MTE and Thornton Engineering Awarded AS/NZS ISO 3834 Certification >>>

Weld Australia Launches Welding Inspector - AS 1796 Certificate 11 Course >>>

Michelle Bignold, Executive General Manager, Sales & Marketing 0437 106 726 m.bignold@weldaustralia.com.au MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Executive General Manager, Technical Services 0487 487 170 d.yalniz@weldaustralia.com.au

ENGINEERING

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991

v.blain@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901

a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991

v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, General Manager, Engineering – QLD, ACT, NSW, NT 0491 491 888

r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Ian Mackay, Business Development Manager 0493 027 882

i.mackay@weldaustralia.com.au

Weld Connect | April 2024 2 A Message from our CEO 03 Breaking News: Recent Media Coverage 05 Cigweld Guide to Pulse MIG Welding 06 EOIs for Non-Executive Director of Weld Australia 08 News from the Weld Australia Team 09 Last Chance to Register for Australian Manufacturing Week 10 South Australia Industry Drinks Night 11 Robotic Energy Recovery Boosts Sustainable Manufacturing 12 Industry Roadshow: An Exploration of Cobot Welding 14 Industry News 15 Weld Australia Launches Free Welder Safety Courses 18 Membership Matters 20 2024 National Manufacturing Summit 21 ASME B31.3 Process Piping Code Course 22 Pipeline Repair, Hot Tapping & In-Service Welding Course 22 Launch of the MEM Learning Resources 23 Gladstone Try A Trade Day 24 IIW International Welding Practitioner (IWP) 25 Qualification and Certification Update 26 New Course: Welding Inspector - AS 1796 Certificate 11 28 Upcoming Training Courses 29 WeldQ Free Digital ID Card 30 Get IWI-C Qualified with Weld Australia 30 Congratulations to All the Newly Qualified Individuals 31 Weld Australia’s Exam Calendar 31 Fusion Welding Courses 32 IN THIS ISSUE MTE and Thornton Engineering Certified to AS/NZS ISO 3834 26 WELD AUSTRALIA CONTACTS NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 1800 189 900 office@weldaustralia.com.au weldaustralia.com.au Geoff Crittenden Chief Executive Officer 1800 189 900 g.crittenden@weldaustralia.com.au TRAINING Guy Brooks, General Manager, Training Operations 0488 743 322 g.brooks@weldaustralia.com.au

MARKETING

Robotic Energy Recovery Boosts Sustainable Manufacturing 12

As many of you will be well aware, pursuing a career in trades, like welding, offers practical benefits and a pathway to personal growth. A career in welding not only provides a stable and rewarding career path but also instils a sense of accomplishment, purpose, and identity. The hands-on nature of welding requires concentration and precision, which can help individuals focus and find a sense of accomplishment.

The process of learning and mastering a trade can boost self-esteem and provide a supportive community environment that promotes teamwork and camaraderie. A career in welding can be a therapeutic journey, offering younger individuals a chance to rebuild their lives, gain valuable skills, and contribute meaningfully to society.

A Looming Welder Shortage

Welders are more in demand than ever—labour shortages are inhibiting the growth of Australia’s welding industry. According to Weld Australia’s members, 50 per cent of Australia’s welding workshops are currently operating at 80 per cent of their capacity or below. When asked why this is, a lack of skilled workers was the overwhelming answer.

The construction industry recently warned that the federal government’s goal of building 1.2 million new well-located homes in the next five years will begin on the back foot because of a significant worker shortage. The government’s five-year target, which is part of the National Housing Accord agreed to by the states and territories, begins mid-year.

BuildSkills Australia – a group tasked by the government to find solutions to the workforce challenges facing the construction industry – said that to stay on-track, the government would need to build 60,000 new homes each quarter, which would require a workforce of 90,000 people more than currently exists.

This labour shortage comes as no surprise. Weld Australia has been calling for urgent action for over five years. We estimate that Australia will be at least 70,000 welders short by 2030.

And yet, the number of welding trade workers in Australia dropped by 8 per cent in the course of just five years, and completion rates of welding apprenticeships continue to fall by as much as 23 per cent annually. It is essential that welder training is revolutionised with

online, accessible and engaging learning resources. There is no magic solution to Australia’s skills crisis. We need a radical approach. The same old approach that we’ve taken for years will not arm Australia with the skilled workers needed to deliver the record number of projects we’re seeing in industries like defence, renewables and infrastructure.

As such, Weld Australia has implemented a number of programs designed to encourage more young people to explore a career in welding.

Advanced Manufacturing Schools Outreach Program

First piloted by the New South Wales Department of Education in 2020, the Advanced Manufacturing Schools Outreach Program has successfully trained thousands of students.

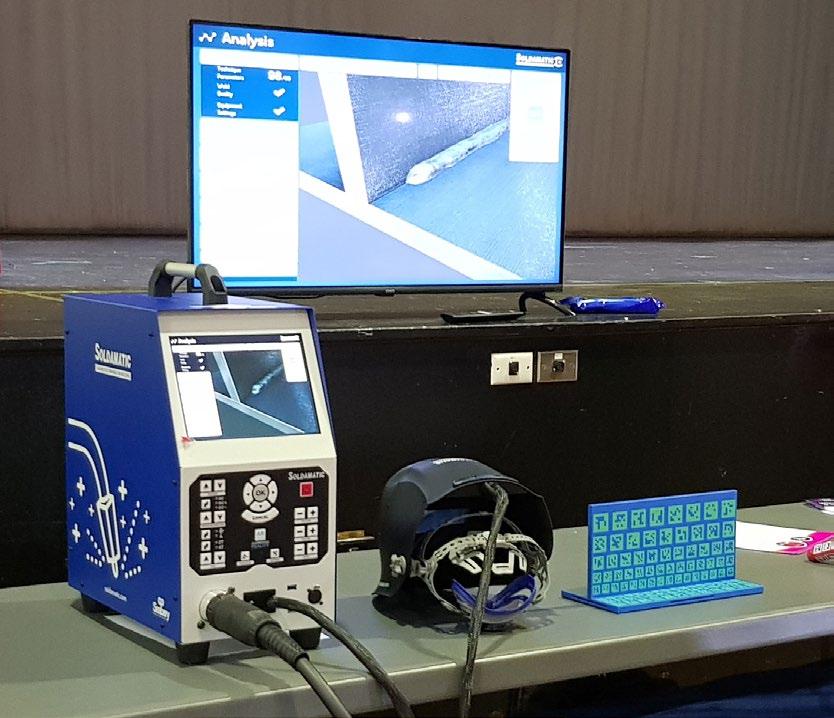

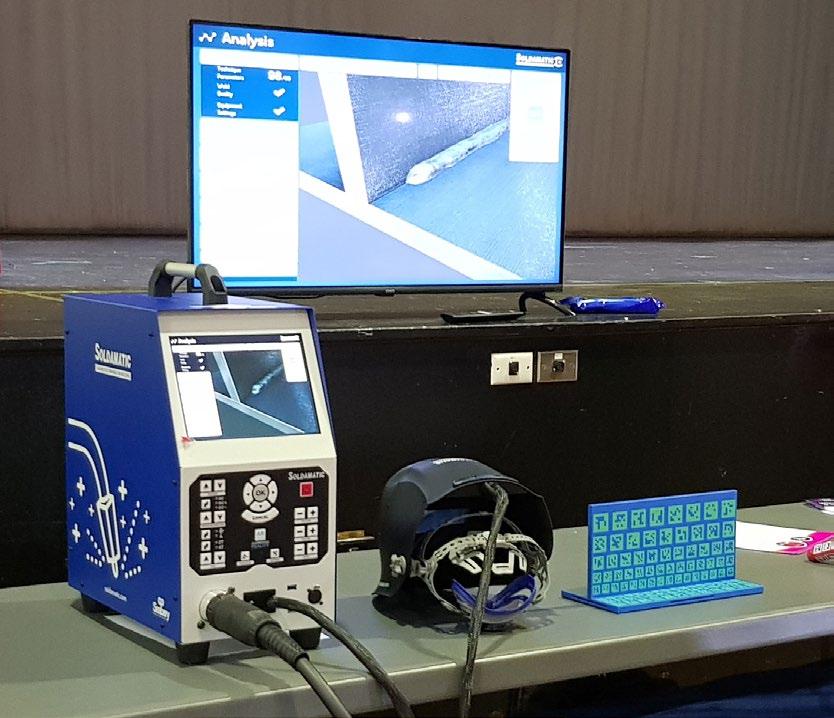

The Program uses cutting-edge training techniques, including augmented reality welding simulators and innovative teacher training delivered by Weld Australia, to teach welding to students in Years 10 to 12 studying Manufacturing and Engineering, and Industrial Technology. The simulators are also used to teach students in Year 9 to develop an understanding of welding using all of the common processes in a completely safe and controlled environment.

The technology is also used by students in years 10-12 to support the delivery of Manufacturing and Engineering and Industrial Technology (Metal), specifically MEM10105 Certificate I in Engineering and MEM20413 Certificate II in Engineering Pathways. Students are able to complete the Certificate I and gain credit against the Certificate II.

The Program started with 30 Soldamatic augmented reality simulators in 16 schools. It proved so popular that it has now expanded to encompass more than 130 simulators in over 65 schools across New South Wales.

Weld Australia is once again trying to persuade other state governments to adopt the program across Australia.

This STEM program is boosting the number of recruits into the trades broadly, and welding in particular. Perception and lack of awareness can create barriers, preventing many young adults from engaging in careers in manufacturing and the trades, and reaching their

Weld Connect | April 2024 3

full potential. STEM opportunities in the manufacturing sector are clean and technically sophisticated, requiring a range of advanced skill sets, as well as traditional skills. This new approach surprised and re-engaged students, demonstrating that there are more paths available than just a university degree.

MEM Learning Resources

Weld Australia has also designed and created a suite of resources for delivery of the 12 welding and fabrication units of competency in the Manufacturing and Engineering (MEM) Training Package at TAFEs and RTOs nationally. Our resources help simplify the learning process for students, teachers and training institutes and—most importantly—place the student at centre of the learning process.

Weld Australia believes that a national industry, which has a national learning package, needs national learning resources. Whether you’re an apprentice in Kalgoorlie, Ultimo or Davenport, you should have access to the same, high-quality training. Our goal is to help ensure that high-quality welder learning is consistent across the country.

Weld Australia formed a national consortium of TAFEs to work on the project. Over the last two years, the consortium has collaborated with us to develop the most engaging, up-to-date resources possible. Members of

the consortium piloted use of the resources, and some TAFEs have already permanently adopted them. Weld Australia’s MEM Resources have been built with students, teachers and training organisations in mind. It reimagines the learning process with its user-friendly interface, diversified delivery methods, and audited and accurate material. The new MEM resources are completely online and accessible via phone, mobile device or computer. This allows students to access learning at the time, place and pace that suits them best.

The MEM Resources have gained industry-wide recognition, winning the Excellence in Manufacturing Skills Development Award at the 2023 Endeavour Awards. Recognised as the premier Awards program within the manufacturing industry, the Endeavour Awards highlight innovative organisations and provide manufacturers from around Australia with industrywide recognition.

We are working to ensure that all students have a positive experience when it comes to a career in welding—both at high school, and at TAFE. This will give students a great first impression of the industry, and should lead to higher apprenticeship completion rates. It is critical that we overcome the skills shortage to ensure a strong, productive local welding industry and Australian economy.

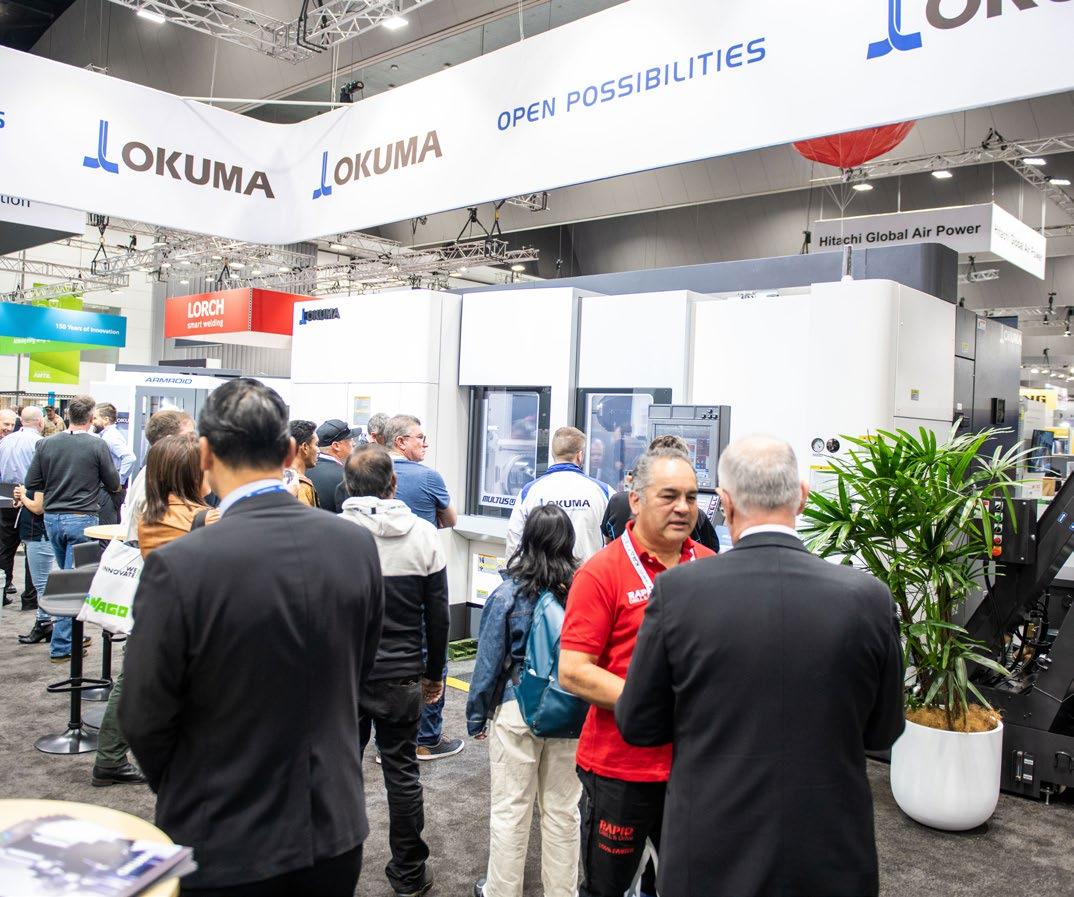

SHOWCASING 7 PRODUCT ZONES

1800AMWSYD24/C AUSTRALIA’S PREMIER MANUFACTURING SOLUTIONS EVENT

APRIL 2024

ICC SYDNEY AUSTRALIANMANUFACTURINGWEEK.COM.AU SCAN HERE TO LEARN MORE

17–19

•

DON’T MISS OUT. REGISTER NOW!

Notice of AGM

Weld Australia’s 2024 Annual General Meeting (AGM) will be held at 9:00am on Wednesday 29 May 2024 AEST originating at 25 Ryde Road, Pymble, New South Wales. The AGM will be a remote meeting, held via Zoom. Members should keep an eye on their inbox for the formal Notice, which will include details on how to register to attend, eligibility to vote and appointing a proxy.

Geoff Crittenden CEO, Weld Australia

Weld Australia would like to welcome all our new Members who have joined in the last month:

CORPORATE MEMBERS

• Williams Metal Fabrications: williamsmetalfabrications.com.au

INDIVIDUAL MEMBERS

• Daniel Swan

• Craig Cottingham

• Mohit Verma

• Michael Bellon

• Jason Weiss

• James Harvey

JOIN TODAY

For further information on the benefits of becoming a Weld Australia member, visit our website, or contact David Choudry (Membership Manager) on d.choudry@weldaustralia.com.au or 0417 878 104.

RECENT MEDIA COVERAGE

Weld Australia launches free online welder safety training courses, published by Manufacturers Monthly

Weld Australia launches two free safety training courses published by AuManufacturing

Weld Australia rolls out free online safety courses published by Australian Manufacturing

Weld Australia launches free online safety courses, published by The Tradie

Weld Australia advocates for stronger measures to boost local manufacturing in renewable energy, published by Australian Manufacturing

Governments must prioritise local content requirements in the transition to net zero, published by Manufacturers Monthly

Community benefits from renewables can be locked in through local content requirements, published by Renew Economy

JOIN TODAY

Weld Connect | April 2024 5

What is Pulse MIG Welding?

Pulse MIG welding is an advanced welding technique that offers precise control over the welding process. It involves alternating the welding current between high and low levels, resulting in a highly controlled arc. This method is particularly effective for welding hard to weld alloys such as, aluminium, stainless steel, and bronze and Pulse welding is also well used for improving the look/appearance of carbon-steel welds.

Single-Pulse or Double-Pulse?

Single-Pulse mode is often used in Steel and Aluminium workshops for larger structures/weldments with plate thicknesses above 3.0mm on longer weld lengths, where aesthetics is very important. Single Pulse MIG is easier to train operator’s on, and is easier to setup, as Single-Pulse MIG offers fewer features and adjustments.

Double-Pulse enhances the advantages offered by SinglePulse mode, such as weld quality and finish/ appearance, to a higher standard. It’s worth noting that not all pulse MIG machines include the Double-Pulse mode.

When to Use Pulse MIG Welding

• Single or Double Pulse: Out-of-position welding

• Single or Double Pulse: Applications where reduced heat input and distortion is required when welding high thermal conductivity metals, like aluminium, stainless steel, and bronze.

• Single-Pulse: Welding medium metal plate thicknesses (>3mm to 12mm) with excellent appearance

• Double-Pulse: provides perfect parameters for welding thinner materials (0.5mm to 3mm)

Benefits of Pulse MIG Welding using the CIGWELD BlueVenom XF353 and Add-on PulseMate are:

1. Improved Productivity & Quality: Pulse MIG welding

which results in stable arcs and aesthetically pleasing welds, whilst also making it faster and more efficient when welding hard to weld metals, than traditional methods, thus cutting down post welding clean-up time and overall labour costs.

2. Heat Control: Pulse MIG welding minimizes heat input, reducing the risk of distortion and burnthrough, especially on delicate or thin materials.

3. Out-of-Position Welding: The controlled arc of pulse MIG welding allows for better control when welding in different positions (Flat, Horizontal, Vertical-Up & Overhead), minimizing the risk of weld burn-through and provides highly controlled penetration profiles.

4. Reduced Spatter and Fumes: Compared to conventional MIG welding, pulse MIG welding helps to eliminate spatter and further reduce fumes, leading to cleaner welds and a safer work environment.

When using the CIGWELD BlueVenom XF353 and add-on PulseMate you will get SimplePulse™: a) Single Pulse in 4 Easy Steps, and b) Double Pulse MIG in 7 Easy Steps.

For Single-Pulse, Simply choose the 1) Single-Pulse mode, 2) select the job (CS/SS/AL/BZ), 3) select your plate thickness, 4) confirm/set the TRIM value to adjust arc length using fine control arc voltage for your particular application, and you’re ready to go! Additionally for Double-Pulse you will also set 5) Background/Base Current %, 6) Double-Pulse Frequency, Hz/Pulse per Sec, 7) Adjust Double Pulse Width (Ripple Gap).

Overall, pulse MIG welding offers numerous advantages over traditional MIG welding methods, and whilst the BlueVenom XF353 is a phenomenal choice for traditional MIG welding, the add-on PulseMate takes its MIG capabilities to another level, making it a great and versatile choice for various high-quality applications, at an affordable price.

This article was supplied as part of a paid sponsorship package.

Weld Connect | April 2024 6

CIGWELD GUIDE TO PULSE MIG WELDING

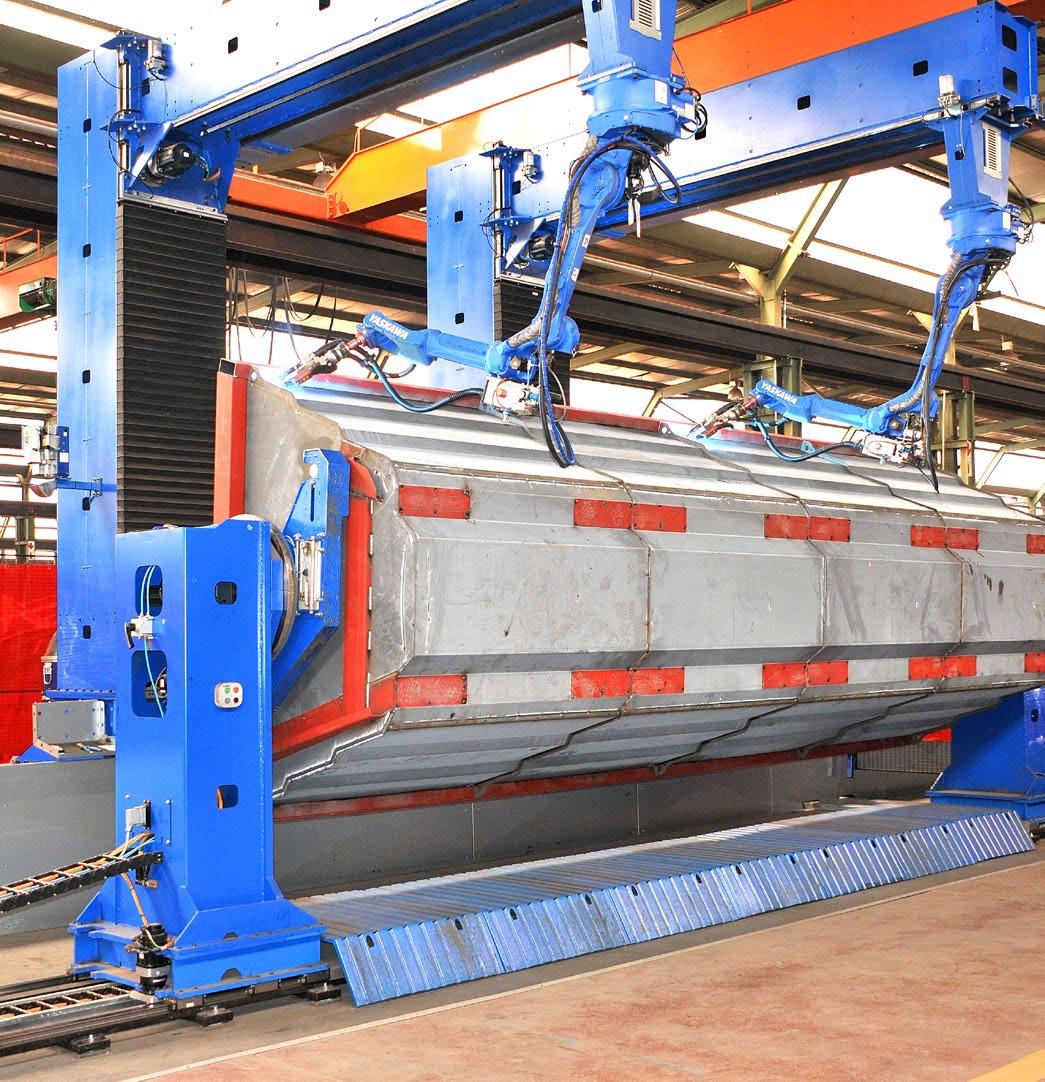

Turn-key Solutions for the Welding Industry.

The Home of Intelligent Automation.

Established in 1988 and over 3,500 solutions installed across Australasia, our extensive experience is your best assurance of quality and value. Robotic

Weld Connect | April 2024 13

1300

sales@ragroup.com.au

www.ragroup.com.au

Automation Pty Ltd T.

552 333 E.

W.

QUEENSLAND ROLLS OUT REZ ROADMAP FOR RENEWABLE ENERGY FUTURE

Queensland has unveiled its Renewable Energy Zone Roadmap (REZ Roadmap), signalling a clear path towards renewable best practices in the state.

Set to be enacted into law, the REZ Roadmap is poised to ensure that local communities receive equitable benefits from the state’s clean energy transition and facilitate the coordinated implementation of renewables across 12 proposed Renewable Energy Zones (REZs).

Key stakeholders, including landholders, local councils, and residents of regional communities, will play a central role in the rollout of renewables in their areas, with each REZ slated to accommodate significant wind, solar, and storage infrastructure connected to the Queensland SuperGrid.

The establishment of the first REZ Local Reference Groups later this year will prioritise community feedback throughout the transition process, ensuring that local voices are heard and integrated into decision-making. Central Queensland, renowned for its existing energy infrastructure, is poised to become the site of the inaugural REZ, with the proposed Callide REZ expected to lead the way in facilitating the transition to clean energy.

EXPORT AGREEMENT FOR AUSTRALIAN-MADE ARMOURED VEHICLES

The Federal Government has entered a defence export agreement to supply Australian-made armoured vehicles to Germany. Under the agreement, more than 100 Boxer Heavy Weapon Carrier vehicles will be built by Rheinmetall at its Military Vehicle Centre of Excellence in Redbank, Queensland and exported for use by the German Army.

“This deal secures well-paid jobs in Queensland and across the country,” said prime minister Anthony Albanese.

This is a significant milestone for Australia’s defence industry: worth over $1 billion to the Australian economy, boosting our sovereign defence industry and securing more than 600 direct jobs in Queensland alone, with even more through the supply chain.

Albanese said, “The agreement will boost Australia’s sovereign defence industry, secure local jobs and contribute to Australia’s economic growth.”

Minister Whan believes the investment in vocational education and training demonstrates the NSW Government’s commitment to fostering a skilled workforce and meeting industry needs.

Weld Connect | April 2024 15

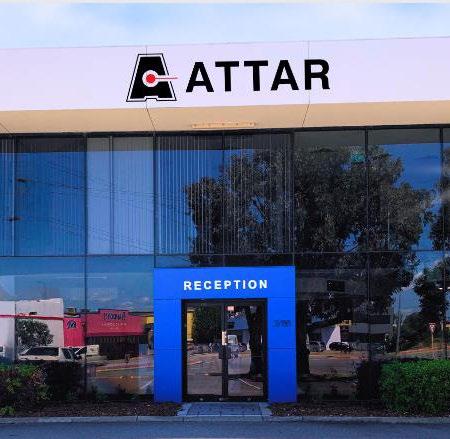

ATTAR UNVEILS WORLD CLASS FACILITIES AND BOOSTS INVESTMENT IN WA

Established in 1986, Advanced Technology Testing and Research (ATTAR) has been at the forefront of pioneering materials testing, research, compliance services and Non-Destructive Testing (NDT) training for the Australian industry. Over the years, ATTAR has continually evolved, leveraging its rich history in conducting cutting-edge forensic engineering, materials research and nondestructive testing to meet evolving market demands.

“Western Australia is an important market with a unique blend of mining, oil and gas as well as other industries that are essential to running the state. By consolidating our presence and increasing our investment in Western Australia, we are better placed to support the needs of our clients and the critical industries that drive this great state,” said Glenn D’Costa, CEO of ATTAR.

ATTAR recently announced a significant stride forward in its operations, marked by a strategic consolidation of facilities in Western Australia. This plan is designed to optimise operations, deliver cutting edge solutions and elevate service standards for clients.

Since the acquisition of Exceed Consulting on 1 July 2022, ATTAR has harmonised systems and substantially broadened its range of services to support the local industry. Having seamlessly integrated the Exceed Consulting business, ATTAR will hold a grand opening ceremony at its world class facility located at 3/88 Welshpool Road, Welshpool, WA 6106.

“We’re pleased to enhance our service delivery from our state of the art facility, with a highly experience team and broad array of services,” said Dr Adrian Grosvenor, General Manager Engingeering Consulting and Principal Engineer at ATTAR.

NEW EQUIPMENT PREPARING TASTAFE STUDENTS FOR THE LATEST

TasTAFE metals and manufacturing students now have the opportunity to use a new state-of-the-art simulator thanks to a partnership with the Tasmanian Minerals, Manufacturing and Energy Council (TMEC).

With support from TMEC, a new CNC simulator has recently been installed at TasTAFE’s Bender Drive training facility in Derwent Park, allowing students to train on fit for purpose equipment that aligns to current future industry training demand.

Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside tools. The CNC simulator allows students and apprentices to get exposure to the set-up, programming and operation of CNCs without the need for an actual machine.

TMEC CEO, Ray Mostogl, said, “TMEC is committed to supporting the manufacturing sector increase productivity which underpins higher wages for more workers and increases state exports. CNC technology is one part of the solution for the manufacturing sector.”

“The simulator enables novices to gain valuable knowledge and skills in a safe environment. TMEC values the partnership with TasTAFE to deliver this first step in upskilling and transforming manufacturing facilities. We continue to look for opportunities to advance the training technology and resources in partnership with TasTAFE,” Mostogl said.

Weld Connect | April 2024 16

CSIRO LAUNCHES $20 MILLION INVESTMENT TO DRIVE SME INNOVATION

Australia’s national science agency CSIRO has unveiled a $20 million investment aimed at providing small to medium enterprises (SMEs) with enhanced access to crucial research and development (R&D) opportunities, facilitating their accelerated growth.

The funding will empower CSIRO’s SME Connect team to extend support to approximately 750 SMEs through a suite of programs and initiatives, the agency said in a news release.

These initiatives encompass facilitation, training, dollar-matched funding, and assistance for startups and SMEs venturing into company-led research projects. Among the initiatives receiving backing is the flagship program of SME Connect, CSIRO Kick-Start. Since its inception in 2017, the Kick-Start program has catalysed over 280 company-led R&D projects, with alumni companies collectively boasting a market value exceeding $2 billion.

Dr Doug Hilton, CSIRO’s chief executive, underscored the significance of this investment and its transformative potential for Australia’s vital SME sector. “SMEs are crucial drivers of Australia’s future and so often the engine room of new, innovative thinking and solutions to many of the challenges our society faces,” Dr Hilton said.

CONSTRUCTION BEGINS ON BOEING’S MANUFACTURING FACILITY IN QUEENSLAND

Construction has begun on Boeing’s new production facility in Toowoomba, Queensland, to support the manufacturing of Australia’s first military combat aircraft. This facility will manufacture the Boeing MQ-28 Ghost Bat.

This will be the first time in over 50 years a military combat aircraft has been designed, developed and manufactured in Australia.

The 9,000 square-metre facility at the Wellcamp Aerospace and Defence Precinct is expected to be operational in the next three years.

The company’s latest investment in Australia will bring new aerospace skillsets and technologies, such as advanced composites manufacturing and robotics to Queensland.

Amy List, managing director, Boeing Defence Australia said, “Boeing Australia is investing to bring this innovative, uncrewed capability to market in the timeframe that supports our customers’ future needs. The MQ-28 is designed to transform air combat and provide affordable mass for Australia and our allies,” she said.

Boeing has partnered with the Queensland Government and Wagner Corporation to build the facility. The MQ-28 production facility will include aerospace manufacturing capabilities, including carbon fibre composites manufacture, along with advanced robotic assembly for major components, and final assembly and test capabilities.

Weld Connect | April 2024 17

WELD AUSTRALIA LAUNCHES FREE WELDER SAFETY ONLINE TRAINING COURSES

Welding is a potentially dangerous process, with many hazards and risks to people’s health. These risks are compounded by the fact that welding is undertaken across a wide range of locations and situations, from workshops and field work, through to confined spaces, underground mine sites, and more.

Hazards in each of these situations will be different, and require different controls to keep welders and others in close proximity safe.It is critical to manage these risks and hazards so that people working in the welding industry are kept safe and return home at the end of each day without injury.

To this end, Weld Australia has developed and released two free online welder safety training courses.

About the Courses

Weld Australia has developed two comprehensive online welder safety training courses – one course aimed at welders, and the second aimed at welding engineers and supervisors. These courses are now online and freely available to the public.

The objective of these courses is to improve safety awareness, knowledge and outcomes across the welding industry.

The courses cover a broad range of subject material across welding processes. They provide details of hazards that may be encountered and how to manage them in the workplace. The hierarchy of controls are discussed, with a particular focus on engineering controls and the correct use of PPE.

The courses also reinforce procedures that should be used, such as correct set up and use of equipment and the correct handling of gas cylinders and welding machines. Assessment and certification for course participants is also available.

How to Access the Courses

The courses can be accessed via the Weld Australia website or directly via: https://weldtraining.online

To start the courses, all you need is an account for Weld Australia’s online training platform. If you don’t already have an account, you can quickly and easily create one via the link in the top right-hand corner of the platform’s homepage.

Further Information

For further information contact: Andrew Davies (Manager, Technical Industry Networks, Weld Australia) a.davies@weldaustralia.com.au or 0438 428 966.

Weld Connect | April 2024 18

ACCESS THE COURSES NOW

Incorporating the welding safety courses into your induction process for new hires ensures all employees start with a solid foundation in safety practices. It helps set a company-wide safety standard from day one.

By undertaking these courses, you can gain essential knowledge on how to protect yourself from hazards like burns and harmful fumes. Learning about PPE and emergency procedures can be life-saving.

The courses can be used as part of an ongoing training program to keep employees up to date with the latest safety techniques. Regular refreshers help maintain safety awareness, reducing risk of accidents.

Looking to start or advance a career in welding?

Completing the courses demonstrates to employers that you’re serious about your career and committed to safety, making you stand out in the job market.

By leveraging the courses, organisations can help ensure compliance with safety laws and regulations. This helps avoid legal issues and fines and, more importantly, creates a safer working environment.

If you’re a hobbyist welder (or know someone who is), safety education is just as important. Free courses can provide the knowledge to safely enjoy welding at home, protecting yourself, your family, and your property.

Educating employees on safety can reduce workplace accidents, leading to lower workers’ compensation claims and insurance costs. A well-trained workforce is less likely to engage in unsafe practices.

By educating yourself, you contribute to a culture of safety. Sharing knowledge with peers, and practicing safe welding can influence others to prioritise safety, reducing overall welding-related accidents.

Weld Connect | April 2024 19

FREE MEMBER EVENT

The State of the Australian Industry: Productivity and Robotic Automation in Welding

Tuesday 14 May | 10.00am to 12:00 noon AEST Online via Zoom

This webinar brings together national and international welding automation experts. Attendees will receive up-to-date information on the current state of welding automation in Australia.

Learn what technologies are available, the benefits associated with welding automation, and walk away with a thorough understanding of both the ease and challenges of technology adoption in the Australian welding industry.

This event will centre around the current trends on technology and automation in the welding industry in Australia, focusing on the benefits and obstacles associated with automation in the Australian welding industry. It will also showcase a few case studies highlighting the positive impact automation can have for fabricators.

This event is FREE to attend. Registered attendees will receive the Zoom link before the event.

Presenters include:

• Brad Walsh and Pete Benicevic (Novarc Technology)

• Jeremy Vives (Robotic Automation)

• Cornelis Van Niekerk (Weld Australia)

REGISTER NOW

FREE MEMBER RESOURCES

Did you know that Weld Australia makes a range of resources available to the welding industry? Some are free for anyone to download, while others are discounted or free for certain member types.

Just some of the free resources on offer include Safety Alerts, Technical Guidance Notes and general resources, on topics as diverse as:

• Minimisation of Fatigue in Welds

• Weld Defects

• Fume Minimisation Guidelines

• A Guide to AS/NZS ISO 9606-1

• Australian Welding Standards Map (see image below)

• Safety Alert: Welder’s Clothing Catching on Fire

• Safety Alert: Hand-Held Laser Welders

• How to Recruit and Retain Staff

• How to Write an Effective Job Advert

Questions? Queries? Wondering how Weld Australia can help support your business, staff or career progression? Feel free to reach out to our Membership Manager, David Choudry, on 0417 878 104.

LEARN MORE

Weld Connect | April 2024 20

© April 2024 1800 189 900 PO Box 197, Macquarie Park BC, NSW 1670 ABN 69 003 696 526 Quality Requirements for Welding Design AS 4100, AS/NZS 4600, AS 3990, AS 5100 AS/NZS 1664.1 .2 Materials AS/NZS 1595, AS/ZS 3678, AS/NZS 3679.1, AS/NZS 3679.2, AS/NZS 3679.1, AS 3597, AS/NZS 1874 AS/NZS 1554, AS/NZS 1665 Welding Supervision, Coordination Inspection AS/NZS 1554 AS/NZS 1665 AS 1796, AS 2214, AS/NZS ISO 14731 Material Groupings SA/SNZ TR ISO 15608, ISO/TR 20172, ISO/TR 20173, ISO/TR 20174 Concrete & Composite Structures Design AS/NZS 2327, AS 3600 Bridges AS 5100 Welding, WPS AS/NZS 1554.2, .3 Pressure Equipment Materials AS 1548 AS 4458, AS 3509 Personnel Qualifications AS 1796, AS 3992, AS/NZS ISO 9606.1 AS1796, AS 3992, ISO 9606-2 AS1796, AS 3992, ISO 9606-3, -4, -5 Brazing Brazing Consumables AS 3992, AS/NZS ISO 17672 Inspection AS 3788 Flanges & Piping AS 2129, AS 4331 Conformity Assessment Castings Materials AS 2074 Welding AS/NZS ISO 13918 Measurement of Arc Energies Inspection Testing After Welding NDT General Rules AS 1101.3, AS 1929, ISO 17635 Visual Testing Ultrasonic Testing AS 1710, AS 2207, Magnetic Particle Testing AS ISO 9934 series Macro & Microscopic Testing Eddy Current Testing AS ISO 15549, AS ISO 17643 AS ISO 9712, AS ISO 20807 Classification of Welding Consumables Non-Alloy High-Strength Creep Stainless & AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS 16834 AS/NZS 21952 AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO GTAW AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO SAW Electrodes AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO AS/NZS ISO Shielding Gas AS/NZS ISO 14175 Weld Destructive Testing All-weld Tensile AS 2205.2.2 Trans Joggle Tensile AS 2205.2.1 Tensile Cruciform ISO 9018 Trans Joggle Butt Wrap AS 2205.3.4 Tongue Bend Test Macroscopic AS/NZS 2205.5.1 Dropweight Fracture AS 2205.7.2 Hot Cracking AS 2205.9.1 Delta Ferrite ISO 17655 Welding Consumables Testing ISO 15792-1, -2, -3, 6847, 14372, 8249, 3690, 2401 Environment, Health & Safety Fume Sampling in Breathing Zone AS 3853.1, AS 3853.2, AS3640 Protective Clothing AS/NZS 2161, AS/NZS 2210, ISO 11611 Welding Curtains Confined Spaces AS 2865 Electrical Safety AS 1674.2, AS 60479.1 Ionising Radiation AS 2243 series Laser Safety Welding Equipment Arc Welding Power Sources AS 60974.1, AS 60974.6, AS 60529, AS 2799, AS 4417.2, IEC 60974–14 Gas Hoses AS/NZS 1335, AS/NZS 1869 Gas Cylinders & Reticulation AS 1345, AS 1596, AS 4289, AS 4332, AS 4484, AS 4645.2, AS 4839 Others Symbols Welding Positions AS/NZS 3545 Materials Groupings SA/SNZ TR ISO 15608, ISO 20172, ISO 20173, ISO 20174 Mechanical Equipment Steelwork AS 3990 Metal Finishing Prep. Australian & Australian/New Zealand Standards for Fusion Welding “Standards do not replace education, sound judgement and good engineering practice”, Mathias Lundin TGN-SG07 costs or expenses incurred as result of or in connection with the reliance whether whole partial by any person as aforesaid upon any part the contents this Technical Guidance Note. Should expert assistance be required, the services of competent professional person should sought.

Weld Australia is excited to announce that registrations are now open for the 2024 National Manufacturing Summit.

The Summit will see a diverse group of industry stakeholders assemble in Brisbane on 31 July and 1 August 2024.

Building on the momentum of the 2023 National Manufacturing Summit, which focused on the Renewable Energy: Challenges and Opportunities, the 2024 Summit embarks on an ambitious journey with its theme: Pathways to Success…Making the Renewable Energy Revolution a Reality

The Australian Government’s commitment to reducing emissions by 43% by 2030 and achieving net zero by 2050, as outlined in the Climate Change Act 2022, sets the stage for a transformative era in renewable energy.

With an anticipated growth in renewable energy generation from 64GW to over 218GW by 2050, the manufacturing sector is at the forefront of this change, presented with unparalleled opportunities and significant challenges.

The 2024 Summit will delve into the practical aspects of manufacturing within the renewable energy sector, highlighting the essential components that will drive Australia’s transition to a sustainable future.

VENUE

The 2024 National Manufacturing Summit will be held at the Amora Hotel in Brisbane.

Discount Room Rates for Delegates

Book your stay at the Amora Hotel during the Summit and enjoy an unparalleled 15% discount off the best available rate at the time of booking. This discount will apply from 30 July 30 to 2 August. This special offer is designed exclusively for our delegates, ensuring your experience is not just memorable, but also more affordable.

Rate URL: https://reservations.travelclick. com/113954?RatePlanId=8550782

Access Code: WELD24

SPONSOR THE SUMMIT

To tailor a sponsorship package, or for further details, conact Michelle Bignold (Executive General Manager, Sales & Marketing, Weld Australia) on +61 437 106 726.

DOWNLOAD

Weld Connect | April 2024 21

SPONSORSHIP PROSPECTUS >>> LEARN MORE

A COPY OF THE

ASME B31.3 PROCESS PIPING CODE COURSE IN NOVEMBER 2024

Weld Australia is looking at hosting a three day course on the ASME B31.3 Process Piping Code in November 2024, in both Brisbane and Perth.

To register your interest, please email: Danielle Pennington (Corporate Engagement Manager, Weld Australia) on d.pennington@weldaustralia.com.au

About the Course

This course provides an introduction to the ASME B31.3 Process Piping Code. It covers the requirements of B31.3 for design, analysis, materials, fabrication, testing and inspection of process piping systems. It explores the rules for various components including fittings, connections, bends, valves and specialty components.

Other topics include dimensions and ratings of components, fluid service requirements for joints, piping flexibility and support, welding, heat treatment, bending and forming, brazing and soldering, assembly, erection, examination and inspection.

By participating in this course, you will learn how to successfully:

• Identify the responsibilities of personnel involved in the design, fabrication, assembly, erection, examination, inspection, and testing of process piping

• Describe the scope and technical requirements of the ASME B31.3 Code

• Apply and implement the quality requirements that are defined in the ASME B31.3 Code.

PIPELINE REPAIR, HOT TAPPING & IN-SERVICE WELDING COURSE IN MAY 2024

Brisbane: Wednesday 22 and Thursday 23 May 2024

Perth: Tuesday 28 and Wednesday 29 May 2024

Please note: in order for the course to go ahead, minimum attendee numbers must be reached.

To register, please email: Danielle Pennington (Corporate Engagement Manager, Weld Australia) on d.pennington@weldaustralia.com.au

About the Course

This two day course provides an in-depth overview of the various aspects of pipeline modification and repair to address the concerns associated with welding onto inservice pipelines. A thorough understanding of the factors that affect welding onto in-service pipelines helps avoid pipeline shutdowns and interruptions of service, thereby bolstering both economic and environmental benefits for operators and welders alike. Plus, repairs can be undertaken efficiently, effectively and with full confidence.

Facilitated by US expert, William (Bill) A. Bruce, the course includes a review and critical analysis of available thermal analysis models, including the original Battelle model, the heat sink capacity method and the PRCI thermal model for Hot Tap Welding. Course attendees will learn why these models, while useful as planning tools, should not be regarded as ‘magic bullets’ against hydrogen cracking in hot tap welding by utilising comparative examples.

The course will dispel a number of misconceptions that have developed pertaining to operating practices required to safely weld onto an in-service pipeline.

Weld Connect | April 2024 22

LEARN MORE

LEARN MORE

GLADSTONE TRY A TRADE DAY

Weld Australia is proud to have supported the annual Try a Trade Day at CQUniversity Gladstone Campus, organised by the Department of Youth Justice, Employment, Small Business and Training.

This incredible community-driven event empowers Year 10 female students by providing them with first-hand exposure to diverse career opportunities within the central Queensland industry.

Weld Australia was on-hand to showcase the exciting career pathways available within the welding industry and share our experiences. We also had our Soldamatic welding simulators, available for students to try their hand at welding—most for the first time.

CHARLEVILLE CAREERS EXPO

Weld Australia’s interactive stand at the Careers Expo in Charleville proved extremely popular with students. Students were keen to try their hand at welding for the first time using our highly interactive Soldamatic augmented reality simulators. The Expo in regional south-west Queensland provided regional students with the opportunity to discover the diverse range of careers, education, pathways and employment available across the region. The event included a range of workshops, demonstrations and talks to provide students with the opportunity to engage and interact with local businesses and trades to see what the workplace is all about.

Weld Connect | April 2024 24

MTE AND THORNTON ENGINEERING AWARDED AS/NZS ISO 3834 CERTIFICATION

Weld Australia is pleased to congratulate both MTE and Thornton Engineering on being awarded certification to AS/NZS ISO 3834.

MTE

MTE is an Australian, high-performance engineering and manufacturing company. MTE was established in 2014 originally as ‘Mine Tech Engineering’ by Matt Glasser and Tom Glazbrook. From humble beginnings with just two boilermakers, a single truck, a simple workshop and some basic equipment, the company is now a 200+ strong workforce across four operational facilities, building Australia’s sovereign supply chain capability across different industries.

MTE has grown to a leading national supplier of structural, mechanical, and fabrication services, delivering growth through quality tradecraft and quality people. Their capabilities extend to:

• Manufacturing and fabrication services covering structural, mechanical, piping (SMP), sheet metal, CNC machining, and polyethylene pipe welding.

• Premium industrial blast and paint, powder coating, and stainless steel passivation.

• Expert SMP construction, assembly, and remediation services with a large fleet of advanced equipment, including cranes, excavators, loaders, and more.

• Committed to the highest industry standards including 1SO9001, 14001 and 45001 certifications, MTE provides material testing, NDT inspections, ITPs and MDRs to customer requirements.

• MTE has a growing fleet of prime movers, trucks, low-loaders and trailers to meet a range of bulk and heavy haulage requirements.

Thornton Engineering

Thornton Engineering provides design and fabrication of structural steel, pressure vessels, heat exchangers, plate and piling steel products for major projects Australia wide. They work closely with project management, engineering firms and direct clients operating in the oil

L to R: MTE team members Mark Sims, Susan Strachan and Bec Cameron, with Victor Blain (Weld Australia’s General Manager, Engineering - VIC, TAS, SA, WA).

and gas, power, petroleum, mining, infrastructure and construction industries.

Established in 1975, from a small workshop in Penshurst, Victoria, the family-owned business has grown to become one of the leading steel fabricators in Australia. The company has evolved significantly from its humble beginnings but maintains its strong family values and philosophies from the early years.

In 1999, Thornton Engineering established its head office and fabrication facility on a 100,000m2 site in Geelong, Victoria. The site is strategically positioned close to a major seaport (5km), international airport (15km) and over-dimensional transport route, ensuring they can deliver finished product to all corners of the globe.

In total, Thornton Engineering operates five extensively equipped, efficient and experienced workshops, including their dedicated vessel shop, two beamlines, a plate shop and their Penshurst workshop, which enable the company to produce a diverse range of products.

Weld Connect | April 2024 26

SUCCESSFUL SURVEILLANCE RE-CERTIFICATION AUDITS ACROSS THE COUNTRY

Over the last month, Weld Australia conducted a number of successful audits, including for Moxon Industries, Precision Metal Group, Outdoor Fabrication, and NWEC.

Moxon Industries

Moxon Industries underwent AS/NZS ISO 3834.2 surveillance and EN 15085 CL1 certification audits. Established in 2001, Moxon Industries is based in south west Sydney. Their 3,000m² state of the art facility houses over 200 machines, including some of the latest CNC machine technology. Moxon Industries is dedicated to providing the highest level of engineering excellence and customer service across key industry sectors such as rail, food, concrete and masonry, civil and defence. Moxon specialises in the design, project management and manufacture of special purpose machines, precision component machining, toolmaking, fabrication and site work.

Precision Metal Group

Precision Metal Group underwent AS/NZS ISO 3834.2 surveillance, EN 15085 CL1 re-certification and DIN 2303 re-certification audits. Established in 2000, Precision Metal Group are specialists in mechanical engineering services, onsite machining, machinery maintenance, machinery relocation and welding. PMG works across a range of sectors, from defence, infrastructure and construction, through to oil and gas, maritime, mining and rail.

Outdoor Fabrication

Outdoor Fabrication had their first AS/NZS ISO 3834.2 surveillance audit. Outdoor Fabrications was established in 2000 as a specialist outdoor advertising sign construction company. Until then, most outdoor advertising signs were built by general steel fabricators and designed by engineers with little experience in the intricate workings and needs of safe sign installation.

Outdoor Fabrications has pioneered many safer and more economic ways of installing and maintaining large outdoor advertising signage, including but not limited to LED signs, monopoles and lightboxes, and the manufacturing and supply of structural steel.

NWEC

NWEC had their AS/NZS ISO 3834.2 re-certification audit. NWEC (NEW WORLD ENGINEERING & CONSTRUCTION) is a specialist steel fabrication, installation, construction management and welding resource supply company. For over 40 years, NWEC has provided first class services to the petrochemical, rail, road, gas, mining and heavy industry sectors across Australia. NWEC first began providing high quality on-site welding and boiler making services to the Sydney, Brisbane and East Coast heavy industry market. In response to the changing requirements of clients and the growing need for off-site fabrication and associated project installation services, NWEC opened a major fabrication facility in 1982. In the years following, NWEC has continued to evolve its product offering and expertise in line with its core competencies in steel fabrication and installation.

Weld Connect | April 2024 27

NWEC’s workshop.

Members of the Thornton Engineering team

Weld Australia is pleased to announce the launch of a brand new training course in line with the requirements of Welding InspectorAS 1796 Certificate 11. The first session of the course will kick off on Monday 15 July.

The Certificate 11 is an Australian Welding Inspection qualification that was recently introduced to AS 1796 Pressure equipment — Qualification of welders, welding supervisors and welding inspectors. This qualification builds upon the foundation knowledge expected of a Welding Supervisor with a distinct emphasis on inspection activities related to pressure equipment.

The Certificate 11 training is run online over six weeks, followed by a two-day practical training session. The course includes a mixture of interactive online material, live online lectures and in-person training.

Participants will gain an understanding of the roles and responsibilities of a welding inspector, and the comprehensive documentation associated with the role, including:

• Understanding AS/NZS ISO 9606.1 Qualification testing of welders and how to apply it

• Welding imperfections and defects in various materials

• Non-destructive and destructive testing

• Limits of imperfections and acceptance criteria

• Understanding and implementation of AS/NZS ISO 9001 and AS/NZS ISO 3834

• WPQR and WPS

• Welder qualification

The practical training covers:

• Visual examination of weld samples

• Reading and understanding the implications of testing reports, including destructive, radiographic, ultrasonic, liquid penetrant, and magnetic particle

• Documentation verification

This course is designed to equip participants with the skills and knowledge to excel as a proficient welding inspector, ensuring compliance with the latest edition of AS 1796.

Prerequisites

Students must hold an AS 1796 Certificate 10 qualification to meet the requirements for this course.

Please note: Students with an AS 1796 Cert 10 qualification, and an IIW International Welding Inspector - Standard (IWI-S) qualification can apply for the Certification 11 without further training or examinations. Please email qnc@weldaustralia.com.au to apply.

Further Information

For further details, download the Course Schedule, or contact training@weldaustralia.com.au

Weld Connect | April 2024 28

ENROL NOW

FACE-TO-FACE IWI-B TRAINING IN WOOLLONGONG

Starts 20 May

This face-to-face training runs over a 1-week block at our Wollongong office. The first 4 days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

FACE-TO-FACE IWI-S TRAINING IN WOLLONGONG

Starts 20 May

This course provides advanced knowledge of welding and inspection, including NDT, mechanical and visual inspection, acceptance criteria, identification of weld imperfections and more. The training runs over 8 days at our Wollongong office. The first 7days consist of theory and practical training, with the final day a practical exam.

FACE-TO-FACE IWI-B TRAINING IN BRISBANE

Starts 27 May

This face-to-face training runs over a 1-week block at our Wollongong office. The first 4 days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

FACE-TO-FACE IWI-B TRAINING IN PERTH

Starts 24 June

This face-to-face training runs over a 1-week block at our Wollongong office. The first 4 days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

ENROL NOW

FACE-TO-FACE WELDING SUPERVISOR AS1796 & AS2214

Starts 8 July

A Welding Supervisor qualification expands your career horizons enormously. Both AS 2214 and AS 1796 Certificate 10 meet the requirements outlined in AS/NZS 1554.1 to supervise the welding of structural steel. Similarly, AS 1796 Certificate 10 meets the requirement for a welding supervisor under AS 1210 for pressure vessels.

ENROL NOW

WELDING INSPECTOR - AS1796 CERTIFICATE 11

Starts 15 July

The Certificate 11 is an Australian Welding Inspection qualification recently introduced to AS1796, this qualification builds upon the foundation knowledge expected of a Welding Supervisor with a distinct emphasis on inspection activities related to pressure equipment, as well as the documentation associated with this role.

Weld Connect | April 2024 29

ENROL NOW Need help? Contact our Training team via training@weldaustralia.com.au ENROL NOW ENROL NOW ENROL NOW

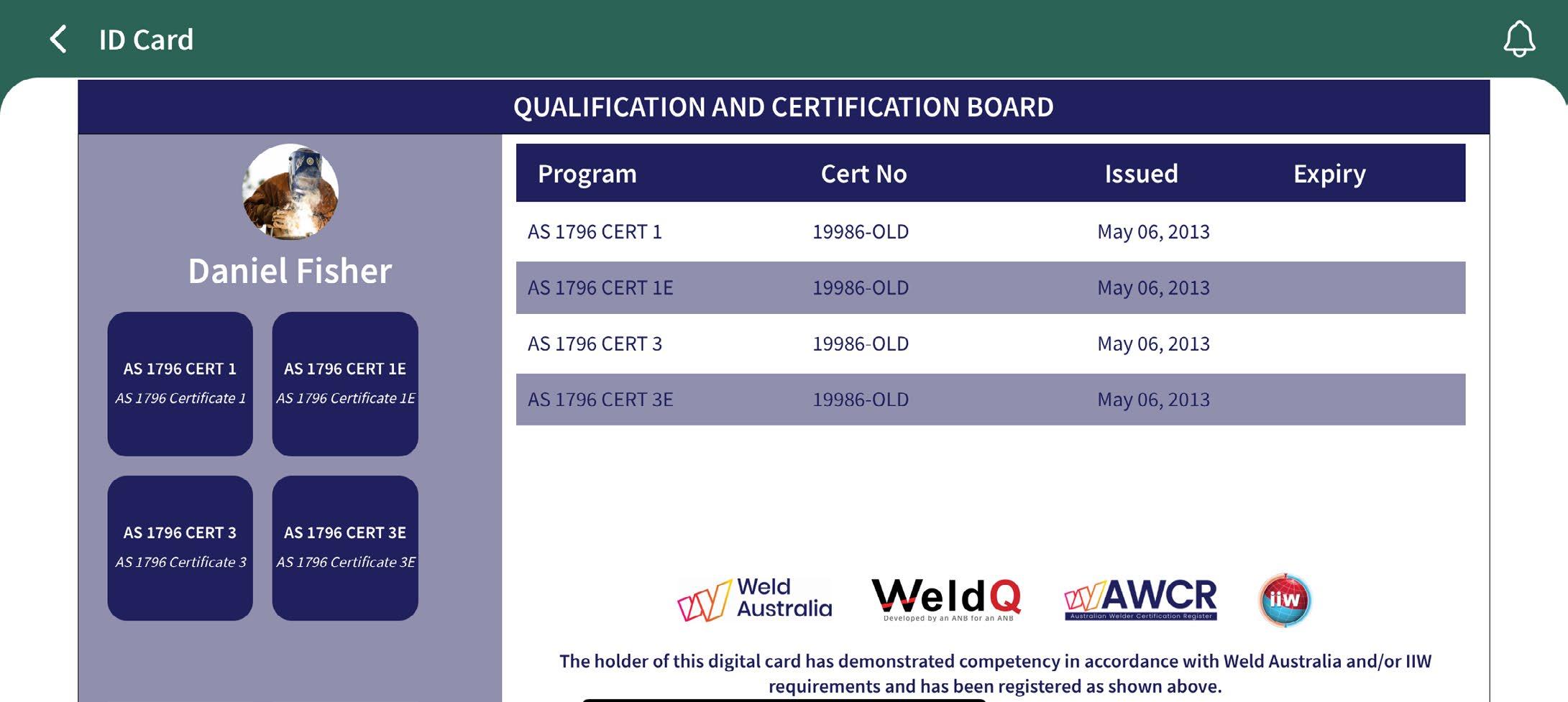

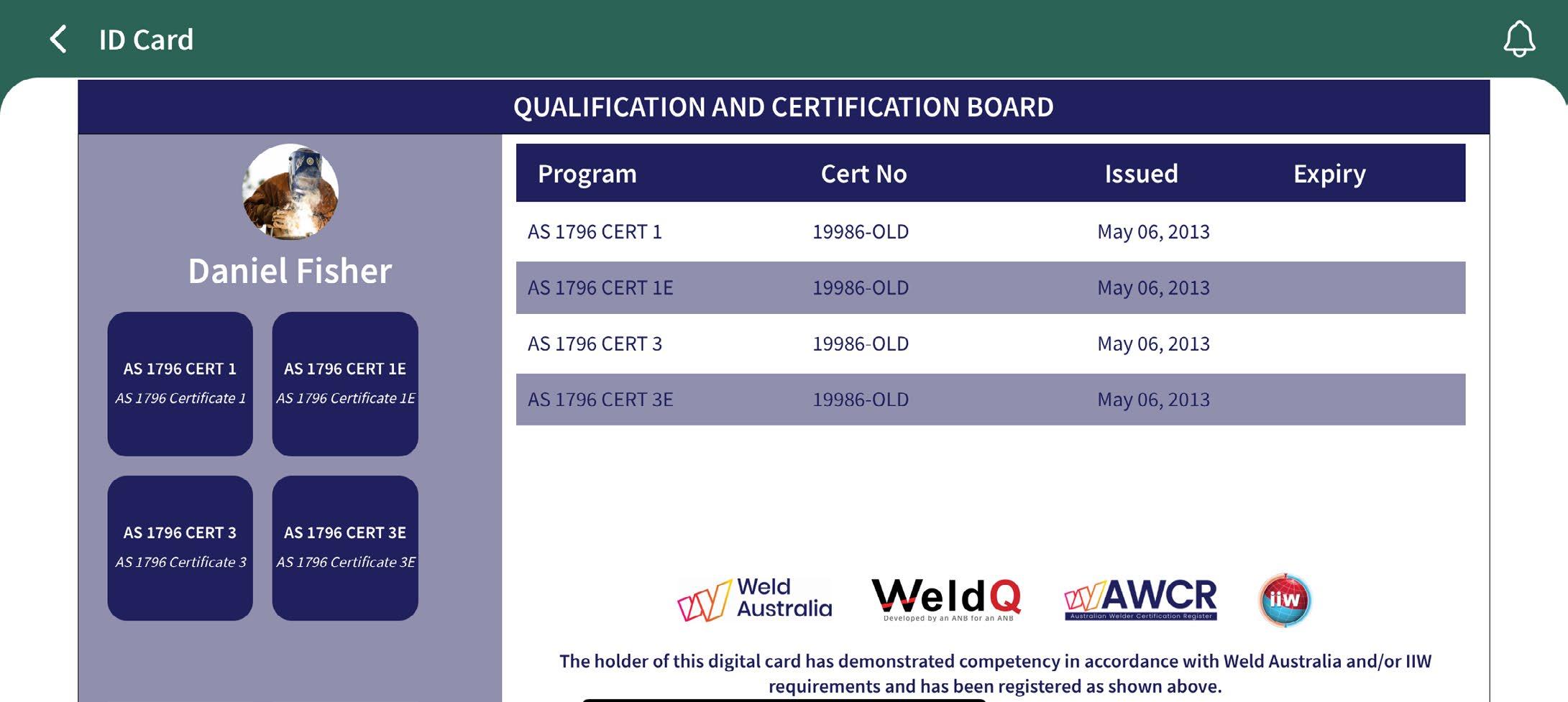

WeldQ FREE DIGITAL ID CARD

Weld Australia has an online platform for qualifications and certifications called WeldQ

The WeldQ platform is a fully internet enabled cloud based system with a supporting mobile app. Through WeldQ you can apply for examinations and certifications online, and keep a detailed record of your work history and qualifications—without needing a plastic ID card.

WeldQ is available for welders, inspectors, supervisors, and coordinators to manage their qualifications and certifications, and to use as a digital ID card or wallet (see the screenshot below). The WeldQ app can be used to view your digital Welder, Supervisor or Certification cards, awarded diplomas and certificates, status and results of applications, and WeldQ emails.

WeldQ is connected to the Australian Welder Certification Register (AWCR) which is managed by Weld Australia.

Do You Have an Existing WeldQ Account?

A WeldQ profile was created by Weld Australia for all people who gained qualifications or certifications from 2000 onwards both through Weld Australia (formerly known as the Welding Technology Institute of Australia, (WTIA)), and the IIW (issued in Australia). To check if you have an existing WeldQ profile, send an email to qnc@weldaustralia.com.au with your full name, date of birth and mobile phone number.

GET IWI-C QUALIFIED

Did you know that Weld Australia now offers qualification to IIW International Welding Inspector - Comprehensive (IWI-C)?

IIW IWI-C is the highest level of qualification available for Welding Inspectors. Individuals with this qualification possess in-depth knowledge of welding and inspection theory and application.

This knowledge enables them to tasks like:

• Manage Welding Inspection activities

• Supervise the activities of, and provide instructions to, people who hold IWI-S and IWI-B qualifications

• Act as a technical expert for the Welding Inspection function

• Develop, comment and review Quality Control Plans and Inspection Testing Plans for applications not covered by product standards, codes, specifications, drawings and regulatory requirements

• Manage inspection activities for nonconventional applications with reference to materials, processes, and advanced destructive testing and NDT techniques

Weld Connect | April 2024 30

Weld Australia would like to congratulate everyone who qualified in March.

AS 1796 CERTIFICATE 10

• Matthew Amaira

• Ryan Carr

AS 1796 CERTIFICATE 11

• Ali Rafieeye

• Jason Gibson

• Lymon Pahau

• Sean Castafaro

• Seyed Hossein Elahi

• Tony Robinson

• True-love Madide

IIW INTERNATIONAL WELDING INSPECTOR BASIC (IWI-B)

• Andrew Parisi

• Anton Kovacev

• Jesse Snow

• Liam O’Neil

• Michael Stock

• Philip Wilkins

• Robert Stout

• Sunil Kamalasanan

• Uzzal Adhikary

• Victor Michael Mantos

AS 2214 WELDING SUPERVISOR

• Jacobus Johannes (Kobus) Beets

• Mehdi Fillabi

FURTHER INFORMATION

Questions? Queries? Concerns?

For further information about exams and qualifications, simply email our team via: qnc@weldaustralia.com.au

WELD AUSTRALIA’S EXAM CALENDAR

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2024, making planning ahead as simple as possible. Just some of the upcoming exam dates include:

• Monday 22 April: IWI S: WIE-S Online Exam

• Wednesday 24 April: National Welding Supervisor Exam Paper A - Session 8

• Friday 3 May: IWE/IWT - EA1/TA1 Online Exam

• Tuesday 7 May: WTE-B and WTE-S Online Exam

• Friday 24 May: IWI-B Face-to-Face Woolongong - PEB

• Wednesday 29 May: National Welding Supervisor Exam Papers B1 and B2

• Friday 31 May: IWI-B Face-to-Face Brisbane - PEB

• Tuesday 4 June: WTE-B and WTE-S Online Exam

• Thursday 6 June: IWI-B - Face-to-Face NSW, QLD, WA - WIEB (online exam)

• Friday 7 June: IWI-B - Session 14 PE-B (Practical Exam)

• Wednesday 12 June: National Welding Supervisor Exam Papers A B1 and B2 - No Training

Weld Connect | April 2024 31

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

TRANSITION WORKERS

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 9606-1 (Steels – carbon steels)

EXPERIENCED WELDERS

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

FURTHER INFORMATION

For further information, contact: training@weldaustralia.com.au

ENROL IN A FUSION WELDING COURSE TODAY

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

ACT

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland

TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania

Tasmanian Minerals and Energy Council tasminerals.com.au

13 Wellington Street, Burnie

Victoria

Box Hill Institute boxhill.edu.au

465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au

23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat

Weld Connect | April 2024 32

For further information, contact Michelle Bignold on m.bignold@weldaustralia.com.au