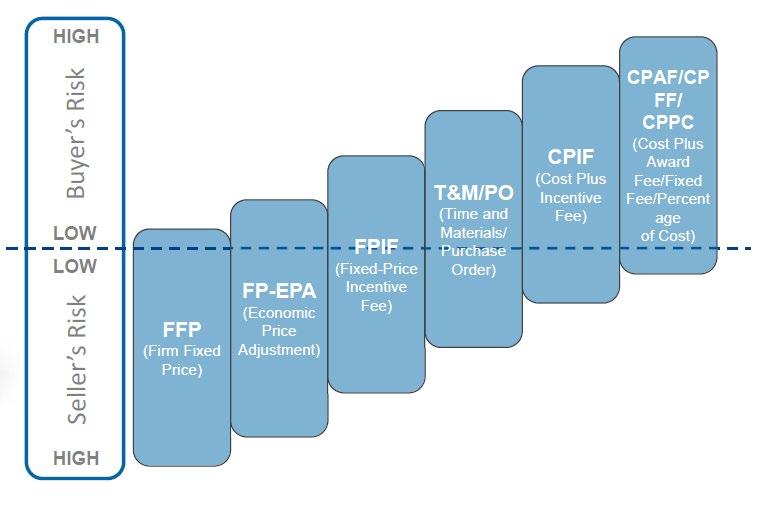

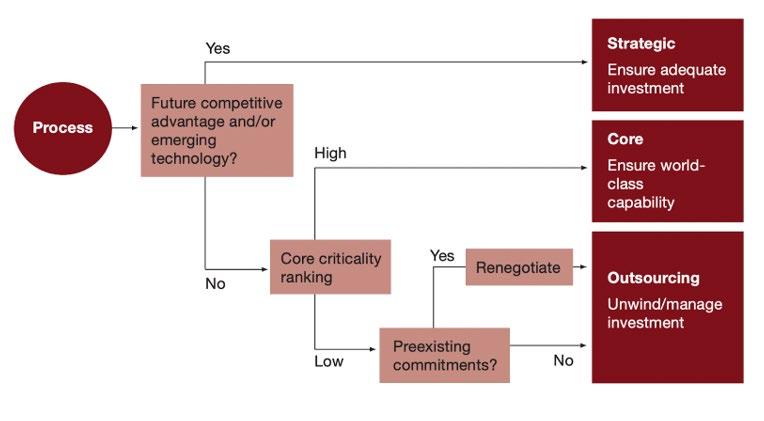

Figure 25: Cost Control Procedure

Figure 25: Cost Control Procedure

https://silo.tips/download/patricia-mast-lcls-project-controls-manager-mark-reichanadter-lcls-deputyprojec

6.0 Project Quality Management Plan

6.1 Quality Management Planning

6.1.1 Identify Roles and Responsibilities for QM team Roles Quality Responsibility Level of Involvemen t

Project Manager

Quality Manager

Site Manager

During the implementation phase, monitor if the project's quality is up to standard in accordance with the requirements. Pay close attention to quality issues during the project implementation phase, quality issues during the completion process, and quality issues that extend beyond the first set. Help standard goods attain higher quality. Little need to decrease rework. Extreme

Ensure the vendor's quality system is evaluated. Ensure that all quality requirements are met and provide feedback to consumers when faults arise.

Manage trade monitoring, measurement, and evaluation on a regular basis. Hold a quarterly management review meeting. Track the product throughout the implementation process to ensure that every step is completed correctly. Inspect the goods at all stages and produce reports to document any production issues. Conduct a thorough record examination of the completed product to ensure that it meets industry and business requirements. Eliminate subpar items and figure out what's causing the product problems HighExtreme

Communicate with the Project Manager and the

Quality Manager Supervise the operation of the whole project during the construction phase to ensure that it is completed on schedule, within budget, and achieves the project's quality objectives. Ensure that the project is completed on schedule and that all subcontractors and project teams adhere to all quality standards and management plans. Utilize all funds and resources to the fullest extent while avoiding project flaws. Responsible for the implementation of quality assurance and reporting any defective items to the High

Site Engineer

Supervision Engineer

Quality Inspector

Contract Administrat or

project manager and quality management.

Reports to both the Project Engineer and the Site

Manager. Ensure that all structural and technical operations onsite satisfy project quality requirements. If any flaws are discovered throughout the building process, attempt to resolve them as soon as possible. Responsible for professional specialized quality management work during the project procurement and construction process, as well as managing Trades to guarantee optimum quality is reached. High-Med

Coordinates with the Site Manager to ensure that quality standards are met. In charge of the specific execution of professional supervision Examine the construction contractor's plans, applications, and modifications. Report to the site manager on a regular basis on the implementation of professional supervision activity. Create a supervision diary based on the project's particular implementation; gather, summarize, and arrange data; and assist in the production of the monthly report. Low-Med

Supervises all material testing activities and reports directly to the superior. In charge of inspecting and testing building projects. Responsible for gathering and sorting quality inspection and evaluation data, as well as helping the quality manager in performing outstanding quality management. In charge of monitoring rectification implementation and supervising the construction crew. Directly report to the construction quality manager. Med-High

Ascertain that the contract satisfies all quality standards. All quality concerns should be reported to the project manager. Take part in project meetings and evaluations. Low

6.1.2 Quality Standards and Requirements

Planning quality management defines the process of identifying quality requirements and standards for the project’s deliverables and documenting how the project will demonstrate compliance with quality requirements and standards.

Rumane (2018, p122) states that quality standards are the key to any conformity assessment activity, which are used to ensure that a product or system meets specifications and requirements. The standard setting is one of the first issues in developing quality assurance systems and serves as a reference base to justify the adequacy of a quality system, covering all the activities leading to the finished products.

6.1.2.1 Standards Organisations

There are many well-known organisations that produce standards in the quality field and those standards will be employed in Sydney Metro Project:

● International Organisation for Standardisation (ISO)

● International Electrotechnical Commission (IEC)

● American Society for Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE)

● AS/NZS Australian Standard/ New Zealand Standard

● Building Code of Australia (BCA)

● The Australian Institute of Refrigeration, Air conditioning and Heating (AIRAH)

6.1.2.2 Quality Standard Applied in Respective Working Activity in Sydney Metro Project

In this report, the construction stage and its relevant working activities of Sydney Metro Project are extracted, and associated standards applied to them are demonstrated in Table 8.