Type SM Decking Fixing

Suitable for use with SigDeck 100 decking profiles manufactured by Sigmat.

Designed to fit inside the dovetail re-entrant channels of popular composite decking profiles, Lindapter’s high quality, cost effective fixings for securing building services fixings provide a zero-impact method that avoids delamination and damage to the decking.

Key Benefits

• Quick and easy to install

• Adjustable for precise alignment

• Zero-impact installation

• No damage to the decking

• No drilling so no exposure to silica dust

• No specialist labour or tools required

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.24, which can be downloaded from www.Lindapter.com/lindapter-ce-marked-products

WWW.ENGINEERING-UPDATE.CO.UK AUGUST 2023 Sponsored by ENGINEERING PDATE For more information please contact Lindapter’s Technical Support Team: Call: +44 (0)1274 521444 | Email: support@Lindapter.com | Visit: www.Lindapter.com

®

SigDeck 100 Profile Pattern

NEW PRODUCT DATA

Plated (BZP) Safe Working Load (FoS 3:1) Product Code Rod min 4.6 Tensile / 1 Rod Tightening Torque SM10 M10 1.0kN 8Nm*

Wedge Locking Plate Washer (optional, not supplied) Flange Nut (supplied) Nut (not supplied)

Material: Mild Steel and Bright Zinc

* As a guide, finger tighten the nut plus one full turn of the spanner.

LINDAPTER EXTEND PRODUCT RANGE WITH THE TYPE SM DECKING FIXING.

Lindapter, a renowned name in the construction industry, continues to innovate and improve with the recent launch of their latest product, the Type SM Decking Fixing. This groundbreaking addition to their product range marks a significant advancement in the field of building services suspension and offers numerous benefits that enhance both efficiency and safety on construction sites.

The Type SM is the first and only zero-impact fixing developed to enable building services to be suspended from SigDeck100 decking profile manufactured by Sigmat.

This innovative method offers the contractor real efficiency gains because it can be installed on-site in a matter of seconds without the need for specialised

With the addition of this new fixing, customers now have access to a broader selection of high-quality Decking Fixing products.

Lindapter’s high-quality, cost-effective fixings for securing building services are designed to fit inside the dovetail re-entrant channels of the composite decking profile completely removing the need to drill through the deck into the concrete above which can be hazardous.

According to HSE who commissioned the research, high concentrations of silica-containing dust can be produced when drilling into concrete without adequate dust controls. Silicosis is a serious lung disease characterised by scarring and stiffening of the lungs, kidney disease, and chronic obstructive pulmonary disease; it is caused by breathing in dust that is 100 times smaller than a grain of sand. More than 500 construction workers die every year from inhaling silica dust. More information can be found here www.hse.gov.uk/pubns/indg463.htm

In contrast to drilling or shot firing methods, Lindapter’s fixing method offers multiple safety benefits including, eliminating silica dust exposure for the operative and preserving the fire integrity of the decking profile. Another important advantage is that the strength of the decking profile is preserved, and delamination is avoided (separating the steel from the concrete).

The wedge and locking plate made of pressed steel has been developed with a Bright Zinc Plated (BZP) finish to protect against corrosion and oxidation. To keep the wedge from rotating after installation, the locking plate is designed to fit over the wedge.

With a reassuring safety factor of 3:1, the Type SM has a capacity of 1.00kN per fixing and holds building services equipment securely thanks to Lindapter’s independently approved safe working loads and stringent quality procedures.

With a reputation synonymous with safety and reliability, Lindapter’s new product is CE Marked, verifying that the product performance has been independently evaluated and certified to satisfy internationally and domestically recognised standards. This adds another layer of reassurance for Engineers, Specifiers, and Contractors.

Moreover, Lindapter’s commitment to sustainable practices and environmental consciousness has been a driving force behind the development of the Type SM Decking Fixing. By eliminating the need for drilling into concrete, the product contributes to a reduction in the generation of construction-related dust and minimises the environmental impact associated with dust control measures.

August 2023 ENGINEERING PDATE NEW PRODUCT LAUNCH

Key Benefits

• Quick and easy to install

• Adjustable for precise alignment

• Zero-impact installation

• No damage to the decking

• No drilling so no exposure to silica dust

• No specialist labour or tools are required

To ensure broad availability, Lindapter has made the Type SM available through its extensive distributor network. Clients can easily obtain further information, including a full specification data sheet and an installation video, on Lindapter’s website https://www.lindapter.com/product/typesm-decking-fixing

With their commitment to innovation and safety, Lindapter continues to be a reliable partner for construction projects worldwide.

Lindapter Decking Fixings are an excellent example of how innovative engineering solutions can improve workplace safety while maintaining high levels of performance and efficiency. By incorporating innovative solutions like Lindapter Decking Fixings, we can create safer and more efficient workplaces for construction workers, ensuring that they can carry out their work safely and effectively.

August 2023 ENGINEERING PDATE

WWW.LINDAPTER.COM SALES@LINDAPTER.COM

The next level of modular industrial connectors.

Han-Modular ® Domino ModulesRobust technology for industrial transformation.

The first modular connector with a hybrid module configuration

■ Smaller and lighter connectors allow space savings of up to 50%

■ Compatible with components of the Han-Modular ® series, the market standard for modular industrial connectors

■ Flexible and scalable to the respective need

■ Sustainability through consistent modularisation

■ Reduction of installation times by combining several individual connections

One Range. No Limits: www.HARTING.com/domino

24/7 boiler room performance monitoring with Babcok Wanson’s Navinergy 14 AUGUST 2023 Flow Meter Reliability Critical for On-line Analysers Servicing the Oil and Gas Industry 16 |3 Seven reasons to implement a clear desk policy in your workplace 22 Supercapacitors offered by Viking Introducing the supplier and their remarkable range of products. 20 How teaching in Further Education can inspire the next generation into Industrial Design 19 To SpeAk To A member of The TeAm please call 020 805 09659 or email hello@engineering-update.co.uk

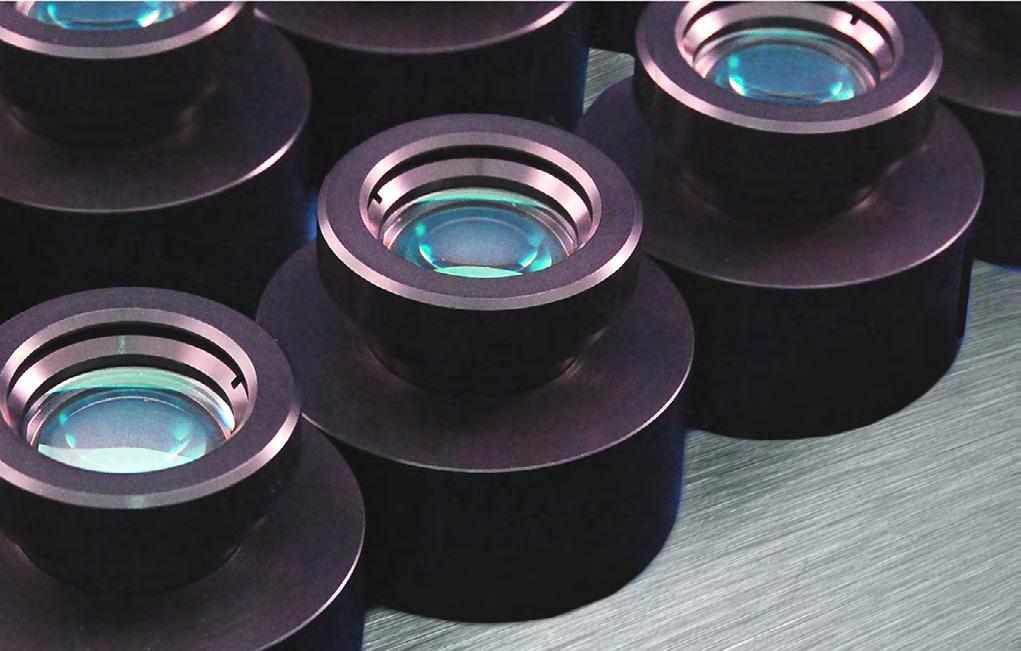

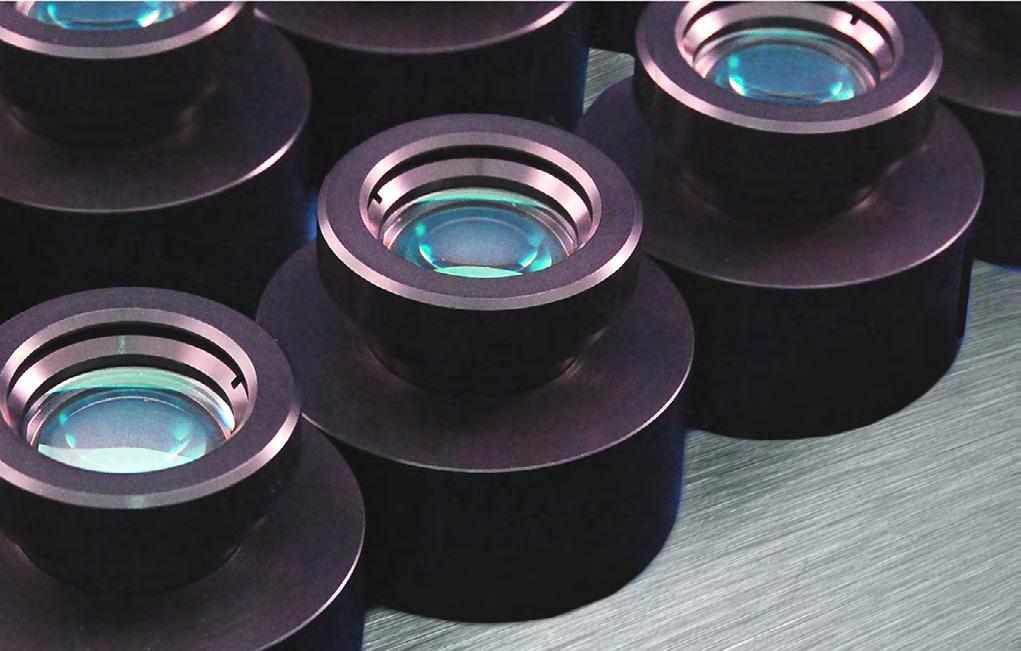

SWIR lenses for demanding Imaging application

For imaging applications that are difficult or impossible to perform using visible light, such as agricultural produce sorting, materials recycling and inspection of printed circuit boards – Short Wavelength Infrared (SWIR) offers a solution.

Resolve Optics is a leading supplier of SWIR lenses designed specifically to provide optimal performance in specific wavebands in the 900 nm to 2300 nm range. This not only allows for a simpler more optimised design, but it also enables higher performance in the required wavebands. Where applications require good optical performance throughout the SWIR spectral waveband - Resolve Optics additionally offers focus corrected SWIR lenses that deliver unmatched resolution and colour correction ensuring that you get the best possible image from your camera or sensor. In addition, these lenses offer the benefit of removing the need for constant refocusing to achieve optimised, high resolution images at all SWIR wavelengths.

For further information on application optimised SWIR lenses please visit www.resolveoptics.com/uv-ir-swir-lenses/ or contact Resolve Optics on +44-1494-777100 / sales@resolveoptics.com

August 2023 4| ENGINEERING PDATE

Innovative Liquid Flow Measurement Solutions

Titan Enterprises is a leading design and manufacturer of innovative end user and OEM high-performance flowmeters and flow measurement instrumentation, used within a wide range of processes, environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• NSF-Approved mini turbine flowmeters Titan’s liquid flowmeters are designed and manufactured to ISO 9001 with traceable calibrations.

+44 (0)1935 812790 sales@flowmeters.co.uk www.flowmeters.co.uk

REQUEST A FREE QUOTE TODAY Breakthrough

|5 August 2023 ENGINEERING PDATE

Ultrasonic Flowmeters Turbine Flowmeters Oval Gear Flowmeters Instrumentation

Flowmeter Technology

Find out more: www.ksb.co.uk - 01509 231872 - sales@ksb.com MAXIMISES EFFICIENCY. MINIMISES PROBLEMS. Engineering Update; 130x190; August 2023.indd 1 29/06/2023 13:48:57

Eta delivers on its promise - over an entire life cycle. That’s why it is the ideal pump for your business.

FORTRESS LAUNCHES MULTI-MACHINE DATA

Hall 5, Stand B01

Responding to repeatable calls by food manufacturers for a single centralised data collection package that can work across an unlimited number of inspection machines - including checkweighers, metal detectors, x-ray and even label and coding machines - Fortress Technology has sourced a compatible and affordable solution.

Featuring a simple front-end system, manufacturers can connect as many or as few inspection devices on one software system, even non-Fortress machines. Giving food and beverage factories total quality control and oversight across their entire production lines. Machine data connections can even be made across multiple sites and monitored remotely.

Once installed, the subscription-style data collection package can be easily scaled up to incorporate more machines. Options range from an industry-standard weight and quality monitoring system that captures and records incoming data against pre-determined target ranges by product, to monitoring and reporting COP checks. All data is date and time stamped, logged, and reports all non-conformities. Alerts by email can be issued when corrective actions are required.

Report and analysis tools can be displayed on any business PC via internet browsers. Reducing manual paperwork and eliminating unreliable, labourintensive record-keeping.

“With these new data package options, the front-end structure has been kept simple. This is intentional as it helps to keep data manageable, as well as delivering meaningful quality oversight for production and quality managers. In addition to recording data, the software analyses the data generated in real-time, immediately highlighting any critical parameters, such as contaminant reject trends and weight overfill costings, as well as red flagging processes that might be drifting from specification,” explains Fortress Europe’s Commercial Manager, Jodie Curry.

Additional reports that can be extracted include line efficiency, production rates, batch performance, Trading Standards records and audit data. Detailed records can be produced for any defined timeframe detailing what was happening during the inspection of product packs.

Available on an affordable monthly subscription, once the software has been installed, additional devices, locations and sites can be added without having the repurchase the software.

For a full demonstration on how to quickly implement a more robust data collection package that suits your real time food and beverage processing needs, visit Fortress Technology, Stand B01, PPMA 2023.

6| August 2023 ENGINEERING PDATE

For food processors seeking fully-integrated, paperless and automated data collection from across their entire inspection machine fleet, PPMA 2023 is a must-visit event. This year, Fortress Technology presents its latest data communication solutions, engineered to work on all their inspection machinery, as well as a number of other makes, models and brands.

PACKAGE AT PPMA 2023

At PPMA 2023, Fortress Technology presents its latest data communication solutions engineered to work on all their inspection machinery, as well as other makes, models and brands.

|7 August 2023 ENGINEERING PDATE DATA CONNECTION

Credit: Image by Traimak_Ivan

What’s new?

• 80% of stand space already sold

• Powell Electronics confirms headline sponsorship alongside Wurth Elektronik and Solid State Supplies

• Dassault Systemes returns as gold lounge sponsor and sponsor for The Engineer conference and Eureka conference

• Mouser Electronics confirm lanyard sponsorship

Design Show!

Previous exhibitor, Adam Miller, Field Sales Engineer from Ineltek commented on last year’s show:

“The resurgent Engineering Design Show exceeded expectations. Ineltek’s stand had a steady stream of relevant visitors from a variety of technology businesses. The two days flew by; we never reached the point where we had to kill time visiting other stands. EDS is back with a bang!”

The Engineering Design Show (EDS) returns to The Coventry Building Society Arena on the 11th – 12th of October 2023. This two day exhibition has been curated specifically for design engineers and will bring together over 200 suppliers, thousands of products and all the latest industry innovations.

The exhibition is set to be jam-packed with hundreds of stands already booked. Exhibitors include Moons Industries, Technosoft, Telsonic, Smallfry, McLennan, Thermal Vision Research, Etal, Quickparts, Hoover, The Robot Studio and Reliance Precision and many more!

Alongside the exhibition, visitors can attend 30+ hours of free conference sessions and workshops, bringing together the biggest names in the industry. There will also be ample space for one-to-one meetings and time to network, with the dedicated gold lounge, sponsored by Dassault Systemes, a central café and a drinks reception held at the end of the first day.

EDS has everything to support UK design engineers in 2023. Register your interest here to be the first to find out when registration opens and to keep abreast of all the latest show news: https://www.engineeringdesignshow.co.uk/register-interest

Interested in exhibiting?

Exhibiting at EDS is a fantastic way to maximise your organisation’s exposure to the UK’s design engineering community. For more information, visit engineeringdesignshow.co.uk and find out how we can tailor your package to meet your exact requirements.

8| August 2023 ENGINEERING PDATE

Hundreds of exhibitors are already confirmed for this year’s Engineering

Interested in exhibiting? Get in touch with simon.bonell@markallengroup.com HEADLINE SPONSORS THE UK’S BIGGEST EVENT DEDICATED ENTIRELY TO ENGINEERING, ELECTRONICS AND EMBEDDED DESIGN 11-12 October 2023 Coventry Building Society Arena Join thousands of design engineers this October! Source the latest products, services and innovations available to the sector. Register your interest today. www.engineeringdesignshow.co.uk @EngDesignShow #EngDesignShow Interested in Exhibiting? Visit the website to find out more.

The

Sponsors and Partners: Hosted by:

Live Demos Innovation Discussion Training

networking exhibition for the lifting equipment industry

liftex.org #liftex2023

Packed show floor of lifting equipment and services

21-22 November Exhibition Centre Liverpool

FREE TO ATTEND FOR USERS AND BUYERS OF LIFTING EQUIPMENT ACROSS MULTIPLE MARKETS

Ultrasonic

Innovative Liquid Flow Measurement Solutions

Flowmeters

• Excellent accuracy and repeatability

• Measure low to high flow ranges

Oval

• High chemical resistance

• OEM bespoke design capability

REQUEST A QUOTE TODAY +44 (0)1935 812790

sales@flowmeters.co.uk

www.flowmeters.co.uk

|11 August 2023 ENGINEERING PDATE Fluid Carr ying Flexibility Swivel Joints Bingswood Trading Estate Whaley Bridge | High Peak | SK23 7LY | UK Articulated Pipework Torsion In Hoses Rotating Cylinders Swivel joints allow pipework to pressure 1/4” to 40” and beyond. Vacuum to over 20,000psi Stock and bespoke production. Unique bearing/seal design for longer life. ISO 9001 CE marked where applicable. Tel: +44(0)1663 735003 E-mail:

Titan is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications. Flowmeters

Gear Flowmeters

Turbine

Instrumentation

• Compact, robust, reliable

24/7 boiler room performance monitoring with Babcock Wanson’s Navinergy

Now available from industrial process heating specialist Babcock Wanson is the Navinergy digital platform for 24/7 boiler room performance monitoring. This innovative system allows customers to monitor their boiler room from any device, anywhere in the world, to optimise energy and water efficiency, and ensure regulatory compliance.

The Navinergy platform integrates all the components needed to supervise and operate the boiler room, including control, regulation, recording, visualisation and communication.

Using a local Modbus TCP network, Navinergy gathers, records and stores field data from all the connected boiler room equipment. The data is presented in the form of graphs or a performance report, which can be customised to customers’ precise needs. These are sent to customers at regular intervals, but can also be easily generated whenever required, for up to date information.

Where deviations in the operation of boiler room equipment are identified by Navinergy, alerts are sent to customers directly to enable them to assess the situation and decide if action is required. Alert levels are customisable to best manage and prioritise them.

In this way, Navinergy not only delivers information to be acted upon and periodically reviewed, but also provides customers with complete traceability.

Several modules are available with Navinergy, including a module to list actions to be taken in the boiler room, a drift alert module, and the eWater

module which monitors water quality to prevent boiler breakdowns. eWater enables operators to determine whether the water quality is in line with Babcock Wanson’s recommendations, in order to ensure equipment longevity. Where water quality dips below predetermined levels, Navinergy proposes corrective actions. In case of a major problem, a Babcock Wanson expert can also be notified to take proactive measures to address and solve the issue.

Navinergy is available with all Babcock Wanson firetube boilers and is fitted as standard with Babcock Wanson’s BW7DAYS seven day unattended boiler operating system.

Babcock Wanson offers a complete range of products and services for boiler houses and other process heating needs, including firetube boilers, coil type steam generators, thermal fluid heaters, hot water boilers, VOC and odour treatment by thermal oxidation, water treatment and process air heating solutions. The company aims to help optimise customer’s energy production with high quality products and efficient service.

For more information, including a short video on the benefits of Navinergy, go to www.babcock-wanson.com, or contact Babcock Wanson on 020 8953 7111 / info@babcock-wanson.com.

August 2023 14| ENGINEERING PDATE

Safe for use in hazardous areas, ATEX certified installed LED lighting is now available from Wolf Safety

Wolf Safety have introduced a powerful new range of ATEX certified LED installed lighting, designed for permanent use in potentially explosive atmospheres.

The world’s leading manufacturer of portable and temporary ATEX and IECEx certified hazardous area safety lighting, Wolf have been keeping people safe for more than 110 years.

The company’s designers and production engineers have now brought their vast knowledge and expertise to bear on a new range of highly effective LED installed lighting, which is safe to use in Zones 1 and 21 hazardous areas.

The range includes:

• Linear luminaires featuring the new, revolutionary Directional Linear Optics (DLO) or standard Forward Facing Array LED configurations (with battery back-up emergency versions also available);

• Floodlights with a market leading maximum light output of up to 25,932 lumens;

• Bulkhead lighting, also featuring DLO (with battery back-up emergency versions also available);

• High bay lighting.

DLO directs light exactly where it’s needed and is ideal for use in specific, close-up workspaces, reducing glare to avoid people being ‘blinded’ by the emitted light, while its excellent colour definition facilitates safety critical hazardous area tasks.

Forward Facing Array (FFA) technology can be preferable for safely illuminating large hazardous areas which need wide, even and bright light coverage, where lights are mounted away from people or at heights where glare and intensity can’t have an adverse effect on the working environment.

Says Miles Jackson, Wolf Safety’s Sales and Marketing Director:

“We know that users of Wolf products trust us to keep them safe, especially when they need to work in highly volatile atmospheres and other hazardous workplaces.

“All the values people expect from Wolf - and are seen in our portable and temporary lighting ranges - can now be found in this new installed lighting range, which we are proud to introduce.”

For detailed technical information visit: www.wolfsafety.com

|15 August 2023 ENGINEERING PDATE

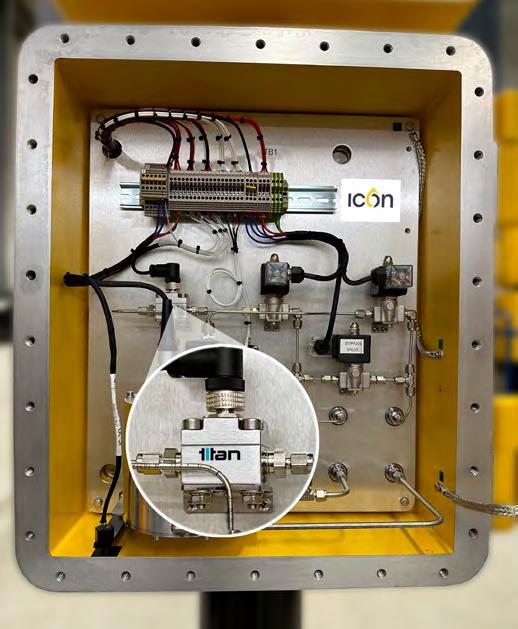

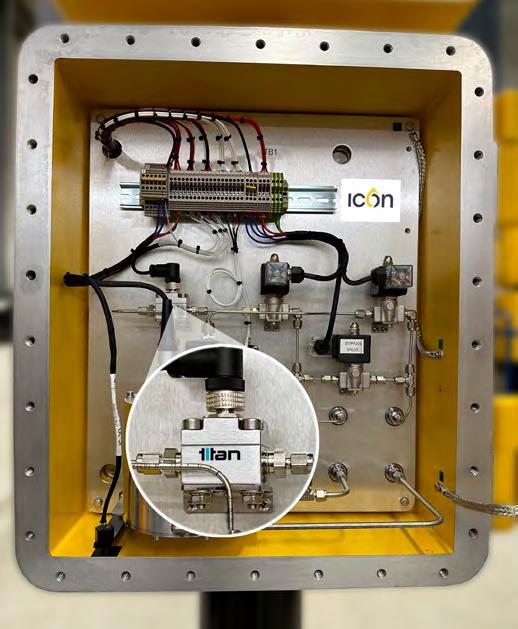

Flow Meter Reliability Critical for On-line Analysers Servicing the Oil and Gas Industry

Titan Enterprises’ Oval Gear (OG) flow meters have been an intrinsic component within Icon Scientific’s on-line analysers for over 10 years.

Serving the oil and gas industries, Icon Scientific are a specialist designer and manufacturer of physical property on-line analysers used in refineries, crude oil processing, LNG, LPG and offshore applications. The real-time analysers are connected to a process and measure certain physical properties, such as colour, viscosity, distillation, flash point, vapour pressure, cold properties, etc.

Innovative online analytical instruments permit continuous process control, enhancing process efficiency, increasing productivity, improving product quality and safe storage, and enabling real-time decision-making.

Dave Thompson, Icon Scientific’s Engineering and Development Director, comments: "Our on-line analysers offer highly reliable, accurate and automated measurement solutions, adhering to international standards.”

“The challenge”, Dave suggests, “was Icon needed a liquid flowmeter that was highly reliable to operate within our precision analysers. We chose Titan’s OG1 model with the reed switch sensor that interfaces with our advanced software and we enclose this within an explosion proof casing.”

Titan’s OG Series flow meters are designed to give reliable, high performance across a wide range of applications. Almost immune from the effects of varying liquid viscosity, density and temperature, the measurement performance of these oval gear flowmeters improves as liquid viscosity increases, making them ideal for the chemical, biofuel and petrochemical industry.

Neil Hannay, Senior R&D Engineer with Titan Enterprises says: “Titan’s oval gear flow measuring devices are an ideal low-cost component for OEM applications , combining durable materials, robust design and proven technology to ensure they will have a long product life with reliable, accurate operation throughout.”

“We’re a tightly focused organisation,” adds Dave, “pushing the boundaries of what’s achievable in our field and so working with a comparable organisation such as Titan with the same outlook, is very desirable.”

As software capabilities and technological advancements continue for these sophisticated online process analysers, the demand for flow monitoring devices that perform well

with a variety of fluid viscosity levels and at lower flow rates increase. “Although Titan’s 800 series turbine flowmeters and our Atrato® ultrasonic meter range are ideal for low flows down to 2ml/min, they are not explosion proof,” explains Neil. “Working with OEMs such as Icon, our R&D team are pushing the flow range boundaries of our oval gear meters with the aim of adding a more compact, lower flow unit to our oval gear range.”

For further information on Titan’s oval gear flowmeters please visit flowmeters.co.uk/oval-gear-flow-meters/ To discuss an optimised flow measurement device for your OEM application please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk

For information about Icon Scientific visit www.iconscientific.com

August 2023 16| ENGINEERING PDATE

Obso Global advises UK manufactures to act now ahead of summer factory shutdowns

As the summer months roll in, factory managers across the UK are advised to proactively prepare for upcoming planned maintenance during the shutdown period, by ensuring an adequate supply of machine parts and spares. Obso Global (Obso), a leading supplier of both active and obsolete industrial automation parts, urges manufacturers to take preemptive measures in order to minimize downtime and streamline repair processes during the scheduled maintenance period.

The summer season often presents an ideal opportunity for factories to carry out routine services and crucial maintenance activities, equipment upgrades and repairs. However, without proper planning and the timely procurement of necessary machine components, factories may face unexpected challenges that can disrupt operational efficiencies.

To address this issue, Obso encourages factory managers to place orders for machine parts well in advance of shutdowns to ensure the availability of essential components, reduction of lead times and mitigate the risk of extended downtime.

In addition to procuring the relevant inventory, factory managers must also consider the involvement of workers and specialized contractors for specific maintenance tasks. Some factories may require contractors to perform oil changes and annual servicing for motors and robotics - ensuring optimal performance and extending the lifespan of critical machinery. To allow this to work seamlessly, factory managers must ensure contractors are booked in advance to coincide with shutdown dates, and that the relevant inventory is readily available in time for both shutdowns and for when contractors have been booked in.

Experts at Obso also advise planning for the start-up of machinery at the end of the shutdown period. After weeks of inactivity and extreme heat, machinery can be unpredictable, and so to avoid any extra downtime in the event of issues upon start-up, factory managers should prepare for the potential manpower, spares and equipment needed to ensure the process runs smoothly.

