2 minute read

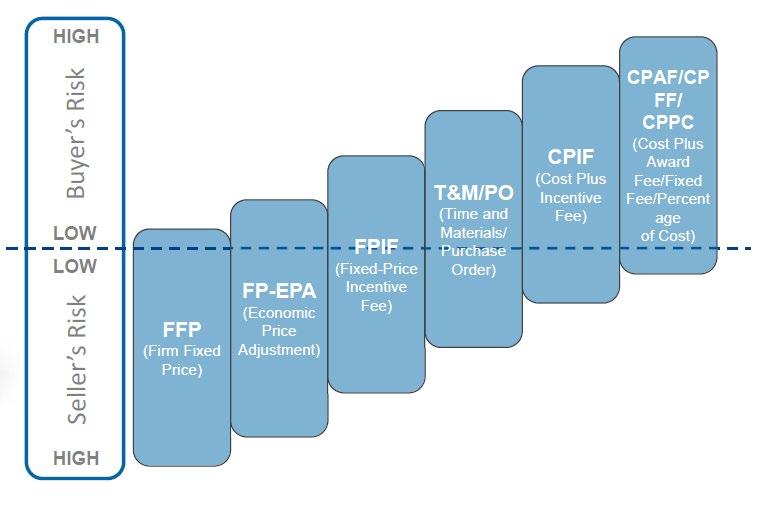

Figure 46: Procurement Process for Head Contractor

9.2 Procurement Process Diagram

Figure 46: Procurement Process for Head Contractor

9.3 Procurement Information Table

180

9.4 Hire or buy analysis/make or buy analysis

A make-or-buy analysis is used to decide whether project work or deliverables should be completed by the project team or purchased from outside sources. Sydney Metro's current resource allocation, employees' skills and talents, the need for independent or specialized expertise, and the desire to avoid expanding permanent employment obligations are factors to consider in the make-or-buy decision. It also entails assessing the risks associated with each buy-or-make choice.

9.4.1 Direct and indirect costs

Both direct and indirect costs should be taken into account when comparing producing the component in-house with outsourcing the work packages. The direct costs are those of making or acquiring the product, while the indirect costs are the support costs for the product. For instance, the implementation of fully automated trains and other forms of autonomous operation in rail operations has resulted in the new workplace and job designs, as well as new skill requirements. The ability to employ communications technology and massive data created by wireless signalling and sensors for predictive monitoring and maintenance systems is now a necessity. (Australian Industry Standards, 2017). Indirect costs arise as a result of the training required for team members who will use it and the need for technology upgrades. Another indirect cost is the cost incurred if the component's quality does not meet criteria, whether such specifications are imposed by the company's control limitations or the government restrictions (Rowley, 2013). Non-conformance expenses may include the following: • the expenses of scrapping or fixing non-conforming components, as well as warranty and product liability costs if they are detected during the inspection process. • the expenses of warranty/product liability claims/lawsuits if non-conforming components are not identified during the inspection process and passed on to the customer.

As a result, a high-risk component (such as the construction of lifts) may be best left to a company with specific competence in making them. Purchasing high-risk components rather than manufacturing them in-house is one form of risk response strategy (transferring).

9.4.2. Business strategy

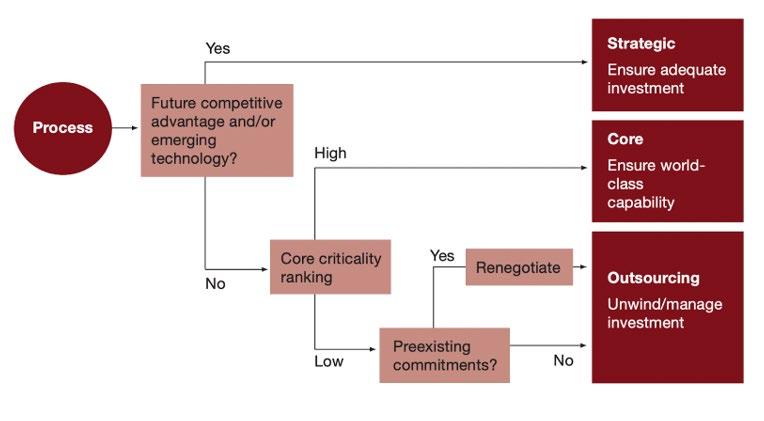

Business strategy includes the strategic importance to the company of the product or service that is being considered for outsourcing, as well as the process, technologies or skills required to make the product or deliver the service (Figure 47). These considerations must be made not