IN THIS ISSUE

ALSTOM’S FIRST TRAIN FOR METRONET LEAVES BELLEVUE FOR TESTING | PAGE 6

UPDATES TO WELD AUSTRALIA’S TECHNICAL AND TECHNICAL GUIDANCE NOTES | PAGE 7

HM LANGI KAL KAL PRISON HOSTS WELDING EMPLOYMENT EXPO | PAGE 11

ALSTOM’S FIRST TRAIN FOR METRONET LEAVES BELLEVUE FOR TESTING | PAGE 6

UPDATES TO WELD AUSTRALIA’S TECHNICAL AND TECHNICAL GUIDANCE NOTES | PAGE 7

HM LANGI KAL KAL PRISON HOSTS WELDING EMPLOYMENT EXPO | PAGE 11

NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 02 8748 0100 office@weldaustralia.com.au weldaustralia.com.au

Geoff Crittenden Chief Executive Officer 02 8748 0100 g.crittenden@weldaustralia.com.au

ENGINEERING

Victor Blain, Engineering Team Manager 0409 823 991 v.blain@weldaustralia.com.au

TRAINING

Guy Brooks, Training Manager 0488 743 322 g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, National Manager, Sales & Marketing 0437 106 726 m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Qualification and Certification Team Manager 0487 487 170 d.yalniz@weldaustralia.com.au

NEW SOUTH WALES & NORTHERN TERRITORY

Arya Sharifian, Welding Engineer 0419 414 901 a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, Engineering Team Manager 0409 823 991 v.blain@weldaustralia.com.au

QUEENSLAND

Ross O’Bryan, Welding Engineer 0491 491 888 r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Mehdi Tajfar, Senior Welding Engineer 0417 044 370 m.tajfar@weldaustralia.com.au

The Federal Government hosted the Jobs and Skills Summit from 1 to 2 September. Led by the Prime Minister and Treasurer, and supported by other key ministers, the objective of the Summit was to recommend immediate actions and opportunities for medium and long-term reform to address employment concerns and skills shortages.

I was invited to attend two key events over the last month, the outcomes of which were presented at the Jobs and Skills Summit. These events included IBSA Group’s Manufacturing Skills Forum, and the Climate and Energy Mini Jobs Summit.

I was invited to attend the IBSA Group’s Manufacturing Skills Forum in Melbourne on 17 August. IBSA Group brought together manufacturers, union leaders, peak bodies and training providers to share opinions and insights into the strategies needed to address the skills needs of the manufacturing sector. The Forum highlighted the need for a collaborative and systematic approach to address the skills crisis facing Australian’s manufacturing industry, which threatens to limit manufacturing growth and sovereign capability.

The Federal Minister for Skills and Training, the Hon Brendan O’Connor MP opened the Forum and highlighted the challenges facing industry and the need for government and industry to work together to seize the opportunities that lie ahead. He also emphasised that supporting skills and training is crucial to the continued growth of manufacturing.

Expertly hosted by ABC journalist Ellen Fanning, other speakers at the Forum included Andrew Dettmer (National President, Australian Manufacturing Workers’ Union), Innes Willox (Chief Executive, Australian Industry Group) and Sharon Robertson (Chief Executive Officer, IBSA Group). It was an interesting, thought provoking day.

As a result, Weld Australia submitted a brief to Minister O’Connor, outlining a practical, actionable plan to overcome Australia’s welder shortage. Weld Australia proposed a two-pronged approach: a radical overhaul of welding apprenticeships; and tapping into hidden sources of talent.

The existing Certificate III in Engineering (Fabrication) is a nominal 720 hours of face-to-face teaching at a TAFE interspersed with practical experience in the workplace via an apprenticeship. This is spread over three years.

Weld Australia proposed that the current course is condensed into one year, with the existing training package taught in two 24-week blocks. Once the course is completed, competency will be assessed and the Certificate III qualification awarded. Graduates

will then be required to qualify to the International Standard for Welding Competency (ISO 9606).

An analysis of people identifying as welders indicates that less than 50% have any formal welding qualifications. Clearly, there are a significant number of welding jobs that require a Skill Set (practical competence) without necessarily having the full range of trade skills.

Weld Australia has had significant success in offering Skill Set training—based on existing Units of Competency in the Certificate III in Engineering (Fabrication)— to disadvantaged Australians. This training ultimately leads to employment as a welder. As such, Weld Australia proposed that a series of courses covering basic welding Skill Sets are funded and included within the scope of all RTOs teaching welding.

Not long after IBSA Group’s Forum, I attended the Climate and Energy Mini Jobs Summit at Parliament House. Hosted by the Federal Minister for Climate Change and Energy, the Hon

Chris Bowen MP, the Summit brought together key stakeholders to help discuss energy industry jobs now and in the future.

This event examined the investments and pipelines required to upskill workers in preparation for the opportunities in renewables across the country. Independent modelling of the Federal Government’s Powering Australia plan shows that over 600,000 jobs will be created in the energy sector by 2030—a large portion of which will be welders.

In June 2022, Prime Minister Anthony Albanese pledged to cut carbon emissions by 43% from 2005 levels by 2030, up from the previous government’s target of between 26% and 28%. The new target brings Australia more in line with other developed economies’ Paris climate accord commitments. For instance, Canada is aiming for a reduction of 40% by 2030 from 2005 levels, while the United States has a target of up to 52%.

When Australia manufactured and erected the existing power grid, it took between 40 and 50 years. With Albanese pledging to cut carbon emissions by 43% from 2005 levels by 2030, we have just eight years to manufacture and erect the assets required for the shift to renewables. It is an enormous project that must be completed in a very short space of time.

It will necessitate the manufacture of thousands of wind towers and transmission towers, as well as thousands of kilometres of transmission lines. All this will require millions of tonnes of steel, and a highly skilled workforce. Estimates indicate that Australia will need to double its existing welder workforce to deliver on the Federal Government’s promises.

The outcome of the discussions at the Climate and Energy Mini Jobs Summit indicated very strong support for the development of sovereign manufacturing capacity for the renewable energy market.

Clearly, the welder skills shortage and the issues discussed at these Forums and Summits, are a significant concern for industry.

Over the last month, I’ve met with representatives from the National Transport Commission, South Australia’s Department for Education and Department for Energy and Mining, Supashock, Samaras Group, BAE Systems, and Defence SA. All of these meetings had a common denominator: a focus on overcoming the welder skills shortages. Whether through innovative training, or recruitment programs focused on Indigenous Australia, industry is on the hunt for solutions. Importantly, industry stands ready to work collaboratively with governments, TAFEs and one another to implement these solutions.

Geoff Crittenden

CEO, Weld Australia

NON-ACCREDITED COURSES

Introduction to Welding (24 Hours)

Hobbyist Course (8 hours) ACCREDITED COURSES Cert

in Engineering – Fabrication Trade (MEM30305/30319) Construction Induction White Card (CPCCWHS1001)

AS1796 Pressure Tickets 1-9 Short Courses

MEM05012 – Perform Manual Metal Arc Welding (100 hours) MEM05017 – Weld Using Gas Metal Arc Welding (100 hours)

MEM05047 – Weld Using Flux Core Arc Welding (100 hours)

MEM05019 – Weld Using Gas Tungsten Gas Arc Welding (100 hours)

CONTACT US

69 Melbourne Road, Riverstone, NSW 2765

Phone: (02) 9627 6237

Email: academy@fabinox.com.au Website: www.fabinoxweldingacademy.com.au

WHY US?

• Practical Training: Our school boasts 13 training bays with the latest high-tech welding machines and fume extraction units

• Theoretical Training: Our classrooms have been designed to create a friendly interactive environment for learning

• Virtual Reality / Real-Weld Training: We have acquired some of the most modern and up-to-date visual reality machines, to enhance our students learning.

SafeWork NSW accredited for general construction induction (White Card) training.

Equal to the size of two houses and taking 45,000 hours, the first steel ‘block’ has been constructed by shipbuilders working on the Hunter class frigate program at the Osborne Naval Shipyard in South Australia. Shipbuilders are initially manufacturing five prototype ship blocks to test and refine the processes, systems, tools, facilities and workforce skills ahead of construction of the first Hunter class frigate.

There are 22 blocks in each Hunter class frigate. The first prototype block, known as Block 16, weighs more than 140 tonnes and its construction involved the expertise of 35 different trades, including engineers, boiler makers, welders, fabricators and project managers.

This first prototype block (without any Hunter class design changes) would form part of the middle of the ship where there are accommodation spaces. Over the coming weeks and months, the Hunter program will continue constructing the second and third prototype blocks, each more complex than the last. In mid2023, the prototyping program will commence the production of additional blocks incorporating the Hunter class design changes, with these blocks actually being used in one of the first three ships.

GFG Alliance’s mining arm, SIMEC Mining has produced its first high quality GREENSTEEL pellets that will underpin the future of decarbonised steel production in Whyalla, South Australia. The pellets were produced from the company’s Duchess South drill core in the Southern Middleback Ranges using innovative technologies proposed for SIMEC’s magnetite expansion operations. As part of routine production, a small parcel of concentrate was successfully converted to pellets in the existing pellet plant.

The successful production of the Direct Reduction grade pellets is another significant step forward in GFG Alliance’s GREENSTEEL transformation at Whyalla, and is coupled with the successful commissioning of a 400tph demonstration pilot plant to test an innovative technology integral to current and future mining operations. Both milestones build on GFG’s announcement earlier this year of its magnetite expansion project and construction of a debottlenecking process to increase magnetite concentration production.

The process, known as a Dry Low Intensity Magnetic Separation (DLIMS) plant, is designed to reject nonmagnetics from a coarse crushed fraction of the feed material, thereby upgrading the quality of feed to the magnetite concentrator. Performance of the plant has exceeded expectations by rejecting over 20% of the feed mass as waste, while still recovering more than 98% of magnetics to product.

The first Alstom C-series railcar built in Western Australia (WA) for METRONET has completed high-voltage testing and will move to the Nowergup depot next month for an extensive dynamic validation testing period.

The train will soon conduct dynamic testing to ensure the units will move more than 103,000 passengers daily as safely, efficiently, and smoothly as possible.

Testing will include braking and acceleration, operational systems, passenger comfort, and energy consumption, ensuring the train is ready for passenger service. It is crucial the train is tested in a live environment, with existing signalling and communications systems. This will be conducted outside regular passenger service hours where possible to minimise disruption to the network.

The first unit is expected to roll onto the network and into passenger service in late 2023.

The new C-Series railcars, and Australian railcars will be delivered over a 10 year period as part of a contract that Alstom has with the Public Transport Authority of Western Australia (PTA).

Under the contract, Alstom is responsible for the design, supply, manufacturing, testing and commissioning of 41 x 6-car electric (EMU) and 2 x 3-car diesel (DMU) trains and 20 years maintenance of the EMU trains and maintenance support services for the DMU trains. These new railcars will run along the Joondalup and Mandurah lines, two of the busiest services on the Perth network.

In WA, this is the first time since 1994 that locally built railcars will have at least 50% local content, in a commitment to supporting local jobs. This contract will also provide a positive boost for the state’s rolling stock supply chain, jobs, and skills development.