Partnering with Obso can ensure access to expert advice and a wide range of new, active, and obsolete industrial

automation spares thanks to its connections with original equipment manufacturers (OEMs) and a global MRO supply chain. Even offering a repairs/reconditioning programme, part replacement and service-exchanged parts to support maintenance operations.

Andrea Ducker, Sales and Operations Director at Obso Global, comments: “This is the last chance for factory managers and machine operators to get their parts ordered ahead of upcoming summer shutdowns. We know that our stockists have spares ready and waiting to go out, which means we can actually get inventory to our customers faster than even the OEM can.

“Most of the items we secure can be shipped worldwide for free, which is a great bonus to enjoy at a time when investments are focused on maintenance and repair operations. Although we strongly advise pre-planning and ordering parts way ahead of shutdown to ensure parts arrive on time, we are here to provide support with lastminute, unexpected orders by offering next-day or even same-day deliveries in many cases.”

For further information on how Obso can assist with your summer shutdown operations, call 0800 36 888 17 to speak with an experienced Obso advisor, or simply visit www.obsoglobal.com/uk.

|17 August 2023 ENGINEERING PDATE

How Networks Aid 4.0 Industries

Emmanuel Routier, Vice President Smart Industries, Orange Business

Challenges faced by the industrial sector, such as pandemic-related logistics disruptions, data sovereignty concerns, and the need for sustainable growth, are driving the demand for digital transformation. Whilst technologies like 5G, IoT, cloud computing, analytics, and machine learning can be adopted to optimise operational processes, no technology (or technology combination) can do the job on its own. The success of digital transformation initiatives often crucially relies on the choice of an infrastructure and systems integrator.

5G and data play a vital role in identifying areas for improving operational performance through datacollection and analysis. In this way, production can be enhanced and logistics chain performance improved – all while reducing downtimes. 5G stands out for its ability to seamlessly integrate with customer processes, providing guaranteed bandwidth, low latency, and a global network, even in densely populated or highly mobile environments.

5G Steel

An example of a transformative network is ‘5G Steel’ deployed at ArcelorMittal, which is the largest 4G/5G network implemented in an industrial environment. It covers complex industrial sites, including areas beneath high-rise metal structures, offering robust coverage and spectrum availability at a lower cost compared to Wi-Fi alternatives. The network, combined with other industry 4.0 technologies, improves reliability, operator safety, productivity, and quality across ArcelorMittal factories. Leveraging 5G Steel, ArcelorMittal Digital Labs drives transformation through various industrial use cases within the value chain.

How to choose a digital transformation partner

Specialised support is required to digitally transform networks and selecting the right partner is essential. Look for one that can assess production process requirements, assemble components from diverse ecosystems, and provide best-of-breed solutions for process automation, performance enhancement, and employee safety.

Data security should be a priority, requiring a partner with cybersecurity leadership. Collaborating with an operatorintegrator enables access to infrastructure solutions like mobile private networks, managed OT/IT gateway services, cloud infrastructure, and critical cybersecurity measures for industrial plant data.

Additionally, legacy network infrastructures may require replacement. By collaborating with an operator-integrator, industrial companies can readily access infrastructure solutions such as mobile private networks, managed OT/IT gateway services, cloud infrastructure, and critical cybersecurity solutions for industrial plant data.

Given the challenges involved, partnering with an experienced infrastructure and systems integrator is crucial for industrial transformation. Ensure that the chosen partner supports all phases of the end-to-end business solution, tailored to industrial needs. By meeting these criteria, you can find the right partner to embark on a successful digital transformation journey.

August 2023 18| ENGINEERING PDATE

How teaching in Further Education can inspire the next generation into Industrial Design

Rosa Wells, aged 42, has been a Further Education (FE) teacher for 18 years and has recently been promoted to FE College Principal at University College Birmingham leading the delivery of FE courses.

I worked in a number of different roles within the engineering and manufacturing sector for 5 years, from aerospace manufacturing and industrial design for manufacturing, to focusing more on the research side of the industry. While I found this interesting and enjoyed my time in the sector, I missed interacting with people, sharing my knowledge and working with others. Looking for a role that required my industry skills and experience, a friend suggested teaching engineering in Further Education (FE).

At first I thought I wouldn’t be qualified as I didn’t have a teaching degree, but the local college I applied to reassured me it was my experience from industry that was key for thriving in the role. My skills were more valuable than I realised and I was able to start right away and do my teacher training on the job.

Since becoming an FE teacher, I’ve realised what an important role we play in inspiring, training and preparing more talent to enter the industry. Research among industrial design firms showed that 61% felt more training of existing or new talent would help address the engineering sector skills shortage. Industry professionals turned FE teachers are well placed to deliver this.

FE providers train a wide range of learners from school leavers to adults looking to upskill or retrain into a new career. But what these learners have in common is an interest in joining our profession. This is something we need to foster through sharing our skills and real life experiences of working in the industry. There are a wide range of engineering and manufacturing courses taught within FE, from aerospace to electrical engineering, design manufacturing and many more – whatever your role in the sector, there’s a job in FE to match.

I’ve seen first-hand the impact that sharing my engineering skills can have on the industry - during

the Covid pandemic, I supported our apprentices in designing and manufacturing ventilators, installing lighting for the Nightingale hospitals and working on building maintenance within NHS hospitals. My real-world industry experience was invaluable in helping to bridge the gap between the theory and implementation on the ground.

I have recently taken on a new role as FE College Principal where I use my industry expertise to help develop the engineering curriculum. Ensuring the courses we deliver best equip students with the knowledge and practical skills they need to join the sector is really rewarding.

I love working in FE, particularly giving learners the opportunity to get that hands-on experience that’s reflective of the working world they’re moving into. Knowing you are changing learners’ lives and hearing about the challenges they’ve faced and what they want to achieve in their careers is a privilege. And it can be really flexible too, with opportunities to teach full time, part time or on an ad-hoc basis alongside your existing job or personal commitments.

We can instil the next generation of engineers with the skills and confidence they need to kick start their careers in our industry. If you’ve got industry experience, you already have what it takes!

If you’re interested in finding out more about how you could share your skills by teaching in further education, visit gov.uk/teach-in-further-education

|19 August 2023 ENGINEERING PDATE

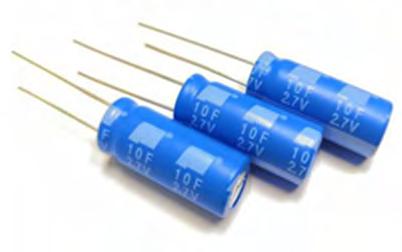

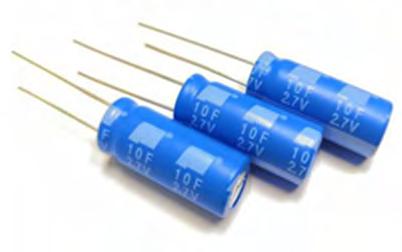

Supercapacitors

offered by Viking Introducing the supplier and their remarkable range of products.

Because of the growing market of EVs and renewable energy systems, manufacturers increasingly often recognise the potential of high-capacitance capacitors, also called supercapacitors. Although those components still have not become a real alternative to battery cells, they have proven to be irreplaceable in a number of applications...

Recently, the TME catalogue has been expanded to include products from Viking. The brand is owned by a Taiwanese manufacturer of electronic components. The Viking portfolio includes products such as THT resistors, miniature MLCCs, chokes and EMI/EMC ferrites. Their production facilities have all the certificates allowing for the manufacturing of components that are compliant with industrial, medical and automotive standards and get distributed all around the world.

Below, we present a remarkable fraction of the Viking offer – a selection of supercapacitors which provides a choice of different product variants and a wide range of parameters. Make sure you familiarise yourself with the information provided below and take a look at the products offered in our catalogue.

In this article, we mention the following topics:

• Applications and general features of supercapacitors

• Deciphering the symbols used in the Viking offer

• Operating voltages of high-capacitance capacitors

• Coin type and combined supercapacitors

• Capacitance of supercapacitors and how it is marked

• Components with a higher thermal and voltage tolerance

Supercapacitors from Viking

The application of supercapacitors is determined by their increased capacitance and short charge and discharge cycles. This allows them to store large amounts of energy and provide high amperage. Thanks to these features, in some respects, supercapacitors have an advantage over “traditional” modes of storing electrical energy, such as batteries. As a consequence, they are used in electric vehicles, regenerative braking mechanisms, for high-power motor start-up (e.g. in rail transport), in renewable energy systems (wind turbines) as well as energy storage and emergency power supply controllers.

The body of a supercapacitor is almost identical as the body of a standard capacitor.

The advantages of supercapacitors also include long service life – in terms of the number of charge/discharge cycles, they outmatch Liion and Li-poly batteries (the number of cycles is equal to almost 500,000 when appropriate conditions are maintained). What is more, the components are virtually maintenance-free, thanks to the fact that they operate on the basis of physical phenomena, instead of chemical ones. Supercapacitors also exhibit an immensely high efficiency and energy density, which expands their range of applications.

It is also important to note that the technologies used in supercapacitors are constantly evolving. The Viking portfolio is a perfect illustration of the diversity in this field. The products offered by the supplier are available in a number of formats, intended for different applications. The type and specification of the capacitor is indicated by the product symbol.

To continue reading, please click here

August 2023 20| ENGINEERING PDATE

The essential tool for Zone 0 Explosive Atmospheres cygnus-instruments.com • sales@cygnus-instruments.com • Certified to ATEX, IECEx, UKEX for Zone 0 and NRTL for Class 1, Division 1 • 3 measuring modes for corrosion, various materials and through-coat measurements

Manual Measurement Mode allows gates and gain to be configured to suit your application

Live A-Scans and B-scan for visual verification

4 quick function keys for easy control

Comprehensive data logging for easy reporting The Cygnus 1 Ex Ultrasonic Thickness Gauge is a rugged, intrinsically safe instrument designed for taking thickness measurements in Zone 0 explosive atmospheres. LNG/LPG TANKERS STORAGE

OFFSHORE

MINES OIL AND GAS REFINERIES DISCOUNT CODE EU2023

•

•

•

•

TANKS

PLATFORMS

Seven reasons to implement a clear desk policy in your workplace

1)

2)

As an increasing number of workplaces mandate a hybrid return to the office, expert Tom Armenante, director at GTSE gives advice and tips on how a clear desk policy can help Reduce business risk through clear desk policies, improving health and safety, GDPR practices and office atmosphere

Despite many businesses asking employees to return to the office over the past couple of years, the topic is still making headlines as owners and management try to balance work demands with staff needs. Hybrid working and hot desking are now popular, with three quarters of UK businesses offering it (according to CIPD), which is why GTSE have shared their advice on clear desk policies and their increasing importance.

A clear desk policy or CDP, is an initiative where employers and their workers agree that at the end of each day all desks much be left “clear”. That is, clear of all paper or digital documentation, personal items and notes. The idea behind such policies being to reduce business risk and create a safe working environment.

Tom Armenante, director at GTSE cable ties discusses the benefits of CDPs further, citing seven advantages for businesses.

1. Better compliance with GDPR

One of the key drivers for CDPs is the need for better data protection, in line with GDPR best practice. By clearing away all documents, notes and information left on desks at the end of the day, there is less chance that sensitive information will fall in to the wrong hands. It’s not just employees who have access to your office space, often there will be visiting clients, interviewees, tradespeople and of course cleaners. Depending on the nature of your business, poor data security could pose a huge risk to you, your clients and ultimately your financial success.

2. Creates a professional atmosphere

Walking into a clear workspace creates a great first impression for anyone who works or visits the building. Staff, clients and other stakeholders may perceive an office which is free from clutter as being more organised, professional and create a sense of pride in the workspace.

3. Modernises businesses

Going digital by removing the amount of paper documentation in your business or even going fully paperless has multiple benefits, helping to modernise processes. Digital documentation allows for better collaboration internally and with other stakeholders too, but particularly with remote and hybrid teams.

Paperless files can also make finding the right document more efficient, giving your employees quicker access to files, allowing them to spend time working on more profitable tasks. Cloud based backups also gives more security should physical copies or equipment be lost or damaged.

In addition, there will be a less need for physical storage space in the office, less time spent shredding and less waste for recycling and landfill. Making it better for the environment too.

4. Encourages hot desking and collaboration

In addition to modernising collaborative processes, a clear desk policy can encourage hot desking as employees are less tied to a specific seat in the office for document access or personal items. Hot desking can greatly improve team cohesion and culture in many respects. It can help foster inclusivity, adaptability and creativity amongst your teams.

22| August 2023 ENGINEERING PDATE

5. Improved health and safety

According to HSE, businesses must create a safe place of work for their employees and the public. A workspace which is clear of belongings and documentation provides a safer working environment by removing hazards which could harm employees. This not only includes reduced risk of fires but, the removal of slip and trip hazards too. Additionally, clearer workspaces will undoubtedly have fewer germs as they can be cleaned more easily. In turn this can help keep your workforce healthy and in work.

6. Keep belongings safe

As your business grows, there will be an increasing number of people coming in and out of the space. This makes it easier to lose personal belongings and work equipment by misplacing them, by other employees moving them, borrowing or even being taken intentionally. A CDP makes these things less likely, placing more responsibility on individuals to look after their own possessions.

7. Productivity

The phrase ‘tidy house, tidy mind’ is popular for a reason and the same logic can be applied to workspaces. One study suggests that workers are able to work for on average 7.5 minutes longer before losing focus when they have a clean desk, increasing productivity and persistence by 84%.

In addition to work-based benefits, the individual is likely to have greater mental stability, better sleep, reduced stress and are even more likely to make healthier choices when it comes to food.

Advising on how to implement a clear desk policy, expert Tom Armenante, director at GTSE said,

“Clear desk policies can have a real and positive impact for businesses. With the current trend towards hybrid workspaces and hot desking, it’s no wonder we’re seeing workplaces implement such policies.

Whether overseen by an office manager, CEO, operations department, security team or HR, businesses can easily and affordably make this change. Key ways to get started could be moving business documentation online, acquiring safe storage for private documents and personal belongings and importantly, ensure that loose wires are kept tidy using cable ties, baskets or sleeves.”

For further information on the benefits of a clear desk policy and what you will need visit, gtse.co.uk/cable-ties

|23

BUNTING SPONSORS REPM 2023

Bunting has signed up as a gold sponsor of REPM 2023, the 27th international workshop on rare earth and future permanent magnets and their applications (3-7 September, University of Birmingham, UK). The biennial workshop is co-organised by SUSMAGPRO partner University of Birmingham and brings together scientists and engineers working on rare-earth permanent magnets and their applications. The workshop and conference provide the platform to facilitate exchange of recent results and ideas on topics such as raw materials, resources, processing and properties of rare earth and future permanent magnets.

24| August 2023 ENGINEERING PDATE

Bunting is one of the world’s leading designers and manufacturers of magnets, magnet assemblies and magnetising equipment. The Bunting European engineering and manufacturing facilities are in Berkhamsted and Redditch, both in the United Kingdom.

The REPM workshop was initiated by Karl J. Strnat in 1976 with the aim of providing the rare-earth permanent magnet industry a platform to exchange research ideas and applications such as raw material availability and resources, and the processing and properties of rareearth and future permanent magnets.

The conference programme includes opening remarks from Masato Sagawa, the Japanese scientist and entrepreneur who invented the sintered permanent rare-earth magnet Neodymium Iron Boron (NdFeB) in the early 1980s. The neodymium magnet has since become one of the most important materials in the world and is critical to a wide range of technologies from computers to electric vehicles and wind turbines.

The 2023 REPM conference focuses on maintaining and developing the vitally important supply chain for NdFeB applications. This includes developing new resources, reclaiming and recycling magnets, and the development of new magnet materials. The diverse range of papers cover topics from magnet recycling, to nanocomposite and thin film magnets, and rare earth free magnets.

Bunting is at the cutting edge of magnet material development and utilisation. As a member of the EU-funded SUSMAGPRO (Sustainable Recovery, Reprocessing and Reuse of Rare Earth Magnets in a European Circular Economy), Bunting is working with European companies to develop a recycling supply chain for rare earth magnets in Europe and to demonstrate the effective reuse of recycled rare earth materials within several industries.

Bunting joins eight other industry leading companies sponsoring the event in a bronze, silver and gold capacity.

Bunting’s Technical Products Manager and the UK Magnetics Society’s Chair, Matthew Swallow is attending the workshop. “The importance of the REPM conference cannot be understated,” explained Matthew. “The rising number of applications will stretch supply and availability, driving vital innovation in recycling and new materials. The presentations in the REPM conference cover such areas of concern, looking at maintaining availability and new magnet technology. As a leading European supplier of magnet materials, we are proud to support the event as a Gold sponsor.”

For further information, please contact us on press@buntingmagnetics.com or visit our website:

Bunting-Berkhamsted www.bunting-berkhamsted.com

|25 August 2023 ENGINEERING PDATE

Lamonde Automation Limited Quality Products: Expert Advice sales@lamonde.com www.lamonde.com +44 (0)20 3026 2670 PLC Web Browser OPC UA Server WebView In Excess of 300 Communication Drivers Event Bar Chart Database Server SQL Query Energy Demand Display/Setting Features Include: