Calbah Certified to AS/NZS ISO 3834 >>>

Aerison Re-Certified to EN 15085 CL1 >>>

Weld Australia and Investment NSW Steel Industry Roundtable >>>

Calbah Certified to AS/NZS ISO 3834 >>>

Aerison Re-Certified to EN 15085 CL1 >>>

Weld Australia and Investment NSW Steel Industry Roundtable >>>

NATIONAL OFFICE

PO Box 197, Macquarie Park BC NSW 1670 1800 189 900 office@weldaustralia.com.au weldaustralia.com.au

Geoff Crittenden

Chief Executive Officer 1800 189 900 g.crittenden@weldaustralia.com.au

TRAINING

Guy Brooks, General Manager, Training Operations 0488 743 322 g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, Executive General Manager, Sales & Marketing 0437 106 726 m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Executive General Manager, Technical Services 0487 487 170 d.yalniz@weldaustralia.com.au

ENGINEERING

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991 v.blain@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901 a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991 v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, General Manager, Engineering – QLD, ACT, NSW, NT 0491 491 888 r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Ian Mackay, Business Development Manager 0493 027 882 i.mackay@weldaustralia.com.au

Weld Australia’s 2024 AGM

Weld Australia recently held its 2024 Annual General Meeting (AGM). At the meeting, Madeleine du Toit was appointed as our new Chair. Madeleine du Toit joined the University of Wollongong as Professor in the School of Mechanical, Materials, Mechatronic and Biomedical Engineering in 2014, and currently serves as Associate Dean for Equity, Diversity and Inclusion in the Faculty of Engineering and Information Sciences.

Madeleine holds BEng, MEng and PhD degrees in Metallurgical Engineering, and a Masters degree in Welding Engineering. She is a Fellow of the Institution of Engineers Australia, a qualified International Welding Engineer (IWE) and a Certified Materials Professional (CMatP) with Materials Australia.

Madeleine served as the President of the Council of the Southern African Institute of Welding (SAIW) from 2010 to 2014, and has been a Director of Weld Australia since 2015. She was elected Deputy Chair of our Board in May 2023.

Several new Directors were also appointed to the Board in casual vacancies, including:

• Brenda Micale (General Manager Training Services South Metro TAFE)

• Mick Cameron (Director and Chief Executive Officer, MC Quality Control)

• Bec Cameron (Senior Welding Coordinator, MTE)

I’d like to congratulate Madeleine, Brenda, Mick and Bec on their appointments. I am looking forward to working with all of them.

I’d like to extend my thanks to Dan Hayward (Team Leader Integrity Engineering, Santos) and Chris Brugeaud (CEO SSS Manufacturing and IR4) who stepped down from the Board.

I’d like to take this opportunity to thank David Lake, who stepped down as Chair, for his advice and support over the last 10 years. David’s career has spanned over 45 years, and encompassed roles at Olex Cables, BHP, Austral Bricks and ATTAR. He was, for many years, a welding inspector and metallurgist, writing and approving weld procedures and specifications in the mining and refining industries.

David has developed significant technical knowledge

in areas ranging from engineering, materials science, metallurgy and non-destructive testing.

In addition to volunteering as a member of Weld Australia’s Board for over 10 years, David also works with AINDT, Engineers Australia, Materials Australia, and the Australasian Corrosion Association. His commitment to advancing the industry is clear.

Finally, I’m pleased to announce that Ben Mitchell has stepped down from our Board, because he has joined the Weld Australia team as our new Executive General Manager, Strategic Partnerships. We’re excited to have Ben on the team—he brings a wealth of knowledge, experience and industry insights to the role. To learn more about Ben, see the article on page 6.

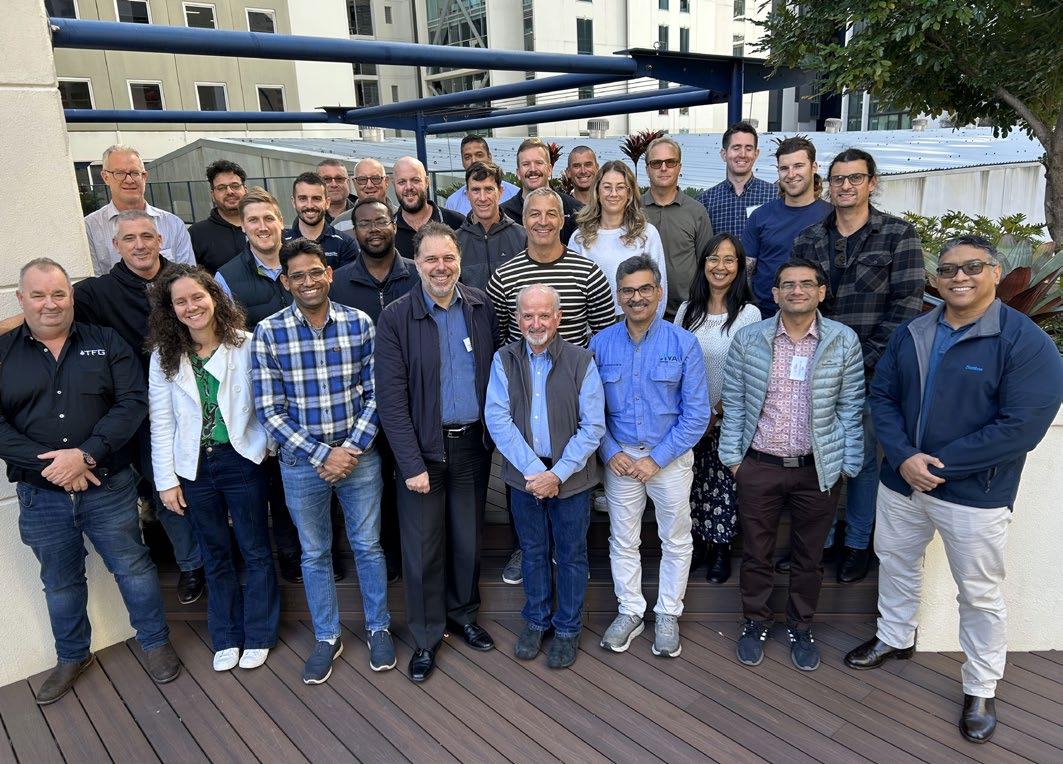

Earlier this month, Weld Australia and Investment NSW hosted an outstanding roundtable meeting for the steel industry. A range of topics were discussed, including:

• Working with Tier 1 Contractors; Government Support for Regional Manufacturing Precincts

• Working with Defence and Transport Primes

• TAFE and Apprenticeship Pipeline

• Immigration and Skilled Workforce

• Current and Future NSW Government Sector Activities

Investment NSW has a mandate to deliver on the NSW Government’s priorities to build a strong economy, attract local and international investment and help NSW businesses find new export markets.

I’d like to thank Pablo Santos from S&L Steel for chairing the meeting and leading the discussion. For further details, see the article on page 21

I attended the Boiler Industry Group in late May at Loy Yang B Power Station in Victoria. This was the first meeting of the newly combined Boiler-Turbine Industry Group, which included presentations for both boilers and turbines.

Of particular note, Toshiba attended and presented on turbine life issues. This was followed by other presentations on BLP Turbine Rotor Refurbishment (CS Energy), High Energy Piping – Callide B (CS Energy), Boiler Integrity Program (EnergyAustralia), Loy Yang B Unit 1 Reheater Tube Replacement Strategies (Loy Yang B), and Close Proximity Radiography (IRIS NDT).

The meeting also included a site inspection of the Loy Yang B boilers and turbines which was appreciated by all. The meeting was very well attended with 25 participants in person and a further 15 online, from around the country.

This was followed by the very successful two-day boiler engineering training course. Day One focused on the structure of boilers, explored their components, and discussed common failure mechanisms. Day Two focused on boiler inspection techniques.

Earlier this month, I visited Adelaide and had two very productive meetings. The first was with Cameron Baker, the South Australian Skills Commissioner. We discussed a range of topics related to VET training in South Australia. The South Australian Skills Commission is responsible for advising the Minister for Education, Training and Skills on how the skills sector is performing and will engage directly with industry and employers to deliver the skills they need for future jobs in South Australia.

I then met with David Price, Fabrication and Piping Training Superintendant at ASC. We discussed the new training program that ASC has established.

We recently launched the program for the 2024 National Manufacturing Summit. If you haven’t already, I urge you to download a copy of the program and take a look.

The Summit will see a diverse group of industry stakeholders assemble in Brisbane on 31 July and 1 August 2024.

Building on the momentum of the 2023 National Manufacturing Summit, which focused on the Renewable Energy: Challenges and Opportunities, the 2024 Summit embarks on an ambitious journey with its theme: Pathways to Success…Making the Renewable Energy Revolution a Reality

The Australian Government’s commitment to reducing emissions by 43% by 2030 and achieving net zero by 2050, as outlined in the Climate Change Act 2022, sets the stage for a transformative era in renewable energy.

With an anticipated growth in renewable energy generation from 64GW to over 218GW by 2050, the manufacturing sector is at the forefront of this change, presented with unparalleled opportunities and significant challenges.

The 2024 Summit will delve into the practical aspects of manufacturing within the renewable energy sector, highlighting the essential components that will drive Australia’s transition to a sustainable future.

Register for the Summit now.

Weld Australia would like to welcome all our new Members who have joined in the last month:

CORPORATE MEMBERS

• Auto Control Systems: autocontrols.com.au

INDIVIDUAL MEMBERS

• Daniel O’Connor

• Jung Cha

• Alexander Mejia

• Ellie Jay Ramos

• Constantino Adamidis

• Jordan Crothers

• Nimanshu Kapadiya

• Swedenborg Pablo

• Trent Robson

JOIN TODAY

For further information, contact David Choudry (Membership Manager) on d.choudry@ weldaustralia.com.au or 0417 878 104.

Weld Australia urges government clarity on wind tower manufacturing, published by Australian Manufacturing

Productivity: An essential ingredient for sustainable economic growth, published by Manufacturers Monthly

Productivity report reveals urgency: Weld Australia published by The Tradie Towers to be built by Australia or China? Weld Australia published by The Tradie

National network of Indigenous welding schools would help close the gap: Weld Australia, published by National Indigenous Times

Weld Australia would to welcome the newest member of our team. Based in Adelaide, Ben Mitchell has joined us in the role of Executive General Manager, Strategic Partnerships.

Ben has over 20 years’ experience in all aspects of marketing, strategy, leadership, management, innovation and business acumen. He has successfully worked across an extensive range of commercial sectors, from welding and agriculture, through to automotive, aerospace, building and construction.

This diverse experience, combined with Ben’s ability to combine a commercial mindset and people first approach to culture has seen Ben play a pivotal role in various organisational transformation projects.

Ben joined Weld Australia in 2024 as Executive General Manager, Strategic Partnerships. Prior to this, he took on several roles at K-TIG, including Chief Executive Officer, and Chief Marketing Officer, during which he was responsible for the company’s global marketing strategy, designing and implementing initiatives that build the brand and generate sales opportunities.

Ben also spent 15 years at Nitto Denko where he was promoted through the ranks to the role of Director of Strategic Planning and Marketing. Here, he was a member of the senior management team, tasked with creating and overseeing strategic direction, governance and policy.

Ben oversaw the effective transition and diversification of the business into new fields with regional impact and global adoption and scalability, with a focus on generating intelligence to determine best market practice and behaviours.

Ben holds several professional qualifications, having completed an MBA in 2018 at the University of South

Australia; Business in Emerging Markets at the Instituto Panamericano Alta Direccion de Empresa (IPADE) Mexico; Business Innovation at the International Institute for Management Development (IMD Business School) in Singapore; and a Diploma of Business (Marketing) via Thomson Education.

• Masters of Business Administration (MBA) Marketing

• Business in Emerging Markets

• Business Innovation

• Diploma of Business (Marketing)

Weld Australia, in partnership with CIGWELD, is excited to announce an exclusive giveaway for our members!

Win a top-of-the-line CIGWELD multi process welding inverter and bring precision and efficiency to your projects.

The new BlueVenom XF353 is a 3-in-1 multi process welding inverter that has been specifically engineered to be narrower in size for easy access in tight and constrained areas but also as a modular arc station

The XF353 can deliver awesome arc characteristics in the most popular processes of MIG (QuickSet and manual modes, gas and gasless operation, single and double pulse MIG with the optional PulseMate™), STICK (MMA with VRD for extra safety) and TIG DC-Lift welding modes For details on the BlueVenom XF353, visit Cigweld’s website

Follow both Cigweld and Weld Australia on LinkedIn.

Find the competition post on LinkedIn and tag a friend

Make sure you’re a member of Weld Australia

Fill out this short online form to enter the draw

The winner will be chosen at random and announced via Linkedin The competition is neither sponsored by, nor endorsed by, LinkedIn

In the realm of repair and maintenance as used in the mining, construction, fabrication industries and where precision and safety intertwine with high-pressure gas welding applications, the importance of reliable safety equipment cannot be overstated. Among the array of tools and technologies essential for ensuring safety, COMET Flashback Arrestors (FBA’s) stand out as indispensable guardians against potentially catastrophic events.

Flashbacks, backfires, and sustained backfires represent not just operational hazards but existential threats to fabrication and industrial endeavours. The COMET range of flashback arrestors offers a robust defence mechanism, effectively neutralising these risks and instilling confidence in operators even in the most demanding conditions.

CIGWELD’s flashback arrestor design is a commitment to proactive safety measures. By addressing the root causes of flashbacks—where mixed gases ignite and burn back through the system—COMET flashback arrestors provide a reliable barrier against the domino effect of sooting, equipment fires, and potentially fatal explosions.

The speed at which flashbacks can occur is alarming (faster than the speed of sound), surpasses the reaction time of operators. This threat is mitigated through a combination of innovative features attributed to the COMET range. The non-return valve prevents reverse flow of gases, while the stainless-steel flame arrestor swiftly extinguishes any returning flame. The gas flow is automatically shut-off if the arrestor becomes overheated, adding an extra layer of fail-safe protection. Furthermore, the dust filter protects the gas non-return valve against contamination offering added security.

Moreover, compliance with stringent standards such as AS 4603 and ISO 5175 and UL 1357 listing underscores the commitment of the COMET brand to delivering not just products but peace of mind. This adherence ensures that these flashback arrestors meet the highest levels of safety and reliability in industrial environments where every precaution counts.

In the dynamic landscape of mining and construction operations, where conditions can change in an instant, the versatility of COMET flashback arrestors shines through. Whether mounted on regulators or torches, these devices offer seamless integration into existing systems, allowing for quick identification and deployment tailored to specific needs.

The inclusion of features such as date stamps and part numbers for easy tracking of replacement cycles further enhances the operational efficiency of COMET flashback arrestors. The color-coding, gas-type, flow direction, maximum gas working pressures and thread type markings allow for quick identification to whether the unit is designed for oxygen or fuel use – removing any potential frustrations.

In essence, investing in COMET flashback arrestors isn’t just about adhering to regulations—it’s about safeguarding the lives of workers, protecting assets, and ensuring the continuity of operations. By embracing these cutting-edge gas safety solutions, organisations signal their dedication to a culture of safety-first, where every precaution is taken to mitigate risks and secure a brighter, safer future for all stakeholders.

As mining demolition and construction operations navigate the complexities of today’s challenges using gas cutting, heating and welding equipment, the choice is clear: Get serious about gas safety with the industry leading COMET range, serving Australia since 1922.

This article was supplied as part of a paid sponsorship package.

The ESAB CarryVac 3 ensures a healthier work environment by extracting harmful fumes directly at the source.

Lightweight and portable, it is designed for maximum flexibility and features a nanofiber filter with 99% efficiency. With Auto Start/Stop Technology (AST), it is perfect for any light-duty welding applications.

• The CarryVac 3 contains automatic flow adjustment to maintain correct airflow and suction during operations

• Designed to be carried to the working area, it can be connected to either a fume extraction welding torch or to the extraction nozzle to extract fumes

PSF 415C Fume Extraction MIG Gun

• Leather protected hose

• Robust steel knuckle-joint for improved mobility

• Remote and rotatable T-piece

• Extensive and robust genuine ESAB PSF wear parts system including CuCrZr

• Weld fumes are filtered and captured in a hygienicallypacked filter that offers complete protection from particles keeping them isolated from welders even when performing a filter change

The CarryVac is designed to work with ESAB, CIGWELD and TBi range of Fume Extraction MIG Guns: ESAB PSF 415C Fume Gun, TBi 240 E3 BZL Style Fume Gun & TBi 360 E3 BZL Style Fume Gun.

TBi Guns BZL COMPATIBLE

• High extraction capacity

• Very robust design of the torches

• New ball joint for better handling

• Leather protective cover on all models

• Energy-efficient due to minimised leakage

The Australian Government has declared an offshore wind zone in the Pacific Ocean off the Illawarra in New South Wales.

The zone will be 20km from the coast and excludes significant environmental areas including the Biologically Important Area for the Little Penguin, the Shelf Rocky Reef Key Ecological Feature and the Southern Right Whale migration and reproduction area. The final area for the zone is 1,022 km2 – reducing the zone by a third from the originally proposed zone.

It is expected to bring new employment opportunities to the Illawarra, creating an estimated 1,740 new jobs during construction and 870 ongoing jobs. The zone will also power existing heavy industry with cleaner, cheaper energy, helping secure the future of thousands of existing industrial and associated jobs in the Illawarra as well as providing opportunities to attract new job-creating industries using clean energy.

It has the potential to generate an estimated 2.9 GW of electricity, enough to power 1.8 million homes.

Funding outlined in the 2024-2025 Budget will deliver on continuing the transformation of Queensland’s energy sector and powering more jobs across the Sunshine State.

The $26 billion investment in renewable energy over the next four years is projected to yield an estimated $430 billion and create 145,000 jobs for Queenslanders by 2050. It will allow publicly owned energy businesses to invest in new wind, solar, storage, and transmission infrastructure.

Modelling by Deloitte forecasts investment in regional Queensland will spike $218 billion, attracting more than 85 per cent of the new jobs if the state reaches its 75 per cent emissions reduction target by 2035. $8.686 billion in capital investment will be delivered in the 202425 financial year alone. In 2024-25, Powerlink will invest $109.4 million to accelerate the state’s SuperGrid, for early works on Central Queensland transmission works and connection of the Borumba Pumped Hydro Energy Storage, and a further $712 million to continue delivery of CopperString 2032.

The Australian Government’s Department of Industry, Science and Resources has released the National Robotics Strategy. The Strategy outline’s the Government’s plan for Australia’s robotics ecosystem.

It is designed to help build a stronger, more unified robotics industry and harness the benefits of robotics and automation across our economy.

The Australian Government developed this strategy in consultation with the robotics industry, researchers, state and territory governments and the Australian public. It was guided by an advisory committee of Australian robotics and technology experts.

Weld Australia was pleased to contribute to the Strategy, including a case study.

Cobots: Robots designed for direct interaction with a human in a defined collaborative workspace. Peak body Weld Australia uses a welder training system with augmented reality. The system teaches welding skills to apprentices while evaluating their performance in a hands-on, interactive and controlled environment. TAFEs, high schools and registered training organisations have used the system in their own training programs.

The augmented reality system has also been integrated with a cobot. This lets an apprentice safely learn automated robotic welding skills as well as the skills to use robotics in other applications. This helps future welders gain skills and self-confidence in both manual and robotic welding before moving into real-world welding workshops. Click here to read more.

The Defence Industry Development Grant (DIDG) program, announced in the Defence Industry Development Strategy, is now open for applications.

The new grant program will provide over $150 million over four years dedicated to supporting Australian small to medium-sized businesses. The DIDG program has four dedicated streams which support:

• Sovereign Industrial Priorities

• Exports

• Skilling

• Security

Minister for Defence Industry, the Hon Pat Conroy MP said the grants will help local businesses to grow, innovate and create jobs.

“The new program places stronger emphasis on our need to focus financial support on industry priorities which have flowed from the Defence Strategic Review, through the Defence Industry Development Strategy which I released in February, and with clear alignment to the National Defence Strategy which was released in April,” said Conroy.

The DIDG program replaces and expands previous defence industry grant programs. Initial batch closing dates are 31 July 2024 for the Export and Skilling streams, and 31 August 2024 for the Sovereign Industrial Priorities and Security streams.

More information on industry grant programs can be found via: defence.gov.au

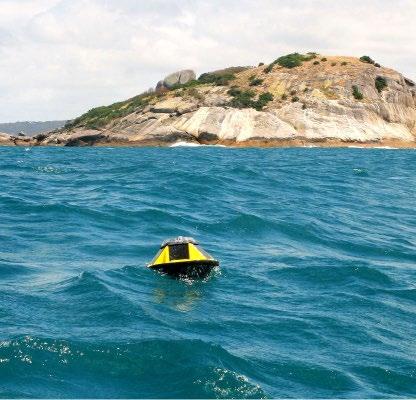

Earlier this month, Weld Australia had the opportunity to view the truly inspiring M4 (short for ‘Moored MultiModal Multibody’) Wave Energy prototype by UWA, SMC Marine, and Everett Consulting.

The project will demonstrate the long term potential to provide a constant electrical supply into a coastal microgrid to local customers through the conversion of wave energy into electricity.

Many projects have been sourced off-shore, owing to cheaper material and labour costs for manufacturing and therefore the ‘perception’ that overall, it is the cheapest option. However, when including international transport and quality assurance and control rework into overseas project management, West Australian companies can be surprisingly competitive.

It was therefore gratifying to hear that the vast majority of the M4 wave project, including material supply, manufacture, electrical integration and transport have all been sourced locally. The only item that has been purchased off-shore is the highly bespoke power generator.

The project lead, Marine Energy Research Australia (MERA) is headquartered at the Albany Campus of The University of Western Australia (UWA), and has been supported by six local businesses.

Just a 10-minute drive out of town, at MCB Construction, specialists in the manufacture of structural steel, steel beams are being welded for the forward frame and trailing arm of the 22-metre long M4 superstructure. In the same industrial area, the four floater buoys have been assembled,

each large enough to fit a full-grown adult, until they are filled with sand for ballast.

The M4 wave energy device, comprising a triangular forward frame and a trailing arm, with the power generator on the connecting hinge, were manufactured from structural steel beams with four steel floater buoys, providing both buoyancy and ballast.

Funded by the Blue Economy Cooperative Research Centre (a Commonwealth scheme), the WA Department of Primary Industries and Regional Development (Royalties for Regions) and UWA, the project will be deployed for the 2024-2025 summer period in King George Sound, just off Albany’s Historic Whaling Station.

Over the six months at sea, electricity will be generated from the hinging motion, and data will be used to model wave energy’s potential for 24/7 baseload energy potential and the device’s performance and survivability in different sea conditions.

The data will be publicly available in real-time, and the project will evaluate if a full scale device could potentially provide power to a microgrid for locals.

Our thanks to all who participated; it was a remarkable insight into the future of wave energy and its’ contribution to the renewable mix.

Weld Australia looks forward to returning to Albany in Spring and seeing the completed prototype being towed out to its new home.

Welcome to the Kemppi Art of Welding Competition 2024. The competition is open to anybody involved with the “art of welding”, including welders, apprentices, welding teachers, researchers, students, hobbyists and artists working with metals.

This year’s competition will again include a dedicated Amateur Prize for the best amateur entry. If an amateur wins 1st, 2nd or 3rd prize in the competition, then the Amateur Prize will go to the next best amateur entry.

To enter all you need to do is send us a photo of a piece of “Welding Art” which you have created. What is welding art? - it could be a welded sculpture, a pattern design, a motif, an object - which must have been created by welding. The welding can be done manually or using more advanced techniques such as robotics, lasers, or friction welding.

1. Take a digital photo of your “welding art” 2. Go to: KemppiArtOfWeldingCompetition2024 and complete the electronic Kemppi Art of Welding Competition 2024 Entry Form, attach your digital photo and forward both to Kemppi Australia

The competiton opens from Wednesday 1st May and will close at 1600hrs AEST on Monday 30th September 2024. Any queries: email skettos@skettos.com.au

The competition will be judged by a panel of 4 members of the Kemppi organisation. The successful entrants will be notified by Monday 14th of October 2024 and their names published on Kemppi Australia’s social media channels.Only the successful entrants will be notified. Any entries found to be the work of people other than the entrant will be voided.

The winning entrant will receive a Kemppi MinarcMig 190 Auto portable welding package, Gamma 100A welding helmet, a Kemppi welding jacket and pair of gloves.

The runner up will receive a Kemppi Minarc Mig EVO 170A portable welding package, a Kemppi BETA e90Awelding helmet and pair of gloves.

3rd place will receive a Kemppi Minarc EVO 140 portable welding package, a Kemppi welding jacket and pair of gloves.

The dedicated Amateur Prize is a Betae90A welding helmet, a Kemppi t-shirt and pair of gloves.

To enter this competition you must be over the age of 18, and reside in Australia or New Zealand. Only one entry and one piece of artwork is permitted per person.No prize can be exchanged into cash in whole or in part. The judges decision is final and will not be open to discussion. The organiser of the competition reserves the right to exclude individuals who have broken the rules or who can be suspected of using unfair methods to participate. Personal data provided in connection with the competitionshall be handled in accordance with the currently applicable Privacy Act.Kemppi Australia Pty Ltd is not responsible for any possible problems associated with data connections (e.g. outages) while participating in the competition or for any resulting lost submissions. Kemppi Australiais not liable for damages or expenses resulting from participating in the competition or from redeeming and using the prize. Kemppi Australia is not obligated to pay compensation if the winners cannot use the prizes themselves.

Need help or further details? Contact events@weldaustralia.com.au

REVOLUTIONISING WELDING EDUCATION WITH XIRIS WELDING CAMERAS

The ability to visualise and record the weld during classes helps instructors more clearly articulate the learning components and helps students get the most out of their training experience. Playbacks for review and discussion can highlight what went well and opportunities to improve. This webinar will introduce weld cameras as an educational tool, with a walkthrough of the camera and discussion of sample videos.

EVENT DETAILS

• Date: Thursday 27 June

• Time: 11.00am to 12 noon

• Venue: Online via Zoom

• Cost: Free for Members; $45 for Non-Members

REGISTER NOW

WELDING FUMES: WHAT HAS CHANGED AND WHAT DOES THE FUTURE HOLD?

The panel will discuss the recent change to the welding fume (not otherwise specified) exposure standard, how can exposure to welding fumes be controlled, how can occupational hygienists help the industry understand the risks associated with welding fumes and what does the future hold with the announced Workplace Exposure Limits. Bruce Cannon (Principal Welding Engineer, Weld Australia) will join the panel of experts to discuss this important topic. Discount is applied at the check-out.

EVENT DETAILS

• Date: Friday 28 June

• Time: 12 noon to 1.00pm

• Venue: Online via Zoom

• Cost: Free for Members; $35 for Non-Members

REGISTER NOW

Adelaide: 3 to 5 December 2024

Brisbane: 10 to 12 December 2024

Facilitated by US expert, Jim E. Meyer, this three day course provides an introduction to the ASME B31.3 Process Piping Code. It covers the requirements of B31.3 for design, analysis, materials, fabrication, testing and inspection of process piping systems. It explores the rules for various components including fittings, connections, bends, valves and specialty components.

Other topics include dimensions and ratings of components, fluid service requirements for joints, piping flexibility and support, welding, heat treatment, bending and forming, brazing and soldering, assembly, erection, examination and inspection.

By participating in this course, you will learn how to successfully:

• Identify the responsibilities of personnel involved in the design, fabrication, assembly, erection, examination, inspection, and testing of process piping

• Describe the scope and technical requirements of the ASME B31.3 Code

• Apply and implement the quality requirements that are defined in the ASME B31.3 Code.

Location TBC: 11 to 13 February 2025

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications.

The course will be facilitated by Walter J. Sperko, P.E., the President of Sperko Engineering Services, a consulting firm specialising in metal fabrication technology. He has particular experience in piping and pressure vessel fabrication, installation, maintenance and repair.

Mr. Sperko is also a past-Chairman of the ASME Welding, Brazing and Fusing Standards Committee IX and a member of ASME Subcommittee III, Nuclear Components.

This three day course will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

Weld Australia is currently taking Expressions of Interest in this course. To lodge your interest, contact: Danielle Pennington (Corporate Engagement Manager) on d.pennington@weldaustralia.com.au or 0493 024 505.

Weld Australia is excited to announce that the program for the 2024 National Manufacturing Summit is now available.

The Summit will see a diverse group of industry stakeholders assemble in Brisbane on 31 July and 1 August 2024.

Building on the momentum of the 2023 National Manufacturing Summit, which focused on the Renewable Energy: Challenges and Opportunities, the 2024 Summit embarks on an ambitious journey with its theme: Pathways to Success…Making the Renewable Energy Revolution a Reality

The Australian Government’s commitment to reducing emissions by 43% by 2030 and achieving net zero by 2050, as outlined in the Climate Change Act 2022, sets the stage for a transformative era in renewable energy.

With an anticipated growth in renewable energy generation from 64GW to over 218GW by 2050, the manufacturing sector is at the forefront of this change, presented with unparalleled opportunities and significant challenges.

The 2024 Summit will delve into the practical aspects of manufacturing within the renewable energy sector, highlighting the essential components that will drive Australia’s transition to a sustainable future.

The 2024 National Manufacturing Summit will be held at the Amora Hotel in Brisbane.

Book your stay at the Amora Hotel during the Summit and enjoy an unparalleled 15% discount off the best available rate at the time of booking.

This discount will apply from 30 July to 2 August.

This special offer is designed exclusively for our delegates, ensuring your experience is not just memorable, but also more affordable.

Rate URL: https://reservations.travelclick. com/113954?RatePlanId=8550782

Access Code: WELD24

Earlier this month, Weld Australia hosted the Queensland and Northern Territory Industry Drinks Night. Weld Australia partnered with Maxisafe to bring this event to members. It was night of networking with industry colleagues, drinks and canapés. Attendees heard from industry experts, including Geoff Crittenden (CEO, Weld Australia).

Maxisafe is a family-owned Australian company dedicated to providing a broad range of Personal Protective Equipment (PPE) solutions. They specialise in safety products for head, eye, hand, foot, height, and site safety, with particular expertise in glove and respiratory protection. Their commitment to innovation and quality is their priority, as they ensure that all products comply with or meet rigorous Australian Standards.

Maxisafe has been at the forefront of introducing the latest innovation in Powered Air Purifying Respirators (PAPR) to the Australian market. They pride themselves on offering high-quality products, never compromising on the standard of what they deliver.

The journey at Maxisafe is measured not by the products they supply to the market, but by the lives they impact. Together with industry, Maxisafe is crafting a safer tomorrow, today, with a dedication to protecting every Australian worker.

Weld Australia’s Welding Excellence Awards are the most prestigious event on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2024 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Winners will be awarded in each state for each of the award categories below.

Entries must be submitted via the specific online form for each category by midnight on 23 August 2024. These forms can be found on the Weld Australia website. Before starting your entry, it is download the Award Criteria:

• Company of the Year – Fabrication

• Company of the Year – Supplier

• Indigenous Company of the Year

• Health & Safety in Welding

• Project of the Year

• Welding Professional of the Year – Welding Coordinator

• Welding Professional of the Year – Welding Supervisor

• Welding Professional of the Year – Welding Inspector

• Young Trades Person of the Year (under 25 years of age)

• Trades Person of the Year (25+ years of age)

• Young Indigenous Trades Person of the Year

• Training and Education Award – Organisation

• Training and Education Award – Individual Teacher

• Ken Trevena Award – South Australia Only

• Mick Cudmore Award – Western Australia Only

ENTER THE AWARDS NOW

The awards will be presented at events held across the country in October and November:

• Queensland & NT: Wednesday 9 October at Waters Edge, 39 Hercules Street, Hamilton

• NSW & ACT: Wednesday 24 October at Kirribilli Club, 11 Harbourview Crescent, Lavender Bay

• Victoria & Tasmania: Wednesday 6 November at Crowne Plaza Melbourne, 1-5 Spencer Street, Docklands

• Western Australia: Thursday 21 November at Burswood on Swan, 1 Camfield Drive, Burswood

• South Australia: Thursday 28 November at Kooyonga Golf Club, May Terrace, Adelaide

WITH THANKS TO OUR AWARDS SPONSORS

Weld Australia recently hosted the Pipeline Repair, Hot Tapoing and In-service Welding course. Held in both Birsbane and Perth, the course provided an overview of the various aspects of pipeline modification and repair (full encirclement sleeves, hot taps and so on) and addressed the concerns associated with welding onto in-service pipelines.

Attendees walked away with a thorough understanding of the factors that affect welding onto in-service pipelines, which will help avoid pipeline shutdowns and interruptions of service, improving both economic and environmental benefits for operators and welders alike.

The course was facilitated by US expert, Bill Bruce. With a career in pipeline welding research and its practical application spanning more than 40 years, Bill’s areas of interest include repair welding, inspection techniques and failure analysis. Bill is an American Welding Society representative on the American Petroleum Institute API 1104 Committee and is the Chairman of the Maintenance Welding Subcommittee. He has received numerous awards, including a Distinguished Researcher Award from the Pipeline Research Council International.

Bill holds a Bachelor of Science in Welding Engineering and is a Registered Professional Engineer, an IIW International Welding Engineer (IWE) and an AWS Certified Welding Engineer (CWEng).

Feedback from attendees was very positive, with everyone taking a range of key learnings away from the course.

Earlier this month, Weld Australia and Investment NSW hosted a roundtable meeting for the steel industry. The meeting was highly successful.

A range of topics was discussed, including:

• Working with Tier 1 Contractors; Government Support for Regional Manufacturing Precincts

• Working with Defence and Transport Primes

• TAFE and Apprenticeship Pipeline

• Immigration and Skilled Workforce

• Current and Future NSW Government Sector Activities

The event was attended by representatives from industry, including Pablo Santos (S&L Steel), Mick Cameron (MC Quality Control), Emily Scivetti (Oceanex Energy), Kyle Scott (BOC), Daniel Davis (BlueScope); from TAFE, including Stephen Brady (TAFE NSW); and from Investment NSW, including Anne McCotter (Associate Director Business and Skilled Migration), and Maroun El Khoury (Executive Director, Industry and Investment).

Investment NSW has a mandate to deliver on the NSW Government’s priorities to build a strong economy, attract local and international investment and help NSW businesses find new export markets.

Working across key industries, their aim is to reinforce NSW’s global position as a safe and attractive place to do business and accelerate investment in priority sectors such as Net Zero, Technology, Modern Manufacturing, International Education, Med Tech and Life Sciences, Agri-business and Defence and Aerospace.

Weld Australia would like to congratulate Calbah for their recent certification to AS/NZS ISO 3834.

Established 30 years ago in Melbourne, Calbah is design, engineering and specialist fabrication personified. At the core of the business lies a team of dedicated engineering professionals, led by Chester Baker. They share a deep passion to ensure every product is designed and manufactured to deliver outstanding performance.

Calbah’s design expertise with its 3D prototyping is supplemented by detailed knowledge of fabrication in various steel, aluminium and exotic alloys to ensure the best outcomes for its clients – no matter how tough the operating environment is.

Calbah’s push for quality and operational excellence led it to design and build its own factory in Melbourne. The purpose-built facility is a model of the precision, environmental sustainability and sophistication that Calbah brings to every job it undertakes – big or small.

The Weld Australia team would also like to congratulate Aerison for their recent re-certification to EN 15085 CL1, the highest level for both production and maintenance.

Aerison has over 30 years successful history providing multi-disciplined engineering design, construction and asset maintenance services. Aerison is a broad based engineering design and construction company selfperforming multi-disciplined EPC, engineering and design, construction and maintenance services to various industries and clients across Australia.

Aerison is also recognised for its specialist expertise in environmental services, including emission mitigation performance studies, compliance testing and custom designed and build solutions engineered to reduce the impact of industry on the environment. The success of Aerison has been built on its ability to provide a quality turnkey service, and this is only possible by having in-house engineering and design, procurement, project management, manufacturing, construction, mechanical installation and commissioning capabilities.

Milspec Manufacturing recently underwent a surveillance audit for ISO 3834.2 and a re-certification audit for DIN 2303.

Milspec Manufacturing was formed in 2002 as a result of a management buyout of what was originally the ADI live fire target site. Since then, Milspec has grown into a successful privately owned australian business. Today, Milspec designs, manufactures and assembles high quality products and subsystems for a range of industries, particularly defence, rail and infrastructure.

Milspec Manufacturing began its corporate life as Australian Defence Industries, which was established in Albury. The business has evolved considerably since then, including a management buyout of the business by the current owners, David and Wendy Cooper in 2002— this was when the Milspec brand was born. Today, Milspec is one of the premier Australian defence SMEs for subsystems, alternators and portable power.

In addition to their focus on supplying quality products to the defence industry, Milspec manufactures enclosure and subsystems for the rail, security, and road and infrastructure industries. Milspec’s history of providing quality, on time products to defence and industries can give defence primes the confidence that Milspec is their partner of choice for subsystems. Built in an environment governed by AS9100 and ISO9001, Milspec’s products are built 100% in-house, eliminating the need for multiple sub-contractors and suppliers.

Hanlon Industries’ Queensland facility also underwent an audit for AS/NZS ISO 3834.2 Hanlon Industries is a premier steel and construction partner, delivering quality steel manufacturing and solutions-driven project and site management for a broad range of clients.

The company was founded in Geelong in 2000 as a specialist steel fabrication business. Since then, Tom Hanlon and his team have grown the company’s facilities and reach across Australia. Throughout its success, Hanlon Industries has stayed true to its core of supporting professional development and training the next generation of industry practitioners.

For over 20 years, Hanlon Industries have delivered quality steel manufacturing solutions to clients across Australia in a safe working environment. Experienced tradespeople and professionals operate across steel fabrication and infrastructure, with a core focus on servicing communities, employees and customers.

This opens the door for Hanlon Industries to work with clients on road, rail, aviation and commercial development projects. Personnel operate out of four workshops and fabrication facilities in Geelong, Victoria; Alexandria in New South Wales; Narangba in Queensland; and Malaga in Western Australia.

These facilities offer advanced manufacturing capabilities including the Voortman beamline, and cranes able to support up to 25 tonnes. Trades staff are encouraged to share their best ideas and collaboratively work towards common goals in line with the company’s values of safety, respect, relationships, wellbeing, culture and innovation.

Joe Sandor (Senior Welding Technology Trainer, Weld Australia) has been busy delivering several IIW International Welding Inspector - Basic (IWI-B) training courses over the last month or so.

First up, Joe took students in Wollongong through their paces with both theory and practical classes, before he headed up to Brisbane to do it all again.

Backed by the International Institute of Welding (IIW), the International Welding Inspector – Basic (IWI-B) qualification expands your career as a welding inspector. This qualification is recommended in both AS/NZS ISO 3834 and AS/NZS 1554.1.

This internationally recognised course provides extensive knowledge surrounding welding, inspection theory and application. It includes theoretical components such as mechanical and visual inspection techniques; inspection procedures and acceptance criteria; identification of weld imperfections associated with pre-production; fabrication and post fabrication; and much more.

By all accounts, the students enjoyed the courses, learning plenty along the way—it’s little wonder with such a great teacher like Joe.

Joe Sandor (Welding Technology Trainer, Weld Australia) was also busy delivering our AS 1976 Certificates 1-9 theory in-house course for Birdon Group in Port Macquarie this month.

An AS1796 Welding certificate is one of the accepted welder certifications. It is used in both structural and pressure equipment Standards. It is by far the most well known and requested welder certification nationally. It covers a range of topics, including safety precautions, welding terms and symbols, cutting and gouging, welding of alloy steels, welding regulations, testing of welds, welding procedures, and GTAW, GMAW and FACW equipment.

A privately owned company, Birdon has a hard-won reputation as a global maritime engineering company. They are a proudly Australian manufacturer and industry partner, providing whole of life solutions to multinational defence, government, maritime, energy and resource sectors. Birdon operates across three divisions: defence, maritime and environment.

Founded in Port Macquarie, NSW, nearly 50 years ago, Birdon has an operational footprint that now includes Australia, the United States, Europe and Asia. Employing over 500 personnel across the globe, Birdon uses an advanced ‘Digital Shipyard’ system to engineer and deliver the right maritime solutions for their customers.

Weld Australia is pleased to announce the launch of a brand new training course in line with the requirements of Welding InspectorAS 1796 Certificate 11. The first session of the course will kick off on Monday 16 October.

The Certificate 11 is an Australian Welding Inspection qualification that was recently introduced to AS 1796 Pressure equipment — Qualification of welders, welding supervisors and welding inspectors. This qualification builds upon the foundation knowledge expected of a Welding Supervisor with a distinct emphasis on inspection activities related to pressure equipment.

The Certificate 11 training is run online over six weeks, followed by a two-day practical training session. The course includes a mixture of interactive online material, live online lectures and in-person training.

Participants will gain an understanding of the roles and responsibilities of a welding inspector, and the comprehensive documentation associated with the role, including:

• Understanding AS/NZS ISO 9606.1 Qualification testing of welders and how to apply it

• Welding imperfections and defects in various materials

• Non-destructive and destructive testing

• Limits of imperfections and acceptance criteria

• Understanding and implementation of AS/NZS ISO 9001 and AS/NZS ISO 3834

• WPQR and WPS

• Welder qualification

The practical training covers:

• Visual examination of weld samples

• Reading and understanding the implications of testing reports, including destructive, radiographic, ultrasonic, liquid penetrant, and magnetic particle

• Documentation verification

This course is designed to equip participants with the skills and knowledge to excel as a proficient welding inspector, ensuring compliance with the latest edition of AS 1796.

Students must hold an AS 1796 Certificate 10 qualification to meet the requirements for this course.

Please note: Students with an AS 1796 Cert 10 qualification, and an IIW International Welding Inspector - Standard (IWI-S) qualification can apply for the Certification 11 without further training or examinations. Please email qnc@weldaustralia.com.au to apply.

For further details, download the Course Schedule, or contact training@weldaustralia.com.au

FACE-TO-FACE WELDING SUPERVISOR AS1796 & AS2214

Starts 8 July

A Welding Supervisor qualification expands your career horizons enormously. Both AS 2214 and AS 1796 Certificate 10 meet the requirements outlined in AS/NZS 1554.1 to supervise the welding of structural steel. Similarly, AS 1796 Certificate 10 meets the requirement for a welding supervisor under AS 1210 for pressure vessels.

FACE-TO-FACE IWI-B TRAINING IN PERTH

Starts 2 September

This face-to-face training runs over a 1-week block in perth. The first four days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

WELDING INSPECTOR - AS1796 CERTIFICATE 11

Starts 16 October July

The Certificate 11 is an Australian Welding Inspection qualification recently introduced to AS1796, this qualification builds upon the foundation knowledge expected of a Welding Supervisor with a distinct emphasis on inspection activities related to pressure equipment, as well as the documentation associated with this role.

ONLINE AS1796 CERTIFICATE 1-9 THEORY

Starts 2 September

An AS1796 Welding certificate is one of the accepted welder certifications. It is used in both structural and pressure equipment Standards. It is by far the most well known and requested welder certification nationally. The course is delivered online over 15 sessions, live via Zoom. Participants will have the opportunity to ask questions.

FACE-TO-FACE IWI-B TRAINING IN MELBOURNE

Starts 26 August

This face-to-face training runs over a 1-week block in Melbourne. The first four days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

Starts 19 September

The course is specially designed for all technical personnel including designers, draughts people, production and workshop managers, project managers, quality managers and engineers. This allows tailored content to be delivered in an interactive format, and through the eyes of industry experts. It’s run live via Zoom.

Weld Australia would like to congratulate everyone who qualified in May.

AS 1796 CERTIFICATE 7

• James Harvey

• Mitchell Zatta

• Zackary Rice

AS 1796 CERTIFICATE 10

• Anthony Gerald Santos

• Bradley Knoop

• Caleb Rozman

• Dale Bray

• David Ritter

• Hongtao Li

• Jarrad Spratt

• Lewis Williams

• Luke Denison

• Mitchel Beckett

• Rhys Bunting

• Sebastian Materne

AS 1796 CERTIFICATE 11

• James Park

• Joshua Kennedy

• Richard Ayton

IIW INTERNATIONAL WELDING INSPECTOR BASIC (IWI-B)

• Patrick Power

• Scott Daniel Richardson

• Aaron Hicks

• Benjamin Leuverink

• Colby Jachmann

• Corey Murphy

• David Van Der Meer

• Gokhan Sacli

• Jackson Purcell

• John Mclennan

• Kiah McCreadie

• Marcus Sloane

• Nathan Brown

• Steven Hingst

• Stuart Dyble

• Sungwoo Koo

• Trevor Peake

• Clancy Crerar

• Craig Dean

• Dan Bagorio

• Dirk Boyce

• Joshua Kennedy

• Luke McGeachie

• Peter Kuiters

• Savinesh Narayan

• Sungmook Park

• Thomas Amrein

• Travis Van Rooy

Do you need to book an exam through WeldQ? We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2024, making planning ahead as simple as possible. Upcoming exam dates include:

• Friday 21 June: IWE and IWT - EA.21/TA2.1 Online Exam

• Friday 28 June: IWI B Face to Face WAPEB

• Wednesday 3 July: WTE-B/WTE-S (Online Exam)

• Friday 5 July: IWI-S - Session 5 - PE-S NSW and WA (Practical Exam)

• Wednesday 10 July: IWS - SA2 (Online Exam)

• Friday 12 July: IWI-S - Session 5 - WIE-S (Online Exam)

• Friday 19 July: IWI-S - Session 5 - PE-S Victoria (Practical Exam)

• Friday 26 July: National Welding SupervisorPaper A Exam- F2F Wollongong

• Friday 2 August: National Welding Supervisor Exam Paper A - Session 9

• Wednesday 7 August: WTE-B/WTE-S (Online Exam)

• Friday 9 August: National Welding Supervisor- Paper B exam- F2F Wollongong

For further information about exams and qualifications, simply email our team via: qnc@weldaustralia.com.au

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 9606-1 (Steels – carbon steels)

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

For further information, contact: training@weldaustralia.com.au

ENROL IN A FUSION WELDING COURSE TODAY

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

Canberra Institute of Technology cit.edu.au 81 Mildura Street, Fyshwick

Queensland TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania Tasmanian Minerals and Energy Council tasminerals.com.au 13 Wellington Street, Burnie

Victoria Box Hill Institute boxhill.edu.au 465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au 23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat

Welding is a potentially dangerous process, with many hazards and risks to people’s health. These risks are compounded by the fact that welding is undertaken across a wide range of locations and situations, from workshops and field work, through to confined spaces, underground mine sites, and more.

Hazards in each of these situations will be different, and require different controls to keep welders and others in close proximity safe. It is critical to manage these risks and hazards so that people working in the welding industry are kept safe and return home at the end of each day without injury.

To this end, Weld Australia has developed and released two free online welder safety training courses.

Weld Australia has developed two comprehensive online welder safety training courses – one course aimed at welders, and the second aimed at welding engineers and supervisors. These courses are now online and freely available to the public.

The objective of these courses is to improve safety awareness, knowledge and outcomes across the welding industry.

The courses cover a broad range of subject material across welding processes. They provide details of hazards that may be encountered and how to manage them in the workplace. The hierarchy of controls are discussed, with a particular focus on engineering controls and the correct use of PPE.

The courses also reinforce procedures that should be used, such as correct set up and use of equipment and the correct handling of gas cylinders and welding machines. Assessment and certification for course participants is also available.

The courses can be accessed via the Weld Australia website or directly via: https://weldtraining.online

To start the courses, all you need is an account for Weld Australia’s online training platform. If you don’t already have an account, you can quickly and easily create one via the link in the top right-hand corner of the platform’s homepage.

For further information contact: Andrew Davies (Manager, Technical Industry Networks, Weld Australia) a.davies@weldaustralia.com.au or 0438 428 966.

Incorporating the welding safety courses into your induction process for new hires ensures all employees start with a solid foundation in safety practices. It helps set a company-wide safety standard from day one.

By undertaking these courses, you can gain essential knowledge on how to protect yourself from hazards like burns and harmful fumes. Learning about PPE and emergency procedures can be life-saving.

The courses can be used as part of an ongoing training program to keep employees up to date with the latest safety techniques. Regular refreshers help maintain safety awareness, reducing risk of accidents.

Looking to start or advance a career in welding? Completing the courses demonstrates to employers that you’re serious about your career and committed to safety, making you stand out in the job market.

By leveraging the courses, organisations can help ensure compliance with safety laws and regulations. This helps avoid legal issues and fines and, more importantly, creates a safer working environment.

If you’re a hobbyist welder (or know someone who is), safety education is just as important. Free courses can provide the knowledge to safely enjoy welding at home, protecting yourself, your family, and your property.

Educating employees on safety can reduce workplace accidents, leading to lower workers’ compensation claims and insurance costs. A well-trained workforce is less likely to engage in unsafe practices.

By educating yourself, you contribute to a culture of safety. Sharing knowledge with peers, and practicing safe welding can influence others to prioritise safety, reducing overall welding-related accidents.