1 minute read

Figure 32: Quality Assurance Cycle

service that does not satisfy the specific standard requirements. The quality planning and quality assurance process would be continuously reviewed and updated as necessary throughout the whole project lifecycle. This may involve the application of a third-party quality audit. All quality requirements and milestones should be incorporated into a project quality register or matrix, which must be included in the project quality management plan. The project quality management plan must detail the definitions and instructions on the utilisation of FDRs, NCRs, CVNs, ORs, and Submittals on the Sydney Metro Project. Moreover, it would be specific for each work package and item within Level 3 of the WBS. Additional quality requirements may be further introduced into the project quality requirements upon client specification, specifically for highly complex areas of the stage or design.

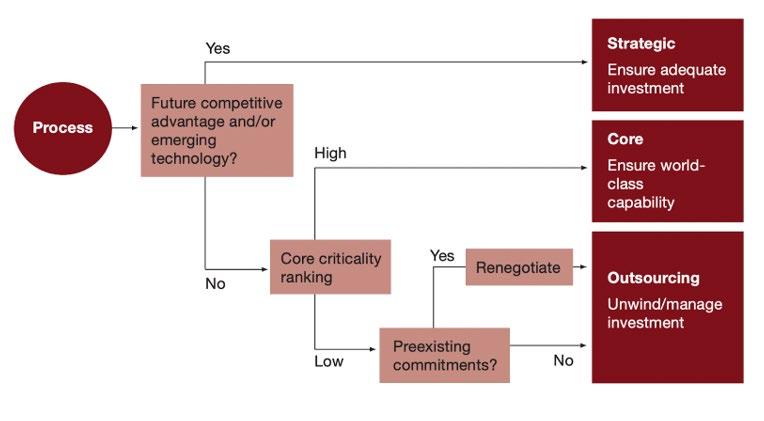

The below diagram shows where the Quality Control process sits in the Quality Assurance cycle (Hellgren, 2013):

Figure 32: Quality Assurance Cycle

Quality Control can be implemented in both products and services in the construction industry, while it is implemented by testing and inspecting during the manufacturing process of producing a product before the final product is released. In services, the installation is tested and inspected throughout the rough-in and fit-off phases before commissioning.

The overall quality control process implemented in the Sydney Metro Southwest Project is illustrated in the below flowchart: