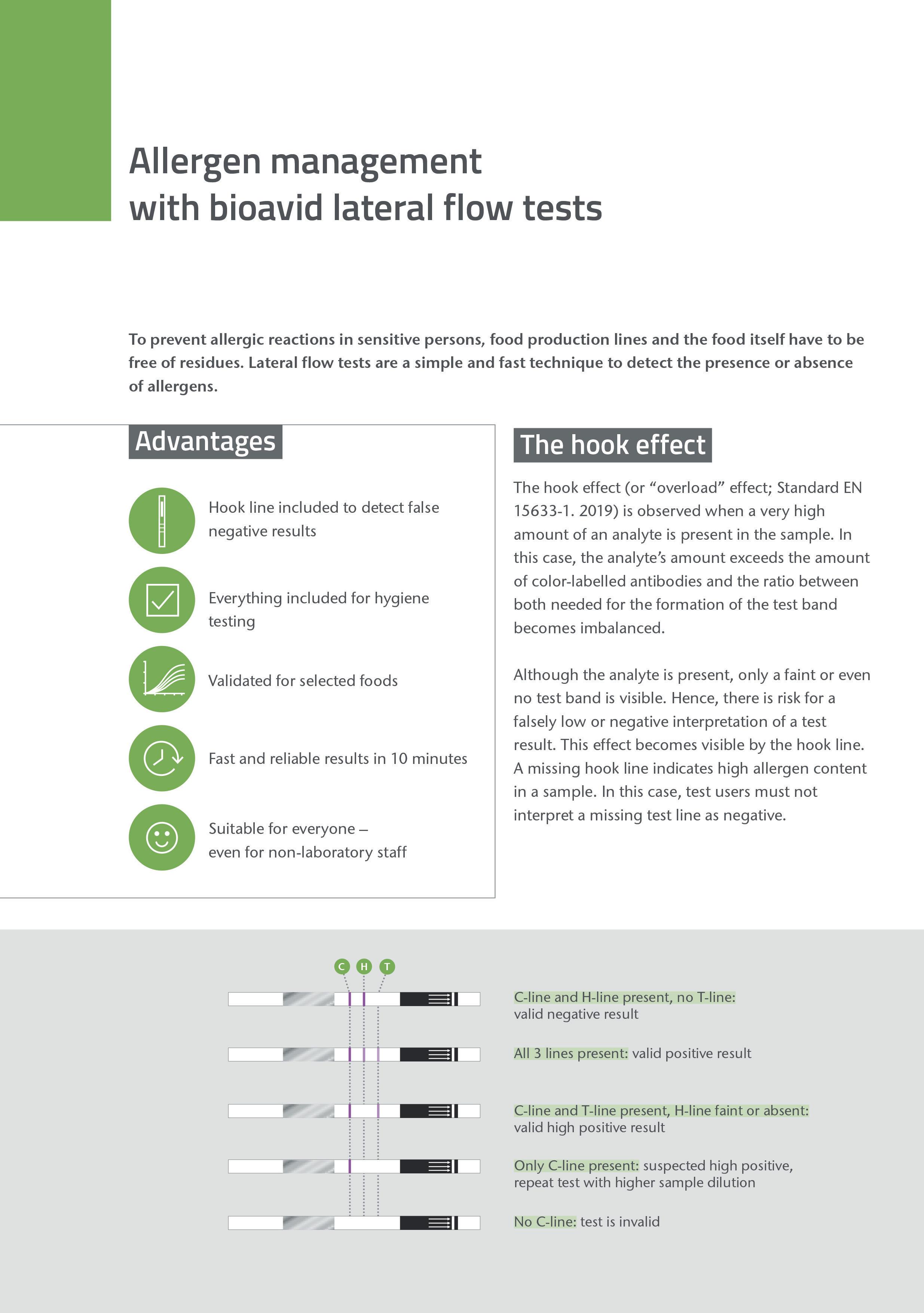

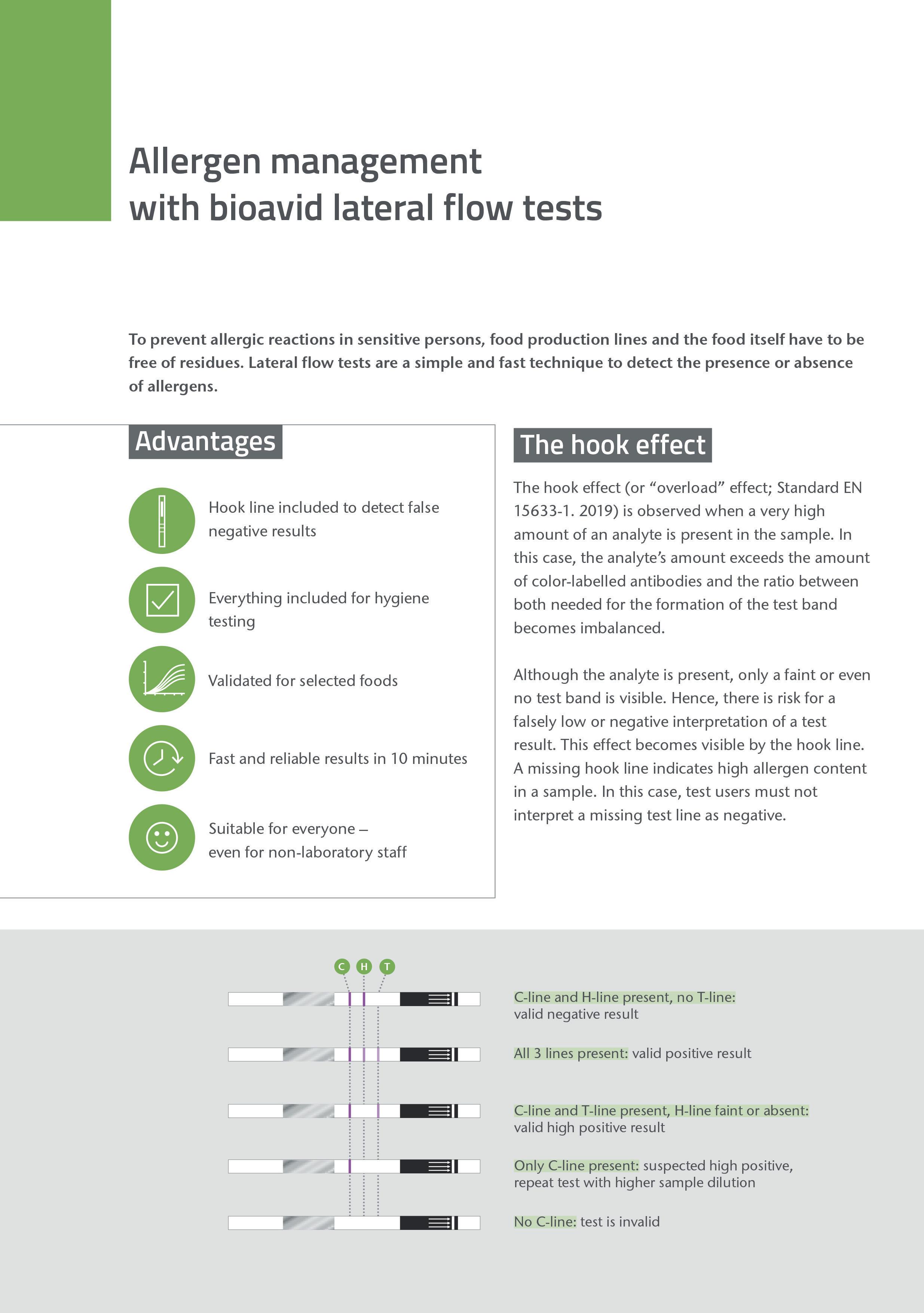

VOLUME 23 • ISSUE 06 ISSN: 2056-8347 foodanddrinknetwork-uk.co.uk Achieving Allergen Control Excellence through Operator Engagement Safeguarding Quality and Compliance in Manufacturing GET READY SUMMER! FOR WE HAVE HUNDREDS OF RANGES, READY TO SAVE YOU TIME AND MONEY THIS SUMMER! Providing hygienic furniture and equipment to help you manage risk and meet compliance standards. We have hundreds of ranges, ready to save you Ready to go. When it comes to food production, absolute safety is key. The JACOB Food Grade Line is a modular stainless steel pipework system that meets both FDA and EC 1935/2004 Food Grade Standards. Our expertise puts us at the very forefront of industrial lubrication PERFORMANCE YOU CAN TRUST For more information turn to page 21... +44 (0)113 232 2600 | customer.service@rocol.com | rocol.com Reliable allergen analysis and identification of also high positive samples Allergen management with bioavid lateral flow tests R-Biopharm hô d Block 10 Todd Campus, Acre Road, Glasgow WOSSP info@r-biopharmrhone food.r-biopharm.com https://r-b.io/bioavid_EN More information: 10/2022 Perfect for cleaning controls Direct analysis of rinse water samples (CIP water) Versatile – also applicable for food testing See more on Page 27 Allergen management with bioavid lateral flow tests To prevent reactions in sensitive persons, food production lines and the food itself have to be free of residues. Lateral flow tests are a simple and fast technique to detect the presence or absence of allergens. See more on Page 28

InfraLab Series 9

At-Line Analyzer

Sample measurements in only 5 seconds: Moisture, Fat and Oil, Protein, Degree of Brownness, Degree of Roast.

■ Replace time-consuming laboratory methods

■ Deliver deeper process insight for consistent production output

■ Reduce company’s operational expenditure (OPEX)

Series 9 On-Line Color Gauge

Simultaneously measures the key constituents: Moisture, Fat, Protein and Color.

■ Meet product quality demands and efficiency goals

■ Increase productivity

■ Realize immediate and long-term value

Maximize Your Process Performance & KPIs NEW!

NDC Products

https://www.ndc.com/food

EDITORIAL:

ANICCA DIGITAL

CLARION EVENTS

HARFORD CONTROL

MARBLES PR

MPR COMMUNICATIONS

PPMA

PR SCHULZ

PUBLICITY OVERLOAD

PUBLISH LAB PR

REDLINE PUBLIC RELATIONS

RESONATES THE REGENCY GROUP

TRANSATLANTIC ENTERTAINMENT

ADVERTISEMENT SALES:

KIMBERLEY READ (Advertisement Sales Manager)

GINA MADDISON

ACCOUNTS & ADMINISTRATION:

AMANDA WALMSLEY

EVELYN WOOLSTON

GRAPHICS DEPT:

STUART TURNBULL - Studio Manager

RACHEL RILEY - Designer

PUBLISHED BY:

WALTONS PUBLICATIONS LTD

46 HENEAGE ROAD, GRIMSBY

N.E. LINCOLNSHIRE DN32 9ES

TELEPHONE:

EMAIL:

Kimberley Read at: kimberley@ foodanddrinknetwork-uk.co.uk or Gina Maddison at: gina@foodanddrinknetwork-uk.co.uk

WEBSITE:

foodanddrinknetwork-uk.co.uk

ISSN:

02 News Network

SOLO COFFEE secures major cold brew deal with Hollywood A-lister

Our expertise puts us at the very forefront of industrial lubrication

Matara to exhibit at inaugural Automation UK event.

19 UKIVA 2023

06. The

07.

Find us on

Artisan Drinks Company

Ultra-efficient RO Technology halves water treatment energy consumption

TWITTER:

FACEBOOK:

@fdnetworkuk /fdnetworkuk

12 issues - £84.00 (inc.postage)

LinkedIn Copyright

09

Safeguarding Quality and Compliance in Manufacturing

10. Have your cake and eat it: reduce energy, decarbonise and earn additional revenue.

Stringent hygiene routines and regulations are crucial in the food and drink processing environment.

Atlas

Copco expands its vacuum range with DB Side Channel Blowers

Dry, clean and oil-free

All rights reserved. No part of Food and Drink Network UK Magazine may be reproduced or stored in a retrieval system or transmitted in any form, electronic, mechanical or photocopying, without prior written permission of the publishers. The publishers do not accept responsibility for views expressed, or statements made, or in those reproduced from any other source. No responsibility is borne by the publishers for any errors made in any advertisement, or for claims made by any advertiser which are incorrect. The publishers cannot be held responsible for any breach of copyright arising from any material supplied. This includes copy, design and/or images. © 2023 All Rights

Reserved.

01472 359036

CO2 from renewable energy - Sustainability is at the heart of Apsley Farms. 2056-8347 04 15 20 23 24 Beverages Automation UK Food Manfacturing Hygiene & Safety Vacuum Solutions Multimodal 2023 26 30 28 Allergens Materials Handling Specialist View Businesses should take more responsibility to prevent food allergy deaths Why there is so much air in crisps packets Bespoke conveying system from Spiroflow and Cablevey delivers on its promise Achieving Allergen Control Excellence through Operator Engagement 32 25 Food Machinery Auctions R&D Tax Credits Claims Introducing THE Food & Drink Machinery Auction Experts... INDUSTRIAL AUCTIONS Are you worried about your R&D Tax Credits Claim? VOLUME 23 • ISSUE 06 Produced in Europe’s Food Town 21. Rocol - Performance you can trust: Don’t let a lack of lubrication catch you out 05. One Small Step for Can: How drinks brands can make the leap to sustainability 17. Registration is now open for Automation UK - where automation and robotics come to life. 27. Allergen management with bioavid lateral flow tests 31. KAUP expands its e-op range

Multimodal 2023 will celebrate sixteen years of putting shippers, retailers, manufacturers, wholesalers, importers, and exporters in front of exhibitors who offer the latest logistics and supply chain solutions.

secures first Nationwide Listing at The Alchemist with perfect serve cans

Hygienic Stainless Steel Equipment

13

Register now to attend UKIVA’s Machine Vision Conference (MVC) from 20-21 June 2023 at the Coventry Building Society Arena to discover the very best in machine vision and industrial technology.

Decarbonisation & Sustainability

14. Industry leading speakers lead this year’s Multimodal 2023 conference with additional training sessions also available for all visitors.

SUBSCRIPTION:

PERFORMANCE YOU CAN TRUST

Huboo helps alcohol brands battle HMRC red tape and boost cash flow with launch of one of UK’s largest excise warehouses

• Global eCommerce fulfilment provider Huboo is empowering alcohol brands’ growth with launch of one of the UK’s largest excise warehouses, approved for the storage of all categories of alcoholic beverages under excise duty suspension

• Huboo’s HMRC approved warehousing space enables alcohol brands of all sizes to defer excise duty payments until their goods leave the warehouse

• Huboo offers expert guidance to assist alcohol brands with complex excise duty questions and issues

Global eCommerce fulfilment provider Huboo is expanding its support for alcohol brands everywhere with the introduction of a dedicated, excise duty suspended warehouse, one of the largest of its kind in the UK.

An excise warehouse is a secure, HMRC approved space in which goods that are liable to excise duty and VAT - such as alcohol - may be held with both the excise duty and VAT suspended.

Huboo’s approved premises, located at its 103,000 sq ft Chippenham warehouse, mean that alcohol brands can defer the payment of excise duty and VAT on their products, rather than

paying all duties prior to the arrival in the warehouse. For example, goods sold and removed on June 15 need only pay the excise duty due on July 29.

Using Huboo’s excise warehouse, alcohol producers free up cash flow by only paying duty to HMRC once items are dispatched. They also reduce the red tape involved in processing duties, with Huboo’s team of beer, wine and spirits (BWS) experts able to log and declare all removals from the warehouse to HMRC on the producers’ behalf and provide answers to any complex excise duty-related questions that brands might pose. Huboo can advise alcohol brands on their own HMRC licensing and compliance requirements.

It’s an approach that frees up time and resources for alcohol brands to focus on other aspects of their day-to-day business and offers a welcome boost to operational efficiency following months of rising inflation and operating costs, not to mention UK Government’s pending plans to increase duty rates on alcohol from August 1, 2023.

• The 103,000 sq ft warehouse provides long-term, safe and compliant storage for alcohol brands to maximise e-Commerce sales potential release alcohol bottle by bottle, rather than just per case, or at the pallet level - ideal for bespoke eCommerce orders. With just a minimum of five orders required per day, it is perfect for aspirational startup alcohol brands, while offering a scalable solution that can meet even the needs of large, wellestablished brands with high storage requirements.

The Wiltshire-based warehouse is strategically located near the thriving market town of Chippenham on account of its excellent transport links to all conurbations along the M4 and M5 corridors, up to and including the M32, as well as its access to major ports such as Southampton and Bristol. Thanks to this domestic and global connectivity, Huboo’s excise warehouse helps brands achieve significant supply chain savings by delivering goods closer to their final destination, reducing transport costs and potential damages, and allowing storage under excise duty suspension.

Huboo’s warehouse offers a compliant storage solution for all alcohol products, ensuring they hold their value for longer, while Huboo has batch control and quality assurance measures in place, ensuring that products do not exceed best before dates. Warehouse staff are able to respond to alcohol orders with 99.9% accuracy, resulting in faster deliveries, while ensuring minimal breakages and a seamless returns process.

The warehouse has the capability to

Huboo’s Co-Founder and CEO Martin Bysh said: “Our goal is to offer unparalleled support to alcohol clients, regardless of their size and specialism, giving them a fulfilment platform from which they can keep on growing and harness every new commercial opportunity. By launching one of the UK’s largest excise warehouses, we’re able to give more alcohol brands the chance to reach their full eCommerce potential, helping them reduce red tape, free up cash and continue to prioritise market expansionat home and overseas.”

The launch of Huboo’s first excise warehouse closely follows another key milestone for the business, with the announcement that Huboo has become a fully-certified TikTok Shop partner, placing the fulfilment provider at the heart of the UK’s burgeoning social commerce movement.

For more information, please contact Huboo on 0330 808 0909 or visit www.huboo.com

Babcock Wanson to talk on Alternative Energy at Malt Distillers Association of Scotland Conference

Industrial process heating equipment and solutions specialist Babcock Wanson will be providing a presentation on Alternative Energy at the Malt Distillers Association of Scotland (MDAS) technical conference on 12th June (Grant Arms, Grantown on Spey).

The MDAS boilerhouse working group created this half day event to address key technical aspects of running and maintaining a boilerhouse, including boilerhouse efficiency; modular boilers; challenges and opportunities when it comes to new designs and building flexibility into the boilerhouse for future proofing; SEPA –MCPD and Hydrogen; and alternative energy.

As a manufacturer of a wide range of products and services for boiler houses, with extensive experience in the brewing and distilling industries, and a leading light in developing decarbonised product, Babcock Wanson is well placed to advise on latest developments in alternative energy solutions. Etienne

Fourie, Babcock Wanson’s Technical Sales Manager, Process Engineering Division, will be focussing his presentation at the conference on hydrogen trials, electric boilers and converting existing plant. He will look at the options for de-carbonising distilleries, along with Babcock Wanson’s capabilities in this field.

Babcock Wanson works with a number of leading distillers in Scotland and around the UK, providing energy efficient process heating solutions to match specific customer needs.

Babcock Wanson’s product range includes steam generators, thermal fluid heaters, hot water boilers, VOC and

odour treatment by thermal oxidation, water treatment and process air heating solutions. The company aims to help optimise customer’s energy production with high quality products and efficient service.

For more information, please contact Babcock Wanson on 020 8953 7111 or info@babcock-wanson.com or go to website: www.babcock-wanson.com

foodandrinknetwork-uk.co.uk 02 News Network To read any of these stories in full or to find many more Food & Drink Industry articles visit: foodanddrinknetwork-uk.co.uk/

Porta 6 Launch Brut Sparkling Wine

Porta 6, the leading Portuguese wine brand in the UK, today launches a new Sparkling Wine in time for summer drinking. Porta 6 Brut Sparkling Wine will be available in Asda stores and online at an RRP of £10.

It is a delicious alternative to Cava and Prosecco and joins the iconic Porta 6 range of great tasting red, white and rosé wines which are well-priced and widely available from all six of the major UK supermarkets, as well as Majestic and Costco.

Porta 6 Brut Sparkling Wine is made using the Charmat method. The base wine, consisting of 70% Arinto, 25% Fernão Pires and 5% Chardonnay grapes, is fermented in controlled temperature conditions, with the second fermentation carried out in closed tanks followed by isobaric bottling to maintain the fine bubbles. The vineyards on clay limestone soil, located in the mountains north of Lisbon, benefit from the effects of the Atlantic Ocean on the climate.

Porta 6 Brut Sparkling Wine is ideal as an appetiser and pairs equally well as an accompaniment to a variety of dishes, from seafood and fish to meat and pastas.

The Porta 6 wine bottle has a unique label which features a painting showing a slice of Lisbon life; a relaxed

scene with of one of the city’s famous yellow trams. Street artist Hauke Vagt, originally from Germany, settled in Lisbon in the early ‘90s, when he fell in love with the city and its relaxed lifestyle. He sold his paintings to tourists outside the Castle of St. George, never imagining this particular image would find itself on wine shelves in almost every corner of the world.

Luis Bio, Managing Director of Vidigal Wines in Portugal, the producers of Porta 6, says: “We’re really excited to be launching the new Porta 6 Sparkling Brut Wine in the UK at Asda. We are looking forward to building on Porta 6’s success in the UK in a new category.”

Porta 6 Brut Sparkling Wine Tasting

Notes: Citrus colour, fine and persistent bubbles. Fresh, fruity aroma with hints of green apple, citrus fruit and lemon. Elegant and light on the palate, with fruity notes of green apple, this dry fizz has a well-balanced acidity, and a fresh, pleasant finish.

RRP: from £10. Available from: Asda. ABV 12.5%

The Isle of Wight Distillery gains international recognition winning multiple gold awards at The American Distilling Institute Awards

The Isle of Wight Distillery is delighted to announce it has been awarded seven gold medals across different categories at the prestigious American Distilling Institute Awards 2023 (ADI).

ALL NEWS IS GOOD NEWS!

If you would like to see your Newsworthy articles , regarding the Food & Drink Industry, published in the next issue of ‘Food & Drink Network UK’ email:

graphics@waltonspublications.com

Your release will also be placed on our website: foodanddrinknetwork-uk.co.uk

Mermaid Zest Gin topped the medal table with three gold medals in Best in Category, International Flavoured Gin, Brand Identity and Excellence in Packaging. Mermaid Pink Gin and Mermaid Gin were also awarded gold medals in the Brand Identity Category and Excellence in Packaging.

The American Distilling Institute’s annual Judging of Craft Spirits recognises the top craft spirits in the US and around the world. Started in 2007, the competition brings together approximately 50 spirit judges to evaluate submissions from small and medium-sized producers. Every spirit entered is tasted and evaluated blind by the expert panel of judges who use a scoring system to decide on what, if any medal should be awarded.

Alongside the usual listing of Bronze, Silver, Gold and Double Gold, the ADI’s craft spirit also recognises the Best of Category and Best of Class. These are the top entrants among the gold medal winners, with Mermaid Zest Gin achieving this accolade in Best in Category.

The Isle of Wight Distillery achieved the following awards:

• Best of Category – Distilled Spirit –International Flavoured Gin, Gold Medal: Mermaid Zest Gin

• Gold Medal Brand Identity: Mermaid Gin

• Gold Medal Brand Identity: Mermaid Pink Gin

• Gold Medal Brand Identity: Mermaid Zest Gin

• Gold Medal Excellence in Packaging: Mermaid Gin

• Gold Medal Excellence in Packaging: Mermaid Pink Gin

• Gold Medal Excellence in Packaging: Mermaid Zest Gin

• Silver Medal: Mermaid Gin

Silver Medal: Mermaid Pink Gin

Mermaid Gin launched three gin expressions within its spirits portfolio in the US earlier this year, Mermaid Gin, Mermaid Pink Gin and Mermaid Zest Gin. Mermaid Gin is produced in the UK at the Isle of Wight Distillery, the first and only distillery on the Isle of Wight, a small Island to the south of mainland England.

Mermaid Gin RRP from £38.00. ABV: 42%. Available from Amazon, John Lewis, Master of Malt, The Whisky Exchange, Harvey Nichols, Fenwick, Tesco, M&S, Waitrose and Isle of Wight Distillery

Mermaid Pink Gin RRP from £38.00. ABV: 42%. Available from Amazon, John Lewis, Master of Malt, The Whisky Exchange, Harvey Nichols, Fenwick, Tesco, M&S, Waitrose and Isle of Wight Distillery

Mermaid Zest Gin RRP from £39.90. ABV 40%. Available from John Lewis and Isle of Wight Distillery

News Network foodandrinknetwork-uk.co.uk 03 To read any of these stories in full or to find many more Food & Drink Industry articles visit: foodanddrinknetwork-uk.co.uk/

...and on our TWITTER Social Media Platform

SOLO COFFEE

secures major cold brew deal with Hollywood A-lister

Celebrity partnership, US launch and investment round fuelling record year.

• Solo Coffee signs deal as supplier to Millie Bobby Brown’s coffee brand

• Startup is expected to hit £4m revenue in 2024

• The record year is also due to major UK listings, international expansion and £1m fundraise

• Co-Founder, Theo Garcia, said: “Solo Coffee has been catapulted with a series of incredible successes”

Stranger Things’ have happened, but rarely to a young challenger brand like Solo Coffee, who was approached by representatives for Hollywood megastar, Millie Bobby Brown’s new venture. The white label deal secures Solo as coffee concentrate supplier for Brown’s new ‘Florence by Mills Coffee’ brand.

It launched on 18th May 2023, and features the line “Created by Solo Coffee” on back of pack. It will be distributed D2C via her brand’s website in the US and the UK.

In the past financial year Solo managed to achieve £1.1m revenue, nearly three times higher than the year prior. This new celebrity deal, in conjunction with other business

milestones, is fuelling record success for Solo, which is expecting to hit £4m next year.

The 19 year-old British actress and producer became the youngest person to make the Time 100 list for the ‘world’s most influential people’ in 2018. Her global platform and massive social media following will help supercharge Solo’s vision of changing the world’s perception of coffee.

SPOTLIGHT SET TO TURN COFFEE CONCENTRATE INTO ‘NEXT BIG THING’

The coffee challenger has seen strong success in the on-trade, estimated to be the key ingredient in 1 of every 30 espresso martinis served in UK bars and restaurants.

Solo’s main challenge for mass adoption as been educating consumers on how to use coffee concentrate at home. The colossal global spotlight that Florence by Mills Coffee will shine on it is set to turn the innovative format into the ‘next big thing’. This is great news for brands, retailers and the category overall.

2023 IS SET TO BE A RECORD YEAR

Solo Coffee is currently in the process of raising a £1m investment to support rapid growth. This is complemented by the company’s planned launch into the US in June in partnership with one of the largest coffee distributors in the country, with access to 60,000 sites nationwide. Another growth driver is a series of major UK on-trade listings, including Stonegate, owners of Slug & Lettuce and Be At One; and Mitchell’s & Butler’s, owners of All Bar One and Miller & Carter.

Theo Garcia, co-founder of Solo Coffee, commented, “2023 promises to be a recordbreaker. It is our most ambitious year ever, packed with a celebrity partnership, a major fundraise, significant UK listings, and our first step across the pond. Solo Coffee has been catapulted with a series of incredible successes into an incredibly exciting new chapter, transforming the business. It feels as though this is the inflection point in our mission to redefine the world’s perception of coffee and energise our generation.”

04 foodandrinknetwork-uk.co.uk

Beverages

‘

One Small Step for Can: How drinks brands can make the leap to sustainability

Not that long ago, the demand for eco-friendly food and drink products was limited to only the most eco-conscious of consumers. Yet in 2020 alone, 85% of UK consumers were making more sustainable life choices.

For many growing brands such as Gunner Cocktails, achieving environmental success can seem like an expensive

companies must scrutinise the environmental impact of their raw materials: how they are sourced, manufactured, and transported.

Beverages foodandrinknetwork-uk.co.uk 05

originalgunner.com

The Artisan Drinks Company Secures First Nationwide Listing at The Alchemist with Perfect Serve Cans

The Artisan Drinks company is delighted to announce their first nationwide listing at The Alchemist Bar and Restaurants. Artisan Drinks mixer cans are now served at all 22 Alchemist sites, replacing London Essence as their sole tonic offering. As a result of this new listing, Matthew Clark wholesalers are now stocking the full Artisan Drinks range nationally.

The 100% natural ingredient mixer brand takes a fresh approach to pairing mixers with spirits. Each of the Artisan Drinks mixers are created to complement a wide variety of spirits outside of gin, including whisky, tequila, sake, amaretto, bourbon and rum, adding an exciting dimension to cocktail creation.

Not only are Artisan Drinks the first mixer cans to come in a 200ml size, which ensures the perfectly sized serve every time, the cans also deliver numerous practical benefits such as a shorter chilling time as well as saving 40% more fridge space compared to storing bottles. Switching from glass mixers to cans also provides major environmental

advantages; less weight means lower recycling costs and lower carbon emissions to transport. Globally the rate of recycling cans is much higher than glass and each can contains up to 73% recycled materials, 20 times higher than the glass equivalent.

Jenny McPhee, Brand Director at The

Alchemist comments, “We are thrilled to be offering our customers across the country Artisan Drinks mixers. The quality and multiple benefits of their 200ml can range mean we are able to change from our previous 200ml bottled tonic offering, without a loss in product quality or having to alter our serves.”

Available here from Matthew Clark: www.matthewclark.co.uk/products/softdrinks/softs-packaged/artisan-classic-london-tonic-can-20-cl-x-24/ Instagram: @artisandrinksco • artisandrinks.com • thealchemist.uk.com/

Classic

Amalfi

Dry Gin, Tequila and Vodka

Pink Citrus Tonic pairs with Juniper

Forward Gin, Tequila and White Rum

Skinny London Tonic pairs with

Non-Alcoholic Gin, Contemporary Gin and Sloe Gin

Fiery Ginger Beer pairs with Rhubarb

Gin, Vodka, Rum and Bourbon

06 foodandrinknetwork-uk.co.uk

Beverages

‘

London Tonic pairs with London

Dry Gin, Old Tom Gin and Vodka

Lime Tonic pairs with London

Artisan Drinks Cans Range

Ultra-efficient RO Technology Halves Water Treatment Energy Consumption

Te-Tech Process Solutions will manufacture the new groundbreaking SAM50 reverse osmosis (RO) system. The batch RO features a unique energy recovery pressure exchanger and reduces energy consumption by over 50% compared to competing technologies.

RO has been the water treatment process of choice for the food and beverage industry for many years. Whether it’s process water – including brewing liquor reprofiling, soft drinks manufacturing, bottled water or food processing – or utilities water, reverse osmosis delivers high quality water. And with no hazardous chemicals during operation, RO satisfies all the requirements of HACCP. But conventional RO is traditionally energy intensive and, increasingly, expensive to operate.

The SAM50 technology was developed, over the past 10 years, by University of Birmingham spin out Salinity Solutions. SAM50 offers a small footprint, with modular units using standard 8” RO membrane cartridges and featuring “plug and play” installation.

“The SAM50 RO system is a gamechanger for the food & beverage industry,” said Mike Froom, Business Development Director, Te-Tech Process Solutions. “This technology offers unparalleled energy efficiency, helping companies reduce their environmental impact and operating costs. The system is modular and scalable and with high water recovery.”

The high recovery operation means up to 80% reduction in wastewater by comparison with conventional reverse osmosis plant. Ideal for the environment, for water conservation and for your bottom line.

For more information on the SAM50 RO, please contact Te-Tech Process Solutions at enquiries@te-tech.co.uk or visit: https://www.te-tech.co.uk/news/ quenching-the-thirst-of-thefood-and-beverage-industry/

07 foodandrinknetwork-uk.co.uk Beverages

CC-en91-AZ211_01-23indd.indd 1 27.01.2023 07:52:32

Food & Drink Network UK, 133 x 186 mm, Digitalisation M, CC-en91-AZ211 01/23

Contact us: 01264 554455 apsleyfarms.com Apsley Farms is a trusted supplier of bulk food-grade carbon dioxide, operating a fleet of tankers that deliver across mainland UK. We offer 24/7 onsite testing facilities of CO2 using our state-of-the art testing laboratory. Book your appointment now! Do you need a reliable source of liquid CO2 for your business? ^= éêçÇì Åí çÑ=ÖêÉÉå= ÉåÉêÖ ó A product of green energy 08 foodandrinknetwork-uk.co.uk

CO2 from renewable energy

Sustainability is at the heart of Apsley Farms

Apsley Farms in Hampshire is a supplier of high quality, food-grade carbon dioxide that is indispensably used within the food and drinks industry. We operate our own fleet of CO2 tankers and professional drivers to provide businesses with regular deliveries of liquid carbon dioxide.

Our CO2 is sustainably produced as a byproduct of the renewable energy production at the biogas plant at Apsley Farms. Every step in its production is grounded in sustainable and efficient practices at the Farm, as part of their commitment to reducing their environmental impact.

This includes the use of advanced farming techniques to reduce tillage, which in turn reduces the release of CO2 release during the growing of crops for our biodigesters. The storage and transport of crops is optimised for maximum efficiency, again lowering the carbon footprint of the raw materials.

The Farm has now invested in the Uni Sensor Carboscan system, a state-of-the-art automated laboratory. This system allows for the provision of CO2 testing services onsite at the Farm, 24/7.

CO2 testing services are offered to any commercial operation. A Certificate of

Completion is offered after successful testing which takes just under an hour to complete.

09 foodandrinknetwork-uk.co.uk Decarbonisation & Sustainability

on

554455 or

www.apsleyfarms.com

Contact us

01264

visit

HAVE YOUR CAKE AND EAT IT: reduce energy, decarbonise and earn additional revenue

Over the past century, the F&B sector has produced sufficient food to sustain population growth, while reducing its real price to improve affordability and helping to reduce world hunger. The result is a global food system valued at around $8 trillion, or 10 per cent of the global economy.

Going forward, the sector faces a significant challenge; to grow sustainably so that it can provide food and drink for a population that is forecast to reach over 10 billion by the end of the century. Achieving sustainable growth will require fundamental changes that address land degradation, biodiversity loss, changing consumer preferences and, not least, greenhouse gas (GHG) emissions.

Food production is already responsible for 30% of global energy consumption and over a third of global GHG emissions today – figures that are predicted to increase dramatically by 2030 as populations grow and climate changes impact the supply chain.

Food production and energy consumption are intrinsically linked. The entire supply chain depends on having access to reliable – and increasingly low-carbon – sources of energy. With rising volatility in world energy markets, growing pressure to decarbonise and questions

over security of supply, the imperative to reduce energy use and seek more sustainable sources has taken on new urgency.

It is more important than ever that large energy users deploy holistic energy strategies and work to reduce their energy use and emissions, engage with the grid and seek low-carbon, sustainable energy sources.

Understanding energy use and emissions reporting

Emissions reporting is becoming increasingly important, whether for compliance reasons or as part of a broader Environmental Social and Governance (ESG) initiative. Of the top 100 global F&B companies, only about half have measured, disclosed and set goals for their scope 3 emissions, which on average account for 88% of a company’s emissions across the entire value chain.

Accurately measuring energy usage and reporting emissions is an increasingly complex task, especially for businesses that operate globally within extensive supply chains. Utility bill management (UBM) systems provide a detailed picture of utility expenses allowing bill checking, comparisons across sites based on number of staff, operating hours and facility

size, as well as identifying opportunities to reduce energy consumption and reduce emissions. UBM data provides an effective baseline for further efficiency measures and data to facilitate supply chain disclosures for upstream and downstream partners.

Engaging with the gridasset flexibility

Demand Side Response, or DSR (also referred to as Demand Response or DR), is the mechanism typically used to deliver flexibility to grid operators at times of grid stress, when there is an imbalance between supply and demand. Businesses can deploy strategies that suit individual operational requirements e.g. change heating or cooling temperatures, switch off machinery or shift to backup systems such as onsite generation or battery assets to support grid stability – typically for only a handful of hours each year.

In return, participants in DR programmes benefit from an additional revenue stream of up to £30,000 per MW per year over the next 4 years. They also reduce carbon emissions and improve business resilience through regular testing of backup systems.

DR programmes help to prevent local and

10 foodandrinknetwork-uk.co.uk

As businesses in the food and beverages (F&B) sector look for ways to reduce their energy spend, Barry Hurst Head of Sales B2B, UK and Ireland, Enel X outlines how participating in flexibility programmes can generate revenue while supporting grid stability and reducing emissions.

Barry Hurst Head of Sales B2B, UK and Ireland, Enel X

regional power outages and are also an important tool to facilitate the integration of higher levels of renewable generation on the system without increasing costs to consumers. Renewable generation by its nature is intermittent, fluctuating with weather conditions, which makes it harder for grid operators to keep supply and demand in balance.

With the cooperation of large energy users participating on the demand side, grid operators can manage fluctuations without the need to call on conventional fossil-fuel generators to increase output or pay for renewable generators to reduce their output.

Decarbonisation and Sustainability

that consolidates and coordinates a range of distributed energy resources (DER), including equipment, infrastructure, storage assets, backup generators and so on. The VPP enables aggregation of a host of smaller assets to provide a larger asset with electricity, equivalent to what might be available from a large power generator – but without having to construct the physical asset.

There is a host of equipment that businesses have invested in right across the F&B value chain, which can be utilised in a VPP. For a food processor with cold storage, for example, those assets could include chillers, compressors and any DER that has flexible attributes, which can be harnessed to deliver value to the grid. In agriculture, water pumps can be used. Grocery stores typically have HVAC systems and refrigeration that have thermal mass and are ideal for flexing.

Planning for energy flexibility

Businesses are increasingly informing their investment in new assets not just on how the asset will fulfil its operational role, but also based on how it might be used as part of a VPP. In other words, flexibility becomes part of the business case for the new equipment.

For example, a flour milling company is looking to develop a new site. They are familiar with the concepts of flexibility and are prepared to change the operating model of that site to deliver real cost advantage. By using energy market signals as one of the key drivers for the design of the site, and by investing in control and automation, they can shift their energy demand to reduce costs and generate revenue by participating in the flexibility market. And this can be done without compromising production schedules.

features improves the tolerance for more strategic energy consumption and increases the dispatchable capacity. These measures give the business more versatility to generate additional revenue while improving the stability of the grid.

Procuring low-carbon energy

Measures that improve efficiency and optimise energy demand using flexibility can only go so far; the next step is to look at sourcing green electricity for power.

Good procurement of renewable contracts is a complex issue and can dramatically reduce emissions. A typical requirement is to make a long-term Power Purchase Agreement (PPA) with an energy company that can guarantee to deliver a supply of clean electricity sufficient to meet an organisation’s changing needs. PPAs guarantee supply, signify a long-term commitment to the zero-carbon agenda and help to reliably predict future energy costs.

Use the experts

As large energy consumers and one of the fastest growing users of power, the F&B sector has the potential to make a tremendous impact on grid innovation and sustainability. Given the F&B and power industries’ interdependence, the evolution of grid flexibility services and the rise of renewable energy, there has never been a better time for F&B businesses to demonstrate support for the low-carbon agenda and become even better grid citizens.

Virtual

power plants: an exceptional opportunity for F&B

A virtual power plant (VPP) is a platform

In another scenario, a business operating a cold storage facility could choose to specify higher capacity chillers and compressors, improved temperature control, regulation and insulation. Investing in these incremental

For most F&B businesses, sustainable energy is not a core business competence. Implementing a comprehensive energy strategy takes knowledge and expertise and a current understanding of energy markets and the ability to navigate regulatory and compliance issues. Engaging third-party experts to help plan and implement a holistic energy strategy will help to achieve the best outcomes.

11 foodandrinknetwork-uk.co.uk

The future food supply chain depends on having access to reliable and low-carbon energy Credit: Shutterstock / Olena Yakobchuk

The imperative to reduce energy use and seek more sustainable sources has taken on new urgency Credit: Shutterstock

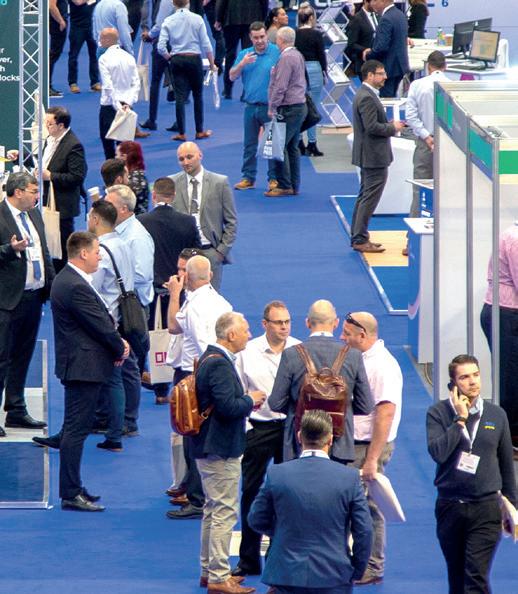

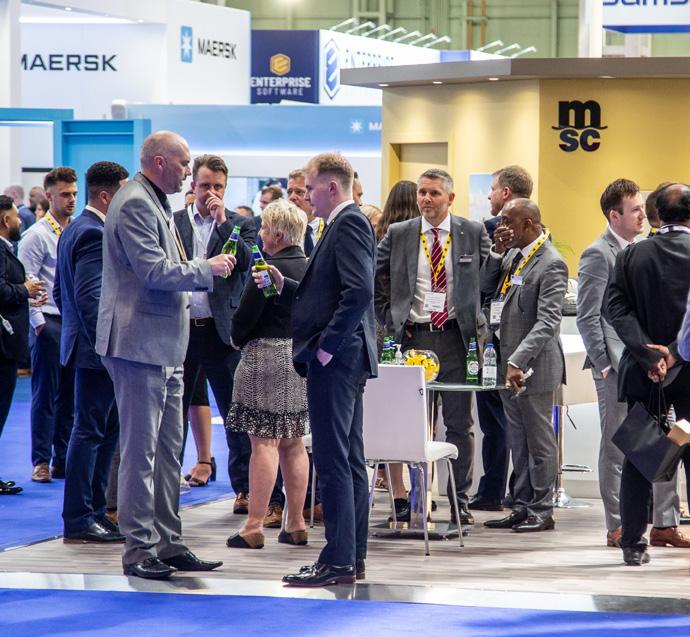

Multimodal 2023 celebrates 16 years of bringing together shippers and cargo owners with exhibitors and sponsors who can offer products and services to help them make their supply chains more efficient and more cost effective. Visitors attend to meet new suppliers, compare new routes and modes, source new products and ideas to improve their efficiency and to network with the industry.

foodandrinknetwork-uk.co.uk 12 13 - 15 JUNE 2023 NEC BIRMINGHAM LOGISTICS & SUPPLY CHAIN MANAGEMENT FOR CARGO OWNERS 300 Exhibitors 60+ Conferences CPD

Visitor & Exhibitor networking

Contact Us To Find Out How To Get Involved.

Hours

drinks

REGISTER IN ADVANCE AT www.multimodal.org.uk Established since 2008 Free to attend Supported by Google Digital Garage sessions MM23 visitor ad 186x270.indd 1 20/04/2023 13:24

Sweet sixteen for Multimodal in 2023

Multimodal 2023 will celebrate sixteen years of putting shippers, retailers, manufacturers, wholesalers, importers, and exporters in front of exhibitors who offer the latest logistics and supply chain solutions.

training, giving practical advice and guidance on best practice for international trade to and from the UK. Delegates taking part in the seminars will qualify for IOE&IT Continuing Professional Development (CPD) points.

Multimodal continues to work with the leading industry trade associations, including the Rail Freight Group, The Chartered Institute of Transport and Logistics, the British International Freight Association, Institute of Export and International Trade, the United Kingdom Warehousing Association and Logistics UK to deliver content and insight at the seminars.

Hall is held on 14 June from 5pm, giving everyone a chance to mingle in a relaxed atmosphere.

The three-day show between 13-15 June 2022 at the Birmingham NEC, will offer a unique opportunity to make valuable face-to-face contact with new prospects and existing companies.

Shippers and cargo owners at the free-toattend show improve their businesses by finding ways of moving their products more efficiently and by meeting new suppliers.

The Multimodal exhibition will include hundreds of companies showcasing the latest innovations in supply chain, including DP World, Port of Tyne, CEVA, Malcolm Logistics, Maritime Transport, Freightliner, Bristol Port, CMA CGM, Mediterranean Shipping Company, and ONE.

This year’s seminar series will focus on resilient, innovative and sustainable logistic strategies for business and people and Multimodal has once again teamed up with the Institute of Export and International Trade (IOE&IT), who will be presenting two days of

Multimodal also hosts the Multimodal Awards on the first evening of the show, 13 June at the VOX centre, Resorts World at the NEC, entertaining 850 industry professionals in the Awards that recognise excellence in air, road, rail, maritime, and freight forwarding services. One of the fairest industry Awards, the Multimodal Awards are nominated and voted for by the industry for the industry through an independent Awards nomination and voting system, and via an independent judging panel. Winning an Award is a true independent endorsement of a company’s excellence. The presenter this year is Vicki Butler-Henderson whose extensive knowledge and experience is invaluable to Fifth Gear on Five. She joined the team after presenting Top Gear for the BBC from 1998 to 2001, Top Gear Gti for UK Horizons from 2001 to 2002 and UK Horizon’s Top Bikes.

Last year Multimodal was attended by over 9000 delegates, with a record-breaking 840 guests taking part in the Multimodal Awards event.

This year, we expect thousands more to attend and will be hosting the Awards dinner on the 13th of June – nominations for the awards are open online.

To find out more about attending, entering the awards, exhibiting, or sponsoring, visit www.multimodal.org.uk, or contact Robert Jervis, Director on +44 (0) 20 7384 7760 or robert.jervis@clarionevents.com

Another networking event is the Multimodal Mixer, open to all visitors and exhibitors, hosted by DP World on their stand in the www.multimodal.org.uk/exhibition

13 foodandrinknetwork-uk.co.uk Multimodal 2023

Industry leading speakers lead this year’s Multimodal 2023 conference with additional training sessions also available for all visitors.

With registrations up 49% on last year, visitors to Multimodal 2023 are set to benefit from a cutting-edge line up of speakers during the free, three-day conference. In a new addition to the programme, attendees can also benefit from skills training and mentoring thanks to Google Digital Garage, which will deliver a broad range of digital and social media tactics to visitors.

Running across four theatres, the core conference theme focuses on sustainability, resilience, technology and people, and boasts a stella line-up of leading industry speakers. These include:

• Jon Gore, Head of Primary & Global Logistics, Tesco

• Sally Wright, Head of Delivery Transport Hub, Nestlé UK and Ireland

• John Lucy, Director, Liverpool Freeport

• Hizmy Hassen, Chief Digital & Supply Chain Officer, Apollo Tyres

• Christian Pryce, Chief Commercial Officer, Port of Dover

• Joep Kusters, Senior Vice President, Head of Europe, Coyote

Discussions and themes are built around the most pressing issues and relevant industry topics, covering:

• Peak Season Preview 2023

• Digitalisation of International Trade and Transport

• A Rail Retail Revolution

• Roadblocks to sustainable freightand how to overcome them

• Cargo integrity

• The UK’s new approach to import controls – understanding the Target Operating Model

Multimodal brings together businesses, thought leaders and associations from across the supply chain industry from June 13th to 15th, with the most outstanding firms and individuals recognised at its glittering Awards ceremony.

The addition to this year’s conference is the Google Digital Garage, which offers a range

of courses and learning for some of the most sought-after marketing skills, whether visitors are looking to grow their business, start a career, or just want to try something new. The programme is made up of eight immersive 15-minute power sessions and 11 in-depth 45-minute sessions covering topics such as:

• Digital Marketing Strategy

• Boost Online Sales with a Google Business Profile

• Writing for social media

• Build Engaging Presentations

• Get Your Business Visible on Google

Interest for the 2023 event has been bigger than ever, with record numbers of visitor registrations, new and existing exhibitors, and outstanding nominations for the Awards.

Commenting on this year’s visitor programme, Multimodal 2023 Event Director Robert Jervis said: “We are

delighted to be joined by Google and its Digital Garage as it will be bringing a new twist to the support we offer visitors. Digital skills are vital, whatever area of the supply chain you are in or what level you are. Visitors will be spoilt for choice thanks to our full conference programme featuring industry experts, plus the new digital training sessions. Multimodal is a unique industry event; now it offers additional value thanks to the Google Digital Garage.”

Debbie Weinstein, Managing Director of Google UK & Ireland added: “Digital technologies are truly transformative and can help businesses and individuals across the UK to increase their earnings, boost their productivity and unlock their full potential. As a former business owner myself, I understand how tough it is to know where to turn to for advice. That’s why we’re providing handson support as part of our nationwide digital skills drive to help equip more people with invaluable skills that help to create jobs and economic opportunities.”

Find out more about Multimodal 2023 via https://www.multimodal.org.uk/ and view the full seminar programme here: https://www.multimodal.org.uk/conferences-2023#/seminars/ 14 foodandrinknetwork-uk.co.uk Multimodal 2023

Matara to exhibit at inaugural Automation UK event

Matara UK Ltd, specialist in automation, pneumatics and linear motion products, is pleased to be exhibiting at the inaugural Automation UK exhibition on 20-21st June 2023 at the Coventry Building Society Arena.

Supported by the British Automation & Robotics Association, this new event will showcase the latest industrial products and services, robots, robotic systems, systems integration, automation control parts and systems, sensors, and machine safety available in the UK today.

For Matara, the key product focus on its stand will be linear actuators which, along with the motor, are the driving force of a linear motion system. Linear motion systems are used extensively in industrial automation applications to move parts of a machine in a straight line - up and down or back and forth - in a pre-determined and controlled manner. Linear motion systems ensure smooth, accurate, reliable movement, and

are simple and cost-effective to maintain.

Matara offers a substantial range of belt driven and ballscrew linear actuators, including the best-selling MTB and MTS series belt driven actuators, which will be on display at Automation UK, including a working version using a Gapp Automation control unit; Gapp Automation has recently joined Matara’s parent company, Rubix.

For any actuator to perform consistently at its optimum level it needs the correctly specified motor, gearbox coupling and control system. Matara will therefore also be exhibiting its linear motors, servo motors, stepper systems, gearboxes and automation solutions.

Other Matara products and services aimed at the automation and robotics sector include aluminium profile safety guard frames, pneumatic grippers, linear rail and guides, rolled ballscrews and ballscrew nuts, linear motors.

Commenting on the company’s decision to exhibit at Automation UK, Japh Humphries, Matara’s UK Sales & Commercial Manager, said: “the robotics and automation markets are a growth area for Matara. We have experience in this sector and we have the products. Automation UK will provide us with the opportunity to showcase these to the right people. We are excited to be involved in this new event and are looking forward to welcoming visitors on to our stand.”

Matara is part of Rubix, Europe’s largest supplier of industrial maintenance, repair and overhaul products and services.

For more information, please go to www.matara.com/, or contact Matara at sales@matarauk.co.uk or on 01684 850000. For information on Automation UK visit www.automation-uk.co.uk/

15 foodandrinknetwork-uk.co.uk

Automation UK

NEW EXHIBITION Free Entry Bringing industrial automation and robotics to life Visit Automation UK – See live demonstrations of the latest automation and robotics technology. automationukshow automationUK_23 automation UK automationukshow Co-located with Register for your FREE visitor pass today, visit automation-uk.co.uk foodandrinknetwork-uk.co.uk 16

Registration is now open for Automation UK – where automation and robotics come to life

Register now for the UK’s newest exhibition highlighting the importance of robotics and systems integration to the future growth of the UK economy. Owned by BARA (British Automation & Robot Association), the respected advocate of the UK robotics and automation industries. BARA promotes the use of and assists in the development of Industrial Robots and Automation in British industry. It provides strong support to assist with the growth of the automation sector in the UK, as well as having a presence overseas.

Mark Stepney, Managing Director of Schubert UK and a PPMA Board Member, said: “Automation UK and MVC will be the largest annual event in the UK to showcase leading robotic and vision suppliers. Its legitimacy is underlined by the backing of two leading industry associations – BARA and UKIVA – and will be an event not to be missed. Aside from being able to view live demonstrations of the latest machines, talk to exhibitors face-to-face and gain the latest market intelligence from industry experts, we have a very competitive offer for exhibitors and one we believe they will find very attractive, not least because the show is open to all suppliers and prospective purchasers.”

Recognising the vast potential of automation and robotics to British industry, BARA is launching a dedicated trade show for the sectors, which is set to be the new benchmark exhibition for the UK automation and robotics industry.

Automation UK, which debuts at Coventry Building Society Arena between 20-21 June 2023, is a content-led event offering UK audiences the latest automation and robotics solutions available, all under one roof. It will be the perfect place for stakeholders to come and view the best new products and services on the market.

The event will shine a spotlight on the latest technologies and highlight their true value to the wider economy. Co-located with UKIVA’s Machine Vision Conference, it will be the largest annual gathering of industry

experts under one roof in the UK.

The event has been specially designed for businesses operating in the automation and robotics markets. Showcasing live demonstrations of the latest products and services, exhibitors will span a range of sectors including: >>>

• Robots / Robotic Systems

• Automated Assembly Machines and Systems

• Parts Handling Equipment / Conveyors and Materials

• System Integrators

• Industrial Automation Control

• Manufacturing Sensors and Sensor Integrated Systems

• Automatic Identification and Data Collection (RFID)

• Machine Safety

• Education and Skills

Both BARA and UKIVA are part of the PPMA (Processing and Packaging Machinery Association) Group, a coalition that spans the breadth of the automation and robotics sector. The PPMA itself represents and lobbies on behalf of suppliers of processing and packaging machinery to both the domestic and overseas markets. The PPMA group comprises more than 550 member companies and its unique structure enables it to be the authoritative voice of the automation and robotics sector, and why it delivers such a compelling offer to this new event.

Book your free visitor pass today at www.automation-uk.co.uk

Automation UK

foodandrinknetwork-uk.co.uk 17

foodandrinknetwork-uk.co.uk 18

REGISTRATIONS ARE NOW OPEN FOR UKIVA’S MACHINE VISION CONFERENCE

Register now to attend UKIVA’s Machine Vision Conference (MVC) from 20-21 June 2023 at the Coventry Building Society Arena to discover the very best in machine vision and industrial technology.

With its wide-ranging conference programme this live, two-day event will once again act as a focal point for the latest vision trends and technologies and their uses in real-life applications, as well as offering the opportunity to see the latest vision products in action.

Now in its seventh year, MVC 2023 has established an impressive reputation for its far-reaching educational and technical conference programme. This year’s seminar programme, delivered by experienced and knowledgeable vision specialists, will focus on six specific themes:

Understanding Vision Technology; Deep Learning & Embedded Vision; 3D Vision; Optics & Illumination; Camera technology; Systems & Applications.

Content has been designed for a range of skills, from experienced practitioners who are keen to explore the latest developments and innovations, to those new to the industry who want to learn more about the fundamentals of vision technology. Visitors can tailor their own programme from the multiple technical seminar theatres that run in parallel throughout the day.

MVC 2023 will represent an excellent cross-section of the industrial vision industry, with many world-renowned manufacturers, leading vision technology suppliers, distributors, and vision systems integrators available to demonstrate their products, then discuss how their specialist expertise can help solve vision problems.

An essential component of MVC 2023 is a focus on NPD and the very latest vision technology. New image sensors with exciting new capabilities have been developed; new illumination sources have emerged, AI capabilities have improved, and image processing toolkits have been enhanced.

MVC 2023 will represent an excellent crosssection of the industrial vision industry, with many world-renowned manufacturers,

The conference theatres are conveniently located around the exhibition space with plenty of opportunities for visitors to visit all the stands in between seminars.

MVC 2023 is an ideal event for anyone who is actively involved in the design, or implementation of a vision system, or who has a problem that might be solved using industrial vision. With relevance to a host of industries including food, beverage, pharmaceutical, healthcare, automotive, aerospace, medical devices, packaging, solar energy, electronics, semiconductor, sport, traffic & transport and more, MVC 2023 is the perfect opportunity to investigate the latest vision technology on offer.

UKIVA 2023

Book your free visitor pass today at www.machinevisionconference.co.uk

foodandrinknetwork-uk.co.uk 19

Why There Is So Much Air in Crisp Packets

Crisps are a staple snack enjoyed by millions, but opening a bag and finding it only half full can be disappointing. It might seem like a way for brands to cut down on the number of crisps they put in each packet and give the illusion that you get more for your money, but there’s a sound reasoning behind all that ‘air’.

CRISP PACKAGING: The Science behind the Air

At first glance, the air in crisp packets may seem to be taking up valuable snack space. However, it’s not really air but nitrogen.

Nitrogen is used to modify the atmosphere of the crisp packet. One of the chemical characteristics of nitrogen is its highly stable triple bond, which minimises any reaction with the ingredients within the crisp packet and keeps crisps fresh, tasty and crunchy.

This is important, as crisps contain moisture, meaning they will quickly go stale when exposed to the oxygen. Nobody likes a soggy crisp, so manufacturers reduce the amount of oxygen inside by filling the packets with nitrogen, which prolongs the crisps’ shelf life.

The Role of Moisture Measurement in Ensuring Freshness

Moisture is a critical factor in determining the shelf life and quality of crisps. Too little moisture and crisps will be hard, while too much can cause crisps to lose their crunch. Therefore, ensuring crisps remain fresh and tasty requires

precise control over the moisture content during production.

Manufacturers achieve this by using Near Infrared (NIR) moisture gauges. Advanced food processing equipment such as the NDC Moisture Analyzer allows producers to maintain optimal freshness and taste by measuring moisture levels in real-time.

Because NIR gauges are non-contact, they can be used to measure moisture without physically touching or destroying the product.

They work by emitting a NIR light at specific wavelengths known to interact with water (moisture) molecules. When the light reaches the crisps, the crisps absorb some of it and reflect the rest.

The light absorbed by the water molecules in the crisps depends on the moisture concentration, with high-moisture crisps absorbing more light than those with less water.

Then, a detector measures the intensity of the reflected light to accurately, quickly and continuously calculate the moisture content.

From here, manufacturers can adjust cooking times, temperatures or the drying process to ensure optimised moisture levels, consistent quality and the right balance of crunch and flavour.

The “wasted space” in crisp packets may seem excessive at first glance, but now you can see it’s not just a clever marketing trick — it is a precise solution to maintain high-quality standards and keep crisps fresh and delicious throughout their shelf life.

LIMAB UK is an exclusive distributor of moisture measurement and seal integrity testing equipment. Visit https://www.limab.co.uk/ or call +44 (0)1823 668633 to speak to a product specialist.

20 foodandrinknetwork-uk.co.uk Food Manufacturing

Don’t let a lack of lubrication catch you out

Food manufacturers face a unique set of challenges when it comes to maintaining machinery to ensure peak performance and audit compliance. From facing regular washdowns to dealing with heavy loads, operating at extreme temperatures or at high speeds, a strict preventative maintenance regime is needed to make sure that stringent hygiene and food safety regulations are met, downtime is reduced, and equipment operates at a consistently high level to deliver high-quality outputs.

Products need to leave your factory unspoilt and free from potentially harmful contaminants and you need the peace of mind that production equipment is working as hard as possible to meet delivery schedules.

Expanded audit criteria

The BRC began auditing against the new Global Standard Food Safety (Issue 9) in February this year. BRCGS Issue 9 puts an increased focus on creating a strong product safety culture across food manufacturing facilities. It states the safety, quality and operational criteria that manufacturing organisations are measured against to ensure legal compliance and the protection of the end consumer.

These standards extend food safety criteria across a wider range of companies, which means that more facilities that operate at every point in the food supply chain are being audited to the same stringent criteria. This makes selecting the right maintenance products vital to ensure compliance.

Andy Howard, Food and Hygiene Segment Specialist at ROCOL looks at what you should consider when choosing the products and methods for lubricating the machinery on your factory floor.

Getting the right product for the job

Food-grade lubricants are commonly used in most food and drink production facilities as they reduce contamination risk. With so many lubricants on the market, how do you select the right one for your factory?

The first thing to look for is NSF registration. All registered lubricants must display both the logo, the relevant category code(s) for which they are registered and the NSF registration number.

There are different NSF categories that cover maintenance products, which indicate where and how they can be used in food and drink production facilities. As different machinery and production facilities have different requirements when it comes to maintenance, it isn’t as straightforward as selecting an NSF-certified product and assuming it will be suitable for use in every area of your factory.

It is important to know what different NSF classification codes mean, and where and how different food-grade lubricants can be used. For example, is the equipment operating in an area where incidental contact between a lubricant and the food product is tolerated? If so, you will want to look for NSF H1 lubricants. If there is zero risk of the lubricant contacting a food product, then an NSF H2 product may suffice.

The term food-grade is widely used, but there are differences between lubricants, so it is important to select the right lubricant to protect the machinery or risk a product entering the food chain in a way which could lead to a product recall.

Specific products for specific uses

Food-grade lubricants have become more and more sophisticated. Today we have lubricants designed for specific sectors and machinery, which means you no longer need to rely on a general lubricant for a specific application.

For example, if you operate in the meat industry, you may have chains that must withstand regular washdowns, conveyors, presses, and slicers. Each operates in different conditions and has different lubrication requirements. Actively seeking out products that have been specifically designed to withstand washdowns, for example, will help extend equipment life.

An additional consideration is supply chain integrity. For example, vegan food product manufacturers may not be aware that many of the food-grade lubricants in the FOODLUBE range have been certified with The Vegan Society’s Vegan Trademark. Using lubricants with this registration will help manufacturers reinforce their vegan manufacturing credentials and demonstrate a commitment to quality throughout the supply chain.

Don’t neglect technique

Ensuring that your maintenance team is correctly trained on the effective use of lubrication products not only protects machinery, but it also stops potential contamination.

Here, technique is key. One piece of advice that we regularly share is that the recommended amount is the correct amount. Too much or too little lubricant can lead to issues with equipment performance or contamination.

Investing the time to make sure that your team are skilled and confident in the application of lubricants will pay dividends in the long run. Getting it right means that you won’t overspend due to lubricant overuse, and your machinery will remain in peak condition with the right amount of lubricant applied at the right time. If you feel that there are knowledge gaps in your team, it is worth investing in training for them.

If you are in any doubt about which lubricants are most suitable, or you would like to know more about the training we can offer, contact a member of the ROCOL team who can help guide you.

+44 (0)113 232 2600 customer.service@rocol.com rocol.com

21 foodandrinknetwork-uk.co.uk Food Manufacturing

WE HAVE HUNDREDS OF RANGES, READY TO SAVE YOU TIME AND MONEY THIS SUMMER!

foodandrinknetwork-uk.co.uk Check out our prices! 01603 788 833 | teknomek.co.uk GET READY SUMMER! FOR

22

Stringent hygiene routines and regulations are crucial in the food and drink processing environment. Equipment and furniture must be easy to clean, sanitise and maintain.

All food and drink manufacturers must therefore ensure that they are investing in the very best solutions in order to comply with strict hygiene and safety standards and to avoid contamination of ingredients and food and drink products. The importance of exceptional food safety and hygiene therefore cannot be undervalued, and it is imperative that food and drink manufacturers, processors, suppliers and retailers invest in effective and reliable hygienic solutions to meet stringent health and safety standards throughout the supply chain.

With rigorous audits taking place across the food and drink industry, we are seeing more and more businesses working hard to improve and enhance their food safety management systems. The aim is to operate a clean and sanitised production area, where contamination is minimised. Strict guidelines must be followed to ensure that all areas of the factory floor are spotless, equipment is easy to washdown, and excellent hygiene and sanitation standards are maintained.

Today’s food processing facilities must meet the requirements of regular audits. It is crucial to have in place systems and solutions which will pass the high standards of sanitation needed in today’s fast-paced food processing environments. When investing in furniture and equipment for your food or drink processing facility, it is therefore important to select hygienically designed stainless steel solutions. Experts in this sector can design, build and supply high-quality, hygienic furniture and equipment to help you to manage risk and meet the strict

Hygienic stainlessequipment steel

compliance standards that are required. These products are manufactured to exacting standards with precision welding of 304 or 316 grade stainless

steel, making them hardwearing, long lasting and corrosion resistant, as well as being suited to rigorous hygiene and HACCP routines.

foodandrinknetwork-uk.co.uk 23 Hygiene & Safety

Atlas Copco expands its vacuum range with DB Side Channel Blowers

Dry, clean and oil-free

Atlas Copco, the specialist for high-quality vacuum solutions, is expanding its comprehensive vacuum pump portfolio with the side channel blowers DB series. Based on an efficient operating principle, the vacuum is created by the kinetic energy of the rotating impeller. The impellers are connected to the motor shaft and enable suction of the pumped medium, which is accelerated in the side channel.

Suitable for rough processes

Side channel blowers are designed for applications where high flow rates are required. This makes the dry rough vacuum of the DB models suitable for rough industrial processes - such as drying, pneumatic conveying or suction processes. The modular design ensures high efficiency, reliable performance and quiet operation.

No emissions or contamination

Thanks to the dry, non-contact pumping principle, the exhaust air of the DB vacuum pumps cannot be contaminated; the vacuum is completely free of oil and dust, without any emissions or impurities.

The models are equipped as standard with IE3 motors in eco-design and comply with cURus standards. This certification meets all safety requirements for the Canadian and American markets.

Optional single- or two-stage design

Depending on the required vacuum performance, Atlas Copco offers the DB series in single-stage and two-stage versions, optionally with one impeller or twin impellers each. The single-stage version release the pumped medium after it has gone through just one stage, while in the two-stage version it enters the second stage after the first one. Operation with twin impellers increases the blower’s capacity. The two-stage version achieves a higher vacuum level. The combination of both results in larger air flows and higher vacuum level with just one machine.

Regular maintenance reduces operating costs

Atlas Copco takes care of maintenance planning and regular servicing of the DB pumps, if required. “Our ‘Preventive Care Plan’ is tailored exactly to the pump’s needs. Since the vacuum pumps are maintained using state-of-the-art technologies, we also achieve a high level of energy efficiency as a result,” Carol Pignatelli, the responsible product manager at Atlas Copco, emphasises. Thus, regular maintenance ultimately helps to reduce operating costs and increase process productivity by minimising unplanned downtime.

The advantages of the DB series at a glance

• Non-contact, oil-free operating principle prevents oil and dust contamination. - Suitable for global installations

• Wide range of voltages and frequencies available from 50 and 60 Hz - Housed in closed aluminium enclosure

• Virtually maintenance free

- Low noise thanks to effective blade design.

24 foodandrinknetwork-uk.co.uk

Vacuum Solutions

DBD – Double Stage and single impeller

DBt - Twin impellers and single stage

Are you worried about your R&D Tax Credits Claim?

This would appear to be a knee jerk reaction to the criticism levelled against the organization during the House of Lords debate on the 2022 Finance Bill, which also had a number of senior figures from within the Science and Technology community and a couple of representatives from the R&D Tax Credits Industry.

In earlier years HMRC had a network of regional areas of expertise in their R&D Units, these have pretty much been disbanded and centralized. HMRC have also recruited around 200 new “Case Workers”. These case workers have had 12 – 18 months of training and education in the R&D Tax Credits Scheme Rule book, the Corporate Intangibles and Research and Development (CIRD) Guidelines. They have come from a variety of backgrounds but from anecdotal evidence and a little bit of first hand experience, that experience is not generally from an Industrial, Mechanical or Technologically focused role.

This is not new, for years the Inspectors who were the backbone of the investigative teams within the R&D Units had “specialized” in a particular industry, but they weren’t technically competent professionals. The difference is the Inspectors had had a number of years of training and it felt like they had a reasonably sound understanding of some of the more technical elements of their area of specialty and a sound knowledge of the CIRD guidelines built up over a number of years supporting previous Inspectors. That is not the case today.

The approach to enquiries also appears to have changed significantly. In the past it has always felt as though enquiries were a collaborative approach to ensure that the

tax payer (and the advisor, if there was one) understood the eligibility criteria and that the competent professionals within the company, were able to demonstrate their competence and understood the boundaries of their R&D projects. They would also then be discussing the financial elements and challenging percentages and costs to determine they met the eligibility criteria.

Finally, after several weeks of back and forth, If errors were found, there was always a rather mumbled apology along the lines of “well we have found an error, we will have to discuss penalties with you, but you’ve worked with us, If you can provide us with evidence that you can prevent it happening again then we can probably waive those in this instance.” It was all rather softly, softly and more of an educational experience.

Today’s approach seems to be a blanket “it’s not eligible” and as a result we are going to be charging a penalty, here’s how we calculate penalties. It is also a lot more combative and it’s often not because HMRC are coming from a position of strength. They are often relying on a company fearing penalties and being unwilling to take them to a Tribunal, which is an expensive affair and often more costly than the tax benefit being claimed.

It feels like they are using this fear to prove that there is extensive fraud and error in the SME scheme and use this evidence as the driving reason to harmonise the two schemes into the RDEC scheme.

Having previously reviewed a claim by a top 10 firm of accountants who had used sampling to review a number of projects, they claimed for about 75% of projects, on closer review of each of the projects in the following year, our detailed review established that only around 40% of projects were eligible and this was for a large international company claiming under RDEC.

If you do get an enquiry, don’t panic answer the questions honestly and openly and if you really are worried consult a professional advisor, they might be able to help you, but do it sooner rather than later.

If you would like to have a conversation about an enquiry or your R&D claim before you submit it, you can book some time to discuss your R&D projects with me by booking a free, no obligation discovery session at calendly.com/cooden/fandd Article supplied by

foodandrinknetwork-uk.co.uk 25

Simon Bulteel, Lead Consultant of Cooden Tax Consulting

Since the start of the year, the R&D Tax Credits industry has been shaken to its core by an ultra aggressive stance taken by HMRC when it comes to tax enquiries into R&D Claims.

Allergens

Businesses should take more responsibility to prevent food allergy deaths

The technology already exists to prevent tragic deaths from food allergies but the hospitality industry is being slow to adopt it.

That’s according to Regency Purchasing Group, one of the UK’s leading procurement businesses, whose managing director Alex Demetriou has been campaigning for decades for more to be done to make allergy information much clearer.

Mr Demetriou said businesses need to take more responsibility for protecting staff from being put in a tragic situation where they may feel to blame for someone’s death when the technology is now available to provide businesses and their staff members with easy access to up-to-date allergen information.

Mr Demetriou spoke out in the aftermath of a Parliamentary debate in Westminster Hall last week on two petitions, one calling on the Government to appoint an allergy tsar and the other calling for Owen’s Law to be introduced.

Owen Carey was celebrating his 18th birthday in 2017 when he bought a chicken burger.

Although he told the server about his dairy allergy, the server was unaware that the chicken had been marinated in buttermilk.

Since Owen’s tragic death his family have been campaigning for the introduction of Owen’s Law, which would compel restaurants to state the allergens in their dishes, specifically on the face of the main menu.

Regency Purchasing Group works with more than 5,000 businesses across the UK, supplying food and drink to hotel groups, restaurant chains, zoos, farm parks, visitor attractions and others.

The group also runs several successful hospitality businesses, giving it a unique insight as both a supplier and an operator.

26 foodandrinknetwork-uk.co.uk

Mr Demetriou said: “One of the issues raised in the Parliamentary debate concerned more training for staff, to ensure that they are aware of all the allergens. But many businesses employ lesser experienced, transient staff, many of whom tend to be young – for some it may well be their first job – and on minimum wage, all of which means that the skill sets to understand all there is to know about dishes, ingredients and allergies simply doesn’t exist.

“The emphasis should be placed more on business owners to ensure that updated information is easily accessible and readily available to all staff members, to alleviate the pressure placed on the individual, especially in a sector where staff turnover is so high.

“Perhaps some businesses – particularly in the current financial climate – are concerned about the costs of introducing technology to help their staff.

“Many other sectors have embraced technology in recent years to deliver efficiencies, yet the food and beverage sector seems slow to use technology which, ultimately, can prevent tragic loss of life which, in turn, would have a positive impact on consumer confidence.

Mr Demetriou added: “Thousands of people have signed the petitions for Owens Law, and for the introduction of an allergy tsar.

“Owen’s family don’t want to see his death be in vain, and for other families to have to suffer the kind of loss they have. The technology is there now to make this happen, it just needs more businesses in the sector to take more responsibility and embrace it.

“Perhaps this is something that the Government can do quickly in response to the petitions,

which is to look at the technology already out there and compel businesses to adopt it and protect their customers and, in doing so, their businesses.

“There’s nothing more heart-breaking than a death which could so easily have been preventable. The way to stop more senseless tragedies like Owen’s story exists and is out there now.

“We just need the Government and the sector to wake up to it and let today’s technology protect people and increase consumer confidence, which can only be good for food and beverage businesses.”

Mr Demetriou concluded: “Here at Regency, we have developed and launched MenuIQ, an allergen management system to help operators ensure compliance and reduce (and hopefully eliminate) allergy incidents within their businesses.

With the right allergen management system in place, business owners are not just protecting their customers and their business; they’re also building an allergy-friendly brand, gaining trust, loyalty and repeat visits from allergy sufferers.”

To find out more about Regency Purchasing Group and MenuIQ, visit: www.regencypurchasing.co.uk / www.menuiq.co.uk

Regency Purchasing Group Managing Director, Alex Demetriou

Regency Purchasing Group Managing Director, Alex Demetriou

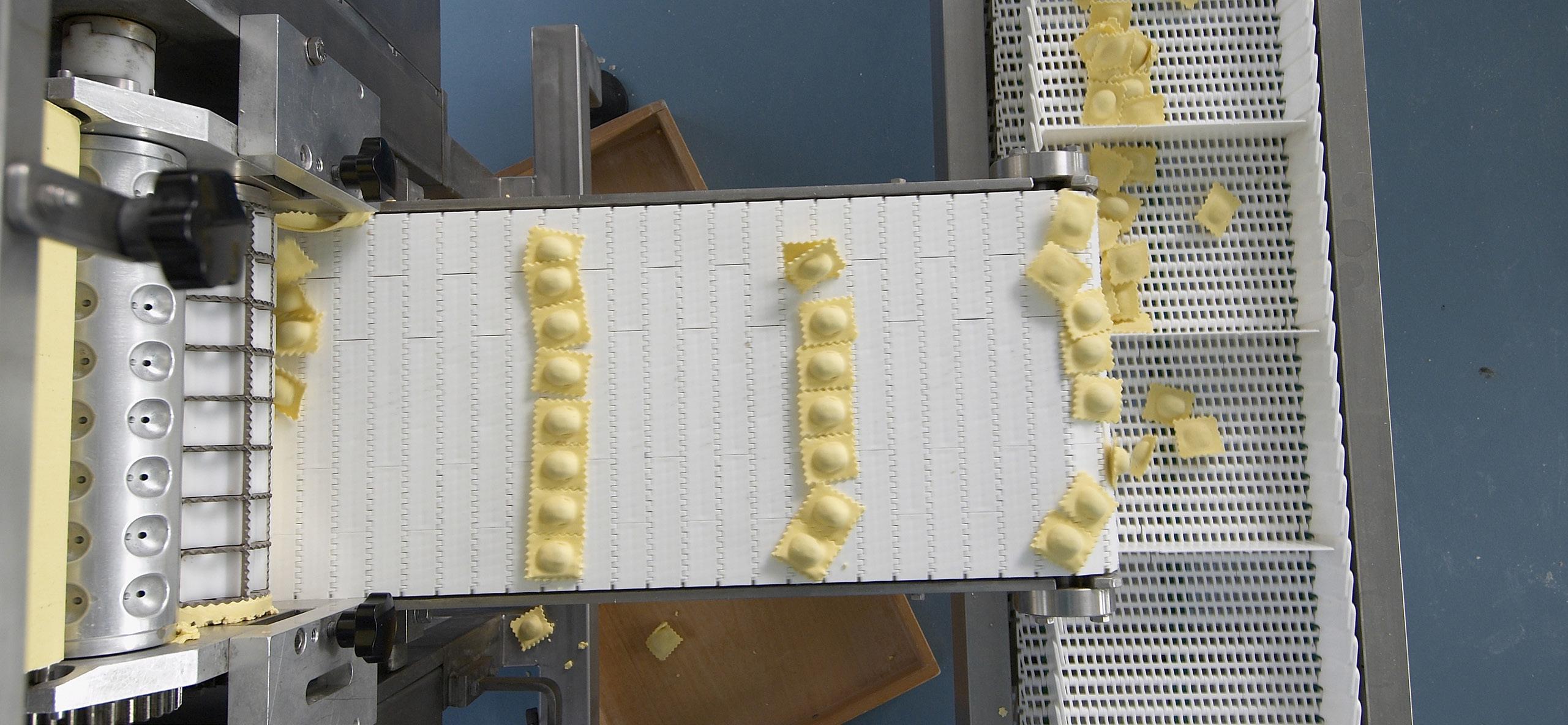

Perfect for cleaning controls

Direct analysis of rinse water samples (CIP water)

https://r-b.io/bioavid_EN

Versatile – also applicable for food testing

Allergens foodandrinknetwork-uk.co.uk 27 Reliable allergen analysis and identification of also high positive samples Allergen management with bioavid lateral flow tests R-Biopharm R Rhône Ltd Block 10 Todd Campus, Acre Road, Glasgow WOSSP• info@r-biopharmrhone.com • food.r-biopharm.com

More information: 10/2022

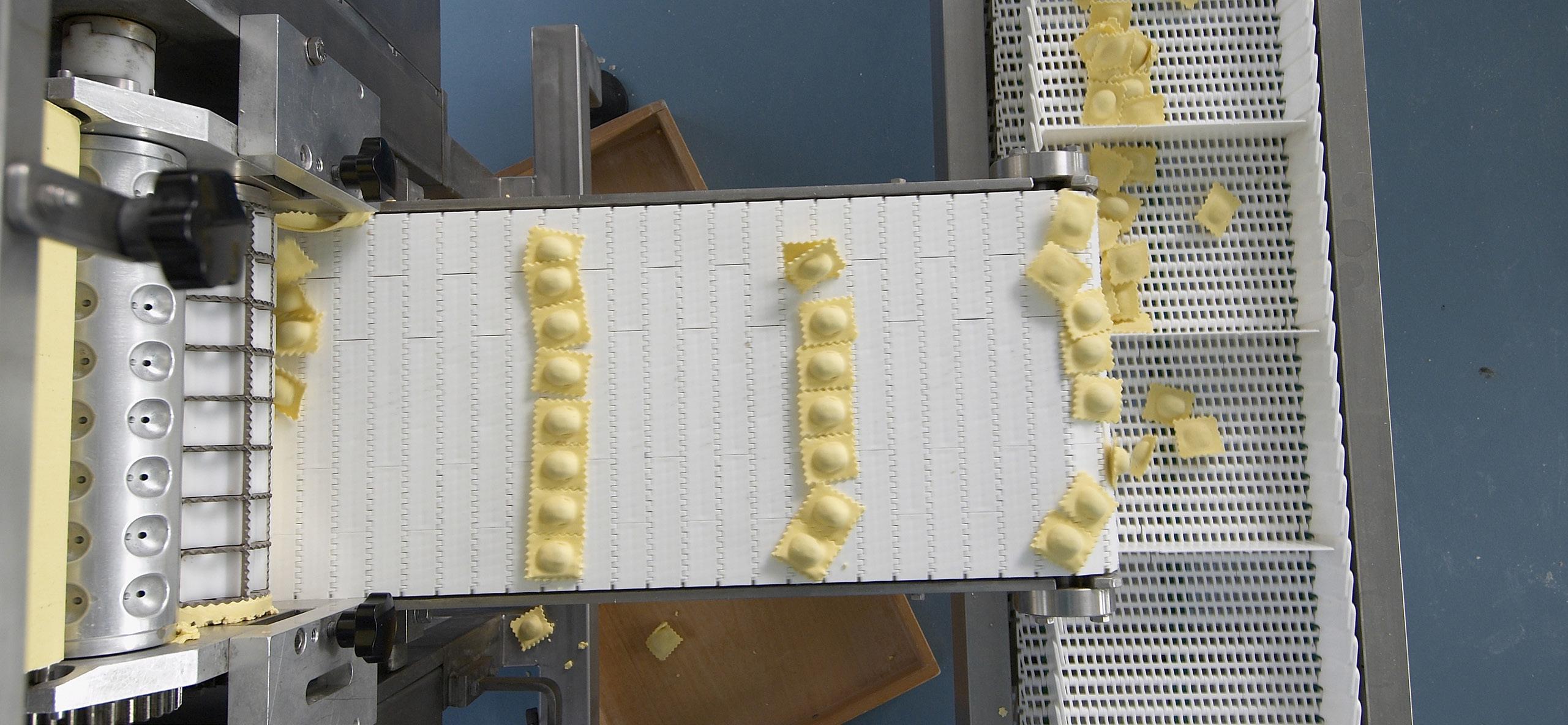

Achieving Allergen Control Excellence through Operator Engagement – Safeguarding

Quality and Compliance

in Manufacturing

Following our last two articles on allergen control, we have been overwhelmed by the responses and interest that we received, asking for further information about allergen control in manufacturing. It’s great to see the industry take allergen control so seriously.