Q&A with a Weld Australia

Member: Hayden Fox Page 32

Q&A with a Weld Australia

Member: Hayden Fox Page 32

14

The WHAT-ME Project What began as a discussion on the health and safety of pregnant welders in a Canadian Standards Association conference room in Toronto in early 2002, finally became an accredited, published work over 20 years later on 30 April 2022.

22

Leading New South Wales Steelworks Goes Nationwide Rose Valley Steel Works provides a variety of metal fabrication services. Thanks to a recent upgrade of its welding technology and gas use with the help of BOC Gases, the company is taking a national focus.

32

Q&A with a Weld Australia Member: Hayden Fox Hayden completed his apprenticeship with Bridgeman and is now a qualified tradesperson, recognised as one of Bridgeman’s best welders. Hayden won Weld Australia’s 2022 Young Indigenous Tradesperson of the Year.

Reimagined Welding Platforms Deliver Performance Boost

38

WIA’s 2023 range Stick, MIG and TIG welders incorporate new operating platforms that provide full digital control over the welding process for efficiency and precision. 40

How Automation Can Help Solve the Imminent Squeeze for Infrastructure

Australia will soon be facing huge demand for infrastructure, amid welder shortages. Fabrication are looking at robotic welding to help solve this challenge 46

Australian Standards in Protective Clothing

A number of serious incidents involving welders’ cotton drill clothing catching fire have been reported to Weld Australia. The use of welders leathers is highly recommended.

34 A&B Welding: Opportunities Abound in the Northern Territory

National Office PO Box 197 Macquarie Park BC NSW 1670 02 8748 0100 office@weldaustralia.com.au weladustralia.com.au

Chief Executive Officer Geoff Crittenden 02 8748 0100 g.crittenden@weldaustralia.com.au

ENGINEERING

Victor Blain, Engineering Team Manager 0409 823 991 v.blain@weldaustralia.com.au

TRAINING

Guy Brooks, Training Manager 0488 743 322 g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, National Manager, Sales & Marketing 0437 106 726 m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION Deniz Yalniz, Qualification and Certification Team Manager 0487 487 170 d.yalniz@weldaustralia.com.au

Subscription to Australian Welding is a Weld Australia member benefit included in annual membership fees. All rights reserved. No part of this publication may be reproduced or copied in any form without the written permission of Weld Australia. Weld Australia and its agents are not responsible for statements or opinions expressed by contributors in this publication, which are not necessarily those of Weld Australia. Publication of any advertisement does not constitute endorsement by Weld Australia of any product, nor warrant its suitability.

Weld Australia will embark on Joint Accreditation System of Australia and New Zealand (JAS-ANZ) accreditation for our AS/NZS ISO 3834 Quality requirements for fusion welding of metallic materials scheme. JAS-ANZ accreditation confirms that you have been approved by an independent third party as a professional conformity assessment body that acts with integrity when certifying or inspecting for conformity assessment.

In 2023, Weld Australia will focus on several areas, including expanding its certification services, and introducing a Welding Supervisor and Welding Inspector licensing scheme. We will also continue to deliver quality training, services and events to our members.

Welcome to a new year and the first edition of Australian Welding for 2023.

As always, Weld Australia’s activities in 2023 will be guided by our vision and mission; our primary goal is to ensure that the Australian welding industry remains locally and globally competitive, both now and into the future. We have a host of exciting plans for the year ahead.

Over the next 12 months, Weld Australia plans to expand its certification services. We are looking at introducing certification services for AS/NZS ISO 9001 Quality management, AS/NZS ISO 14001 Environmental management, and AS/NZS ISO 45001 Occupational health and safety management

We will look to strengthen and grow our partnerships with TÜV and IAS: IIS, expanding into additional areas of certification. We currently partner with TÜV to deliver DIN 2303 Welding and allied processes - Quality requirements to be met by production and maintenance companies for military products certification; and with IAS: IIS to deliver EN 15085 Railway applications — Welding of railway vehicles and components certification.

Weld Australia is committed to ensuring that no Australian lives are lost through an accident caused by non-compliant welding, without causing undue regulatory burden on industry. As such, in 2023, Weld Australia will commence work on establishing a licensing scheme for Welding Supervisors and Welding Inspectors.

There is currently no mandated licensing system for welders, Welding Supervisors or Welding Inspectors in Australia. And yet, to carry out electrical or plumbing work in Australia, tradesmen must be licensed. Similarly, in Europe and North America, not only is compliance with International Standards mandatory, it is also compulsory that all welding is carried out by a qualified and certified welder.

Working in collaboration with the National TAFE Consortium, Weld Australia has made great progress this year with the development of nationally consistent online learning resources for the Metals and Engineering (MEM 2.0) training package. In a very important step for

the entire industry, these learning resources will be launched in 2023.

In Western Australia, South Metropolitan TAFE has already adopted the use of these resources, and there are plans to do so on a state-wide basis. We are hopeful that all the other TAFEs that have participated in their development will do likewise. This represents a huge overhaul of welder training in Australia. It will help ensure consistent welder training, regardless of where in the country students undertake that training. The new resources are completely online and accessible via phone, mobile device or computer. This will allow students to access learning at the time, place and pace that suits them best.

Following on from a successful return to in-person events this year, Weld Australia will strengthen its calendar of events in 2023. In exciting news, the Weld Australia team is working with The Australia Institute - Centre for Future Work on a major conference. To be held at Parliament House in Canberra, the theme of the conference will be Renewable Energy Manufacturing.

In conjunction with the 76th Annual Assembly of International Institute of Welding (IIW), the Singapore Welding Society (SWS) will host the International Conference on Advances in Welding, Joining and Additive Manufacturing.

The Conference will be held from 16 to 21 July 2023 at the Marina Bay Sands. The event aims to provide a platform for knowledge exchange and networking among scientists, researchers and industry experts in the field of welding and joining.

Presentations will cover topics such as: mirco and nano joining, cold spray technology, additive manufacturing, laser welding, numerical modelling of welding process, non-destructive testing, and fatigue, fracture and corrosion of welded joints.

For further information or to register for IIW 2023, visit: iiw2023.com

Weld Australia has welcomed the Federal Government’s New Energy Apprenticeships program, and the updated Australian Apprenticeships Priority List. The financial support provided by the initiatives will be a drawcard for some businesses and apprentices. However, according to Weld Australia, much more must be done to tackle the nation’s deficient of skilled welders. Weld Australia is calling for a radical three-pronged approach to overcome the nation’s skilled welder shortage that includes: an overhaul of welder training; a focus on STEM training in schools; and investment in TAFEs nationally.

There is no magic solution to Australia’s skills crisis. We need a radical approach. The same old approach that we’ve taken for years will not arm Australia with the skilled workers needed to deliver the record number of projects we’re seeing in industries like defence, renewables and infrastructure.

A veritable army of skilled workers, including welders, will be required to build and install the infrastructure needed to achieve the Federal Government’s 43% emissions reductions target by 2030 and net zero by 2050. Unless action is taken now, Australia will be at least 70,000 welders short by 2030.

It truly is the definition of insanity: doing the same thing over and over again, and expecting different results.

The Federal Government has committed to spending over $95 million to support 10,000 new apprenticeships under the New Energy Apprenticeships program, and another $1 billion on a 12-month Skills Agreement that promises to deliver 180,000 Fee-Free TAFE places to priority groups in 2023. While these initiatives will provide

welcome financial incentives for both employers and their apprentices, this is just one small piece of the puzzle. These initiatives alone will not solve the skills crisis.

The Federal Government appears to have given little thought to encouraging young people into an apprenticeship. It’s all well good offering fee-free TAFE places—so long as they are filled. This is why STEM training in schools must be a focus. We need to educate kids, and their parents, so that they understand all the opportunities a career in STEM can deliver.

STEM training in schools must be refocused to showcase the opportunities in trades and encourage women and other underrepresented groups into careers in STEM. Weld Australia has been working with the New South Wales Department of Education for the past three years on an Advanced Manufacturing School Outreach Program for schools.

This program relies upon the use of augmented reality welding simulators to give kids a real welding experience.

Weld Australia proposes that this Program be rolled out nationally.

Despite the Federal Government announcing funding for 190,000 TAFE places nationally, there has been no additional funding allocated to TAFEs to enable the delivery of training for all these additional places. Governments must invest in TAFEs nationally so that apprentices receive the best training possible, ensuring that they are job-ready and actually complete their apprenticeships.

National data reveals that just 54% of trade apprentices who started in 2017 completed by the end of 2021, down from 57% of those who started a year earlier. One in three drop out in their first year.

TAFE requires proper funding to invest in new technology and equipment that better reflects what is in use in industry. Not only will this better prepare graduates for the workplace, it will also keep them engaged and should see completion rates improve. TAFEs also require funding so that they can employ the best possible teachers—people who are passionate about the trade and

understand the industry.

It is imperative that sufficient investment be made in the TAFE system to ensure that it is a world class technical teaching organisation capable of meeting Australia’s demand for skilled tradespeople. Weld Australia proposes that funding properly reflect the cost of infrastructure, equipment, time, and materials required to teach to internationally recognised Standards.

A welding apprenticeship currently takes three years to complete. This means that new welders will not be qualified until at least 2026 and, even then, will not be skilled or experienced. We simply won’t have the skilled welders required to build and instal the green energy infrastructure to meet the 2030 targets.

This is why Weld Australia proposes that the current welding apprenticeship is condensed into one year.

The existing Certificate III in Engineering (Fabrication) is a nominal 720 hours of face-to-face teaching

at a TAFE interspersed with practical experience in the workplace via an apprenticeship. This is spread over three years. If this was condensed into one year, the existing training package would remain unchanged but would be taught in two 24-week blocks consisting of 14 weeks of face-to-face training, and 10 weeks of Structured On the Job Training (SOJT) in the workplace.

Once an apprenticeship is complete, competency will be assessed and the Certificate III qualification awarded. Graduates will then be required to qualify to ISO 9606, the internationally recognised standard for welding competency. The shorter course will be less daunting to school leavers and will encourage mature aged applicants. Training will be more intensive and is therefore likely to be more efficient. The number of apprentices graduating should increase, and the skills of welders should increase dramatically.

Welder training courses also need to be overhauled. The TAFE welding course and curriculum has not been updated or revised since 1998. It is a wonder that new welders complete their training, based as it is on theory

“ There is no magic solution to Australia’s skills crisis. We need a radical approach. The same old approach that we’ve taken for years will not arm Australia with the skilled workers needed to deliver the record number of projects we’re seeing in industries like defence, renewables and infrastructure.”

and textbooks which hardly relate to the work they hope to make into their career.

Welding is an exciting, innovative, and dynamic industry – but the training offered to aspiring welders is dry and static. As covered above, this situation is no way the fault of TAFEs, or of TAFE teachers; they are at the mercy of the government funding merry-go-round.

Weld Australia is already working to overcome this situation. We have designed and released advanced learning resources mapped to the national Metals and Engineering (MEM) the MEM training package. These new resources are completely online, allowing students to access learning at the time, place and pace that suits them best. Highly interactive and featuring the latest technology, these learning resources keep kids engaged and enthusiastic.

These resources are already in use in several TAFEs in Western Australia, but need to be rolled out nationally.

The Federal Government recently added an extra 39 occupations to the Australian Apprenticeships Priority List. The list has grown to encompass 111 occupations, as Australia continues to struggle with skills shortages across a range of different sectors—particularly welding and fabrication.

Several occupations related to welding and fabrication were added to the Priority List, including Welder, Pressure Welder, Fitter, Metal Fabricator, Metal Machinist, Metal Casting Trades Worker, Sheetmetal Trades Worker, and Blacksmith. In fact, 11% of the occupations included in the Priority List are now related to welding.

Occupations on the Priority List are eligible for financial support through the Australian Apprenticeships Incentive System. A wage subsidy of 10% is provided to businesses in the first and second year, and then it drops to 5% in the third year. Up to $5,000 in direct payments is made to apprentices across two years.

The skills crisis is not unique to Australia; the US fabrication industry will face a shortage of 500,000 welders by 2030, and by 2050 Japan will need around 250,000 welders. This means that we cannot rely on skilled migrants to fill workforce vacancies, nor can we import wind towers and other green energy infrastructure—global capability is at capacity.

This global shortfall of welders is driving most developed nations to implement extraordinary measures to resolve it. Australia must follow suit. We need a practical, actionable plan that can be implemented now to overcome the welder skills shortage—a plan that delivers more than just financial support to employers.

We must take three key actions to overcome the nation’s skilled welder shortage: welder training courses must be overhauled; STEM training in schools must be a focus; and our governments must invest in TAFEs nationally.

The House Standing Committee on Industry, Science and Resources has launched an inquiry into advanced manufacturing, with the aim of supporting Australian industry, creating jobs and reviving Australia’s ability to make world class products.

According to Committee Chair, Rob Mitchell MP, “Supporting the growth of advanced manufacturing is about enhancing the things we do well by taking advantage of new and improved processes.”

“We need to ensure that we are well-positioned as a nation to take advantage of new technologies, and that our strategic decisions are informed by the right data. We want to hear from stakeholders across industry, our tertiary sector and government about what it will take to make things better – and how we can ensure reliable growth within Australia’s manufacturing sector,” said Mitchell.

Submissions for the Inquiry into Developing Advanced Manufacturing in Australia are now open

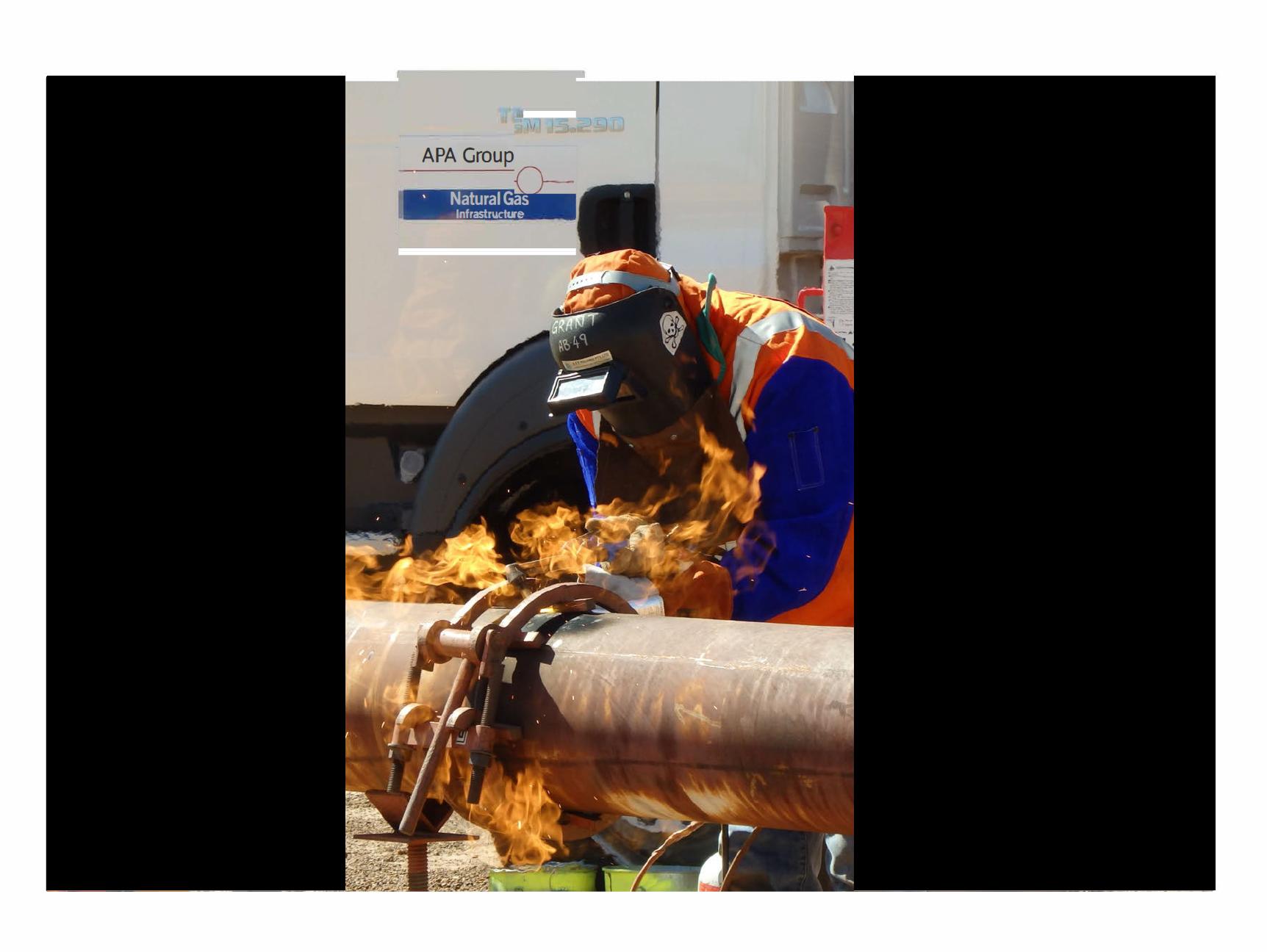

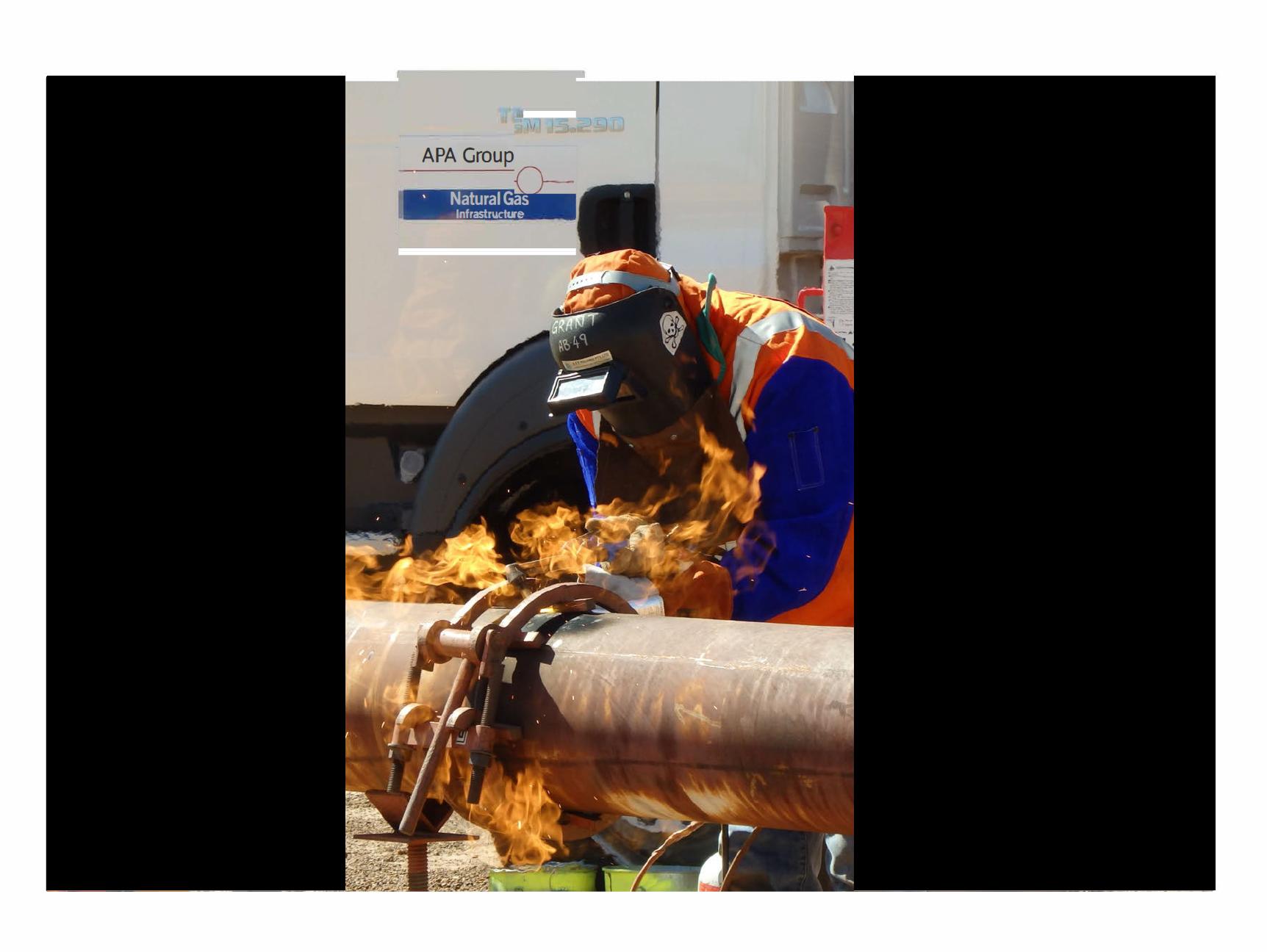

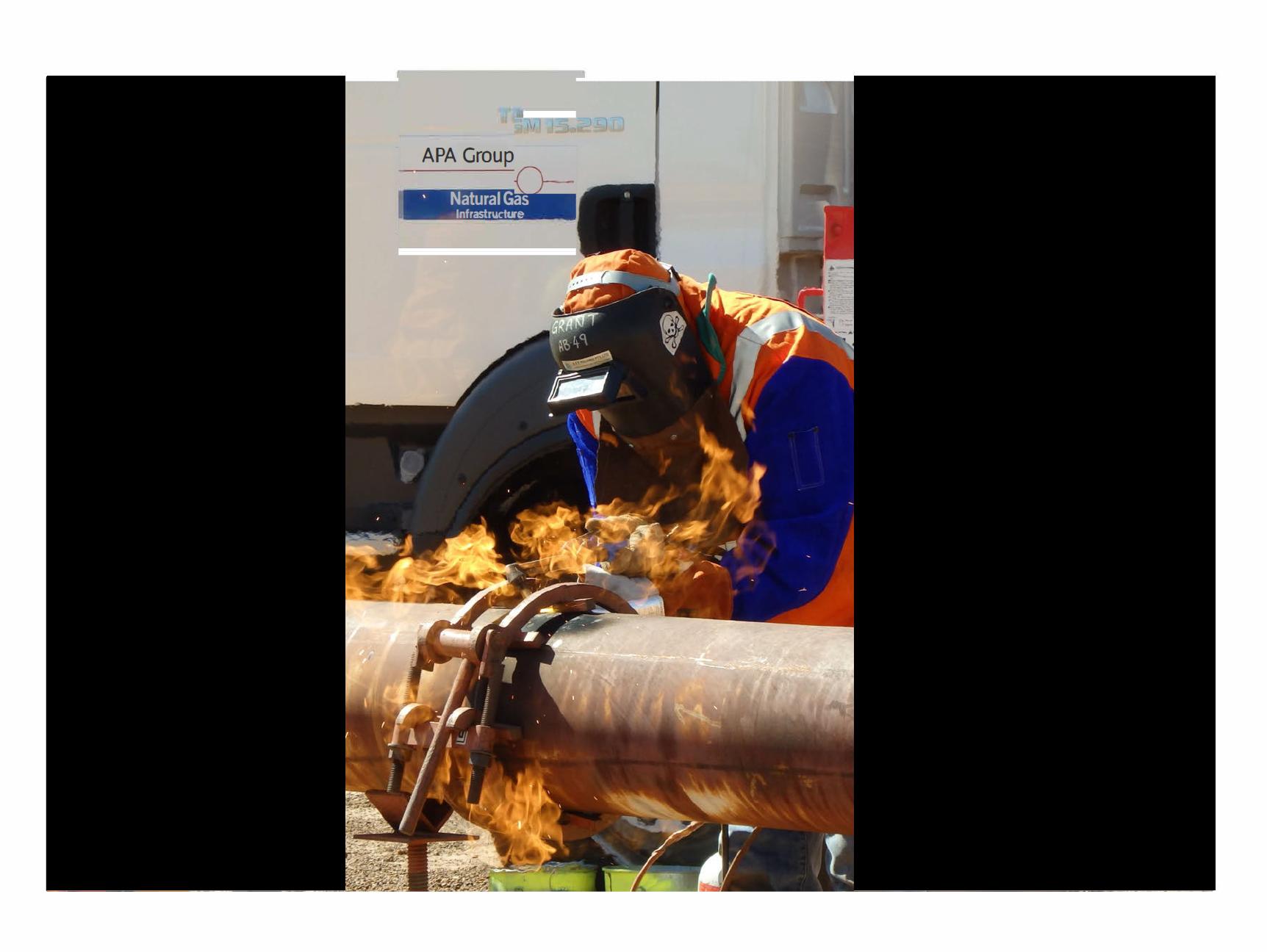

The Queensland Government recently announced that the $983 million Fitzroy to Gladstone pipeline is officially approved for construction.

The Fitzroy to Gladstone Pipeline will deliver water security to the Gladstone region to support job creating industries. Hydrogen proponents under development with future water requirements include the Fortescue Future Industries hydrogen electrolyser manufacturing facility, Mitsubishi Gas’ hydrogen to green methanol plant, the Stanwell / Iwatani Central Queensland Hydrogen Project, Orica and H2U’s green ammonia plant, and Rio Tinto and Sumitomo’s hydrogen plant.

According to Premier Palaszczuk, “Nearly $1 billion has been committed to this important project, which guarantees water security and sends a powerful signal to the hydrogen sector that Queensland is the place to be for clean energy. Gladstone will be the engine room when it comes to delivering our landmark Queensland Energy and Jobs Plan – that means good secure jobs now, and into the future.”

Shipbuilding unions have called for the Federal Government to build conventional submarines in Australia to protect local manufacturing and defence capability.

A recent report released by the Australian Shipbuilding Federation of Unions (ASFU) calls for urgent political action to build at least four, and up to six conventional submarines commencing by 2026. This would create up to 2,500 secure jobs.

The report states this will fill a capability gap between when the Collins-class submarines reach their end-of-life and the nuclear-powered vessels arrive in up to three decades, as part of the AUKUS arrangement.

The dumping of the French Naval Group deal has left the local shipbuilding industry in jeopardy and thousands of jobs at risk while we wait for the nuclear-powered vessels, according to the ASFU. The report adds that seven in ten Australians say submarines should be built in Australia, even if they will cost more.

Registrations are open NOW for Australian Manufacturing Week (AMW2023) at the Melbourne Convention and Exhibition Centre (MCEC) from 9 to 12 May 2023. Organised by the Australian Manufacturing Technology Institute Limited (AMTIL), AMW2023 will occupy more than 10,000 square metres of exhibition space at the MCEC, with almost 300 organisations taking stands to showcase the latest manufacturing technologies, processes, and support services.

There will be seven zones at AMW2023, which will occupy almost all of the vast floorspace at the MCEC. Each zone will focus on a specific aspects of manufacturing in Australia. The zones include:

• Austech Machine Tools, sponsored by ISCAR

• Additive Manufacturing Zone

• Australian Manufacturers Zone, sponsored by Sutton Tools

• Manufacturing Solutions Zone, sponsored by Adobe

• Robotics & Automation Zone

• Weld and Air Solutions Zone, sponsored by AtlasCopco

• Plastic Technology Zone

Sponsored by Atlas Copco, the Weld & Air Solutions Zone will highlight advanced welding processes, and provide high-quality interactive experiences that demonstrate developments and applications in the welding sector. Welding is critical in metal fabrication and manufacturing today. In fact, it is used in creating more than half of the products manufactured in Australia. Welders, cutters, solderers, and brazers use hand-held or remotely controlled equipment to join or cut metal parts.

Attendees can expect to see demonstrations, technology and equipment covering all the various types of welding at AMW2023, including Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), Shielded Metal Arc Welding (SMAW) and Flux Cored Arc Welding (FCAW). With such an extensive array of technologies on display, AMW2023 is the place to be for all welding enthusiasts and professionals.

For the duration of AMW a Future Solutions Speaker Program will be on the expo floor and will have over 30 speakers covering various topics around 3D printing, new and emerging technology, research and development, manufacturing success stories and more. This Program is free to attend and is located on the floor of the AMW exhibition.

Australian Manufacturing Week 2023 will take place at the Melbourne Convention and Exhibition Centre (MCEC) from 9 to 12 May 2023.

Don’t miss out! Register online now: australianmanufacturingweek.com.au

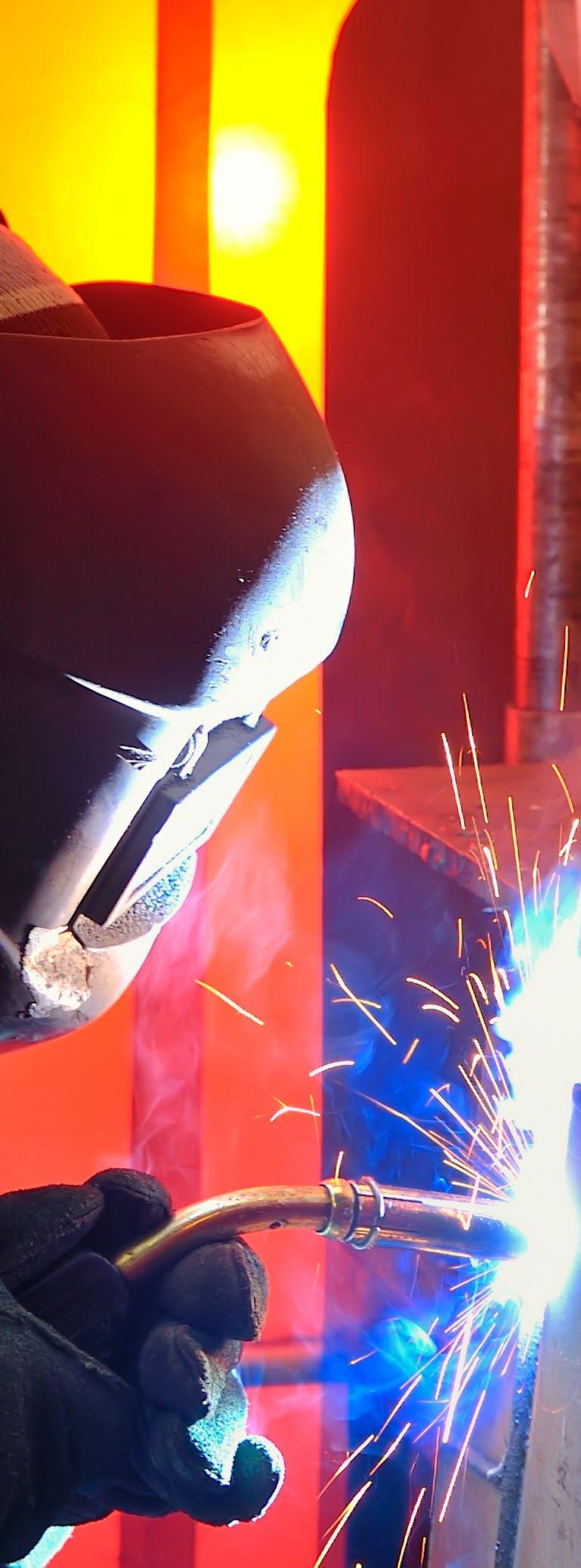

There is nothing more important than safety. And yet, in 2022, 16 manufacturing industry workers died as a result of workplace injuries. Another 14,663 workers lodged serious claims as a result of workplace injuries. Manufacturing took out the dubious honour of the third most likely industry for serious worker injuries in Australia. Workplace health and safety can—and should—define a whole raft of actions within the manufacturing and welding industries.

Welders and their employers cannot optimise operations, improve productivity and efficiency, or alter procedures without taking health and safety into account. Safety must be the number one priority for every manufacturing industry worker, particularly welders.

Welding can and should be considered a safe occupation; when proper precautions are taken, welders have no cause to fear accident or injury. But when safety isn’t taken seriously in the workplace, welders face a range of potentially dangerous hazards that can cause burns, electric shock, and even fatality.

Within the last few months alone, Weld Australia has been made aware of various accidents and incidents that have seen welders sustain serious injuries. In some instances, the welders were hospitalised for assessment and treatment, with one requiring two skin grafts. While they recovered, this was more by luck than judgement.

There is a common misconception in industry that cotton clothing is appropriate and safe to wear while welding. While cotton drill is a dense, heavy fabric, it is simply not flameresistant unless treated—it will ignite and burn. There have been several incidents recently across Australia in which welders’ cotton drill clothing has caught fire, causing serious injuries such as second degree burns.

Synthetic materials such as nylon and polyester are difficult to ignite, however, when heated, severe melting occurs and the material can adhere to the skin. For this reason, synthetic materials are not suitable to wear when welding. Welders need to be mindful of this when selecting undergarments.

Welders must wear outer garments that have a fire resistant rating or use welders’ leathers. Weld Australia’s Technical Note Health and Safety in Welding outlines further details.

In recent years, the welding industry has become increasingly aware of the hazards posed by metal fume produced during the welding process. This fume, comprising of microscopic particles of hot metal and gases, poses serious risks when inhaled by welders.

Some of the known health effects caused by welding fume exposure include fever, stomach ulcers, kidney damage and damage to the nervous system. Welders can suffer from asthma, eye, nose and throat irritation, and even lung infections that can lead to pneumonia. In early 2017, the International Agency for Research on Cancer classed welding fumes as ‘Carcinogenic to Humans’. It is vital that appropriate strategies are in place to reduce welder exposure to fumes and prevent the long-term health effects that can result from exposure.

All welders should receive training on methods to mitigate the effects of weld fume, including positioning themselves to reduce exposure and investigating less toxic alternatives where possible.

Local Exhaust Ventilation (LEV) systems and on-torch stems capture and extract welding fume at or close to the source and are a proven way of reducing exposure. All workplaces should have fit-for-purpose LEV systems installed and regularly maintained. In addition, welders should use Powered Air Purifying Respirator (PARP) helmets to minimise their exposure to weld fume. These helmets pull contaminated air through an intake filter on a belt worn by the welder. The air is pushed through a filter that traps contaminants, cleaning the air. The clean air is then pumped up to the welder’s face creating a positive pressure and excluding contaminated air so that they can breathe clean air while welding.

Weld Australia’s Technical Guidance Note Fume Minimisation Guidelines: Welding, Cutting, Brazing and Soldering includes all the information required to help protect workers from the hazards associated with welding fumes.

Electrical safety is another area which must be seriously considered when reducing risks to welders. Electricity is a vital part of welding work, but when mishandled it can result in serious injury and death.

Electric shock remains a consistently significant issue, particularly among maintenance welders and those using Manual Metal Arc Welding (MMAW). All too often, the voltage reduction device is switched off, leading to electric shock. Why? Because, time and again, it is reported to Weld Australia that the electrodes are too difficult to start when a voltage reduction device is in use. This is simply incorrect—with the correct arc striking techniques in place, there will be minimal (if any) impact on starting the electrodes.

All welding professionals need to familiarise themselves with processes to minimise the risk of electric shock. Simple actions such as checking that equipment

is dry and well maintained, installing shut down mechanisms like fuses and low voltage safety switches, and using voltage reduction devices can save lives. Weld Australia’s Technical Guidance Note Welding Electrical Safety includes further details.

Weld Australia is working to educate companies and individuals on the risks associated with welding. We are working to offer sensible, practical, cost effective solutions to help minimise these risks.

In 2019, Weld Australia established the Welding Safety Council to provide a forum for industry and legislative safety authorities to identify solutions to safety problems. The mission of the Council is to maintain the infrastructure required to identify and analyse welding risk and formulate and execute mitigation strategies.

The Welding Safety Council is currently addressing several areas of concern, including protective clothing, electric shock, and the dangers of welding fume, as well as hand held laser welders and the lack of standards and regulations around their use.

The Weld Australia website was recently reconfigured to enable the issue of Safety Alerts. These Alerts will draw attention to welding safety incidents, including the known causes of the incident and what steps can be taken to help prevent a similar incidents occurring.

Weld Australia is developing two comprehensive online training courses designed to improve safety outcomes across the country. One course is tailored for welders, while the other is aimed at welding engineers and supervisors. These courses cover a raft of activities across a range of welding processes, from electric arc welding and flame cutting, through to topics like welding in confined spaces, at heights, or in hot and humid conditions. These courses will be completed towards the end of this year and made freely available via the Weld Australia website.

In 2023, Weld Australia’s goal is to help ensure every welder makes it home safely at the end of every day.

What began as a discussion on the health and safety of pregnant welders in a Canadian Standards Association conference room in Toronto in early 2002, finally became an accredited, published work over 20 years later on 30 April 2022. The research study demonstrates that female welders, whether pregnant or not, can continue in their chosen profession of welding, so long as all Health and Safety Standards are followed, and the workplace is as safe as possible for all welders.

The discussion originated from a concerned program administrator at Keyano College in Alberta, Canada. The administrator asked: What are the hazards to my possibly pregnant welder apprentices?

She was concerned about her apprentice welders, who she was placing into welding shops and other workplaces in an oil sands mining environment. This environment features heavy fabrication, and the installation of a large volume of hard facing. The fumes and particles associated with these projects was a real concern to the program administrator. With oil sands mining typified by a very high wear rate environment, the welding trade was in high demand. Women were filling the roles, and some fell pregnant while working as a welder.

The common practice for many workplaces in Canada in 2002 was to move the pregnant welder to other work, or remove them from the worksite entirely. As an apprentice welder, this disrupted their training. For some, it meant joining the unemployment line. Neither option was acceptable.

This paper became the closing argument in a series of nine papers published by Dr Nicola Cherry and her team from the University of Alberta, in Edmonton, Canada. The paper closed out the What-Me Project study; Pregnancy Outcome in Women Exposed to Metal Fume in Welding:

A Canadian Cohort Study1. What-Me is an acronym for Women’s Health in Apprenticeship Trades – Metalworkers and Electricians.

While the study was initially a femaleonly study, Alberta Labour soon realised that we would understand more about female welders than we did about male welders. And so, an Alberta only study on male welders was begun and funded by Alberta Labour. Now we were monitoring males and females in both welding and electrical trades in Alberta, while the female-only study continued across Canada.

Women, and the foetus if they become pregnant, may face poorly documented hazards as they move into work traditionally carried out by men. Welding tasks entail heavy physical and ergonomic demands, together with exposure to metals and particles in welding fume. There have been few studies of such working conditions on the foetus. This study shows that exposures in welding may result in fetal loss and shorter gestation, with manipulating heavy loads, whole-body vibration, and perceived intensity of noise and heat exposure being more important

than welding fume in determining pregnancy outcome. Ergonomic interventions to reduce workplace hazards would improve conditions for pregnant welders.

Recruitment questionnaire was completed by 885 women and 1,000 men. There were 447 female and 554 males in the welding category. The comparison cohort were electricians, comprised of 438 females and 446 males. Female welders from all Canadian provinces and territories were recruited, with 69.8% of the 447 women welders coming from the province of Alberta.

This study is unique in that it progressed in real time and followed the women for five years. Approximately two years were spent in program development. Then, on 8 January 2011, the first female welder completed her questionnaire. Follow-up continued until 27 August 2018. The questionnaires enabled the collection and tabulation of detailed information.

While working actively in the welding

trade, 234 pregnancies occurred and information on ergonomic information was available for 144 of those pregnancies. Information was gathered to allow welding fume exposure estimates for 122 pregnancies.

Initally, numbers were the problem. There just weren’t enough female welders in 2002 for a representative sample size. However, in late 2009, Alberta Labour announced that they had just signed the 1,000th female welder apprentice. Dr Cherry responded immediately; she would begin work on the study.

The official findings state: “The study was unable to show an independent effect of exposure to metal fume constituents.”

“In this group of women actively engaged in welding during the time surrounding conception, the outcome of pregnancy was strongly related to work exposures, particularly vibration (reported in grinding tasks), manipulation of heavy objects, and perceived intensity of noise and heat.”

Among welders, this study identified that fetal loss increased with whole body and hand arm vibration. In the electrical trades, fetal loss increased with work schedules of greater than eight days without a rest day.

Given the findings of the study, it is essential that both male and female welders follow all relevant Health and Safety Standards. The Canadian Welding Standards will soon be adding an Annex to their relevant

Standard ( CSA W117.2 Safety in Welding Cutting and Allied Processes) to put the learnings contained in this series of papers into an easy-tounderstand format.

Keep in mind that jurisdictional guidelines for welding fume exposures are steadily decreasing, wearing the correct head gear, and breathing protection is of paramount importance. A study presented at the recent IIW Commission VIII conference at Tokyo3 demonstrated that a Powered Air Purifying Respirator (PAPR) is shown to be the best breathing protection for all types of welding. NOTE: PAPR is not recommended for use in confined spaces.