The METRONET project provides a unique opportunity for Western Australia to manage Perth’s projected future growth while re-establishing its railway manufacturing industry, creating jobs, investing in infrastructure and supporting local manufacturing and supply chains.

“Alstom is delighted to have completed the first six-car train in the Bellevue facility. These locally manufactured trains will provide a boost to the local economy and provide ongoing local jobs for local workers. The next 12 months of dynamic testing will ensure these trains meet Alstom’s rigorous quality standards in order to provide a safe, comfortable, and reliable public transport option for the people of WA,” said Mark Coxon, Managing Director for Alstom ANZ.

Several of Weld Australia’s Technical Notes and Technical Guidance Notes have been updated recently. All of our Technical Notes and Technical Guidance Notes are available via our website. Technical Notes are available for sale at a discounted price for Weld Australia members. Technical Guidance Notes are free of charge.

This Technical Note is a revision of the 1987 edition and is designed to give practical guidance together with some background information on the welding of various castings. It is intended to assist all involved in the welding repair and fabrication of castings in the foundry, maintenance and fabrication shop. This edition includes reference to the latest workplace health and safety requirements and standards. Importantly, references to welding consumables have been updated to align with current recommendations and designations. Consistent with best practice, it also refers to a variety of welding application standards for the qualification of weld procedures for specific materials. Qualification of weld procedures is essential to demonstrate the sound application of the requirements specified within. Similarly, welders are also required to demonstrate their ability to follow defined weld procedures.

Users should be aware that whilst some of the standards referenced in this Technical Note have been withdrawn, many of the materials referenced within remain in common use, particularly in the mining industry, hence reference to these materials has been retained.

Technical Guidance Note TGN-PG02: Minimisation of Fatigue

This Technical Guidance Note is a revision of Weld Australia’s Technical Guidance Notes on fatigue improvements of welds including the dressing of welds to minimise fatigue, originally published by the Welding Technology Institute of Australia (WTIA). This guide is designed to assist the fabricator in the enhancement of weld bead shape when conformance with AS/NZS 1554’s Category FP and fatigue improvement methods have been specified.

Technical Guidance Note TGN-PG03: Control of Distortion in Welded Structures

This Technical Guidance Note is a revision of Weld Australia’s Technical Guidance Notes on distortion control, originally published by the Welding Technology Institute of Australia (WTIA). This Technical Guidance Note is designed to assist the fabricator in the production of welded structures with minimal distortion, and where distortion occurs, provides guidance on distortion correction techniques.

Take advantage of our advertising packages. With a multi-channel marketing approach, you can reach as big an audience as possible. Plus, Weld Australia members get a significant discount on all our advertising rates.

Diamond Package: $6,000

If you have a ground-breaking story to tell, or a brand new product or service to launch, take advantage of our ‘Diamond Package’ for maximum impact and exposure:

1. Australian Welding: 1 x full page inside cover ad

2. Weld Connect: 1 x third of a page front cover ad

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 4 x editions

4. 3 x social media posts

Gold Package: $5,000

Our ‘Gold Package’ provides great value for money, as well as fantastic impact and exposure:

1. Australian Welding: 1 x full back cover advert

2. Weld Connect: 1 x back cover advert

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 3 x editions

4. 2 x social media posts

Silver Package: $4,000

Our ‘Silver Package’ provides great value for money, as well as great impact and exposure:

1. Australian Welding: 1 x full page advert

2. Weld Connect: 1 x full page advert

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 2 x editions

4. 1 x social media post

Weld Australia would like to welcome the following new members who have joined over the last month.

CORPORATE MEMBERS

• ACL Industrial Technology: aclconnect.com.au

• Bowhill Engineering: boweng.com.au

• Empire Industrial Engineering: empireindustrialengineering.com.au

• Getronics: getronics.com

• Komatsu Training Academy: komatsu.com.au

INDIVIDUAL MEMBERS

• Jayke Gatt

• James Darmody

• Kenneth Kavanagh

• Lee Sharp

• Peter Kuiters

• Reneie Gadin

• Ronald Smith

• Rhyan Eales

Weld Australia membership is an investment in the success of your career or your business. We will help you increase your income, decrease your costs and give you a competitive advantage over companies or people who aren’t members.

Questions? Queries? Wondering how Weld Australia can help support your business, staff or career progression?

Contact David Choudry (Membership Manager, Weld Australia) on d.choudry@weldaustralia.com.au to set up a 30 minute Zoom chat. Michelle will take you through the ways that Weld Australia can help.

Weld Australia would like to welcome Bailey Greathead to the team. Based in our Wollongong office, Bailey is taking on the role of Welding Technology Trainer.

Prior to joining the Weld Australia team, Bailey was a Boilermaker at K&R Fabrications in Uanderra for over six years. In this role, he undertook a variety of fabrication work, manufacturing all types of components and structures in all grades of carbon steel, as well as aluminium and stainless steels. Highly proficient in stick, TIG and MIG welding, Bailey has worked across projects as diverse as simple stairways and handrails, right through to major structural steel for mining and heavy industry, and pressure vessels.

Bailey holds a Certificate III in Engineering (Fabrication Trade) and a Certificate IV in Engineering (Heavy Fabrication). He is an AS 2214 certified Welding Supervisor, and an International Institute of Welding (IIW) International Welding Inspector Basic (IWI-B). A highly motivated and driven team player, who enjoys the challenge of a fast paced work environment, Bailey has a genuine interest in lifelong learning and skills development.

Bailey is sure to be a valuable addition to the Weld Australia team. Be sure to make Bailey feel welcome, should you have the chance to meet him.

