IN THIS ISSUE

WRAP-UP: 2023 NATIONAL MANUFACTURING SUMMIT

FORGING A SKILLED WORKFORCE: DEVELOPING LOCAL TALENT IN PNG

AN UPDATE ON THE REVISIONS OF EN 15085

WRAP-UP: 2023 NATIONAL MANUFACTURING SUMMIT

FORGING A SKILLED WORKFORCE: DEVELOPING LOCAL TALENT IN PNG

AN UPDATE ON THE REVISIONS OF EN 15085

WELD AUSTRALIA CONTACTS

NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 02 8748 0100

office@weldaustralia.com.au

weldaustralia.com.au

Geoff Crittenden Chief Executive Officer 02 8748 0100

g.crittenden@weldaustralia.com.au

TRAINING

Guy Brooks, Training Manager 0488 743 322

g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, National Manager, Sales & Marketing 0437 106 726

m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104

d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Qualification and Certification Team Manager 0487 487 170

d.yalniz@weldaustralia.com.au

ENGINEERING

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901

a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, Engineering Team Manager - East 0491 491 888

r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Mehdi Tajfar, Senior Welding Engineer 0417 044 370

m.tajfar@weldaustralia.com.au 7 2023

In late July, I attended the 76th Annual Assembly of International Institute of Welding (IIW) and International Conference on Welding and Joining in Singapore.

I am pleased to report that Weld Australia received two commendations at IIW 2023. The first recognised our donation to the Ukraine charitable fund.

At IIW 2022, Weld Australia suggested that the IIW Board establish a charitable fund to help ensure that the Ukraine could continue to participate in IIW activities amid the conflict with Russia. The IIW enthusiastically adopted the suggestion, established the fund, and waived all fees for Ukrainian members. Although we

the IIW, Weld Australia was the first organisation to donate to the fund. During the IIW Conference, I met with several CEOs and Presidents of much larger members and hope that they will follow our lead.

The second commendation Weld Australia received at IIW 2023 was in recognition of our work with the Italian Institute of Welding on establishing the Paolo Corronca Scholarship. When our friend and colleague, Paolo, passed away earlier this year, Weld Australia created a Scholarship to fund an exchange program that will enable an Italian welding engineer to work in Australia each year.

Work on the Scholarship is well underway. We have established a

ASIA-PACIFIC’S INTERNATIONAL MINING EXHIBITION

administration, comprised of myself, and two of Weld Australia’s Directors: Madeleine du Toit and Simon Doe. The Steering Committee recently met with representatives from the Italian Institute of Welding and made some adjustments to the criteria for Scholarship applications.

We are confident that we will have a candidate for next year. The Scholarship recipient is likely to be a PhD student, who will complete half of their International Welding Engineer (IWE) studies in Italy, and half in Australia. Whilst in Australia, the recipient will be exposed to a range of activities throughout Weld Australia’s engineering, qualification, certification and training teams.

Weld Australia and the Italian Institute

250+ expert speakers 50+

the IIW for our collaborative working relationship. One of the IIW’s strategic objectives is to foster closer collaboration between its member organisations. Historically, Weld Australia has had a very strong relationship with both the Italian Institute of Welding (working together on EN 15085 certification).

Bruce Cannon (Principal Welding Engineer, Weld Australia) gave two presentations to IIW Commission VIII Health, Safety and Environment. The first presentation focused on the work done by David Chippendale (Director Sales and Marketing, AWS Welding) on the effectiveness of welding fume product controls.

Bruce’s second presentation focused on welding and related safety in Australia, including an update on safety standards, fire precautions, welding electrical safety and welders’ clothing. Bruce provided details of the two Safety Alerts published by Weld Australia—one regarding welders’ clothing, and the other on hand-held laser welding machines. This generated much discussion, with several attendees requesting copies of the alert on hand-held laser welding machines, with similar problems in their home countries.

Bruce spoke briefly about the weld fume update and cancer awareness campaign being conducted by the AMWU and weld fume hazard levels currently under review by SafeWork Australia. Finally, Bruce presented a sample of the two welder safety training videos that Weld Australia is currently developing. These courses cover a raft of activities

Learn new fabrication and welding skills in days or weeks. Build your career with a range of specialised short courses.

NSW Short Courses

across a range of welding processes, from electric arc welding and flame cutting, through to topics like welding fume safety, and welding in confined spaces, at heights, or in hot and humid conditions. These courses will be completed at the end of the year and made freely available via the Weld Australia website.

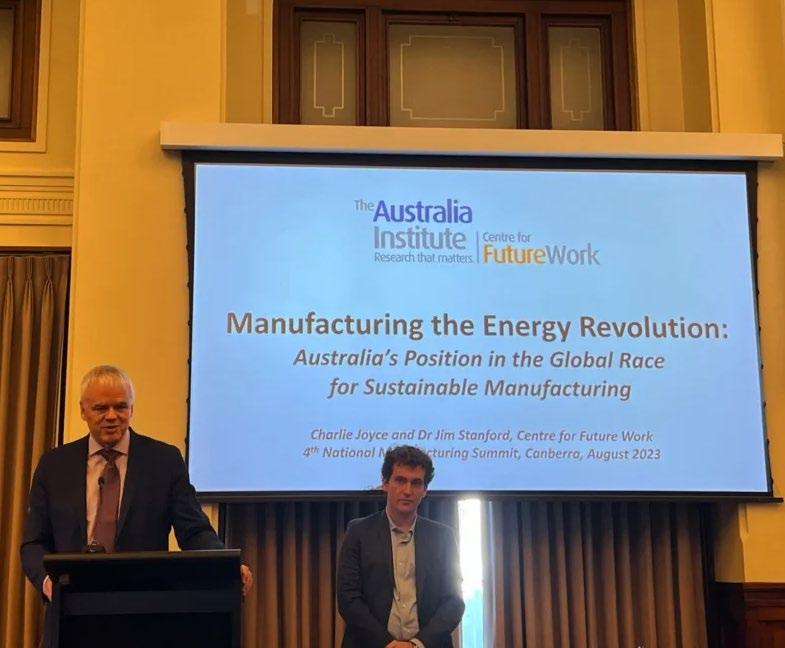

Weld Australia, in collaboration with the Australia Institute’s Centre for Future Work, hosted the National Manufacturing Summit at Old Parliament House on 2 and 3 August. With the theme of Manufacturing the Energy Revolution: Industrial Opportunities from Renewable Energy, the Summit was an extraordinary success.

Manufacturing and energy industry leaders—from union representatives, developers and business owners, through to academics, economists and government ministers—gathered in Canberra to discuss the challenges and opportunities presented by the renewable energy revolution.

The message was clear: if Australia is to meet its net zero targets by 2050, our Federal Government must enact transformative national policy that delivers secure supply chains and a diverse renewables and clean energy economy, all of which can be sustained by the manufacturing industry. Australia must take inspiration from the United States, and their Inflation Reduction Act (IRA), which has allocated upwards of US$500 billion in new spending and tax breaks that aim to boost clean energy.

In Australia, the task of responding to the IRA seems to have created such an insurmountable challenge that we have ground to a halt. A policy of fiscal conservatism driven by Treasury is obstructing any type of progress. We are defeated before the first shot is fired. Adjusted for the scale of the Australian economy, the Australian Government must commit $300 billion—approximately $12 billion a year to 2050—to a program similar in size and scale to the IRA.

Australia must embrace the golden opportunity that the renewable energy revolution presents. We must become a clean energy manufacturing powerhouse, that exports value-added products to world. In this way, Australia will create thousands of new jobs, reduce our risks to volatile international markets, reduce the cost of living for Australian families, and play an essential role in global decarbonisation

It is already too late. Australia must act now. We must act bravely and fund our renewable energy revolution properly. Australia’s governments must have the courage to act now.

Finally, I would like to thank all of our speakers, particularly our keynote speaker, Adam Hersh, for joining us from the United States. Adam’s insights into the initiatives in place in the US and their potential impact on not only the US but the global economy were invaluable. I would also like to thank all our sponsors, including the Australia Institute’s Centre for Future and Carmichael Centre; Oceanex Energy; the Department of Industry, Science, Energy and Resources; and BlueScope.

Geoff Crittenden CEO, Weld Australia2GB Sydney Radio Interview with Michael McLaren

Australia gets wake-up call on materials manufacturing, published by the West Australian

Manufacturing Australia’s answer to the climate crisis, published by the Canberra Times

Australia gets wake up call on materials manufacturing, published by The Queenslander

National manufacturing policy for net zero transition, published by auManufacturing

Radical national strategy needed in Australia’s renewable energy journey, industry says, published by Australian Manufacturing

Australia gets wake up call on materials manufacturing in surge to renewables, published by Renewable Energy Economy

Massive, powerful and now, published by AMTIL

Manufacturing Australia’s answer to the climate crisis, published by Hunter Valley News

Manufacturing summit: Calls for urgent action on energy, published by Food & Drink Business

How industry can realise the benefits of advanced technology, published by Manufacturers’ Monthly

Mitigating the impact of welding fumes, published by Climate Control News

This is a must attend event for railway industry personnel. A follow-up on some of Weld Australia’s previous workshops, this event will deliver insights and practical recommendations on how to implement the new requirements of the EN 15085 series of Standards in your workshop—over the last three years, five revisions of the Standards have been released. The event will also cover how to gain certification, and be in a position to partner with companies like Alstom, CAF, Siemens, Hitachi and others playing a role in the various railway projects across the country.

EN 15085 was introduced to harmonise the requirements for welding materials during the manufacture and maintenance of railway vehicles, and builds upon the requirements outlined in ISO 3834 Qualityrequirementsfor fusionweldingofmetallicmaterials . While the international uptake of this certification has grown in recent years, in Australia there are still very few EN 15085 certified manufacturers. Clearly, the potential market share that newly EN 15085 certified Australian manufacturers could capture is huge. The benefits associated with EN 15085 certification are myriad, including: independent confirmation of welding capacity, competence and employee capabilities within a defined scope of activity; and the potential to participate in large, profitable international supply chains, thereby increasing orders and work won. More and more, EN 15085 certification is gaining interest and attention from government departments and railway industry manufacturers as part of the tender assessment process. This workshop is the perfect place to start if you’re considering EN 15085 certification for your business.

Presenter: Victor Blain

(Engineering Team Manager – South & West, Weld Australia)

Victor is a solution oriented engineer with over 15 years’ experience in materials and welding. Prior to joining Weld Australia, Victor worked in manufacturing, at Bombardier Transportation. His main achievements are related to project start-up, welding coordination and suppliers audit and support in multiple countries, including Canada, China, New Zealand, Malaysia and Australia. Victor has in-depth knowledge of the ISO, EN, AS/NZS, CSA and AWS welding standards, and holds a trade qualification in Welding, a degree in Metallurgy, a Bachelor of Mechanical Engineering, and is an International Welding Engineer (IWE).

• Date: Thursday 24 August

• Time: 10.00am to 1:00pm AEST

• The workshop will be hosted via Zoom, with login details supplied upon registration. Please ensure you have suitable internet access.

• Note that places are capped to 20 people.

• Registration Costs:

• Weld Australia Members: Free

• Non-Members: $95 (inc GST)

This workshop will be limited to 20 participants. So register now, before it’s too late! To register, visit: https://portal.weldaustralia.com.au

For further information about the workshop, contact Victor Blain (Engineering Team Manager - South and West, Weld Australia) on 0409 823 991 or v.blain@weldaustralia.com.au

Weld Australia, in collaboration with the Australia Institute’s Centre for Future Work, hosted the National Manufacturing Summit at Old Parliament House on 2 and 3 August. Its theme was Manufacturing the Energy Revolution: Industrial Opportunities from Renewable Energy

International expert, Adam Hersh, addressed the opportunities and challenges presented by Australia’s renewable energy revolution at the Summit Dinner, while Emily Scivetti, Chief Operating Officer at Oceanex Energy, gave an insightful overview of Oceanex operations, as well as the inherent benefits of offshore wind energy.

The Hon Tim Ayres, Assistant Minister for Manufacturing and Trade, opened the 2023 National Manufacturing Summit. According to Ayres, “Australia will work cooperatively with our key trading partners like the United States, Japan and the Republic of Korea on our shared clean energy and green industrial objectives. Because the global challenge of decarbonisation requires a global solution. And Australia is set on playing its part.”

“The Australian Government will support our trading partners in their own transition to net zero – including by being a reliable supplier of the resources they need during the process.”

“Ensuring the transformation of our nation into a highvalue, high-wage modern green economy needs to be a collaborative effort. It will involve governments, industry, unions, the research sector and other stakeholders. If we work together Australia will reach our emissions reduction goals while placing ourselves in the forefront of advanced manufacturing nations. Because there is too much at stake to simply retreat or be resigned to another decade of slipping down the global value chain.”

Australia risks being left out of lucrative new markets for renewable energy-related manufacturing unless government provides an urgent, domestic response to match powerful incentives introduced by the US and several other industrial nations.

The finding was published in a new report released by the Australia Institute’s Centre for Future Work, as part of the National Manufacturing Summit, held in Canberra last week.

According to the report, there is an overseas manufacturing boom in the productions of batteries, electric vehicles, renewable energy generation and transmission equipment, and other renewable energy products. This boom is being driven by incentives provided by the Biden Administration’s Inflation Reduction Act, and similar supports in the European Union, China, Japan, Korea, and Canada.

Meanwhile, Australia is considering its response, but no clear strategy has been announced.

Several qualitative best practices should also be included in the Australian response to the IRA to generate maximum economic, social, and environmental impact. These include strong labour and environmental standards attached to subsidised projects, public equity participation, and parallel investments in training for workers.

“The extraordinary response by industry to the U.S. measures confirms that these policies are having an outsized effect on the volume and location of sustainable manufacturing investment,” said Dr Jim Stanford, Director of the Centre for Future Work and co-author of the report.

“It also confirms that Australia must move quickly with its response to this new industrial landscape, or risk losing its chance to leverage our

renewable energy resources into lasting, diversified industrial growth.”

Charlie Joyce, a research fellow at the Centre and co-author of the report, noted: “The global race for clean technology manufacturing is well underway, and Australia is barely on the track.”

“Australia has many advantages when compared to other competitors in this market, including an unmatched endowment of renewable energy sources and ample deposits of critical minerals. However, the painful legacy of decades of policy neglect for domestic manufacturing has left our industrial base in poor shape to seize the opportunities opening up ahead of us.”

“If we don’t support domestic manufacturing to quickly enhance its production, skills, and technological capabilities, all that will happen is we will replace one set of unprocessed minerals: coal, oil and gas; with another: raw lithium and related critical minerals.”

“Without action, most of the spinoff benefits of the renewable energy revolution for industry, technology, value-added and diversification will pass us by,” said Joyce.

The report estimates the proportional investment required to match the American IRA in the Australian context at between $83 to $138 billion over 10 years in fiscal supports and incentives to match US benchmarks.

“That is a big fiscal ask by any standards, but not out of reach for Australia,” said Dr Stanford. “But the common claim that Australia cannot afford to undertake proportionately equivalent measures is not convincing.”

“Our federal budget is in much better shape than the US And the government has committed to other, less pressing priorities which are just as expensive – such as nuclear submarines, Stage 3 tax cuts, and ongoing fossil fuel subsidies.”

Dan McKinna, General Manager at Keppel Prince Engineering, kicked off session two, speaking about the opportunities and challenges in manufacturing onshore wind towers in Australia at the 2023 National Manufacturing Summit.

According to Dan, “We need to incentivise investment. We must have certainty of demand—if local manufacturers are going to invest in factories, we need certainty that those factories will be fed. We need local content targets. The potential demand need not be 100%. We need to remove the peaks and troughs; we need a baseline demand for an extended period of time.”

Simon Preston, Group General Manager at Allthread Industries, presented a case study focused on the Murra Warra II wind tower project. Given the size, scale and weight of the turbines, a robust anchor cage

solution was required; the expertise of Allthread Industries was required. Allthread Industries supplied a unique solution that competed with cheaper overseas imports based on the value delivered throughout the construction phase—not just on the cost of steel.

“We were able to provide an Australian-made solution. Our solution used all Australian steel, and on analysis used 97% Australian content and 50% recycled content,” said Simon.

Emily Scivetti, Chief Operating Officer at Oceanex Energy, spoke about the potential economic and regional benefits of offshore wind energy.

These benefits include $10 billion estimated capex and $200 million in DEVEX for up to 5 to 7 years; 3,000 direct jobs duration the construction period of three to four years; and 300 jobs during the 30 year operation and maintenance life.

The offshore wind energy revolution creates an immense opportunity for businesses and workforces that possess complementary manufacturing and fabrication skills to transition to a new industry.

The Hon Lance McCallum, Assistant Minister for Energy Queensland, provided an overview of the Queensland state government’s work in renewables.

Queensland has set a bold clean energy future—a 70% renewables target by 2032—as part of the $62 billion Queensland Energy and Jobs Plan.

The Plan includes initiatives such as: a commitment to progress two new pumped hydro projects by 2035; a pathway to build the new Queensland SuperGrid, which will connect solar, wind, battery and hydrogen projects across the state and unlock new capacity and storage; a commitment to convert all of Queensland’s publicly-owned coal-fired power stations into clean energy hubs by 2035, backed by a Job Security Guarantee for workers; and substantial investment across the state, with 95% of clean energy infrastructure investment anticipated to be in regional Queensland.

“We are sending a very clear message to manufacturers—those already established in Queensland, or looking to the future—you are welcome in Queensland. We have a renewable energy plan, a myriad of opportunities directly related to the plan (and indirectly related to the plan throughout the supply chain), as well as opportunities for the 2032 Olympics and everything associated with that,” said Minister McCallum.

Fredrik Andrén-Sandberg, Head of Public Affairs APAC, Vestas Asia Pacific, and Tim Buckley, Director, Climate Energy Finance, also gave highly informative and engaging presentations during this session.

industry.gov.au/major-projects-and-procurement

Katie Hepworth PhD, Political and Strategic Advisor, Australian Manufacturing Workers Union, presented on the heavy vehicle manufacturing industry.

According to Katie, there is a real need for regulatory certainty and harmonisation of standards, a steady supply of work and a smoothing of demand, and workforce skills development in both R&D at a high level and in trade skills.

“We cannot rely on narrow local content rules. While these are an important part of the equation, we need to determine how we target funding. Where are we funnelling the money?”

“We cannot just ask for government funding and tax credits, the money needs to be targeted to gain a competitive advantage. We need a response that is commensurate to the US Inflation Reduction Act. We’re calling for $150 billion,” said Katie.

Australian Council of Trade Unions President, Michelle O’Neil, made it clear that there shouldn’t be a single worker made redundant by the phase-out of fossil fuels.

“If we miss out on this opportunity to become a renewable manufacturing powerhouse, we’ll be leaving jobs and wealth on the table.”

“Don’t leave behind those people

who make everything you use every day,” she said. “There are so many manufacturing sectors hitting the new learning curve.”

For further details about the Summit, including in-depth coverage of all the opportunities and challenges discussed, be sure to keep an eye out for the upcoming edition of Australian Welding magazine.

Katie Hepworth.

Michelle O’Neil.

Katie Hepworth.

Michelle O’Neil.

Weld Australia is proposing to establish a Renewable Energy Industry Group to bring together existing generators, new players, manufacturers, suppliers, specialists and consultants.

Interested in joining? To register your interest, please contact Andrew Davies (Manager Technical Industry Networks, Weld Australia) on 0438 428 966 or a.davies@weldaustralia.com.au

The Federal Government has established a policy and targets to reduce carbon emissions by 43% by 2030, and reach net zero by 2050. These targets will play a key role in limiting global temperature increases and ensuring Australia’s transition to a low carbon future consistent with our commitments under the Paris Agreement. These targets will necessitate the construction of new infrastructure on a massive scale. Local manufacturing and supply chains will need substantial growth to provide resources and materials for the planned renewable infrastructure. A massive increase of skilled workers will also be required.

Australia’s renewable energy industry will need to deal with raft of issues to deliver on these ambitious projects, including:

• Manufacturing and fabrication capacity

• Raw materials (such as steel and copper)

• Skills and labour

• Contracting and contractor resources

• Regulatory approvals

• Connection to the grid

All this is within the context of several broader Australian energy market issues, including:

• Market volatility

• Grid stability

• Thermal electricity generation operational limitations

In face of these challenges, Weld Australia’s new Renewable Energy Industry Group will bring together existing generators, new players, manufacturers, suppliers, specialists and consultants to:

• Share knowledge experience, and learnings

• Discuss and workshop renewable energy issues

• Network and collaborate with like-minded industry colleagues

• Develop younger and less experienced staff

The purpose of the Weld Australia Renewable Industry Group will be to grow, strengthen and support the local Australian Renewable Energy Industry. The Renewable Energy Industry Group will bring together like-minded companies in the renewable energy sector to meet and discuss issues facing the industry. Weld Australia will also manage and facilitate meetings and act on behalf of its members in addressing issues that arise from the Group.

The Renewable Energy Industry Group will commence with an online webinar on Thursday 28 September from 10:00am to 12:00 noon. A broad agenda for this meeting will include:

• Introductions and group overview

• Technical presentations

• Open discussions of issues and group structure

• Details for the next meeting

The Federal Government recently announced the Board of the $16 billion National Reconstruction Fund (NRF).

With expertise drawn from across different corners of the country, the Board will ensure the NRF has a national focus. The independent Board will make independent investment decisions. The Board’s specialist knowledge spans the NRF’s seven priority investment areas: Renewables and low emissions technologies; Medical science; Transport; Value-add in the agriculture, forestry and fisheries sectors; Value-add in resources; Defence capability; and Enabling capabilities.

Members appointed to the Board include:

• Martijn Wilder AM (Chair), Founder and CEO of Pollination

• Ahmed Fahour AO, Chairman of Invest Victoria

• Dr Katharine Giles, CEO and Managing Director of OncoRes Medical

• The Hon Kelly O’Dwyer, Non-Executive Director of Barrenjoey, Equity Trustees, and HMC Capital

• Daniel Petre AO, Co-Founder and Partner Emeritus of AirTree, the Chair of Vera Living, and a Director of MetaOptima Technology

• Kathryn Presser AM, Chair of the South Australian Department of Treasury and Finance’s Risk and Performance Committee

• Karen Smith-Pomeroy, Chair of the Regional Investment Corporation and the National Affordable Housing Consortium

• Daniel Walton, Director of AustralianSuper

The Victorian Government is supporting the state’s defence industry with new grants to help Victorian businesses compete for and win major contracts, growing local defence capabilities and creating jobs.

Minister for Manufacturing Sovereignty Ben Carroll visited Amiga Engineering and announced round two recipients of the Victorian Land Systems Fund – Supply Chain Uplift Program, which will support Victorian companies to become part of Hanwha Defense Australia’s LAND 8116 supply chain.

A total of more than $275,000 in grants will be awarded to four local companies that specialise in land systems defence to grow their business competitiveness and capabilities, supporting them to become part of Hanwha’s delivery of the Commonwealth Government’s $1 billion LAND 8116 Self-Propelled Howitzer program.

Hanwha has also secured the contract for the multibillion LAND 400 Phase 3 program, the largest land defence contract ever awarded in Victoria. Around 600 direct jobs will be created from delivering the defence projects and hundreds more indirect jobs across the supply chain.

Hanwha is establishing a $170 million Armoured Vehicle Centre of Excellence at the Avalon Airport Industrial Precinct and will require a strong local supply chain to deliver its defence programs in Victoria.

Victoria’s defence sector supports around 24,300 jobs across the sector and contributes $8.4 billion to the Victorian economy each year.

To learn more and apply for the Supply Chain Uplift Program visit business.vic.gov.au/scup.

Source: https://www.manmonthly.com.au/

The arrival of the Austal-built Littoral Combat Ship, USS Canberra (LCS-30), into Sydney Harbour ahead of its official commissioning is a proud moment for the Western Australian-headquartered company.

The vessel, one of 19 Littoral Combat Ships the company’s USA subsidiary is building for the US Navy, arrived after transiting across the Pacific. Once officially commissioned, it will be the only US Navy vessel ever to be commissioned outside of the United States of America, a reflection of both the important relationship that exists between the USA and Australia as well as the ship’s Australian heritage.

The vessel’s distinct triamaran design, which gives it a shallow draught and incredible stability to operate in inshore (littoral) waters, is based on a design pioneered at the Company’s Henderson shipyards in Western Australia.

Austal Chief Executive Officer Paddy Gregg said it was a proud day for the Company, which began life building aluminium crayfishing boats in Western Australia.

“Watching an Austal-built US Navy warship sail into Sydney Harbour, with the iconic Sydney Harbour Bridge and Opera House in the background, was an absolutely special moment for our Company,” Mr Gregg said.

“Austal’s Alabama-based shipyard is currently contracted on 11 different vessel programs for the US Navy and Coast Guard, and it is a source of pride seeing this vessel visiting our home. Plus, its Australian and historical heritage makes it all the more special.”

In addition to its US orderbook, Austal is also constructing two vessel classes for the Commonwealth of Australia at its WA shipyards, the Evolved Cape Class Patrol Boat for the Royal Australian Navy and the Guardian Class Patrol Boats for the Commonwealth of Australia to be gifted to Pacific Island nations.

Coregas, the largest Australian owned industrial gases company, has launched the Coregas H2Station, Australia’s first hydrogen refuelling station for heavy vehicles. The H2Station is leading the clean mobility revolution and will stimulate Australia’s emerging hydrogen sector.

Construction of the $2 million H2Station has been assisted by a $500,000 New South Wales Government grant. The H2Station will facilitate the introduction of zero emissions hydrogen fuel cell trucks to the Illawarra-Shoalhaven region.

Local heavy vehicles will be encouraged to access the H2Station, which can rapidly refuel up to 10 vehicles daily. The H2Station is a lowcost commercial solution capitalising on existing infrastructure aimed to seed a future network of hydrogen fuelled transport.

According to Alan Watkins (Executive General Manager at Coregas in Australia), “Locating H2Station alongside Coregas’ existing hydrogen production plant and transport hub for bulk hydrogen in Port Kembla created operational and cost efficiencies. The H2Station will allow hydrogen trucks to access the majority of the Illawarra-Shoalhaven region and reach metropolitan Sydney.”

Transitioning Coregas’ diesel truck fleet to FCEVs is a cornerstone of the company’s decarbonisation roadmap. “Coregas’ diesel truck fleet travels almost six million kilometres every year,” said Alan. “That’s equivalent to driving 150 times around the world, which contributes to 54% of Coregas’ carbon emissions.”

The Australian Cobotics Centre is a collaboration between researchers and industry, funded by the Australian Research Council. The Centre aims to increase the use of collaborative robots (cobots) in manufacturing.

A cobot is a robot that works with people in a shared workspace. Although the use of robots of fully automated production is well known within manufacturing, cobots remain relatively underused, despite the benefits they bring, especially for small businesses (who will win on process innovation and lower costs), manufacturing workers (whose jobs will become safer and higher-skilled), and the economy (through the growth of jobs and exports).

As a proud partner of the Australian Cobotics Centre, Weld Australia is working with their team to find solutions to some of the key challenges facing our members (including labour shortages and safety of workers), and to understand how we can increase adoption of cobots and other technology.

The Centre’s research programs address both the technological advances and the human and design factors that need to be considered when adopting collaborative robotics.

Through their research projects, the Centre can provide solutions to the above challenges and is seeking partners to work with. The Centre needs examples to test and validate research outcomes in areas like:

• Advanced cobotic welding

• Understanding skills and training needs for new ‘hybrid’ welders working with cobots

• Quality assurance and compliance of cobotic welding

Being part of these projects gives your organisation a competitive edge and allows you to be at the forefront of technological innovation, without the significant financial investment usually required.

The Benefits of Cobots

Cobots are specifically designed to share the work space with human beings, making automation easier for businesses of all sizes, particularly SMEs. Cobots are generally versatile, lightweight, require relatively little space, and are much easier to program than their industrial counterparts. They can also capture large volumes of data that can be deployed in areas such as predictive maintenance. Just some of the benefits delivered by cobots include:

• Improved productivity and profitability

• Superior quality and repeatability

• Growth in domestic and export markets for SMEs

• Safer working conditions

• Greater job satisfaction

Weld Australia’s Advanced Manufacturing Industry Network will host a free webinar in conjunction with the Australian Cobotic Centre on Tuesday 29 August. The webinar will delve into topics like how cobots work, the benefits they can deliver, how to train staff in their use, and integration of cobots throughout the Australian manufacturing industry.

Event Details

• Date: Tuesday 29 August

• Time: 10am to 12 noon

• Location: Online via Teams

To register contact Cornelis Van Niekerk (Business Manager, Defence Welding, Weld Australia) via c.vanniekerk@weldaustralia. com.au

Weld Australia’s Excellence Awards are the most prestigious event on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2023 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Winners will be awarded in each state for each of the award categories below.

Entries must be submitted via the specific online form for each category by midnight on 15 September 2023. These forms can be found on the Weld Australia website, by clicking on the relevant red button. Download the Award Criteria via:

• Company of the Year – Fabrication

• Company of the Year – Gas & Gear

• Indigenous Company of the Year

• Health and Safety in Welding

• Project of the Year

• Welding Professional of the Year – Welding Coordinator

• Welding Professional of the Year – Welding Supervisor

• Welding Professional of the Year – Welding Inspector

• Young Trades Person of the Year (under 25 years of age)

• Trades Person of the Year (over 25 years of age)

• Young Indigenous Trades Person of the Year

• Training and Education Award – Organisation

• Training and Education Award – Individual Teacher

• Ken Trevena Award – South Australia Only

• Mick Cudmore Award – Western Australia Only

The awards will be presented at events held across the country in October and November:

• Perth: Wednesday 18 October at Beaumont on the Point

• Sydney: Wednesday 25 October at Waterview in Bicentennial Park

• Adelaide: Wednesday 1 November at Glenelg Golf Club

• Brisbane: Wednesday15 November at Indooroopilly Golf Club

• Melbourne: Wednesday 29 November at Huntingdale Golf Club

Registrations for the events are now open, and can be booked by clicking on the links above. The 2022 award events sold out in record time, so be sure to register early to avoid disappointment.

Melbourne: 12 & 13 October |

to brush up on residual stresses and distortions?

Facilitated by USA expert Pingsha Dong, this two day course will cover the fundamentals that every engineer should know when designing welded components. From weld in-situ strength, residual stresses, and geometric discontinuities, every aspect plays a different role in contributing to resultant joint strength, and fatigue resistance. Implications on metallic additively manufactured (AM) parts will also be discussed.

With plenty of opportunities for questions, this course can help attendees mitigate the detrimental effects of welding defects, reducing inefficiencies and costs, and improving project schedules and productivity.

Professor Pingsha Dong of the University of Michigan, is the inventor of the mesh-insensitive structural stress method (also referred to as the Master S-N Curve Method) adopted by the 2007 ASME Div 2 and API 579/ASME FFS-1 Codes and Standards mandated by over 50 countries worldwide. Over the past 20 years, Professor Dong has taught courses in fatigue design, fracture control, residual stress and distortion control in over a dozen countries around the globe. Professor Dong has published more than 260 peer-reviewed papers in archive journals and major conference proceedings, including over 20 plenary and keynote lectures at major international conferences.

Perth: 17 & 18 October

This course will address fundamental aspects that engineers should know when designing welded joints. It will incorporate key findings from the most recent research developments in analytical and computational modeling of welded joints and welding processes. Proper design and costeffective construction of welded connections require considerations of some of the unique issues associated with welding, in addition to specific loading environments. Modules include:

• Unique issues associated with welded joints and design implications, and implications on metallic AM parts

• Basic considerations in design of welded joints and analysis methods

• Joint design for static and fatigue performance

• Residual stress and distortion control in construction

This course will delve into how residual stresses and distortions are developed during fusion and solid-state welding, and related manufacturing processes, including metal 3D printing and additive manufacturing. Simple analytical models will be used to describe the underlying mechanisms, and computational modeling results will then be used to demonstrate the relevance of these analytical results for deriving effective solutions to various residual stress and distortion problems experienced by various industry sectors, including aerospace, automotive, heavy equipment, and shipbuilding.

Then, the principles for residual stress and distortion mitigation techniques will be discussed and illustrated with various real-world applications. In addition, how residual stresses and distortions affect components’ structural performance (such as fatigue capacity) will be discussed, including how to effectively treat their effects in structural integrity evaluation, based on the most recent research findings.

REGISTER FOR

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications. This three day course in Adelaide will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

This course is intended for people who are involved in writing and qualifying welding and brazing procedure specifications, qualifying welders, brazers and operators, reviewing suppliers procedures, auditing or reviewing in-house procedures and qualifications and estimating jobs which impose the requirements of Section IX.

Welding Engineers, quality assurance personnel, auditors, testing laboratory personnel, maintenance personnel and jurisdictional inspection personnel will find this course interesting, exciting and beneficial.

Course Overview

A review of the welding processes and variables, and basic steel welding metallurgy will be conducted to provide all participants with sufficient background in welding technology to interpret and understand Section IX. The mechanics of using Section IX and how to address its requirements will be explained in a simple, straightforward manner.

Emphasis will be placed on writing welding procedures so that they contribute positively to the manufacturing process and on qualifying procedures in a cost-effective manner.

The requirements for welders and operators will be examined with particular emphasis on minimising the cost and maximising the usefulness of qualifications.

Time will be provided to address individual participant’s problems and concerns. Attendees will receive copies of the course notes covering the course’s content. Attendees must bring a copy of the current edition of Section IX. Multiple choice tests will be given for each section.

Course Details

Date: 1 to 3 November 2023

Venue: Stamford Grand Adelaide – Glenelg

Address: 2 Jetty Road, Glenelg, SA 5045

Room: Moseley Room

Time:

• Registration first day: 8:00am

• Course time: 8:30am to 4:00pm

Cost

Weld Australia Members: $3,610 inc GST

Non Weld Australia Members: $3,810 inc GST

Further Information

For further information, contact: Michelle Bignold (National Manager, Sales and Marketing) on 0437 106 726 or m.bignold@weldaustralia.com.au

Maximum capacity is 30 people. Get in quick to avoid disappointment! Click on the button below, or register online via: https://weldaustralia.com.au/ asme-section-ix-three-day-course/

UPCOMING MEMBER EVENT IN ADELAIDE FUEL YOUR FUTURE WITH HYDROGEN TECHNOLOGIES: A PRACTICAL PERSPECTIVE

Are you ready to delve into the world of hydrogen technologies, safety, compliance, and applications? This upcoming FREE member event will bridge theory with practical insights, giving attendees an opportunity to learn more about the growing hydrogen industry.

Our guest speaker—Matt Wagenfeld, Head of Operations at Hydrogen Systems Australia—will explore how hydrogen technologies can bolster regional energy security and unlock significant economic opportunities. Understand how you, as an individual or a business, can contribute to de-carbonising our economy using existing and emerging hydrogen technologies.

Event Details

• Date: 21 September 2023

• Time: 5.30pm to 7.00pm

• Venue: Coopers Alehouse

• Address: 560 Main North Road, Blair Athol, Adelaide, South Australia 5084

• Cost: Free for Weld Australia members

Weld Australia would like to welcome all our new Members who have joined in the last month:

CORPORATE MEMBERS

• Elphinstone: elphinstone.com

• Knox Engineering: knoxeng.com

• Nix Engineering: nixengineering.com.au

• Crisp Bros Haywards: crispbroshaywards.com.au

• JB Specilised: jbspecialisedengineering.com.au

• Lucky Strike Welding

• Komatsu: komatsu.com.au

• Nexsa: nexsa.com.au

INDIVIDUAL MEMBERS

• Evan Butler

• Orlan Cas

• Phillip Clerke

• Anthony Duran

• Aaron Hicks

• Lee Lacour

• Daniel James Middleton

• Elangovan Murugasu

• Muhammad Majid Saleem

• Kieran Sheahan

• Rod Mackay Sim

• Warrick Smith

• Patrick Victor

• Ryan Williams

• Thomas Wilmann

Weld Australia would to welcome the two newest members of our team. Ian Mackay has joined us in the role of Business Development Manager based in Perth, while Ashkan Abdibastami has taken on the role of Welding Engineer.

Ian Mackay, Business Development Manager

Ian is a results-driven leader with over 30 years of management experience across various market-leading organisations. With a strong background in metallurgy and a focus on quality control and process improvement, Ian has consistently demonstrated their commitment to excellence and driving positive change within organisations.

Ian has held Senior roles at Downer EDI, Toyota Motor Corporation, Chess WA and Davy International, among others. His experience ranges from managing small specialist businesses through to large corporate business units with turnovers ranging from $8 million to $800 million and up to 600 personnel. Ian’s notable career achievements include his role as National Product Sales Manager at REMA TIP TOP Australia, where he enhanced site safety protocols, introduced ISO 9001, and successfully built critical business teams, resulting in improved performance outcomes.

Ashkan Abdibastami, Welding Engineer

Ashkan is a highly accomplished materials engineer with a strong academic background and extensive experience in the field. Currently pursuing a PhD in Structure and Dynamics of Materials at the University of New South Wales (UNSW), he demonstrates a passion for research and advancement in the materials engineering domain. His PhD is focused on magnetic materials as tracers for Magnetic Particle Imaging (MPI) application, design and synthesis of metal-doped iron oxide nanoparticle materials as tracers for MPI application, and materials characterisation and processing of metal-doped iron oxide nanoparticle materials for MPI application.

Prior to joining Weld Australia, Ashkan played a crucial role in quality control and assurance in the oil and gas industries in Iran. As a materials and welding engineer, Ashkan undertook materials testing, quality engineering, and inspection. His responsibilities included developing Welding Procedure Qualification Records (WPQR) and Specifications (WPS), and coordinating welding repairs.

Asia Pacific’s International Mining Exhibition (AIMEX) is back at Sydney Showgrounds from 5 to 7 September, and the largest free-to-attend conference program in Australia has officially been released, to accompany the AIMEX exhibition.

Over 25 leaders from resources, minerals processing, METS and policy will gather to move industry agendas forward with presentations, panel discussions and keynote speeches at Australia’s longestrunning mining event.

Each day of the three-day conference will address a specific theme. Day one covers decarbonisation in mining, one of the biggest topics for the industry currently. The opening day will have panel discussions featuring leaders from METS Ignited, Australian Hydrogen Council, ISN and the International Copper Association Australia.

John Fennell, CEO of the International Copper Association Australia, says the conference comes at a critical time for the resources sector.

“The world’s move to electrification has compounded supply and demand issues across industry. There are key technologies that will help us to move forward with higher operational efficiency and lower emissions, but in order to implement these technologies industry-wide we need to talk about them as an industry first.”

Day two will cover technical innovation, with a keynote from Nathan Kirchner of Robotics Australia Group, plus panel discussions with academic experts from the University of Newcastle and UQ’s Sustainable Minerals Institute, and contributions from Accenture, CR Powered by Epiroc and Fleet Space Technologies.

The final day of the conference will focus on the hot-button topic of ESG, with speakers discussing renewable integration, the circular economy, and leveraging technology.

Associate Professor Liza Forbes from UQ’s Sustainable Minerals Institute is speaking as part of two panels at the conference, and notes the importance of industry collaboration and conversation.

“One of the biggest barriers to industry collaboration is that systemic incentives for academic work are often not in step with industry needs, resulting in siloed operations. It is vital for academic research to build and maintain industry relevance by staying abreast of the common problems that industry encounters and the solutions that are sought for such problems,” Dr Forbes said.

“By coming together at events like AIMEX, we open important channels for discussion and collaboration that work towards removing those knowledge silos.”

The conference runs alongside the AIMEX exhibition, with over 250 national and international exhibitors making the three-day event a

superior platform for sourcing mining industry expertise. New features of the exhibition this year include the Transformative Technology Pavilion and the Decarbonisation Zone, further emphasising the importance of technology innovation and decarbonisation to the industry’s future.

AIMEX Exhibition Director Samantha Martin says this is no coincidence, and the focus reflects industry trends and attendee feedback across multiple events.

“We aim to make our events both a gathering place for the industry at all points of the supply and value chain, and a launching pad to move industry discussions forward into a sustainable future. I’m excited about the conference program at this year’s AIMEX, with plenty of content for attendees from engineers to management, consultants, decisionmakers and suppliers.”

Workshops and networking events are also held adjacent to AIMEX, with a Wednesday morning workshop run by TUNRA Bulk Solids, a Wednesday evening networking function cohosted by NSW Mining and a Tuesday evening Austmine member networking event.

It’s free to register to attend AIMEX 2023, including both the conference and exhibition.

Register today at aimex.com.au

See Australia’s best young welders – and apprentices from over 55 other skill and trade areas – put their handywork to the test at the nation’s biggest skills competition.

Discover exciting career opportunities, meet industry experts and see where your trade can take you at the largest and most exciting skills and careers event of the year.

At WorldSkills Australia, we want one thing: for young Australians to have access to vocational education and training that measures up on an international stage.

Why? Because we know that skills and trades are critical for building thriving economies, productive communities and confident young members of society. We know that skills excellence opens up career pathways and opportunities for our young people. And we know that skills and trades shape the world around us.

The main way we support skills excellence in Australia is through our skills competitions – which we’ve been running for over 40 years. Skill competitions happen at a regional, national and international level, and allow young people to benchmark their skill level against their peers.

Competitors who do well at a regional competition are invited to compete at the national championships, where tens of thousands of spectators watch Australia’s best trades and skills talent compete.

From there, you may even be asked to join the Skills Squad, where you’ll have the opportunity to travel internationally and test yourself against the best trades and skills talent in the world.

Competing in a WorldSkills competition opens up pathways you never even thought possible. Get started on your journey today.

When you attend a WorldSkills Australia National Championship,

you’re not just witnessing some of Australia’s best trades and skills talent show off their talent

You’ll also:

• Try out a number of skills and trades at our Try’aSkill booths

• Learn just how many career pathways are available to you via the vocational education and training

• Witness the best trainees and apprentices in Australia compete for gold

• Talk to the employers, training organisations and skills organisations who build opportunities in trades and skills

• Hear from industry leaders and WorldSkills success stories

• Get the information you need to make informed decisions about your education and career

Over the last month, Weld Australia has visited several schools to provide demonstrations and introduce students to what a career in welding might look like. We visited Grace Lutheran College’s Caboolture Campus, Caboolture State High School and Glenala State High School. We also visited several TAFEs, including TAFE Hervey Bay and TAFE Bundaberg.

We had the Soldamatic augmented reality welding simulators on-hand, which all the students were keen to try. By developing fine motor skills and good welding practices, the students were able to achieve fantastic results throughout the session. These visits help students gain insight into trade skills and career pathways, including local employment opportunities.

Try A Trade is a unique hands-on expo, that allows students across Maribyrnong and Moonee Valley in Melbourne to discover the world of trades and vocations in a fun, interactive way.

Over 350 year 9 to 12 students visited the expo throughout the day, giving them a better understanding of the career pathways available in trades and vocations. As always, Weld Australia’s welding simulator was a big hit with the crowd, giving students the opportunity to try welding in safe, controlled environment.

Weld Australia delivered ‘Train the Trainer’ courses to two organisations this month: Melbourne Polytechnic and Rural Industries Skills Training (RIST), both located in Victoria.

Both Melbourne Polytechnic and RIST have recently invested in Soldamatic welding simulators and are set to introduce augmented reality into their welding curriculum to help train the next generation of welders. Soldamatic simulators have just been delivered to the training organisations, with Weld Australia rolling out training to their teachers, in both ISO 9606 and the use of the simulators.

Weld Australia provided their teachers with the expert knowledge and hands-on understanding of how to best use the Soldamatics to educate their students. The training was enjoyed by all the teachers—they all seem to be looking forward to getting students onto the simulators.

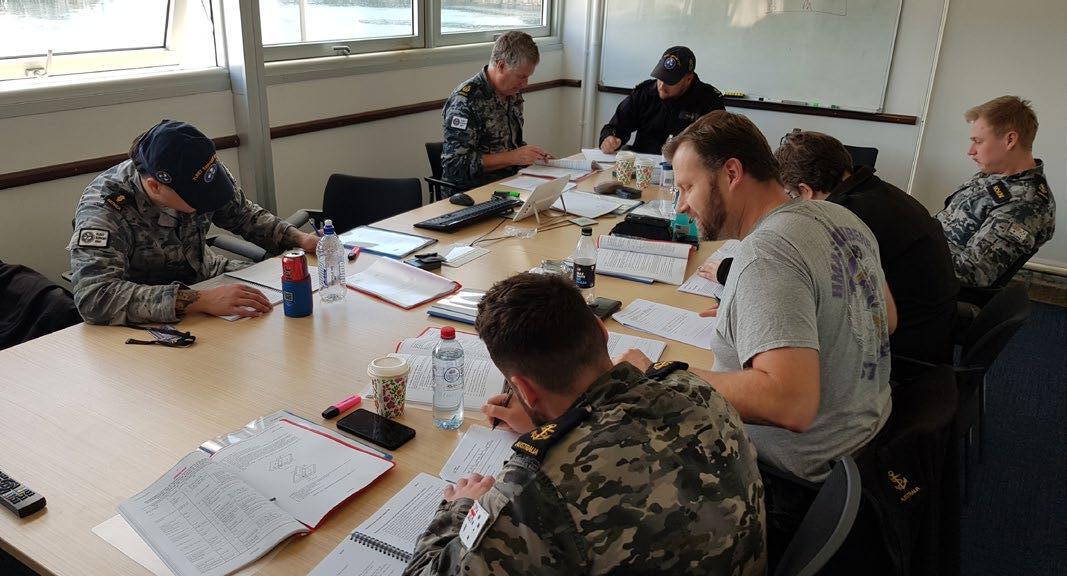

Over the last couple of months, Port Moresby in Papua New Guinea was home to a suite of successful welding training programs, bringing together ten citizen employees from both Monadelphous and Santos across their Lihir and Monadelphous Worley Joint Venture (MWJV) operations. In collaboration with Weld Australia, Monadelphous conceptualised and coordinated two welding upskilling programs including Welding Technology Basics and International Welding Inspector - Basic (IWI-B).

Led by Weld Australia’s experienced trainer, Joe Sandor, the comprehensive program covered welding processes, codes, standards, inspection techniques, and safety protocols. Participants engaged in theoretical sessions and practical demonstrations, gaining handson experience and a deep understanding of welding inspection procedures.

Mark Potts, Quality and Welding Manger for Monadelphous said, “This is a first for us all in PNG, and a fantastic example of our commitment to corporate social responsibility by training some of our national employees in welding inspection. By investing in the development of local talent, Monadelphous is not only bridging the skills gap but also empowering the local workforce to make significant contributions to their communities, and the broader nation. I’m proud of our ongoing dedication to creating sustainable opportunities and fostering economic growth in PNG.”

The success of the IWI-B course in Port Moresby was further bolstered by the proactive support and engagement of the site teams across Lihir and MWJV. The collaboration between the site teams, Weld Australia, and the participants fostered a strong sense of teamwork, highlighting the collective effort to advance welding inspection practices.

“Upskilling initiatives like this showcases the value of professional development opportunities in PNG, allowing employees to acquire essential skills and expand their knowledge in line with international best practices. We anticipate that the newly acquired expertise will have a positive impact on welding inspection practices across our operations, promoting higher quality standards and safety measures – which is great for everyone,” said Sean Lavin, Learning and Development Advisor (Eastern Region), Monadelphous.

The successful conclusion of the course resulted in the participants being awarded internationally recognised certifications as Welding Inspectors, acknowledging their enhanced skills and competence in welding inspection. These certifications will further empower the employees from Lihir, MWJV, and Santos to contribute significantly to their respective organizations and promote higher standards of quality control.

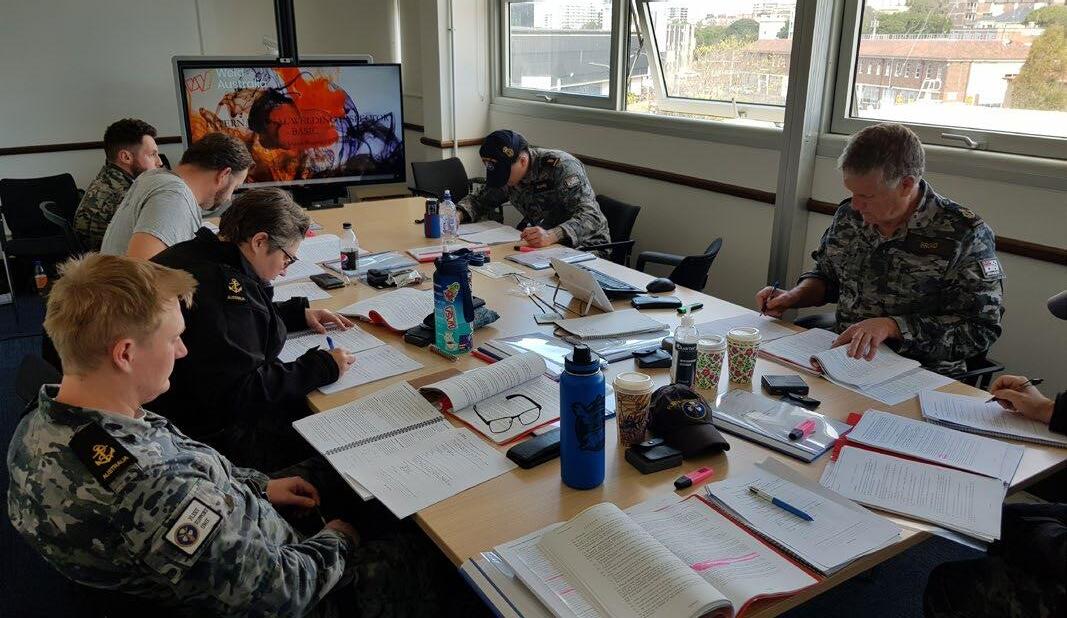

Over the last month, Weld Australia has facilitated a number of IIW International Welding Inspector - Basic (IWI-B) in-house courses. This included a course for BAE Systems in Adelaide, as well as for the Navy at HMAS Kuttabul in Sydney.

Backed by the International Institute of Welding (IIW), the International Welding Inspector – Basic (IWI-B) qualification expands your career as a welding inspector. This qualification is recommended in both AS/NZS ISO 3834 and AS/NZS 1554.1.

This internationally recognised course provides extensive knowledge surrounding welding, inspection theory and application. It includes theoretical components such as mechanical and visual inspection techniques; inspection procedures and acceptance criteria; identification of weld imperfections associated with pre-production; fabrication and post fabrication; and much more.

Weld Australia recently facilitated its popular Welding Supervisor course in a face-to-face format in Gladstone, Queensland.

A Welding Supervisor qualification expands your career horizons enormously. Welding Supervisors play a vital role in industry—they understand the factors that influence welding quality, how to oversee welders effectively, and the variables that help maximise productivity.

The Welding Supervisor course includes three, one week blocks of face-to-face teaching, focused on:

• Welding processes, terminology and technology

• Welding metallurgy

• Weld testing and inspection

• Standards and specifications

• Steel structures

All the feedback received from students has been exceptionally positive.

Best of all, Weld Australia currently has a few—very rare—one-week blocks available in September, October, November and December.

All our in-house training courses need a minimum of 10 students.

For further information, or to book your in-house course, contact us via 02 8748 0103 or training@weldaustralia.com.au

IIW International Welding Inspector - Basic (IWI-B)

An IWI-B qualification expands your career as a welding inspector, particularly as its recommended in both AS/NZS ISO 3834 and AS/NZS 1554.1. This internationally recognised course provides extensive knowledge surrounding welding, inspection theory and application.

Welding Fundamentals

The Welding Fundamentals course gives professionals an understanding of some of the significant issues that may arise with welded components, and provides an overview of welding processes, weld defects, testing and welder qualification as required by various Australian and international Standards.

Welding Supervisor - AS 2214 and Welding Supervisor - AS 1796 Cert 10

Welding Supervisors play a vital role in industry—they understand the factors that influence welding quality, how to oversee welders effectively, and the variables that help maximise productivity. Our Welding Supervisor course covers topics like welding processes, terminology and technology; welding metallurgy; weld testing and inspection; standards and specifications; steel structures

An AS1796 Welding certificate is by far the most well known and requested welder certification nationally. It is used in both structural and pressure equipment Standards. Delivered live online over 15 sessions, this course covers safety precautions, welding terms and symbols, preparation and set up, cutting and gouging, arc conditions, procedures and more. This highly engaging online course will start on 14 August 2023

The IWI-B course is a globally recognised International Institute of Welding (IIW) qualification. This course provides general knowledge of welding, inspection theory and application, including: non destructive testing; mechanical and visual inspection techniques,; inspection procedures and acceptance criteria; and identification of weld imperfections. Kicking off on 30 January 2024, get your New Year off to a great start.

This course provides advanced knowledge of welding and inspection theory and application, including NDT, mechanical and visual inspection techniques, inspection procedures and acceptance criteria, identification of weld imperfections associated with pre-production, fabrication, and post fabrication, and more. This highly engaging online course will start on 30 January 2024. Get in now, before its too late.

Weld Australia would like to congratulate the following people on becoming newly qualified in July.

AS 1796 CERTIFICATE 7

• Bailey Vulin

• Corbin Blair McDonald

• Craig Ross

• Danny Pellegrino

• Gavin McKeown

• Luke Pollock

• Taylor Doherty

AS 1796 CERTIFICATE 10

• Andrew Meikle

• Beau Ryan

• Glenn McGowan

• Greg Jones

• Igor Stankov

• Joel Loukas

• Karim Shokri

• Kenneth Winning

AS 2214

• Adam Wade

• Andrew Cain

• Ashley Pinal

• David Houlihan

• David Peters

• Dwayne Pfeiffer

• Gavin Bennett

• Jeremy Rishani

• Joe Mullington

• Juan Jose Atienza Jr

• Michael Light

• Savinesh Narayan

• Shannon Haber

• Shaun Brown

• Timothy Hayes

• Wade Robinson

IIW INTERNATIONAL WELDING INSPECTOR BASIC (IWI-B)

• Balstan Papua

• Bradley Paluka

• Christopher Carpenter

• Chuck Ansphil

• Igibe Hare

• Jimmy Marai

• Joel Hendrie

• Keenan Siegers

• Lionel Hagua

• Matthew Brewer

• Mervin Kendino

• Mina Mapi

• Paul Dennis

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2023, making planning ahead as simple as possible.

Just some of the upcoming exam dates include:

• Wednesday 16 August: National Welding Supervisor Exam A-B1 and B2

• Thursday 17 August: IWS SA2 Online Exam

• Tuesday 5 September: IIW IWI-B and IWI-S WTE S and WTE B Online Exam

• Wednesday 6 September: IIW IWE and IWT EA2.2 and TA2.2 Online Exam

• Wednesday 13 September: National Welding Supervisor Exam B1 and B2

• Friday 22 September: IIW IWI-B PE B (C3) Practical exam (New South Wales, Victoria, Queensland, South Australia and Western Australia)

• Tuesday 26 September: Re-sit/Online Exam (All Qualifications)

• Wednesday 27 September: IIW IWI-B WIE B (B5) Online Exam

• Tuesday 3 October: IIW IWI-B and IWI-S WTE S and WTE B Online Exam

• Wednesday 4 October: IIW IWS SA3 (Online Exam)

• Monday 9 October: National Welding Supervisor Exam Paper A (Training)

• Monday 16 October: AS1796 Cert 1-9 Theory Online Exam

• Wednesday 18 October: National Welding Supervisor Exam A-B1 and B2

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 9606-1 (Steels – carbon steels)

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

For further information, contact: training@weldaustralia.com.au

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania Tasmanian Minerals and Energy Council tasminerals.com.au

13 Wellington Street, Burnie

Victoria Box Hill Institute boxhill.edu.au

465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au

23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat