FOOD AND DRINK NETWORK

Excelerate is your stretch film partner, specialising in both perforated pallet wrap and sustainable pallet wrapping materials, crafted with innovation and a passion for excellence.

Our high-strength perforated (breathable) stretch films allow air flow through your goods, providing an array of benefits.

Discover our ExcelAir perforated pallet wrap designed for high performance. Engineered to facilitate maximum air flow through pallets, our wrap enables products to breathe freely, effectively eliminating moisture, heat, and gases.

Our high-performance solid pallet wrap provides amazing load stability, minimal plastic usage and the lowest possible cost to wrap a pallet.

Our extensive range of Goliath solid pallet (stretch) wrap has been crafted with sustainability at it’s core, allowing you to vastly reduce your volumes of plastic without compromising on load stability and performance.

EDITORIAL:

Akabo Media - Intralogistex USA

Easyfairs - London Packaging Week

Harford Control

OTSA ltd - BrauBeviale

Automate UK - PPMA

The Engineering NetworkMachine Building Live Yakult UK

ADVERTISEMENT SALES:

KIMBERLEY READ (Advertisement Sales Manager) JOANNE MURPHY

AMANDA WALMSLEY EVELYN WOOLSTON

RACHEL RILEY - Designer

WALTONS PUBLICATIONS LTD

46 HENEAGE ROAD, GRIMSBY N.E. LINCOLNSHIRE DN32 9ES

Kimberley Read at: kimberley@ foodanddrinknetwork-uk.co.uk or Joanne Murphy at: joanne@foodanddrinknetwork-uk.co.uk

foodanddrinknetwork.co.uk

Cablevey Conveyors, part of Automated Handling Solutions (AHS), the leading provider of automation solutions and specialised material handling equipment, has announced the launch of its new metal-detectable cable assemblies for tubular drag conveyor systems. The innovative product is designed to meet the evolving needs of the food processing and material handling industries, providing enhanced safety and operational efficiency.

The metal-detectable cable assemblies feature metal-detectable additives in the coating and discs, ensuring that standard metal detectors in processing plants can quickly identify potential contaminants. This solution prevents potential contamination of food products, which is crucial for maintaining the highest quality standards and consumer safety.

The assemblies incorporate a proprietary blend of metal-detectable materials designed to ensure that in the unlikely event of any fragments of the assemblies coming loose during operation, they are detectable by conventional metal detection systems used in food manufacturing. This advancement is particularly relevant for industries where even the smallest

Solopress, a leading name in UK online print services, is excited to announce

its venture into the packaging sector with the launch of its new Standup Pouch Packaging. This move marks a significant step in Solopress’ commitment to providing innovative and sustainable packaging solutions for various industries, including food and beverage, health supplements, and beauty products.

Manufactured in a food safe environment, they’re ideal for ingredients, snacks and supplements, as well as pet foods.

The BOPP material is recyclable at store front recycling points Full colour, all-over print gives brands the opportunity for maximum impact Options include multiple sizes, hanging holes, degassing valves and a choice of white, metallic or clear interior film barriers.

Stand-up Pouch Packaging represents a versatile and eco-friendly alternative to traditional packaging methods. Crafted from strong, tear-resistant BOPP (biaxially oriented polypropylene), these pouches are designed to be both durable and fully recyclable at store front recycling points.

Jane Wickens, Head of Marketing at Solopress, commented on the launch: “Introducing Stand-up Pouch Packaging is aligned with our strategy to diversify our product offerings and meet the evolving needs of our customers across multiple sectors. While this is a new venture for us, our expertise in delivering high-quality, reliable print solutions translates seamlessly into our packaging offerings.

“We wanted to expand our range to cater to the increasing demand for sustainable packaging options and allow our customers to boost the visual appeal freshness of their products.”

contaminants can compromise product integrity and safety, such as in coffee, snacks and various powdered food products.

In addition to its detectable properties, the new cable assemblies offer robust performance and durability. It is designed to integrate seamlessly with existing systems, allowing for straightforward retrofitting and inclusion in new installations. This flexibility ensures that manufacturers can upgrade their safety protocols without extensive system overhauls. The metal-detectable cable assemblies are available now to order.

For further information about Cablevey Conveyors and its new metal-detectable cable assemblies, visit cablevey.com

The new resealable pouches feature all-over print, so brands can completely cover their packaging in whatever colours, patterns, lettering and graphics – even on the base. They come in several sizes and feature customisable options such as hanging holes, degassing valves and a choice of white, metallic or clear interior film barriers.

Opting for the metallic silver film layer means designers can achieve a foiling effect by leaving blank areas in their artwork. Similarly, a window effect can be achieved with the clear film option. In either case, white ink printing means that even without a white background, white artwork elements can still make their mark.

Manufactured in a food safe environment, they’re ideal for a wide range of goods, including gourmet snacks, coffee, pet foods, nutritional supplements and personal care products.

For more information on Solopress’ new Stand-up Pouch Packaging and to see how it can transform product presentation, please visit https://www.solopress.com/packaging/

• Sustainable filling and capping owing to new media-saving options

• More compact machine delivers the same performance due to new automatic CIP cups

sustainable performance

analytical tools and intelligent operator prompting concepts: Our digital services help you keep processes and optimise both costs and output resources.

Food and Drink Network, 133 x 186 mm, Image, CC-en46-AZ452 05/24

From user-friendly analytical tools and intelligent operator prompting right through to AI-based concepts: Our digital services help you keep on top of complex processes and optimise both costs and output while also saving valuable resources. krones.com

• Increased flexibility in production as a result of optimised and automated operator interventions

synergise the advantages of both systems. For example, a revamped arrangement of the individual functions within the filling valve results in optimised flow conditions. That, combined with “lower” vacuum levels in the filling process, enable the Modulfill HES to set entirely new standards for oxygen pickup and CO2 consumption in conventional beer filling.

DIGITAL FEATURES

CC-en35-AZ002_06-24_FoodDrinkNetw.indd

Yet another plus in terms of product quality is the intelligent processgas control system. A sensor measures the residual oxygen in the headspace of the filler bowl and thus makes it possible to monitor and dynamically regulate oxygen pickup to the desired level.

CC-en35-AZ002_06-24_FoodDrinkNetw.indd

REDUCE THE NEED FOR MANUAL INTERVENTIONS

Krones has added automation to the probe adjustment and to the CIP cups which makes it possible to achieve the same performance on a more compact machine using the automated CIP cups. During cleaning, the necessary interventions are reduced to an absolute minimum, which, in turn, significantly shortens scheduled machine downtimes and increases overall equipment effectiveness (OEE). Machine change-over times are likewise shortened due to the use of the latest generation of the MultiGuide Base multi-functional clamping starwheel.

It’s important to look beyond the short term, which is why Krones is working on “Solutions beyond tomorrow”. Be it beverage and food production lines, digital services or plastics recycling: Krones’ innovative solutions combine superior performance with sustainability. krones.com

A further digital feature is the automatic filling-pressure control system. Inline measurement of the product temperature inside the filler bowl and information on the CO2 content (based on the product at hand) can be combined to calculate the real saturation pressure and thus regulate the filling pressure. This reduces the need for operator interventions when restarting the machine, for instance in order to prevent foam-over.

When we help, the Harford system is built to scale across each factory, from goods-in to despatch. With Harford's MIS/MES solutions, all production-related information is available within a single system. All collected data is analysed, prioritised & distributed to networked factory screens, PCs, laptops, tablets and mobile phones, in real time, so that operators can make immediate adjustments to improve performance.

UK total production costs have increased by 9.2% on average over the year to March 2024. As costs have been rising for manufacturers at a faster pace than retail prices, manufacturers are stuck between a ‘rock and a hard place’ and believe they have had to absorb the cost hikes.

The latest FDF State of the Industry Report found that businesses are left with no choice but to reorganise their operations and improve their productivity. However, change has never been easy. Niccolò Machiavelli, a 15th-century politician, diplomat, and philosopher, put it this way:

“It must be remembered that there is nothing more difficult to plan, more doubtful of success, nor more dangerous to manage than a new system. For the initiator has the enmity of all who would profit by the preservation of the old institutions and merely lukewarm defenders in those who gain by the new ones.”

If Machiavelli experienced such problems 500 years ago, it is very thought provoking to see that, in the implementation of change (any change), the same old problems often still confound management today.

Change management within an organisation is complicated. It involves overcoming fear of the unknown, potential failure, increased workloads, lack of understanding, inadequate support, and attachment to the comfort zone. Resistance to change is common, with some naysayers anticipating failure as inevitable and ready to say, “I told you so. We shouldn’t have changed this.”

In this article, we explore some of the reasons behind resistance to change, why some attempts at change are ineffective, and how to successfully implement effective change and embark upon a journey of continuous improvement within the food and drink manufacturing industry.

Some people are too accustomed to the old ways of doing things and are unwilling to adopt change, and yet these same people who resist

change have, it would appear, easily adopted and adapted to changes in their personal lives, where it benefits them to do so. During past training sessions, the acceptance of new systems to improve production performance has proven difficult for some manufacturers. Comments like “I can’t change now at my age” and “We always end up going back to the old ways” are common. In response, we might ask, “Do you drive a 50-yearold car?” to which they usually answer, “Of course not.” Or we might ask, “Do you use a smartphone?” to which the usual answer is “Yes, of course,” often adding how they “can’t imagine managing without it”.

We might then ask “How much change did you have to get used to with your modern car or smartphone?” This analogy often helps some see the benefits of new systems. However, in some cases, we still encounter blank faces or comments like, “So?” as if our point has no relevance to the topic at hand. Despite these challenges, it is crucial to persist in promoting the advantages of modernising production processes, as the benefits of effective change far outweigh the initial resistance and discomfort. Those 7 most expensive words in the English language “We have always done it this way” are always at hand to reset the ‘change’ monitor to zero.

Nevertheless, not all change is effective nor beneficial. Some manufacturers opt for quick and easy fixes that fail to bring about meaningful and lasting improvements and such companies are almost certain to fail in the long term.

One user told us that they wanted to make a positive change and, as a result, purchased an OEE solution. Since the installation of their XYZ system, their OEE had increased to 85%. However, they went on to say, “We left out Quality and we allow 20 minutes morning startup time and 20 minutes close down time at the end of each shift. We also leave out product changeover times, planned maintenance, tea breaks, lunch breaks, and time allowed for team meetings.”

It can be difficult to convince such users that, while their measures are probably very useful to them and have helped to make significant gains, these measures fall a long way short of true OEE. But even true OEE is by no means a panacea.

Dr Wheeler, one of the few living gurus continuing the work of Dr Edwards Deming, said of OEE “Utter nonsense. OEE is like taking our weight x our height x our systolic blood pressure as a measure of how good looking we are.” This attempts to illustrate the lack of confidence where OEE is done badly. It doesn’t change the fact that OEE can be an extremely useful performance metric, when measured well and consistently.

OEE takes no account of manning levels when it’s measured strictly by the book. A production manager may need to increase the crew size due to product quality issues. Additional metrics such as ‘units per man-hour produced’ can also be very revealing and help to drive improvement actions.

Many ‘me too’ OEE systems lack highlevel ‘top losses’ management analysis and detailed drill-down capability and therefore provide little or no opportunity to drive performance improvements. To achieve true performance improvement, it’s crucial to adopt a holistic approach that includes comprehensive metrics, drill-down root cause analysis capabilities, all of which requires full operator engagement.

More than 30 years ago, Nevin McMillen wrote in his easy introduction to ‘SPC and Company Wide CI’ “Companies today should be concerned about two issues:- 1. The Management of Quality 2. The Quality of Management”.

A holistic approach and effective change management will involve a clear vision with agreed objectives, stakeholder engagement, leadership commitment, cultural change, effective tools and systems, a communication plan, all with full training and support.

Harford’s end-to-end MIS/MES system integrates risks, variables, and efficiency constraints to deliver a comprehensive, realtime view of compliance, quality, yield and operational efficiency. This holistic approach ensures that all factors are considered, providing the most accurate insights into performance and enabling proactive management. Alongside our end-to-end MIS/ MES system, we also provide comprehensive training and consultancy to empower operators and leaders to effectively adopt and utilise these systems. These measures can help support the factory in achieving positive change management and embark on its journey of continuous improvement.

When looking for a performance improvement partner with the right toolkit and comprehensive training program, please reach out to us at info@harfordcontrol.com or call us at +44 (0)1225 764461.

*Harford Control announced a solution range update earlier this year and we will showcase our latest end-to-end MIS/MES system on Stand B46 at PPMA, from 24th to 26th September at the NEC.

Food & Drink Network prides itself in providing the very latest industry news from the Food & Drink Industry, selected from 13 sector headings including Exhibitions, Packaging & Labelling, Beverages, Machinery, Food Science, Processing, Warehousing, Tranport and Logistics & more...

Visit our Stand: H85 at PPMA Show 2024 and speak to us about how we deliver exactly what we promise which is successful, reliable advertising.

You can filter news from 13 sector headings including Exhibitions, Packaging & Labelling, Machinery, Ingredients & Product Development, Beverages, Food Science, Processing, Food Safety & Hygiene Warehousing, Tranport and Logistics & more...

When selecting from this box or the ‘Our Magazines’ tab at the top of the website you can read the latest magazine online for free via our e-book hosted by Issuu. You can also access the back catalogue of the ‘Food & Drink Network’ and ‘Industry Insight’ magazines

Visit our featured suppliers and customers via these interactive logos. Click the logos to visit their website and support them as industry experts within their field and to the Food & Drink Industry.

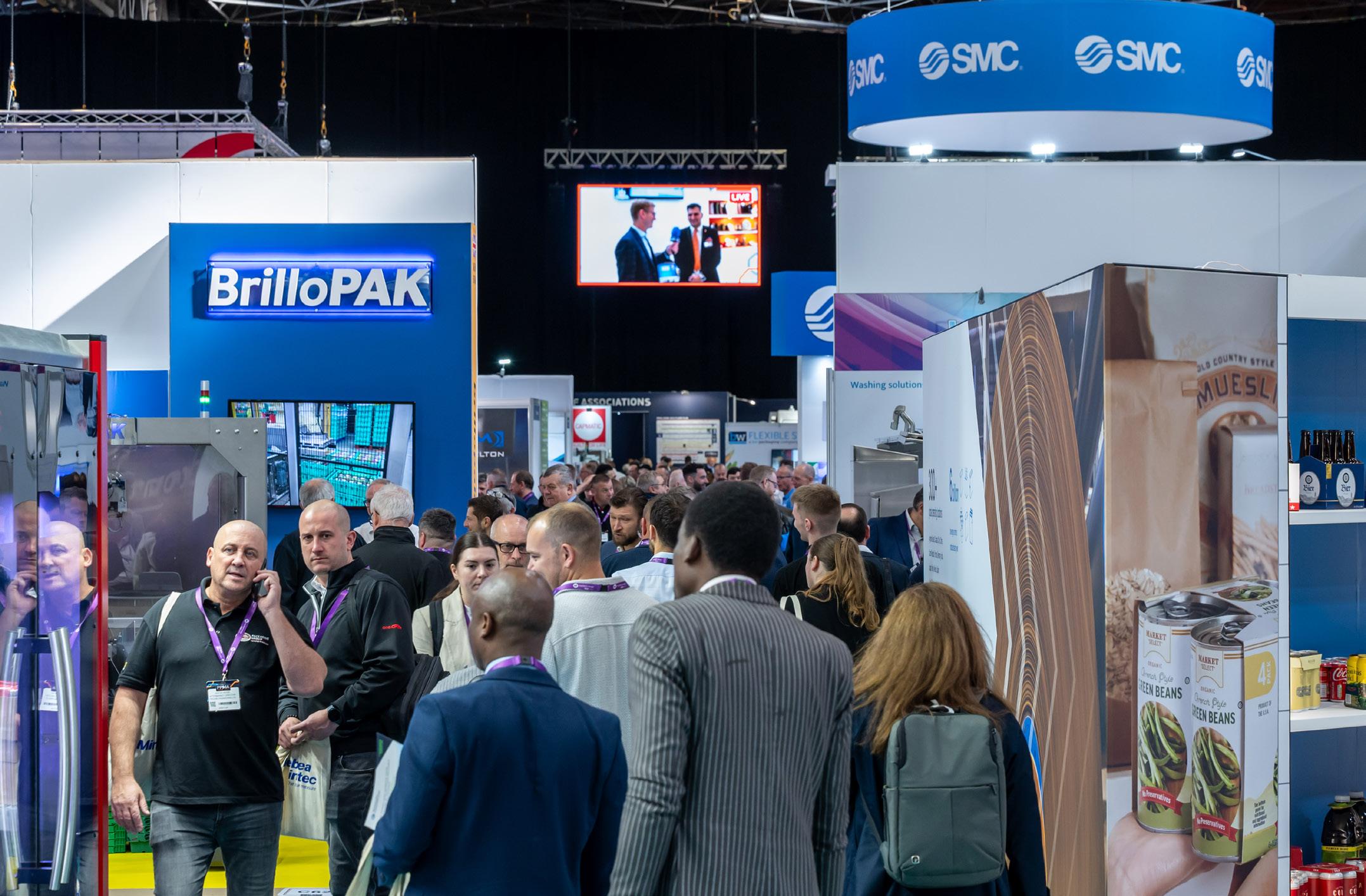

For over 35 years the annual PPMA Show has been a highlight of the processing and packaging industry’s calendar. This event, between 24-26 September at the NEC in Birmingham, is renowned for bringing together thousands of visitors and exhibitors from the FMCG sector. It is anticipated that hall 5 will once again be filled with excitement and anticipation, providing visitors with a perfect platform to network with well-known exhibitors and learn about their latest state-of-the-art technologies and solutions.

Owned and organised by Automate UK, the PPMA Show is recognised as the industry leading event. It brings together the very best suppliers of processing and packaging machinery, robotics and industrial vision systems with the capability to deliver significant benefits to a wide range of businesses. These include cost reductions, increased efficiency, quality improvements, and reduced downtime and turnaround, all of which can deliver a healthy return on the investment in these technologies.

The show provides a unique opportunity for visitors to experience a complete production line with every aspect of it being represented, from labelling, filling and packaging to processing, robotics, automation and industrial vision systems.

Visitors will be able to see the latest innovations from an impressive line-up of over 350 exhibitors, comprising over 1,500 brands. These exhibiting companies will be showcasing

their latest cutting-edge solutions for the full spectrum of the manufacturing industry, including pharmaceuticals, food and beverages, building materials and suppliers, pet care, and microbrewers and distillers.

The show floor is expected to be vibrant with live demonstrations and product launches, along with experts on hand to help the visitors find the right solutions for their needs. It is anticipated that the show will deliver impressive results with many business transactions taking place during the three-day show.

Aaron Moore, Asset Maintenance Manager, Nestle, said this about the 2023 PPMA Show: “Fantastic day here at the PPMA Show, lots of suppliers that we work with. Some really innovative solutions, and a lot of relatable things for us, so we are taking lots of lessons home.”

Here are just some of the hundreds of exhibitors taking part in the show:

Reiser (D110) has been a leading supplier of processing and packaging equipment for the meat, food, pet food, bakery, and cheese industries for over 60 years. From single machines to complete process-to-packaging production lines, their solutions combine specialised equipment, custom engineering, and in-depth expertise to meet customer challenges.

Videojet (E30) is one of the world-leading manufacturers of coding and marking systems. The company’s portfolio includes its full end-to-end suite of primary, secondary and tertiary equipment, including printing date or batch codes onto a food package and labelling full traceability information on a pallet.

ULMA (B20) provides the most extensive selection of packaging machinery and applications on the market. ULMA’s product range also includes fully automated solutions encompassing crate/case loading, product handling, pick and place, palletizing, end-of-line, and comprehensive turnkey project management.

Ishida (B50) is a world leader in the design, manufacture and installation of end-to-end weighing, packing and safety solutions for the food industry. The company helps manufacturers increase automation and compliance, reduce cost and downtime, increase operational efficiencies and brand protection, and maximise profits.

The comprehensive exhibitor listing is available online to help visitors plan their visit:

https://www.ppmashow.co.uk/exhibitors-2024#/ exhibitors/

One of the show highlights is its informative and inspiring expert talks which provide visitors with a wealth of knowledge to take with them to consider how they can apply this to improve their businesses. This year’s keynote speakers are:

Jessica Sansom, Huel: The manifestations of climate change - rising to the challenge and adapting to a new normal

The food industry is responsible for more than a quarter of all global greenhouse gas emissions. Without significant change in this industry, it will be impossible to limit global warming to under 2 degrees.

134 countries at COP 28 signed a declaration on sustainable food systems, meaning that they must now include food in their national climate action plans, including a commitment to shift from higher greenhouse gas-emitting practices to more sustainable production and consumption approaches.

Jessica’s presentation explores what needs to happen in the processing equipment and packaging machinery sector in order to meet those targets.

Stefan Casey, Nestlé: The digital transformation of FMCG industry: How digital technology is bringing both challenges and opportunities in packaging across the whole value chain

Stefan’s talk will focus on affordable personalisation and customisation in packaging design through to production. His presentation will cover points such as the needs for more flexible packaging production solutions, cost effective solutions by optimising end-to-end from design through to manufacturing, and quality control and safety.

Visitors will also have an opportunity to hear from leading industry speakers including Matt Androsiuk - Cobots and Machinery Safety Ltd, Dr Martin Kidman – SICK UK Ltd, Adam Dickins - AD Frameworks Ltd, and Chris Whyborn - Thornton Tomasetti. The seminars provide a wealth of valuable insights covering a wide range of topics, such as industry standards, CE and UKCA marking, automation to reduce carbon footprint, and many more inspiring subjects.

In addition to the seminars UK Automation Forum will be hosting a panel discussion on ‘What would make UK food businesses adopt more robots?’. The panel is hosted and facilitated by Gail Hunt from Automate UK, who will be joined by industry experts including Mike Loughran - Rockwell Automation, Chris RooumMTC - Manufacturing Technology Centre (MTC), Mike Wilson - Manufacturing Technology Centre (MTC), Prof Phil Webb - Cranfield University, and Oliver Selby - FANUC UK. The discussion will focus on the positive impact that adopting automation can have on the sector as well as sharing advice and learnings that can help to deliver successful outcomes.

In addition to discovering and exploring various innovations and solutions, experiencing live demonstrations, seeing product launches first-hand and learning at seminars, visitors will have plenty of opportunities to make new business connections and network with industry peers.

Automate UK wants to ensure that visitors have a standout show experience; one of the new features at this year’s show is the free PPMA Show app. This will allow visitors to plan their day, have easy access to their entry ticket and discover all aspects of the show, from exhibitors and products through to a complete list of seminars and speakers.

Scott McKenna, Chief Operating Officer at Automate UK, said:

“We’ve been working hard to ensure that the PPMA Show continues to live up to its reputation as the UK’s largest event showcasing innovative technology from the processing and packaging industry. Our aim is to ensure that the show continues to evolve and as such we’ll be introducing new features to enhance the show experience for both visitors and exhibitors.”

For more information, please visit: https://www.ppmashow.co.uk/

In a new packaging development partnership, SN Maschinenbau and Südpack have developed an overall concept for the in-house production of stand-up pouches with spouts, which is designed for the packaging of paste and liquid products. The concept is aimed at food manufacturers and bottlers who previously use premade spout bags and will be presented at Anuga FoodTec 2024.

makes handling much easier and allows staff to process a larger number of pouches more efficiently, for example because there is no need for timeconsuming separation of the rails. The low-maintenance machine works highly efficiently and, thanks to its compact design, can also be used in production environments with limited available floorspace. This means it can be set up flexibly either directly on the filling machine

With the corrugated packaging market seeing strong growth that will continue over the coming years, it’s no wonder exhibitors at London Packaging Week are making the most of the opportunity.

The evolution of the corrugated industry continues at pace and is to be realised at London Packaging Week 2024 when the show returns on 11 & 12 September at ExCeL.

Megatrends such as “paperfication” of the packaging industry and a global health crisis have given corrugated a hefty shove in the right direction, supported by developments in materials, hardware and design that make the material an increasingly adaptable and appealing packaging medium.

Today, this makes corrugated as suitable for shipping luxury cosmetics and beverage products directly to the customer’s door, as much as it is for distributing goods throughout supply chains.

This variety and versatility will be showcased in volume at London Packaging Week 2024, taking place 11 & 12 September at ExCeL.

Exhibitors McLaren Packaging (K60) and The Box Factory (A10) and their respective product portfolios illustrate this perfectly. The former is a Scottish manufacturer of high-quality corrugate packaging, serving the UK food and drinks sector. It specialises in presentation and transport packaging, so delivering great shelf appeal as well as robust packaging that protects products in transit, or both. This includes drop-in cases for shipping, wraparound cases, product boxes and trays, on-shelf presentation shippers, mailer packs, and more. Bespoke options create exacting corrugated packaging to protect and present products, whether for transit, shelf display or e-commerce deliveries direct to the customer. The latter, one of the largest independently-owned, high-volume manufacturers of FSCcertified corrugated packaging in the UK, designs, manufactures, stores and delivers all types of corrugated boxes. From regular cases to shelf-ready packaging (SRP) and die-cut boxes, these are suitable for a range of end uses and applications. Corrugated

fittings are also offered as alternatives to plastic, polystyrene or foam. These can be bespoke designs and are fully recyclable.

Fittings are an example of items that complement corrugated boxes in their pure form and function. Others, such as CorruLoc from Item Products (D12), similarly show what can be introduced to enhance the capabilities of corrugated. CorruLoc is an integrated fastener that cannot be removed or lost from a pack, while Corra-Screw is used to bind and release multiple layers of board. It eliminates the need for tape and staples. Carry handles, clips and closures, and detachable wheels and feet are other options to increase the usability of corrugated boxes. Garment transit rails transform boxes into wardrobe removal cases used to ship items produced by the clothing industry.

Corrugated can also aid in the shipping of chilled items. Kite Packaging (B14) offers insulating corrugated box liners. These are made of double-wall corrugated constructed with 125gsm paper, giving them the same temperature controlling qualities as polystyrene and making them suitable for use in temperature-controlled packaging for food, fish and pharmaceuticals. As well as providing safe transportation for such items, their core material is widely recycled both domestically and commercially, so contributing to the Circular Economy.

Another use for corrugated is as sleeving for fragile containers. Kite Packaging’s flexible, protective corrugated sleeving is similarly good for the environment by being 100% recyclable and biodegradable, but rather than protecting product integrity it protects the packaging itself – bottles, glass, ceramics, jars, small metal items and others.

Stone corrugated boxes and cylindrical wine boxes, as offered by Mercury Global Packaging (H44), further example the role corrugated continues to play in protecting products.

Many of the above can be decorated using various print and finishing techniques, depending on their intended application. From simple, two- or four-colour flexo and offset prints that aid the integrity of the supply chain, to full-colour digital options that

allow for short-runs, versions and personalisation. Digital print options for corrugated were one of those to benefit during the Covid-19 pandemic owing to the rise of e-commerce.

E-commerce is an area of packaging that was already on the rise as more consumers were starting to shop online. The prolonged closure of brick-and-mortar retail and enforced periods indoors during the recent Covid times meant this trend was accelerated, and with it demand for packaging appropriate for e-commerce applications. This is a trend that has not reversed as the world has embraced its “new normal” where “next-day” is now the norm.

Packaging has responded in kind – lightweight, single-wall structures with crash-lock bases that allow fast assembly time, while hinged lids can be closed quickly and securely. In the case of Kite Packaging, an integrated peel-and-seal strip removes the need to apply tape, speeding up the fulfilment processes and shortening the time from order to delivery. A tear strip is included to open the package without difficulty.

With white and brown e-commerce postal boxes available off-the-shelf, bespoke colours and custom prints are available to match branding. Coloured postal boxes and custom printed postal boxes can be manufactured to meet Royal Mail’s PiP guidelines.

SR Mailing (C22) offers boxes that are available in a range of different sizes within the specifications that Royal Mail stipulates to be PiP compliant. They are made from 100% recycled corrugated material. Not only are they made from recycled material, they are easy to recycle and can be added to household recycling. They are biodegradable and compostable too, so allowing recipients to safely dispose of the box however they choose.

On show in the Innovation Gallery, Re-Zip (A14) is a return system for circular packaging, which makes it possible to reuse the packaging for shipping several times As a circular packaging concept for the e-commerce industry, Re-Zip offers a variety of reusable boxes and bags suitable for use by webshops to reduce CO2e by up to 80%, water consumption by 89%, wood consumption by 93% and packaging costs by as much as 100%. For customers, they use an app to find the nearest mailbox or parcel shop through which to return the packaging and are then rewarded with a voucher for the webshop for using the service.

The above examples provide a glimpse into the current possibilities for corrugated and showcase future capabilities. This will see corrugated go from strength-to-strength as a packaging medium of choice for an endless array of brands, retailers, applications and environments.

These and other examples from the show floor are sure to be ones to watch out for when London Packaging Week 2024 takes place 11 & 12 September at ExCeL.

This article is part of a series published ahead of London Packaging Week 2024, outlining products, trends and industry developments to look out for at the show.

Nordson Measurement & Control Solutions (formerly NDC Technologies) introduces the Series 9 Food Color Gauge.

The Series 9 gauge is a best-seller in the food industry. It is specially engineered for 24/7 duty, helping manufacturers to meet product quality demands and efficiency goals.

Installed directly on-line, it delivers unparalleled measurement performance while maintaining simplicity and versatility in design and operation. It doesn’t require special operator skills or expert knowledge, yet it allows experienced users to access the enhanced interaction capabilities as desired.

In addition to the key constituents, the Series 9 gauge can detect the change in brownness on the surface of a baked or fried product as a result of the Maillard reaction – called degree of bake.

However, surface browning is not the only color measurement required by the industry. That’s where the new Series 9 Color Gauge comes in.

Building on the existing flexible, future-proof platform, the NDC Products team by Nordson has expanded the capability of Series 9 to create a unique gauge capable of simultaneously measuring the color and the key constituents of food products. The NEW Series 9 can now measure the full-color spectrum in a wide range of standard scales, as well as color tolerance and difference outputs, for CIE (L*, a*, b*), RGB, CIE LCh (L*, C*, h), ΔE* & ΔEcmc and Degree of Roast (DOR).

Application tests in leading companies have proven that repeatable numeric color readings, combined with other critical measurements such as moisture, fat/oil, and protein, can be confidently used as part of a process control strategy to deliver consistent product quality every time. The Series 9 color gauge already counts numerous success stories in the industrial production of various foods, namely nuts, snacks, dehydrated fruits, coffee, etc.

Overall, the Series 9 Color Gauge keeps you ahead with:

■ Evolutionary technology that is flexible, adaptable and scalable to meet your changing needs

■ Enterprise-level intelligence compatible with Industry 4.0

■ Easier operation and maintenance

■ Lower cost of ownership over a long lifetime of operation

Avondale Foods (Craigavon) Ltd. was founded in 1965 by Harry and Derek Geddis. The brothers started in business growing vegetables at their family farm for distribution to local markets and retail outlets.

As Avondale Foods expanded, produce was outsourced to local growers while the company focused on product development. In the late 1970s, Avondale Foods became the first company in Northern Ireland to manufacture coleslaw and quickly became one of the leading suppliers of coleslaw in the United Kingdom and Ireland.

To this day, Avondale Foods remains a family company with the founding members still involved in the day-to-day running of the business. The second generation of the family have also key roles within the senior management team.

Adelphi – also a family owned and managed business – has been proud to work alongside Avondale, creating machinery to support their impressive trajectory of growth. Read on to find out more…

Hygiene is Paramount

Preventing mould and microorganism growth in oat drink and oat latte filling machinery is of utmost importance for several crucial reasons:

• Food Safety: Mould and harmful microorganisms, such as bacteria and fungi, can contaminate these drinks, leading to foodborne illnesses if consumed. Ensuring the machinery\ remains free from these contaminants is essential for safeguarding public health.

• Compliance with Regulations: Food safety regulations and standards mandate the prevention of contamination in dairy products. Oat drinks producers must adhere to these regulations to operate legally and maintain the trust of consumers and regulatory authorities.

• Prolonged Shelf Life: Mould and microorganism growth can accelerate spoilage, significantly reducing the drink’s shelf life. By preventing their presence in filling machinery, oat drink producers can extend the product’s freshness, reducing waste and ensuring consumers receive high-quality products.

• Maintaining Product Quality: Microorganisms can alter the taste, texture, and nutritional composition of these oat drinks. Preventing their growth ensures that the drinks retain their intended flavour and nutritional value, meeting consumers’ expectations and industry standards.

• Avoiding Cross-Contamination: In a manufacturing environment where multiple products might be processed, preventing mould and microorganism growth helps in avoiding cross-contamination. This is crucial, especially in facilities where various dairy products are produced, preventing unwanted flavours or substances in the final product.

It was with all of these reasons in mind, that Adelphi Masterfil developed the following hygiene-focussed machine modifications, tailored specifically for a custom filling and capping line for Avondale. The machinery needed to play its part in ensuring that every drop of product reaching consumers maintains the highest standards of purity and safety.

The line incorporated an S1200-A ‘Multifil’ automatic filling machine, and a Mastercap automatic screw capper. The customer also invested in a S5000-S twin head semi-automatic filling machine with similar hygienic features, as insurance against any downtime with their planned maintenance schedule together with product development projects which could be carried out on a smaller scale.

Grill style laser-cut stainless steel machine covers were used as an alternative to plastic or glass, which would be damaged by the aggressive cleaning chemicals used in the company’s fastidious cleaning process. LED illuminated lighting built into the filler ensure operators can still visually oversee the filling process.

All welded product contact parts were passivated, to slow down or eliminate the corrosion which can occur when cleaning chemical containing chlorides react with free iron on the surface of the metal.

Preventing dust or particulates from entering the milk was also an essential factor for consideration. Conveyor covers were added to prevent things dropping in from above, with an angled design to avoid dripping from condensation.

Product building up on – or in – the machine needed to be avoided entirely. A custom wash-bath was added for the conveyor slats, to prevent any product build-up there, whilst recessed cylinders were specified to provide a thorough cleaning/flushing of any deposits which may form on the underside/around the piston seals. Spray balls thoroughly wash the interior walls of the product tank, meaning that from one shift or production run to the next, no historic product will remain. Nozzle scabbards enable cleaning of both the inside and outside of the filling nozzles, connecting to a single point drain manifold which can in turn be connected either to a CIP return system, or directly to a drain.

Adelphi Masterfil’s team collaborated with Avondale throughout, to ensure the machine’s CIP (clean-in-place) functionality would connect with the Avondale site’s SCADA (Supervisory Control and Data Acquisition) system. This included a series of handshake signals between the filler and SCADA system to control the customer`s pumps and valves and feedback diagnostics.

This was successfully installed and tested, through a combination of Adelphi engineers on-site and remotely via a EWON COSY Industrial LAN router modem fitted to the filler.

Both Adelphi and Avondale pride themselves on their commitment to excellence. To this end, Adelphi partnered with world-leaders Roxtec to incorporate Roxtec glands and IP66 rated electrical cabinets (higher than the typical IP30 rated components). IP66 rating states that the cabinets are “dust tight” and “protected against heavy seas or powerful jets of water”, which will enable cables to run in and out of the cabinets, whilst withstanding the customer’s vigorous cleaning process.

Food grade pushbuttons, indicators and selector switches from Schmersal were utilised. These offer the highest protection class of IP69K and have been designed specifically to be used in applications where hygiene is paramount.

Other machine adaptations specific to the dairy industry included:

• 1200ml cylinders were included instead of the standard 1L or 5L cylinders, to enable filling up to the dairy industry frequent fill of 1136ml volume (2 pints).

• Visual inspection and swab testing were carried out after a test run of the CIP process during the Site Acceptance Test (SAT), to verify the cleanliness.

The meticulous prevention of mould and micro-organism growth in oat drink and oat latte processing machinery stands as a cornerstone of responsible and high-quality production. All modifications discussed herein collectively contribute to a safe, high-quality, and sustainable production process. Avondale can now uphold their stringent quality controls, ensuring that each carton or bottle of drink reaching households is a testament to uncompromised quality and safety.

Adelphi are proud to have worked alongside Avondale on this project, and look forward to supporting the team further in the future.

Eriez’ unique Hi-Vi magnetic drive circuit provides a simple yet powerful solution to difficult material-feeding applications.

With totally enclosed magnetic drives, these feeders can handle practically any bulk material, from micron size to bulky chunks. Solid-state controls operate the feeders with “watch–like” precision.

Eriez has standard models for the majority of feeding applications. Special units such as multiple drives, enclosed trays, or screens can be designed to suit application requirements. Additionally, a wide variety of standard and special trays are available.

The smallest feeder in the line, this economical model will give precise feeding of the most minute amounts of materials. Model A Feeders are ideal for feeding regulated amounts of granular to small lump material from a hopper to a second process in small packaging operations or laboratory use.

These feeders control material flow from a few kilograms per minute to two metric tons per hour (a few pounds per minute to two tons per hour).

Model C Feeders

Model HS Feeders

Eriez AC-operated Hi-Speed Feeders are designed for exceptionally high-speed feeding of light, bulky materials. They provide greater economy and efficiency in feeding, filling, and more. They are ideal for use in conjunction with many weigh scale and packaging machines.

Model HS Feeders operate at speeds up to 75% greater than standard models yet include the basic tried and proven mechanical design and construction features of other Hi-Vi feeders.

Model HD Feeders

Eriez_EveryChallenge_HalfPg.-FDN_9_24.qxp_Layout 1 8/11/24 8:15 PM Page 1

Larger than Model A Feeders, these units use the same drive to provide the best linearity in the industry.

Eriez High Deflection Vibratory Feeders combine the higher deflection 4.8 mm (3/16 inch) and lower frequency (30 cps) advantages of a mechanical feeder with the trouble-free service of an electromagnetic feeder. The Model HD is designed to handle powders and leafy products that cannot typically be fed successfully with an electromagnetic feeder. Feed rates of up to 24 meters per minute (80 feet per minute) are possible for products with a bulk density of less than 0.16 gm/cc (10 lb/ft³).

Energy efficient electromagnetic drives providing precise flow of dry granular products

Rapid On/Off cycling of light, bulky materials for packaging applications

Handles difficult hard-to-feed materials including fine powders, leafy, and sticky products

The food processing industry is currently experiencing a significant transformation, with innovation and new product development taking centre stage. As the global demand for food products continues to soar, the food processing equipment market is set for steady growth, propelled by factors such as an increasing population and the integration of advanced automation technologies.

Bakery and Confectionery: Leading Growth in Food Processing

The bakery and confectionery segment is a key driver of this growth. Increasing demand for these products is shaping the

future of the food processing equipment market. Simultaneously, a growing preference for hygienic meat products is boosting sales in the meat and poultry sectors, reflecting consumer focus on safe, high-quality food.

Investment in the food and drink sector is increasingly directed towards innovative solutions like modular pipework systems. These systems are crucial for maintaining safety and reliability in food processing plants. High-quality hygienic pipework, or food grade lines, are essential for meeting stringent hygiene standards, offering ease of sanitisation, costeffectiveness, and straightforward installation.

Pipework systems in the food and drink sector use stainless steels, typically V2A/1.4301 grade, which comply with European EC 1935/2004 regulations and FDA standards in the US. These materials are designed to withstand mechanical loads, high temperatures, and chemicals, ensuring durability and safety.

Collaborating with clients, experts develop bespoke pipework solutions that exceed industry hygiene and safety standards. This tailored approach ensures optimal operational efficiency while maintaining the highest levels of food safety.

Pipework systems are the backbone of modern food processing, essential for meeting the growing demand for safe, high-quality food products. Through continued innovation and customisation, the industry is wellequipped to face future challenges, delivering sustainable and superior products globally.

At Cross+Morse we aim to fulfil all industry demands, from the simplest to the highest level of precision required. Our objective is to offer a complete solution - not just products - to your power transmission challenges.

Cross+Morse are known in the industry as pioneers in quality standards, which is why we take our quality control processes very seriously. Quality assurance is central to our organisation with controls encompassing all aspects of design, manufacture, logistics and customer service. We are ISO 9001:2015 accredited and have been for over 30 years.

freewheels, roller ramp clutches, combined sprag and bearing units and many more.

At Cross+Morse we have continuously invested in top of the range measuring equipment: Co-ordinate Measuring Machine (CMM), digital tri-bore gauges and micrometers which are constantly calibrated to comply with ISO standards. Our stringent inspection process guarantees that when manufacturing each operation is thoroughly inspected by either a highly trained shop-floor staff supervisor or an inspector, ensuring that manufacturing is only allowed to continue when each phase has been approved. Our hardening treatment is checked using either our Rockwell or Vickers hardness testing machines.

We review our quality procedures continuously to provide up-to-date mechanisms for ensuring conformity to the quality system; different audits are carried out on all activities in the company throughout each year.

Cross+Morse is the largest authorised distributor and stockist for American transmission products manufactured by RegalRexnord (formerly EPT) in the United Kingdom. The range includes Sealmaster®, Browning®, Jaure®, Kop-Flex®, McGill® and Morse®.

Inverted tooth chain: including the standard SC type from 3/16” to 2” pitch and HV type from 3/8” to 2” pitch; as well as conveyor chains up to 12” width in centre or outside guide construction. We manufacture standard and special sprockets in-house for a complete drive solution.

We pride ourselves in offering a complete range of overload protection devices ranging from the simplest to the most accurate and precise overload clutch: Sheargard range of overload clutches, wedge pin type, available as a chain coupling and the option of low inertia rubber elastic couplings for higher speed drives. The Crossgard range, ball detent type, comes in 3 versions and also available with roller chain and low inertia rubber coupling option. The Safegard CS series, ball/roller detent type, comes in 2 two basic types (standard or mini) and also available as shaft couplings. Series CZ and CN zero backlash Safegard clutches for responsive overload protection, available in both basic and shaft coupling types.

We offer a wide stock range of flexible shaft couplings to accommodate different types of misalignment: Jaw couplings, elastomeric couplings, roller and Delrin® chain couplings, gear couplings GFA & GFAS, polymer gear couplings, Morflex elastomeric disc couplings and Crossflex disc couplings.

Our Crossbore® rework service includes reboring, keywaying and setscrewing of standard sprockets, pulleys and gears in a dedicated production area with specialised CNC machines for a rapid response. Induction hardening of teeth is also offered in-house.

Shaft clamping elements for precision transmission of torque with no backlash: a complete range from stock. Three ranges of locking devices available in corrosion resistant stainless steel.

Our range of Freewheel clutches for overrunning, indexing and backstopping applications; including sprag clutches, industrial ratchet

For further information contact:

Telephone: +44 (0) 121 360 0155

Email: sales@crossmorse.com or visit www.crossmorse.com

WEDNESDAY 2ND OCTOBER 2024

08:30 - 15:00

FREE TO ATTEND

Visit machinebuilding.live to find out more

Whether you’re a machine builder, systems integrator or an OEM engineering professional keen to automate, this is a unique opportunity to meet face-to-face with the largest array of machine building technical experts ever assembled in one place at one time in the UK. They are here to offer insight, expertise and experience that could prove invaluable as you design and manufacture the machines and systems that help keep the UK so competitive.

This is a one-day only event that is FREE TO ATTEND and uses a unique format to provide you with maximum information in the minimum of time. You can get here easily, park at zero cost right outside the entrance, get in, get round, get all the answers you seek and get back to work in short order - and you can also take in the superb National Motorcycle Museum collection too, with a free pass otherwise valued at £15!

Check out the all-new action in the Compton Suite!

New at MachineBuilding.Live for 2024 is an Action Arena. It features some of the latest developments from leading suppliers and they are being demonstrated by the experts behind them. Seeing is believing when it comes to the speed, precision and repeatability you will witness before your very eyes!

Head for the Compton Suite when you arrive to see some of the most fascinating and potentially game-changing innovations to have emerged onto the machine building scene recently.

Secondary

Our social enterprise, Community Shop, provides spaces for communities to come together, share and learn. In the past year alone, we’ve helped support nearly 30,000 households. From money management to CV support to free cookery classes for adults and kids, we’re helping our members gain confidence and pick up valuable new skills to expand their opportunities.

Change begins with what iff...

Watch our film to find out more

With over 100 years of expertise, Biffa is an established leader of sustainable waste management in the UK. Our purpose is to change the way people think about waste and our team of more than 10,000 key workers provide unrivalled end-to-end waste and recycling solutions for thousands of businesses and millions of households each day. Biffa continues to help businesses of all sizes across the UK reduce waste, recycle more and reduce carbon emissions.

Underpinned by our low carbon collection network, we’re at the forefront of enabling the UK circular economy by continuing to build our plastic recycling capacity, investing in energy recovery and growing the amount of surplus produce we redistribute through Company Shop.

Biffa also help thousands of businesses prepare for and manage new regulations. As the UK and devolved governments’ resources and waste strategies roll out, UK businesses face a period of unprecedented change in the way waste and recycling are collected and processed. Having the right partner to bring stability through this transition is critical.

Biffa also helps businesses manage the materials flowing through their operations, from consulting on packaging to sustainable management at end-of-life. Recycling more materials and recycling better helps keep valuable materials in the UK, meaning they do not have to be replaced with new materials – most of which are imported through global supply chains. “Recycling not only protects resources, but in many cases, it reduces carbon emissions.”

Since 2002 we’ve cut our carbon emissions by 70% and aim to be net zero by 2050. Our long-standing Biffa Award programme and our proud partnership with WasteAid also contribute to major environmental benefits for the UK and beyond.

In today’s rapidly evolving food industry, sustainability has transitioned from being a mere buzzword to a core business value. The growing awareness of environmental issues and the increasing demand from consumers for eco-friendly products have driven food manufacturers to rethink their processes. Central to this shift is the focus on waste recycling and sustainability, which not only benefits the environment but also enhances brand reputation and operational efficiency.

The food manufacturing sector is a significant contributor to waste, with substantial amounts of food and packaging materials discarded at various stages of production. Waste in food manufacturing can take several forms, including by-products, surplus production, packaging waste, and unsold finished products. Not only does this waste represent a loss of valuable resources, but it also contributes to the environmental burden through increased landfill usage and greenhouse gas emissions. To address these challenges, companies are increasingly turning to innovative waste recycling and reduction strategies that align with broader sustainability goals.

One of the most effective ways food manufacturers can reduce waste is through the implementation of robust waste recycling programmes. These initiatives often involve the conversion of food waste into valuable products, such as animal feed, compost, or bioenergy. For instance, many companies are now partnering with bioenergy firms to transform organic waste into renewable energy, which can then be used to power their operations or sold back to the grid.

Another promising approach is upcycling, where food by-products that would typically be discarded are repurposed into new, valueadded products. This not only reduces waste but also creates new revenue streams. For example, fruit peels can be converted into natural flavourings or dietary fibres, and spent grain from breweries can be transformed into protein-rich flour for baking.

Moreover, advancements in technology are playing a pivotal role in waste reduction. Automated sorting systems, for instance, can separate waste at the production line, ensuring that recyclable materials are properly processed. Additionally, precision agriculture and smart manufacturing techniques enable food producers to optimise resource use, reducing waste at the source.

Packaging waste is another significant concern in the food manufacturing industry. Single-use plastics and other nonrecyclable materials have long been a staple in packaging, leading to vast amounts of waste that are difficult to manage. However, the move towards a circular economy—where products and materials are kept in use for as long as possible—offers a sustainable solution.

Many companies are now investing in eco-friendly packaging alternatives, such as biodegradable materials, recyclable plastics, and reusable containers. For instance, plant-based packaging made from corn starch or sugarcane is gaining popularity due to its ability to decompose naturally without leaving harmful residues. In addition, some manufacturers are experimenting with edible packaging, which can be consumed along with the product, leaving no waste behind.

To further reduce packaging waste, companies are also adopting minimalist packaging designs that use fewer materials and are easier to recycle. These efforts are often supported by extended producer responsibility (EPR) programmes, where manufacturers are held accountable for the entire lifecycle of their packaging, from production to disposal.

Achieving sustainability in the food manufacturing sector is not a solitary endeavour. It requires collaboration across the supply chain, from raw material suppliers to retailers and consumers. Companies can work together to share best practices, invest in research and development for sustainable technologies, and create industrywide standards for waste reduction.

For example, food manufacturers can partner with packaging suppliers to develop more sustainable packaging solutions or work with waste management firms to improve recycling processes. Additionally, consumer education plays a crucial role in sustainability efforts. By informing consumers about proper recycling practices and the benefits of eco-friendly packaging, companies can drive demand for sustainable products and reduce waste at the consumer level.

Food safety is critical to the success of your business. Yet, in any drive to remain competitive, you could be sacrificing food safety for more efficiency, sustainability, and productivity.

Doing more with less - in less time, using less chemicals, and less water – is a constant pressure. Sometimes it feels an impossible challenge. Your hygiene program is already designed to meet/ exceed regulatory standards necessary to ensure food safety.

However, with water scarcity, climate change, and new product expectations, the requirements of retailers, consumers, and regulatory bodies are also changing, driving demands for higher standards.

• Meet higher standards with specific chemistryincreasing rinsing time and water consumption.

• Meet water savings targets - risking residues and wastewater costs.

• Aim to save time - and risk impacting hygiene standards.

Jeopardizing hygiene standards pursuing resource savings and production time, can lead to lower quality products, consumer dissatisfaction, and product recall.

If you’re reluctant to change traditional cleaning processes you’re limiting your potential to meet demands, and relying on outdated practices that deny new technology benefits. The right balance requires an innovative solution that challenges traditional cleaning procedures, while harnessing the power of innovation to deliver the results you need.

Cleaning procedures have always incorporated rinse steps. Prerinse, between steps, and a final residue removal rinse before production. What if, instead of a final rinse, you use naturally

occurring ingredients to remove this requirement, improve hygiene results, and eliminate the risk of biocide residues?

Divosan Dew’s innovative approach enables these choices. Its formulation removes final rinse requirements, without the risk of chemical residues associated with traditional biocides based on Quaternary Ammonium Compounds, Hypochlorite, or Akylamines.

Realizing water savings is a priority for any responsible producer. Divosan Dew’s rinse-free application and streamlined process saves water and time, with benefits from reduced wastewater, and less chemical components in your wastewater stream requiring further treatment.

Your cleaning cycle cuts into available production time with significant cost, especially if you have capacity constraints. Divosan Dew releases time back from your cleaning schedule, turning it into profitable production capacity, without impacting food safety. You can achieve reliable and substantial savings of up to 20% of time, water, and wastewater.

Changing to Divosan Dew is a controlled, thorough process leading to technological benefits, and peace of mind knowing you have the best current process for your specific circumstances. You can meet production requirements, stay competitive, and reduce consumption of resources and time – all without risking your crucial food safety standards.

Do more with less - Divosan Dew - Find out here https://www.solenis.com/en/Dew

Providing hygienic furniture and equipment for every stage of the changing room process, our innovative designs speed up the changing room flow and increase clean down efficiency. We break down some of our key hygienic design aspects below:

We use seamless welding techniques, such as electrochemical weld cleaning, to create smooth joins that eliminate crevices where dirt, bacteria and contaminants can accumulate.

Where possible, we have removed unnecessary flat surfaces where organisms can accumulate in favour for sloped tops. This small change to our cabinets, lockers and wash troughs makes a big difference in the fight against bacteria.

The majority of our furniture, equipment and accessories are made from 304L-grade stainless steel with the option to upgrade to 316L on request. This ensures that our products can withstand stringent hygiene processes with high chemical and corrosion resistance.

Call now on +44 (0)1603 788 833, visit teknomek.co.uk or email mail@teknomek.co.uk

Creating a sterile environment starts with the people

sterile environment people

with up to 15 operatives being able to progress through the station in one minute (depending on the hygiene station used).

with up to 15 operatives being able to progress through the station in one minute (depending on the hygiene station used).

Teknomek has partnered with ACO, one of the world’s leading commercial drainage specialists to create the UK’s only Hygiene First drainage kits. Instead of customers having to purchase individual components, the Teknomek kits contain all the elements needed to install drainage systems that enhance cleanliness and food safety.

with up to 15 operatives being able to progress through the station in one minute (depending on the hygiene station used).

with up to 15 operatives being able to progress through the station in one minute (depending on the hygiene station used).

fundamental aspect of the for the food sector in order audit-ready and compliant with regulations. To prevent crossenhance this should before reduce

Sanitisation is a fundamental aspect of the hygiene process for the food sector in order remain audit-ready and compliant with hygiene regulations. To prevent crosscontamination and enhance workplace safety, this hygienic focus should begin with staff before they enter the workplace environment.

Sanitisation is a fundamental aspect of the hygiene process for the food sector in order to remain audit-ready and compliant with hygiene regulations. To prevent crosscontamination and enhance workplace safety, this hygienic focus should begin with staff before they enter the workplace environment.

Offering a highly efficient solution

Offering a highly efficient solution

Apron washers and motorised boot washers are also available to suit your cleaning environment.

Apron washers and motorised boot washers are also available to suit your cleaning environment.

Like Teknomek, ACO is committed to reducing the risk of food contamination and optimising cleaning costs, two of the biggest priorities for the food industry. ACOs Hygiene First drainage channels and gullies reduce the risk of bacterial growth and accompanying bad odours, with an easy to clean design. The drainage systems have been designed to reduce the risk of water pooling and the associated hygiene problems that stagnant wastewater can cause.

enforcing strict hygiene protocols, employers can reduce risk of external contaminants entering zones where hygiene imperative. As solution to this, now offer a range of hygiene stations boot washers to help maintain hygienic standards across various environments.

Designed for hygiene-conscious industries, the boot washer can remove debris from the soles and sides of both high and low boots for the highest level of hygiene.

Apron washers and motorised boot washers are also available to suit your cleaning environment.

Designed for hygiene-conscious industries, the boot washer can remove debris from the soles and sides of both high and low boots for the highest level of hygiene.

So why is Hygiene First ideal for food processing facilities, especially high-care areas?

The ACO Hygiene First range is available in both 304-grade and 316-grade stainless steel and engineered with the highest standard of cleanliness and hygiene as its primary focus. This proactive approach aims to limit the possibility of harmful bacterial and pathogen contamination in food in compliance with BS EN 1672, BS EN ISO 14159 and EHEDG Document 8,13, and 44 for gully design.

By enforcing strict hygiene protocols, employers can reduce the risk of external contaminants entering zones where hygiene is imperative. As a solution to this, we now offer a range of hygiene stations and boot washers to help maintain hygienic standards across various environments.

The hygiene stations also offer a tool-free, quick and easy-to-remove brush system for effortless cleaning between shifts and maintenance. Spare brushes are also available to purchase from our website for use during the washing process.

Designed for hygiene-conscious industries, the boot washer can remove debris from the soles and sides of both high and low boots for the highest level of hygiene.

The hygiene stations also offer a tool-free, quick and easy-to-remove brush system for effortless cleaning between shifts and maintenance. Spare brushes are also available to purchase from our website for use during the washing process.

Preventing cross-contamination via staff cleaning processes

range of hygiene stations to help maintain hygienic various cross-contamination via processes

Michelle Locke, product and marketing manager at Teknomek, comments:

The hygiene stations also offer a tool-free, quick and easy-to-remove brush system for effortless cleaning between shifts and maintenance. Spare brushes are also available to purchase from our website for use during the washing process.

“As one of the world’s leading commercial drainage specialists, ACO understands the critical role that drainage

Preventing cross-contamination via staff cleaning processes

constructed from 304-grade or 316-grade stainless steel. Different versions are available for varying gully top sizes as well for both concrete and vinyl flooring

stations also offer a tool-free, quick and easy-to-remove brush system for effortless cleaning between shifts and maintenance. Spare brushes are also available to purchase from our website for use during the washing process.

The gully’s design prioritises hygiene, with all internal radii being equal to or larger than 3mm, significantly enhancing the effectiveness of cleaning. The hygienic joints formed by a deep-drawn body, ensure smooth contours eliminating any crevices that could potentially house harmful bacteria. The entire unit undergoes a thorough pickle passivation process, ensuring joints are free from corrosion, reducing crevices and potential bacteria traps.

Our range of hygiene stations provide an intuitive one step process to the changing room flow by combining hand sanitisation sole washing in one tidy package. With poorly washed hands and unclean footwear being two of the major sources of cross-contamination in the food industry, this automated equipment removes the possibility of human error and ensures that each staff member is suitably sanitised before proceeding through the turnstile to the next station.

hygiene stations provide an process to the changing combining hand sanitisation in one tidy package. With hands and unclean two of the major sources of cross-contamination in the food automated equipment possibility of human error and staff member is suitably proceeding through the next station.

equipment, employers cannot staff members are equally sanitised. These stations time-efficient solution

environment aspect of the sector in order compliant with crossstations maintain hygienic cross-contamination via provide an changing sanitisation package. With unclean sources of equipment error and is suitably through the employers cannot are equally stations solution

The vinyl edge gully is designed with an upper surface edge in-fill that helps to reduce movement in relation to the surrounding floor, thereby lowering the chances of floor cracks that could potentially house microorganisms.

The sanitisation process is a crucial aspect of hygienic environments, but it is not just restricted to the cleaning process of the equipment, staff can easily cause cross-contamination and the spread of bacteria without a focus on hygiene culture. The use of our hygienic equipment, such as our hygiene stations and boot washers, maintains an emphasis on hygiene and reduces the chance of human error or staff negligence via the implementation of an

Without this equipment, employers cannot certain that all staff members are equally effectively sanitised. These stations create a hygienic, time-efficient solution

The sanitisation process is a crucial aspect of hygienic environments, but it is not just restricted to the cleaning process of the equipment, the staff can easily cause cross-contamination and the spread of bacteria without a focus on hygiene culture. The use of our hygienic equipment, such as our hygiene stations and boot washers, maintains an emphasis on hygiene and reduces the chance of human error or staff negligence via the implementation of an automated process.

Teknomek’s ACO Hygiene First drainage channel kits are perfect when there is one point of drainage with a large water catchment area. They are available in either 630 or 1530mm length with a vertical or horizontal orientation and a 157mm or 218mm body diameter. The drainage channel kit with vinyl edge is perfect where one point of drainage with a large water catchment area is required on vinyl covered floors.

The sanitisation process is a crucial aspect of hygienic environments, but it is not just restricted to the cleaning process of the equipment, the staff can easily cause cross-contamination and the spread of bacteria without a focus on hygiene culture. The use of our hygienic equipment, such as our hygiene stations and boot washers, maintains an emphasis on hygiene and reduces the chance of human error or staff negligence via the implementation of an automated process.

Want to know how our hygienic equipment can speed up your hygiene flows?

Want to know how our hygienic equipment can speed up your hygiene flows?

Want to know how our hygienic equipment can speed up your hygiene flows?

Please call our Teknomexperts on

Please call our Teknomexperts on +44(0)1603 788 833

Hygiene First products are designed for easy inspection and maintenance including a fully removable and easily cleaned stainless steel foul air trap, which mitigates the risk of food particle accumulation and rodent entry and a slip-resistant ladder grating which is fully welded with rounded corners, it is designed to handle a load class of M125 which is ideal for heavy duty industrial areas subject to forklift traffic, such as; food processing areas, chemical or processing plants.

Please call our Teknomexperts on +44(0)1603 788 833

We have utilised over 30 years experience in the industrial cleaning sector to design and manufacture high performing cleaning equipment. Combine this with ease of use and British manufacturing and our cleaning apparatus is among the best available.

We believe in building products that find solutions to existing cleaning problems, improve ease of use and longevity of product life. Our commitment to quality has lead us to create the CHESS range of equipment which is fully interchangeable and is designed with you in mind. Parts can be integrated together to create a solution that is unique to your requirements.

• Established for over 30 years

• Our expert engineers design all products in-house and fully test them before adding our seal of approval for sale.

• The highest quality British manufacturing means your products have a much longer life than inferior imported equivalents.

• We continually evaluate, add, and develop our products so you can be totally satisfied that by using Central Hygiene, you are buying the best on the market.

Discover state-of-the-art solutions for the production of beer, wine, spirits and more at BrauBeviale in Nuremberg. Expand your network and discuss current topics. Be there when industry leaders set the course for tomorrow!

• Impulses from the BrauBeviale 2024 supporting programme

• Comprehensive presentation programme for the wine sector

BrauBeviale 2024, scheduled from 26 to 28 November in Nuremberg, is set to offer a comprehensive package for attendees, including a diverse exhibitor portfolio covering brewery, beverage, and wine sector technology. Complementing this, the conference programme promises to provide extensive insights and inspiration for industry professionals.

The forums in Halls 1 and 9 will serve as key platforms where experts from research and industry will discuss critical topics related to raw materials, marketing, technology, and packaging. In addition, special areas dedicated to Start-ups & Young Talents, Logistics, and Wine & Spirits will be available for visitors. A highlight of the event will be the Craft Drinks Area, a must-visit for craft brewers, and Hall 6 will once again host home and hobby brewers. Updated programme details, including confirmed topics and speakers, will be accessible from late August at www.braubeviale.com.

Hall 1 will focus on raw materials and marketing, aligning with the exhibitor offerings in this space. The forum here will tackle essential questions regarding raw materials, including discussions on climate-resilient barley varieties, the challenges of malt production amid climate change, and the potential of new hop varieties. Environmental protection and economic efficiency in hop cultivation, as well as future scenarios for yeast cultivation, will also be covered. These discussions will take place on 26 and 28 November 2024.

The marketing segment in Hall 1 will explore what it takes for a beer to succeed in the market, balancing the fine adjustments between marketing and technology. Topics will include innovative thinking for revitalising beer, the success factors behind beverage innovation, and lessons from successful brands and newcomers. This marketingfocused content will be presented on 27 November 2024.

Hall

In Hall 9, the focus will be on technology and packaging, under the guidance of the Verband Private Brauereien Bayern e.V., the conceptual sponsor of the exhibition. On 26 November, the programme will delve into “Energy efficiency for SMEs,” discussing sustainability in new building projects, energy management systems, and the use of heat pumps. Integrated energy concepts for SMEs will also be highlighted.

On 28 November, the forum will explore “Non-alcoholic beers,” focusing on the role of yeast in production, product development, and best practices from European Beer Star winners. Attendees will have the opportunity to engage with experts about the processes used in this segment.

Packaging will take centre stage on 27 November, with discussions on the preferences of young consumers regarding glass, metal, and composites. The implementation of the PPWR in various markets will also be addressed, providing an assessment of implications and solutions for beverage packaging in Europe. Marketing specialists are encouraged to attend on this day to gain insights into key areas of marketing and packaging.

Special Areas and Initiatives

Wine@BrauBeviale, located in Hall 4A, will provide a platform for winegrowers, featuring a varied programme focused on cellar technology, sustainability, quality assurance, wine marketing, distribution, operations management, and digital developments. The programme is supported by key players in the wine sector, including the German Winegrowers’ Association, LWG, Geisenheim University of Applied Sciences, and HBLA Klosterneuburg, Austria. The next generation of winemakers will also be a focal point, with an innovations-forge dedicated to young talent.

Following its successful debut in 2023, the LOGISTICS LOUNGE returns, doubling in size and emphasising “The efficiency of reusable logistics.” The lounge, now centrally located, will feature a wide range of digital solutions, particularly for the digitalisation of logistics processes. The participation of diverse partners from logistics and digitalisation sectors will enrich the offering.

The Craft Drinks Area will once again be a vibrant space for professional tastings, discussions, and the presentation of the winning beer from the Maisel & Friends hobby brewing competition. Additionally, the recruitment of young talent remains a pressing issue, which is why the Start-up Area and Young Talents Camp have been integrated into Hall 6, providing a dedicated forum for these groups to connect and explore opportunities within the beverage production and machine manufacturing industries.

Free entry to BrauBeviale 2024 voucher code BB24UK

Yakult announces a new addition to its range of fermented milk drinks –Yakult Plus Peach which will be on sale from 1st September 2024.