Weld Australia recently appeared on ABC’s Q+A. The espisode focused on Workers, Taxes and Getting a Fair Go. Bailey Greathead asked a fantastic question around how the government plans to de-stigmatise apprenticeships versus a career path that starts with a university degree.

Weld Australia recently exhibited at the Canberra CareesXpo at Exhibition Park. An annual event, the Canberra CareersXpo is conducted in conjunction with ACT Education. It seeks to provide valuable career guidance and advice on career opportunities available to secondary students throughout the ACT and surrounding NSW schools network. This CareersXpo is the largest event of its type in the region with over 100 local and national exhibitors. The feedback from attendees was overwhelmingly positive.

Weld Australia’s Excellence Awards are one of the most prestigious events on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism.

Winners will be awarded in each state for each of the award categories below. Award entries close on 1 October 2022. The Award Categories are outlined below.

Company of the Year

The Company of the Year Award recognises superior performance across a comprehensive range of business metrics. There are three sub-categories:

• Company of the Year – Fabrication Award Criteria | Enter Now

• Company of the Year – Gas & Gear Award Criteria | Enter Now

• Indigenous Company of the Year Award Criteria | Enter Now

Welding Professional of the Year

This Award recognises professionals who are making a valuable contribution to the welding industry. There are three sub-categories:

• Welding Professional of the Year – Welding Coordinator Award Criteria | Enter Now

• Welding Professional of the Year – Welding Supervisor Award Criteria | Enter Now

• Welding Professional of the Year – Welding Inspector Award Criteria | Enter Now

Project of the Year

Award Criteria | Enter Now

The Project of the Year Award recognises excellence in welding and fabrication projects, with a focus on exceptional craftsmanship, a commitment to Standards, environmental sustainability and innovation.

Young Trades Person of the Year

Award Criteria | Enter Now

This Award recognises people under the age of 25 who are

The awards will be presented at events held across the country in November 2022. The ticket price of just $35 per person includes a two-course meal and drinks. Please book tickets ASAP to help with planning:

• Perth: 14 November at Bells Functions

• Adelaide: 17 November at the Terrace Hotel

• Brisbane: 24 November at Victoria Park Golf Course

• Sydney: 29 November at Strathfield Golf Club

• Melbourne: 1 December at Box Hill Golf Club

making a valuable contribution to the Australian welding and fabrication industry.

Young Indigenous Trades Person of the Year Award Criteria | Enter Now

This Award recognises indigenous trades people under the age of 25 who are making a valuable contribution to the Australian welding and fabrication industry.

Training and Education Award – Organisation Award Criteria | Enter Now

The Training and Education Award recognises the outstanding achievements of a STEM or VET provider or program.

Training and Education Award – Individual Teacher Award Criteria | Enter Now

This Award recognises and the outstanding achievements of a STEM or VET teacher at TAFEs, independent RTOs and private companies.

WITH THANKS TO OUR SPONSORS

In conjunction with Weld Australia, Langi Kal Kal Prison recently hosted a Welding Employment Expo to help facilitate connections between prisoners and prospective employees.

According to Geoff Crittenden (CEO, Weld Australia), “Australia’s prison population is rapidly expanding, and is increasingly comprised of younger people and reoffenders. This gives rise to the need for practical rehabilitation and vocational education and training (VET) programs that can help alleviate recidivism.”

“A recent study confirmed that participation in VET whilst incarcerated helps prisoners to remain custody free post-release. In fact, prisoners who successfully completed VET were 59.96% more likely to remain custody free at two years post-release; and 78.23% more likely to remain custody free at five years postrelease.”

Given the proven success of VET programs for prisoner rehabilitation, in 2022, Corrections Victoria expanded the VET Centre of Excellence model to deliver Fusion Welding to ISO 9606 certification standard to complement their Metal Fabrication industry at HM Prison Langi Kal Kal. Federation University delivers the training program with the support of Weld Australia and on-site prison industry staff.

