VOLUME 23 • ISSUE 07 ISSN: 2056-8355 foodanddrinknetwork-uk.co.uk Audit-ready hygienic furniture Helping your business exceed BRC Standards. Expert Partner in Hygienic Solutions 01603 788 833 mail@teknomek.co.uk teknomek.co.uk How switching to laser coding can help with your sustainability KPIs The new generation of eco-savvy consumers are demanding more sustainable packaging as part of concerted efforts to reduce manufacturing’s environmental footprint, particularly in the fast-moving consumer goods (FMCCG) sector. See more on Pages 24-25 Corrosion Resistant Solutions from Cross+Morse A balance of material strength, corrosion resistance, sealing and lubrication are required for all products used where hygiene is of paramount importance. See more on Pages 18-19 Instant buildings for better workflow Within most businesses there is scope to improve production and general workflow processes through the introduction of additional workspace. At Smart-Space this requirement makes up a large proportion of the buildings we install, week in, week out. See more on Page 30 “It came all the attention, the Glenn INSTANT BUILDINGS Temporary, How smart-space.co.uk STORAGE I PRODUCTION I WAREHOUSE by Smart-Space For more information turn to page 21

Visit us at PPMA 2022 Booth C70 markem-imaje.com Printer Intelligence. Packaging Intelligence. Brand Intelligence. Intelligence, beyond the mark. Smarter printers, packaging operations and brand protection solutions to connect and protect every product— from production to your consumer’s hands. PPMA-2022_186x270.indd 1 7/19/22 3:34 PM Visit us at PPMA 2023 Booth C70

EDITORIAL:

BACCHUS AGENCY

BRAND DIALOGUE

EASYFAIRS

FAIR COMMUNICATIONS LTD

HARFORD CONTROL

KEOLNMESSE

MARBLES PR

PHD MARKETING

PPMA

SPRINGBOARD COMMUNICATIONS

WALKI GROUP

ADVERTISEMENT SALES:

KIMBERLEY READ (Advertisement Sales Manager) GINA MADDISON

ACCOUNTS & ADMINISTRATION:

AMANDA WALMSLEY

EVELYN WOOLSTON

GRAPHICS DEPT:

STUART TURNBULL - Studio Manager

RACHEL RILEY - Designer

PUBLISHED BY:

WALTONS PUBLICATIONS LTD

46 HENEAGE ROAD, GRIMSBY N.E. LINCOLNSHIRE DN32 9ES

TELEPHONE:

EMAIL:

Kimberley Read at: kimberley@ foodanddrinknetwork-uk.co.uk or Gina Maddison at: gina@foodanddrinknetwork-uk.co.uk

WEBSITE:

foodanddrinknetwork-uk.co.uk

ISSN:

TWITTER: FACEBOOK:

@fdnetworkuk /fdnetworkuk

All rights reserved. No part of Food and Drink Network UK Magazine may be reproduced or stored in a retrieval system or transmitted in any form, electronic, mechanical or photocopying, without prior written permission of the publishers. The publishers do not accept responsibility for views expressed, or statements made, or in those reproduced from any other source. No responsibility is borne by the publishers for any errors made in any advertisement, or for claims made by any advertiser which are incorrect. The publishers cannot be held responsible for any breach of copyright arising from any material supplied. This includes copy, design and/or images.

News Network

02

Find us on LinkedIn Copyright © 2023 All Rights Reserved. 01472 359036

PPMA

showcase the latest developments in the UK’s processing and packaging industry.

05 15 18 21 Specialist View

Processing

Resistant Components Hygiene & Safety 12 08 Packaging Anuga 2023 The Future of Retail Packaging looks like value Anuga 2023 places the focus on Sustainable Growth as its key theme. 32 20 30 Food Machinery Auctions X-Ray Inspection Warehousing & Storage Online auctions for the food and beverage industry. Loma Systems launch X% 4” pipeline X-Ray Inspection System. Instant buildings for better workflow VOLUME 23 • ISSUE 07 Produced in Europe’s Food Town 17. Walki Group’s next generation production line inaugerated in Valkeakoski 16. ’Finishing touches’ key in competitive poultry market. 31. Enhancing food and drink industry efficiency: Smart warehousing and Storage Solutions. 13. Eating with your eyes Corrosion Resistant Solutions from Cross & Morse. Proof of intelligenthygienic design? It’s all in the detail 07 PPMA Show 2023 SUBSCRIPTION: 12 issues - £84.00 (inc.postage) Robots get sacked! Rediscover the Syenergy between AI and Humans in manufacturing. 11 10 Global Connected Packaging Summit London Packaging Week Back by popular demand, 2023 Connected Packaging Summit - July 5th-6th London Packaging Week to dock at the home of world-leading events - ExCel London. Zeus acquires James Hamilton Group as part of 2023 growth strategy Growth & Expansion 14 22 Sustainability 24. How switching to laser coding can help with your sustainability KPIs. 27. Giving more to the world than you take. Sustainability still a priority for cash-strapped Brits when eating out. 28 Food Waste Bon appetit: How we all have a duty to eradicate food waste 29. Food retailers spending up to £50,000 a year sending food waste to landfill. furniture Helping your business exceed BRC Standards. Expert Partner in Hygienic Solutions 01603 788 833 mail@teknomek.co.uk teknomek.co.uk

Fulton introduces two new larger outputs to expand its VRST Range

Show set to

2056-8347

Food

Corrosion

Babcock Wanson Thermal Fluid Heaters Prove Robust, Reliable Solution for Malting Company

Industrial process heating equipment and solutions specialist Babcock Wanson has supplied a new TPC-B Thermal Fluid Heater to Crisp Malt to replace the existing Babcock Wanson heater that has been in operation for an incredible 30 years!

Crisp Malt, a British malting company dating back to 1870, supplies high quality English, Scottish and Organic malts to award-winning breweries and distilleries across the globe. Crisp Malt combines traditional and modern malting techniques at its sites in England and Scotland. An important part of the process is the drying of the malt. At its Fakenham site, a Babcock Wanson Thermal Fluid Heater has been performing this task for the past 30 years. Having well and truly served its purpose, a replacement was required and the company naturally returned to Babcock Wanson. A new TPC 6000B Thermal Fluid Heater was recommended, based on its reliability, high efficiency and large output.

The TPC 6000B is the largest Thermal Fluid Heater in the TPC-B range. These fully automatic coil type, multipass heaters come complete with

integrated burner, control system and safety devices. They provide optimal distribution of the heat, high fluid velocity in the exchange tubes and continuous flow monitoring to ensure long thermal fluid and system life and the highest level of safety.

The new TPC 6000B Thermal Fluid Heater installed at Crisp Malt offers several advantages over its elderly predecessor, including improved controls, Human Machine Interface and overall efficiency, plus a considerable reduction in emissions to comply with current regulations.

The TPC 6000B Thermal Fluid Heater was supplied by Babcock Wanson along with new pumps and valves.

Whilst the new heater was being produced, Crisp Malt took advantage of Babcock Wanson’s Thermal Fluid

Heating system rental service. Two ‘plug and play’

TPC 2000B Thermal Fluid Heaters were delivered to site and set up by Babcock Wanson’s experienced commissioning engineers to guarantee production.

Following the installation of the new heaters, a full service agreement has also been implemented.

Babcock Wanson offers a complete range of products and services for boiler houses and other process heating needs, from steam boilers, thermal fluid heaters, rapid steam generators and hot water boilers to VOC and odour treatment by thermal oxidation, water treatment or process air heating solutions. The company aims to help optimise

customer’s energy production with high quality products and efficient service.

For more information, please contact Babcock Wanson on 020 8953 7111 or info@babcockwanson.com or go to www. babcock-wanson.com

Simply Roasted launch new flavour this June - ‘Duck and Hoisin’

Simply Roasted, the award-winning ‘better for you’ crisps range, announces the launch of its new limited edition flavour, Duck & Hoisin. The NPD marks the first new product since the brand launched in 2021 and will be available throughout all Wasabi sites nationwide as well as Amazon from the 12th June.

Using entirely plant based ingredients, the new on trend flavour will be fragrant, sweet and rich in flavour, and available to enjoy in the on-thego format. The expansion has been developed in response to the growing demand from consumers who are actively seeking out better for you plant-based options in the snacking category, enabling Simply Roasted to focus on flavour first with taste at the forefront.

Sam Carter, product development at Wasabi says: “Simply Roasted Duck & Hoisin crisps are the perfect balance of umami, meaty notes from the Duck with a sweetened Asian twist you expect from an indulgent & fragrant Hoisin Sauce.”

Ruth Fittock, Marketing Director at Simply Roasted says: “At Simply Roasted we are all about creating the best possible tasting crisps, and this new flavour is an exciting edition to our range. We can’t wait for crisp fans to try this new limited edition flavour’

Always roasted and never friedmaking it the only roasted potato crisp on the market - Simply Roasted crisps are made by triple cooking a simple, whole slice of potato - offering all the flavour and more crunch than a traditional fried crisp but with 50 percent less fat, 25% less salt and under 99 calories (per serving).

The Duck & Hoisin flavours joins the

ALL NEWS IS GOOD NEWS!

If you would like to see your Newsworthy articles , regarding the Food & Drink Industry, published in the next issue of ‘Food & Drink Network UK’ email:

graphics@waltonspublications.com

Your release will also be placed on our website: foodanddrinknetwork-uk.co.uk

...and on our TWITTER Social Media Platform

existing 4 strong portfolio of flavours:

Sea Salt & Cider Vinegar: clean and crisp with a sharp tangy finish

Mature Cheddar & Red Onion: a rich full bodied vegan cheese balances red onion’s bite

Sea Salt: perfectly seasoned to let the potato do the talking

Black Truffle: rich deep umami indulgence

Simply Roasted Duck & Hoisin flavour will launch in Wasabi, Amazon.co.uk and Simplyroastedcrisps.co.uk from the 12th June. Impulse bags are priced

at £1.00 per pack and cases of 24 will be priced at £24.00 on the Simply Roasted website.

Find out more at:

www.simplyroastedcrisps.co.uk

www.instagram.com/ simplyroasted_

foodandrinknetwork-uk.co.uk 02 News Network To read any of these stories in full or to find many more Food & Drink Industry articles visit: foodanddrinknetwork-uk.co.uk/

Parma Ham Consortium Unveils Eco-friendly Packaging Goals

Research, carried out by the Consortium of Parma Ham, has identified alternative materials for pre-sliced packs

Prosciutto di Parma takes up the environmental challenge and carries out research to identify more sustainable alternatives to the traditional packaging of pre-sliced product.

Driven by consumption habits that have strengthened considerably during the pandemic period, sales of Parma Ham packs performed exceptionally well in recent years. Despite the fact that consumers’ purchasing choices have privileged the deli-counter after the limitations imposed by Covid-19, in 2022 more than 90 million packs were sold in Italy and in foreign countries including the UK, a figure well above that of 2019.

The great success of the presliced product in packs now poses a new challenge: reducing the environmental impact of packaging.

Research

With the aim of strengthening the environmental sustainability and circular economy of Parma Ham, the Consortium carried out in-depth research in collaboration with the Experimental Station for the Parma Food Conservation Industry (SSICA), to test alternative and more sustainable materials than those traditionally used for packaging pre-sliced ham.

In this context, shelf-life tests were carried out with packaging from several sources and with different recycling methods, such as paper, recyclable PET and compostable bioplastics.

The use of these materials stems from the desire to guarantee a supply of raw materials of renewable origin that are sustainable for the planet, and from the need to foster every possible form of reuse or recovery of waste after consumption. The selected materials were combined in different types of packaging and used for packaging trials in a protective atmosphere with Parma Hams from different producers and maturation periods, ranging from 16 to 20 months.

“At the end of the monitoring period, the packs underwent chemicalphysical, sensory and microbiological analyses with extremely significant results. We highlight the fact that packs consisting of paper tray and paper top (with or without transparent window), yielded even better preservation performance than traditional materials, also in terms of durability. Paper is therefore an excellent solution for the packaging of our pre-packed products, thanks to its recyclability, ease of reuse and origin from a renewable source, “comments Alessandro Utini.

Lakeland Dairies Launch Plant-Based Comelle Vegan Ice Cream Mix

With more than 70 years expertise in creating delicious, well-loved soft serve ice cream mix, Lakeland Dairies has drawn on their vast sector knowledge to launch a brand-new Vegan Ice Cream Mix, under their trusted Comelle brand.

Introducing Comelle Vegan Soft Serve Ice Cream Mix

Lakeland Dairies Comelle Vegan Ice Cream Mix, is a deliciously smooth 100% plant based ice cream mix which can also be used to create thick shakes. It’s vanilla flavour is a great balance of sweetness with a super smooth texture. A great solution for operators and consumer seeking a plant-based option.

Consumer Choice

Launched in Spring 2023 and available now through wholesalers, the Comelle Vegan Ice Cream Mix delivers greater choice for operators and consumers. Jean Cattanach, Marketing Controller Lakeland Dairies explains, “As experts with a long and renowned heritage in soft serve ice cream mix, we are extremely well placed to deliver ice cream products which not only taste great but also offer consumer choice. With the development of our new Comelle Vegan Ice Cream Mix we are supporting operators to offer a wide choice of high-quality soft serve ice cream options, which in turn helps them to meet

consumer demand and drive revenue.”

Comelle soft serve for every business

Comelle Vegan Ice Cream Mix joins the popular Comelle family of ice cream mixes. This includes the heritage Comelle Ice Cream which has been enjoyed since 1951 and a new Comelle Dairy Ice Cream, which has a luxurious creamy taste and replaces Lakeland Dairies SpringCool Ice Cream Mix.

Comelle Vegan Ice Cream Mix is available in 1 x 5L packs and is available now from Brakes from £20.39

But the other materials tested did not disappoint expectations either: the PET tray, with a shorter shelf-life than paper, is suitable for sale in transparent packaging, while the compostable bioplastic-based packages guarantee a shorter shelf-life, compatible with the ‘take away’ sales formula.

For more information, please visit www.prosciuttodiparma.com

Coperion Donates Food Extruder to Purdue University

Coperion donates a ZSK 27 Food Extruder in Hybrid Version to Purdue University based in West Lafayette, Indiana. The extruder will be used by the Department of Food Science — College of Agriculture and the Food Entrepreneurship and Manufacturing Institute (FEMI) at the university. The extruder is designed to the top of its class in both technology and innovation. This co-rotating twin screw extruder includes the latest in controls capabilities, customized configurations and process parameters to allow the study of emerging markets such as plantbased meat substitutes, hemp, the production of cereals, snack foods including puff snacks, pet food and the development of many new extruded processed food products. To complement the extruder, the donation includes two Coperion K-Tron loss-in-weight (LIW) feeders, for powders and liquids, designed with the latest generation of controls and load cells to ensure the highest accuracy of ingredient delivery to the extruder.

“This is a huge win for all, and Purdue is very excited about the partnership. The students and staff are ready to conduct research on the new stateof-the-art extruder with all the bells and whistles”, says Allison Kingery, Executive Director Life Science and Agriculture at Purdue University. “The new extruder replaces a working

25-year-old Coperion extruder, but we are looking forward to having a new, up-to-date extruder that includes new controls and new technology. This is a major donation for the students; they will be able to say they have utilized a modern, highly engineered extruder while in school and will be that much further ahead when graduating. The students will certainly benefit from utilizing a machine with such an exceptional reputation in the food industry.”

Kingery goes on to say, “Purdue and Coperion already has companies eager to sign up for the use of the extruder, from smaller start-up companies to large corporations. The setup at the university includes a full-scale kitchen next to the plant. The addition of the extruder to the test lab will not only open opportunities for the testing of products but also will allow the study of the final extruded product to be used in the kitchen and basically bring the product to life.”

For further information please visit www.coperion.com

News Network foodandrinknetwork-uk.co.uk 03 To read any of these stories in full or to find many more Food & Drink Industry articles visit: foodanddrinknetwork-uk.co.uk/

Out with the Old. In with the New. Modern Technology Gives Students a Leading Edge Come Graduation.

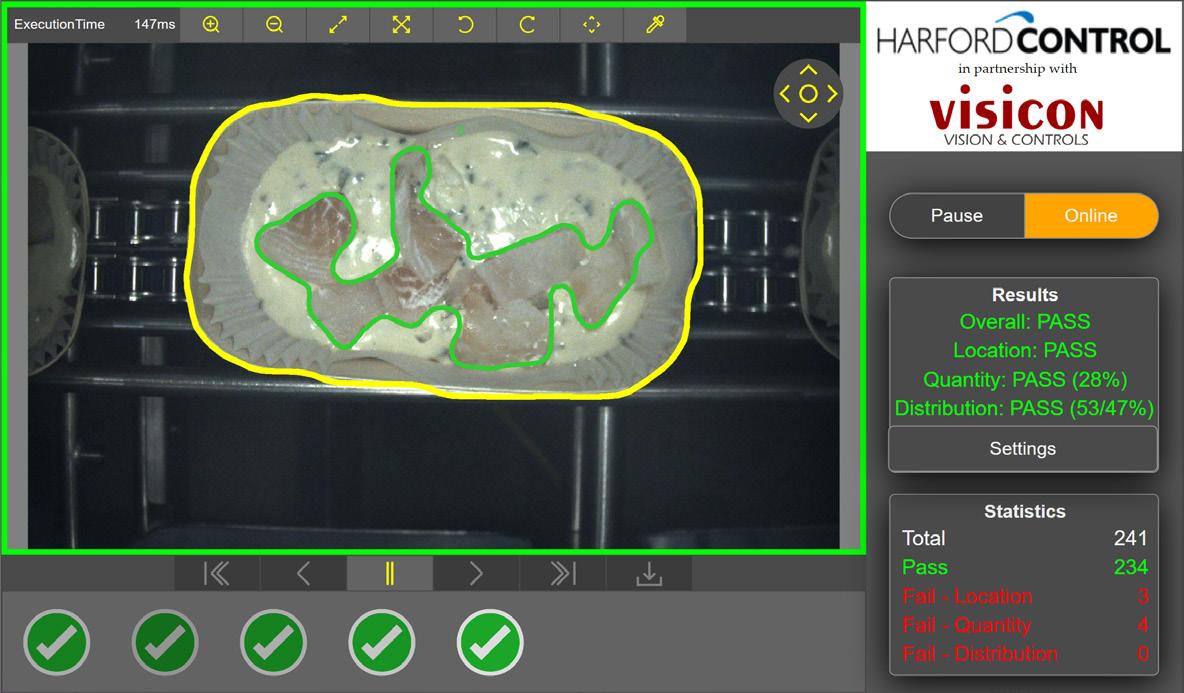

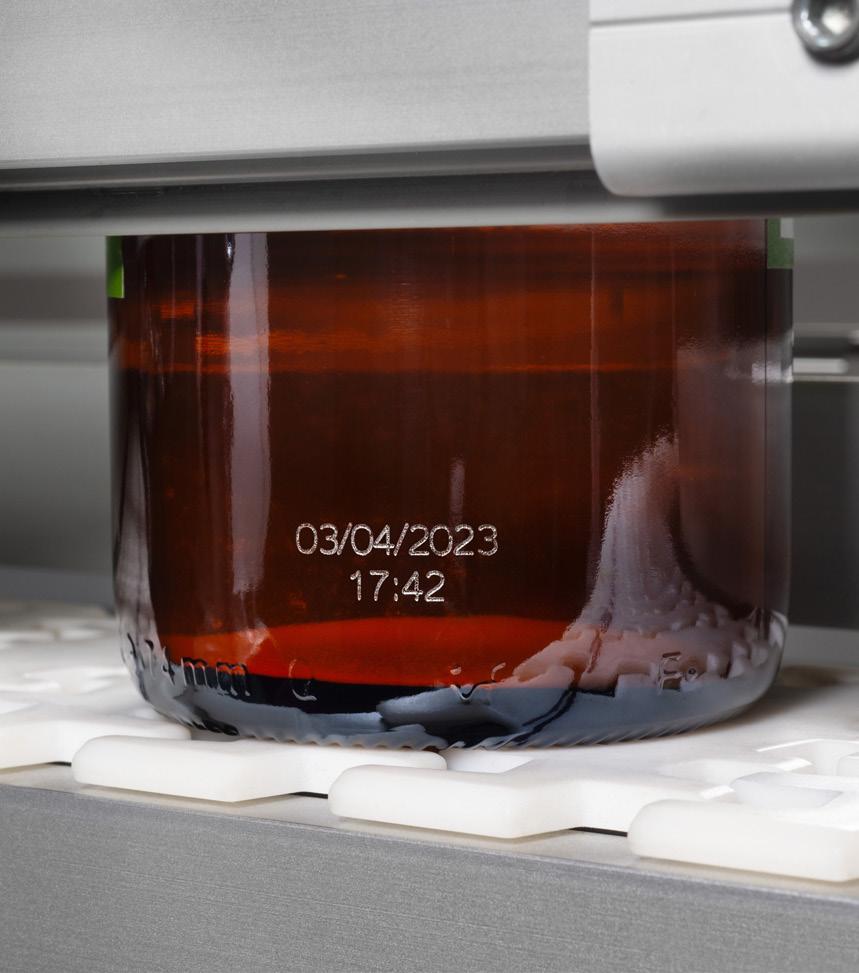

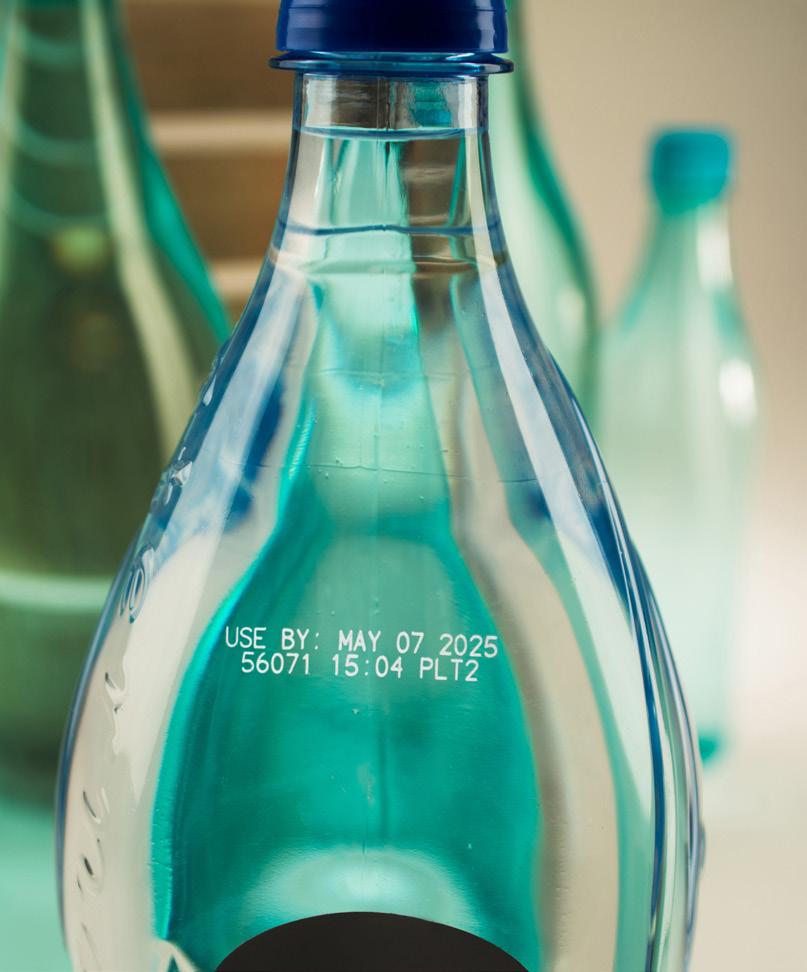

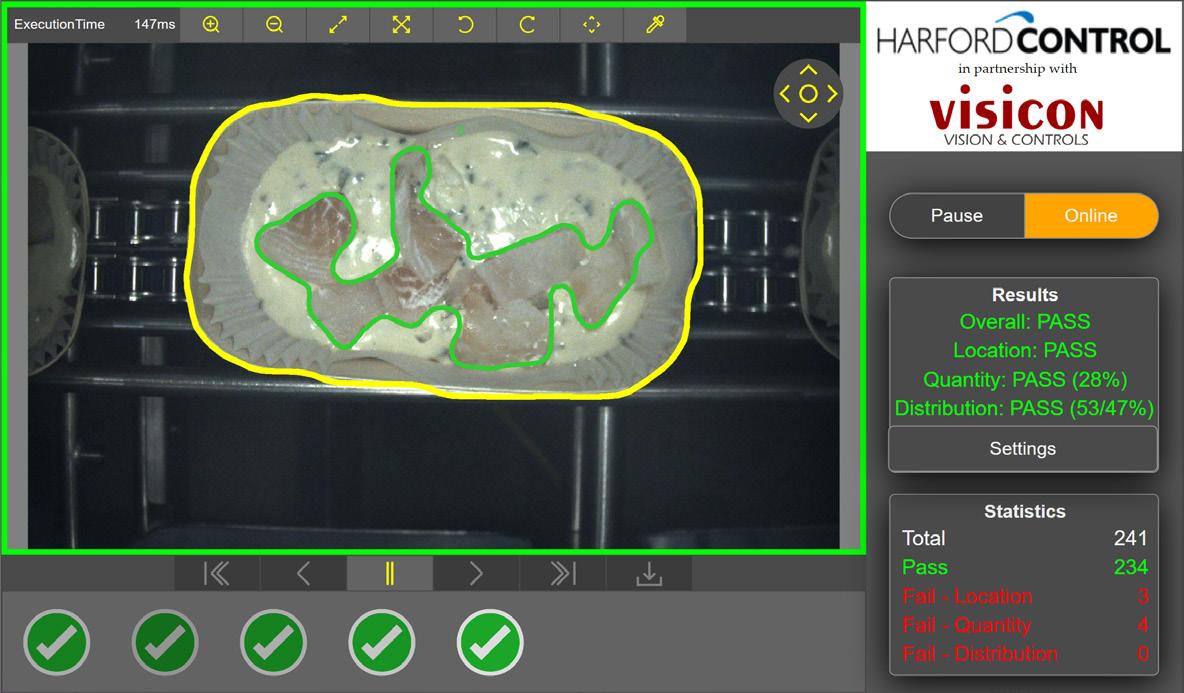

Ensure product quality and compliance with advanced machine vision solutions and deep learning software Learn more +44 (0)1225 764461 www.harfordcontrol.com Harford vision inspection solutions go far beyond accurate label verification, accurate recognition of printed text, and 2D code assessment. With automatic rejection systems, pattern matching and 100% inspection capabilities, our solutions ensure exceptional product quality through the additional use of SPC to prevent rejects. *See us on Stand B46 at PPMA 2023

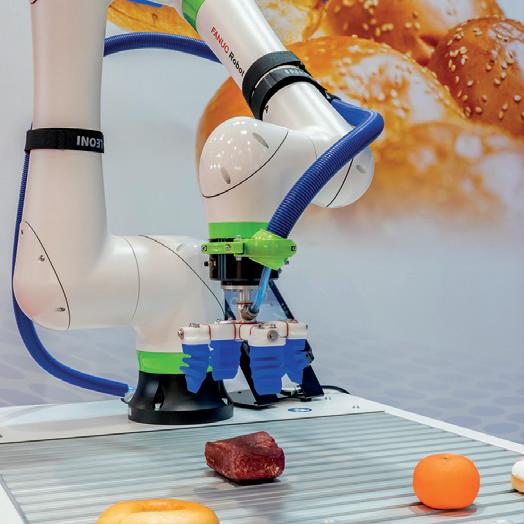

With the development of AI, the manufacturing industry is considered one of the most impacted industries across different sectors. In the manufacturing industry, a capital-intensive industry, AI-powered machines will eliminate malfunctioning machines and idle equipment, whilst generating consistently improving rates of return, culminating in 39 per cent profit growth by 2035 (Accenture Report).

While AI improves efficiency and production, it also raises worries about job displacement and ethical ramifications. As a result, seeking a balance between exploiting AI’s benefits and addressing humanitarian concerns is critical for a responsible and sustainable manufacturing future. In this article, we discuss some good practices of AI in the manufacturing industry and rediscover the synergy between AI and humans.

There have already been some innovative practices within the manufacturing industry. McKinsey predicts that by 2030, fully autonomous cars will be able to operate “anywhere, anytime” with Level 5 technology, without the need for drivers. As yet, none are available to the general public. Imagining a world where vehicles operate autonomously is truly fascinating, offering the potential to reduce accidents caused by fatigue or impaired driving. It paints a picture of an ideal future where safety and convenience go hand in hand.

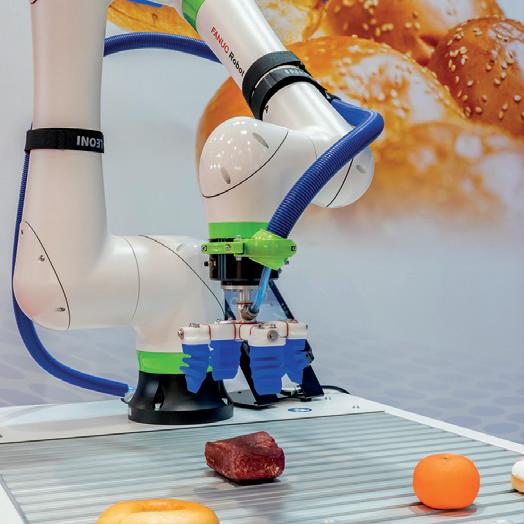

In addition to the exciting advancements in autonomous vehicle technology, there are other notable innovations taking place in the manufacturing industry. The University of Lincoln, in collaboration with industrial partners, has revolutionised fruit picking through the development of innovative robots that aid growers in vital tasks. I witnessed a demonstration of strawberry-picking robots in Lincoln last year. The robots picked the strawberries accurately and at a decent pace. We can see this remarkable technology has the potential to greatly enhance the efficiency and productivity of fruit harvesting processes.

Embarking on the exciting journey of AI development, Harford continuously improve our solutions to support manufacturers in their journey towards operational excellence. To that end, we’ve strengthened our partnership with Visicon to innovate our Vision Inspection Solutions. Using sophisticated cameras with ‘Deep Learning’ software, we have already helped manufacturers detect and quantify the ingredients in ready meals even when the ingredients have similar colours to the background.

With the rapid development and increasing impact of AI in factories, more and more people are concerned about technology. Will autonomous vehicles displace drivers? Will robots replace workers? Will machines take over human operators?

identify opportunities for continuous improvement. Only humans possess the ability to approach management teams to present innovative ideas and propose optimised processes and waste reduction ideas. Human’s invaluable contribution and creativity go beyond the capabilities of robots alone.

Having said that, the concerns about job displacement due to AI integration in manufacturing are still valid. Companies should invest in training programs to equip workers with the necessary digital skills and knowledge to collaborate effectively with AI systems.

It’s the spirit of a human-centric, smart technology approach to automation that can drive manufacturing performance to a new level. AI has great potential to transform the manufacturing industry, but it should not replace human workers. Through combining the creativity and capabilities of human workers with cutting-edge AI technologies, factories can continuously improve their efficiency and reduce wastage.

Despite the widespread adoption of AI and robots in the manufacturing industry, Toyota has taken a unique approach by reintroducing human workers to assembly lines and workstations that were previously automated. Mr Kawai, the Toyota VP, noticed some of the robots on the production line were underperforming. In the welding process of the Toyota Land Cruiser, Mr Kawai discovered that although the quality of the welded parts was satisfactory, there was room for improvement in terms of consistency.

Beyond addressing the under-performance of robots, factories that only implement robots can become stagnant in their development stage. While robots excel at executing repetitive tasks, they lack the creative thinking and discernment needed to

At Harford, we not only offer cutting-edge MIS/ MES systems to help factories eliminate risk, reduce wastage and improve performance, but also provide a consultative approach for manufacturers to give them practical advice on how to further reduce wastage and improve their efficiency. All our customers can receive 24/7 support and operator training after they integrate the Harford system.

The journey toward a tech-centric and humancentric manufacturing industry requires responsible MIS/MES technology and worker empowerment. By embracing collaboration between AI and humans, we can create a harmonious ecosystem where technology and humanity thrive together.

We are equipped with advanced technology and specialised expertise tailored for FMCG, Food & Beverage, Health & Beauty, Pharmaceutical and Chemical manufacturers. Share your problems with us and we can help improve your manufacturing performance.

foodandrinknetwork-uk.co.uk 05 Roy Green, Harford Control Ltd. July 2023

our

us at www.harfordcontrol.com/contact/ See us at PPMA23 on Stand B46

To find out more, call

team on 01225 764461 or contact

The Rise of AI in the Manufacturing Industry

Robots get Sacked: Humans Reclaim the Spotlight

Specialist View

The Synergy of Human-Centricity and AI

26-28 SEPT HALL 5 • NEC PPMASHOW.CO.UK

The PPMA Show returns to the NEC Birmingham this September, bigger and better than ever, with over 350 exhibitors showcasing more than 2,650 brands from the full spectrum of the industry.

PPMA Show set to showcase the latest developments in the UK’s processing and packaging industry

The PPMA Show is the UK’s largest processing and packaging machinery exhibition, established over 37 years ago. Each September, leading companies gather to display the latest in processing and packaging machinery, robotics and industrial vision systems, as well as the latest innovations in materials, containers and packaging design.

The show is organised by the PPMA Group of Associations, which comprises the Processing and Packaging Machinery Association (PPMA), British Automation and Robot Association (BARA) and UK Industrial Vision Association (UKIVA). These three specialist trade associations serve over 550 member and affiliate member companies.

The show, taking place in Hall 5 between September 26th to 28th, will be a fantastic representation of this fast-growing industry, featuring food, beverage, pharmaceuticals, household products and toiletries, building materials and supplies, pet care, microbrewery and distilleries, FMCG, as well as contract packers and more.

The exhibition is designed specifically for decision makers including CEOs, MDs, Directors, Managers, and other key staff members who play vital roles within their

companies, including engineers, production specialists, designers, buyers, processing specialists, and project managers. It will offer a chance to gain new insights and knowledge that could benefit their businesses.

The event delivers an exciting opportunity for existing processing and packaging machinery users to keep abreast of the latest cutting-edge products and services. For those new to the industry, the show provides an excellent platform to learn and explore what this dynamic industry has to offer.

There is the added benefit for visitors of being able to take advantage of fantastic networking opportunities, live demonstrations, source new ideas and solutions, and meet with potential new suppliers and technical experts.

Richard Little, the PPMA Show Director commented: “Between the 350+ companies exhibiting there are thousands of years of experience in packaging, processing and automation machinery. Visitors are encouraged to bring their problems and requirements to the show. There will be people in the show who know what to do and there will be plenty of machines to look at actually doing it.”

The best and brightest businesses of this

industry will be eager to demonstrate to visitors how they can improve their businesses with the latest and greatest technologies.

Some of the companies exhibiting include Advanced Conveyor Group (G42), BrilloPak (C62), Clearview Imaging (E24), Excel Packing Machinery (A86), IDEM SAFETY Switches (E60), Lafert Electric Motors (A13), Mil-Tek UK Recycling & Waste Solutions (J50), Premier Labellers (A94), and Westrock Packaging Machinery & Automation (D50).

With such an impressive array of exhibitors to choose from, visitors will have a tough time deciding which ones to visit.

They can take their time browsing through all the exhibitors on the PPMA Show website: www.ppmashow.co.uk/ exhibitors-2023#/exhibitors/

This is a rapidly growing industry with immense potential with exciting new products and technologies are being developed all the time; an industry that is constantly innovating and evolving.

No matter what your level of interest or expertise in the processing and packaging industry, the upcoming PPMA Show is sure to have something for you.

07 foodandrinknetwork-uk.co.uk PPMA Show 2023

Register your interest today to make sure you stay ahead of the game; attendance is free & for more details visit: www.ppmashow.co.uk/visit.

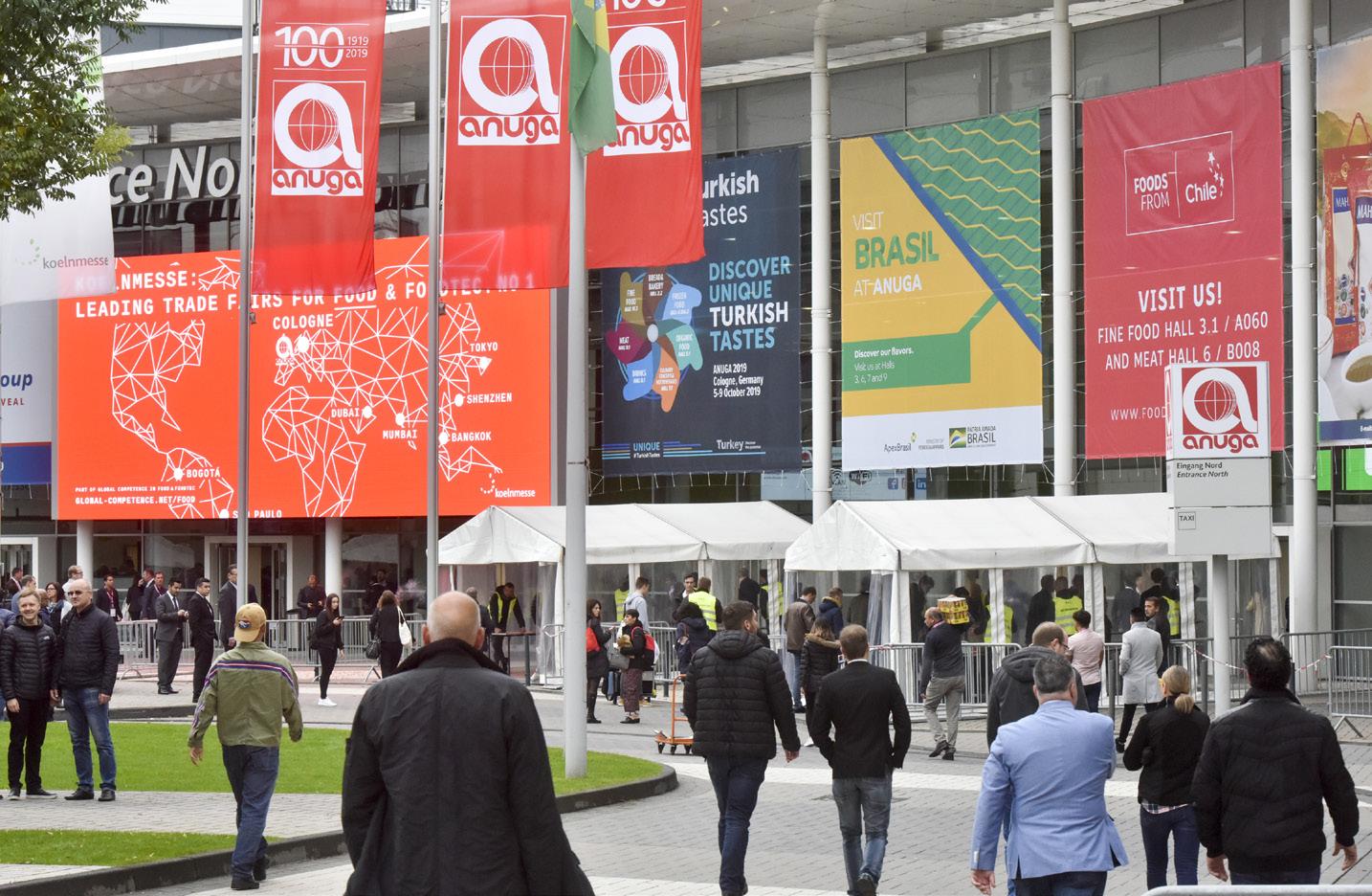

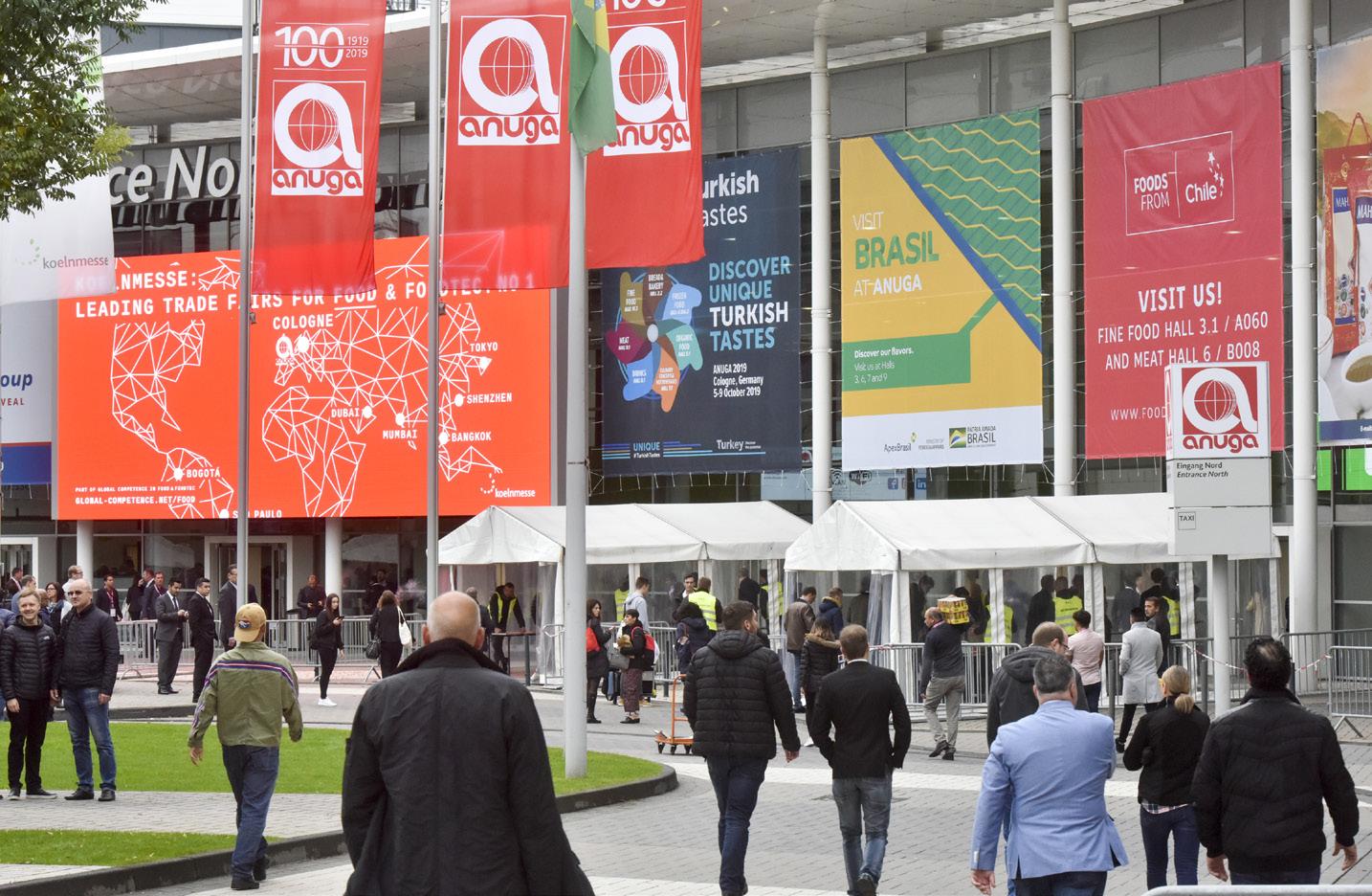

The Anuga experience can be described in a few key words: 10 trade fairs under one roof, the world’s largest business and inspiration platform for the food industry with the largest international industry community and at the same time an innovative marketplace and trend show for superlative food products.

Facts and figures

This year, Anuga will take place with over 150,000 expected trade visitors and more than 7,500 expected exhibitors. With currently around 165,000 m² (net) of booked space from more than 100 countries, Anuga is completely booked and thus confirms its No. 1 position among the world’s food trade fairs. The Anuga concept ensures clear thematic allocations: 10 trade fairs under one roof. Each of the individual trade fairs is unique and in some cases even a leader in its segment.

Leading theme Sustainable Growth

“Sustainable Growth” is the key theme of Anuga 2023. As an international trading platform and trendsetter, the leading global trade fair for food and beverages is thus placing one of the central themes of the industry on the agenda. The emphasis lies on different issues, such as for instance how the area of tension between economic growth and sustainability can be conciliated in the food section, which

facets sustainable growth offers and which solutions and approaches are globally possible. By addressing “Sustainable Growth” Anuga is also placing the focus on the commitment and the solutions of the industry with regards to environmental and climate-related aspects. These and other topics are not only covered in the 10 trade shows, they will particularly be discussed in the scope of Anuga’s event and congress programme.

The key challenge of the future will be to promote economic growth and sustainable

development while ensuring that the necessary natural resources continue to be available. At a time of disruptive change that is having a lasting impact on the global market, Anuga joins forces with exhibiting companies and leading institutions and experts at Anuga to offer the opportunity for an intensive exchange of ideas and solutions. Our aim is to provide a holistic and international overview of approaches for a sustainable food system.

The focus will be on different questions, such as how the conflicting priorities of economic

Anuga 2023 foodandrinknetwork-uk.co.uk 08

Anuga 2023 places the focus on Sustainable Growth as its key theme

growth and sustainability can be reconciled in the area of nutrition, which facets sustainable growth offers and which paths and approaches are possible globally. With “Sustainable Growth”, the trade fair is also focusing on the commitment and solutions of the industry, including environmental and climate aspects. These and other topics are not only reflected in the 10 trade fairs but are also discussed in particular as part of the Anuga event and congress programme.

New partners

In order to show new ways and solutions as well as opportunities for sustainable growth, Anuga has gained new strategic partners for our congress and event programme this year.

One of these is EIT Food, Europe’s leading initiative for food innovations. The aim is to foster the dialogue and interdisciplinary cooperation towards a sustainable food system in the spirit of Anuga’s main theme “Sustainable Growth”. For example, EIT Food

will offer a panel discussion on the topic of innovation and the role of start-ups and bring the industry together with relevant experts from business and science in a speed dating event. There will also be a Communication Breakfast for the press, where a best practice case will be presented.

For the first time, Anuga is also partnering with UNIDO, a United Nations organisation that focuses on promoting sustainable industrial development worldwide.

With UNIDO, the trade fair has gained a strong partner that is committed to sustainable industrial development worldwide. Contributing to a world without hunger is a top priority at UNIDO.

With a special focus on agribusiness and food systems, UNIDO aims to build the capacity of smallholder farmers and agro-processors to enhance agricultural production and promote rural economic development and structural change in the agricultural economy.

The topic of trends and innovation has always had an important place at Anuga. With the Boulevard of Innovation, the fair is creating a hub on the North Boulevard that specialises in precisely these topics. In addition, Anuga offers a programme of our new Anuga Horizon format, which is colocated with Anuga.

There will be a congress dealing with forward-looking topics such as sustainability, alternative products, new nutrition, ecosystem and Internet of Food. Investors, multipliers and stakeholders will also get their money’s worth at Anuga HORIZON.

Branded under the flag of Anuga Horizon, the leading trade fair for food and beverages will also be offering our trade fair guests the familiar Anuga event formats such as the Speakers Stage “Anuga Trend Zone” and the “Anuga taste Innovation Show” as central contact points for compact and clear trend information.

foodandrinknetwork-uk.co.uk 09

Visit us online: www.anuga.com Anuga on facebook: www.facebook.com/anugacologne Anuga on Instagram: www.instagram.com/anugacologne/ Anuga on LinkedIn: www.linkedin.com/company/anugashowcase/?viewAsMember=true

As the world’s leading trade fair for food and beverages, Anuga is bringing the largest international industry community together and generating a positive spirit of optimism.

What else can be expected at Anuga

London Packaging Week to dock at the home of worldleading events – ExCeL London

• Discover the latest industry insights and trends at ExCeL London on 21 & 22 September 2023

• As one of the world’s most connected venues, getting to ExCeL couldn’t be easier

• Event organisers are already fielding huge demand from potential exhibitors and visitors

• PROPER snacks founder Cassandra Stavrou, Liz Earle MBE and Candy Kittens co-founder Jamie Laing confirmed as the first speakers

• Secure your place today!

London Packaging Week will again assume its rightful place at the epicentre of the packaging industry later this summer, but in a brand-new home - the world-famous ExCeL Centre in London.

London’s premier international convention and events venue, situated on the historic Royal Victoria Dock’s northern quay, will host four co-located events – Packaging Premiére, PCD, PLD, and Food & Consumer Pack – held on 21 & 22 September.

Event organiser, Easyfairs, is delighted to secure such an iconic venue. The docks continue to draw people and produce from all over the world some 167 years after their opening.

As one of the world’s most connected venues, the ExCeL offers more space, extra parking, and improved transport links. With more convenient hotels, London Packaging Week promises an enhanced visitor experience for the thousands of anticipated visitors.

“We’re already fielding an increased number of enquiries from people wanting to find out what

opportunities might lie within this showpiece event for their business,” said Renan Joel, Managing Director, Packaging at Easyfairs.

“There’s a reason London Packaging Week remains the beating heart of a global network of brands, innovators, designers and creators –its credentials in breaking down what the next 12 months and beyond have in store for the world of package design, branding, and material innovation, are second to none.”

PROPER snacks healthy foods founder Cassandra Stavrou, wellbeing guru Liz Earle MBE, and Candy Kittens confectionary cofounder Jamie Laing have also been revealed as the first confirmed headline speakers, with more very exciting names set to be confirmed soon. The full content programme is set to be released in early June.

The four shows combine to capture the inspiring free-spiritedness of the art and fashion worlds and blend them with the cutting-edge science and technology of packaging to create a unique showcase.

Packaging Premiére is focused on the future

of luxury packaging. It matches visitors from the ExCeL Design – combines the world’s most cutting-edge cosmetics packaging solutions under one roof. Meanwhile, PLD focuses on Premium and Luxury Drinks packaging, connecting designers, specifiers, and buyers across the premium beverage industry. Completing the event is Food & Consumer Pack, which highlights the latest innovations in the food and FMCG sector and attracts global brands and manufacturers.

“Exhibitor slots have begun to fill up rapidly, with some of the biggest names in the food, BPC, premium, and luxury packaging industries already on board,” added Joel.

“LPW is renowned as one of the premier exhibitions for sustainable and stylish packaging solutions worldwide. Top luxury brands will once again walk the floor of the ExCeL on the lookout for sophisticated packaging that prioritises their environmental commitments while adhering to aesthetic expectations.”

Over 5,000 expected visitors will have access to over a hundred of the best packaging suppliers and innovative solutions in design, sustainability, branding, e-commerce and more!

Registrations for attendees will open shortly. To register interest in visiting, or to enquire about exhibiting at the show, visit www.londonpackagingweek.com today.

foodandrinknetwork-uk.co.uk London Packaging Week

Renan Joel, Managing Director, Packaging at Easyfairs

Back

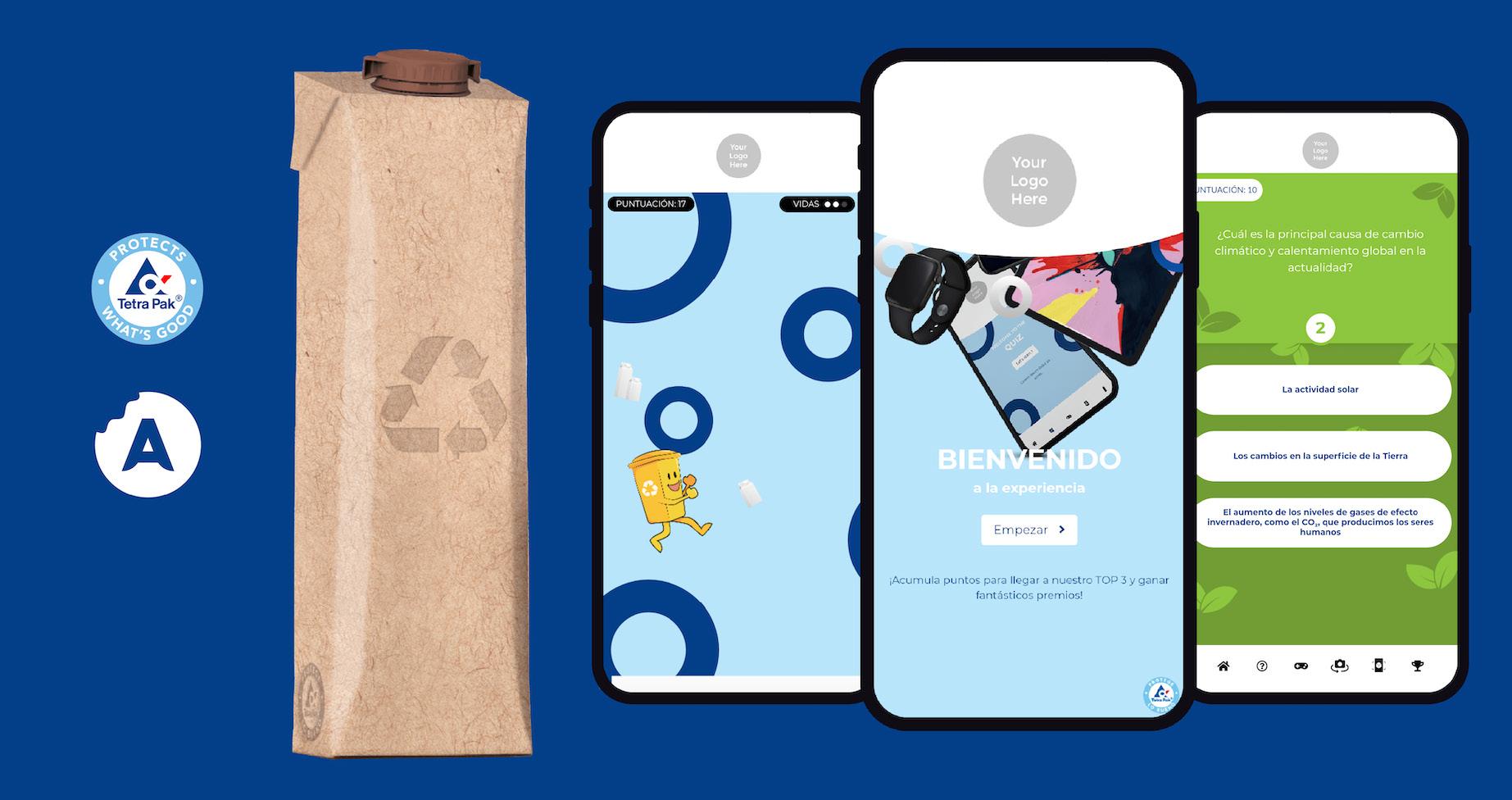

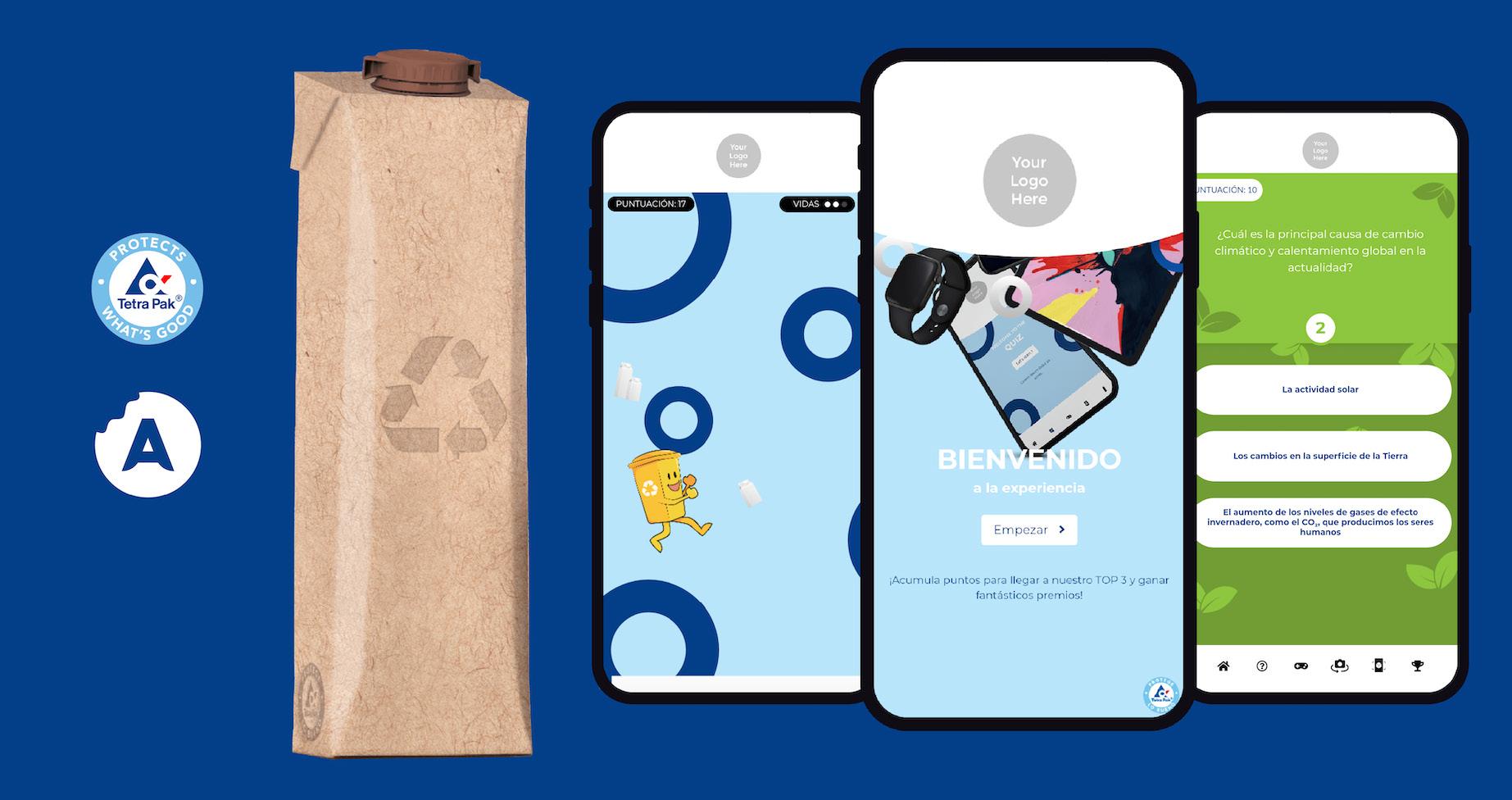

is proud to present the third annual virtual Global Connected Packaging Summit on Wednesday 5th and Thursday 6th July 2023, featuring Technology, Innovation, Packaging and Sustainability experts sharing insights, advice, and topical discussion.

The two-day conference will bring together industry leaders, experts, and innovators to explore the transformative potential of connected packaging in creating seamless connections across both digital and physical spaces.

The Global Connected Packaging Summit will feature thought-provoking discussions and presentations by leaders from renowned organisations including Tetra Pak, Kellogg, Amazon, AB InBev, SIG, The Pack Hub, Seaman Paper, Plastic Bank, Takeda Pharmaceuticals, and more. These experts will explore the integration of cutting-edge technologies including QR codes, NFC, AR, AI, ad technology, packaging, and marketing. The summit will place a strong emphasis on innovation and sustainability, highlighting how these advancements can deliver stunning results for the industry’s most prominent players.

This year’s event will once again be hosted

by Jenny Stanley, Managing Director at Creative technology studio Appetite Creative. As technology continues to shape our behaviours, emotions and daily experiences, Jenny will help attendees explore the value connected packaging can deliver across meaningful, unique and personalised customer engagement.

According to the research from Appetite Creative’s second annual connected packaging survey released earlier this year, connected packaging has experienced a rise in popularity in the last 12 months, with over four-fifths (81%) of those surveyed stating they have used connected packaging, compared to just over half (54%) in 2022.

“Despite the cost-of-living crisis and global economic uncertainty, investment in connected packaging experiences continues to rise,” said Jenny Stanley, Managing Director at Appetite Creative. “No longer only a data collection tool, connected packaging is now a long-term

customer relations and educational media channel, which helps companies navigate ever-changing sustainability requirements and inform product development and marketing decisions. Moving from a tipping point into mainstream usage this year, the perceived value of connected packaging has shifted to a business ‘must-have’.”

By bringing together the offline and digital landscapes, the conference aims to highlight how businesses can adopt connected packaging to create engaging customer experiences, gather valuable first-party data, and drive increased sales. Attendees will gain insights into the evolving landscape and discover new strategies to enhance their brand’s competitiveness in an increasingly digital world.

Tickets are free.

For more information and to register visit: connectedpackagingsummit.com

11 foodandrinknetwork-uk.co.uk

Global Connected Packaging Summit

by popular demand, creative technology studio Appetite Creative

The Future of Retail Packaging looks like value

Tessa Stuart has carved her own path when it comes to understanding the importance of packaging’s role in shopper purchasing behaviour. Shifting her focus to shopper market research conducted at the point of purchase rather than collecting data from “our better selves that are often projected in focus groups”, Tessa believes her method provides invaluable real-life consumer opinions. With a background of working with brands like Innocent Drinks, Unilever, Kellogg’s, Oatly, Rude Health, and Nestle, to name but a few, London Packaging Week was delighted to have the chance to talk to Tessa and learn from her valuable insights into consumer behaviour and the impact of packaging on purchasing decisions. In this interview, we delve into Tessa’s experiences and explore the trends she observes for the future of retail packaging.

Explaining that her journey into shopper market research was motivated by a desire for more flexibility and relevance, she said: “At the time, Innocent Drinks was bursting onto the scene, and I was determined to work with them. I stalked them for two years until I got my first brief. I tried a new approach: shopper market research, interviewing in-store at the point of purchase as people buy the product.

“They (Innocent Drinks) used this approach to test a new concept.” The brief involved testing new packaging concepts directly in-store, focusing on consumer reactions and preferences. One experiment involved placing packaging mock-ups alongside an existing Innocent product, with and without a window.

She added: “We found that shoppers were more interested in gravitating towards the pack where they could see through a vertical window; they could see the different layers of the product. But we were also looking to see if they noticed various crucial instructions which would give away the nature of the products.

“We found that they missed a lot of the cooking cues, which was why they picked it up and shook it. I did 40 shopper intercepts at the point where the shopper had touched the product independently; I wasn’t intervening in the process. I waited until the packaging had done its job and brought them to the shelf then, I intercepted them.”

Over time, Tessa’s work has expanded to include packaging design, particularly in the context of

An Interview with Tessa Stuart, shopper stalker, author and market research expert

environmentally responsible alternatives.

“A lot of what I do is the external packaging design,” explained Stuart. “But increasingly, I’m called upon when companies are looking to switch to a more sustainable packaging format, and so I look at that with consumers. Over the last three years, I would say companies are increasingly focused on environmental concerns, recycling issues, and more companies are wanting to become B Corp.

“One of the quick ways brands and manufacturers can improve sustainability is to come out of plastic and go into glass. There are also many considerations for companies wanting to cut packaging costs. They may look at taking out inner packaging and researching how consumers might react to that in the context of a premium product where you might expect a degree of unboxing.”

The discussion then turned to the role of packaging in the current economic landscape, characterised by rising inflation and the cost of living. Tessa emphasised the importance of price per unit measurement, with consumers closely scrutinising the value proposition of products.

“Shoppers are increasingly looking at price per volume of the products they’re getting,” she added. “In many categories, especially where shoppers are trying to balance their budget, they will look at multi-buys and determine from the information if the multi-buy is better value than buying a larger pack size.” Further demonstrating the vital role packaging plays in communicating value and volume.”

When asked whether shoppers’ interest in packaging has increased to an all-time high, given the many factors they now must consider when reaching for products on the shelf, Tessa said: “People are incredibly aware of shrinkflation, number one—and number two, the fact that food and drink prices seem to keep on rising. People look at products like butter and say, ‘I can’t believe butter is this price!’.

“I’ve worked in categories recently where the two main leaders have increased their prices, and the category growth has stalled because shoppers will not pay the full price. They might pay a promotional price. So, then they are driven to look at the promotions in the category and will now consider a wider range of brands to get the money off.

“Tesco Club Card has also been very influential. While Aldi and Lidl are increasingly growing in market share, consumers often return to the big four for things like

toiletries and beauty. Tesco Club Card prices are a leading price mechanism, causing other retailers to pull up their price mechanisms, like Sainsbury’s Nectar Prices. Because you have this price message being reinforced by all the retailers at all times, consumers are conditioned to look at volume for the price. Packaging can help accentuate that value message or detract from it in terms of what you’re getting.”

Further, on sustainability, Tessa expressed her opinion that there appears to be a disconnect between consumers’ professed willingness to pay more for sustainable packaging and their actions in the shopping aisle.

“When asked, ‘Would you pay more for sustainable packaging?’ Some people said that they would,” she explained. “But you know, I doubt it. I think people expect companies to do it, but they don’t want to pay for it. However, I did some work with Little Dish as they were transitioning from expensive bespoke moulded plastic pots into recycled plastic trays, which they felt was better. With recycled plastic comes a huge variability in colour. It can be brown, grey, or a khaki colour. So, for a brand where the colour of the tray is not consistent, it was a valid question to ask, ‘Would consumers mind that?’

“I tested this with consumers and showed them different shades and how it looks. The mums who buy Little Dish for their kids were relieved to be able to buy something that didn’t further contribute to more plastic waste. When I returned, my client was slightly surprised when I said they’re 100% for it!”

Tessa concluded, “It isn’t only that people want it to be sustainable, though. When I’ve worked in sectors such as craft chocolate, consumers also want the packaging to look good, especially for gifting. We are still attracted by gold foil and craft cardboard and paper- those materials where you can feel the difference and the quality. I think that has remained consistent the whole time I’ve worked in food branding.”

In the ever-evolving world of retail supermarket packaging, Tessa’s insights shed light on the importance of clear messaging, value perception, and environmental considerations. As brands seek to adapt and meet consumer demands, Tessa’s expertise and research continue to contribute to the future of packaging design in retail.

Packaging foodandrinknetwork-uk.co.uk 12

Being a little smaller than a ping pong ball, with an average diameter of 24mm and a weight of about eight grams, each of your eyes is a perfect example of how good things come in small packages.

Packaging design surrounds us wherever we are. Creating an eye-catching packaging design that suits the product, stands out on crowded shelves, and doesn’t cost a fortune to produce is a real challenge.

A good packaging design is one of the most compelling factors in a business’s growth. Attractive packaging designs that trigger the right emotions in the minds of your customers are the key to effectively motivating your consumer’s purchasing decisions. It sets the wheels in motion. But all of this is contingent on the same eye–hand coordination that is fundamental to learning how the brain produces internal models of the activity space and induces movement within it. It is at the heart of our everyday acts and experiences with objects and people around us. And it is at the heart of what we choose to purchase.

Mass marketing, or the casting of a proverbial net far and wide, still has tremendous appeal to advertisers, big and small. The appeal of millions of eyeballs appears timeless, even if brands have no idea who they belong to.

Humans are visual learners. Although most people have five working senses, they aren’t used equally; with a third of the human brain’s cortex dedicated exclusively to vision, these visual elements automatically have a heavier influence on your perceptions.

It’s quite fascinating, but what does it have to do with retailing and marketing? The answer, quite simply, is everything. The saying “We eat with our eyes first” can easily be said another way: We consume with our eyes first. What we consume, as potential purchasers of a product, is information.

Eye level is buy level

Developing packaging can be an expensive process. But when you consider the thousands of products on store shelves and that eye-catching packaging design is the only on-the-spot tool that you have to encourage sales, it is money well spent.

Most shoppers aim to spend as little as possible, while the main objective of supermarkets is to encourage us to spend as much money as possible. But what makes certain pack designs catch the eye while consumers pass other products by?

Eating with your eyes

Packaging, one of the last vehicles for brand messaging consumers see before purchasing, is critical in motivating shopper behaviour. Seeing your packaging through the eyes of consumers is an important exercise toward designing a functional, attractive, and effective design that drives sales and influences shopper behaviour.

When you are so familiar with your packaging design and haven’t considered it from the perspective of a new customer in a while, it may be difficult to identify what stands out. That’s where it pays to involve those immersed in the packaging design world. London’s vibrant home for packaging innovation and design will walk you through that immersive process, where the right materials and shapes are matched to the desired sensory cues that trigger a positive response in the consumer’s mind. From material research to manufacturing and finishing processes, the twoday, four-sector showpiece events are designed to help luxury brand owners leverage the potential that materials have to fine-tune the perceived value of the packaging design and, therefore, the brand.

The first bite is with the eyes

Colour can be extremely effective at grabbing our focus. Certain colour wavelengths have been shown to attract human attention. Shape, too, has the potential to be the single most unique identifier for your product packaging.

Your pack design should clearly and effectively show the product contained within. If a consumer looks at your packaging and cannot identify what you’re selling, they are likely to walk on by. And that goes for an honest depiction of what you’re selling too!

In a perfect world, everyone who sees your packaging would be motivated to pick it up and take it home. For that reason, you must take touch or haptics into account when planning your design. The aim is to create positive tactile experiences for consumers, layering features into your brand packaging to remove barriers to sale.

Your brand messaging should be streamlined so customers can scan the pack and immediately understand the key takeaway of your product. And don’t overlook the importance of font choice in your design – it is key to delivering your literal message and should align with your overall aesthetic.

Packaging helps customers form a clear connection with your brand. It enables them to envision how using your product will impact their lives. And for brand owners, packaging design must interrupt consumers on autopilot.

If this is overdone, you risk overloading the consumer.

When there’s too much going on, whether in the design or the copy, consumers won’t know where to look, and they’ll switch off. This can also apply to the fonts used; simplicity is key.

Crave appeal

Does this product look good to me as a potential buyer? Is how it is packaged, presented, and displayed attractive to me as a potential buyer? These are the questions we process when we see a product for sale.

The Roman gourmet Apicius famously stated two thousand years ago, “We eat first with our eyes.” He was one of the first people to realise that the appeal of a dish is not just a matter of what goes into our mouths. Much of our experience is set by our expectations.

Visual stimuli can come in shapes, sizes, colours, and designs. While no one can know what specific style and design will appeal to every person on the planet, we do know the general outline of what will make a good visual.

In what ways is your product packaging visually distinct from your competitors? Outside of your logo, do your customers associate you with a specific visual feature, such as a colour?

Our job as brands and producers is to drive that desire to satisfy. To create a literal hunger and trigger a primordial desire for the product. To do this, creating something visually distinct that elevates the senses and taps into visual appetite appeal is the way to go.

While there is no doubt that we have a captive audience, we don’t have long to land our message. A huge part of that is conjuring a unique sensorial consumption moment – allowing people to taste a product without even taking a bite. Think KFC and ‘Finger-lickin’ chicken, the distinctive sound of a chocolate-cracking bite of a magnum, Lurpak butter sizzling in a hot pan.

The appeal of a pack has the potential to trigger impulsive buying even for consumers with no intention to make a purchase. Your packaging design should speak loudly and clearly for your product.

In the ever-evolving world of retail supermarket packaging, juggling demands such as the importance of clear messaging, value perception, and environmental considerations should be undertaken alongside creating something that is a feast for the eyes from the get-go. And what better way to do that than hearing about the hard and fasting learnings from people who’ve done it at London Packaging Week?

Packaging foodandrinknetwork-uk.co.uk 13

With vision declared as a VIP amongst the senses, Parisa Maleki explains why you won’t go far wrong with packaging that creates a visual appetite

Zeus acquires James Hamilton Group as part of 2023 growth strategy

With annual sales of €18 million and a dedicated team of over 120 employees, James Hamilton Group is a provider of comprehensive packaging, label production, office supplies, and personal protective equipment solutions across multiple sectors including retail, food & beverage production, logistics and distribution. This acquisition forms the next part of Zeus Group’s 2023 growth strategy that is expected to see group revenues surpass €500 million.

Keith Ockenden, CEO of Zeus Group, said: “We are tremendously excited about the prospects of this acquisition of one of Northern Ireland’s oldest packaging businesses. By harnessing the synergies between Zeus and James Hamilton Group across the island of Ireland, we can offer a more comprehensive range of solutions and manufacturing capabilities. Our commitment is to deliver exceptional value to our customers while driving innovation and sustainable practices.”

By joining forces with James Hamilton Group, Zeus will expand its current offering in the food and retail packaging sector, leveraging the combined purchasing power and unlocking operational efficiencies across our combined operations in Northern Ireland. With an unwavering focus on customer satisfaction, the collaboration between the two companies will result in an enhanced service, product quality, and manufacturing capabilities, ensuring effective fulfilment of customers’ unique requirements.”

The acquisition of James Hamilton Group expands the product portfolio and service capabilities while bringing local manufacturing expertise in printed packaging.

With its proficiency in retail food packaging, food sleeves and cartons, and state-of-theart label production, James Hamilton Group significantly increases Zeus Group’s ability to cater to the needs of customers in the food, beverage, and retail industries.

Keith Hamilton, Managing Director of James Hamilton Group commented: “We have enjoyed watching our business expand and evolve during its 100 year history, we are delighted to have finalised an agreement with Brian and his team. It was important that we found a partner who shared the same ‘family’ values as ourselves, a business who will further invest, look after our staff and importantly, bring a more enhanced offering to our loyal customers.”

James Hamilton Group will continue to operate under its well-established brand, leveraging its existing manufacturing expertise and management team. Zeus is dedicated to fostering a seamless integration, maintaining business continuity, and nurturing the strong customer relationships that James Hamilton Group has cultivated over the years.

For further information visit www.zeuspackaging.com and jameshamiltongroup.com

Growth & Expansion foodandrinknetwork-uk.co.uk 14

Zeus Group, the Irish-owned global packaging solutions business, has announced the acquisition of James Hamilton Group, a leading Northern Irish print and packaging business.

FULTON INTRODUCES TWO NEW LARGER OUTPUTS TO EXPAND ITS VSRT RANGE

Claimed to be the most radical change to vertical steam boiler design since it first pioneered the vertical tubeless boiler in 1949, Fulton’s VSRT has rocked the steam boiler market since its launch in 2018 to become class-leading and a symbol of efficiency, with many users benefitting from generous savings in gas and water consumption in addition to CO2 and NOX emissions.

At launch, the seven-model VSRT range was available with outputs from 160 to 960 kg/h, but with demand increasing for an energy efficient boiler with larger outputs like those of horizontal reverse-flame steam boilers, Fulton is now expanding the range and introducing two new re-designed VSRT models with outputs of 1565 and 1956 kg/h.

Commenting for Fulton, managing director Carl Knight says: “These new models are ground-breaking for their output range! When you consider the VSRT-100 and VSRT125 models, there are no truly-efficient tubeless vertical steam boilers in the marketplace with similar output ranges, the VSRT is the only tubeless boiler available with the capability of efficiently producing nearly two tonnes per hour of steam.

“In short, what we are delivering with these new models is much higher output versions without compromising efficiency!”

These new, larger-output VSRT models maintain exceptionally high operating efficiencies (up to 86% gross thermal efficiency compared to approximately 80% from typical boiler designs), which results in lower operating and lifecycle costs and improved return on investment. The latest models also continue to achieve ultra-low NOx emissions of less than 20ppm and 10:1 turndown capability.

The water volume of these latest VSRT models is far greater than equivalent horizontal shell and tube boilers and steam generators, combined with an impressive steam chest volume giving it the ability to react quickly to changes in steam demand. The VSRT still boasts a start-up time of approximately 20 minutes and achieves a 99.75% steam quality, a detail most manufacturers are unwilling to publish.

Like the existing models in the range, the two new models come with the assurance

HELPING YOUR FACILITY ON THE ROAD TO NET ZERO

Our class-leading range of fuel-fired and electric steam boilers and portfolio of aftercare solutions can help with your decarbonisation strategy and put your company on the Road to Net Zero.

As a complete solutions provider, Fulton can provide your food processing facility with:

· fuel-fired and electric steam boilers

· off-grid and point-of-use solutions

· ancillary plant / engineered systems

· steam surveys

· project management

· water treatment contracts

· accredited / certified training

· installation / commissioning / upgrades

· repair / service / maintenance programmes

of a 10-year “unparalleled” warranty on the pressure vessel, double that of the industry standard. Additionally, like all Fulton VSRT and electric boilers, they contain no refractory and have no requirement for five-yearly, non-destructive testing, which contributes to reduced lifecycle costs when compared to standard shell and tube boilers.

These advanced, energy-saving and environmentally-beneficial features are standard across the now expanded VSRT range. Compared to equivalent vertical tubeless steam boilers, the VSRT is a more durable, and in many cases, compact boiler that is energy-efficient, produces an increased volume of higher quality steam, is easy to maintain and backed by an unparalleled warranty. Additionally, the VSRT complies with the City of London Air Quality Strategy and MCPD regulations, is constructed to BS EN 12953 and UKCA/CE marked to PED.

For further information scan the QR code, visit www.fulton.co.uk, email sales@fulton.co.uk or call the office on +44 (0)117 972 3322.

Food Processing

FBW253 - Net Zero Advertisement - FDN.indd 1 14/06/2023 11:22

15 foodandrinknetwork-uk.co.uk

‘Finishing touches’ key in competitive poultry market

Poultry continues to be one of the most important sectors in the meat industry with over half of the meat consumed in the UK being chicken, turkey, goose and duck. According to the British Poultry Council people in the UK eat, on average, 35kg of poultry meat annually.

It is therefore not surprising that a wide range of equipment is used in the processing of poultry, particularly given the versatility of chicken which remains a staple on the British dinner table. We eat an average of over 400 chicken dinners yearly and, when you consider the multitude of dishes which feature chicken as a main component, the contribution that this meat makes to the economy is considerable –some £4.2bn of sales annually.

The poultry market is naturally therefore a competitive one and making a product stand out on the supermarket shelf is a key contributor to achieving sales. We all know that with meat the appearance is an important part of the purchasing process. When cooking poultry at home, achieving the grill marks is the goal of many a wannabe chef. On a commercial scale, achieving this look is therefore a key focus for a wide range of products, drawing in the customer by improving the product appearance and also encouraging repeat purchases by enhancing the flavour profile.

Interfood has extensive experience in this market, working with Marlen, a company that specialises in the manufacture of innovative flame-grilling, roasting and bar-marking solutions for the food processing industry. One of the most popular options is the Afoheat Select Flame Searer, a continuous grill equipped with gas-powered direct flame technology to add finishing touches to pre-cooked poultry products. Machines can be custom-built to a customer’s specific requirements and it is therefore the ideal option for bespoke applications, whether it’s bulk or convenience foods.

Steve Naylor is Manager of Interfood’s Cooking & Cooling/Pasteurisation Division and comments - “A current focus for food processors with the uncertainties surrounding soaring energy prices is the running costs of equipment. The Afoheat flame searer has been designed to offer premium quality roasting and searing capabilities but with low energy consumption through the pre-mix burner control. It is also characterised by its short grilling times, with adjustable burner power (flame length and intensity) and adjustable convectional heat. Chilling of the products post-roasting can also be reduced as the core temperature during the process has a minimal increase compared to traditional batch roasting systems. It can accommodate raw, cooked, chilled or frozen product and can operate as a stand-alone solution or installed in a line with other cooking equipment.”

Interfood also offers a range of systems for cooking processes prior to flame searing, including the Alco Flattener ASP, the Alco Spiral Cooker and Maurer Atmos Batch cookers.

Naylor continues – “A significant proportion of our customers are involved in the production of poultry-based products. The cooking element of their processing operations is a vitally important factor in adding value so we work closely to ensure that the equipment supplied meets the

specific needs of every given application.”

The popularity of poultry, particularly chicken, continues to endure. The perception of it being a healthier alternative to some meats is undoubtedly a contributary factor, as is the trend for consumers to eat more high-protein foods.

This has led to a proliferation of new and often innovative poultry-based products, creating a competitive market where standing out from the crowd is increasingly important. It is an old adage but true nonetheless that ‘we eat with our eyes’. As such, ways of creating visual appeal which attracts customers’ attention when faced with such a wide range of options can be a significant contributor to a successful product. Technologies for grilling, roasting, searing and grill marking will continue to play an important role in this process.

For further information contact Interfood Technology E: info@interfoodtechnology.com or visit the Website: www.interfoodtechnology.com

Food Processing foodandrinknetwork-uk.co.uk 16

Walki Group’s next generation production line inaugurated in Valkeakoski

The next generation production line in Walki’s Valkeakoski plant was officially inaugurated today with a festive ceremony that brought together customers and other stakeholders from various parts of the world.

The 13 MEUR investment – one of the most significant in Walki’s history –is an important step forward in the company’s strategy to transform materials towards a circular future.

“With this milestone investment, we are expanding our technology base to secure the recyclability of our fibrebased products to meet the strictest requirements of expected future regulations”, says Leif Frilund, President and CEO.

“This new production line will cater to the fast-growing demand for fibre-based and recyclable materials, both in our consumer packaging and construction materials segments”, adds Frilund.

The novel coating technology – a combination of dispersion and impregnation

technology – is enhancing Walki’s capabilities to produce high barrier fibre-based materials with a low carbon footprint.

“The unique production line has been completely designed inhouse and is the most modern in the world. Dispersion technology is a sustainable way to achieve barrier properties for fibre-based packaging without compromising recyclability in fibre streams”, says Kari Salminen, Deputy CEO and Executive Vice President, Engineered Materials.

In addition to packaging materials, the production line will be serving customers in the construction industry, who are under pressure to comply with tightened regulations regarding both fire safety and recyclability of construction materials.

“Regulation creates the need for materials that can replace aluminium in construction facings without compromising flame-retardance. We will produce new facings coated with a flame-retardant substance for polyurethane insulation”, says Kari Salminen.

The new production line was a true team effort involving not only Walki employees but also a wide range of suppliers, as well as the support from customers.

“Everything has gone according to plan, which we can see in our excellent safety statistics relating to the project”, says Kari Salminen.

Walki received financing from Business Finland’s circular economy funding for this investment.

17 foodandrinknetwork-uk.co.uk

Food Processing

CORROSION RESISTANT SOLUTIONS FROM

In an environment of increased operational requirements and tough regulatory guidelines, today’s bearings and power transmission products are exposed to a host of demanding conditions. Such conditions may include corrosive cleaning agents, high pressure washdown and a wide array of environmental factors that can negatively impact performance. Overall, a balance of material strength, corrosion resistance, sealing and lubrication are required for all products used where hygiene is of paramount importance.

Due to the pandemic we’ve seen increased attention to cleanliness, washdown procedures and prevention of foreign contaminants from getting into the manufacturing process within fish, food and beverage processing companies. Recently there has been

18 foodandrinknetwork-uk.co.uk

Corrosion Resistant Components

For further information please contact Cross+Morse

Telephone: +44 (0) 121 360 0155

Facsimile: +44 (0) 121 325 1079

Email: sales@crossmorse.com or visit www.crossmorse.com

even when using some of the newer, harsher cleaning chemicals. Stainless steel tends to hold up the best, allowing for more pressure, more soap and a little faster cleaning time. Alternative surface treatments such as nickel plating and Aquaproof are also available.

There is tremendous benefit to selecting products that support a reduced maintenance schedule. For example, corrosion resistant high performance bearings can prevent contaminants such as water and dirt from entering the bearing. New equipment is not always an option, so the ability to adapt to the situation with the right components with the best seals can be a game-changer.

perform in corrosive and contaminated environments.

Cross+Morse offer an entire range of stainless steel products suitable for washdown environments: Roller chain and attachments, sprockets, taper bushes, shaft clamping elements; along with the whole selection of McGill® cam followers and Sealmaster® bearings and gearboxes. Corrosion Resistant Products

Introducing CRS from Cross+Morse: a comprehensive line of corrosion resistant power transmission products engineered to

There is tremendous benefit to selecting products that support a reduced maintenance schedule. For example, corrosion resistant high performance bearings can prevent contaminants such as water and dirt from entering the bearing. New equipment is not always an option, so the ability to adapt to the situation with the right components with the best seals can be a game-changer.

If there is a not an off the shelf solution, Cross+Morse also have the ability to manufacture sprockets, platewheels, gears, bevel gears, helical gears and timing belt pulleys in non-corrosive material to your exact specifications at our factory here in Birmingham.

LOMA SYSTEMS® LAUNCH X5

4”

PIPELINE X-RAY INSPECTION SYSTEM

Loma Systems, a global leader in inspection technologies for food quality and safety, has introduced a new product into its Pipeline portfolio with the launch of a 4” option.

Perfect for inspection of pumped and free-flowing applications, such as large-formed hams and gammons, the product complements Loma’s Pipeline family, which is already available with product pipes of 2.5 and 3”, all offering excellent detection across a wide range of contaminants.

Following customer feedback highlighting the need for a product with 4” couplings and higher throughput, Loma redesigned the Pipeline’s inlet and outlet manifold to accommodate the increase in diameter. The X-ray section itself is now rectangular, which changes the shape of the contents passing through the system, rather than compressing them. Additionally, the feed to the X-ray section is on a gradual incline to aid flow and reduce back pressure.

With its concentric diameter pipe, small footprint and great detection performance, the new X5 4” Pipeline includes all of the standard features from the X5 range, but also has upgrades from the previousgeneration model including a removable cassette for easy cleaning, integrated safety sensors and an easy-to-use capacitive 8” touchscreen, thereby ensuring the highest levels of regulatory compliance through realtime data collection. Providing easy access to all machine areas and rated to IP69 as standard, the system is designed to be used within a high-care or high-temperature, high-pressure wash-down environment.

Equally adept at inspecting fast, free-flowing products such as jam, chutneys, and even soups or sauces, the X5 Pipeline is the next generation in food contaminant detection and can be used for a variety of applications. Providing peace of mind that no contaminants will pass inspection, the unique X5 detector design offers excellent detection levels of all major contaminants, including bone, ceramic, glass and dense plastics as

well as stainless steel, ferrous and nonferrous metals.

The X5 Pipeline can be fitted with ARU (2.5”) and ARL (2.5” or 3”,4”) automatic reject options to reduce waste and increase productivity, and is designed to be compatible with vacuum-filling machine brands such as Handtmann, Vemag and Risco.

“The addition of the new 4” X5 Pipeline shows Loma’s continued commitment to developing new and innovative inspection systems to meet industry needs,” said Loma’s Toby Kemp, director of marketing and innovation. “Listening to customers is key to understanding their pain points, enabling Loma to develop new products that not only create added-value, but also help build on our heritage.”

For more information on Loma’s ‘Check & Detect’ solutions, www.loma.com/en-gb

20 foodandrinknetwork-uk.co.uk

X-ray Inspection

It’s all in the detail

The importance of hygiene cannot be overstated when processing food. The potential impacts of an inadequate cleaning regime can range from the expensive, in the case of a failed audit, to the catastrophic, should a food poisoning outbreak be traced back to your facility.

So it should go without saying that instilling a hygienic culture in your organisation is imperative.

Cleaning processes must be robust. But this means that cleaning is also time-consuming and often arduous, placing a significant demand on resources. And it’s not just the production floor that demands rigorous cleaning standards, changing rooms, wash rooms and packing areas are significant . The truth is that audits can be passed or failed anywhere in a facility and it’s easy to fall down on a factor that could be simply overlooked.

However, maintaining hygienic standards doesn’t need to be nightmare. Making informed choices when you are investing in new furniture and equipment can play a massive role in reducing cleaning times, to save you money, and minimising risk, to protect your reputation.

Fixtures, fittings, and food

The trick to investing wisely is to think like an auditor. It makes sense to work backwards, starting with the practicalities of the cleaning regime. Consider the form factor of the furniture and equipment; careful design choices can reduce clean down time simply by offering easier access. For example, when an auditor assesses a storage locker they aren’t just considering how easy that fixture is to clean in isolation – rather, they are also looking at the areas around it, including underneath and behind.

The working environment should be representative of the hygienic standards you wish to encourage in your organisation. You want your staff to take pride in their surroundings but in a production environment, function is always going to take precedence over form. No matter how space-age a piece of furniture may look at first glance, poor quality design can create a breeding ground for germs.

And this is what we mean by hygienic design. From advanced, high-end machinery to the simplest of waste bag holders, furniture and support equipment aimed at workplaces that deal with food should have hygiene factored into the design from outset. . Any gap, ledge, corner, raised weld or fold should be considered a potential dirt trap and therefore a hygiene hazard. . If you are dealing with any liquids, be sure to check for ledges or other flat surfaces where liquids, and germs, can pool. (and There should always be clear drainage points and especially around taps. When assessing potential new equipment or furniture, past experience of previous dirt

odours from meat juices, granules, fruit or dairy products will not be transferred from one batch of food to the next when cleaning between uses.

304 grade stainless steel is also extremely tough. It is resistant to corrosion and robust enough to withstand even harsh cleaning and sterilisation processes, such as high pressure and high temperature cleaning. It’s ‘clean-ability’ comes down to its chemical composition: 304 grade is an austenitic stainless steel with added nickel, it has no pores or cracks that may harbour contaminants and this factor makes it as easy it is to clean as china or glass.

One final point to consider is how dirt can make it into the facility in the first place? The flooring and matting you use can play an important role in helping to reduce risks. Walk-through foot baths are used to remove contaminants from clogs and boots as the final hygiene point after boot wash scrub down. These mats are most commonly placed at entrances/exits to the production floor but can be used strategically throughout the facility as part

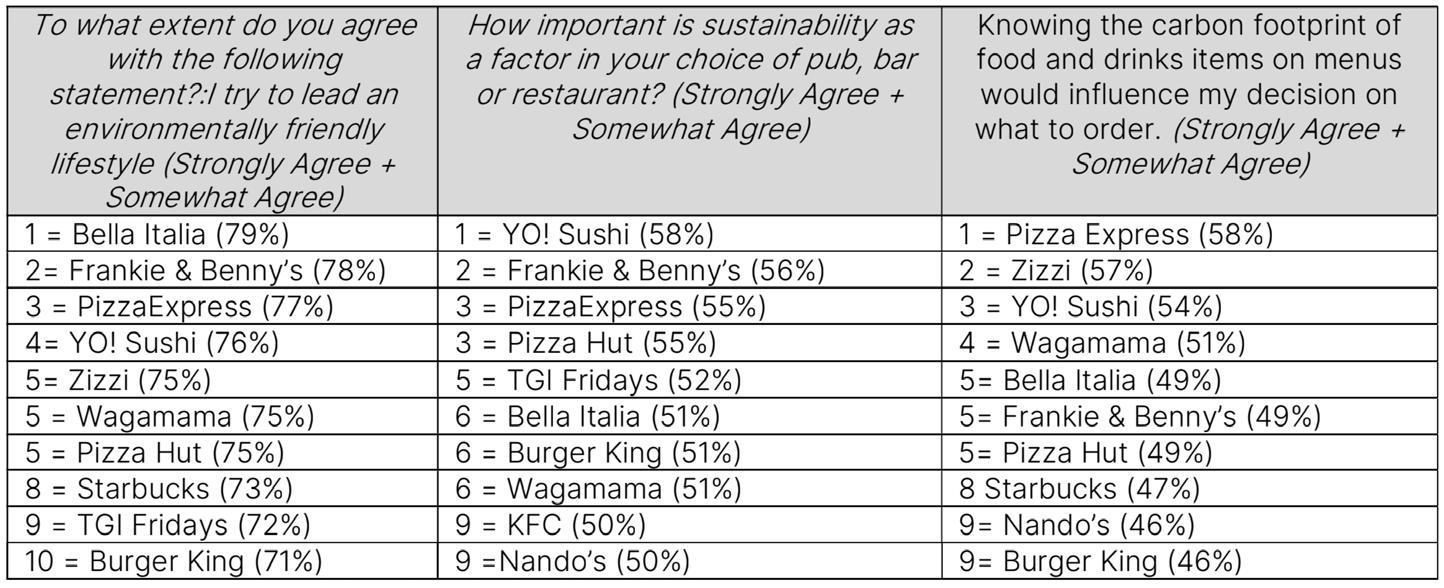

Making minor changes across a site, from signage to matting, can reinforce the overall