To reduce and end welder death by electrocution from welding machines, we have collected fatality statistics for over 30 years. In that time, no data on the death of a female welder from electrocution has been found –we would very much like to see that trend continue.

The interpretation of this author is that female welders, whether pregnant or not, can continue in their chosen profession of welding, while striving to make the workplace as safe as possible for all welders.

References

1 Jean-Michel Galarneau, Jeremy Beach, Nicola Cherry, Pregnancy Outcome in Women Exposed to Metal Fume in Welding: A Canadian Cohort Study, Annals of Work Exposures and Health, 2022, wxac024, https://doi.org/10.1093/annweh/wxac024

2 Health Effects of Welding and Cutting Fume – an update Gary M Liss MD. MS. FRCPC Ontario Ministry of Labour 1996

3 Experimental Study of Measures Preventing Welders from Fume Exposure (VIII2344-22) by Stephan Egerland

Dave Hisey is now retired and lives in Drumheller, Canada. Currently, chair of the T/C for CSA W117.2; chair of CSA C232 (CSC26) Electric Welding Equipment and a member of national Canadian Electrical Code CSA C22.1. He also represents Canada on Commission VIII Welding Health and Safety with the International Institute of Welding. A volunteer, Dave, is sponsored in this work by the CWB Group. Please contact him via drhisey@shaw.ca with your comments on this article, if you have questions on welding safety, or if membership on CSA W117.2 or CSA C232 technical committees is desired.

BAE Systems is progressing the world’s most advanced antisubmarine warfare frigate and building a critical industrial capability that will contribute to keeping our country safe for generations.

We face increasing geopolitical tension in the region and continuing uncertainty in global supply chains. Developing a strong sovereign shipbuilding capability will grow Australia’s industrial resilience.

We have seen how important it is to maintain a stable supply of data and power often provided by undersea cables. At the heart of the Hunter frigate is the latest anti-submarine warfare technology - specifically designed to detect, deter and defend against such offensives.

We have always been confident in our

ability to deliver the Hunter program successfully and this is reinforced by the quality of the work being achieved already by our highly skilled workforce.

Shipbuilding has undergone a digital revolution and we have invested in upskilling our workforce to adopt modern techniques that are both cost effective and provide for a safer and more efficient work environment.

A key focus is Australia’s first digital shipbuilding course, the Diploma of Digital Technologies. This equips our employees with digital skills for modern shipbuilding, combining classroom theory with hands-on skills.

Using smart, advanced manufacturing and bringing streamlined, data-driven efficiencies to ship design and build processes also helps to attract the next generation of shipbuilders –‘digital natives’ who expect to connect with technology in the workplace.

Growing an industry requires innovation and through digital shipbuilding, we will attract a new cohort of STEM students who want to design, build and support new technologies and equipment that helps protect our nation.

At the Osborne shipyard, we recently developed a digital twin of our ship build process. By analysing the data produced by our manufacturing equipment, we can connect and convert the information into valuable predictive outcomes.

Smart algorithms run simulations and we compare this information to our existing schedule, cost and capability decisions. This has resulted in an ever-increasing optimised build program that gives greater certainty of outcomes.

At the Factory of the Future, within the Tonsley Innovation District in South Australia, we are collaborating

The Hunter class frigates are based on BAE Systems’ Type 26 Global Combat Ship design, currently being constructed in Glasgow, Scotland, for the United Kingdom’s Royal Navy. The nine frigates are being modified to meet the Royal Australian Navy’s operational requirements. These modifications include incorporating the leading-edge Australian CEA phased-array radar, the Aegis combat management system and the integration of the Seahawk Romeo Maritime Combat Helicopter.

Each warship will be constructed on an acoustically-quiet hull and feature unique sonar capabilities, modular digital design and open systems architecture to facilitate through-life support and upgrades as new technology develops. The formidable fleet is being designed for maximum versatility and flexibility in operational roles, from humanitarian and disaster relief operations to high-intensity warfare. The integrated mission bay and hangar is capable of supporting multiple helicopters, unmanned vehicles, boats, mission loads and disaster relief stores. A launcher can be provided for fixed-wing unmanned aerial vehicle operation, and the flight deck is capable of landing a Chinook helicopter.

with researchers, academia and industry partners to test manufacturing technologies before adapting them into the shipyard. Across all areas of our Maritime business, we have learnt and achieved so much very quickly and we’re gaining more confidence as we refine and extend the boundaries of advanced manufacturing.

I am very proud of the ingenuity of our team who took on challenges – like the COVID-19 pandemic and global supply chain issues – as opportunities. The team found new ways of working, embraced innovation and adopted digital technologies to progress the program.

When we move from prototyping to building the first Hunter frigate blocks in May 2023, we will have accelerated the program by some 12 months than previously announced in 2021. These blocks will become part of the very first Hunter frigate.

This is an enormous achievement for our workforce and showcases their incredible skill and adaptability. It also reflects our growing confidence in the technology we’re using which is producing exceptional results. We are revolutionising modern shipbuilding, exporting the technologies and

knowledge globally, with many other shipbuilding nations now wanting to learn from us.

Much is made about the program, but what is being built before our eyes at Osborne shipyard is a capability the nation should be proud of. And, from what I have seen from our Australian supply chain partners, I am very optimistic that we will set the standard in embracing innovation and technology into what can be an exciting career for many Australians for generations to come.

Eighty six young people are preparing to start their careers with BAE Systems Australia after the Company recruited a record number of graduates. The recruitment effort reinforces the BAE ’s commitment to invest in the next generation, with graduates securing roles working on some of the most important defence programs being delivered across Australia.

Most have been employed in Victoria (28) and South Australia (50) supporting the Hunter Class Frigate Program, the Jindalee Operational Radar Network upgrade and the development of new technologies for the Australian Defence Force.

32% of the new graduates are female, reflecting BAE Systems Australia’s commitment to improving diversity in STEM roles.

A further 30 apprentices will join the national defence engineering and technology business later in the year. Half of this cohort will begin their careers in advanced manufacturing and aircraft sustainment roles. The other 15 will join the Hunter Class Frigate Program, almost doubling the number of apprentices supporting the delivery of the future ships.

Advanced manufacturing is a critical sector for Tasmania, generating turnover of more than $7 billion annually and employing more than 18,000 people locally. TMEC is delivering support to this key industry, strengthening job opportunities, as well as the local and national economy.

As the world began its recovery from the COVID-19 pandemic, Tasmania’s economy rebounded with great strength.

Figures from the ABS confirm State

Final Demand increased by $2.2 billion to $40.3 billion in the year to June 2022. This was an increase of 5.8% over the 2020-2021 financial year, meaning that Tasmania experienced the second strongest growth of all Australian states.

These strong results were driven by growth in consumption and investment across both the private and public sectors. Private sector investment in 2021-2022 was 7.5% higher than the previous financial year, with public sector investment 5.5% higher.

There is a continued push toward sovereign capability led by both the market and government that has opened-up new market opportunities. An unemployment rate of 3.8% (as of December 2022), one of the lowest on record, shows the strength of the Tasmanian economy. This success

also brings challenges through accessing and retaining appropriately skilled employees. This is a challenge being felt across Australia. Around 95% of Australian businesses report difficulties in finding staff to fill positions, with the greatest impact factor being a lack of applicants.

Supply chain disruptions also continue across the mining, energy sectors, with manufacturing businesses reporting the greatest disruption. This and other challenges including increased input costs have made for a challenging business environment across Tasmania.

There are good opportunities for Tasmania and its manufacturing sectors. As specialists in the design and development of niche and bespoke products, a great opportunity exists for Tasmanian companies to expand into the growing domestic market and to develop export opportunities.

However, there are challenges facing the industry, particularly around labour availability and skills, and

costs. Skilled labour availability will continue to be a key challenge for manufacturing in Tasmania, and across the country. The shortage of suitable workers is a constraint on growth and innovation in the sector.

The Tasmanian Minerals, Manufacturing and Energy Council (TMEC) is working to help manufacturers overcome some of these challenges. TMEC represents member businesses involved in the state’s exploration, mining and mineral processing, manufacturing and energy sectors, along with companies and individuals in associated supply chains.

TMEC represents the views of industry to Local, State and Federal Governments, non-government agencies and the public. The Council gives members a united voice, ensuring the priorities of industry are well understood and sustainable development can be achieved both through identification of opportunities and assisting with the resolution of sector-wide challenges.

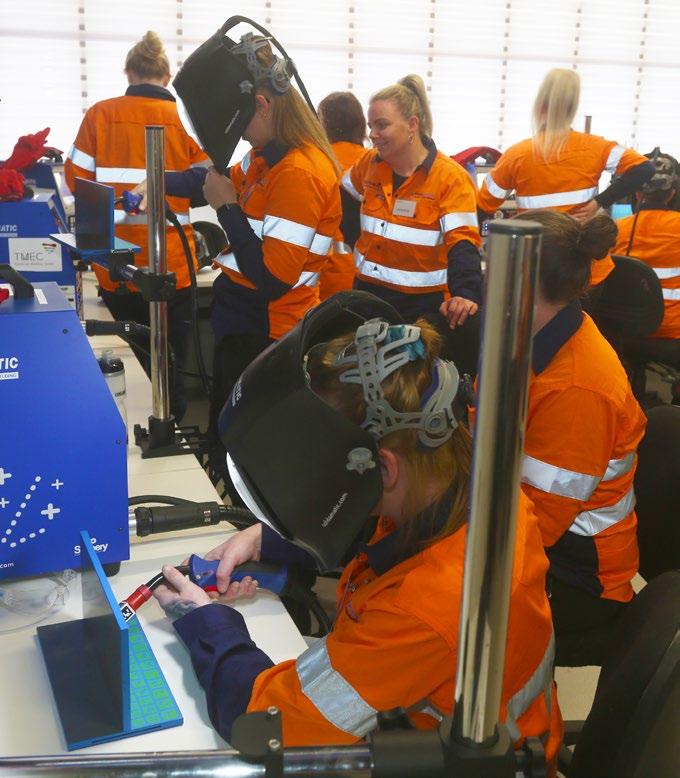

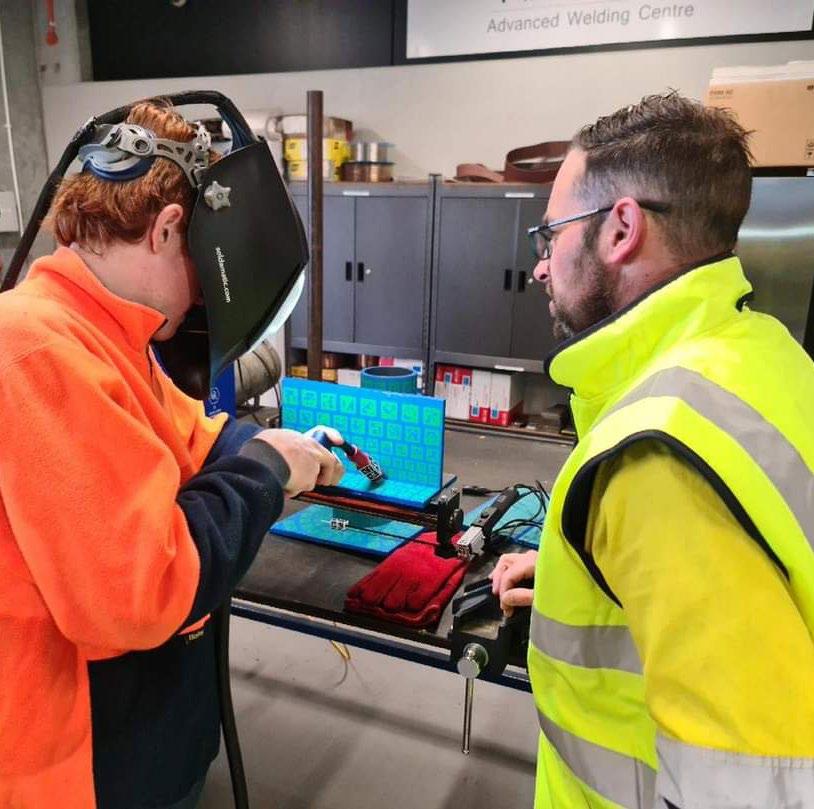

TMEC’s Advanced Welding Centre

One of the measures implemented by TMEC to help its members overcome sector-wide labour shortages is its Advanced Welding Centre.

The Centre features eight Soldamatic welding simulators available for use by industry, schools, TAFE students and trainers to develop welding skills in a safe environment. The virtualreality simulators mimic real welding experiences and are compatible with live welding equipment. They provide statistical feedback on weld quality, accuracy and comparative improvements in technique.

TMEC is an approved Weld Australia certifier and is able to upskill existing staff as welding inspectors and supervisors.

A total of $650,000 has been invested by the Australian Government in establishing the Centre, with a further $100,000 to ensure Tasmanian TAFE trainers have the skills and knowledge to deliver world-class training.

TMEC recently appointed Kiah

McCreadie as Welding Supervisor at the Centre. With over 15 years’ experience, Kiah commenced his career in a sheetmetal apprenticeship in 2004.

Since that time, Kiah has built up an impressive body of qualifications and skills. He currently holds both a Certificate IV in Training and Assessment, an International Welding Specialist (IWS) and an International Welding Inspector - Basic (IWI-B) qualification. Kiah has worked across a broad range of projects, gaining valuable experience as a supervisor, team leader and fabricator in the health, food, manufacturing and mining industries. Kiah won Weld Australia’s 2022 Tasmanian Welding Inspector of the Year Award.

TMEC has partnered with TasTAFE in the delivery of a vocational and industry awareness program for learners undertaking the MEM20413 Certificate II in Engineering Pathways at TasTAFE in 2022. The three-day program consists of learners using the augmented simulated welding technology to undertake a variety of different welding techniques that will

be intertwined with the delivery of the Certificate II qualification. TMEC is recognised as an endorsed training provider with Keystone. This will open further funding to support businesses undertaking structural steel work within the construction sector. We see this as a unique offering which will further the Tasmanian based support for Tasmanian Businesses.

TMEC provides several other types of welder training, including a PreScreen Welder Validation. A TMEC Industry Specialist can assess the welding and fabrication experience and knowledge of potential candidates for employers. They will also offer recommendations for future training if required.

Aimed at candidates who have had prior exposure to welding but no official qualifications, TMEC’s Mentoring Program helps fast track people into a career in manufacturing. TMEC provides information on skillsets, techniques and the expectations of a manufacturing position to help ensure participants have the requisite skills to enter the sector.

TMEC offers a non-accredited short course in how to perform Gas Metal Arc Welding. Learners use Soldamatic augmented reality welding simulators to develop muscle memory and welding techniques in a controlled and safe environment, before moving into live welding bays.

In partnership with Weld Australia, TMEC recently introduced a structured pathway to upskill Tasmanian welders and improve in-house welding capability for local enterprises. The Welding Inspection pathway consists of three levels: Basic Welding Inspector training; AS1796 Certificate 10 Pressure Welding Supervisor or AS 2214 Structural Steel Welding Supervisor; followed by International Welding Specialist (IWS). Additionally, TMEC provides welder training sessions to AS/NZS ISO 9606-1:2017 welder certification.

The Elphinstone Simulated Work Environment (SWE) is one of only three Lean training facilities of its kind in the Southern Hemisphere, and the only facility in Australia. The facility is located in TMEC’s Manufacturing Centre of Excellence in Burnie.Training is based on Elphinstone Production Systems methods to boost productivity, cost effectiveness and quality while reducing safety related issues in any industry.

Drawing on Lean Principles, including Chase Waste, Make it Visual, Go See Act, and Put Safety First, the training encourages continuous improvement with an emphasis on collaboration and team communication as participants work within a simulated production-line environment.

For more information about TMEC, visit: tmec.com.au

The Tasmanian Advanced Manufacturing Action Plan 2024 sets out a series of activities that the government will deliver to support the industry’s growth and resilience into the 2022-2023 financial year. This includes administration of a range of grant programs including the Advanced Manufacturing Accelerating Growth program, which provided around $1.5 million to successful applicants in 2021-2022, with another $1.5 million over two rounds is available in 2022-2023. Several Tasmanian Government Advanced Manufacturing grant programs are available:

• Accelerating Growth Program

• Business Improvement Program

• Skill2Manufacturing Program

• Tender Incentive Program

• Quality Assurance Program

Full details are available at: stategrowth.tas.gov.au.

The Tasmanian Government is working with TMEC and other organisations to raise the profile of manufacturing in Tasmania to attract people into the sector and inform them of the wide range of career opportunities available. The Department of State Growth will also facilitate the completion of Tasmania’s Advanced Manufacturing Workforce Development Plan that will lay out a series of actions to help to address industry’s training needs. TAFE reforms are also ongoing.

In an increasing number of cases businesses are also working to address their resource needs by adopting different training approached and increased automation and operational efficiencies to reduce their labour needs.

The Department of State Growth continues to work closely with TMEC to support industry, partnering on the delivery of programs, including industry promotion, funding Industry 4.0 activities being delivered by TMEC and the popular industry Insights tours, funded and delivered with the Department of State Growth.

The Tasmanian Government’s $2 million SKILL UP program is delivering fee-free training and will be complemented by 180,000 fee-free TAFE places for 2023. Tasmania leads the nation in VET completion rates, skilling up Tasmanians who want a job in our critical industries.

The Tasmanian Government has eight international trade missions planned through 2024, supported by our trade advisors and Defence Advocate. Recent trade missions to New Zealand, Singapore and Vietnam have already resulted in contracts for Tasmanian manufacturers.

After re-joining the national Industry Capability Network (ICN) during 2021, the volume and scale of projects listed on the network continues to grow, exceeding $1 billion worth of projects at the end of 2022. Industry is encouraged to engage with the ICN Industry Advisors located around the state to take advantage of these opportunities. The network connects suppliers with opportunities to supply into a project, as well as acting as a procurement tool for proponents.

New generation projects continue to be attracted to Tasmania, offering significant opportunity for local manufacturers and contractors. There are currently two proposed wind energy projects for the north-east include a 210 turbine, 1260MW, on-shore wind farm and up to 70 turbines located 30km offshore, generating up to 1000 megawatts.

The Tasmanian Government is working with industry to identify the opportunities for Tasmanian businesses including manufacturers able to support the construction and sustainment of these types of projects.

Source: TMEC’s 2021-2022 Annual Report

Advanced manufacturers operate across all of the state’s manufacturing sub-sectors including food and beverage processing, smart technologies, forestry, maritime, mining equipment technology and services, renewable energy, transport equipment and the defence industry.

Manufacturing is the fifth largest industry in Tasmania by Gross State Product (GSP) generating $1.8 billion and a turnover of over $7.3 billion in 2018-2019. The sector employed 18,000 people directly and is a key provider of high paying and skilled jobs. It is Tasmania’s largest industry for interstate and export sales combined.

In line with national trends, manufacturing as a contribution to GSP has declined over the last 20 years. However, the sector continues to deliver a disproportionate benefit to the economy through high value employment opportunities, regional wealth generation and its role in supporting supply chains within the state.

Prior to the COVID-19 pandemic manufacturing in Tasmania was performing well and experienced 3% growth in 2018-2019. This was in contrast to the national situation where manufacturing continued its contraction.

Manufacturing is an important contributor in both metropolitan and regional areas. Hobart and the south east contributed 42%, Launceston and the north east 34%and the north west and west 24% of total GSP. On a per capita basis, Launceston and the north east had the highest contribution to GSP at $4,509 per resident. The west and north west is second at $4,242 per capita, and Hobart and the south east third with $3,104 per capita.

Manufacturing also supports numerous supply chains throughout Tasmania, underpinning thousands of jobs in other sectors including services, primary production and raw material production, such as forestry.

It is estimated that there was a $3.2 billion flowon impact to GSP in 2018-2019, generating an additional 31,400 non-manufacturing jobs, building on the 18,000 direct jobs already created. It is understood that most major manufacturing subsectors generate more indirect employment in the supply-chain than direct jobs.

Source: stategrowth.tas.gov.au

A custom steel fabrication manufacturer in New England, New South Wales, Rose Valley Steel Works provides a variety of metal fabrication services to both industry and individual customers. They stock a range of their own agricultural products, from stock feeders, panels and gates, through to stay systems. Their sheet metal shop fabricates alloy, stainless and mild steel products, including ute trays, ladder racks, canopies, and tool boxes. Their steel processing capabilities extend to shearing and punching, drilling, plasma and oxy cutting, and bending and rolling of pipe and RHS. Thanks to a recent upgrade of its welding technology and gas use, the company is taking a national focus.

Owner, Phil Macfarlane, explained he bought Rose Valley Steel Works around 18 years ago. Back then, the company had two employees and the main item on their production line was the farm gate.

Since then, Rose Valley Steel Works has expanded and moved premises to accommodate the growth of the business. It even incorporates another business – ShedBoss Armidale – which is a fantastic subsidiary to the structural side of the business.

“When I bought the company, I was not an experienced welder. I was a fitter and machinist with an agricultural background. At the time we only had two and a half employees, including me,” said Phil.

“Now we operate with 14 full-time staff and BOC’s help with upgrading technology and welding techniques has been key. We can now find many

innovative solutions to the most challenging needs and make anything out of metal for our customers.”

As well as fulfilling customers’ needs, Rose Valley Steel Works also creates its own products. One new product, a Rose Valley Feeders designed animal feeder, will take them from a local base to a national focus.

“This new animal feeder is unique because it can be flat packed, making national shipment more cost effective,” Phil explained. “We are getting a lot of interest from farmers around the country for these new feeders, so by designing and making this product ourselves using our state-of-the-art technology is helping expand our national reach.”

This path to progress involved a step-by-step build-up of staff, who required training, and a major equipment upgrade to produce the top-class metal fabrication.

When Phil bought the steel works, the original equipment was basic and the use of gases for welding, limited. This meant that taking on more sophisticated jobs and increasing commercial opportunities had its limits. The old equipment used was not power efficient, had more waste and took more time. This was a key issue that had to change if the company was to grow and offer more services.

Staffing was another challenge as finding highly skilled, fully trained welders was not an easy task. This is where the apprenticeship program with the local TAFEs has provided support, and the valuable advice and hands on training by BOC’s representative came to the fore.

“We’ve been using BOC gases for many years, and about four years ago the local BOC representative I

was building a good relationship with explained to me what the latest state-of-the-art machines can do, and how certain gases make a huge difference in quality, efficiencies and output,” Phil said.

“Once I had this knowledge and understanding, it was a no brainer. The investment had to happen, so we went ahead and upgraded around three years ago and haven’t looked back.”

Rose Valley now has a fleet of EWM welding machines, notably the Tetrix 300AC/DC Water Cooled, Taurus 400 Water Cooled, Phoenix 355 Water Cooled and a new Phoenix 400XQ Water Cooled. Three of these machines use Metal Inert Gas (MIG) and the other Tungstan Inert Gas (TIG).

“This new equipment reflects my desire to keep up with technology and has provided growth opportunities for us,” said Phil.

There are three major benefits this new welding system brings to Rose Valley Steel Works. The first is the initial and ongoing training

BOC provides on how to best use it, which now works hand-in-hand with what Rose Valley Steel Works’ five apprentices learn at the local Armidale and Tamworth TAFEs, because they purchased the same equipment, thanks to BOC’s advice and guidance.

“Our BOC representative taught us how to maximise our new machines and use the best gases to create top quality outcomes. The added benefit is that TAFE now has the same technology resulting in good cohesion between work and training,” said Phil.

A second benefit relates to efficiencies in waste and better working conditions. According to Phil there is less clean-up because the machines allow operators to create neater welds with less waste. Water-cooled torches mean there’s no overheating so there are less stoppages and safer conditions for operators.

“These machines have more weld settings and scope, so can be more controlled, and operators benefit because there is less mess and splatter. However, they still need to wear the safety gear, such as

air-filtered welding helmets, leather gloves, jacket and steel capped boots,” he said.

The third benefit is better running costs and better outputs. This welding equipment eliminates pre and post welding work, which saves money in time and electrical power. In terms of products, it is the skies the limit for Rose Valley Steel Works as the company now offer a multitude of services. But for the farmers who feed us, feeding their animals is a key objective for the Rose Valley Feeder Australian made range.

“The design of our feeders is such that when you put the hay in less drops on the ground which is usually trampled on and made inedible, so our farmers benefit by saving on feeding costs for their animals. Ultimately, our focus is on making great products for our farmers and provide top services to our customers,” concluded Phil. Further Information

For further information, visit: boc.com.au

Stainless steels are usually specified because of their enhanced corrosion resistance, high temperature oxidation resistance, or their strength. With various types of stainless steel available, there are specific welding processes and techniques that must be employed to ensure that the corrosion and oxidation resistance, and other mechanical properties are not impaired. This two day course will give participants a working knowledge of the welding metallurgy and weldability of stainless steels. Attendees will walk away with an understanding of the various types of stainless steel, and how to pre-heat, weld and post-heat treat them without introducing imperfections, causing cracking or otherwise disrupting their beneficial mechanical properties.

Dr Lippold is Emeritus Professor in the Welding Engineering Program at Ohio State University (OHU). He retired from OSU in 2016 after more than 20 years. He received his Bachelor, Master and PhD degrees in Materials Engineering from Rensselaer Polytechnic Institute. He worked at the Sandia Livermore Laboratory in California for seven years, and at the Edison Welding Institute for 10 years. Over the past 40 years, Dr Lippold has been involved in research activities designed to gain a better understanding of the welding metallurgy and weldability of engineering materials. Based on this research, Dr Lippold has published over 300 technical papers and reports and three widely used textbooks.

This highly engaging two day course will cover the following topics:

• Introduction to Stainless Steels

• Phase Diagrams

• Constitution Diagrams

• Stainless Steels Alloy Systems

• Martensitic

• Ferritic

• Austenitic

• Duplex

• Dissimilar Welds

• Case Studies

Registration is at 8:30am on day one for a 9:00am start. Ends at 3:00pm each day. Morning tea and lunch are both provided.

Melbourne:

Date: 10 and 11 July 2023

Venue: Cliftons - Freshwater Place Level 18, 2 Southbank Blvd, Southbank

Brisbane:

Date: 13 and 14 July 2023

Venue: To be confirmed

Please note: in order for the course to go ahead in two locations, minimum attendee numbers must be reached.

Weld Australia Members: $1,650 inc GST

Non Weld Australia Members: $1,850 inc GST

Payment is required at the time of booking. Cancellation two weeks prior to the start date will not be refunded. A certificate of attainment will be issued by Weld Australia at the end of the course.

For further information, simply contact: Michelle Bignold (National Manager, Sales and Marketing) on 0437 106 726 or events@weldaustralia.com.au

The new world-class Allianz Stadium in Moore Park was designed to create an unrivalled experience for spectators, athletes, and entertainers. The New South Wales Government invested over $830 million in the development, which is located on the site of the nowdemolished original stadium, completed in 1988 as one of Sydney’s major bicentennial projects. Expert steel fabricator, S&L Steel was contracted to undertake fabrication of the stadium’s roof.

The new stadium features a seating bowl that positions spectators closer to the action than ever before. With a capacity of 42,500, there are three levels of seating on either side of the playing arena, with two levels at the ends. A steep incline ensures all seats are close to and on top of the action with not a bad seat in the house.

Inside the venue is a 360-degree concourse that houses approximately 65 food and beverage outlets, and provides greater accessibility to the entire stadium. The venue is home to the Sydney Roosters, NSW Waratahs, and Sydney FC, with the Roosters hosting the first ever event at the stadium on 2 September 2022.

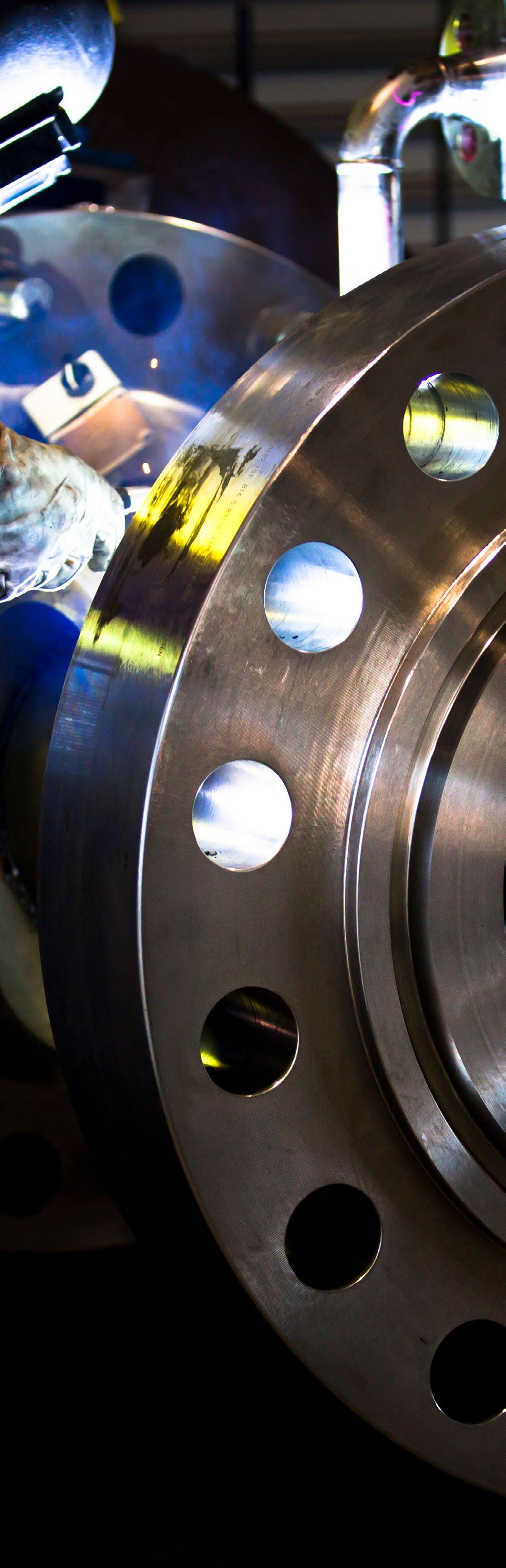

One of the primary features of Allianz Stadium is its spectacular roof. Based in Western Sydney, S&L Steel was contracted to fabricate the Allianz Stadium roof. Their scope of work consisted of: a tension ring located on the outside perimeter of the roof; four derricks that support the roof in the four corners; and ten truss sections that are complemented by the diagrid and a combination of RHS and CHS members. This scope included primary and secondary steel members for following trades, such as fabric and lighting.

The roof line pays homage to the legacy of the previous Sydney Football Stadium, rising majestically from Moore Park Road and falling again towards the iconic Sydney Cricket Ground. The drip line extends beyond the first row, meaning all seats are covered and protected from the weather.

To achieve this result, the 2,000 tonne roof structure is shaped as a synclastic diagrid shell. This is being supported by four corner ‘super columns’ (derricks). Spanning between the derricks are inner arched trusses that measure approximately 140m and 90m in length, connected by large 260mm diameter pins. The structural design also includes an outer tension ring and underlying columns which connect and support the roof to the stadium ‘bowl’ steelwork.

The sweeping roof ‘floats’ over the seating areas, and is lighter than traditional stadia, using up to 40% less steel in its construction, and

The roof form and geometry resulted in one of the most technically complex stadia roofs in Australia, with 4,000 individual pieces of steel, each with pre-set lengths and geometry.

creating a more sustainable project, while still covering every seat in the stadium and providing fans with clear views of the playing field.

The roof form and geometry resulted in one of the most technically complex stadia roofs in Australia, with 4,000 individual pieces of steel, each with pre-set lengths and geometry. Connecting each roof element precisely on site with accurate fabrication required digital engineering techniques to model the entire roof geometry through all construction stages. The roof is the stadium’s architectural signature. Its long spans—and their integral connection to the superstructure— drove the construction of the entire project, right from the earthworks

and substructure. The success of the entire project hinged on the successful fabrication and erection of the roof.

The roof was erected in large preassembled modules weighing up to 130 tonnes each. These modules were prepared on the pitch before they were safely lifted into place. The roof modules, splice locations and geometry were carefully planned, right from the initial tender period. Every element was considered to ensure their transportation, access, temporary works and cranage was cost effective and enabled rapid construction. This resulted in improved safety by reducing the number of connections required at heights and improved quality assurance.

The new stadium consists of over 5,000 tonnes of Australian fabricated steel through the bowl (seating structure), roof, façade and miscellaneous items.

Procurement for the roof structure consisted of primarily CHS and RHS members, with plate supplied by BlueScope. Processing of CHS was undertaken by numerous businesses in New South Wales, while RHS hot rolled bending was undertaken in Victoria.

The procurement process took over 12 months, with additional testing of materials carried out by ILAC accreditors. Approximately 18km of material was procured for the 2,000 tonne roof structure.

The roof structure was detailed and fabricated in a way that it was doubly symmetrical. Items such as the diagrid nodes were very complex, with 528 unique instances of connections geometries and details proposed in the reference design. Hence, collaboration in decision making, such as adjusting the geometry of the roof, which had no axis of symmetry in the reference design to a structure that was doubly symmetric, created repetition and reduced the shop detailing effort to improve efficiency and quality assurance. The symmetry reduced fabrication effort and minimised overall temporary works including all fabrication and onground assembly jigs.

It enabled the same section profiles, welding setup, and additional flexibility in the fabrication and installation sequence. Collaboration between Aurecon, COX Architecture, S&L and DBM Vircon enabled computational engineering techniques to be adopted for the design and detailing of the connections which simplified the 528 connections into only five connection types for the entire roof diagrid.

The steel connections within the roof sculpture, which are all exposed, are some of the most intricate in Australia. Aurecon, S&L Steel and DBM Vircon developed a bi-directional analysis, design and model workflow, enabling the shop detailer and engineer to work in parallel. The shop detailer’s model was also translated into analysis and design software to ensure design integrity. The design team was able to implement design automation and data analytics to process over two million data sets to ensure an efficient and safe design. This saved the project months in the design and shop detailing process.

The temporary works associated with the roof and erection engineering represented a significant cost and risk element to the project. Efficiency was achieved through modular roof construction and erection engineering that considered the impacts on temporary works.

A combination of fabricated and proprietary systems was adopted that incorporated safe access systems and designed for robustness and consideration of other stadium construction activities. Key elements were the temporary support towers which had large foundations and header beams which provided access for erection and de-jacking, the arch ties which provided preset geometry of the diagrid roof modules to enable fit-up and fabrication and assembly jigs which allowed the structure to be part built on the ground for installation.

One of the key challenges during the project was the hot induction bending process. The roof structure required approximately 3km of RHS 400x200 in 8mm,10mm,12.mm and 16mm to be hot induction bent to specific radius. As the material was high grade steel, the testing of prototypes was challenging due to the heat applied to the steelwork. Modifications were made on the coils to discharge the heat on the steelwork. In Australia, there is only one supplier skilled and experienced in this type of work. By collaborating with this supplier, S&L Steel was able to achieve a successful outcome for the project.

The other major challenge was safety during the installation of the roof. The installation of the 2,000 tonne, 25,000m2 roof at height required careful consideration and planning. The project team developed a strategy in which large segments of trusses and diagrid could be assembled on the ground and then lifted into position. The on-ground processing included safety netting and ancillary items required for fabric

deployment and finishing works completed by other trades. This solution was achieved by designing roof elements that were stable as partially-constructed modules that could be easily lifted into place. As a result, over 85% of the roof steelwork installation was undertaken at ground level, including associated fabric and finishing elements.

The S&L Steel project team adopted a Construction Category 3 sitewide standard for Allianz Stadium. As a result, S&L was able to certify the production of each member, and meet strict quality assurance criteria and full traceability for the procurement, fabrication and erection of the steel.

This high level of traceability allows for future flexibility over the 50 year design life, improves the ability of the steel structure to be maintained and contributes to its longevity.

As with any diagrid or form-found structure, the behaviour is sensitive to the geometry of the structure. The implementation of full scale pre-assembled sections of critical

elements in the workshop validated the sensitive geometry, enabled any adjustments to be made prior to arriving on-site and improved the speed of assembly and installation on-site. This was critical to ensure all delivered steel was installed without the need for site modifications and enabled efficient use of the laydown and working areas on-site.

A three-coat protective paint for the stadium steelwork was selected to achieve a massive 25 years life to first maintenance warranty. In addition, all sharp edges and welds were rounded to ensure an appropriate application.

The stadium was designed with environmental sustainability in mind and is on track to achieve a US Green Building Council LEED gold rating. The roof structure was redesigned to require 40% less steel in its construction compared to the original reference design.

The stadium features solar panels and water harvesting systems on its roof, while its carefully designed profile will reduce the building’s overall impact on its parkland

is a fantastic achievement for the entire S&L Steel fabrication, design and site construction team.

location. The design of the roof provides containment of noise, offering ongoing noise pollution reduction to the surrounding area.

The early contractor involvement with S&L Steel was critical in minimising steel waste. With the accelerated construction program and multiple work fronts across a number of buildings, extensive traceability was put in place by the project team to ensure that each steel member was traced from the source of origin to the final erection within the designated building.

Indigenous sense of place was also an important environmental consideration for the project. The Moore Park area of Sydney is part of the traditional lands of the Gadigal people. As such, it was critical to tie in the sense of place from the traditional custodians of the land. The seating pattern was designed by awardwinning Indigenous artist Tony Albert, with the theme of ‘Two Worlds Colliding – Water and Land’. The abstract designs features topographical views of Sydney, whale and goanna totems.

Allianz Stadium strengthens Sydney as a destination for major sporting and entertainment events, while enhancing the surrounding precinct with public places and spaces year-round. The project was delivered on time and on budget by more than 200 people, despite disruptions to procurement and construction due to COVID-19. Winner of Weld Australia’s 2022 NSW Project of the Year Award, Allianz Stadium is a fantastic achievement for the entire S&L Steel fabrication, design and site construction team.

Located in Western Sydney, S&L Steel are expert fabricators. S&L specialises in everything from bridge works, pressure vessels and pipework, through to commerical buildings, power stations and major infrastructure.

Fabrication is facilitated by their two sixty tonne overhead cranes that transfer product between the fabrication, paint-shop and despatch areas. To complement the workshop, there are six full factory length overhead cranes with a 10m hook height. To supplement the overhead crane, S&L has 20 boom hoists with 1 tonne capacity located throughout the workshop.

With over 6,000m2 of open yard space, S&L Steel can accommodate a number of large projects at any given time, and conduct trial assemblies if required. With modern facilities for blasting and painting and PCCP accreditation, S&L Stee deliver a quality finished product every time.

S+L Steel is certified to AS/NZS ISO 3834.2 and pre-qualified by Transport for NSW.

For further information about S&L Steel and their capabilities, visit: slsteel.com.au

Hayden completed his apprenticeship with Bridgeman and is now a qualified tradesperson. He has actively sought more responsibility in his role and is now an experienced site installer—a role that is only given to the most trusted and highly skilled Bridgeman employees. Hayden has been working on the Queensland Correctional Services Bunk Bed rollout project for the past year during which he has demonstrated a superb work ethic, outstanding productivity and is recognised as one of Bridgeman’s best welders. In the very early stages of his promising career, Hayden already displays dedication to the welding profession. He is often paired with new employees as a role-model for both workmanship and commitment. Hayden won Weld Australia’s 2022 Young Indigenous Tradesperson of the Year.

Can you describe your job?

I am employed at Bridgeman Manufacturing working on metal fabrication projects. Some of the projects that I have been working on recently include a variety of cell furniture for correctional centres, scraper arms and a large clarifier for a sewerage treatment plant and scullery, pack bench and warmer drawers for a large food chain.

Tasks include fabrication of stainless

benching, handrails, balustrades, cell furniture items, marking up, pressing, welding, polishing, refrigeration, framework and custom fabrication items.

What inspired you to choose a career in welding?

Prior to commencing work at Bridgeman, I was a labourer and pipe welder. One day I was installing pipework at a service station and something clicked and I thought to

myself, I need to get a trade to fall back on and I’ve never looked back. Some of my family are also in the sheet metal industry, so it is in my genes.

What do you enjoy most about your job and welding?

I enjoy working with my hands and the job satisfaction I get when a job is completed. It’s great to look at the finished product and think ‘I built that’. Also, Bridgeman is a great

company to work for. I always feel supported and the team of people I work with are great too. Everyone gets along really well.

Why do you think other young people should consider a career in welding?