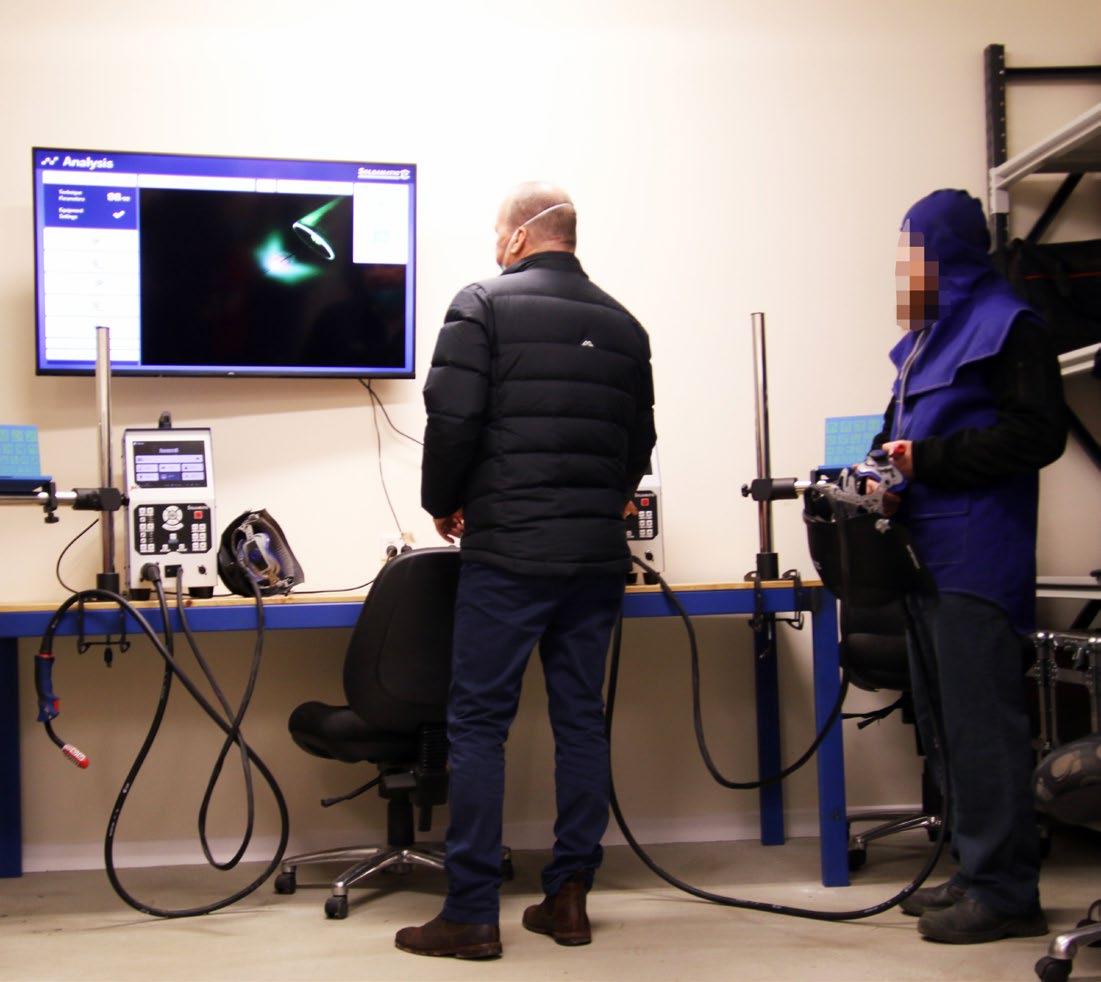

As part of the program, augmented reality training was introduced to expand the welding skills of the prisoner learners to meet international standards. A welding workshop sits alongside the augmented reality training room so that participants can work on projects to use and practice their welding skills in the physical as well as virtual environments.

To participate in the program, prisoners are invited to submit an Expression of Interest and then selected through an interview process. Up to eight participants can be accommodated in the intensive 14-week program.

Student *Daine said, “I wanted to take part in this course to not only further my knowledge and experience of welding but to be able to give myself the ability to provide a positive, reliable, and sustainable future for my family.”

“When I am released, I am keen to find as much work as possible in the engineering trade working in the railways, or similar areas that require good welders. I don’t see my life revolving around prison and I want to have real work opportunities in the community when I’m released.”

The VET Centre of Excellence model links participating prisoners with prospective employers and pre- and post-release support service providers. These connections provide prisoners with sustainable pathways to employment and support to reintegrate to society post-release.

The Welding Employment Expo was attended by several Weld Australia members, including Jeff Wanliss (Engineering and Business Development Manager, Keppel Prince). Based in Portland, Victoria, Keppel Prince specialises in the construction, fabrication and maintenance of industrial structures and equipment, ranging from wind farms to bridges.

“I didn’t really know what to expect from the Employment Expo, but the experience was a big eye-opener for me,” said Wanliss. “During the tour of the facilities, one of the prisoners produced an industry standard vertical up weld—one of the hardest

welds to do. We would have accepted that weld in our workshop. It can be difficult to find potential employees with the skills and experience needed in our workshop. I’d definitely consider employing any of the guys based on the standard of welding they’re doing.”

“These types of training and rehabilitation programs are so important. They help give prisoners purpose. Many of the prisoners have obviously faced challenges in the past, but, this is a delineation point—it’s like drawing a line in the sand and saying ‘the past is the past’. VET and training programs like this one equip prisoners with knowledge and give them practical skills that they can use on release. It is an essential step to ensuring that their future is successful,” said Wanliss.

“Australia is facing a looming shortage of skilled welders—70,000 additional welders will be needed in the next 10 years. VET training and employment pathways as part of prisoner rehabilitation could help alleviate some of these skills shortages,” said Crittenden.

“However, this will require commitment and collaboration from industry and government—not only to fund VET training in Australia’s prisoners—but to help provide secure employment opportunities postrelease.”

*Name changed to maintain privacy.

The land where Langi Kal Kal Prison is located was first settled as a 70,000-acre farming property in about 1838. A substantial farmhouse was built in approximately 1900. After World War II, the land was subdivided and the central area, including the farmhouse, was set aside for prison purposes. The first prisoners arrived in September 1950 and the prison was officially opened in February 1951. In 1965

Weld Australia recently appeared on the ABC’s The Drum. Geoff Crittenden (CEO) and Michael Pitt (National Manager Education and Training) spoke about the success of VET programs for prisoner rehabilitation at HM Langi Kal Kal prison.

Situated on the Western Highway at Trawalla approximately 140km west of Melbourne, Langi Kal Kal is an open camp, minimum security protection prison with all prisoners required to work during their stay unless they are over retirement age. As a prerelease prison, Langi Kal Kal specialises in getting prisoners ready for release through on-the job training and employment in a range of industries.

Welder qualification is a crucial component to ensuring businesses and teams are in the best position to secure work. As we emerge into the new normal, your welder’s capability to create welds to what the market is requiring is paramount.

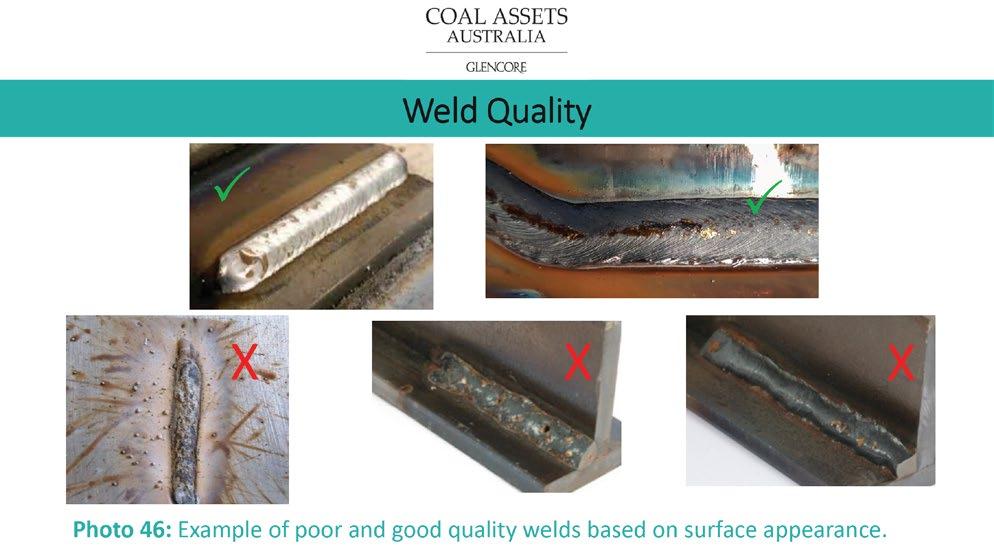

This recent event delved into The Glencore GCAA Welder Qualification Scheme. It provided insights into the types of welder qualification required, why Glencore implemented the scheme, and the factors that will set businesses up for success.

The session was presented by Garry Horner, who has worked in the coal industry for his entire career— from the CSIRO in the early days, The Electricity Commission of NSW, Shell Service and Shell corporate, and now for Glencore Coal Assets Australia Corporate Engineering Group as their Group Reliability Engineer –Condition Monitoring and Failure Analysis.

Glencore’s Engineering Group started to see a number of weld repairs on major open cut assets failing after a short period of time after the asset was returned to service. With the assistance of MC Quality and Weld Australia, Garry developed a GCAA Welder Competency training program for Glencore’s full time boilermakers and third party repairers performing these weld repairs. Now, this training program is distributed to a large number of offsite repairers, OEMs and other coal companies. Glencore is starting to see extended life from its assets after repair.

This recent event was an opportunity for members in South Australia to see the latest welding automation technology. It highlighted a broad range of applications to improve welding ergonomics, and increase productivity and quality.

It also covered various cost saving applications that can easily double the production rate of a welding workshop by increasing the arc time and reducing labour, gas and filler metal costs (P/m, P/f) compared to manual welding.

Held on-site at the TAFE SA Regency Campus, the presentation demonstrated the AristoMig 4004i Pulse welding machine with RobustFeed U6 and Pulse using the RailTrac B42, MiggyTrac B501 and MiggyTrac B5001 welding tractors.

Learn how to minimise cost and maximise qualifcation usefulness.

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications. This three day course will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

The course will be facilitated by Walter J. Sperko, P.E., the President of Sperko Engineering Services, a consulting firm specialising in metal fabrication technology. He has particular experience in piping and pressure vessel fabrication, installation, maintenance and repair. Mr. Sperko is also a past-Chairman of the ASME Welding, Brazing and Fusing Standards Committee IX and a member of ASME Subcommittee III, Nuclear Components.

This course is intended for people who are involved in writing and qualifying welding and brazing procedure specifications, qualifying welders, brazers and operators, reviewing suppliers procedures, auditing or reviewing in-house procedures and qualifications and estimating jobs which impose the requirements of Section IX.

Perth

Date: 16, 17 & 18 November 2022

Venue: Novotel Perth, 388 Murray Street, Perth Room: Cottesloe Room

Registration first day: 7:30am

Course time: 8:00am – 5:00pm

Brisbane

Date: 22, 23 and 24 November 2022

Venue: Novotel Brisbane, 38 Cordelia Street, Brisbane Room: Musgrove Room

Registration first day: 7:30am

Course Time: 8:00am – 5:00pm

A review of the welding processes and variables, and basic steel welding metallurgy will be conducted to provide all participants with sufficient background in welding technology to interpret and understand Section IX. The mechanics of using Section IX and how to address its requirements will be explained in a simple, straightforward manner.

Emphasis will be placed on writing welding procedures so that they contribute positively to the manufacturing process and on qualifying procedures in a cost-effective manner. The requirements for welders and operators will be examined with particular emphasis on minimising the cost and maximising the usefulness of qualifications.

Time will be provided to address individual participant’s problems and concerns. Attendees will receive copies of the course notes covering the course’s content. Attendees must bring a copy of the current edition of Section IX. Multiple choice tests will be given for each section.

Early Bird Rate:

• Weld Australia Members: $3,610 inc GST

• Non Weld Australia Members: $3,810 inc GST

Rate After 1 September 2022:

• Weld Australia Members: $3,760 inc GST

• Non Weld Australia Members: $3,960 inc GST

Please note: in order for the course to go ahead in two locations, minimum attendee numbers must be reached.

For further information, contact: Michelle Bignold (National Manager, Sales and Marketing) on 0437 106 726 or m.bignold@weldaustralia.com.au REGISTER FOR PERTH

Thursday 15 September at 6:00pm (AEDT)

Many industries (such as rail and roads) are mandating that fabricators hold certifications to AS/NZS ISO 3834 and AS/NZS 5131. Perfect for Fabricators, Inspection Authorities, Project Engineers, this event will outline the benefits and processes involved in gaining the two certifications. Presenters will include Victor Blain (Engineering Team Manager, Weld Australia) and Bushan Salunke (General Manager, Steelwork Compliance Australia). Both Victor and Bushan will field questions from attendees. Please note that this is a face-to-face event, which will be held at Chisholm TAFE in Melbourne (121 Stud Road, Dandenong).

15-17 and 22-24 November

Need to use ASME Section IX? Learn how to minimise cost and maximise qualification usefulness. The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications.

Presented by Walter J. Sperko, this three day course will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

Thursday 29 September at 6:00pm (AEDT)

This webinar will provide an overview of AS/NZS ISO 3834 Quality requirements for fusion welding of metallic materials. It will detail what AS/NZS ISO 3834 is, how it is structured, why you need it, the requirements outlined in the standard, the benefits of undergoing the certification process, as well as the steps involved in this process. If you, or the company you work for, is considering certification, this is the perfect webinar to attend. The webinar will be presented by Weld Australia team members Louis Victor Blain (Engineering Team Manager) and Bruce Cannon (Principal Welding Engineer), who will be more than happy to answer any questions you might have.

The awards will be presented at events held across the country in November 2022. The ticket price of just $35 per person includes a two-course meal and drinks. Register now:

• Perth: 14 November at Bells Functions

• Adelaide: 17 November at the Terrace Hotel

• Brisbane: 24 November at Victoria Park Golf Course

• Sydney: 29 November at Strathfield Golf Club

• Melbourne: 1 December at Box Hill Golf Club

WELD

Do you need help with strategies for avoiding burn through and the development of crack susceptible weld microstructures?

Burn through occurs if the unmelted area beneath the weld pool has insufficient strength to contain the internal pressure of the pipe during hot tapping weld repairs.

Weld Australia’s expert engineers can provide services for burnthrough calculation as per the PRCI Pipeline Repair Manual using thermal analysis computer modelling. Our team understands that the key factors to consider are the material, wall thickness, welding heat input, and operating parameters of the pipeline.

Our burn through calculation can help ensure that your pipeline repair, hot tapping and in-service welding is undertaken in a way that ensures the safety of your workers; reduces the probability of a shutdown, failure or service interruption; and extends the lifecycle of your pipeline systems.

The Weld Australia engineering group has the largest single team of International Welding Engineers (IWE) in Australia. This qualification, issued by the International Institute of Welding, is the highest post-graduate professional welding qualification available.

All solutions delivered by our Engineering Group are reviewed by another Senior Welding Engineer and often, depending on the complexity of the assignment, one of our Principal Welding Engineers.

By taking advantage of Weld Australia’s consulting services, you will have access to the peak industry body in Australia’s welding industry. This will provide your commercial enterprise with access to our expert engineering services, delivered by highly qualified International Welding Engineers and materials specialists.

With expertise in a wide range of industries, from defence, manufacturing and composites to rail and resources, we have the unique capability to solve your welding problems.

Ross O’Bryan (Welding Engineer, Weld Australia) recently performed a successful surveillance audits for AS/NZS ISO 3834.3 Quality requirements for fusion welding of metallic materials at INGAL EPS

Established in 1969, INGAL EPS is Australia’s leading manufacturer of quality light poles, columns, and structures. As part of Valmont Industries, INGAL EPS has access to a large network of trained specialists who can offer custom solutions for any structural pole design requirement.

With staff and offices located in every state of Australia, the main INGAL EPS manufacturing plant is located in Brisbane. This facility is home to an expert in-house design team that can provide engineering and drafting services, as well as bespoke concepts. INGAL EPS manufactures poles to suit every conceivable requirement for minor and major roads including poles for standard use, frangible poles in the form of impact absorbing and slip base, and an extensive range of decorative poles. Their floodlighting poles are installed at some of Australia’s most well-known sporting grounds.

Ross also undertook testing according to AS/NZS ISO 9606.1 Qualification testing of welders — Fusion welding — Part 1: Steels for three welders at JAG Welding

JAG Welding is a privately owned and operated company with over 22 years experience providing steel fabrication services to south east Queensland businesses. As well as working with mild and galvanized steel, JAG Welding has extensive experience working with structural stainless steel and aluminium. Significant investments in leading edge technologies have allowed JAG to continue providing efficient, responsive and quality services to their customers, and highly competitive pricing.

Weld Australia also facilitated an IIW International Welding Inspector - Basic practical and exam in Brisbane this month. This qualification is recommended in both AS/NZS ISO 3834 and AS/NZS 1554.1. It provides extensive knowledge surrounding welding, inspection theory and application. It includes theoretical components such as mechanical and visual inspection techniques; inspection procedures and acceptance criteria; identification of weld imperfections associated with pre-production; fabrication and post fabrication; and much more.

Weld Australia recently updated the phone app version of the WeldQ platform. These updates included adding digital ID cards and making exam results available, as well as various styling and general bug fixes.

The WeldQ app is available for download via both the Android and iOS platforms. The app makes accessing the WeldQ platform even easier for welders and employers alike. It is particularly handy for use on-site or in a workshop when a computer is not readily available. There are still some tasks for which you’ll need to use the website, including creating and updating your profile, creating and submitting applications (like renewal applications and resits), and exams.

WeldQ is a purpose built software solution that facilitates management of the entire process of handling welder qualifications and certifications, including applications, assessment workflow, conducting examinations, awards, reviews, resits, renewals, and issuing certificates. It is a fully online system, with an easy to use interface.

Welders, inspectors, supervisors and engineers can create their own WeldQ account. You can view all the certifications on offer, create an application, pay fees, get assessed, take exams, view awards or certificates, maintain professional development points, apply for continuity extensions, renewals, and do much more. If you haven’t already created your account, log-in now

Weld Australia is looking to expand its pool of assessors, exam writers and markers. In particular, we need people who are interesting in getting involved in the examination process for the International Welding Inspector - Basic (IWI-B) qualification. Using your knowledge and practical experience, you could help us deliver in-person and oral exams across various locations. To be considered, you must hold an IWI-B qualification.

This is not a permanent position. Your assistance will only be required 1-3 times a year during our exam periods

If you’re interested in giving back to the welding industry, please contact our Qualification and Certification team via: qnc@weldaustralia.com.au

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2022, making planning ahead as simple as possible.

Just some of the upcoming exam dates include:

• Thursday 22 September: AS 1796 Cert 1-9 Theory Online Exam

• Friday 23 September: IIW IWE and IWT EA2 and TA2-Part 2 Online Exam

• Tuesday 11 October: IIW IWS SA2 Online Exam

• Wednesday 19 October: National Welding Supervisor Online Exam

• Friday 28 October: AS 1796 Cert 1-9 Theory Online Exam

• Thursday 10 November: National Welding Supervisor Online Exam

• Friday 18 November: IIW IWE and IWT EA3 and TA3 Online Exam

Welding Supervisors play a vital role in industry, they understand the factors that influence welding quality, how to oversee welders effectively, and the variables that help maximise productivity. This blended learning course can help boost your earning potential and job stability. With three modules, this course will kick off on Wednesday 1 February 2023. If you’re keen to have a successful career in the supervision of welding, the best place to start is this course

The Welding Fundamentals online course gives professionals an understanding of some of the issues that may arise with welded components, and provides an overview of welding processes, weld defects, testing and welder qualification as required by various Australian and international Standards. This highly engaging online course will start on Wednesday 8 February 2023. It might not be until next year, but the course is already filling fast. Don’t miss out—book now!

Over the last few months, QMEA, the education arm of the Queensland Resources Council (QRC), has been delivering its Tradies for a Day program. The program is a day of exciting, resources-related activities with a focus on science, technology, engineering and maths (STEM) as well as trade roles.It involves activities including orientation for the workshop, opportunities to hear from tradespeople and other industry experts about their roles in the minerals and energy sectors, and gives students the chance to try some hands-on trade activities.

Weld Australia has assisted with several of the programs throughout the year, providing Soldamatic augmented reality welding simulators with pre-loaded exercises, all ready for students to try their hand at welding.

According to Phil Moller (VET Project Officer, QMEA), “The Soldamatic welding activity is fast becoming the most popular activity with students, teachers and tradespeople that attend the program and is getting rave reviews from educators as an advanced learning experience for their students.”

Just some of the schools that have used the Soldamatics as part of the program include Moura State High School; Pioneer State High School in Mackay and Blackwater State High School (with these events held in partnership with BHP and the BHP Mitsubishi Alliance); and Kirwan and Capella State High Schools (with these events held in partnership with Glencore).

QRC Director of Skills, Education and Diversity, KatrinaLee Jones said the workshop allowed students to learn about the different types of rewarding careers on offer in the minerals and energy sector.

“One in every six jobs in Queensland is in the minerals and energy sector, which is experiencing a skills shortage, so there has never been a better time to pursue an exciting career in a STEM or trade-based role,” Jones said.

“The QRC recently launched the ‘Shape Your Future. Innovate Our World’ campaign centred around the Top 10 hottest jobs in Queensland resources right now as a way to attract more young people to work in our sector. The resources sector is undergoing an intense and immense period of change, as companies move to lower emissions and become more environmentally sustainable. Getting more young people on board with us on that journey is the key to success.”

The academy encourages a talent pipeline of employees into vocational and professional careers, with a focus on female and Indigenous participation. The QMEA currently engages with 90 schools and is a partnership between the QRC and the Queensland Government under its Gateway to Industry Schools program.

In late August, over 30 students from St Columban’s College in Brisbane took part in welder training utilising the Soldamatic augmented reality simulators. The students were given an opportunity to learn about welding, including quality control, safety aspects and following welding procedures.

After just a few hours of practice, the students were achieving results required to achieve qualified welder status. This demonstrates just how much augmented reality can accelerate the learning process for students.

From the group, 12 students in Years 11 and 12 were selected to attempt a real welder qualification test in line with AS/NZS ISO 9606 Qualification testing of welders — Fusion welding. Weld Australia’s Engineering Team Manager, Ross O’Bryan facilitated the testing and was impressed with the results; 11 of the students passed the test with flying colours. This is an excellent achievement for the students involved, who will be able to take that qualification out into industry.

Over 20 students from Caboolture State High School recently had the chance to try their hand at welder training, using the state-of-the-art Soldamatic augmented reality welder simulators. Adam Coorey (Regional Training Coordinator, Weld Australia) facilitated the training for the students.

The training took place in Caboolture State High School’s newly constructed technology building. The school offered prizes to the best performers of the day, and throughout the sessions.

During the final hour of the afternoon, four of the highest scoring student welders competed in a ‘weldoff’. The event was attended by the local member for Caboolture and Longman, Terry Young, as well as Caboolture State High School’s Head of Department.

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 96061 (Steels – carbon steels)

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

For further information, contact: training@weldaustralia.com.au

ENROL IN A FUSION WELDING COURSE TODAY

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania Tasmanian Minerals and Energy Council tasminerals.com.au 13 Wellington Street, Burnie

Victoria Box Hill Institute boxhill.edu.au 465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au 23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat