IN THIS ISSUE

WELD AUSTRALIA LAUNCHES NATIONAL RESOURCES FOR MEM TRAINING PACKAGE

2023 WORLDSKILLS NATIONAL CHAMPIONSHIPS

WELD AUSTRALIA EXHIBITS AT THE 2023 AIMEX CONFERENCE

WELD AUSTRALIA LAUNCHES NATIONAL RESOURCES FOR MEM TRAINING PACKAGE

2023 WORLDSKILLS NATIONAL CHAMPIONSHIPS

WELD AUSTRALIA EXHIBITS AT THE 2023 AIMEX CONFERENCE

WELD AUSTRALIA CONTACTS

NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 1800 189 900 office@weldaustralia.com.au weldaustralia.com.au

Geoff Crittenden Chief Executive Officer 1800 189 900 g.crittenden@weldaustralia.com.au

TRAINING

Guy Brooks, Training Manager 0488 743 322 g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, National Manager, Sales & Marketing 0437 106 726 m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Qualification and Certification Team Manager 0487 487 170 d.yalniz@weldaustralia.com.au

ENGINEERING

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901 a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, Engineering Team Manager - East 0491 491 888

r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Mehdi Tajfar, Senior Welding Engineer 0417 044 370

m.tajfar@weldaustralia.com.au

While in Canberra for the 2023 National Manufacturing Summit, Jim Sanford, Charlie Joyce (both from the Centre for Future Work), Adam Hersh (Senior Economist at the Economic Policy Institute in Washington and our keynote speaker), and I met with representatives of several Federal Government departments.

During these meetings, I was surprised at how often Adam referred to the time, effort and money the Biden Government invested to bring the various interested parties onside prior to ratifying the Inflation Reduction Act (IRA). Adam made it clear that progress would have been impossible without the buy-in of all stakeholders from conservations and farmers, through to unions and planning departments.

Initially, I thought this approach was a reflection of the divided and somewhat acrimonious political environment in the United States. I was convinced that meeting our climate goals was an issue of investment, partnering with the global supply chain and establishing a sovereign manufacturing capability— somewhat typical of ‘engineer thinking’.

By the time the Summit concluded, I had made a complete about-face. Unless we achieve a social license— and quickly—Australia will fail to meet its renewable energy and net zero targets by 2050.

There is nothing difficult about achieving these targets from an engineering or manufacturing perspective, given the right incentives and investments. The challenge we must overcome is achieving a social license from the key interest groups of conservationists, farmers, unions, and planning departments. But, as we’ll explore below, the challenge is not insurmountable.

Our continent is teaming with rare and unique flora and fauna. Since European settlement over 100 species have become extinct. As the planet warms it is envisaged that this number will increase and the rate of extinction accelerate. We therefore face the challenge of how to save the planet without destroying it. There is no question it can be done but, like so many parts to this puzzle, it requires us to radically change the way we think.

The 400MW Willatook wind farm, north of Port Fairy in Victoria, exemplifies this challenge. Conceived in 2010, plans for the $1 billion Willatook wind farm encompass up to 59 turbines (with a maximum height of 250m), up to three 170m-high wind monitoring masts, a substation, battery storage, maintenance buildings, underground cables and above-ground transmission lines.

The site for Willatook wind farm is used for sheep grazing and lies within a zone designated by the Victorian Government as suitable for renewable energy, with easy access to an existing 500kV transmission line. The problem is, the site is also home to the nesting ground of the brolga, a threatened indigenous crane famed for its dancing rituals, and the 55mm-long, cave-dwelling southern bent-wing bat. It is worth noting that environmental reports state that just one pair of brolgas has regularly nested at the site between 2010 and 2021.

After a decade of development work, including the two year environmental impact approval process, the planning conditions imposed to protect these species have effectively killed the Willatook project. The strict conditions cut the number of turbines that can be installed by two thirds and imposing a five month ban on construction work at the site every year.

It is doubtful that there is a renewable energy project in Australia not being delayed by some form of environmental issue. So, we must implement a multifaceted approach to win the support of conservationists for major renewable energy projects like wind farms. This approach must reflect the delicate balance between promoting renewable energy development and addressing environmental concerns, and comprise adaptive management, mitigation strategies and collaborative partnerships.

Farmers

Farmers were one of the first interest groups to be addressed by the US Federal Government in the drafting of the IRA. Understandably, they are a powerful lobby group who will be significantly impacted by the construction of renewable energy infrastructure. The Biden Administration brought the farming lobby onside by agreeing a compensation plan and a set of guidelines for a construction approval process.

In Willatook, the tough planning restrictions are supported by some local farmers who dispute the results of the environmental impact statement which assert that only one pair of brolga has been regularly nesting in the wetland area out of an estimated breeding community of 200 Australia wide. While it would be wrong to question the sincerity of their support for the brolga, it is interesting to note this quote from one local farmer.

“There’s a massive build-up in our area, they are just trying to put them (wind towers) everywhere, all on top of everybody down here,” he said, pointing to the drawcard for developers of the 500 kilovolt transmission line that crosses the region. “There are a lot of people not too happy about it.”

Getting farmers onboard with the construction of renewable energy projects like wind farms on their land must encompass a combination of economic incentives, education, and addressing concerns specific to the agricultural community. We can look to the US where

measures such as tax incentives and lease payments that provide farmers with an additional source of income have been implemented with success.

A social contract with unions that paves the way for the transfer of jobs from the carbon economy to one based on renewable energy is essential. In discussing this issue with Senator Doug Cameron, just prior to his retirement in 2019, he suggested that this would need to be one of the first steps on the pathway to a renewable future. He emphasised that the crucial support required from regional communities reliant on coal mining and coal fired power generation would not be forthcoming unless some guarantees were put in place that offered a pathway to new and comparable jobs.

The Queensland Government has recognised this, incorporating a Job Security Guarantee into its Energy and Jobs Plan. It states that: every energy industry worker is guaranteed a job within the Government owned energy sector as it transforms; and every energy industry worker will be offered agreed financial support and options to support transition to their new career.

It is critical to note that the Queensland Government owns their state energy assets. As such, the government has a substantial financial and moral obligation to find jobs for its employees, as well as the obvious practical consideration of managing a pool of highly skilled labour in a critical shortage. While the Queensland Government has not yet

Introducing

Optishade Technology*

resolved issues with the mining and transport sectors, the Job Security Guarantee is a promising start that should provide a model for other states and the Commonwealth.

During the 2023 National Manufacturing Summit, I was surprised that how often planning constraints were cited as one of the biggest hindrance to progress and investment. While it seems incredible that the bureaucracy and self-interest of one arm of government can confound another, it is clearly the case.

It is hard to describe the chaos in which our planning system finds itself. Unless this problem is quickly and sensibly rectified, Australia will not achieve its climate goals and will be relegated to even more of a ‘dig and ship’ economy. The current planning system not only stymies local development, but eradicates confidence in international investors. In the case of the Willatook wind farm, the site had already been designated by the Victorian Government as suitable for renewable energy. If investors cannot rely on this type of classification, they will simply choose to invest elsewhere.

We need to solve this problem by drastically revising our environmental planning laws. We need to completely remove decision making from the political process, which is too easily influenced by our short term election cycle. We need to set time constraints and provide guidelines that reflect the situation in which we currently find ourselves rather than the one of just a few years ago. Decisions need to be made quickly and objectively by environmental and climate experts rather than lawyers and judges.

One group that cannot be overlooked in our analysis is the ‘Wishful Thinkers’. This group is identified by their promotion of rapid adoption of new (untried) technology to solve all our climate problems. Far be it from me to gain say some of the wonderful and innovative technology currently being developed around the world—but let’s be realistic. Carbon capture technology, Small Scale Modular Nuclear Reactors, Full Scale Nuclear Reactors and commercial scale hydrogen technology are simply not commercial viable at this stage.

To make the renewable energy revolution a reality, we must:

1. Stick with the plan—wind, solar and hydro are our immediate solution.

2. Achieve a social license. All stakeholders must be brought onside with the plan, no matter the cost. It will be negligible in terms of the cost of doing nothing.

3. Resolve the bureaucracy, planning and legal constraints now—make the process efficient, simple and fast.

4. Partner with industry leaders and invest in manufacturing in Australia. There is no alternative. Global supply chains are already effectively empty.

5. Invest $200 billion into our own improved version of the Inflation Reduction Act.

6. Do all of the above yesterday. Tomorrow will be too late.

Geoff Crittenden CEO, Weld AustraliaWeld Australia’s new learning resources gaining rapid industry uptake and positive feedback, published by Manufacturers’ Monthly

New welding and fabrication training takes off, published by auManufacturing

Weld Australia’s manufacturing, engineering resources boost national welder training, published by Australian Manufacturing

Weld Australia launches new manufacturing and engineering training package, published by auManufacturing

Weld Australia launches learning resources for manufacturing and engineering training package, published by Australian Manufacturing

Weld Australia launches new national resources for manufacturing and engineering training package, published by Manufacturers’ Monthly

Training updates for welders, published by Climate Control News

ELEVATE REGISTER TODAY! Book as a group and save up to 25%

YOUR ORGANISATION, & ADVANCE YOUR CAREER

SKILLS,

Weld Australia is proposing to establish a Renewable Energy Industry Group to bring together existing generators, new players, manufacturers, suppliers, specialists and consultants.

Interested in joining? To register your interest, please contact Andrew Davies (Manager Technical Industry Networks, Weld Australia) on 0438 428 966 or a.davies@weldaustralia.com.au

The Federal Government has established a policy and targets to reduce carbon emissions by 43% by 2030, and reach net zero by 2050. These targets will play a key role in limiting global temperature increases and ensuring Australia’s transition to a low carbon future consistent with our commitments under the Paris Agreement. These targets will necessitate the construction of new infrastructure on a massive scale. Local manufacturing and supply chains will need substantial growth to provide resources and materials for the planned renewable infrastructure. A massive increase of skilled workers will also be required.

Australia’s renewable energy industry will need to deal with raft of issues to deliver on these ambitious projects, including:

• Manufacturing and fabrication capacity

• Raw materials (such as steel and copper)

• Skills and labour

• Contracting and contractor resources

• Regulatory approvals

• Connection to the grid

All this is within the context of several broader Australian energy market issues, including:

• Market volatility

• Grid stability

• Thermal electricity generation operational limitations

In face of these challenges, Weld Australia’s new Renewable Energy Industry Group will bring together existing generators, new players, manufacturers, suppliers, specialists and consultants to:

• Share knowledge experience, and learnings

• Discuss and workshop renewable energy issues

• Network and collaborate with like-minded industry colleagues

• Develop younger and less experienced staff

The purpose of the Weld Australia Renewable Industry Group will be to grow, strengthen and support the local Australian Renewable Energy Industry. The Renewable Energy Industry Group will bring together like-minded companies in the renewable energy sector to meet and discuss issues facing the industry. Weld Australia will also manage and facilitate meetings and act on behalf of its members in addressing issues that arise from the Group.

The Renewable Energy Industry Group will commence with an online webinar on Thursday 28 September from 10:00am to 12:00 noon. A broad agenda for this meeting will include:

• Introductions and group overview

• Technical presentations

• Open discussions of issues and group structure

• Details for the next meeting

Incat Tasmania is leading the world in producing pureelectric lightweight zero-emission ferries. Australian shipbuilder Incat Tasmania has under construction the largest lightweight battery electric ship (130 m in length) so far constructed in the world for delivery to its South American customer, Buquebus.

This ship, the world’s largest battery-electric Ro-Pax ferry, will be 100% battery electric. The energy storage system (ESS) battery storage at over 40MWh will be four times larger than any battery installation that has been constructed and installed anywhere in the world for the marine transport environment. The batteries power a series of E-motors which drive the water jet propulsion system. The electrical system integration is by Wärtsilä and ESS by Corvus Energy.

The interest in these battery electric ships is very positive and Incat is now working toward the construction of its second but smaller battery-electric vehicle and passenger ferry.

Incat Founder Robert Clifford said, “We are proud to be building in Tasmania this first in class ship for Buquebus who like us share a vision to be at the leading edge of low emission shipping in the world. Incat has always been an innovator and once again we are leading the world and the world is taking notice.”

“This worldwide interest in Incat’s capabilities to deliver electric ships is a great opportunity for Tasmania and we expect this interest to magnify. We are already increasing our workforce and have just finalised plans for the recruitment of at least another 200 employees over the next 12 months with the expectation that our workforce will more than double in coming years”.

Thales Australia recently welcomed the Minister for Defence Industry, Pat Conroy, to officially open the company’s new advanced manufacturing facility at Lithgow in regional New South Wales. The opening of the new facility is a key milestone in the first phase of Thales’s ambitious industrial plan to transform its Lithgow Arms site into an advanced manufacturing 4.0 and integration hub for the precision manufacture of next generation Australian designed weapon systems - integrating both traditional precision manufacturing and digital technologies, including 3D printing, and the installation of automated electroplating and other metal treatment capabilities.

The new facility will house a new purposebuilt live firing test and evaluation capability to support systems qualification and integration, and the acceleration of research and technology development of digitised small-arms and weapon system platforms. It will support collaboration across research institutions, SME partners, and key industrial partners to create the soldier systems and small arms of the future, as well as train the next generation of skilled advanced manufacturing workers in the central west of New South Wales.

Lithgow Arms exports its world-leading small arms to 17 countries and has been a key industrial partner to the Australian Defence Force providing small arms and weapons systems for more than a century.

A vision to establish an advanced manufacturing and technology hub in the south-west is one step closer to reality, with the Western Australia Government moving forward with planning for the proposed facility.

Regional Development Minister Don Punch recently announced Deloitte as the successful tenderer to deliver a detailed feasibility study and business case for a possible Advanced Manufacturing and Technology Hub (AMTECH). The appointment represents the next step in a bid to create a world-class hub in the BunburyGeographe area that would unlock opportunities for industry in the south-west of WA.

Regional Development Minister Don Punch spoke about the hub. “Regional Western Australia is the powerhouse of the State’s economy and deserves access to infrastructure, technology and training that unlocks opportunities for industry,” he said.

“I am pleased that planning is moving forward in support of the vision for an Advanced Manufacturing and Technology Hub in the South West.”

“This is another great example of industry and government working together with the aim of producing economic outcomes that will transform industry prospects and unlock business and quality job opportunities in the future,” Punch said.

Deloitte will investigate the preferred model, location, structure, and services for AMTECH. A detailed project plan, economic benefit analysis and financial viability plan will be carried out, along with market demand, feasibility, and engineering design studies. Planning efforts have so far included a preliminary assessment report to identify key areas of focus, following industry consultation that informed preliminary scoping.

Source: https://www.manmonthly.com.au

The Queensland Minister for Manufacturing Glenn Butcher has launched the state’s first Manufacturing Month — on now from 1–30 September to showcase capabilities and products, to promote investment and opportunities for manufacturers, and to support workers.

The industry contributes around $20 billion a year to the local economy and employs 180,000 Queenslanders.

The month of events was launched at Pinkenba-based Austrack Equipment which makes SafeVac pipe lifters for the Fitzroy to Gladstone Pipeline. Events in the month include:

• Inside Advanced Manufacturing: 21 advanced manufacturers and 10 manufacturing support organisations across Queensland which have opened their doors to fellow Queensland manufacturers to tell how Industry 4.0 technology and techniques have expanded their businesses.

• Manufacturing Parliamentary Showcase: As part of a Manufacturing Expo at Queensland Parliament House, more than 25 exhibitors will demonstrate and display products and capabilities.

According to Acting Premier, Steven Miles, “As the only state in Australia to dedicate a month to the manufacturing industry, it’s clear that Queensland is blazing a trail for manufacturers around the country. Queensland Manufacturing Month will demonstrate to the rest of the country why Queensland is the best place to build, buy and invest. I want to see more products stamped with ‘Made in Queensland’ and we’re well on that way to that becoming a reality.”

Weld Australia member, Lorch Schweißtechnik GmbH has joined forces with Japanese-based DAIHEN Group to become part of the listed DAIHEN Corporation. With DAIHEN, Lorch has found the desired perfect partner for further long-term expansion. The merger will result in far reaching growth potential for Lorch and DAIHEN and excellent future prospects for Lorch employees and customers.

“The aim is to continue to supply our customers with innovative and smart welding technology solutions Made in Germany in the coming years and to create a long-term perspective for our employees. The takeover by DAIHEN Corporation as a strategic investor for Lorch Schweißtechnik GmbH therefore offers both sides farreaching growth potential,” explained Wolfgang Grüb as managing partner of Lorch Schweißtechnik GmbH.

Lorch will continue to operate independently as a German premium supplier. Their headquarters in Auenwald—where development, production, administration and sales are all based—will be expanded.

The combined technological know-how of DAIHEN and Lorch will be leveraged to develop even better high-end solutions for the worldwide market. In order

to achieve this, very strong investments will be made in the development of new products. Lorch’s foreign subsidiaries will remain unchanged and the efficient partner network will continue to be supported by Lorch Sales.

“With the investment by the strategic partner DAIHEN, Lorch has succeeded in bringing a long-term and strong partner on board and in regulating the entrepreneurial succession,” said Wolfgang Grüb, who has been at the helm of the company for four decades and will move to the company’s advisory board after a transition phase.

“The acquisition of Lorch into the DAIHEN Group represents a significant strategic step for us to strengthen our presence in the European market and beyond,” said Shoichiro Minomo (CEO and President, DAIHEN).

DAIHEN is bolstering its European market presence through its investment in Lorch. This collaboration will not only foster synergies in welding technology development but also enhance cooperation in welding automation, especially in robotics.

While Lorch will maintain its cobot welding division, there are future plans to integrate OTC robots (from the DAIHEN Group). Lorch, having steadily grown its system integration sector over the years, will further enrich its product and service offerings across all sales channels through this partnership.

Weld Australia’s Excellence Awards are the most prestigious event on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2023 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. The awards will be presented at events held across the country in October and November. Registrations for the events are now open, and can be booked by clicking on the links below.

Perth: Wednesday 18 October at Beaumont on the Point

BOOK NOW

Sydney: Wednesday 25 October at Waterview in Bicentennial Park

BOOK NOW

Adelaide: Wednesday 1 November at Glenelg Golf Club

BOOK NOW

The 2022 award events sold out in record time, so be sure to register early to avoid disappointment.

Brisbane: Wednesday15 November at Indooroopilly Golf Club

BOOK NOW

Melbourne: Wednesday 29 November at Huntingdale Golf Club

BOOK NOW

Are you ready to delve into the world of hydrogen technologies, safety, compliance, and applications? This upcoming FREE member event will bridge theory with practical insights, giving attendees an opportunity to learn more about the growing hydrogen industry.

Our guest speaker—Matt Wagenfeld, Head of Operations at Hydrogen Systems Australia—will explore how hydrogen technologies can bolster regional energy security and unlock significant economic opportunities. Understand how you, as an individual or a business, can contribute to de-carbonising our economy using existing and emerging hydrogen technologies.

Event Details

• Date: 21 September 2023

• Time: 5.30pm to 7.00pm

• Venue: Coopers Alehouse

• Address: 560 Main North Road, Blair Athol, Adelaide, South Australia 5084

• Cost: Free for Weld Australia members

Weld Australia would like to welcome all our new Members who have joined in the last month:

CORPORATE MEMBERS

• DVR Engineering: dvrengineering.com.au

• Hofmann Engineering WA: hofmannengineering.com

INDIVIDUAL MEMBERS

• Lachlan Morrow

• Yunhui Jiang

• Jackson Purcell

• Pierre Sambastian

• Neil McCormick

• Dylan Fry

• Aneesh Kumar Ashok Kumar

• John Quinlan

• Amir Kazemi

• Jake Williams

• Marten Karlsson

• Aaron Twigg

• Santhose Raj Radhakrishnan

• Tavengwa George Taviringana

• Morteza Kassiqarvir

• Gholamreza Ghanaatpisheh

For further information on the benefits of becoming a Weld Australia member, visit our website, or contact David Choudry (Membership Manager) on d.choudry@weldaustralia.com.au or 0417 878 104.

Weld Australia recently exhibited at EduTECH—the largest education event in Australia. EduTECH 2023 was held at the Melbourne Convention and Exhibition Centre, and featured over 550 local and international speakers who covered the latest trends and technologies shaping the education sector.

There were also hundreds of international and local exhibitors showcasing cutting-edge solutions, including Weld Australia with the Soldamatic augmented reality simulator. As always, the Soldamatic proved to be very popular with the crowd, with lines forming throughout the day.

The event was attended by over 12,000 people, including a range of educators, from primary, secondary and tertiary institutions, plus school business managers and information and communications technology personnel.

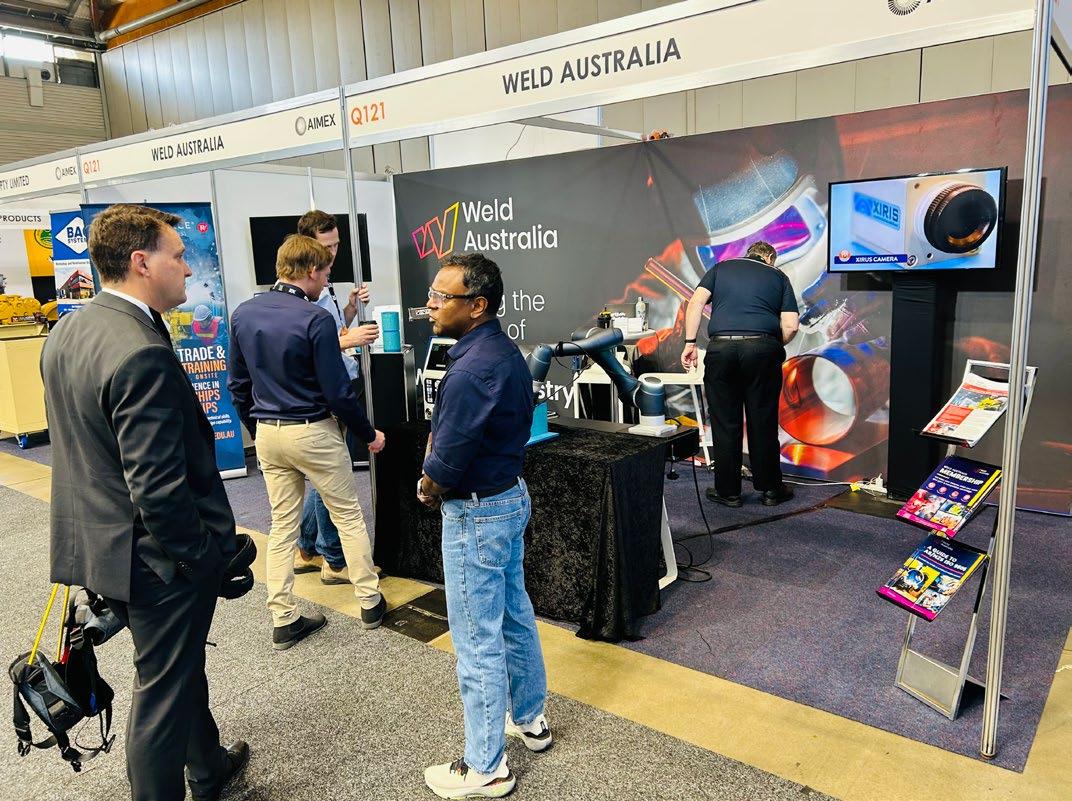

Australia’s longest running mining event, Asia Pacific’s International Mining Exhibition (AIMEX) was back at the Sydney Showgrounds from 5 to 7 September.

Over 250 national and international exhibitors ensured that the three-day event was the perfect opportunity for sourcing mining industry expertise. Weld Australia’s stand proved popular as always, with both a Soldamatic welding simulator and a Dooson welding cobot on display.

Each day of the three-day conference addressed a specific theme. Day one covered decarbonisation in mining, one of the biggest topics for the industry currently. The opening day included panel discussions featuring leaders from METS Ignited, Australian Hydrogen Council, ISN and the International Copper Association Australia.

Day two covered technical innovation, with a keynote from Nathan Kirchner of Robotics Australia Group, plus panel discussions with academic experts from the University of Newcastle and UQ’s Sustainable Minerals Institute, and contributions from Accenture, CR Powered by Epiroc and Fleet Space Technologies.

The final day focused on the hot-button topic of ESG, with speakers discussing renewable integration, the circular economy, and leveraging technology.

Weld Australia recently hosted a very successful workshop focused on the recent revisions to EN 15085 Railway applications – Welding of railway vehicles and components. Over the last three years, five revisions of the Standards have been released.

The workshop was hosted by Victor Blain (Engineering Team Manager – South & West, Weld Australia). A follow-up on some of Weld Australia’s previous workshops, this event delivered insights and practical recommendations on how to implement the new requirements of the EN 15085 series of Standards. The event also covered how to gain certification.

EN 15085 was introduced to harmonise the requirements for welding materials during the manufacture and maintenance of railway vehicles, and builds upon the requirements outlined in ISO 3834 Quality requirements for fusion welding of metallic materials

Weld Australia would like to congratulate all the winners of the 2023 WorldSkills National Championships, held in Melbourne from 17 to 19 August.

180 young apprentices and trainees were presented with medals at a ceremony attended by the Victorian Minister for Training and Skills, Gayle Tierney, Dr Michelle Ananda-Rajah, and invited guests.

Just under 27,000 visitors attended the event, with the majority comprising school students seeking to learn more about the opportunities that vocational, technological and service-oriented careers can unlock. Weld Australia’s shared exhibition stand attracted plenty of attention, with a Soldamatic welding simulator on-hand for everyone to try.

Federal Minister for Skills and Training, Brendan O’Connor, was given a guided tour of the halls for a preview before the event opened to the public.

The winners came from across 59 skills, including welding, plumbing, hairdressing, cyber security, cookery and many more. Winners from the National Championships are now eligible to be selected for the National Team, who will represent Australia at the International Competition, WorldSkills Lyon 2024.

The National Championships was supported by almost 300 volunteers, including judges, site crew, skill managers, assessment advisors and team leaders.

Weld Australia was proud to sponsor the Welding category, and Guy Brooks (Training Manager, Weld Australia) was the Deputy Chief Judge for the Welding category.

WorldSkills Australia CEO, Trevor Schwenke, said: “We were thrilled to bring our biggest and best National Championships to our hometown of Melbourne. It was terrific to see the number of participants across such a vast range of skill categories. We are looking forward to working with each state and territory to make our 2025 Brisbane competition even bigger.”

The winners of the Welding category for 2023 were:

• Gold: Harrison Field, Macquarie, New South Wales

• Silver: Beau Malkin, Tasmania

• Bronze: Maclain Coleman-Locke, Mid Coast, New South Wales

Certificates of Excellence were also awarded to:

• Shaun Meinecke, Illawarra, New South Wales

• Arnekin Loftus, Sydney West, New South Wales

• Jayden Riley, East Coast QLD

• Jacob Barry, Hunter, New South Wales

• Lenoir Rae, Northern River, New South Wales

Weld Australia is pleased to announce the launch of a new suite of learning resources for the Manufacturing and Engineering (MEM) Training Package. Weld Australia has designed and created a suite of resources for delivery of the 12 welding and fabrication units of competency in the MEM Training Package.

According to Geoff Crittenden (CEO, Weld Australia), “Our resources help simplify the learning process for students, teachers and training institutes and— most importantly—place the student at centre of the learning process.”

“Weld Australia believes that a national industry, which has a national learning package, needs national learning resources. Whether you’re an apprentice in Kalgoorlie, Ultimo or Davenport, you should have access to the same, high-quality training. Our goal is to help ensure that high-quality welder learning is consistent across the country.”

Welders are more in demand than ever—labour shortages are inhibiting the growth of Australia’s welding industry. According to Weld Australia’s members, 50 per cent of Australia’s welding workshops are currently operating at 80 per cent of their capacity or below. When asked why this is, a lack of skilled workers was the overwhelming answer.

“This labour shortage comes as no surprise. Weld Australia has been calling for urgent action for over five years. We estimate that Australia will be at least 70,000 welders short by 2030,” said Crittenden.

“And yet, the number of welding trade workers in Australia dropped by 8 per cent in the course of just five years, and completion rates of welding apprenticeships continue to fall by as much as 23 per cent annually. It is essential that welder training is revolutionised with online, accessible and engaging learning resources.”

Weld Australia formed a national consortium of TAFEs to work on the project. Over the last two years, the consortium has collaborated with us to develop the most engaging, up-to-date resources possible. Members of the consortium piloted use of the resources, and some TAFEs have already permanently adopted them.

Weld Australia’s MEM Resources have been built with students, teachers and training organisations in mind. It reimagines the learning process with its user-friendly interface, diversified delivery methods, and audited and accurate material. The new resources are completely online and accessible via phone, mobile device or computer. This allows students to access learning at the time, place and pace that suits them best.

Keen to learn more about the MEM Resources? Come along to our webinar. You can expect:

• A comprehensive tour of our diverse MEM resources, including their features and applications.

• Insightful updates on our roadmap for the next units, highlighting the innovations and improvements you can anticipate.

• An opportunity to engage with our team, ask questions, and share your thoughts on how we can better support your teaching goals.

To find out more about Weld Australia’s new MEM learning resources, email training@weldaustralia, and watch the video below.

Weld Australia recently hosted a Queensland Industry Drinks Night at Black Bird in the Riverside Centre, Brisbane. In partnership with TAFE Queensland and the Outsource Institute (AUS), Weld Australia facilitated a night of networking with key Tier 1 contractors, industry colleagues and government representatives.

Attendees heard from: Kevin Roos (Business Manager Engineering Training, TAFE Queensland Acacia Ridge); Stephen Love (Managing Director, Outsource Institute (AUS)); and Geoff Crittenden (CEO, Weld Australia).

Weld Australia is a highly respected and independent third-party, and is proud to be the International Institute of Welding Authorised Nominated Body for Company Certification. When Weld Australia conducts your certification audits and assessment, you have access to our highly qualified team of experts. Our team values you and your business to improve your existing workplace structures and operations. We will enhance processes and procedures to ensure they’re in-line with all Australian and International Standards requirements. In turn, this delivers better results, including enhanced productivity, greater customer satisfaction and increased profitability.

All our assessors are:

• Qualified and experienced in quality system auditing and experienced in welded fabrication

• Certified in Integrated Management System (IMS) Certifications

• Either IWE or IWT qualified, with at least three years’ experience in welded fabrication

• Extremely familiar with factory production control systems, quality management systems, auditing principles and AS/NZS ISO 19011 – Guidelines for auditing management systems.

For more information, email qnc@weldaustralia.com.au or visit: weldaustralia.com.au/qualification-certification

We are pleased to announce that companies can now be certified by Weld Australia to three new Standards: AS/NZS ISO 9001 Quality Management System; AS/NZS ISO 14001 Environmental Management; and AS/NZS ISO 45001 Occupational Health and Safety

AS/NZS ISO 9001 is a crucial certification for a quality management system. It is used by organisations to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements.

First adopted in 1987, over one million organisations from more than 160 countries have certified to ISO 9001 to meet quality management objectives.

Obtaining ISO 9001 certification offers several advantages. It showcases a commitment to quality, assuring clients of standardised, consistent outcomes. This recognition differentiates you in a competitive market, elevating your business reputation.

The certification processes can help streamline your operations, reducing wastage, and improving efficiency, to translate into cost savings. It also emphasises continual improvement, promoting innovation and adaptability. This

certification enhances customer trust and satisfaction, potentially increasing client retention and referrals.

Lastly, some clients mandate ISO 9001 certification for contractual purposes, widening market opportunities. In essence, ISO 9001 can accelerate growth and boost credibility.

AS/NZS ISO 14001

ISO 14001 is one of the most recognised and advanced environmental management systems in the world. It provides a framework for companies, including welding businesses, to minimise their environmental footprint, ensure compliance with applicable legal regulations, and continually improve in these areas.

For welding businesses, the benefits are manifold. Besides promoting eco-friendly operations, the certificate process can help reduce waste and energy consumption, leading to cost savings. Achieving this certification differentiates a company in the marketplace, highlighting its commitment to sustainability. This attracts environmentally conscious clients and enhances reputation among stakeholders.

Moreover, by adhering to ISO 14001, businesses are better equipped to anticipate and manage environmental risks, ensuring long-term resilience and sustainability. This is essential in an evolving climate, where safer environmental practices should be at a business’ core.

AS/NZS ISO 45001

AS/NZS ISO 45001 has wellbeing and safety at its core to minimise workplace-related injuries and poor health. The leadership-lead approach means AS/NZS ISO 45001 meets moral, legal, ethical and industry-best practice when it comes to an employers’ duty of care over staff.

The certification shares principles with a range of other essential standards within the welding, fabrication and manufacturing space.

This certification offers numerous benefits. It not only helps reduce the incidence of accidents and health-related absences but also demonstrates your commitment to the safety of your workforce. This proactive approach to health and safety can enhance a firm’s reputation, boost employee morale, and potentially decrease insurance premiums.

Moreover, ISO 45001 helps businesses to ensure compliance with legal and regulatory requirements, reducing the risk of penalties and lawsuits.

This course provides you with a detailed understanding of welding technology to enable you to apply your knowledge as an International Welding Engineer (IWE). You’ll be able to comprehensively manage and/or perform, supervise, oversee all company welding and welding-related activities and verify weld quality. This highly engaging online course will start on 14 March 2024. Register now to avoid disappointment.

The IWI-B course is a globally recognised IIW qualification. This course provides general knowledge of welding, inspection theory and application, including: non destructive testing; mechanical and visual inspection techniques; inspection procedures and acceptance criteria; and identification of weld imperfections. Kicking off on 30 January 2024, get your New Year off to a great start.

This course provides advanced knowledge of welding and inspection theory and application, including NDT, mechanical and visual inspection techniques, inspection procedures and acceptance criteria, identification of weld imperfections associated with pre-production, fabrication, and post fabrication, and more. This highly engaging online course will start on 30 January 2024. Get in now, before its too late.

T

Weld Australia currently has a few very rare one-week blocks available in October, November and December. All our in-house training courses need a minimum of 10 students.

IIW International Welding InspectorBasic (IWI-B)

This internationally recognised course provides extensive knowledge surrounding welding, inspection theory and application

Welding Fundamentals

This course covers significant issues that may arise with welded components, welding processes, weld defects and testing, and welder qualification

Welding Supervisor - AS 2214 and AS 1796 Cert 10

Our course covers welding processes, terminology and technology; welding metallurgy; weld testing and inspection; standards and specifications; and more

Weld Connect | September 2023 23 For information, or to book your in-house course, contact us via 1800 189 900 or training@weldaustralia com au

Weld Australia would like to congratulate the following people on becoming newly qualified in July.

AS 1796 CERTIFICATE 2

• Jack Waddell

AS 1796 CERTIFICATE 4

• Jack Waddell

• Mark Walsh

AS 1796 CERTIFICATE 7

• Mark Walsh

• Sukhmander Singh

Handa

AS 1796 CERTIFICATE 10

• Ashley Pinal

• Deon Cauchi

• Gavin Bennett

• HUONG PHAM

• Jasbir Singh

• Justin McGown

• Karl Paterson

• Lachlan Mcquade

• Mark Walsh

• Orlan Cas

• Rasoul Pouriamanesh

• Seyed Hossein Mir

karimi

• Simon Van Someren

• Tom Morrissey

• Travis Aslett

AS 2214

• Indula Udara

Kannangara Koralalage

• Jarrad Julyan

• Jeffrey Celestino

• Karim Shokri

• Ryan Mackintosh

• Sonny WilliamsWade

Robinson

AS 1796 CERTIFICATE 8G

• Clinton Brown

IIW INTERNATIONAL WELDING INSPECTOR BASIC (IWI-B)

• Adam Nelson

• Adam Waddingham

• Ashley Bell

• Craig Street

• Dean Healey

• Dean Narvo

• Dylan Ross

• Jonathon Kalatzis

• Matthew Zacharjak

• Michael Miles

• Nikki Medcalf

• Simon Lahiff

• Warren Broad

IIW INTERNATIONAL WELDING INSPECTOR STANDARD (IWI-S)

• Antonius Vidot

• David Houlihan

• Glenn Northcott

• James Darmody

• Jasbir Singh

• Jeevan Kumar

• Jordan Honeyfield

• Kiah McCreadie

• Richard Lane

• Ryan Palle

• Scott Clarke

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2023, making planning ahead as simple as possible. Just some of the upcoming exam dates include:

• Wednesday 13 September: National Welding Supervisor Exam B1 and B2

• Friday 22 September: IIW IWI-B PE B (C3) Practical exam (New South Wales, Victoria, Queensland, South Australia and Western Australia)

• Tuesday 26 September: Re-sit/Online Exam (All Qualifications)

• Wednesday 27 September: IIW IWI-B WIE B (B5) (Online Exam)

• Tuesday 3 October: IIW IWI-B and IWI-S WTE S and WTE B (Online Exam)

• Wednesday 4 October: IIW IWS SA3 (Online Exam)

• Monday 9 October: National Welding Supervisor Exam Paper A (Training)

• Monday 16 October: AS1796 Cert 1-9 Theory Online Exam

• Wednesday 18 October: National Welding Supervisor Exam A-B1 and B2

• Friday 20 October: IIW IWI-S PE S(C5) NSW and QLD Practical Exam - Classroom

• Tuesday 7 November: IIW IWI-B & IWI-S WTE S and WTE B (Online Exam)

• Wednesday 8 November: IIW IWI-S WIE S (Online Exam)

• Friday 10 November: IWE and IWT EA3 TA3 (Online Exam)

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 9606-1 (Steels – carbon steels)

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

For further information, contact: training@weldaustralia.com.au

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania Tasmanian Minerals and Energy Council tasminerals.com.au

13 Wellington Street, Burnie

Victoria Box Hill Institute boxhill.edu.au

465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au

23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat