IN THIS ISSUE

WELD AUSTRALIA’S 2023 MEMBER SURVEY RESULTS REVEALED

SAVE THE DATE: 2023 NATIONAL MANUFACTURING SUMMIT

WELD AUSTRALIA’S 2023 MEMBER SURVEY RESULTS REVEALED

SAVE THE DATE: 2023 NATIONAL MANUFACTURING SUMMIT

WELD AUSTRALIA CONTACTS

NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 02 8748 0100

office@weldaustralia.com.au

weldaustralia.com.au

Geoff Crittenden

Chief Executive Officer 02 8748 0100

g.crittenden@weldaustralia.com.au

ENGINEERING

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

TRAINING

Guy Brooks, Training Manager 0488 743 322

g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, National Manager, Sales & Marketing 0437 106 726

m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104

d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Qualification and Certification Team Manager 0487 487 170

d.yalniz@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901

a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, Engineering Team Manager - East 0491 491 888

r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Mehdi Tajfar, Senior Welding Engineer 0417 044 370

m.tajfar@weldaustralia.com.au

ISO

We’ve had a busy few months at Weld Australia. We recently had Antonio Claveria Jimenez (Director) and Antonio Fernandez (AMEA Business Director) from Seabery’s head office in Spain visit Australia. Seabery supply the Soldamatic augmented reality simulators.

They were treated to a demonstration of the Advanced Manufacturing Schools Outreach Program at Dapto High School. The Program relies upon the use of augmented reality welding simulators to give kids a real welding experience. To date, 82 welding simulators are installed at 40 high schools across New South Wales.

The simulators are used to teach students in Year 9 to develop an understanding of welding across all common processes in a completely safe and controlled environment. The technology is also being utilised by students in years 10-12 to support the delivery of Manufacturing and Engineering and Industrial Technology (Metal), as part of MEM20413 Certificate II in Engineering Pathways.

The Program is encouraging kids in secondary schools across New South Wales to explore a meaningful career in the trades. It is helping kids realise that a career as a tradesperson is full of potential and helping to reverse the mindset that the only path for kids post-high school is university.

The enthusiasm of both the students and the teachers at Dapto High School for the Program, and the practical, hands-on style of learning it provides was clear. I’d like to thank Andrew FitzSimons, Principal of Dapto High School, and his entire team for hosting us.

A range of media coverage was secured as a result of the demonstration, including;

• Channel Nine News (play video below)

• ABC Radio Interview

• High tech trades class, published by the Illawarra Mercury

• NSW Schools Outreach Program Encourages Trade Careers, published by Manufacturers Monthly

We also hosted an Industry Drinks Night at Cruise Bar in Circular Quay

West. Sponsored by TAFE NSW, the event proved extremely popular, with over 100 people in attendance. I’d like to thank everyone who joined us for this hugely successful and popular event.

Stephen Brady (Managing Director, TAFE NSW) provided an update on the work that TAFE NSW is undertaking in the area of welding and fabrication. He touched on the skills shortages throughout the industry and indicated that TAFE NSW is looking at ways to fast-track welder training, so that apprentices can join the local workforce more rapidly.

Attendees then heard from inspirational keynote speaker, Ben Pettingill. A focus for Weld Australia’s advocacy work in 2023 is encouraging industry to access a diverse range of people to address skills shortages—including people living with disability. Special guest speaker Ben Pettingill helped us launch this initiative.

At just 16 years of age, Ben lost 98% of his eyesight overnight to a rare genetic syndrome, Lebers Hereditary Optic Neuropathy. Initially, Ben

believed that he was just living a nightmare and that he would wake up one morning and be able to see again. He soon came to realise that this was not the case. His syndrome is incurable and he will be blind for life.

While the shock, then grief of losing one’s eyesight cannot be discounted, once Ben processed his new reality he realised that he had to make a choice that would define the rest of his life. He went on to become a construction worker. He spoke to the crowd about how there are 500,000 people with a disability looking for work, and covered practical ways to attract people with a disability.

I have had the chance to visit a variety of Weld Australia members over the last couple of months. Whilst in Tasmania, I visited Incat and TasTAFE, where skills shortages and welder training were high on the agenda.

I met with representatives from the Tasmanian Minerals, Manufacturing and Energy Council (TMEC) and attended their the Industry Engagement Tour, which took in Huon Aquaculture—a local salmon processing plant. In Launceston, I visited Crisp Bros. & Haywards where we discussed the challenges and opportunities available in wind tower manufacturing.

I spent a day at Civmec’s Newcastle facilities. Serviced by 24 cranes, their 15,000m2 fabrication hall has a single-lift capacity of 92 tonnes and can produce up to 35,000 tonnes of steel per annum.

Finally, we recently held a very successful meeting of the Power Generation Group. The meeting was attended by over 30 people representing power generating

companies, consultants and industry suppliers. Much of the discussion was dedicated to issues around the renewable energy transition.

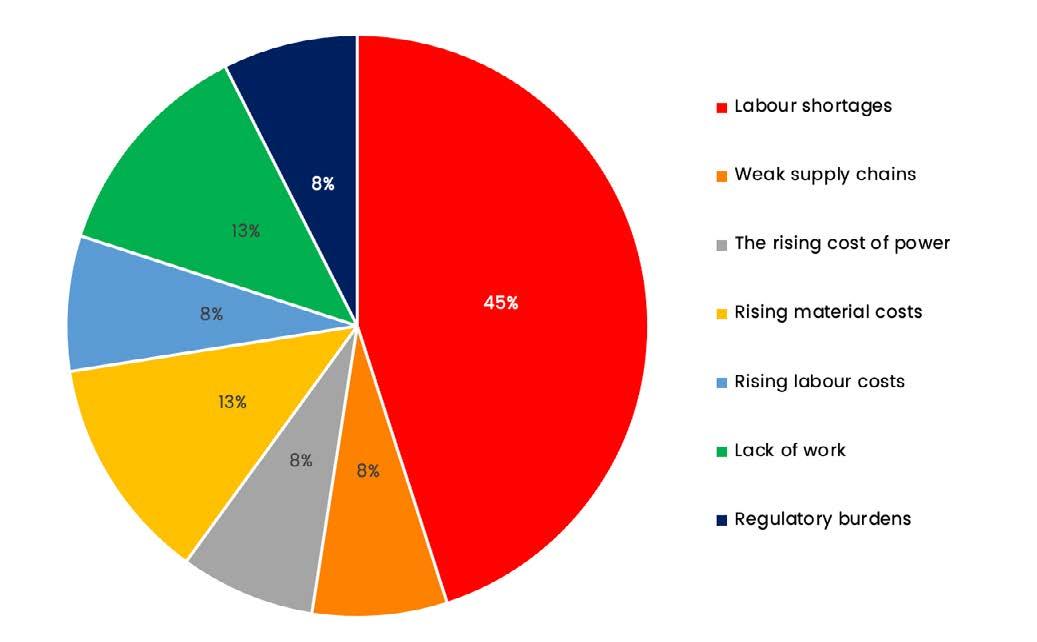

Distributed in March 2023 and completed by over 130 companies, our 2023 Member Survey indicates that labour shortages, and the rising cost of materials, energy and labour remain high on the agenda for the welding industry. Without funding and support from governments at all levels, these challenges will make it nearly impossible for industry to deliver the necessary manufacturing capability required for the Federal Government’s ambitious renewable energy revolution. When asked to select their top two factors, 60% of survey respondents indicated that labour shortages are most likely to inhibit the growth of their business in 2023. When asked what their main concern is right now, 45% confirmed that labour shortages was on the top of their list. 50% of Australia’s welding workshops are operating at 80% of their capacity or below. When asked why this is, a lack of skilled workers was the overwhelming answer. For further details on 2023 Member Survey results:

• See the article on page 13

• Read the media release

• Download a copy of the full Report

Hosted by Weld Australia and The Australia Institute’s Centre for Future Work, the 2023 National Manufacturing Summit will see a diverse group of industry stakeholders assemble at Old Parliament House in Canberra on Wednesday 2 and Thursday 3 August 2023.

The Summit gathers leading representatives from all the

major stakeholders in Australia’s manufacturing sector— business, unions, universities, the financial sector, suppliers, and government—to discuss the sector’s prospects, and identify promising, pragmatic policy measures designed to support an industrial turnaround. With the theme of Manufacturing the Energy Revolution: Industrial Opportunities from Renewable Energy, the aim of the Summit is to leverage the opportunities currently available in the manufacturing sector, and translate these into action.

We have already confirmed international expert Adam Hersh, who will deliver the keynote address at the Summit dinner and participate as a panellist during one of the Summit sessions.

Adam Hersh is Senior Economist at the Economic Policy Institute in Washington, DC—one of Washington’s most influential think tanks. Adam’s work focuses on international trade, industrial, climate, China, and macroeconomic policies. He is currently leading a research project on the industrial opportunities associated with new green energy policies, including the Inflation Reduction Act and the CHIPS and Science Act.

Adam publishes and is cited frequently in both peer reviewed and popular media outlets, regularly provides expert Congressional testimony and advises U.S. and international policymakers and civil society leaders. He is a contributing author of Rewriting the Rules of the American Economy (2015) with Nobel Prize-winner Joseph Stiglitz.

Prior to joining EPI, Adam co-directed the Global Initiative for a Shared Future, working to center environment, social, and governance (ESG) principles in the US-China bilateral investment relationship. He was also Chief Economist for Congressional Joint Economic Committee Democrats, Senior Economist at the Franklin and Eleanor Roosevelt Institute and the Center for American Progress, and worked at the Asian Development Bank.

For information, visit: manufacturingsummit.com.au

ENTRIES NOW OPEN FOR THE 2023 WELDING EXCELLENCE AWARDS

Weld Australia’s Excellence Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2023 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Entries must be submitted online for each category by midnight on 15 September 2023.

Winners will be awarded in each state for the following categories:

• Company of the Year – Fabrication

• Company of the Year – Gas & Gear

• Indigenous Company of the Year

• Project of the Year

• Welding Professional of the Year – Welding Coordinator

• Welding Professional of the Year – Welding Supervisor

• Welding Professional of the Year – Welding Inspector

• Young Trades Person of the Year

• Young Indigenous Trades Person of the Year

• Training and Education Award – Organisation

• Training and Education Award – Individual Teacher

• Ken Trevena Award – South Australia Only

Weld Australia’s work on the establishment of Advanced Welder Training Centres (AWTCs) continues at pace. Using the state-of-the-art Soldamatic augmented reality welding simulators, the training delivered at the AWTCs quickly qualifies welders to the only industry Standard in the world that is accepted in both Europe and America: ISO 9606-1 Qualification testing of welders – Fusion welding. This Standard is the minimum requirement for working on rolling stock, defence and infrastructure projects, which are crucial to onshore Australian manufacturing and a stronger national economy.

Recently, several organisations have adopted the use of Soldamatics. Weld Australia has installed, commissioned and rolled out ‘train the trainer’ courses for Chisholm Institute in Melbourne, ATNZ (Apprentice Training New Zealand) in Auckland, and Melbourne Polytechnic.

Crittenden CEO, Weld Australia GeoffWeld Australia would like to welcome three new team members: Danielle Pennington has come on board as our Corporate Engagement Manager; Mariana Sousa as our Audit Certification Coordinator; and Tracey Carmody as our Office Manager.

Danielle Pennington, Corporate Engagement Manager

With over 20 years experience, Danielle has worked across both the commercial and not-for-profit environments, and brings proven time-management, leadership and communication skills to her new role at Weld Australia.

Prior to joining the team, Danielle was the Training Officer at ACA Health Benefits, responsible for improving all staff’s knowledge of private health insurance regulations. Working closely with the customer service, marking and operations teams, Danielle assisted with sales activities, databases and member communication materials such as newsletters, website content and apps.

Danielle spent seven years working in the immigration sector, taking on various roles at Fragomen and PriceWaterhouseCoopers. She assisted small and multinational corporations with both temporary and permanent Australian visa advice and solutions. She spent time at the Hunter New England Health Service, developing a major training programs for their 15,500 staff.

Danielle holds a Masters in Professional Education and Training, and a Bachelor of Arts and Business.

Mariana Sousa, Audit Certification Coordinator

Mariana Sousa is a highly accomplished professional with a diverse background that spans multiple industries. She began her career as a dietitian in São Paulo, Brazil. Her passion for helping others achieve their health and wellness goals saw her complete a Postgraduate Degree in Public Health.

In 2021, Mariana immigrated to Sydney, taking on the role of Educator at a early learning centre. Here she planned and delivered age-appropriate educational programs, created a safe and nurturing learning environment, and built positive relationships with children and their families.

Prior to joining Weld Australia, Mariana was a National Customer Service Representative at Hilti Australia. In this

role, she assisted customers with their inquiries, resolved complaints and issues, processed orders, and maintained accurate records. Mariana holds a Master of Business Administration (MBA), a Postgraduate Degree in Public Health, and a Bachelor of Dietetics and Clinical Nutrition Services.

With 30 years expertise, Tracey is a highly experienced administration coordinator who has worked across recruitment, human resources and office management in industries as diverse as real estate, information technology, telecommunications, and engineering.

Prior to joining Weld Australia in 2023 as Office Manager, Tracey was the Programs Coordinator at the Starlight Children’s Foundation, delivering administration support to the entire organisation. She also acted as the Administrative Office for CTC Property Solutions in Sydney, responsible for coordinating contracts, liaising with clients, coordinating events and recruitment of contractors. Tracey also owned and operated a swimming school in Orange for several years, managing all the day-to-day operations of a small business.

Tracey brings strong organisational, time management, communication and customer service skills to her new role at Weld Australia. Tracey holds a Bachelor of Social Science (Human Resource Management), an Associate Diploma in Human Resource Practice, and an Advanced Certificate in Management.

Renewable energy revolution needs ‘army’ of welders, published by The West Australian

Renewable energy plans “will simply not be a reality” without industry and skills support: Weld Australia, published by Australian Manufacturing Forum

Labour shortages to make Australia’s renewable energy revolution impossible, survey suggests, published by Australian Manufacturing

A renewable tech bottleneck: Half of Australia’s welding workshops operating at 80 per cent capacity or below, published by The Market Herald

Labour shortages can make net zero transition challenging, published by Manufacturers Monthly

The Victorian government has entered a $2 million partnership with Chislom Institute aimed at helping disadvantaged jobseekers to get into careers in engineering and manufacturing in southeast Melbourne.

Announcing the Jobs Victoria Engineering Project, Minister for Employment Ben Carroll said the partnership will seek to fill 100 engineering roles in manufacturing by April 2023. The project is open to people facing barriers to employment, including women aged 45 and over, individuals from culturally and linguistically diverse backgrounds, and people with disability.

Positions will be opened across southeast Melbourne, including 70 production welder and machine operator roles and 30 fabrication and mechanical apprenticeships. Roles offered in the Jobs Victoria Engineering Project do not require any prior experience and participants are slated to receive 12 months’ secure employment and access to additional support to set them up for long-term careers in a fast-growing sector. Jobseekers interested in joining the program may complete a Certificate II or III in Engineering Studies.

“Victoria is the heart of Australian manufacturing and a major source of jobs – we’re providing opportunities for people who have faced obstacles and making sure businesses can get the workers they need,” said Minister Carroll. “Partnering with institutions such as Chisholm to deliver these programs with Free TAFE is ensuring we’re providing people with the training and skills they need to work in some of our priority sectors.”

Source: https://www.australianmanufacturing.com.au/victorian-govtprogram-to-offer-100-manufacturing-roles-in-southeast-melbourne/

Eighty six young people are preparing to start their careers with BAE Systems Australia this week after the Company recruited a record number of graduates.

The recruitment effort reinforces the Company’s commitment to invest in the next generation, with graduates securing roles working on some of the most important defence programs being delivered across Australia.

Most have been employed in Victoria (28) and South Australia (50) supporting the Hunter Class Frigate Program, the Jindalee Operational Radar Network upgrade and the development of new technologies for the Australian Defence Force.

The remainder will be working across a range of maritime and aerospace sustainment programs and corporate roles in the ACT, NSW, QLD and WA. Thirty-two percent of the new graduates are female, reflecting BAE Systems commitment to improving diversity in STEM roles.

A further 30 apprentices will join the national defence engineering and technology business later in the year.

Half of this cohort will begin their careers in advanced manufacturing and aircraft sustainment roles. The other fifteen will join the Hunter Class Frigate Program, almost doubling the number of apprentices supporting the delivery of future ships.

The Federal Government has offered $3.7 billion for a five-year National Skills Agreement (NSA) to be negotiated with states and territories, in addition to $400 million to support another 300,000 TAFE and VET Fee-Free places.

Subject to successful negotiation of the NSA, this will take total Commonwealth investment in state and territory training systems to $12.8 billion over five years.

Subject to successful negotiations, funds will be available in line with the vision and guiding principles agreed at National Cabinet prior to the Jobs and Skills Summit, to support major reform areas including:

Acoordinated effort to ensure that Australian adults lacking language, literacy, numeracy and digital skills can gain these essential skills.

300,000 Fee-Fee TAFE courses in essential sectors such as clean economy, manufacturing and sovereign capability (including defence industries), construction, cybersecurity and technology.

Working closely with First Nations people, their communities and training providers to support skill development and career opportunities.

Women’s participation and gender equality: coordinated effort to support women to successfully enrol and complete VET courses and apprenticeships, with an emphasis on better paid occupations traditionally dominated by men.

Coordinated national effort to lift completion rates and improve outcomes for VET students and apprentices who face barriers.

TAFE Centres of Excellence to partner with industry, universities, and governments to address critical challenges in our economy such as transition to a clean economy, manufacturing and sovereign capability and care and support.

To be developed in partnership with the sector, a VET Workforce Blueprint will strengthen the sector and support a high-quality VET workforce, which teaches up to date industry relevant curriculum.

All governments have committed to working in partnership to negotiate the NSA to be in place by 1 January 2024.

BOC’s team of technical experts were on-site in Newcastle recently to host personalised welding application review sessions with local customers. In these practical sessions, welding processes were looked in detail to determine the best approach for optimal productivity based on the customer’s own unique situations.

These sessions were a great opportunity for customers to access the decades of welding expertise within the BOC technical team.

BOC recently welcomed Senator the Hon Jenny McAllister, Assistant Minister for Climate Change and Energy, to our Bulwer Island production site in Brisbane for a tour of our green hydrogen facilities. BOC’s Director Clean Energy & Strategy Vesna Olles and our local operations team showed the Assistant Minister our 220 KW electrolyser, which is producing the first green hydrogen in Queensland as part of our Bulwer Island Renewable Hydrogen Production and Refuelling Project.

It was also a great opportunity to discuss BOC’s plans to progress green hydrogen infrastructure in Australia. To learn more about BOC’s work in the clean energy space visit: https://bit.ly/3mXQbY9

Did you know that Weld Australia makes a range of resources available to the welding industry? Some are free for anyone to download, while others are discounted or free for certain member types.

Just some of the free resources on offer include Technical Guidance Notes on topics like:

• Minimisation of Fatigue in Welds

• A Guide to AS/NZS ISO 9606-1

• Australian Welding Standards Map (see image below)

Questions? Queries? Wondering how Weld Australia can help support your business, staff or career progression?

Feel free to reach out to our Membership Manager, David Choudry, on 0417 878 104.

Weld Australia would like to welcome all our new Members who have joined recently:

CORPORATE MEMBERS

• VET Development Centre: vdc.edu.au

• Cop-A-Mate Products: copamate.com

INDIVIDUAL MEMBERS

• Ben Schaber

• Mark Blacklock

• Adrian Kroonstuiver

• Cliff Martin Concepcion

• Nicholas Nakone

• Nathan McElroy

• Kevin Bates

• Vincent Cura

• Alex Marjoribanks

Weld Australia’s Excellence Awards are the most prestigious event on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2023 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Winners will be awarded in each state for each of the award categories below.

Entries must be submitted via the specific online form for each category by midnight on 15 September 2023. These forms can be found on the Weld Australia website, by clicking on the relevant red button. Before starting your entry, it is recommended that you download the Award Criteria via:

• Company of the Year – Fabrication

• Company of the Year – Gas & Gear

• Indigenous Company of the Year

• Project of the Year

• Welding Professional of the Year – Welding Coordinator

• Welding Professional of the Year – Welding Supervisor

• Welding Professional of the Year – Welding Inspector

• Young Trades Person of the Year

• Young Indigenous Trades Person of the Year

• Training and Education Award – Organisation

• Training and Education Award – Individual Teacher

• Ken Trevena Award – South Australia Only

ENTER THE AWARDS NOW

The awards will be presented at events held across the country in October and November:

• Perth: Wednesday 18 October at Beaumont on the Point

• Sydney: Wednesday 25 October at Waterview in Bicentennial Park

• Adelaide: Wednesday 1 November at Glenelg Golf Club

• Brisbane: Wednesday15 November at Indooroopilly Golf Club

• Melbourne: Wednesday 29 November at Huntingdale Golf Club

Registrations for the events are now open, and can be booked by clicking on the links above. The 2022 award events sold out in record time, so be sure to register early to avoid disappointment.

Weld Australia has released the results of its 2023 Member Survey. The results demonstrate that Australia’s welding and fabrication industry is facing a whole raft of challenges that will make the delivery of the Federal Government’s plans for a renewable energy revolution almost impossible—from severe labour shortages that are inhibiting the growth of the welding industry, through to rising material and labour costs. The Federal Government must step in and provide real support to industry to make the renewable energy revolution a reality.

According to Geoff Crittenden (CEO, Weld Australia), “Distributed in March 2023 and completed by over 130 companies, our 2023 Member Survey indicates that labour shortages, and the rising cost of materials, energy and labour remain high on the agenda for the welding industry. Without funding and support from governments at all levels, these challenges will make it nearly impossible for industry to deliver the necessary manufacturing capability required for the Federal Government’s ambitious renewable energy revolution.”

When asked to select their top two factors, 60% of survey respondents indicated that labour shortages are most likely to inhibit the growth of their business in 2023. When asked what their main concern is right now, 45% confirmed that labour shortages was on the top of their list. 50% of Australia’s welding workshops are operating at 80% of their capacity or below. When asked why this is, a lack of skilled workers was the overwhelming answer.

“With a considerable volume of work being onshored and a greater sentiment in the market to ‘buy local’, Australian fabrication companies are so strapped for skilled welders that they are operating well below capacity. They are being forced to turn down jobs because they simply don’t have the manpower to complete the work,” said Crittenden.

“How then, will Australian fabricators cope with the influx of work required to make the Federal Government’s renewable energy revolution reality?”

The Federal Government has legislated emissions reductions targets of 43% (on 2005 levels) by 2030 and net zero by 2050. These targets will necessitate the construction of new infrastructure on a massive scale. Australia’s existing renewable energy generation of 64GW is forecast to grow to over 218GW by 2050. This will comprise 90GW of wind, 39GW of solar, 18.7GW of water, and 35.9GW of battery storage.

It is expected that over 11,000 wind towers will need to be produced, each requiring 500 tonnes of plate steel for onshore towers, or 750 tonnes for offshore wind towers.

To connect all this new generation to consumers, AEMO estimates more than 10,000km of new transmission lines and 25,000 transmission towers (at 30 to 60 tonnes of steel per tower) will need to be constructed.

“All this the renewable energy infrastructure will require a veritable army of skilled workers, including welders,” said Crittenden. “Australia will have a shortfall of at least 70,000 welders by 2030.”

And yet, 45% of survey respondents (compared to 47% in 2022) already have a pipeline of work that extends for six months or longer—this protracted pipeline is necessary in the face of ongoing skills shortages. Another 33% of respondents have a pipeline of work that extends between three and six months. This is a marked increase on Weld Australia’s 2020 member survey results; the most common answers were less than one month (at 28%), one month (19%), and two months (16%).

“While our governments can wish, and hope, and make public pledges about Australia’s transition to renewable energy, at the moment, we simply do not have the sovereign manufacturing capability to make this a reality,” said Crittenden. “According to the results of our survey, at 62%, the majority of the Australian welding industry supports the Government’s carbon emissions reduction targets,” said Crittenden. “However, 75% of the welding and fabrication industry believes that Australia’s governments are not doing anywhere near enough to support industry in achieving these targets. Our governments will need to consider policy and funding opportunities, reduce red tape and regulatory barriers, and support local investment to enable the renewable energy transition.”

“Without a massive investment in fabrication and steelmaking facilities, skills and training in each state, and real, practical support for local industry, Australia’s renewable energy revolution will simply not be a reality,” said Crittenden.

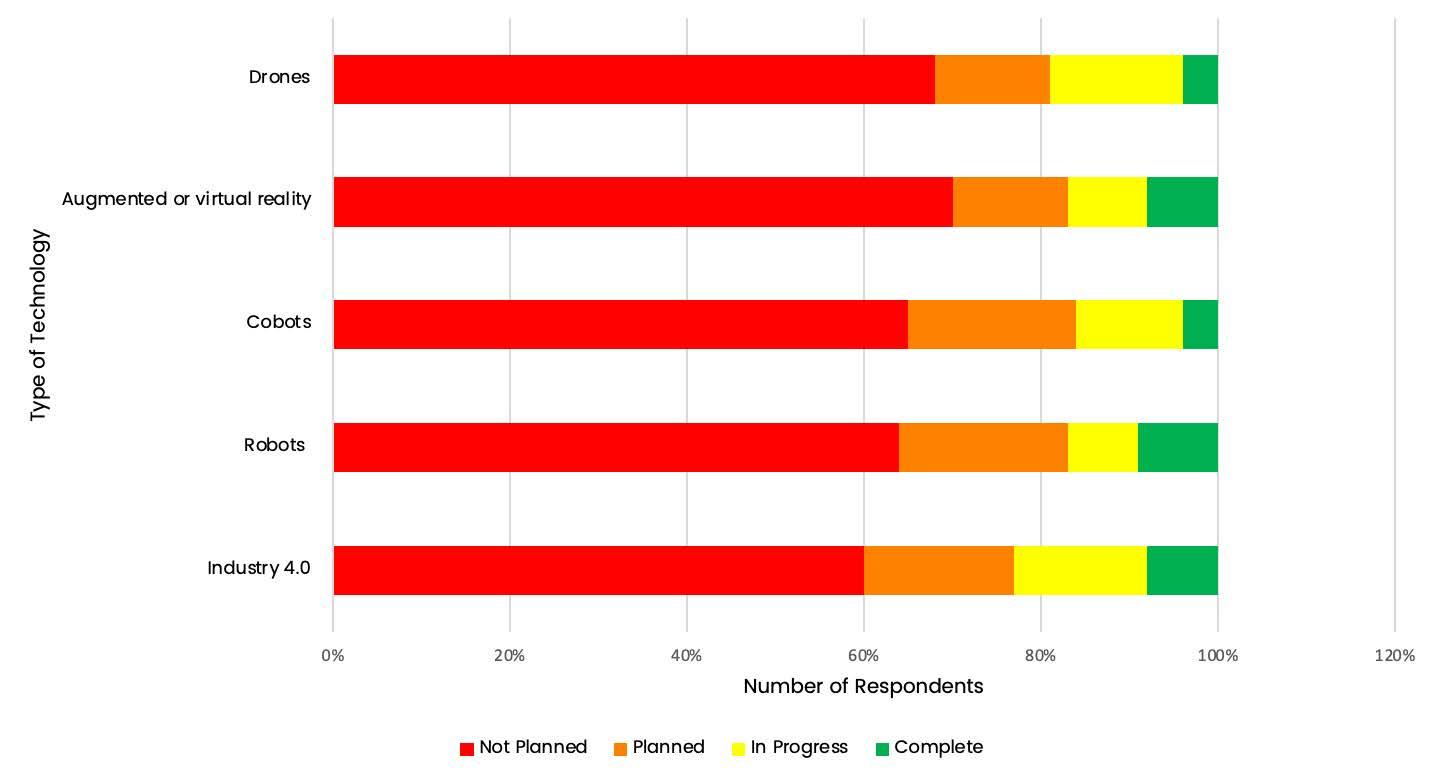

In the meantime, the welding industry is taking steps to try to overcome these labour shortages—without government support. 60% of respondents indicated that they are training or upskilling their existing staff, another 55% are either increasing wages or improving employee benefits, and 32% are leveraging different talent pools, such as apprentices, females and prisoners. Another 57% are either investing in automation and technology, or changing their operational processes. The welding industry strongly supports investment into TAFE to help combat labour shortages; 21% support free TAFE for apprentices, 14% support increased funding to upgrade TAFE facilities, and 64% support both options.

The welding industry is also investing in its own sustainability performance and credentials, and has made significant headway in the last 12 months. Some of these measures include: installing LED or sensor lighting (80%; up from 53% in 2022); waste reduction programs (78%; up from 46% in 2022); recycling, upcycing and repurposing programs (75%; up from 46% in 2022); and implementing a net zero carbon plan (50%; up from 13% in 2022).

Australia’s welding industry is also concerned about rising labour costs and rising material costs, with 50% and 45% (respectively) of respondents indicating that they could inhibit their business growth this year. Only 47% of respondents indicated that their gross profit margin had increased over the last 12 months to help cover these rising overheads. Alarmingly, the welding industry expects these overheads to continue to rise this year, with 82% expecting even higher materials prices and 85% expecting even higher energy prices.

MANUFACTURING THE ENERGY REVOLUTION: INDUSTRIAL OPPORTUNITIES FROM RENEWABLE ENERGY

Hosted by Weld Australia and The Australia Institute’s Centre for Future Work, the 2023 National Manufacturing Summit will see a diverse group of industry stakeholders assemble at Old Parliament House in Canberra on Wednesday 2 and Thursday 3 August 2023.

The Summit gathers leading representatives from all the major stakeholders in Australia’s manufacturing sector—business, unions, universities, the financial sector, suppliers, and government—to discuss the sector’s prospects, and identify promising, pragmatic policy measures to support industrial opportunities.

Hosted by Weld Australia and The Australia Institute’s Centre for Future Work, the 2023 National Manufacturing Summit will see a diverse group of industry stakeholders assemble at Old Parliament House in Canberra on Wednesday 2 and Thursday 3 August 2023.

With the theme of Manufacturing the Energy Revolution: Industrial Opportunities from Renewable Energy, the aim of the Summit is to leverage the opportunities currently available in the manufacturing sector, and translate these into action.

The Summit gathers leading representatives from all the major stakeholders in Australia’s manufacturing sector— business, unions, universities, the financial sector, suppliers, and government—to discuss the sector’s prospects, and identify promising, pragmatic policy measures designed to support an industrial turnaround.

With the theme of Renewable Energy: Challenges and Opportunities, the aim of the Summit is to leverage the opportunities currently available in the manufacturing sector, and translate these into action.

International expert Adam Hersh will deliver the keynote address at the Summit dinner, and act as a panellist. Adam Hersh is Senior Economist at the Economic Policy Institute in Washington, DC, one of Washington’s most influential think tanks. Adam’s work focuses on international trade, industrial, climate, China, and macroeconomic policies. He is currently leading a research project on the industrial opportunities associated with new green energy policies, including the Inflation Reduction Act and the CHIPS and Science Act.

Melbourne: 12 & 13 October | Perth: 17 & 18 October | Brisbane: Expressions of Interest

Need help with the engineering and design of welded structures? Need to brush up on residual stresses and distortions?

Facilitated by USA expert Pingsha Dong, this two day course will cover the fundamentals that every engineer should know when designing welds. From weld in-situ strength, residual stresses, and geometric discontinuities, every aspect plays a different role in contributing to resultant joint strength, and fatigue resistances under different loading conditions. With plenty of opportunities for questions, this course can help attendees mitigate the detrimental effects of welding defects, reducing inefficiencies and costs, and improving project schedules and productivity.

Who Should Attend?

Designers, structural engineers, consultant engineers, mechanical engineers, welding and production engineers, maintenance and quality control engineers, as well as researchers. Attendees are encourages to bring along their design problems to contribute to discussions and local case studies.

What Industries is the Course Relevant to?

The course will be especially relevant to all professionals in automotive, aerospace, steel construction, steel bridge design, power generation, naval and shipbuilding, offshore construction, pipeline and other industries that apply welding.

The course will address fundamental aspects that engineers should know when designing welded joints. Modules include:

• Unique issues associated with welded joints and design implications

• Basic considerations in design of welded joints and analysis methods

• Joint design for static and fatigue performance

• Residual stress and distortion control in construction

The course will delve into how residual stresses and distortions are developed during fusion and solid-state welding, and related manufacturing processes, including metal 3D printing and additive manufacturing. Simple analytical models will be used to describe the underlying mechanisms, and computational modeling results will then be used to demonstrate the relevance of these analytical results for deriving effective solutions to various residual stress and distortion problems. The principles for residual stress and distortion mitigation techniques will be discussed.

Registration at 8:30am on day one for a 9:00am start. Ends 3:00pm daily. Morning tea and lunch provided.

Melbourne: 12 and 13 October 2023 | Venue: TBC

Perth: 17 and 18 October | Venue: TBC

Brisbane

We are accepting Expressions of Interest for a course in Brisbane. Please email events@weldaustralia.com.au.

Membership rates apply to all Weld Australia, Engineers Australia and Australian Steel Institute members.

Early Bird Special ends on 1 July 2023:

Members $3,410

Non members $3,718

Price after 1 July 2023:

Members $3,610

Non Member $3,918

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications. This three day course in Adelaide will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

This course is intended for people who are involved in writing and qualifying welding and brazing procedure specifications, qualifying welders, brazers and operators, reviewing suppliers procedures, auditing or reviewing in-house procedures and qualifications and estimating jobs which impose the requirements of Section IX.

Welding Engineers, quality assurance personnel, auditors, testing laboratory personnel, maintenance personnel and jurisdictional inspection personnel will find this course interesting, exciting and beneficial.

A review of the welding processes and variables, and basic steel welding metallurgy will be conducted to provide all participants with sufficient background in welding technology to interpret and understand Section IX. The mechanics of using Section IX and how to address its requirements will be explained in a simple, straightforward manner.

Emphasis will be placed on writing welding procedures so that they contribute positively to the manufacturing process and on qualifying procedures in a cost-effective manner.

The requirements for welders and operators will be examined with particular emphasis on minimising the cost and maximising the usefulness of qualifications.

Time will be provided to address individual participant’s problems and concerns. Attendees will receive copies of the course notes covering the course’s content. Attendees must bring a copy of the current edition of Section IX. Multiple choice tests will be given for each section.

Course Details

Date: 1 to 3 November 2023

Venue: Stamford Grand Adelaide – Glenelg

Address: 2 Jetty Road, Glenelg, SA 5045

Room: Moseley Room

Time:

• Registration first day: 8:00am

• Course time: 8:30am to 4:00pm

Cost

Weld Australia Members: $3,610 inc GST

Non Weld Australia Members: $3,810 inc GST

For further information, contact: Michelle Bignold (National Manager, Sales and Marketing) on 0437 106 726 or m.bignold@weldaustralia.com.au

Maximum capacity is 30 people. Get in quick to avoid disappointment! Click on the button below, or register online via: https://weldaustralia.com.au/ asme-section-ix-three-day-course/

Weld Australia is creating an Advanced Manufacturing Industry Network. The industry network will launch with an online webinar taking place on 16 May 2023 from 10:00am to 12:00 noon (AEST).

The webinar will focus on the additive manufacturing (AM) of metals and components with prominent technology providers doing talks on the current state of the technology on the market. There will also be a strong focus on the quality assurance of additive manufacturing with a member of ISO Technical Committee 261 – Additive Manufacturing, doing a talk on the standardisation with regards to the qualification of AM processes, personnel, and 3D printed parts.

The detailed agenda is as follows:

• 10:00 – 10:10: Welcome and word from chair Dr Cornelis Van Niekerk

• 10:00 – 10:20: Introduction from Weld Australia CEO, Geoff Crittenden

• 10:20 – 10:30: Technology Provider Presentation –Australian AM industry (TBC)

• 10:30 – 10:50: Technology Provider Presentation –Australian AM industry (TBC)

• 10:50 – 11:05: Facility of Intelligent Fabrication (FIF) on wire-arc AM by Professor Stephen Pan

• 11:05 – 11:20: Quality Assurance: Ongoing work from ISO TC 261 and Standards Australia on AM by Professor Huijun Li

• 11:20 – 11:35: Xiris on the technology available for in-situ quality management of AM, by David Gerrard

• 11:35 – 12:00: Questions, open discussion on the state of the industry, and actions for next meeting

The network is aimed at the manufacturing industry at large, specifically focused on the needs of Weld Australia’s members. Our industry networks aim to facilitate:

• Industry growth and technology adoption.

• Ensuring the manufacturing industry is at the forefront of technological advancement and integration.

• Advocacy to the appropriate levels of government on issues raised during our regular industry meetings (both online and in-person).

• Networking in order to facilitate technology awareness, technology transfer, and sharing of knowledge and experience.

• Improving safety across the industry.

• Auditing and certification services to major Australian and International standards.

• Training services to all levels of welding professionals.

• Expert consultation services.

If you are interested in attending the webinar and joining the Advanced Manufacturing Industry Network contact: Cornelis Van Niekerk (Business Manager Defence Welding) on c.vanniekerk@weldaustralia.com.au or Andrew Davies (Manager Technical Industry Networks) on a.davies@weldaustralia.com.au

The Weld Australia team recently delivered practical training in for the International Welding Inspector Standard (IWI-S) qualification. The practical training was undertaken over the course of two days, with the first day including a review of documentation and the second day spent on welding samples.

These practical training sessions were conducted in Wollongong (with students from Victoria, South Australia and New South Wales in attendance), as well as in Brisbane (with students from right across Queensland). All the students that attended the two days of practical training undertook the rest of the course online. Weld Australian then tailored the practical sessions based on student availability and location.

The IWI-S course provides advanced knowledge of welding and inspection theory and application, including NDT, mechanical and visual inspection techniques, inspection procedures and acceptance criteria, identification of weld imperfections associated with preproduction, fabrication and post fabrication, and more.

An IWI-S qualification is recommended in both AS/NZS ISO 3834 and AS/NZS 1554.1. Welding Inspectors play an important role in performing, supervising and overseeing welding inspection activities in line with the relevant Standards, codes and specifications. For information, visit the Weld Australia website

This month has seen Adam Coorey (Regional Training Coordinator, Weld Australia) run practical, hands-on training sessions for East Coast Apprenticeships

Established over 30 years ago, East Coast Apprenticeships is Group Training Organisation with a footprint right across Queensland. The company operates across a range of industries, including welding. Some of their apprentices are currently learning about the metal and fabrication trades with TAFE Queensland at their Bundaberg and Hervey Bay campuses.

Adam providing welder training and theory to the apprentices using the Soldamatic augmented reality simulators. The training also covered ISO 9606 Qualification testing of welders, a range of welding theory, welding procedures and workplace health and safety. All the apprentices were extremely enthusiastic and had a great time trying their hand at the Soldamatics.

The welder training sessions at TAFE Queensland Hervey Bay were covered by WIN News. To see the story, click here, or press play below.

Joe Sandor (Principal Welding Technology Trainer, Weld Australia) and Bailey Greathead (Welding Technology Trainer, Weld Australia) facilitated a week-long practical training session for students currently undertaking the International Welding Engineer (IWE) and International Welding Technologist (IWT) qualifications. The practical sessions were delivered at TAFE NSW’s Wollongong campus across five days.

An IWE and IWT qualification covers a range of topics, including: Welding processes and equipment; Materials and their behaviour during welding; Construction and design; and Fabrication and applications in engineering.

This course features a blended learning program including pre-recorded material, live online lectures, and other learning resources, supported by innovative, hands-on practical exercises.

An IWE or IWT qualification can expand your career horizons enormously. Companies seeking certification to AS/NZS ISO 3834 need Welding Engineers to fill the role of Responsible Welding Coordinator. Oil and gas companies need Welding Engineers to adhere to the revised version of AS/NZS 2885.2. Welding Engineers and Technologists can work in fields as diverse as structural steelwork, bridges, pressure vessels, pipelines, storage tanks, offshore structures, ship building and repair, and power generation. For information about the course, visit the Weld Australia website.

Weld Australia recently completed successful certification audits at DVR Engineering in line with AS/NZS ISO 3834.2 Quality requirements for fusion welding of metallic materials and DIN 2303 Welding and allied processes - Quality requirements to be met by production and maintenance companies for military products.

DVR Engineering provides manufacturing solutions for a range of clients across the defence, telecommunications, rail, aerospace, mining and marine sectors. The company operates 30,000m2 over two manufacturing facilities, with more than 95 staff operating advanced manufacturing equipment for end-to-end solutions. DVR Engineering’s point of difference is based on: a competitive price, excellent products delivered under time sensitive deadlines, and strong partnerships with clients. These unique advantages have enabled DVR Engineering to win both major clients and major projects.

To meet the demands of their clients, DVR has a wide range of machinery, equipment and fabrication facilities. DVR Engineering utilises UniGraphics NX and PEPS CAD/CAM systems for design, drafting, and engineering analysis of products, importing models from external CAD systems, CNC programming, and manufacturing designed products using machining modules.The company’s manufacturing capabilities include CNC machining, CNC laser cutting, turret punching, roll forming, brake press forming, welding and fabrication, polishing, grit blasting, SurTec 650 coating, wet spray painting, powder coating and assembling.

Questions? Queries? Need Help?

02 8748 0100 or qnc@weldaustralia.com.au

Take advantage of our advertising packages. With a multi-channel marketing approach, you can reach as big an audience as possible. Plus, Weld Australia members get a significant discount on all our advertising rates.

Diamond Package: $6,000

If you have a ground-breaking story to tell, or a brand new product or service to launch, take advantage of our ‘Diamond Package’ for maximum impact and exposure:

1. Australian Welding: 1 x full page inside cover ad

2. Weld Connect: 1 x third of a page front cover ad

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 4 x editions

4. 3 x social media posts

Gold Package: $5,000

Our ‘Gold Package’ provides great value for money, as well as fantastic impact and exposure:

1. Australian Welding: 1 x full back cover advert

2. Weld Connect: 1 x back cover advert

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 3 x editions

4. 2 x social media posts

Silver Package: $4,000

Our ‘Silver Package’ provides great value for money, as well as great impact and exposure:

1. Australian Welding: 1 x full page advert

2. Weld Connect: 1 x full page advert

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 2 x editions

4. 1 x social media post

Weld Australia would like to congratulate the following people on becoming newly qualified in April.

IIW IWE

• Luke Nicholls

• Ryan Palle

IIW IWI-B

• Alexander Haangana

• Dennis Wilkins

• Dylan Clements

• Graham McPherson

• Jacobus Johannes (Kobus) Beets

• Jamahl Heron

• John Hayman

• Joshua Laird

• Kris Mitchison

• Mark David Prulla

• Mathew Hefferan

• Rainer Kiefer

• Scott Maguire

• Stephen McKenzie

AS 1796 CERTIFICATE 2

• Samuel Dwyer

AS 1796 CERTIFICATE 4

• Eythan Stute

• Lincoln Albanese

• Samuel Dwyer

AS 1796 CERTIFICATE 5

• Samuel Dwyer

AS 1796 CERTIFICATE 7

• James Morrow

• Kohan Hanby

• Lukas Scott

AS 1796 CERTIFICATE 8G

• Jamie Watkins

• Matt Davey

AS 1796 CERTIFICATE 10

• James Darmody

• Jarrad Julyan

In conjunction with the 76th Annual Assembly of International Institute of Welding (IIW), the Singapore Welding Society (SWS) is proud to host the International Conference on Advances in Welding, Joining and Additive Manufacturing.

The Conference will be held from 16 to 21 July 2023 at the Marina Bay Sands. The event aims to provide a platform for knowledge exchange and networking among scientists, researchers and industry experts in the field of welding and joining.

Welding technologists, scientists and professionals who are interested in presenting original work are invited to submit abstracts. Topics of interest include:

• Brazing and soldering

• Mirco and nano joining

• Friction stir welding

• Linear Friction welding

• Cold spray technology

• Additive manufacturing:

• Wire arc additive manufacturing

• Laser directed energy deposition

• Powder bed 3D printing

• Laser welding

• Joining of ceramics or dissimilar materials

• Advanced arc welding or other welding processes

• Intelligentised welding manufacturing

• Numerical modelling of welding process

• Design, analysis and fabrication of welded structures

• Non-destructive testing

• Fatigue and fracture of welded joints

• Corrosion of welded joints

For further information, visit: iiw2023.com

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2023, making planning ahead as simple as possible. Just some of the upcoming exam dates include:

• Tuesday 6 June: IIW IWI-S (WTE-S ) and IWI-B (WTE-B ) Online exam

• Thursday 8 June: National Welding Supervisor

Exam B1 & B2 (Training)

• Friday 16 June: National Welding Supervisor

Exam Paper A

• Tuesday 20 June: IIW IWE and IIW IWT EA2.1/ TA2.1 Online Exam

• Tuesday 4 July: IIW IWI-S (WTE-S) and IWI-B (WTE-B) Online exam

• Wednesday 19 July: National Welding Supervisor Exam B1 & B2 (Training)

The course is delivered online over six live sessions. The course covers: common welding processes; welding symbols and welded joint configurations; welding defects; destructive and non-destructive testing methods; PQR / WPS and welder qualifications; and Australian and International welding Standards. This highly engaging online course will start on 17 July 2023. Get in now, before its too late.

A Welding Supervisor qualification enables you to improve your company’s bottom line. Welding Supervisors often make valuable contributions to four of the most important metrics in welding operations: quality, cost, productivity and safety. Not surprisingly then, this qualification can boost your earning potential and job stability. Kicking off on 18 July 2023, there are limited spots available for this course.

An AS1796 Welding certificate is by far the most well known and requested welder certification nationally. It is used in both structural and pressure equipment Standards. Delivered live online over 15 sessions, this course covers safety precautions, welding terms and symbols, preparation and set up, cutting and gouging, arc conditions, procedures and more. This highly engaging online course will start on 14 August 2023

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 96061 (Steels – carbon steels)

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

For further information, contact: training@weldaustralia.com.au

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

ACT

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania Tasmanian Minerals and Energy Council tasminerals.com.au

13 Wellington Street, Burnie

Victoria Box Hill Institute boxhill.edu.au

465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au

23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat