Upton Engineering and IMF Consulting Awarded AS/NZS ISO 3834 Certification >>>

Weld Australia Launches Free Welder Safety Courses

>>>

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Executive General Manager, Technical Services 0487 487 170 d.yalniz@weldaustralia.com.au

ENGINEERING

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991

v.blain@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901 a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991

v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, General Manager, Engineering – QLD, ACT, NSW, NT 0491 491 888

r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Ian Mackay, Business Development Manager 0493 027 882

i.mackay@weldaustralia.com.au

Weld Connect | March 2024 2 A Message from our CEO 03 Breaking News: Recent Media Coverage 05 Navigating Welding Fume Exposure Regulations 06 ‘Celebration of Manufacturing’ to Return in 2024 08 Industry News 09 Weld Australia Launches Free Welder Safety Courses 12 Membership Matters 14 2024 National Manufacturing Summit 15 ASME B31.3 Process Piping Code Course 16 Pipeline Repair, Hot Tapping & In-Service Welding Course 16 Launch of the MEM Learning Resources 17 Victoria Industry Drinks Night 18 WorkLife Resources for Drug and Alcohol Issues 19 NSW Industry Drinks Night 20 Steel Research Hub SME Engagement Program 21 Weldability of Stainless Steels Course 22 Laser Welding and Cleaning: New Technologies 23 Qualification and Certification Update 24 In-house Training for BAE Systems in South Australia 26 IIW International Welding Practitioner (IWP) 27 Upcoming Training Courses 29 Congratulations to All the Newly Qualified Individuals 30 Get IWI-C Qualified with Weld Australia 31 Weld Australia’s Exam Calendar 31 Fusion Welding Courses 32 IN THIS ISSUE Upton Engineering and IMF Consulting Certified to AS/NZS ISO 3834 24 WELD AUSTRALIA CONTACTS NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 1800 189 900 office@weldaustralia.com.au weldaustralia.com.au Geoff Crittenden Chief Executive Officer 1800 189 900 g.crittenden@weldaustralia.com.au TRAINING Guy Brooks, General Manager, Training Operations 0488 743 322 g.brooks@weldaustralia.com.au MARKETING Michelle Bignold, Executive

& Marketing 0437

m.bignold@weldaustralia.com.au MEMBERSHIP

d.choudry@weldaustralia.com.au

General Manager, Sales

106 726

David Choudry, Membership Manager 0417 878 104

Weld Australia Launches Free Welder Safety Courses 12

Welding can and should be considered a safe occupation; when proper precautions are taken, welders have no cause to fear accident or injury. Safety must be taken seriously in the workplace, to avoid the risk of long-term impacts.

As the Responsible International Institute of Welding (IIW) representative in Australia, Weld Australia is at the forefront of global welder safety best practice. We regularly participate in international research and development programs designed to improve welding fume safety practices. In collaboration with industry, Weld Australia has implemented a range of initiatives to help improve welder safety.

Established by Weld Australia in early 2019, the Welding Safety Council provides a forum for industry and legislative safety authorities to discuss issues and work collaboratively to identify solutions. By drawing together key government stakeholders, statutory bodies and industry into a single independent body focused on eradicating welding related injury, the Australian welding industry continues to take significant steps forward in protecting both the general public and welders.

Welder Safety Courses

The Welding Safety Council has been key in developing our two new Welder Safety Courses – one course aimed at welders, and the second aimed at welding engineers and supervisors. These courses are now online and freely available to the public.

The objective of these courses is to improve safety awareness, knowledge and outcomes across the welding industry.

The courses cover a broad range of subject material across welding processes. They provide details of hazards that may be encountered and how to manage them in the workplace. The hierarchy of controls are discussed, with a particular focus on engineering controls and the correct use of PPE.

The courses also reinforce procedures that should be used, such as correct set up and use of equipment and the correct handling of gas cylinders and welding machines. Assessment and certification for course participants is also available.

The courses can be accessed via the Weld Australia website or directly via: https://weldtraining.online

For further information, see the article on page 12.

Changes to Welding Fume Exposure Standards

Safe Work Australia recently announced that Work Health and Safety Ministers have agreed to an immediate reduction in the workplace exposure standard for welding fumes, from an 8-hour time weighted average (TWA) of 5 mg/m3 to 1 mg/m3

This makes Australia one of the leading countries in the world in terms of protecting welders from exposure to hazardous fumes. It is extremely important that we protect our employees and members as much as possible—every welder has a right to go home safe at the end of the work day.

These changes should not come as a surprise to industry. In March 2017, the International Agency for Research on Cancer (IARC) reclassified welding fume from Group 2B Possibly Carcinogenic to Humans to Group 1 Carcinogenic to Humans. Their assessment was subsequently published in IARC’s Monograph 118 in July 2018. These classifications and education around fume safety have been widely communicated since then.

Recommended Actions

As the exposure standard for welding fumes has been reduced, all necessary controls must be implemented to meet this higher standard.

Based on the hierarchy of controls, the following actions are recommended:

1. At-source fume control is recommended to maximise the level of fume captured and controlled as it is generated. Suitable methods include local exhaust ventilation (LEV) such as a hooded fume extractor and/or on-gun fume extraction. Captured fume should be filtered and exhausted to atmosphere, preferably outside the workshop.

2. Welders also require personal respiratory protection, particularly where the welder’s head is likely to be in or near the weld plume. For example, the use of Powered Air Purifying Respirators (PAPRs) offer an

Weld Connect | March 2024 3

excellent measure of protection in most welding situations. Externally air-fed helmets may be preferable or be required in some situations, such as confined spaces where oxygen monitoring is required.

3. Good overall ventilation throughout the workshop to protect the general workforce.

If in doubt, specialist advice should be sought from an occupational hygienist and fume exposure monitoring undertaken.

Need Help?

Weld Australia has established a dedicated hotline to help Australian welders and fabricators who need advice on the changes to the workplace exposure standard for welding fumes.

This can be reached via: 1800 212 988.

Further information is available via: weldaustralia.com.au/welding-fumes

Technical Resources

Weld Australia has published a wide range of welding safety resources, which are available to the public completely free of charge:

• Fume Minimisation Guidelines: Welding, Cutting, Brazing and Soldering, which includes all the information required to help protect workers from the hazards associated with welding fumes. This has been revised in line with the changes, and a new edition is now available for free download.

• Technical Note 7: Health and Safety in Welding, which gives guidance on health and safety practices in welding, cutting and allied processes such as brazing, soldering, pre- and post- weld material treatments and metal spraying, for the prevention of injury, ill health and discomfort, as well as damage to property, equipment and environment by fire, and explosion.

SHOWCASING 7 PRODUCT ZONES GET IN EARLY. REGISTRATIONS NOW OPEN! 1800AMWSYD24/A AUSTRALIA’S PREMIER MANUFACTURING SOLUTIONS EVENT 17–19 APRIL 2024 • ICC SYDNEY AUSTRALIANMANUFACTURINGWEEK.COM.AU SCAN HERE TO LEARN MORE

DOWNLOAD THE UPDATED GUIDELINES

Weld Australia would like to welcome all our new Members who have joined in the last month:

PREMIUM CORPORATE MEMBERS

• Industrial Laser Solutions: industriallaser.com.au

CORPORATE MEMBERS

• WPF Duratec: duratec.com.au

INDIVIDUAL MEMBERS

• Ambrose Keogh

• Matt Rowley

• Stephen Bell

• Mark Walsh

• Ashley Pinal

• Nathan Gregor

• Abdul Jabbar

• Farokh Ankleshwaria

• Ajo Joy

• John Morland

• Adam Wade

• Andrew Hughes

• Caleb Black

• Rhianna Cardamone

• Andrew Morgan

• Danial Goodall

JOIN TODAY

For further information on the benefits of becoming a Weld Australia member, visit our website, or contact David Choudry (Membership Manager) on d.choudry@weldaustralia.com.au or 0417 878 104.

RECENT MEDIA COVERAGE

Network of welding schools, published by Climate Control News

Manufacturing news briefs - stories you might have missed, published by Australian Manufacturing Forum

National network of Indigenous welding schools would help close the gap: Weld Australia, published by the National Indienous Times

Indigenous Welding Schools could help close Australia’s skills gap – Weld Australia, published by Australian Manufacturing

Closing the Gap: Indigenous welding schools to build skills and jobs, published by Education Daily

Welding School Could Ease Mining Skills Shortage and Close the Gap, published by Mining Monthly

Weld Connect | March 2024 5

JOIN TODAY

INDUSTRIAL GRADE MIG A BEAST AT YOUR FINGERTIPS

The BlueVenom XF353 has been designed and engineered in Australia to provide a MIG Inverter solution with modular adaptability. With a large intuitive digital display the XF353 can perform simple MIG welding tasks, using Wire Feed Speed (WFS) and Voltage (V) controls at the touch of a button.

The XF353 can seamlessly connect to the All-New 4R-Rover™ digital remote wirefeed system (sold separately) - a compact 300mm plug n’ play, 4 Roll geared wire drive unit with an 8m lead with low mount handle that you can setup where you need it.

The BlueVenom XF353 is also a single and double pulse work horse! Simply plug in the hand-held PulseMate™ (sold separately) into the XF353 machine or 4R-Rover™ and start getting TIG like looking welds through our simple yet intuitive SimplePulse™ MIG system.

The XF353 has made Synergic Plate Thickness control even easier. The intuitive unit will work out the settings you need for different metal types based on Plate Thickness (mm) settings – no more guessing which synergic settings to use.

And finally for additional scalability, the XF353 can run a direct connect Push-Pull MIG Gun without additional wiring, a Spool Gun, and a TIG Torch to give you the perfect welding setup.

The all new BlueVenom XF353 is a beast - a complete Industrial grade MIG welding system that can tame the toughest welding tasks!

AS

CIGWELD.COM.AU CIGWELD Pty Ltd An ESAB Brand 71 Gower Street, Preston VIC 3072 Australia Email: technical@cigweld.com.au

RRP: FULL PACKAGE

DISPLAYED $8,800

distributors

Available from all good CIGWELD

NAVIGATING WELDING FUME EXPOSURE REGULATIONS

Considering recent legislative changes addressing welding fume exposure, many organisations have asked for clarification on the measures they should take to meet the new regulations.

The new workplace exposure standard dictates that the average airborne concentration of welding fume inhaled by a worker over an 8-hour working day, across a five-day working week, must not exceed 1 milligram of welding fume per cubic meter of air. This standard is applicable to both welders and individuals working near welders.

Let’s Talk about PAPR Welding Helmets

The European standard EN 12941 outlines the criteria for a comprehensive powered air filtration apparatus that incorporates a face helmet or visor. EN 12941 does not establish a separate categorisation for particle filters (P); instead, the particle filter is an integral component of the overall system classification.

The standard defines three performance classes (TH1, TH2, and TH3), each with designated numerical values indicating the level of performance (inward leakage) and the tensile strength of breathing tubes and couplings within each class. TH1 has a maximum allowable inward leakage of 10%, TH2 permits a maximum of 2%, and TH3 allows for a maximum of 0.2% inward leakage.

Various studies, including internal testing by ESAB, outline that PAPR systems are the most effective (93%-99.5%) when compared to on-gun fume extraction (85%-95%) and hooded capture Local Extraction Ventilation (LEV) fixed or wheeled (60%-67%).

Hooded capture LEV proves less effective when the welding joint/pool moves away from the LEV capture point and is very much dependant on the distance from the weldment to the extractor nozzle. LEV’s are especially good at collecting fumes from concentrated areas such as over welding fixtures and jigs.

Highlighting product distinctions, it’s crucial to note that certain PAPR systems may outperform others, with factors like EN 12941 TH3 certification and the presence of a P3 filter differentiating them.

The ESAB Sentinel A60 Air PAPR System is one of a limited number of PAPR helmets on the Australian market that holds both EN 12941 TH3 and AS/NZS 1716 certifications, coupled with a P3 filter.

Moreover, the EN12941 certificate reveals compatibility of older ESAB Air helmets, including the Sentinel A50 Air, with the new EPR-X1 blower unit. This means existing ESAB Sentinel A50 Air owners can attain compliance with the standard by purchasing only the blower unit (EPR-X1), which is EN12941 TH3 certified.

A standalone PAPR unit might not be enough to meet the new minimum regulations on its own. By utilizing various controls, plus a fume MIG Gun with an Extraction Unit in the work area, alongside a PAPR System like the Sentinel PAPR Kit, will ensure the best possible protection factor for all welders.

FURTHER INFORMATION

https://www.cigweld.com.au/

This editorial was supplied as part of a sponsorship package.

Weld Connect | March 2024 7

‘CELEBRATION OF MANUFACTURING’ TO RETURN IN 2024

Australian Manufacturing Week organiser AMTIL wants AMW 2024 to be more than an exhibition, it wants the show to be the centrepiece of a week-long celebration of manufacturing in Australia.

Australia’s premier manufacturing technology trade show, Australian Manufacturing Week is a dynamic event that brings together professionals, companies and experts from many industries related to manufacturing, engineering and technology.

“We are very pleased to have the support of the NSW Government as the Major Sponsor for AMW 2024. Government support is important in delivering the message to our industry that manufacturing is important and that the support mechanisms are there to assist,” said Shane Infanti, CEO of AMTIL. “On the back of the overwhelming success of AMW 2022 in Sydney, we have returned to Darling Harbour, Sydney for April 2024 and we’re excited to be delivering another strong show.”

“We will again be running the Future Solutions Speaker Program on the floor of the show. Themed towards opportunities and managing change, the speaker program is once again free for visitors to attend,” says Kim Banks, AMTIL’s Head of Events. “Our plans for AMW 2024 include expansion of our Welding and Air Technology Zone and Robotics and Automation Zone. This will round out the event in representing the manufacturing technology sectors in Australia.”

A reminder of the seven distinct zones at AMW 2024, each showcasing the highlights of the different active sectors in Australian manufacturing:

The AUSTECH Machine Tool Zone is targeted at the metalworking, machine tool and ancillary market. AUSTECH

covers advanced manufacturing products and processes. The Additive Manufacturing Zone will showcase the most advanced additive technologies and techniques including: stereolithography, selective laser sintering, material extrusion, sheet lamination, binder jetting, cold spray-processing, material jetting, directedenergy deposition, powder-bed fusion, VAT photopolymerisation and wire-arc manufacturing.

The Australian Manufacturers Pavilion showcases the capabilities of Australia’s precision engineering and advanced manufacturing.

The Manufacturing Solutions Zone exhibits solutions to the most common manufacturing challenges — from materials handling and warehousing to integrated manufacturing and safety.

The Robotics and Automation Zone will feature the latest state-of-the-art equipment and processes for the optimisation of manufacturing operations.

The Weld and Air Solutions Zone will highlight advanced welding processes and offers interactive experiences that demonstrate developments and applications.

The Plastics Technology Zone is a hands-on opportunity to see and feel the latest in plastics machinery, mouldmaking technologies, recycling materials, and many processes in plastics manufacturing.

AMW 2024

When: 17-19 April, 2024

Where: Sydney ICC Darling Harbour

Details: australianmanufacturingweek.com.au

This editorial was supplied as part of a sponsorship package.

Weld Connect | March 2024 8

DEFENCE STRATEGY PLANS TO SUPPORT INDUSTRY GROWTH AND NATIONAL SECURITY

The Federal Government recently released a plan that defines the strategic rationale for a sovereign defence industrial base and sets out pathways for maximising support for Australian industry. The Defence Industry Development Strategy (DIDS) articulates the defence industrial base needed, as outlined in the Defence Strategic Review

This strategy details the actions the Government will take to grow that industrial base, which employs more than 100,000 Australians, and deliver a greater partnership between Defence and industry. It also includes increased funding for defence industry grants programs, taking the total investment to $183.8 million.

The Government said that Australia requires strong defence capabilities of our own and a fully integrated Australian Defence Force to contribute to the strategic balance of power that keeps the peace in our region.

Minster for Defence Industry Pat Conroy said, “This strategy will underpin essential reforms that will ensure that critical capabilities are provided to the men and women of the ADF as soon as possible, while also supporting an industry vital to our national security.”

AUSTAL AUSTRALIA AWARDED CONTRACT FOR MORE ROYAL AUSTRALIAN NAVY PATROL BOATS

Austal Australia has been awarded a contract extension for the construction of two additional Evolved Cape-class Patrol Boats for the Royal Australian Navy. The $157 million contract follows the procurement announcement made in November 2023 by the Commonwealth of Australia and brings the total number of Evolved Capeclass Patrol Boats being delivered to the Navy, under the SEA1445-1 Project, to ten.

Austal Limited Chief Executive Officer Paddy Gregg said, “These additional Evolved Capes, designed and constructed by Austal in Henderson, Western Australia, are helping us to retain and build our sovereign, naval shipbuilding workforce and continue to engage supply chain partners from across Australia.”

The Evolved Cape-class Patrol Boats feature larger amenities to accommodate up to 32 people, improved quality of life systems and advanced sustainment intelligence systems that further enhance the Royal Australian Navy’s ability to fight and win at sea. The patrol boats are utilised for a wide variety of constabulary and naval missions and play a critical role in Australia’s national security, as a high-performing, reliable and effective maritime asset.

Weld Connect | March 2024 9

BISALLOY CONTRACTS FOR AUSTRALIAN SSN-AUKUS HULL STEEL QUALIFICATION

The Australian Submarine Agency has entered into a contract with Bisalloy Steels, for the qualification of Australian steel for use on Australia’s SSN-AUKUS conventionally armed nuclear-powered submarines. The contract is for a term of approximately 16 months. The comprehensive qualification process, involving more than 4500 tests, is expected to be completed in the first half of 2025.

Bisalloy Steels will perform the advanced heat treatment process on the raw plate steel to produce high grade submarine pressure hull steel that meets or exceeds both the UK and US standards. The raw plate steel will be supplied by BlueScope.

The qualification of the steel to both the UK and US standards will increase the resilience of the AUKUS trilateral supply chain. Not only will the steel produced under this contract be used for qualification purposes, it will also be used to develop the necessary welding procedures, and used in early production demonstration activities occurring ahead of the commencement of construction of Australia’s first SSN-AUKUS submarine later this decade.

Bisalloy Steel Group Managing Director and CEO, Mr Rowan Melrose said, “Bisalloy is very pleased to reach an agreement with the Commonwealth to supply plates for grade qualification to the UK and US naval hull plate standards. This is a significant announcement for Bisalloy as it highlights the quality of our products, our ability to deliver to the highest standards, and the recognition and trust of a long-standing supply relationship with Australia’s Defence industry. This is a great outcome for Bisalloy, the Illawarra and Australian Manufacturing.”

AUSTRALIAN LABOUR PRODUCTIVITY PLUMMETS, UNVEILED IN LATEST REPORT

The Productivity Commission has unveiled a report shedding light on Australia’s productivity decline, with labour productivity experiencing a sharp downturn in the 2022-2023 period.

Despite a record-breaking surge in hours worked, economic output failed to match the same level of increase, the government said in a media release.

Titled the Annual Productivity Bulletin 2024, the report offers comprehensive insights into the factors driving Australia’s productivity slump during the specified timeframe.

Deputy Chair of the Productivity Commission Alex Robson expressed the importance of addressing Australia’s productivity challenges. “We now have a clearer understanding of what’s behind Australia’s productivity slump. Sharp increases in working hours have seen productivity decline, but this makes policies to boost productivity even more important,” Robson remarked.

Labour productivity plummeted by 3.7%, significantly below the long-term average growth rate of 1.3%. This decline was propelled by a staggering 6.9% surge in hours worked by Australians, marking the highest annual increase in history.

Weld Connect | March 2024 10

GOVERNMENT GRANTS ON OFFER FOR QUEENSLAND BUSINESSES

Manufacturing Energy Efficiency Grant

The Queensland Government’s Manufacturing Energy Efficiency Grant program is available to help manufacturers reduce their energy usage and cut energy costs, by providing direct support to manufacturing businesses. Eligible manufacturers can apply for matched grant funding of between $5,000 and $25,000 to buy equipment or introduce processes that will reduce energy consumption and carbon emissions.

Round 1 is open until 30 June 2024 or until all funding is allocated.

Manufacturing Hubs Grant Program

Businesses across Queensland are also benefitting from the $28.5 million Manufacturing Hubs Grants Program as part of the invaluable support provided through the more than $60 million investment in the six manufacturing hubs in Cairns, Townsville, Mackay, Rockhampton, Gladstone and the Gold Coast. This grant supports development of businesses’ advanced manufacturing capabilities like technology adoption, skills and training and business development.

Round 3 is open until 30 June 2024 or until all funding is allocated.

CAIRNS STEEL FABRICATOR BOLSTERED WITH $720,000 MANUFACTURING GRANT

A Queensland state Government manufacturing grant will enable Cairns manufacturer, CSF Industries to purchase Shotblaster equipment that will expand the manufacturing capacity and grow the business, resulting in as many as 15 new jobs over the next five years.

CSF Industries services the local construction sector, offering steel fabrication, roofing services, coating and finishes, engineering, lifting and transport, and logistics products and services.

Minster for manufacturing Glenn Butcher said, “CSF Industries is a fantastic example of locally made innovation and hard work. The business has gone from strength to strength, since it was founded in 1979, and this $720,000 grant will ensure they can continue to thrive.”

Purchasing the blasting equipment has been made possible thanks to more than $720,000 in funding from Round 5 of the Queensland Government’s Made in Queensland (MiQ) program.

CSF Industries Director Sean Adams said, “This grant has enabled us to purchase new equipment that will help us grow, adding new jobs and benefiting the local economy.”

“This new equipment will mean CSF can significantly increase capacity in its blast and paint facility, reducing blasting times by 67% in the first year, and enabling the business to take on a greater volume of work, and reducing lead times for customer,” said Butcher.

Weld Connect | March 2024 11

WELD AUSTRALIA LAUNCHES FREE WELDER SAFETY ONLINE TRAINING COURSES

Welding is a potentially dangerous process, with many hazards and risks to people’s health. These risks are compounded by the fact that welding is undertaken across a wide range of locations and situations, from workshops and field work, through to confined spaces, underground mine sites, and more.

Hazards in each of these situations will be different, and require different controls to keep welders and others in close proximity safe.It is critical to manage these risks and hazards so that people working in the welding industry are kept safe and return home at the end of each day without injury.

To this end, Weld Australia has developed and released two free online welder safety training courses.

About the Courses

Weld Australia has developed two comprehensive online welder safety training courses – one course aimed at welders, and the second aimed at welding engineers and supervisors. These courses are now online and freely available to the public.

The objective of these courses is to improve safety awareness, knowledge and outcomes across the welding industry.

The courses cover a broad range of subject material across welding processes. They provide details of hazards that may be encountered and how to manage them in the workplace. The hierarchy of controls are discussed, with a particular focus on engineering controls and the correct use of PPE.

The courses also reinforce procedures that should be used, such as correct set up and use of equipment

and the correct handling of gas cylinders and welding machines. Assessment and certification for course participants is also available.

How to Access the Courses

The courses can be accessed via the Weld Australia website or directly via: https://weldtraining.online

To start the courses, all you need is an account for Weld Australia’s online training platform. If you don’t already have an account, you can quickly and easily create one via the link in the top right-hand corner of the platform’s homepage.

Further Information

For further information contact: Andrew Davies (Manager, Technical Industry Networks, Weld Australia) a.davies@weldaustralia.com.au or 0438 428 966.

ACCESS THE COURSES NOW

Weld Connect | March 2024 12

Incorporating the welding safety courses into your induction process for new hires ensures all employees start with a solid foundation in safety practices. It helps set a company-wide safety standard from day one.

By undertaking these courses, you can gain essential knowledge on how to protect yourself from hazards like burns and harmful fumes. Learning about PPE and emergency procedures can be life-saving.

The courses can be used as part of an ongoing training program to keep employees up to date with the latest safety techniques. Regular refreshers help maintain safety awareness, reducing risk of accidents.

Looking to start or advance a career in welding?

Completing the courses demonstrates to employers that you’re serious about your career and committed to safety, making you stand out in the job market.

By leveraging the courses, organisations can help ensure compliance with safety laws and regulations. This helps avoid legal issues and fines and, more importantly, creates a safer working environment.

If you’re a hobbyist welder (or know someone who is), safety education is just as important. Free courses can provide the knowledge to safely enjoy welding at home, protecting yourself, your family, and your property.

Educating employees on safety can reduce workplace accidents, leading to lower workers’ compensation claims and insurance costs. A well-trained workforce is less likely to engage in unsafe practices.

By educating yourself, you contribute to a culture of safety. Sharing knowledge with peers, and practicing safe welding can influence others to prioritise safety, reducing overall welding-related accidents.

FREE MEMBER EVENTS

AS/NZS Welding Standards Update

Thursday 11 April | 12:00 noon to 1.00pm AEDT Online via Zoom

This webinar will focus on various Australian Standards that impact the welding industry, including:

• Revision of design and fabrication standards, such as AS 4100 and AS/NZS 5100.6.

• Revision of pressure equipment standards, such as AS 3788, AS 4343 and AS 4458.

• Revision of structural standards, such as the AS/NZS1554 series, AS 2214, AS/NZS 1665

• Revision of the welding consumable standards

• Revision of the welding safety standards AS 1674.1 and AS 1674.2

• Aged standards update such asthe AS 2205 series

• ISO update, such as the AS/NZS ISO 3834 series and ISO 9606.

There will also be information on the Standards policies and requirements and their influence on the revision process. Learn about the process of how a Standard is revised and how you can get involved, the public review process and more.

The session will conclude with the presentation of an innovative tool to assist standards users to identify standards applicable to their work.

The seminar is designed for Welding Supervisors, Managers, Engineers, and those who use, or should be using, any welding related standard.

It will be presented by Bruce Cannon, Weld Australia’s Principal Welding Engineer and Technical Publications Manager. Bruce is also the Chair of Standards Australia Committee WD-003 and has represented Australia at ISO meetings, including the current revision of ISO 9606-1. This is your chance to hear all Standards from an expert in the field.

Cold Spraying and Additive Manufacturing: Workshop Tour and Demonstration

Thursday 11 April | 5.30pm to 6.30pm

Titomic, Building 3, 270 Ferntree Gully Road, Notting Hill Victoria 3168

Join us for a technical night presented by the Victoria Committee. This in-person event at Titomic—featuring both cutting-edge presentations and invaluable networking opportunities—is free for members.

Learn about an emerging additive manufacturing technology. Cold spray is a method of building up parts and coatings rapidly without heat, enabling noheat repairs, as well as the manufacture of very-large structures from titanium, Inconel, steel, and more. Additive manufacturing is used for maintenance of metal parts, heavy equipment, resurfacing and coatings in the automotive, castings, aerospace, marine and resources sectors.

Event highlights will include:

• A short presentation on what cold spray is and how it works.

• Demonstration of the D523 – a handheld, no heat metal deposition system.

• Demonstration of additive manufacturing with cold spray.

• Network with Weld Australia members and industry partners.

• Light refreshments and non-alcoholic beverages.

Weld Connect | March 2024 14

NOW

REGISTER

REGISTER NOW

The Summit will see a diverse group of industry stakeholders assemble on 31 July and 1 August 2024. The Summit gathers leading representatives from all the major stakeholders in Australia’s manufacturing sector—business, unions, universities, suppliers, and government—to discuss the sector’s prospects, and identify promising, pragmatic policy measures designed to support an industrial turnaround.

Building on the momentum of the 2023 National Manufacturing Summit, which focused on the Renewable Energy: Challenges and Opportunities, the 2024 Summit embarks on an ambitious journey with its theme: Pathways to Success…Making the Renewable Energy Revolution a Reality.

VENUE

The 2024 National Manufacturing Summit will be held at the Amora Hotel in Brisbane

Discount Room Rates for Delegates

Book your stay at the Amora Hotel during the Summit and enjoy an unparalleled 15% discount off the best available rate at the time of booking. This discount will apply from July 30 to August 2. This special offer is designed exclusively for our delegates, ensuring your experience is not just memorable, but also more affordable.

Rate URL: https://reservations.travelclick. com/113954?RatePlanId=8550782

Access Code: WELD24

SPONSOR THE SUMMIT

Weld Australia’s National Manufacturing Summit is one of the most prestigious events on the manufacturing industry calendar. Sponsors are essential to the success of the Summit; without you, we would be unable to facilitate our industry-leading program.

With a diverse range of members from across Australia, we offer curated sponsorship packages that give you unparalleled access to your ideal customer base. Not only will you enjoy superior brand exposure opportunities, you can rest assured that your marketing is reaching an engaged group of industry professionals.

On top of the chance to market your brand in front of industry decision-makers, you will also be reinvesting in the welding and fabrication industry—giving back to the industry that makes your business so successful.

To tailor a sponsorship package, or for further information, conact Michelle Bignold (National Manager, Sales & Marketing, Weld Australia) on +61 437 106 726.

Weld Connect | March 2024 15

>>> LEARN MORE

DOWNLOAD A COPY OF THE SPONSORSHIP PROSPECTUS

ASME B31.3 PROCESS PIPING CODE COURSE IN NOVEMBER 2024

Weld Australia is looking at hosting a three day course on the ASME B31.3 Process Piping Code in November 2024, in both Brisbane and Perth.

To register your interest, please email: Danielle Pennington (Corporate Engagement Manager, Weld Australia) on d.pennington@weldaustralia.com.au

About the Course

This course provides an introduction to the ASME B31.3 Process Piping Code. It covers the requirements of B31.3 for design, analysis, materials, fabrication, testing and inspection of process piping systems. It explores the rules for various components including fittings, connections, bends, valves and specialty components.

Other topics include dimensions and ratings of components, fluid service requirements for joints, piping flexibility and support, welding, heat treatment, bending and forming, brazing and soldering, assembly, erection, examination and inspection.

By participating in this course, you will learn how to successfully:

• Identify the responsibilities of personnel involved in the design, fabrication, assembly, erection, examination, inspection, and testing of process piping

• Describe the scope and technical requirements of the ASME B31.3 Code

• Apply and implement the quality requirements that are defined in the ASME B31.3 Code.

PIPELINE REPAIR, HOT TAPPING & IN-SERVICE WELDING COURSE IN MAY 2024

Brisbane: Wednesday 22 and Thursday 23 May 2024

Perth: Tuesday 28 and Wednesday 29 May 2024

Please note: in order for the course to go ahead, minimum attendee numbers must be reached.

To register, please email: Danielle Pennington (Corporate Engagement Manager, Weld Australia) on d.pennington@weldaustralia.com.au

About the Course

This two day course provides an in-depth overview of the various aspects of pipeline modification and repair to address the concerns associated with welding onto inservice pipelines. A thorough understanding of the factors that affect welding onto in-service pipelines helps avoid pipeline shutdowns and interruptions of service, thereby bolstering both economic and environmental benefits for operators and welders alike. Plus, repairs can be undertaken efficiently, effectively and with full confidence.

Facilitated by US expert, William (Bill) A. Bruce, the course includes a review and critical analysis of available thermal analysis models, including the original Battelle model, the heat sink capacity method and the PRCI thermal model for Hot Tap Welding. Course attendees will learn why these models, while useful as planning tools, should not be regarded as ‘magic bullets’ against hydrogen cracking in hot tap welding by utilising comparative examples.

The course will dispel a number of misconceptions that have developed pertaining to operating practices required to safely weld onto an in-service pipeline.

Weld Connect | March 2024 16

LEARN MORE

LEARN MORE

VICTORIA INDUSTRY DRINKS NIGHT

Held on Tuesday 13 February at Byblos in the Docklands, the Victoria Industry Drinks Night was enjoyed by everyone who attended, despite the wild weather that lashed Melbourne just hours before.

Attendees heard from Geoff Crittenden (CEO, Weld Australia) who provided insights into Weld Australia’s activities, as well as the recent changes to the welding fume exposure standards. Geoff even started his presentation kitted out with a PAPR welding helmet.

Andrew Barnes (National Marketing Manager, Cigweld) also spoke to the crowd, introducing attendees to all to the latest products from CIGWELD and ESAB. Nicholas Raftopoulos took out the lucky door prize, an Arcmaster XC50 Delta Welding Helmet supplied by Cigweld.

Weld Australia would like to thank Cigweld for supporting their event—it is the generous support of sponsors that makes events like this possible.

Weld Connect | March 2024 18

L to R: Andrew Barnes and Geoff Crittenden. Andrew Barnes gives a presentation.

L to R: Winner of the lucky door prize XXXX and Andrew Barnes.

Weld Connect | March 2024 19 WorkLife Acknowledgements WorkLife was funded by the Government of South Australia, led by a project team from NCETA in collaboration with SA Government with advice from the NCETA WorkLife Project Reference Group Free resources to help workers and workplaces identify and respond to alcohol and drug issues WorkLife helps workers and workplaces Understand more about alcohol & other drugs Promote workplace safety Comply with duty of care & legal obligations Increase productivity Improve worker morale & wellbeing Reduce absenteeism The National Centre for Education and Training on Addiction (NCETA) respectfully acknowledges the Kaurna people as the Traditional Owners of the land and waters on which our Centre is located We pay our respects to all Elders past, present and emerging Online Learning Drugs 1 Alcohol Methamphetamine Illicit drugs Pharmaceutical drugs Mental Health, Stress and Fatigue 2 Communication Strategies 3 Policies and Responses 4 Understanding workplace alcohol & drug use Alcohol and drug policies Alcohol and drug testing Fact Sheets Alcohol 1 Alcohol & drug impairment 2 Fatigue & alcohol and drug use 3 Getting help & returning to work 4 Illicit drugs 5 Legal Issues 6 Mental health & alcohol and drug use 7 Methamphetamine 8 Pharmaceuticals 9 Vaping (Electronic cigarettes) 10 Workplace alcohol & drug policies 11 Workplace stress & alcohol & drug use 12 How-To-Guides Assessing workplace alcohol and drug risk 1 Critical alcohol and drug situations 2 Having helpful conversations 3 Organisational change 4 Responsible alcohol service (at work events) 5 Workplace alcohol and drug testing 6 Toolbox Talks Alcohol 1 Alcohol & drug testing 2 Alcohol & drug use and mental health 3 Fatigue at work & alcohol & other drugs 4 Illicit drugs 5 Methamphetamine 6 Our alcohol & drug policy: Consultation 7 Our alcohol & drug policy: Refresher 8 Our alcohol & drug policy: Review 9 Pharmaceuticals 10 Posters & Handouts Ten principles for responding to intoxicated workers 1 Ten management responses to workplace stress 2 Critical response practice 3 Getting help – Alcohol & drug services 4 Getting help – Mental health services 5 Getting help – Organisational supports 6 Overcoming stress, anxiety and depression 7 Workplace fatigue 8

NSW INDUSTRY DRINKS NIGHT

The 2024 New South Wales Industry Drinks Night proved to be a huge success. Held on Thursday 7 March at The Loft waterfront cocktail bar, the event was attended by over 100 people.

Sponsored by TAFE NSW, the event included an informative and engaging presentation from Phil Clarson (Teaching Lead, Engineering and Manufacturing, TAFE NSW). Phil spoke about TAFE NSW’s activities in skilling students to become the next generation in the welding industry.

Geoff Crittenden (CEO, Weld Australia) also provided an overview of Weld Australia’s activities, as well as the recent changes to the welding fume exposure standards.

The night was a great way for welding industry colleagues to catch up and network in a relaxed setting. Weld Australia would like to thank TAFE NSW for the

Weld Connect | March 2024 20

SME ENGAGEMENT & INNOVATION PROGRAM

SMEs have access* to subsidized collaborations with university researchers aligned with the Australian steel industry.

Activities are being delivered as part of the Australian Research Council funded research program – the ARC Research Hub for Australian Steel Innovation (Steel Research Hub) –with the support of Weld Australia

Are you interested in new ways to meet your business innovation needs?

Would you like access to cuttingedge research knowledge, equipment or facilities?

Are you an SME which is, or would like to be, involved in the steel industry?

If you answered yes to the above, we want to hear from you Contact

SMEs often have limited internal resources to engage in R&D. This program aims to help businesses develop new ideas and innovative solutions to meet a range of industry needs. With the potential to access expert advice and state-of-the-art university equipment, infrastructure and facilities Collaborating with the Steel Research Hub could help your business to improve productivity, efficiency and increase the durability or sustainability of your steel products and processes. Give your business a competitive edge or open new opportunities across the steel supply chain.

PROJECTS WILL BE INDIVIDUALLY TAILORED, FOR EXAMPLE, SUPPORTING:

› Product and service development, innovation, or product testing

› Techniques, technologies or processes for advanced manufacturing, construction or fabrication

› Enabling technologies such as automation or data analytics.

DESIGNED IN COLLABORATION WITH UNIVERSITY RESEARCHERS WITH EXPERTISE IN YOUR FIELD:

› Projects are designed to meet the needs and priorities of your business.

› Projects with R&D collaboration objectives offer valuable pathways for mutual knowledge exchange with experts in steel innovation.

› Projects will be supported by matched funding (indicative value of $20,000 to $50,000).

› Small-scale and short-term projects with the potential for ongoing collaboration are welcome

With an easy application process, exploring what is possible begins with a confidential discussion with staff at the Steel Research Hub. Alternatively, first make contact with your industry peak body representative for a chat about the potential benefits of a university collaboration for your business.

* The program is open from November 2023 and will continue to run until the funding is exhausted.

more information

www.uow.edu.au/steel-research-hub

21

steel-research-hub@uow.edu.au

WELDABILITY OF STAINLESS STEELS COURSE

Held on 13 and 14 February in Melbourne, this two day course gave participants a working knowledge of the welding metallurgy and weldability of stainless steels. Attendees walked away with an understanding of the various types of stainless steel, and how to pre-heat, weld and post-heat treat them without introducing imperfections, causing cracking or otherwise disrupting their beneficial mechanical properties.

Stainless steels are usually specified because of their enhanced corrosion resistance, high temperature oxidation resistance, or their strength. With various types of stainless steel available, there are specific welding processes and techniques that must be employed to ensure that the corrosion and oxidation resistance, and other mechanical properties are not impaired.

The course was presented by Dr Lippold, Emeritus Professor in the Welding Engineering Program at Ohio State University (OHU). He retired from OSU in 2016 after more than 20 years on the faculty having trained over 60 graduate students. He received his Bachelor, Master and PhD degrees in Materials Engineering from Rensselaer Polytechnic Institute where he was a student of Dr Warren F. Savage. He worked at the Sandia Livermore Laboratory in California for seven years, and at the Edison Welding Institute for 10 years. In 1995, he joined the faculty of the Welding Engineering Program at OSU. Over the past 40 years, Dr Lippold has been involved in research activities designed to gain a better understanding of the welding metallurgy and weldability of engineering materials. This includes both fundamental and applied topics with a high degree of industrial relevance.

The feedback from all participants has been overwhelmingly positive.

“I found the training to be informative and the opportunity for networking was great; I also really enjoyed the Tuesday [Victoria Industry Drinks] night.”

“Presenter was very knowledgeable, approachable and well spoken.”

“World class expert presenter.”

Weld Connect | March 2024 22

John Lippold

Course attendees

LASER WELDING AND CLEANING TECHNICAL EVENT IN SOUTH AUSTRALIA

The South Australia Committee, recently hosted a technical event focused on new technologies in laser welding and cleaning.

Attendees heard from Markus Lindemann, the Head of Laser Technology Asia Pacific as well as the General Manager for TRUMPF Singapore. He is living in Singapore. Markus started his career in TRUMPF in the year 2000 at the development team for additive manufacturing in the machine tools division of TRUMPF.

In 2006 he moved to the central sales department of TRUMPF’s laser division. In 2011, he became the sales director of TRUMPF China’s laser division in Shanghai. In 2016 he has been promoted to the Director of International Sales Asia and Africa in the TRUMPF Headquarter in Germany. Markus took over the current regional position in Singapore in 2018 and was promoted to General Manager in Singapore in 2022.

Event highlights included:

• Introduction to TRUMPF and Headland: an overview of trailblazers in welding technology.

• Optimised Laser Welding Results with Beam Shaping: techniques that elevate welding precision and efficiency.

• Surface Structuring and Cleaning with Lasers: innovative uses of lasers beyond welding, including enhancing surface properties and cleanliness.

• Interactive Q+A Sessions: attendees had their questions answered by experts on welding, and surface structuring and cleaning.

Weld Connect | March 2024 23

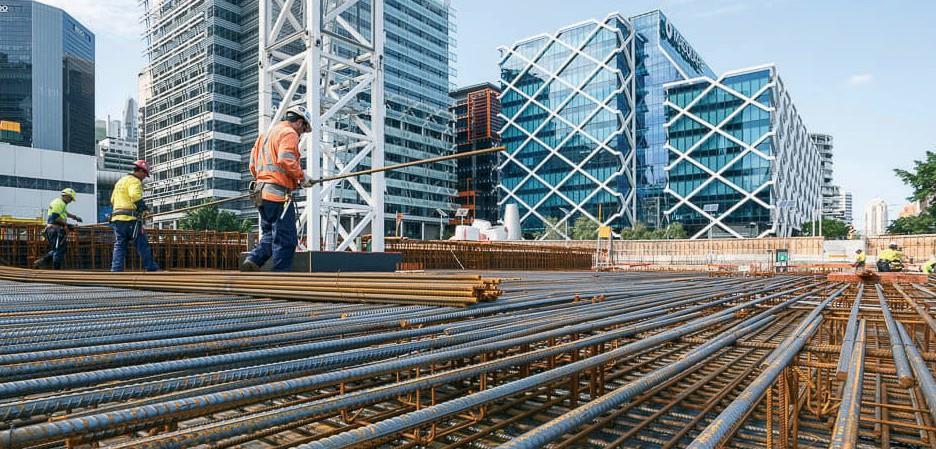

UPTON ENGINEERING AND IMF CONSULTING AWARDED ISO 3834 CERTIFICATION

Weld Australia is pleased to congratulate both Upton Engineering and Manufacturing and IMF Consulting on being awarded certification to AS/NZS ISO 3834.

Upton Engineering and Manufacturing

Upton Engineering and Manufacturing (UEM) is a leading manufacturer and supplier, specialising in the precision overhaul and manufacturing of high tolerance equipment and machined components. Utilising advanced CNC technology and fabrication services to provide high quality service for customers in various industry sectors including aerospace, mining, alumina and smelter refineries, oil, gas, ports and government infrastructure projects, and motorsport.

Based in Gladstone, central Queensland, the company has just moved into a new state of the art facility set up to provide a superior CNC machining, fabrication, assembly and project service to local industry and around Australia. They also offer a comprehensive fabrication service welding, fabrication and break down requirements; using the latest in welding technology with top of the range Millers and Fronius welders. UEM can cater for jobs up to 5t, including everything from ID welding to aluminium TIG.

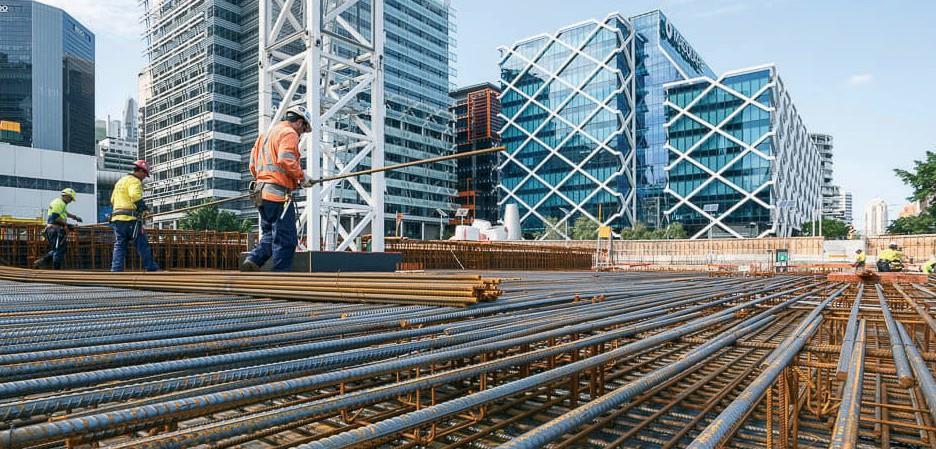

IMF Consulting

IMF specialises in steel construction, mine services and design solutions. Based in the Hunter Valley region of NSW, and working with clients throughout the country, their team of professionals and skilled tradesman have been building Australia’s future since 1994. Steel construction is at the core of their business and has been for nearly 30 years.

IMF provides the highest quality fabricated bespoke steel frames for commercial buildings, utility plants, shopping centres, mining sites, Transport NSW, and more. Their state-of-the-art facility spans over 6,000m² and with nearly 30 years’ experience, they have a proven track record of delivering projects on time, on budget, and to a high quality standard.

Upton Engineering team member hard at work.

HOT ENGINEERING UNDERGOES AN AUDIT FOR ISO 9001 CERTIFICATION

Weld Australia recently conducted a successful site audit at Hot Engineering for their certification to ISO 9001 Quality management system. This is a crucial certification for a quality management system. It is used by organisations to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements.

Hot Engineering is a locally owned engineering workshop based in Mudgee providing services to the mining, agricultural and construction industries. With over 15 years experience and a team of more than 15 experienced individuals, Hot Engineering can help with anything from buildings, infrastructure, longwalls, mechanical projects and more.

Weld Connect | March 2024 24

SUCCESSFUL SURVEILLANCE AS/NZS ISO 3834 AUDITS ACROSS THE COUNTRY

Over the last month, Weld Australia conducted a number of successful AS/NZS ISO 3834 surveillance audits, including for KS Metal Fabrications, Thales and Hard Bakka.

KS Metal Fabrications

Based in Smithfield, KS Metal Fabrications provide a range of sheet metal and general fabrication services - whether it be mild, galvanized, stainless steel or aluminium. KS specialises in quality metal fabrication for the HVAC and construction industries. Their recent projects include cabinets for the M8 Motorway tunnel, Barangaroo Towers plantroom ductwork, and fan housing for data centres.

With exceptional skills and experience, KS provides profile cutting, forming and assembly, including both MIG and TIG welding. To streamline their processes, KS has invested in state of the art machinery that enables them to design and store client jobs on their database for consistent and efficient resupply with minimum turnaround time.

Thales

Thales Australia is a premier provider of systems, products and services in the defence, security and civil markets in Australia and throughout the world. They are part of a leading international electronics and systems group serving defence, aerospace and security

markets. In Australia, Thales has over 4,300 personnel and generated exports of over $1.6 billion in the last 10 years. With over 35 sites around the country, they trace their origins in Australia back to the 1890s. Thales is one of Australia’s leaders in research and development spending around $100 million in self funded R&D per year. They also maintain strong affiliations with the Defence Science and Technology Group (DSTG) and the Commonwealth Scientific and Industrial Research Organisation (CSIRO) and leading tertiary institutions.

Hard Bakka

Hard Bakka is a dynamic steel fabrication company that operates from a 1,100m2 workshop in Bankstown, Sydney. The company specialises in structural steel fabrication, welding and installation for commercial, industrial, and residential projects. The company also supplies sorting machine plant structures, ore bins, rock boxes and complete wash screen units to the mining industry. Hard Bakka has gone from strength to strength in recent years, doubling its size in 2014 and tripling its size in 2018.

With over 30 years of industry experience, Hard Bakka steel fabricators, welders and riggers are ready to supply, fabricate, deliver and install all your structural and architectural steel works, from industrial racking systems and conveyor structures, steel staircases, structural awnings, rails and fences, steel extensions, structural beam supports and bracing, structural shelters-canopies, gantries, steel roof trusses and mezzanine levels. We also fabricate steel and metal shop fittings including shelves, racks, frames and bi-fold doors to individual needs and design.

Weld Connect | March 2024 25

The Upton Engineering team

IN-HOUSE IWI-B TRAINING FOR BAE SYSTEMS IN SOUTH AUSTRALIA

Weld Australia recently facilitated in-house training for BAE Systems in South Australia.

Joe Sandor (Welding Technology Trainer, Weld Australia) presented our International Welding Inspector - Basic (IWI-B) course to 12 of BAE’s staff over three days.

This internationally recognised course provides extensive knowledge surrounding welding, inspection theory and application. It includes theoretical components such as mechanical and visual inspection techniques; inspection procedures and acceptance criteria; identification of weld imperfections associated with pre-production; fabrication and post fabrication; and much more.

BAE Systems is Australia’s most versatile defence and security company. From air and maritime sustainment to shipbuilding, they have a long and proud heritage of providing advanced defence technology which protects both people and national security, keeping critical information and infrastructure secure.

For more information or to book an in-house course for your team, email: training@weldaustralia.com.au

WELDING FUNDAMENTALS COURSE FOR SYDNEY TRAINS

We recently facilitated our highly popular Welding Fundamentals online course for Sydney Trains.

Sydney Trains is the operator of rail services across the metropolitan Sydney area, bounded by Berowra, Emu Plains, Macarthur and Waterfall—it is a network that moves over 1.3 million people per day.

The Welding Fundamentals course gives professionals an understanding of some of the significant issues that may arise with welded components, and provides an overview of welding processes, weld defects, testing and welder qualification as required by various Australian and international Standards.

The course is suitable for engineers, designers, draughtsmen, production and workshop managers, project managers, and quality assurance managers.

Our next Welding Fundamentals course starts on 5 June. Enrol now.

Weld Connect | March 2024 26

AS 1796 CERTIFICATE 1-9 THEORY

Starts 8 April

An AS1796 Welding certificate is by far the most well known and requested welder certification nationally. It is used in both structural and pressure equipment Standards. The course is delivered online over 15 sessions, live via Zoom. Participants can ask questions, in real time, of our experienced welding technology trainer.

ENROL NOW

FACE-TO-FACE IWI-B TRAINING IN BRISBANE

Starts 27 May

This face-to-face training runs over a 1-week block at our Wollongong office. The first 4 days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

ENROL NOW

FACE-TO-FACE IWI-B TRAINING IN WOOLONGONG

Starts 20 May

This face-to-face training runs over a 1-week block at our Wollongong office. The first 4 days consist of theory and practical training, with the final day a practical exam. The theory exam will be scheduled online the following week. The IWI-B course is a globally recognised IIW qualification that covers general knowledge of welding and inspection.

ENROL NOW

FACE-TO-FACE WELDING SUPERVISOR AS1796 & AS2214

Starts 8 July

A Welding Supervisor qualification expands your career horizons enormously. Both AS 2214 and AS 1796 Certificate 10 meet the requirements outlined in AS/NZS 1554.1 to supervise the welding of structural steel. Similarly, AS 1796 Certificate 10 meets the requirement for a welding supervisor under AS 1210 for pressure vessels.

ENROL NOW

FACE-TO-FACE IWI-S TRAINING IN WOLLONGONG

Starts 20 May

This course provides advanced knowledge of welding and inspection, including NDT, mechanical and visual inspection, acceptance criteria, identification of weld imperfections and more. The training runs over 8 days at our Wollongong office. The first 7days consist of theory and practical training, with the final day a practical exam.

ENROL NOW

WELDING INSPECTOR - AS1796 CERTIFICATE 11

Starts 15 July

The Certificate 11 is an Australian Welding Inspection qualification recently introduced to AS1796, this qualification builds upon the foundation knowledge expected of a Welding Supervisor with a distinct emphasis on inspection activities related to pressure equipment, as well as the documentation associated with this role.

ENROL NOW

Weld Connect | March 2024 29

Need help? Contact our Training team via training@weldaustralia.com.au

Weld Australia would like to congratulate everyone who qualified in February.

AS 1796 CERTIFICATE 3E

• Justin McCann

AS 1796 CERTIFICATE 4

• Keith Wilding

AS 1796 CERTIFICATE 10

• Lukas Scott

AS 1796 CERTIFICATE 11

• Andrew Cain

• Antonius Vidot

• Clay Williams

• David Blaby

• James Johnson

• Jason Cable

• Lloyd Thompson

• Mark Rooney

• Mark Silk

• Michael Child

• Richard Lane

• Scott Morriss

• Steven Smith

IIW INTERNATIONAL WELDING INSPECTOR BASIC (IWI-B)

• Richard Crook

IIW INTERNATIONAL WELDING SPECIALIST (IWS)

• Adrian McIntosh

IIW INTERNATIONAL WELDING TECHNOLOGIST (IWT)

• Jake Adie

• Jason Gibson

• Joseph Genrich

• Mathew Lee

• Matthew Wells

IIW INTERNATIONAL WELDING ENGINEER (IWE)

• Craig Stephens

• Hillman Lao

• Noel Straker

• Rhianna Cardamone

INDIVIDUAL CERTIFICATION WITH WELD AUSTRALIA

Weld Australia offers individual certification to deliver ongoing professional development, career opportunities, and greater assurance throughout the welding sector.

Individual certification offers welders a whole range of benefits, from third-party verification of your qualifications and continuous upskilling, right through to a recognised career path. There is also a suite of benefits for companies who hire staff with individual certifications—these people help to bolster profitability and productivity; attract new clients; and enhance workplace culture and development of all staff. Certification is the best way to prove that a welder has the competence, knowledge and skills to complete a specific task.

Weld Connect | March 2024 30

GET IWI-C QUALIFIED WITH WELD AUSTRALIA

Did you know that Weld Australia now offers qualification to IIW International Welding Inspector - Comprehensive (IWI-C)?

IIW IWI-C is the highest level of qualification available for Welding Inspectors. Individuals with this qualification possess in-depth knowledge of welding and inspection theory and application.

This knowledge enables them to tasks like:

• Manage Welding Inspection activities

• Supervise the activities of, and provide instructions to, people who hold IWI-S and IWI-B qualifications

• Act as a technical expert for the Welding Inspection function

• Develop, comment and review Quality Control Plans and Inspection Testing Plans for applications not covered by product standards, codes, specifications, drawings and regulatory requirements

• Manage inspection activities for non-conventional applications with reference to materials, processes, and advanced destructive testing and NDT techniques

For information, contact qnc@weldaustralia.com.au

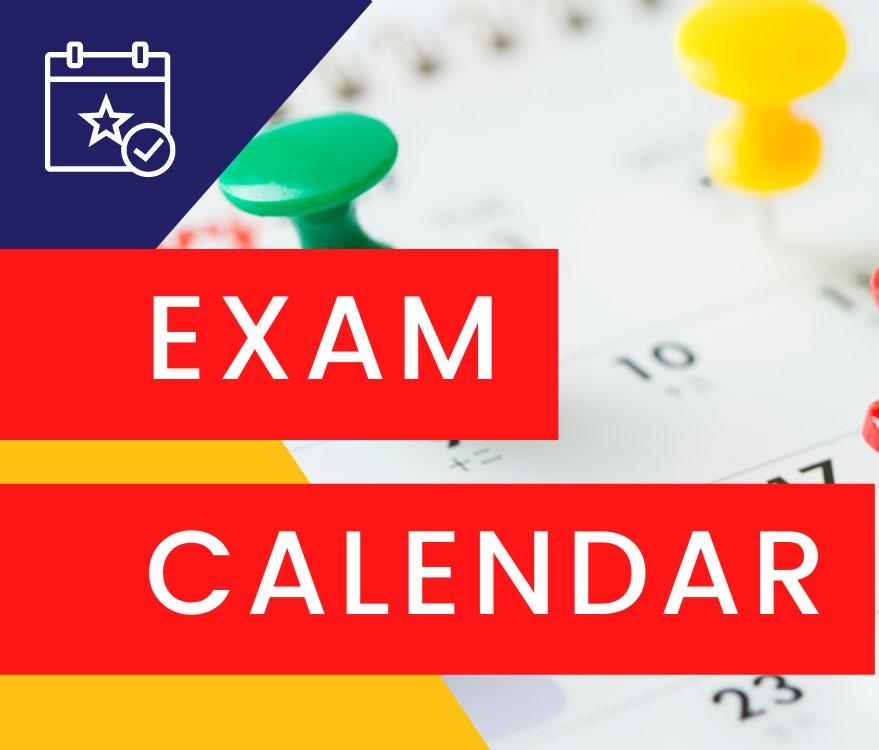

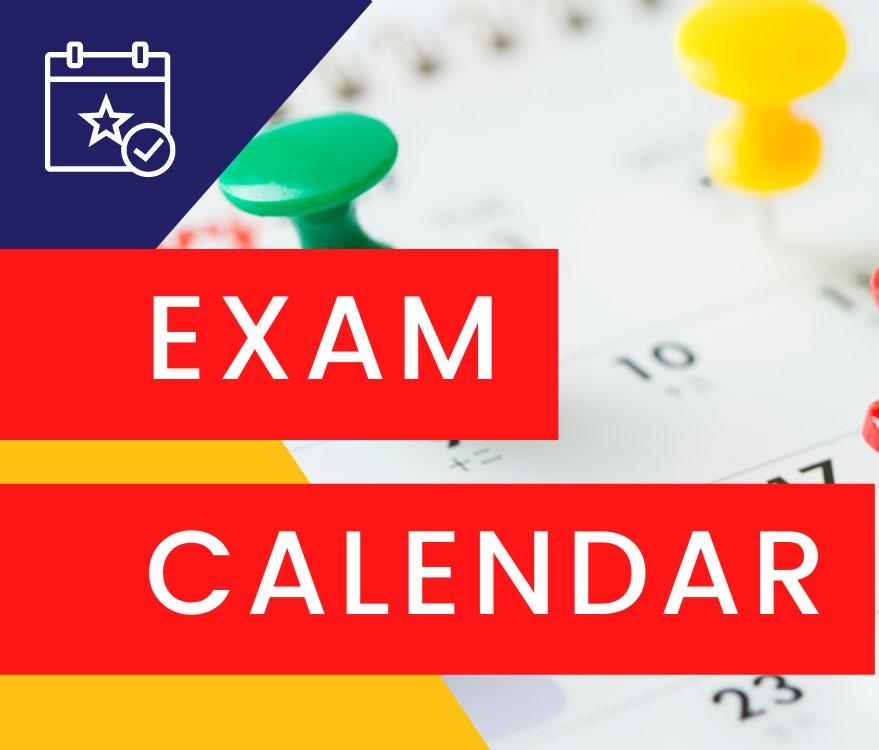

WELD AUSTRALIA’S EXAM CALENDAR

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2024, making planning ahead as simple as possible. Just some of the upcoming exam dates include:

• Friday 15 March: IWI B - Session 13PE-B (Practical Exam)

• Wednesday 20 March: IWI B - Session 13 - WIEB (Online Exam)

• Wednesday 27 March: IWS - SA1 Online Exam

• Tuesday 2 April: WTE-B/WTE-S Online Exam

• Wednesday 10 April: National Welding Supervisor Exam Papers A B1&B2

• Friday 12 April: IWI S - Session 4 - PE-S (Practical Exam)

• Monday 22 April: IWI S: WIE-S Online Exam

• Wednesday 24 April: National Welding Supervisor Exam Paper A - Session 8

• Friday 3 May: IWE/IWT - EA1/TA1 Online Exam

FURTHER INFORMATION

For further information about exams and qualifications, simply email our team via: qnc@weldaustralia.com.au

Weld Connect | March 2024 31

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

TRANSITION WORKERS

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 9606-1 (Steels – carbon steels)

EXPERIENCED WELDERS

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

FURTHER INFORMATION

For further information, contact: training@weldaustralia.com.au

ENROL IN A FUSION WELDING COURSE TODAY

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

ACT

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland

TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania

Tasmanian Minerals and Energy Council tasminerals.com.au

13 Wellington Street, Burnie

Victoria

Box Hill Institute boxhill.edu.au

465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au

23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat

Weld Connect | March 2024 32

For further information, contact Michelle Bignold on m.bignold@weldaustralia.com.au